Page 1

t e m p e r a t u r e

Wide temperature range

ITC-155 -23 to 155°C / -9 to 311°F

ITC-320 33 to 320°C / 91 to 608°F

ITC-650 33 to 650°C / 91 to 1202°F

Improved temperature homogeneity

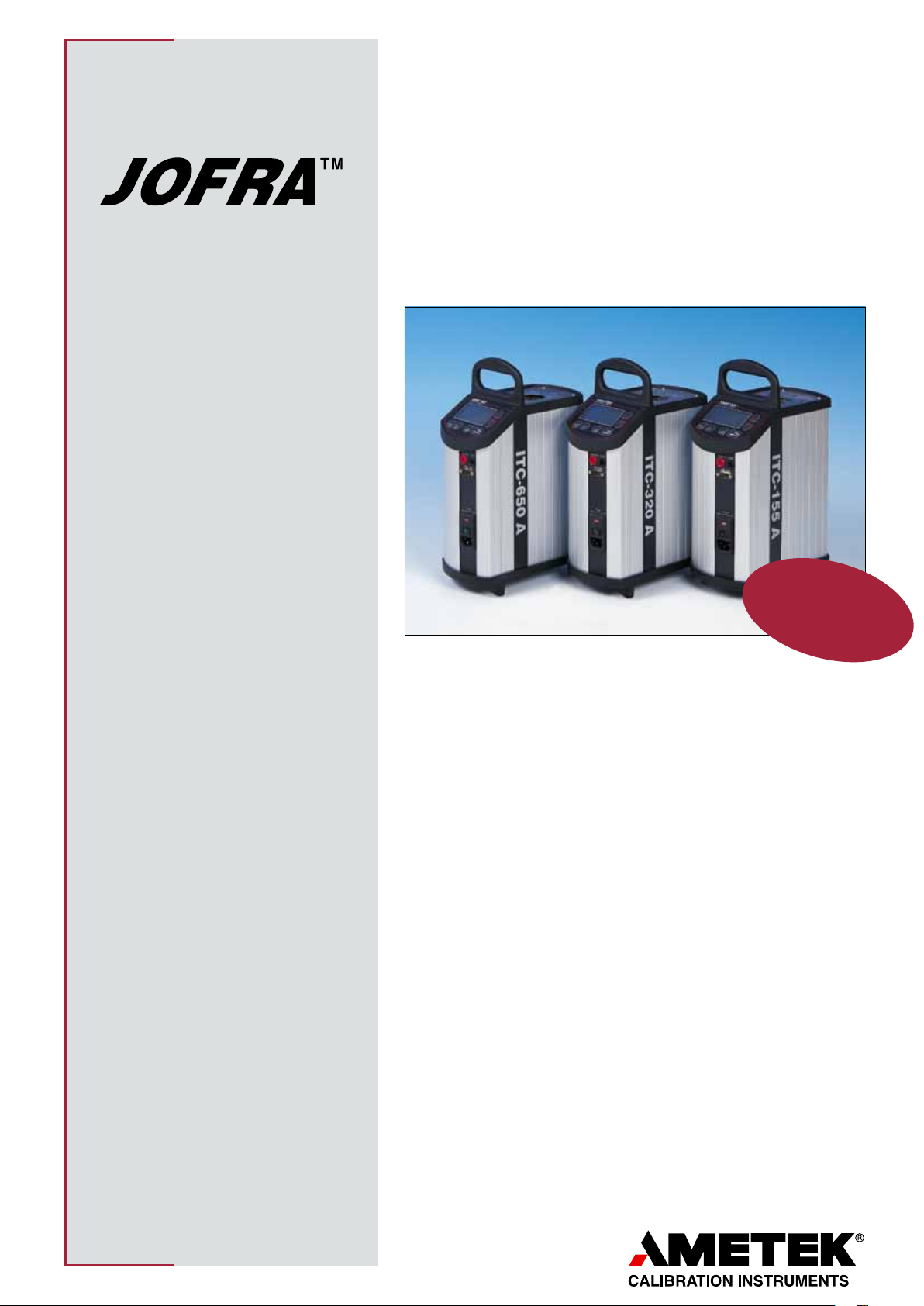

The unique dual-zone heating block

ensures good temperature homogeneity

in the critical calibration zone of the heating

block

Enhanced accuracy and stability

MVI circuitry ensures temperature stability

despite mains supply variations

Timesaving features

Fast one-key-one-function access to the automatic switch test and the step

function

Industrial Temperature Calibrator

ITC-155/320/650

Improved

accuracy

specifications

High accuracy and long-term stability

Specified drift over a one year period

of time. Improves the reliability of the JOFRA

ITC series

Documentation made easy

RS232 communication and JOFRACAL calibration software are included in the standard

delivery

The JOFRA ITC series is the mid-range dry-block calibrator model

offered by AMETEK. The design basis for the ITC series is portability and

ease-of-use supplied at a reasonable cost without sacrificing accuracy,

performance, and features.

