Page 1

Reference Manual

Temperature Calibrator

JOFRA ITC-155/320/650 A

Copyright 2002 AMETEK DENMARK A/S

Page 2

About this manual….

• The structure of the manual

This reference manual is aimed at users who are familiar with

Ametek calibrators, as well as those who are not. The manual is

divided into 10 chapters which describe how to set up, operate,

service and maintain the calibrator. The technical specifications

are described and accessories may be ordered from the list of

accessories.

Along with the calibrator, you should have received a multilingual user manual which sets out the operating instructions for

the instrument. It is designed to provide a quick reference guide

for use in the field.

• Safety symbols

This manual contains a number of safety symbols designed to

draw your attention to instructions which must be followed when

using the instrument, as well as any risks involved.

Warning

Events which may compromise the safe use of

the instrument and result in considerable

personal or material damage.

Caution…

Events which may compromise the safe use of

the instrument and result in slight personal or

material damage.

Note…

2 17-08-2004 123312 03

Special situations which demand the user’s

attention.

Page 3

List of contents

Introduction ..............................................................................4

1.0

2.0 Safety instructions ...................................................................6

3.0 Setting up the calibrator ........................................................11

3.1 Receipt of the calibrator.............................................................. 11

3.2 Preparing the calibrator .............................................................. 13

3.3 Choice of insertion tube .............................................................. 14

3.4 Inserting the sensor .................................................................... 16

4.0 Operating the calibrator.........................................................19

4.1 Keyboard, display and connections............................................ 19

4.2 Starting the calibrator.................................................................. 22

4.3 Selecting the set-temperature .................................................... 22

4.4 Using the SWITCH TEST ........................................................... 24

4.5 Using the AUTO STEP ............................................................... 28

4.6 Using the MENU ......................................................................... 31

4.6.1 Adjusting the temperature unit ....................................... 32

4.6.2 Adjusting the max-temperature ...................................... 33

4.6.3 Adjusting the SWITCH TEST slope rate ........................ 33

4.6.4 Adjusting the extra stability time..................................... 34

4.6.5 Adjusting the temperature resolution ............................. 34

4.7 Simulation/training ...................................................................... 35

5.0 Storing and transporting the calibrator ...............................36

6.0 Errors.......................................................................................38

7.0 Setting the main voltage and replacing the fuses..............40

7.1 Returning the calibrator for service............................................. 41

8.0 Maintenance............................................................................43

8.1 Cleaning...................................................................................... 43

8.2 Adjusting and calibrating the instrument..................................... 44

8.2.1 Adjusting the calibration date ......................................... 46

8.2.2 Calibrating/adjusting the instrument............................... 47

9.0 Technical specifications........................................................51

10.0 List of accessories.................................................................59

123312 03 17-08-2004 3

Page 4

1.0 Introduction

Congratulations on your new Ametek Jofra ITC

Calibrator!

With the Ametek Jofra calibrator, you have chosen an extremely

effective instrument which we hope will live up to all your expectations.

Over the past many years, we have acquired extensive knowledge of

industrial temperature calibration. This expertise is reflected in our

products which are all designed for daily use in an industrial

environment. Please note that we would be very interested in hearing

from you if you have any ideas or suggestions for changes to our

products.

This reference manual applies to the following instruments:

• Jofra ITC-155 A

• Jofra ITC-320 A

• Jofra ITC-650 A

ISO-9001 certified

)

4 17-08-2004 123312 03

Ametek Denmark A/S was awarded the

ISO-9001 certificate in September 1994 by

BVQI - Bureau Veritas Quality International.

Page 5

) CE-label

Your new calibrator bears the CE label and

conforms to the EMC directive and the Lowvoltage Directive.

) Technical assistance

Please contact the dealer from whom you acquired the instrument

if you require technical assistance.

) Guarantee

According to current terms of sale and delivery.

This guarantee only covers defects in manufacture and becomes

void if the instrument has been subject to unauthorised

intervention and/or misuse.

