Page 1

User manual

mA Loop Calibrator

Jofra mAcal

Page 2

Page 3

Page 4

User Manual

mAcal

mA loop Calibrator

Copyright 2005 AMETEK DENMARK A/S

Page 5

LIST OF CONTENTS

1.

INTRODUCTION

1.1 PACKING LIST ................................................................................ 2

2. SAFETY INSTRUCTIONS .................................................... 2

3. OPERATION ........................................................................ 4

3.1 DISPLAY AND KEYBOARD ........................................................... 4

3.2 SWITCHING THE MA

3.3 HOW THE CURRENT IS GENERATED .......................................... 6

3.4 HOW THE CURRENT IS MEASURED ............................................ 7

3.5 HOW THE VOLTAGE IS MEASURED ............................................ 7

3.6 HOW NEW PARAMETERS ARE SELECTED (SETUP) ................ 8

3.6.1 S

3.6.2 S

3.6.3 S

3.6.4 S

3.6.5 S

ELECTION OF

ELECTION OF

ELECTION OF

ELECTION OF

ELECTION OR DE-SELECTION OF AUTOMATIC

CAL

ON/OFF .................................................. 6

MODE .......................................................... 8

SLOPE TIME................................................ 8

STEP SIZE ................................................... 9

STEP TIME .................................................. 9

OFF

FUNCTION

9

4. ERROR SITUATIONS ........................................................ 10

4.1 TEST FOR “OPEN LOOP” ........................................................... 10

4.2 TEST FOR INCORRECT POLARITY ............................................ 10

4.3 TEST FOR “OVERRANGE”.......................................................... 10

4.4 INDICATION OF BATTERY STATUS ........................................... 11

5. HOW mAcal IS ADJUSTED (service mode) .................... 12

6. TECHNICAL SPECIFICATIONS (23°C±3°C) .................... 14

103887 02 1

Page 6

1. INTRODUCTION

The mAcal is a loop calibrator for measuring and generating mA. The

mAcal is specially designed for use in industrial plants with 4-20mA

signals. The mAcal can be operated with one hand, and operation is simple

and intuitive.

1.1 PACKING LIST

When the instrument is received, the box should contain the following:

• mAcal

• Bag

• 2 test leads with crocodile clip

• 4 batteries, type LR6, AA

• 1 USB key containing documentation

2. SAFETY INSTRUCTIONS

Read this manual carefully before using the instrument!

In order to avoid any personal injuries and/or damage to the instrument

all safety instructions and warnings must be observed.

Disposal – WEEE Directive

These calibrators contain Electrical and Electronic circuits and must be

recycled or disposed of properly (in accordance with the WEEE

Directive 2012/19/EU).

WARNING:

• The calibrator must not be used for any purposes other than those

described in this manual.

• Follow all equipment safety procedures.

• The calibrator has been designed for interior use only and should

not be used in hazardous areas, where vapour or gas leaks, etc.

may constitute a danger of explosion.

• Do not apply more than the rated voltage. See specifications for

supported ranges.

• Do not use the calibrator if it is damaged. Before you use the

calibrator, inspect the case. Look for cracks or missing plastic. Pay

2 103887 02

Page 7

particular attention to the insulation surrounding the connectors.

• Select the proper function and range for your measurement.

• Make sure the battery cover is closed and latched before you

operate the calibrator.

• Remove test leads from the calibrator before you open the battery

door.

• Inspect the test leads for damaged insulation or exposed metal.

Check test leads continuity. Replace damaged test leads before you

use the calibrator.

• When using the probes, keep your fingers away from the probe

contacts. Keep your fingers behind the finger guards on the probes.

• Do not use the calibrator if it operates abnormally. Protection may

be impaired. When in doubt, have the calibrator serviced.

• Disconnect test leads before changing to another measure or

source function.

• To avoid false readings, which could lead to possible electric shock

or personal injury, replace the battery as soon as the battery

indicator appears.

• To avoid personal injury or damage to the calibrator, use only the

specified replacement parts and do not allow water into the case.

Caution…

103887 02 3

• Disconnect the power and discharge all high-voltage capacitors

before testing resistance or continuity.

• Use the proper jacks, function and range for your measurement or

sourcing application.

• To avoid damaging the plastic lens and case, do not use solvents

or abrasive cleansers.