The ITC series incorporates the features of the high-end ATC series with

the functionality of the standard CTC series dry-block calibrators.

The ITC series employs the slim and rugged design of the CTC series.

This series also features the intuitive user interface, the clear LCD display, and the functionality that is used in the successful CTC series.

However, the ITC is designed with the state-of-the-art dual-zone heating

block and MVI circuitry that has been adopted from the ATC series. The

MVI circuitry ensures stable temperatures even when the mains supply

is unstable.

The ITC series is designed for both on-site and maintenance shop use.

The applications are generally critical process control but can vary based

on calibration and testing requirements.

The ITC series dry-block calibrators are available in 3 different temperature ranges and all models are equipped with RS232 serial communication capabilities. The standard delivery also includes the JOFRACAL

calibration PC software.

ISO 9001 Manufacturer

Specification Sheet

SS-ITC

Page 2

ITC-320 & ITC-650 dual-zone heating block

The specialized block design increases the temperature homogeneity in the critical calibration zone. It also

minimizes the need to insulate the sensors-under-test

and makes it possible to calibrate liquid-filled and other

mechanical sensors.

The main, or lower, zone ensures optimum heat dissipation throughout the entire block. The secondary, or upper,

zone compensates for the heat loss from the top of the

block and from the sensor-under-test.

ITC-155 heating/cooling block

The model ITC-155 features improved Peltier elements

that employ a ’’Multi-Stage Technology’’. This both

improves efficiency and extends the useful life of the heating/cooling block.

Maximum temperature

From the setup menu, the user can select the maximum

temperature limit for the calibrator. This function prevents

damage to the sensor-under-test caused by the application of excessive temperatures. The feature also aids in

reducing drift resulting from extended periods of exposures to high temperatures. This feature can be locked

with an access code.