123312 03 17-08-2004 5

Page 6

2.0 Safety instructions

Read this manual carefully before

using the instrument!

Please follow the instructions and procedures

described in this manual. They are designed to

allow you to get the most out of your calibrator and

avoid any personal injuries and/or damage to the

instrument.

Warning……

About the use:

• The calibrator must not be used for any purposes

other than those described in this manual.

• The calibrator is designed for interior use only and

should not be used in risk-prone areas, where

vapour or gas leaks, etc. may constitute an

explosives hazard.

• The calibrator must be kept clear within an area of

20 cm on all sides and 1 metre above the calibrator.

• Never use heat transfer fluids such as silicone, oil,

paste, etc.

These fluids may penetrate the calibrator and cause

damage or create poisonous fumes.

• The calibrator must be switched off before any

attempt to service the instrument is made.

• When cleaning the well, REMEMBER, wear goggles

when using compressed air!

About the frontpanel:

• The switch-test connectors, on the front panel of the

calibrator, must NEVER be connected to a voltage

source.

• Thermostats must not be connected to any other

voltage source during a test.

6 17-08-2004 123312 03

Page 7

About insertion tubes and insulation plugs:

• Never leave hot insertion tubes which have been

removed from the calibrator unsupervised – they

may constitute a fire hazard.

If you intend to store the calibrator in the optional

aluminium carrying case after use, you must ensure

that the instrument has cooled to a temperature

below 100°C/212°F before placing it in the carrying

case.

About the fuses:

• The fuse box must not be removed from the power

control switch until the mains cable has been

disconnected.

• The two main fuses must be identical and correspond

to the chosen voltage.