Page 8

3. OPERATION

3.1 DISPLAY AND KEYBOARD

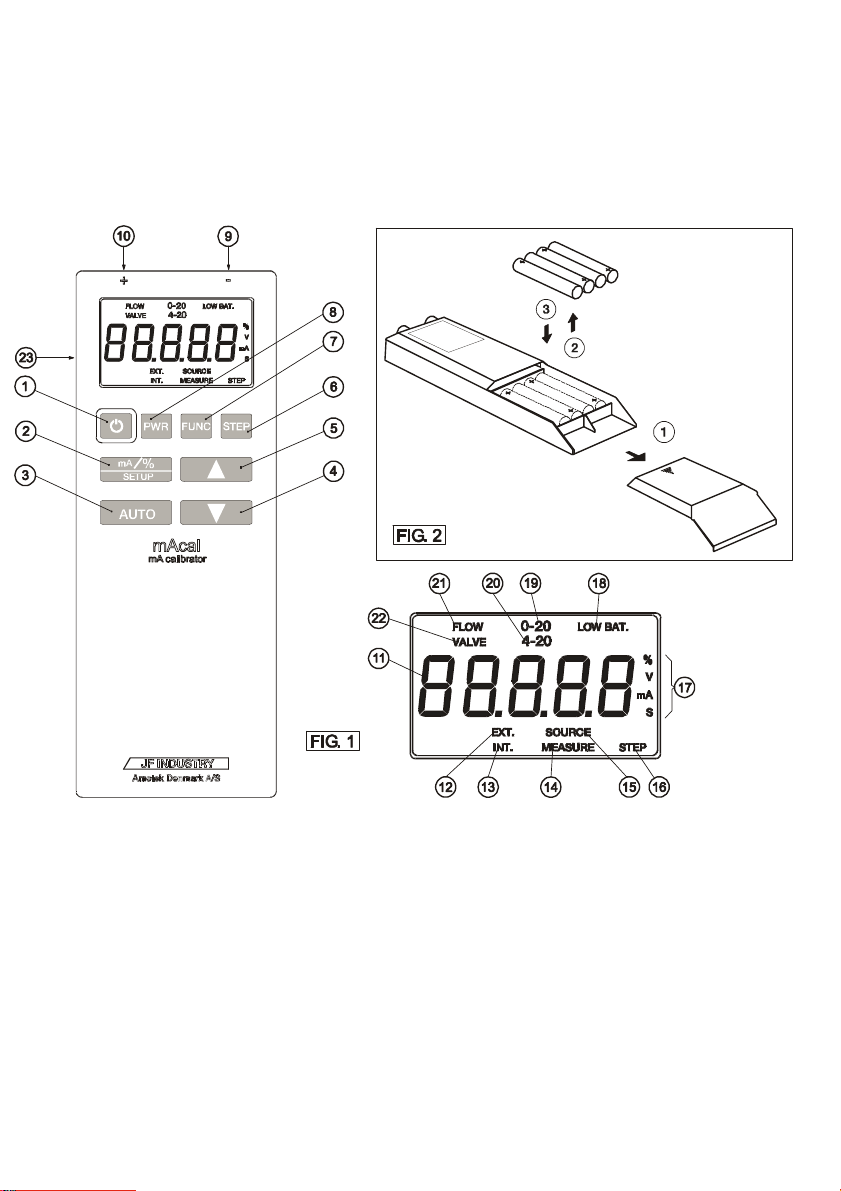

The various keys on the keyboard have the following functions (cf. Fig. 1 on the cover of

the user’s guide):

ITEM KEYBOARD Description:

ON/OFF Switching instrument on/off.

% mA / SETUP Alternating between readout in mA and %. If

AUTO AUTO ramp or AUTO-STEP function is started

DOWN ARROW “Less” key. If the key is held down, the key

UP ARROW “More” key. If the key is held down, the key

STEP The STEP function is activated or de-activated.

FUNC. (FUNCTION) Change-over takes place between SOURCE

PWR. (POWER) Change-over takes place between EXT. (the

The various segments of the display indicate the following (cf. Fig. 1 on the cover of the

user’s guide):

ITEM DISPLAY SEGMENT Description:

EXT (EXTERNAL)

INT (INTERNAL)

MEASURE

SOURCE

STEP

%, s, V or mA

the key is held down for more than 2 sec., a

change to SETUP takes place. Under SETUP

this key is used to select next parameter.

or stopped.

press is repeated.

press is repeated.

mA, MEASURE mA and MEASURE Volt

function.