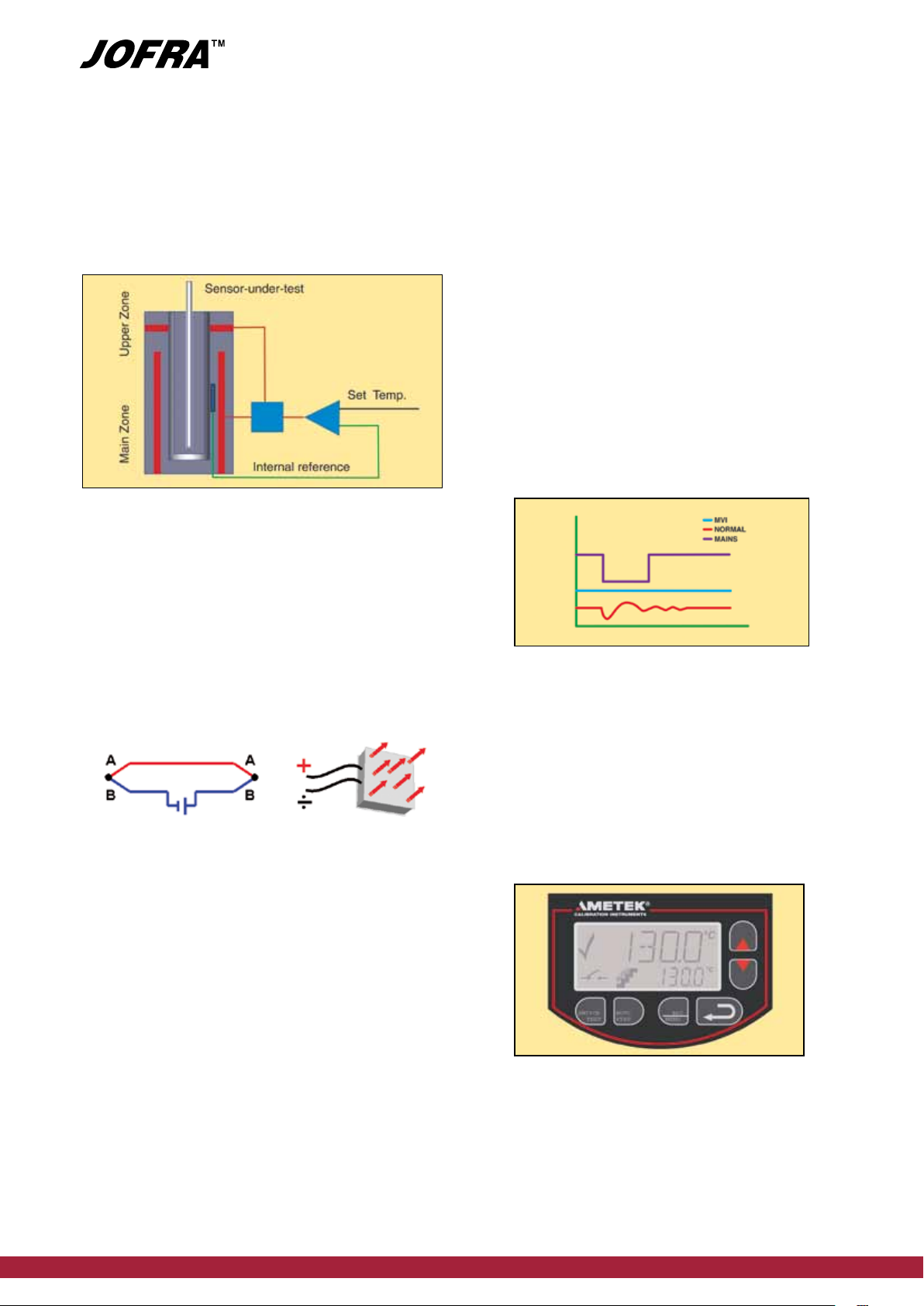

MVI - Improved temperature stability

MVI stands for ’’Mains power Variance Immunity’’.

Unstable mains power supplies are a major contributor to

on-site calibration inaccuracies. Traditional temperature

calibrators often become unstable in production environments where large electrical motors, heating elements,

and other devices are periodically cycled on or off. The

cycling of supply power can cause the temperature regulator to perform inconsistently leading to both inaccurate

readings and unstable temperatures.

The ITC series employ the MVI, thus avoiding such stability problems. The MVI circuitry continuously monitors the

supply voltage and ensures a constant energy flow to the

heating elements.

Peltier effect (ITC-155)

In 1834, Jean Peltier, a French physicist found that an

’’opposite thermocouple effect’’ could be observed when

an electric current was connected to a thermocouple. Heat

would be absorbed at one of the junctions and discharged

at the other junction. This effect is called the ’’PELTIER

EFFECT’’.

The practical Peltier element (electronic heating pump)

consists of many elements of semiconductor material connected electrically in series and thermally in parallel. These

thermoelectric elements and their electrical interconnections are mounted between two ceramic plates. The plates

serve to mechanically hold the overall structure together

and to electrically insulate the individual elements from

one another.

Easy-to-use, intuitive operation

All instrument controls may be performed from the front

panel. The heat source is positioned away from the panel.

This design helps to protect the operator.

The main functions on the ITC series are designed with

one-key-one-function logic. This means that there are no

sub-menus or difficult to remember multiple keystrokes

necessary to access primary functions.

The easy-to-read, backlit display features dedicated icons,

which help in identifying instrument conditions and operational steps.

2 www.jofra.com Industrial Temperature Calibrator • ITC

Page 3

Set temperature

AUTO

STEP

ESC

MENU

SWITCH

TEST

1

2

3

4

START

AUTO

STEP

ESC

MENU

SWITCH

TEST

START

Slope rate

(Ramp)

AUTO

STEP

ESC

MENU

SWITCH

TEST

The ’’Up’’ and ’’Down’’ arrow keys allow the user to set

the exact temperature desired with a resolution of 0.1°.

Instrument setups

The ITC series stores the complete instrument setup,

including: engineering units, stability criteria, resolution,

display contrast, slope (ramp) rate, auto-step settings, and

maximum temperature.

Stability indicator

A bold checkmark on the display indicates that the calibrator has reached the desired set temperature and is

stable. The operator may change the stability criteria and

establish a greater sense of security in the calibration

results. A convenient countdown timer is activated five

minutes before the unit reaches stability.

Automatic switch test

Operators can save a lot of time using the automatic thermoswitch test function to find values for the ’’Open’’ and

’’Close’’ temperatures. Additionally, this feature displays

the hysteresis (deadband) between the two points. The

feature ensures a very high repeatability when testing

thermoswitches. Simply press the ’’SWITCH TEST’’ key to

activate the function.

Re-calibration/adjustments

The ITC series has a very easy and straightforward procedure for re-calibration/adjustment. There is no need for a

screwdriver or PC software. The only thing you need is a

reliable reference thermometer.

Place the probe in the calibrator and follow the instructions on the display. Third-party labs and calibration facilities will be able to perform this function if a certificate

from an independent source is necessary. Of course,

AMETEK can provide you with a traceable calibration certificate from our labs when you require a higher level of

confidence.