123312 03 17-08-2004 7

Page 8

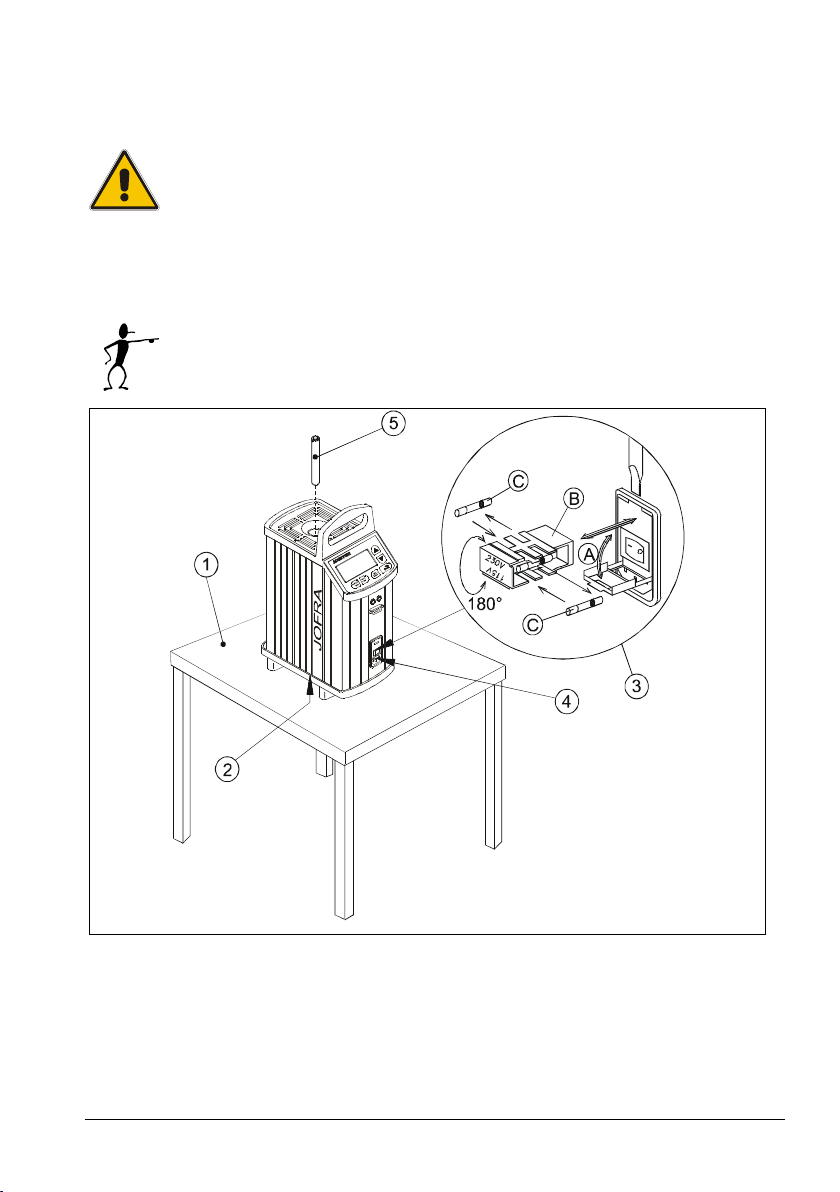

Caution – Hot surface

This symbol is engraved in the grid plate.

• Do not touch the grid plate, the well or the insertion

tube as the calibrator is heating up – they may be

very hot.

• Do not touch the tip of the sensor when it is

removed from the insertion tube/well – it may be very

hot.

• Do not touch the handle of the calibrator during use

– it may be very hot.

• Over 100°C/212°F

If the calibrator has been heated up to temperatures

above 100°C/212°F, you must wait until the

instrument reaches a temperature below

100°C/212°F before you switch it off.

Below 0°C/32°F (applies only to the ITC-155 A

model)

If the calibrator has reached a temperature below

0°C/32°F, ice crystals may form on the insertion tube

and the well. This, in turn, may cause verdigris to

form on the material.

To prevent this from happening, simply heat up the

calibrator to 50°C/122°F.