+24VDC of the current loop is generated by an

external power supply) and INT. (the +24VDC

of the current loop is generated by the mAcal

itself).

Shows numerical value in mA, %, V or sec.,

and for readout of error codes etc.

External loop supply is selected.

Internal loop supply is selected, the internal

+24VDC of the mAcal being used to supply the

current loop with power.

Measurement of current or voltage is selected

(indicated by unit).

Generation of current is selected.

The STEP function is active. When the

segment flashes, this indicates that the AUTOSTEP function is activated.

Indication of unit for readout numerical values.

4 103887 02

Page 9

nectio230mA.n to mains adaptor

ITEM DISPLAY SEGMENT Description:

LOW BAT (LOW

BATTERY)

0-20

4-20

FLOW

VALVE

ITEM CONNECTIONS Description:

-

+

Con

6V DC, 230mA.

When this segment is lit, the voltage in the batteries

is less than 3.5 V, and they should be replaced.

When the segment flashes, the voltage is less

than 3.1 V and the instrument cannot be operated.

0-20mA is selected as the range, which affects the

readout in %, as well as STEP values.

4-20mA is selected as the range, which affects the

readout in %, as well as STEP values

FLOW transmitters are selected, which affects the

readout in %, as well as STEP values.

Proportional transmitters are selected, which

affects STEP values and the AUTO-STEP function.

Connection of black test lead Connection of red test lead +

Note : The mains adapter does not charge

rechargeable batteries.

103887 02 5

Page 10

3.2 SWITCHING THE mAcal ON/OFF

Press

When the unit is switched on, the present battery voltage appears in the display for approx.

1 second.

Fit the red test lead into the connector marked “+”.

Fit the black lead into the connector marked “-“.

The mAcal is now ready for use. The unit automatically starts up in the function (SOURCE

mA, MEASURE mA or MEASURE Volt) which was active when it was last switched off.

and the unit is switched on/off.

3.3 HOW THE CURRENT IS GENERATED

Connect the mAcal to the instrument to be tested as shown in Fig. 3 or Fig. 4 on the cover

of the user’s guide and switch the unit on.

Press

Press

If INT. is selected, the +24VDC of the current loop is generated by the mAcal itself. If EXT

is selected, the +24VDC of the current loop is generated by an external power supply.

Press

The display has the following appearance when 4mA is generated with internal loop

supply:

until the display shows SOURCE mA or SOURCE%.

for selection of INT or EXT (the present selection is shown in the

display).

for selection of readout in mA or %.

Press

Press

Press

on selection of MODE and STEP SIZE).

and the generated current is increased.

and the generated current is decreased.

for activation of pre-defined current values (values depend

6 103887 02

Page 11

Press

(the AUTO-STEP function), change-over takes place automatically between the

pre-defined current values. For proportional transmitters (VALVE), change-over

takes place between 3.8 - 4 - 4.2 - 4..... and 19 - 20 - 21 - 20..... mA

(the range is selected using the “up arrow” or “down arrow” keys).

The mAcal now generates the current shown in the display.

for automatic changing of current value. If STEP is selected

3.4 HOW THE CURRENT IS MEASURED

Connect the mAcal to the transmitter to be tested as shown in Fig. 5 or Fig. 6 on the cover

of the user’s guide and switch the unit on.

Press

Press

Press

If INT is selected, the +24VDC of the current loop is generated by the mAcal itself. If EXT is

selected, the +24VDC of the current loop is generated by an external power supply.

The display thus has the following appearance in the measurement of 20mA in the current

loop.

The current is printed out with a resolution of 0.001mA:

until the display shows MEASURE mA or MEASURE %

for selection of INT or EXT (the present selection is

shown in the display).

for selection of readout in mA or %.

The mAcal now measures the current shown in the display.

3.5 HOW THE VOLTAGE IS MEASURED

Connect the mAcal to the instrument to be tested as shown in Fig. 7 on the cover of the

user’s guide and switch on the unit.

Press

The display thus has the following appearance in the measurement in V. The voltage is

printed out with a resolution of 0.1Volt:

103887 02 7

until the display shows MEASURE V. Readout in %

cannot be selected.