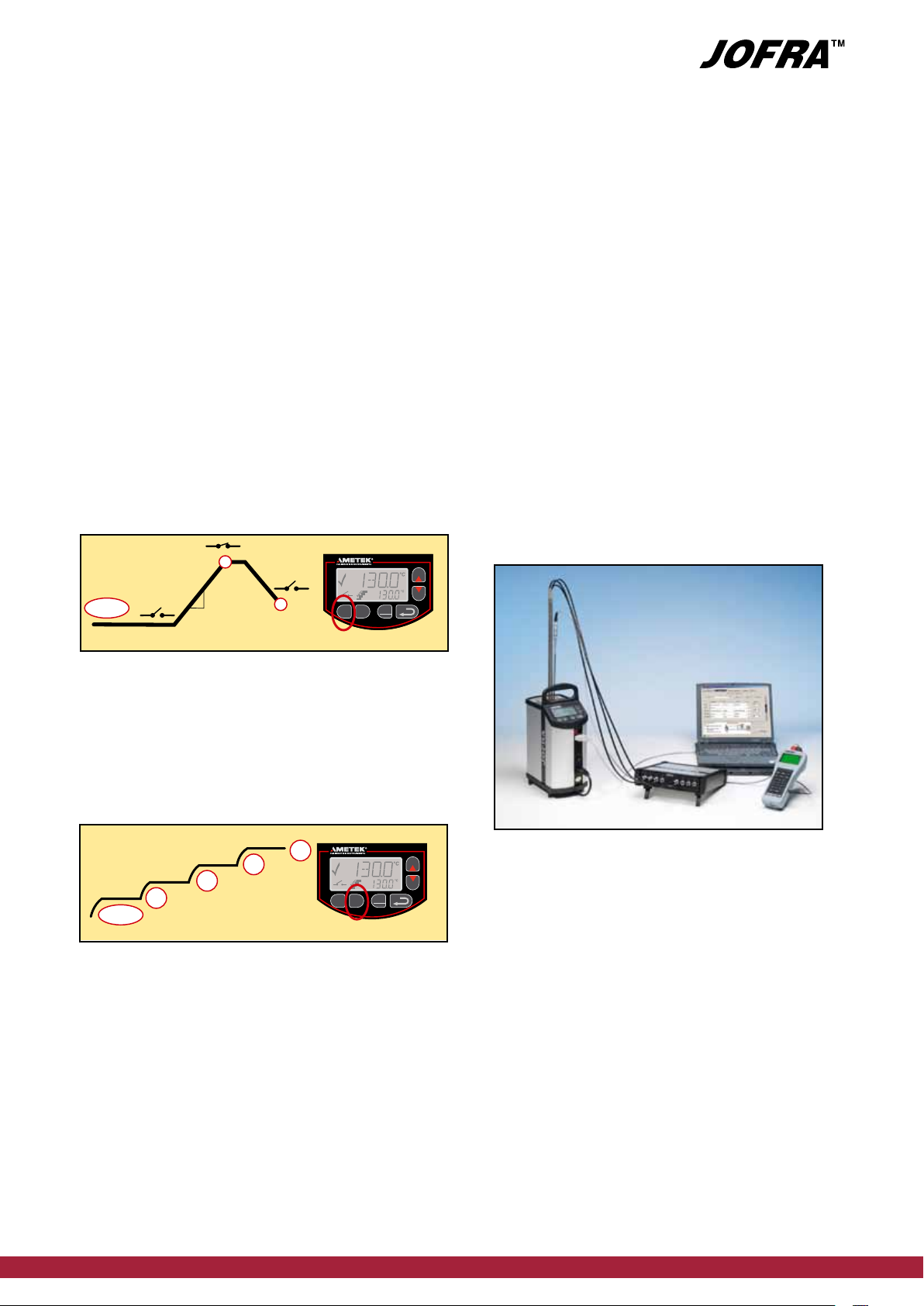

Calibration of up to 24 sensors with JOFRA ASM

Using the JOFRA ITC series together with the ASM

Advanced Signal Multi-scanner offers a great time-saving

automatic solution to calibrate multiple temperature sensors at the same time.

The ASM series is an eight channel scanner controlled by

JOFRACAL software on a PC. Up to 3 ASM units can be

stacked to calibrate up to 24 sensors at the same time.

It can handle signals from 2-, 3- and 4 wire RTD’s, TC’s,

transmitters, thermisters, temperature switches and voltage.

Please also see more in specification sheet SS-CP-2360,

which can be found at www.jofra.com

Auto-stepping

This feature saves manpower. The operator may stay in

the control room, or another remote location, monitoring the output from the sensor-under-test while the ITC

series calibrator is placed in the process and automatically

changes the temperature using a programmed step value

and rate. Up to 9 different temperature steps may be programmed, including the hold time for each step.

www.jofra.com 3ITC • Industrial Temperature Calibrator

Page 4

JOFRACAL CALIBRATION SOFTWARE

JOFRACAL calibration software ensures easy calibration

of RTD´s, thermocouples, transmitters, thermoswithes,

pressure gauges and pressure switches. JOFRACAL can

be used with JOFRA DPC-500, APC, CPC and IPI pressure calibrators, all JOFRA temperature calibrators, as well

as JOFRA AMC900, ASC300 multi signal calibrator and

ASM-800 signal multi scanner.

JOFRACAL calibration software may also be used for

manual calibrations, as it can be set up to accept manual

entry of calibration data together with other liquid baths,

ice points or dry-block heat sources.

The calibration data collected may be stored on a PC for

later recall or analysis. The ITC calibrator stores the calibration procedure and may be taken out to the process

site without using a personal computer.