8 17-08-2004 123312 03

Page 9

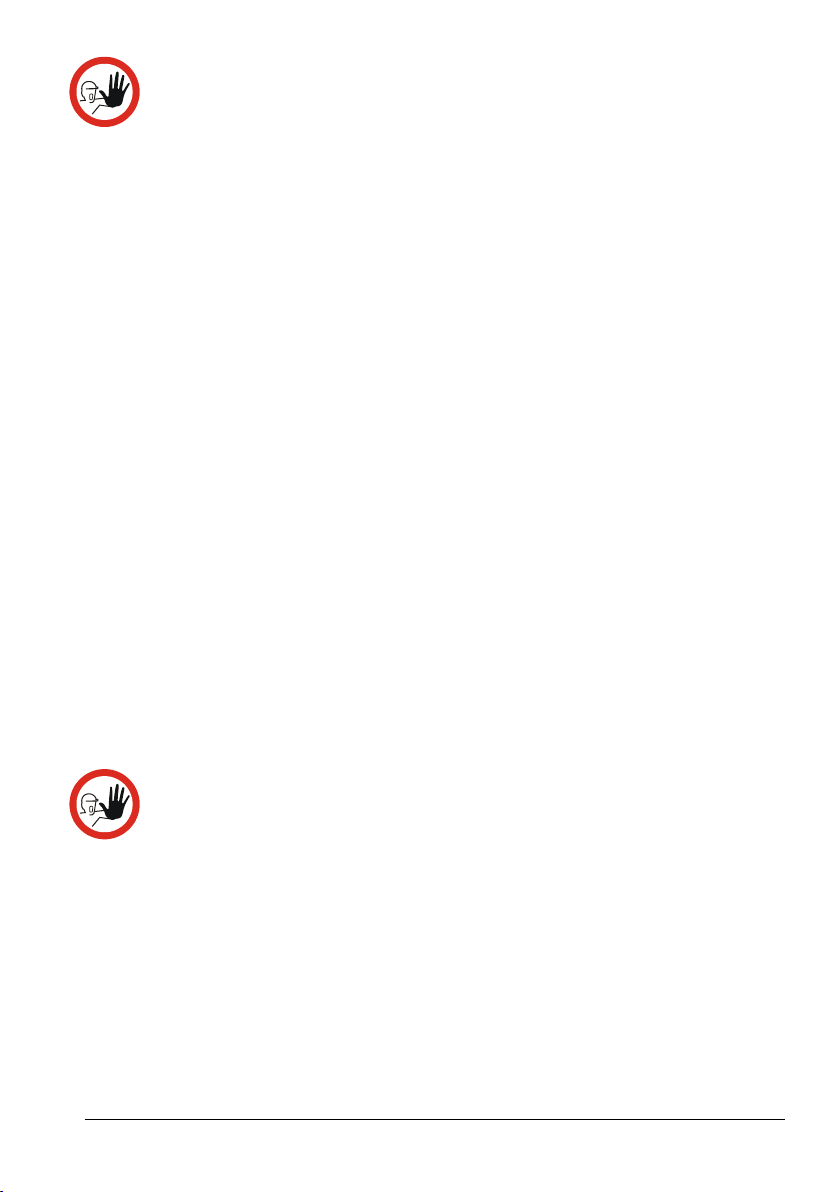

Caution…

About the use:

• Do not use the instrument if the ventilator is out of

order.

• Before cleaning the calibrator, you must switch it off,

allow it to cool down and remove all cables.

About the well, insertion tube and grid plate:

• The well and the insertion tube must be clean before

use.

• Scratches and other damage to the insertion tubes

should be avoided by storing the insertion tubes

carefully when not in use.

• The insertion tube must never be forced into the

well. The well could be damaged as a result, and the

insertion tube may get stuck.

• Before using new insertion tubes for the calibration,

the insertion tubes must be heated up to maximum

temperature - 320°C (608°F) / 650°C (1202°F) - for a

period of minimum 30 minutes.

In order to ensure the best calibration of your

sensors please avoid using insertion tubes in the

ITC-320 calibrator which have been used in the ITC 650 calibrator.

• The insertion tube must always be removed from the

calibrator after use.

The humidity in the air may cause verdigris to form

on the insertion tube inside the instrument. There is

a risk that the insertion tube may become stuck if

this is allowed to happen.

• If the calibrator is to be transported, the insertion

tube must be removed to avoid damage to the

instrument.

123312 03 17-08-2004 9

Page 10

Note…

The product liability only applies if the instrument

is subject to a manufacturing defect. This liability

becomes void if the user fails to follow the

maintenance instructions set out in this manual or

uses unauthorised spare parts.

10 17-08-2004 123312 03

Page 11

3.0 Setting up the calibrator

3.1 Receipt of the calibrator

When you receive the instrument…

• Carefully unpack and check the calibrator and the accessories.

• Check the parts off against the list shown below.

If any of the parts are missing or damaged, please contact the

dealer who sold the calibrator.