Page 12

The mAcal now measures the voltage shown in the display.

3.6 HOW NEW PARAMETERS ARE SELECTED (SETUP)

Press

for approx. 2 seconds. The present selection of

MODE is now shown in the display, e.g.

mA.

to cancel a selection. SETUP is exited and it is necessary to

start all over again. This option can be selected at any time.

3.6.1 Selection of MODE

It is possible to choose between 5 different MODES:

• 4-20mA LIN

• 0-20mA LIN

• 4-20mA FLOW

• 0-20mA FLOW

• 4-20mA VALVE

LIN - % calculated linearly.

FLOW - % calculated logarithmically.

VALVE - % not calculated.

AUTO-STEP function 3.8 - 4 - 4.2 - 4..... or 19 - 20 - 21 - 20..... mA.

Press

Press

or

to save the present selection.

for selection of new MODE.

3.6.2 Selection of SLOPE TIME

After MODE has been selected, SLOP TIME (ramp time in the case of AUTO) can be

changed.

The text s is shown on the display for approx. 1 second.

Press

adjusted between 30 - 999 S.

Press

8 103887 02

or

to save the present selection.

for setting of SLOPE TIME. The time can be

Page 13

3.6.3 Selection of STEP SIZE

After SLOPE TIME has been selected, STEP SIZE (step size in % of range) can be

selected for the transmitter types LIN and FLOW. If MODE 4-20mA VALVE is selected,

a fixed STEP SIZE is applied. The text is shown in the display for approx. 1

second.

Press

made between the step sizes 5%, 10%, 20%, 25%, 50% and 100%.

Press

or

to save the present selection.

for setting of STEP SIZE. A choice can be

3.6.4 Selection of STEP TIME

After STEP SIZE has been selected, STEP TIME (the time between changes in the

AUTO-STEP function) can be changed. Either s or s is shown in the display.

Press

Press

or

to save the present selection.

for setting of STEP TIME.

3.6.5 Selection or de-selection of automatic OFF function

After STEP TIME has been selected, it is possible to select or de-select the AUTOMATIC

OFF function (mAcal automatically switched off approx. 30 minutes after a key has last

been activated).

The text is shown in the display for approx. 1 second. Alongside, the text or

appears.

Press

Press

Press

SETUP is exited and the mAcal is now ready for normal operation with new parameters.

and AUTOMATIC OFF is selected. appears in the

display.

and AUTOMATIC OFF is deselected. appears in the

display.

to save the present selection.

103887 02 9

Page 14

4. ERROR SITUATIONS

4.1 TEST FOR “OPEN LOOP”

The text flashes in the display:

CAUSE

REMEDY

4.2 TEST FOR INCORRECT POLARITY

The text flashes in the display:

CAUSE

REMEDY

4.3 TEST FOR “OVERRANGE”

The text flashes in the display:

CAUSE

REMEDY

The unit is unable to generate the desired current.

The current loop is probably open or selection of PWR is

incorrect.

• Check whether instrument is connected correctly.

• Check that PWR selection is correct.

The unit measures a negative current.

The test leads + and - are probably to be changed over.

The unit measures a current which is greater than 24mA or a

voltage which is greater than +45Volts or less than -45Volts.

• Measure only voltages in the range -45 to +45 Volts.

• Measure only in current loops, where the current is less

than 24mA.

• Check that the instrument is connected properly.

See Fig. 3 to Fig. 7 on the cover of the user’s guide.

10 103887 02

Page 15

inserted.

4.4 INDICATION OF BATTERY STATUS

• The text “LOW BAT” lights up in the display:

• The text “LOW BAT” flashes in the display:

CAUSE

REMEDY

“LOW BAT” lights up:

The batteries are about to be used up. However, the

instrument can still be used.

“LOW BAT” flashes:

The batteries are used up. The instrument cannot be used.

The display goes out. However, the keyed-in values are

retained.