Once all calibrations are completed, the data may be

uploaded to the JOFRACAL calibration software for postprocessing and printing of certificates. The calibration data

collected may be stored on the personal computer for

later recall or analysis.

The JOFRACAL temperature

calibration software may be

donwloaded from our web-page

www.jofra.com.

Please also see more about

JOFRACAL calibration software

in specification sheet SS-CP2510, which can be found at

www.jofra.com

JOFRACAL software

Minimum hardware requirements for JOFRACAL calibration software.

TM

• INTEL

• (PENTIUM

• 32 MB RAM (64 MB recommended)

• 80 MB free disk space on hard disk prior to installation

• Standard VGA (800 x 600, 16 colors) compatible screen

• (1024 x 786, 256 colors recommended)

• CD-ROM drive for installation of the program

• 1 free RS232 serial port

486 processor

TM

800 MHz recommended)

STANDARD DELIVERY

• ITC dry-block calibrator (user specified)

• Mains power cable (user specified)

• Traceable certificate - temperature performance

• Insert (user specified)

• 3 pcs. insulation plugs for 5, 8, 11 mm sensors (ITC-155

only)

• Tool for insertion tubes

• RS232 cable

• JOFRACAL calibration software

• User manual

• Reference manual (English)

• Test cables (1 x red, 1 x black)

ACCESSORIES

122832 Cleaning Brushes - 4 mm - Package of 3 pcs

60F174 Cleaning Brushes - 6 mm - Package of 3 pcs

122822 Cleaning Brushes - 8 mm - Package of 3 pcs

123374 Set of 3 pcs of insulation plugs / 4 mm ref. hole

* 5, 8 and 11 mm / 0.2, 0.31 and 0.43 in. (ITC-155 A only)

125510 Set of 3 pcs of insulation plugs / 1/4 in ref. hole

* 5, 8 and 11 mm / 0.2, 0.31 and 0.43 in. (ITC-155 A only)

125068 Support rod set for sensors, 2 gribs, 2 fixtures

* Support rod set can be mounted on all JOFRA

dry-blocks

125066 Extra fixture for sensor grib

125067 Extra sensor grib

125002 Edge port Converter with 4 pcs of RS232 ports

123396 Carrying Case for ITC Series

Carrying case (Optional) 123396

The optional protective carrying

case ensures safe transportation

and storage of the instrument and

all associated equipment.

Heat shield (Optional) - 104216

An external heat shield is available and may be placed on top of

the calibrator to reduce the hot air

stream around the sensor-undertest. This is especially important for

testing thermocouples having headmounted transmitters with coldjunction compensation.

Support rod set (Optional) 125068

Support rod for sensors to be

mounted on all JOFRA dry-block

calibrators. Holds the sensor under

test in their position, while calibrating. Includes 2 sensors grips and 2

fixtures for sensor gribs.

4 www.jofra.com Industrial Temperature Calibrator • ITC

Page 5

FUNCTIONAL SPECIFICATIONS

Mains specifications

Voltage ITC-155/320 A .........115V(90-127) / 230V(180-254)

Voltage ITC-650 A .............. 115V(100-127) / 230V(200-254)

Frequency, non US deliveries ............... 50 Hz ±5, 60 Hz ±5

Frequency, US deliveries .......................................60 Hz ±5

Power consumption (max) ITC-155 A .......................150 VA

Power consumption (max) ITC-320/650 A ..............1150 VA

Temperature range

ITC-155 A

Maximum ....................................................... 155°C / 311°F

Minimum @ ambient temp. 0°C / 32°F .........-39°C / -38°F

Minimum @ ambient temp. 23°C / 73°F ...........-23°C / -9°F

Minimum @ ambient temp. 40°C / 104°F ........ -10°C / 14°F

ITC-320 A ....................................33 to 320°C / 91 to 608°F

ITC-650 A ..................................33 to 650°C / 91 to 1202°F

Resolution (user-selectable)

All temperatures .................................................... 1° or 0.1°

Stability - NEW

ITC-155 A ................................................±0.01°C / ±0.02°F

ITC-320 A ................................................±0.02°C / ±0.04°F

ITC-650 A ................................................±0.04°C / ±0.07°F

Measured after the stability indicator has been on for 10 minutes.

Measuring time is 30 minutes.

Time to stability (approximate)

All models ...........................................................10 minutes

Accuracy - NEW

ITC-155 A ................................................±0.18°C / ±0.32°F

ITC-320 A ................................................±0.25°C / ±0.45°F

ITC-650 A ................................................±0.45°C / ±0.81°F

12 month period. Specification by use of the internal reference.