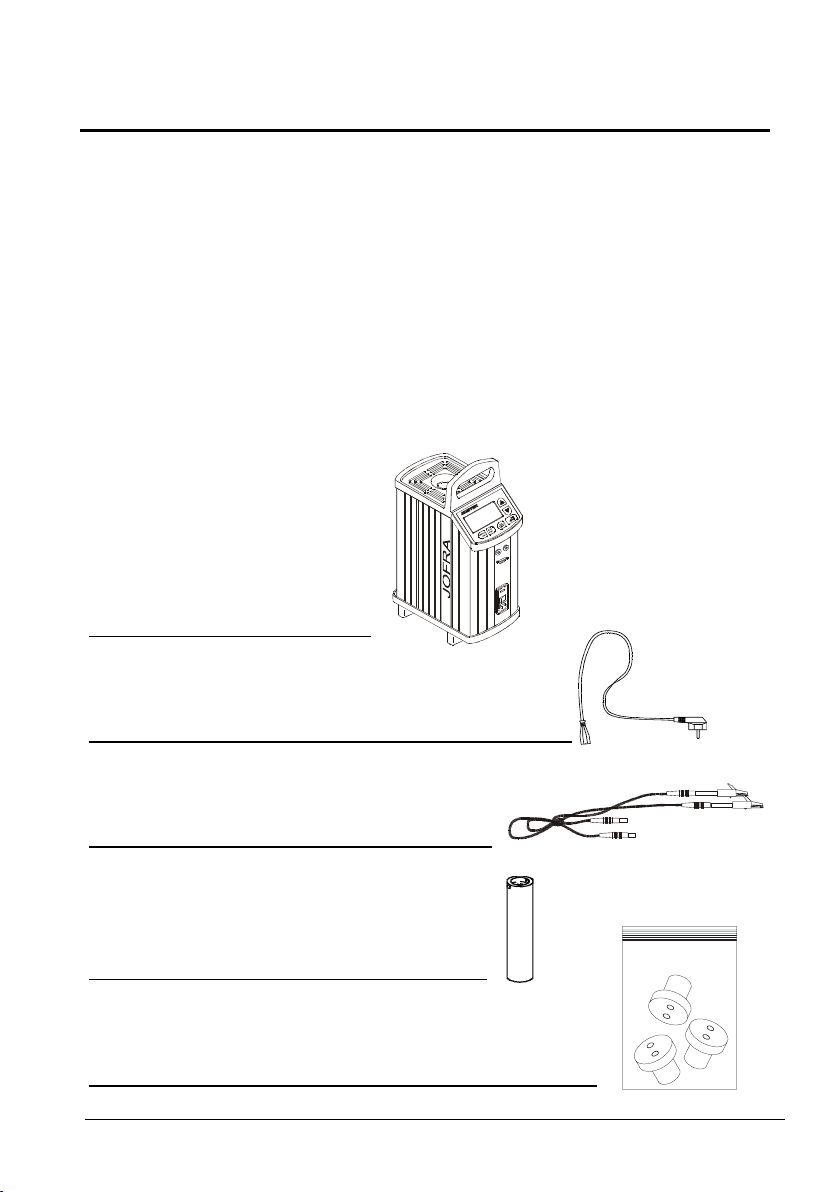

You should receive:

• 1 calibrator

S

T

N

E

M

U

R

T

S

N

I

N

O

I

T

A

R

B

I

L

A

C

• 1 mains cable

• 1 set of test cables (1 black, 1 red)

• 1 insertion tube

• 3 pcs. insulation plugs for 5, 8, 11 mm sensors

(ITC-155 A only)

123312 03 17-08-2004 11

Page 12

• 1 tool for insertion tube

• 1 traceable certificate

• 1 reference manual

Reference Ma nual

• 1 user manual

User Manual

• 1 RS 232 serial cable

• 1 CD-ROM containing software package

“JofraCal”.

When reordering, please specify the parts number found

in the list of accessories, section 10.0.