“LOW BAT” lights up:

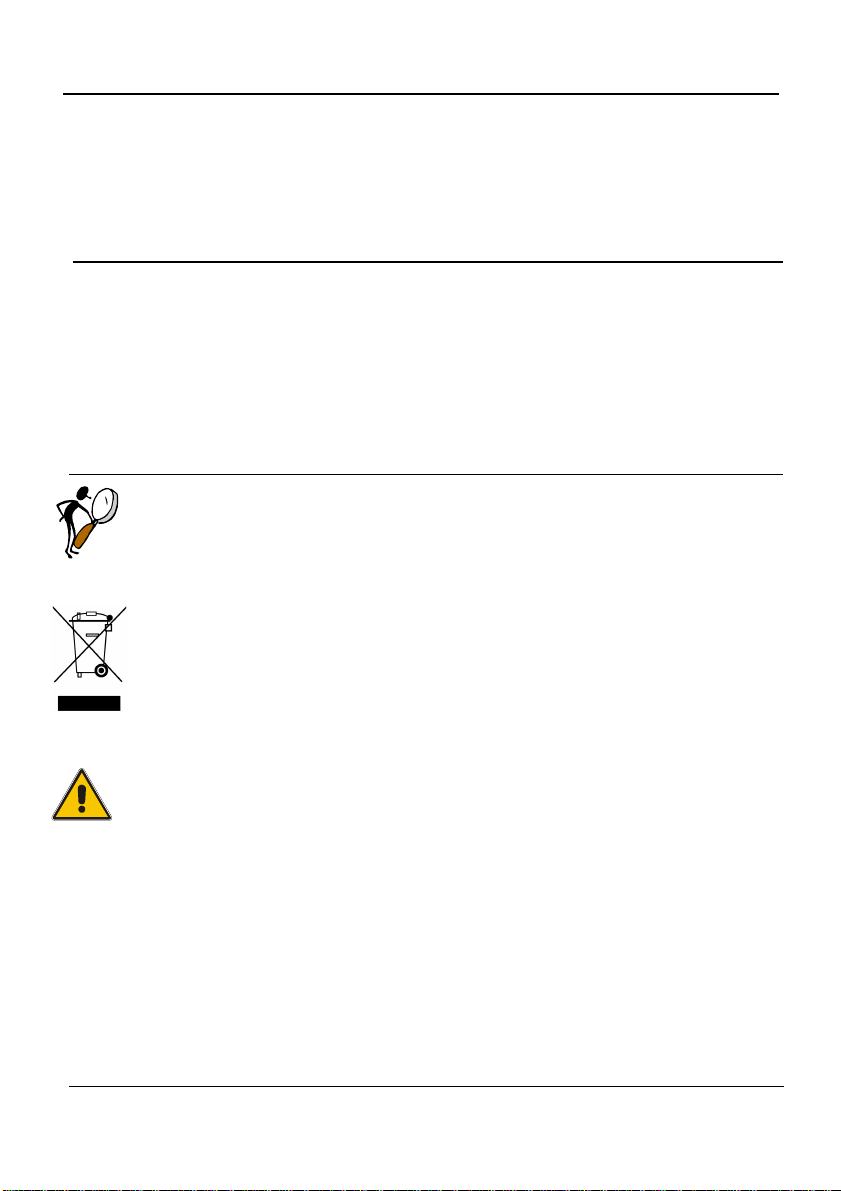

Change the batteries. See Fig. 2 on the cover of the user’s

guide.

“LOW BAT” flashes:

The batteries must be changed. See Fig. 2 on the cover of

the user’s guide.

The 4 used LR6, AA batteries are removed and new ones

103887 02 11

Page 16

5. HOW mAcal IS ADJUSTED (service mode)

Connect the mAcal to an external precision instrument (with an accuracy higher than

0.02% of F.S.) as shown in Fig. 3 on the cover of the user’s guide.

Hold

3 images appear in the display:

• The first display image shows the software version.

• After approx. 1 second, the serial number of the pcb is shown.

• After another approx. 1 second, the text is shown (code must be keyed in).

Press

Key in the following code:

Press

Press

Press

Press

The following display image appears:

down and press

to exit service mode. This option can be selected at any

time.

3 times.

5 times.

Twice.

Once.

Press

Press

12

or

to approve the value.

until the display shows the same value

as that measured with the external

precision instrument.

103887 02

Page 17

The following display image appears:

Press

Press

The mAcal now carries out a self-calibration and adapts its circuits to that measured.

Switch on the mAcal. It is now adjusted and ready for use.

or

to approve the value.

until the display shows the same value as

is measured with the external precision

instrument.

103887 02 13

Page 18

6. TECHNICAL SPECIFICATIONS (23°C±3°C)

Current generation :

Range : 0-24mA

Resolution : 0.01mA

Accuracy (k=2) : 0.05% F.S.