Radial homogeneity (difference between holes) - NEW

ITC-155 A ....................................................0.02°C / 0.04°F

ITC-320 A ....................................................0.04°C / 0.07°F

ITC-650 A ...................................................... 0.1°C / 0.18°F

Immersion depth

ITC-155 A ..................................................160 mm / 6.30 in

ITC-320 A / ITC-650 A ............................. 150 mm / 5.91 in

Well diameter

ITC-155 A ................................................... 20 mm / 0.79 in

ITC-320/ITC-650 A ...................................... 30 mm / 1.18 in

Heating time

ITC-155 A -20 to 23°C / -4 to 73°F .................... 4 minutes

23 to 155°C / 73 to 311°F ............... 14 minutes

-20 to 155°C / -4 to 311°F .............. 18 minutes

ITC-320 A 50 to 320°C / 122 to 608°F ............... 7 minutes

ITC-650 A 50 to 650°C / 122 to 1202°F ........... 25 minutes

1) Improved specifications from January 1, 2008

1)

1)

1)

Cooling time

ITC-155 A 155 to 100°C / 311 to 212°F ............. 4 minutes

155 to 23°C / 311 to 73°F ............... 14 minutes

23 to -20°C / 73 to -4°F .................. 23 minutes

155 to -20°C / 311 to -4°F ...............37 minutes

ITC-320 A 320 to 100°C / 608 to 212°F ........... 30 minutes

320 to 50°C / 608 to 122°F ............ 60 minutes

ITC-650 A 650 to 100°C / 1202 to 212°F ......... 56 minutes

650 to 50°C / 1202 to 122°F ........... 95 minutes

Switch input (dry contact)

Test voltage .............................................Maximum 5 VDC

Test current .............................................Maximum 2.5 mA

PHYSICAL SPECIFICATIONS

Instrument dimensions

L x W x H ............241 x 139 x 375 mm / 9.5 x 5.5 x 14.8 in

Instrument weight

ITC-155 A .....................................................7.6 kg / 16.8 lb

ITC-320 A .....................................................6.5 kg / 14.3 lb

ITC-650 A ..................................................... 8.5 kg / 18.7 lb

Insert dimensions

ITC-155 A Outer diameter ................19,9 mm / 0.78 in

Inner diameter .................16,9 mm / 0.67 in

Length ..............................150 mm / 5.91 in

ITC-320/650 A Outer diameter ................29,7 mm / 1.17 in

Inner diameter (multi hole) . 25,9 mm / 1.02 in

Inner diameter (single hole) 22,0 mm / 0.87 in

Length ..............................160 mm / 6.30 in

Weight of non-drilled insert (approximate)

ITC-155 A .......................................................130 g / 4.6 oz

ITC-320/650 A .............................................. 940 g / 33.2 oz

Shipping (including optional carrying case)

Weight: ITC-155 A ..................................... 14.0 kg / 30.9 lb

Weight: ITC-320 A ......................................13.7 kg / 30.2 lb

Weight: ITC-650 A ......................................15.7 kg / 34.6 lb

Size: L x W x H ..490 x 220 x 405 mm / 19.3 x 8.7 x 15.9 in

Shipping (without carrying case)

Weight: ITC-155 A ......................................11.0 kg / 24.3 lb

Weight: ITC-320 A .....................................10.7 kg / 23.6 lb

Weight: ITC-650 A ......................................12.7 kg / 28.0 lb

Size: L x W x H ..460 x 216 x 405 mm / 18.1 x 8.5 x 15.9 in

Shipping (carrying case only)

Weight: ...........................................................5.0 kg / 11 lb

Size: L x W x H ..490 x 220 x 405 mm / 19.3 x 8.7 x 15.9 in

Miscellaneous

Serial data interface ............................. RS232 (9-pin Male)

Operating temperature ....................0 to 40°C / 32 to 104°F

Storage temperature ....................-20 to 60

Humidity ......................................................... 0 to 90% RH

Protection class ..........................................................IP-10

o

C / -4 to 140oF

www.jofra.com 5ITC • Industrial Temperature Calibrator

Page 6

PREDRILLED INSERTS FOR ITC SERIES - 4 MM REFERENCE HOLE

JOFRA dry-block insert compatibility and materials:

ATC-320 = ATC-650 = ITC-320 = ITC-650 (made of brass)

ATC-155 = ATC-156 (made of aluminum)

ATC-157 = ITC-155 (made of aluminum)

ATC-140 = ATC-250 (made of aluminum)

All specifications on hole sizes are referring to the outer

diameter of the sensor-under-test.

The correct clearance size is applied in all predrilled

inserts.

Probe diameter Insert code 1ITC-155 A ITC-320/650 A

3 mm 003

4 mm 004

5 mm 005

6 mm 006

7 mm 007

8 mm 008

9 mm 009

10 mm 010

11 mm 011

12 mm 012

13 mm 013

14 mm 014

15 mm 015

16 mm 016

Package of the above

inserts

Set of insulation plugs

- 124699 124701

- 123374 N/A

123270 105622

123271 105624

123272 105626

123273 105628

123274 105630

123275 105632

123276 105634

123277 105636

123278 105638

2

123299

123300

N/A 105644

N/A 105646

N/A 105648

105640

2

105642

Probe diameter Insert code 1ITC-155 A ITC-320/650 A

1/8 in 125

3/16 in 187

1/4 in 250

5/16 in 312

3/8 in 375

7/16 in 437

1/2 in 500

9/16 in 562

5/8 in 625

Package of the above

inserts

Set of insulation plugs

Note: All inserts (metric and inches) are supplied with a hole for the

4 mm OD reference probe.