12 17-08-2004 123312 03

Page 13

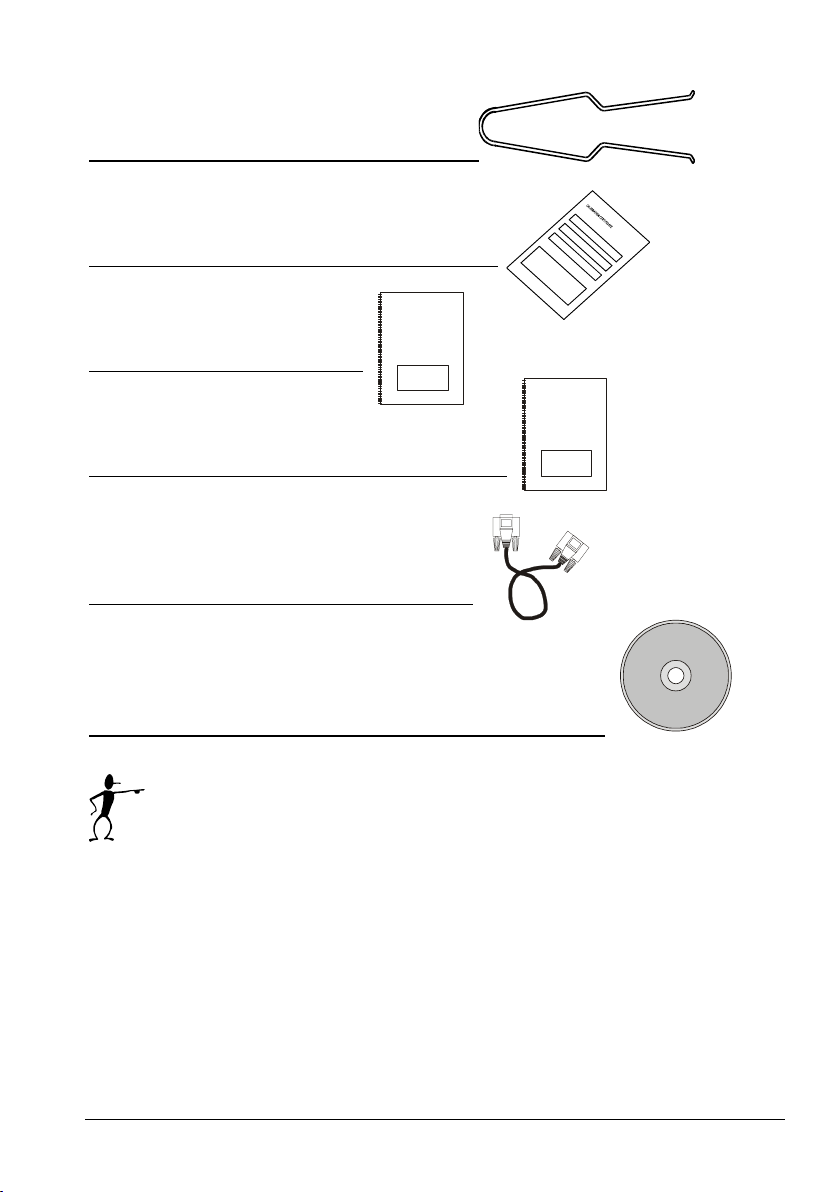

3.2 Preparing the calibrator

Warning

• The calibrator must not be used in areas prone to

explosives hazards.

• The calibrator must be kept clear within an area of 20

cm on all sides and 1 metre above the calibrator.

Note…

The instrument must not be exposed to draughts.

S

T

N

E

M

U

R

T

S

N

I

N

O

I

T

A

R

B

I

L

A

C

Fig. 1

When setting up the calibrator, you must…

Place the calibrator on an even horizontal surface in the spot

you intend to use it.

123312 03 17-08-2004 13

Page 14

Caution…

Do not use the instrument if the ventilator is out of order.

g

The calibrator is now ready for use.

Ensure a free supply of air to the ventilator located at the

bottom of the instrument.

Check the voltage of the power control switch (on/off switch

(230V/115V)). If the voltage of the power control switch

differs from the line voltage, you must adjust the voltage of

the power control switch as follows (see Fig. 1):

A. Open the fuse box lid using a screwdriver.

B. Take out the fuse box.

C. Remove both fuses and insertion tube two new fuses.

These must be identical and should correspond to the

line voltage. See section 10.0.

B. Turn the fuse box 180° and slide it into place.

Check that the earth connection for the instrument is present

and attach the cable.

Select an insertion tube with the correct bore diameter. See

section 3.3 for information on how to select insertion tubes.

3.3 Choice of insertion tube

Caution…

Before using new insertion tubes for the calibration, the

14 17-08-2004 123312 03

insertion tubes must be heated up to maximum temperature

- 320°C (608°F) / 650°C (1202°F) - for a period of minimum

30 minutes.

In order to ensure the best calibration of your sensors

please avoid using insertion tubes in the ITC-320 calibrator

which have been used in the ITC-650 calibrator.

Page 15

Insertion tubes are selected on the basis of the diameter of the sensor

to be calibrated.

Use the table for insertion tubes in section 10.0 to find the correct part

number.

Alternatively, you may order an undrilled insertion tube and drill the

required hole yourself. The finished dimension should be as follows:

• Sensor diameter +0.2

+0.05/-0 mm.