Max. load : 900 Ohm

Current measurement :

Range : 0-24mA

Resolution : 0.001mA

Accuracy (k=2) : 0.05% F.S.

Input impedance : 10 Ohm

Voltage measurement :

Range : OV to +45V

Resolution : 0.1V

Accuracy : 0.5V

Operation temperature : -10°C to +40°C

Storage temperature : -20°C to +50°C

Electromagnetic : Designed for use in basic

environment electromagnetic environment as

defined in EN61326-1 : 2013.

Battery life : 200 hours with external loop pwr.

20 hours with 12mA

output/internal loop pwr.

Battery types : 4 types LR6, AA, 1.5V – Alkaline

Mains adapter : 103950, 6V DC/230mA EURO

with 1.3 mm DC female connector

103957, 6V DC/230mA UK,

with 1.3mm DC female connector

103964, 6V DC/240mA US/JAPAN

with 1.3 mm DC female connector

Dimensions l x w x h : 174 x 66 x 26mm

Weight (incl. batteries,

bag and test leads) : 355 gr.

14

103887 02

Page 19

Standard complied with

Warrenty : (2014/30/EU), EN61326-1 : 2013

Electrical equipment for measurement,

control and laboratory use – EMC

requirements

According to current terms of sale and

Delivery. The guarantee only applies to

factory faults and ceases to apply if the

instrument has been subjected to un authorised interference and/or incorrect

operation.

103887 02 15

Page 20

AMETEK Sensors, Test & Calibration

A busine ss uni t of AMETEK Measurem ent &

Calibration Technologies Division offering the

followi ng industry l eading brand s for test and

Portable dry-block calibrators, precision

therm ometer s and li quid baths. Temper ature

Conveni ent ele ctronic syste ms ran ging from

-25 mbar to 100 0 bar - fully temp eratu re-

compensated for problem-free and accurate

Process sign al meas urement and simulat ion for

easy control lo op cali brati on and me asure ment

Pneumatic floating-ball or hydraulic piston dead

weight te sters with acc uraci es to 0.015% of

readin g. Pres sure ge nerators del iverin g up to

Digital pres sure ga uges a nd calibrator s that are

accurate, easy-to-use and reliable . Designed for

use in the h arsh est env ironments; most pr oduct s

Materials testing machines and software that

guara ntees ex per t materials tes ting so lutions.

Also covering Textu re Analyser s to per form rapid,

gener al food te sting a nd detailed tex ture a nalys is

on a diver se range of food s and cosmetic s.

Allows measur ement a nd characterizati on of

moisture-sensitive PET polymers and polymer

The han d held force gauges and m otoriz ed

tester s have ear ned their reputatio n for qua lity,

reliab ility and acc uracy and they re prese nt the de

facto standard for force measurement.

Hardness testers, durometers, optical systems

and sof tware for data a cquis ition a nd anal ysis.

calibration instrumentation.

JOFRA Calibration Instruments

Temperature Calibrators

sensors for industrial and marine use.

M&G Dead weig ht Teste rs & Pum ps

carr y an IS, IP 67 and DN V rating.

Davenport Polymer Test Equipment

Chatillon Force Measurement

Pressure Calibrators

field use.

Signal Instruments

tasks.

1,000 bar.

Crystal Pressure

Lloyd Materials Testing

dens it y.

Newage Hardness Testing

www.ametekcalibration.com

United Kingdom

Tel +44 (0)1243 833 302

caluk.sales@ametek.com

France

Tel +33 (0)1 30 68 89 40

general.lloyd-instruments@ametek.fr

Germany

Tel +49 (0)2159 9136 510

info.mct-de@ametek.de

Denmark

Tel +45 4816 8000

jofra@ametek.com

Information in this document is subject to change without notice. ©2016, by AMETEK, Inc., www.ametek.com. All rights reserved.

USA

Florida

Tel +1 (800) 527 9999

cal.info@ametek.com

California

Tel +1 (800) 444 1850

crystal@ametek.com

India

Tel +91 22 2836 4750

jofra@ametek.com

Singapore

Tel +65 6484 2388

jofra@ametek.com

China

Shanghai

Tel +86 21 5868 5111

Beijing

Tel +86 10 8526 2111

jofra.sales@ametek.com.cn

Loading...

Loading...