Note: All inserts (metric and inches) for ITC-155 are supplied with a

matching insulation plug.

Note 1: Use the insert code, when ordered as the standard insert

together with a new calibrator.

Note 2: ITC-155 : 12 mm, 13 mm, 7/16 in and 1/2 in inserts are delivered

without the 4 mm reference hole, but supplied with a matching

insulation plug.

- 124700 124702

- 123374 N/A

123279 105676

123280 105678

123281 105680

123282 105682

123283 105684

2

123301

2

123302

N/A 105690

N/A 105692

PREDRILLED INSERTS FOR ITC SERIES - 1/4 IN (6.35 mm) REFERENCE HOLE

Probe diameter Insert code 1ITC-155 A ITC-320/650 A

3 mm 803

4 mm 804

5 mm 805

6 mm 806

7 mm 807

8 mm 808

9 mm 809

10 mm 810

11 mm 811

12 mm 812

13 mm 813

14 mm 814

15 mm 815

Package of the above

inserts

Set of insulation plugs

- 125387 125388

- 125510 N/A

125290 125259

125291 125261

125292 125263

125293 125265

125294 125267

125295 125269

N/A 125271

N/A 125273

N/A 125277

2

123299

123300

N/A 125283

N/A 125285

125279

2

125281

Probe diameter Insert code 1ITC-155 A ITC-320/650 A

1/8 in

3/16 in

1/4 in

5/16 in

3/8 in

7/16 in

1/2 in

9/16 in

Package of the above

inserts

Set of insulation plugs

Note: All inserts (metric and inches) are supplied with a hole for

the 1/4 in OD reference probe.

Note: All inserts (metric and inches) for ITC-155 are supplied with

a matching insulation plug.

Note 1: Use the insert code, when ordered as the standard insert

together with a new calibrator.

Note 2: ITC-155: 12 mm, 13 mm, 7/16 in and 1/2 in inserts are delivered

without the 1/4 in reference hole, but supplied with a matching

insulation plug.

901 125314 125296

902 125315 125298

903 125316 125300

904 125317 125303

905 N/A 125305

906 123301

907 123302

908 N/A 125311

- 125390 125391

- 125510 N/A

2

2

105686

105688

125307

125309

UNDRILLED INSERTS FOR ITC SERIES

Inserts ITC-155 A ITC-320/650 A

5-pack, undrilled inserts

5-pack, undrilled inserts with a 4 mm hole for the reference probe

5-pack, undrilled inserts with a 1/4 in hole for the reference probe

One undrilled insert

Undrilled insulation plug

123286 122719

123285 122721

125313 125287

N/A N/A

123304 N/A

6 www.jofra.com Industrial Temperature Calibrator • ITC

4 mm Reference

sensor

1/4 in Reference

sensor

Page 7

MULTI-HOLE INSERTS FOR ITC SERIES - METRIC (MM)

Spare part no. for multi-hole inserts - metric (mm)

Insert code

M01

M02

M03

M04

M06

M07

M08

1

ITC-155 A ITC-320/650 A

123294 122750

123295 122752

123296 122754

N/A 122756

125377 N/A

125378 N/A

125379 N/A

Note: All multi-hole inserts (metric and inches) for ITC-155

are supplied with a matching insulation plug.

Note: Remember to use matching insulation plugs.

Note 1: Use the insert code, when ordered as the standard insert

together with a new calibrator.

4 mm Reference

sensor

6

Multi-hole M01

(ITC-155 A)

1/4 in Reference

sensor

6

6

6

6

6

4 mm Reference

sensor

5

Multi-hole M02

(ITC-155 A)

1/4 in Reference

sensor

3

5

4

3

6

4

6

4 mm Reference

sensor

4

4

Multi-hole M01

(ITC-320/650 A)

4 mm Reference

sensor

Multi-hole M03

1/4 in Reference

sensor

1/4 in Reference

sensor

4

4

3

3

3

3

333

(ITC-155 A)

3

3

3

3

3

3

3

4 mm Reference

sensor

6

6

1/4 in Reference

sensor

6

6

6

Multi-hole M02

(ITC-320/650 A)

4 mm Reference

sensor

3

3

3

3

3

1/4 in Reference

sensor

3

3

3

3

6

Multi-hole M03

(ITC-320/650 A)

4 mm Reference

sensor

6

3

5

9

4

1/4 in Reference

sensor

3

6

Multi-hole M06

(ITC-155 A)

Multi-hole M07

(ITC-155 A)

Multi-hole M08

(ITC-155 A)

MULTI-HOLE INSERTS FOR ITC SERIES - IMPERIAL (INCH)

Spare part no. for multi-hole inserts - imperial (inch)

Insert code

M02

M04

M05

M06

M09

1

ITC-155 A ITC-320/650 A

N/A N/A

123297 N/A

123298 122758

N/A 122760

125380 N/A

Note: All multi-hole inserts (metric and inches) for ITC-155

are supplied with a matching insulation plug.