123312 03 17-08-2004 15

Page 16

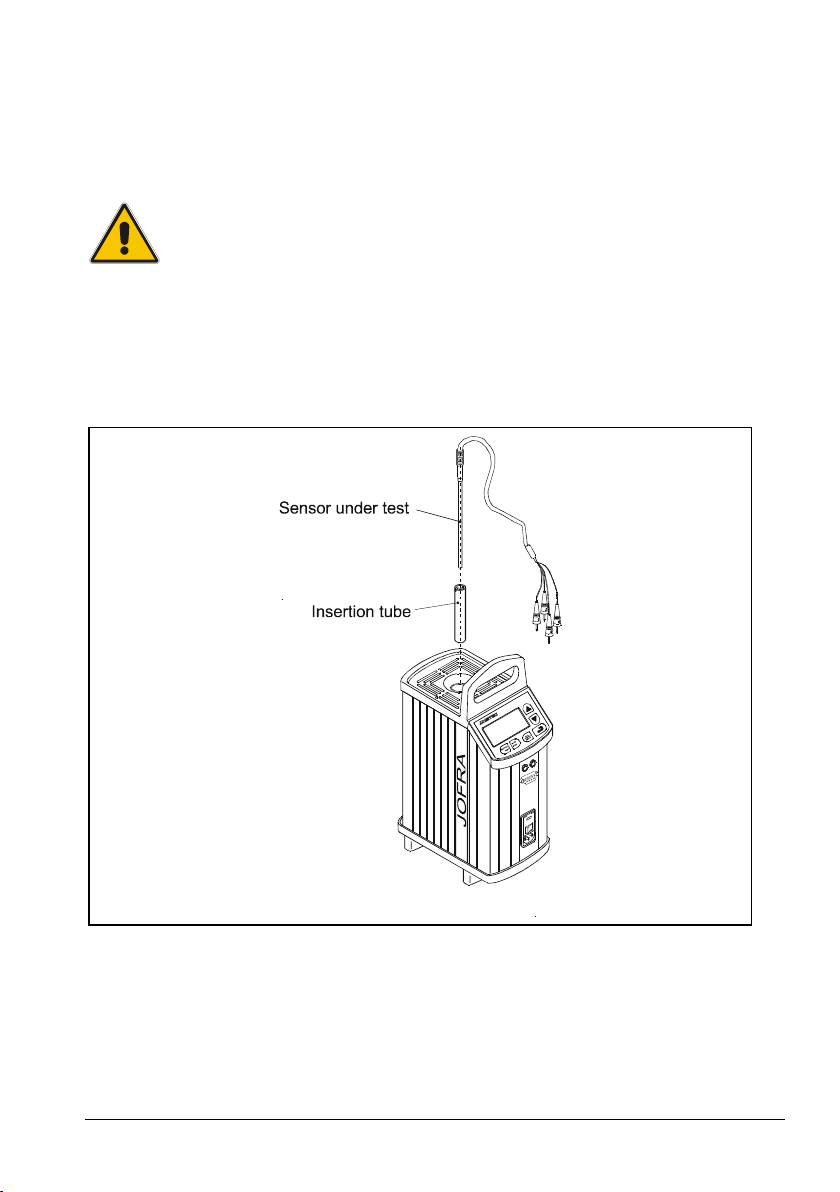

3.4 Inserting the sensor

Before inserting the sensor and switching on the calibrator, please note

the following important warning:

Insert the sensor as shown in Fig. 2.

Fig. 2

In order to spare the sensor and its connections it is recommended to

use a heat protection shield (104216) at high temperatures (see Fig.

3).

Warning

• Never use heat transfer fluids such as silicone, oil,

paste, etc.

These fluids may penetrate the calibrator and cause

damage or create poisonous fumes.