Note: Remember to use matching insulation plugs.

Note 1: Use the insert code, when ordered as the standard

insert together with a new calibrator.

4 mm Reference

sensor

1/8

3/16

Multi-hole M04

(ITC-155 A)

1/8

1/4

4 mm Reference

sensor

1/4

Multi-hole M05

(ITC-155 A)

1/4

1/4

4 mm Reference

sensor

1/4

1/4

Multi-hole M05

(ITC-320/650 A)

1/4

1/4

1/4

1/4 in Reference

sensor

4 mm Reference

sensor

1/4

1/8

1/8

1/4

3/16

Multi-hole M09

(ITC-155 A)

Multi-hole M04

(ITC-320/650 A)

1/8

3/8

1/4

3/16

Multi-hole M06

(ITC-320/650 A)

www.jofra.com 7ITC • Industrial Temperature Calibrator

Page 8

ORDERING INFORMATION

Order number Description

Base model number

ITC155A ITC-155 series, -23 to 155°C (-9 to 311°F)

ITC320A ITC-320 series, 50 to 320°C (122 to 608°F)

ITC650A ITC-650 series, 50 to 650°C (122 to 1202°F)

Power supply (US deliveries 60 Hz only)

115 115VAC

230 230VAC

Mains power cable type

A European, 230V

B USA/CANADA, 115V

C UK, 240V

D South Africa, 220V

E Italy, 220V

F Australia, 240V

G Denmark, 230V

H Switzerland, 220V

I Israel, 230V

Insert type and size

XXX 1 x Insert for dry-block configuration

(please see the previous insert pages for

the right insert codes)

Calibration certificate

F Traceable calibration certificate

(standard for Europe, Asia, Australia and Africa)

G NIST traceable calibration certificate

(standard for Western Hemisphere)

H Accredited calibration certificate

Options

C Carrying case

X No option used

ITC320A115BM06CGXX Sample order number

JOFRA ITC-320 A dry-block calibrator,

115VAC power with US power cord and

predrilled multi-hole insert type 6 including

carrying case and NIST traceable certificate.

AMETEK Calibration Instruments

is one of the world’s leading manufacturers and

developers of calibration instruments for temperature,

pressure and process signals as well as for temperature

sensors both from a commercial and a technological

point of view.

JOFRA Temperature Instruments

Portable precision thermometers. Dry-block and liquid

bath calibrators : 5 series, with more than 25 models

and temperature ranges from - 90° to 1205°C / -130°

to 2200°F. All featuring speed, por tability, accuracy

and advanced documenting functions with JOFRACAL

calibration sof tware.

JOFRA Pressure Instruments

Convenient electronic systems ranging from -25 mbar

to 1000 bar (0.4 to 15,000 psi) - multiple choices

of pressure ranges, pumps and accuracies, fully

temperature-compensated for problem-free and accurate

field use.

JOFRA Signal Instruments

Process signal measurement and simulation for easy

control loop calibration and measurement tasks - from

handheld field instruments to laboratory reference level

bench top instruments.

JOFRA / JF Marine Instrum ents

A complete range of calibration equipment for

temperature, pressure and signal, approved for marine

use.

FP Temperature Sensors

A complete range of temperature sensors for industrial

and marine use.

M&G Pressure Testers

Pneumatic floating-ball or hydraulic piston dead weight

testers with accuracies to 0.015% of reading.

M&G Pumps

Pressure generators from small pneumatic “bicycle” style

pumps to hydraulic pumps generating up to 1,000 bar

(15,000 psi).

AMETEK Denmark A/S

Gydevang 32-34 | 3450 Allerød | Denmark

T: +45 4816 8000 | ametek@ametek.dk

Sales & Service:

Europe, Asia, Africa, Middle East and South America

Information in this document is subject to change without notice. ©2009, by AMETEK, Inc., www.ametek.com. All rights reserved.

8 www.jofra.com

.. .beca use calib ratio n is

a ma tter of c onfid ence

AMETEK Mansfield & Green (North America)

T: +1 800 527 9999 | cal.info@ametek.com

AMETEK Singapore Pte. Ltd. (Singapore)

T: +65 6 484 2388 | aspl@ametek.com.sg

AMETEK Inc. Beijing Rep. Office (China)

T: +86 10 8526 2111 | jofra@ametek.com.cn

AMETEK GmbH (Germany)

T: +49 2159 9136 510 | info.mct-de@ametek.de

AMETEK Calibration Instruments (UK)

T: +44 (0) 1243 833 302 | jofra@ametek.co.uk

www.jofra.com

Pub code SS-ITC Issue 0912

Loading...

Loading...