S

T

N

E

M

U

R

T

S

N

I

N

O

I

T

A

R

B

I

L

A

C

16 17-08-2004 123312 03

Page 17

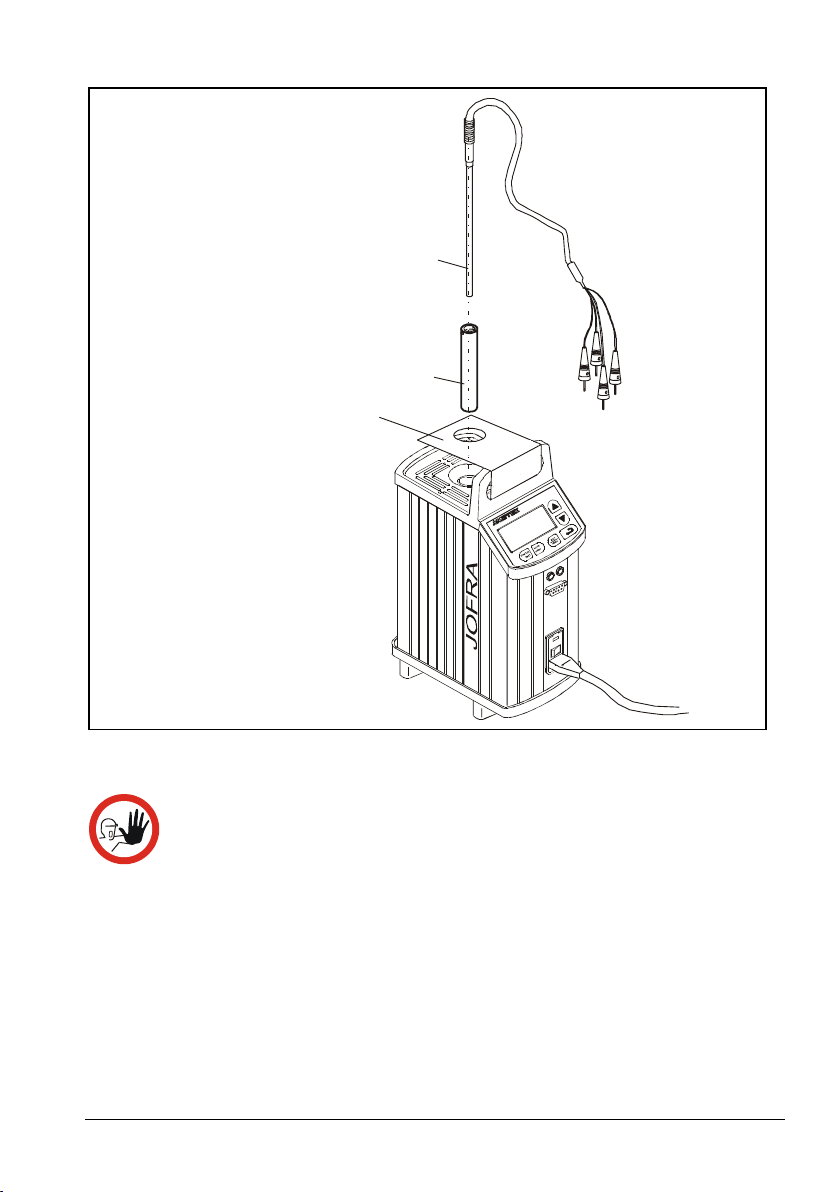

Sensor under test

Thermal protection shield

Insertion tube

S

T

N

E

M

U

R

T

S

N

I

N

O

I

T

A

R

B

I

L

A

C

Fig. 3

Caution…

• The well and the insertion tube must be clean before

use.

• Scratches and other damage to the insertion tubes

should be avoided by storing the insertion tubes

carefully when not in use.

• The insertion tube must never be forced into the well.

The well could be damaged as a result, and the

insertion tube may get stuck.

123312 03 17-08-2004 17

Page 18

Caution – Hot surface

• Do not touch the grid plate, the well or the insertion tube

as the calibrator is heating up – they may be very hot.

• Do not touch the tip of the sensor when it is removed

from the insertion tube/well – it may be very hot.

• Do not touch the handle of the calibrator during use – it

may be very hot.

18 17-08-2004 123312 03

Page 19

4.0 Operating the calibrator

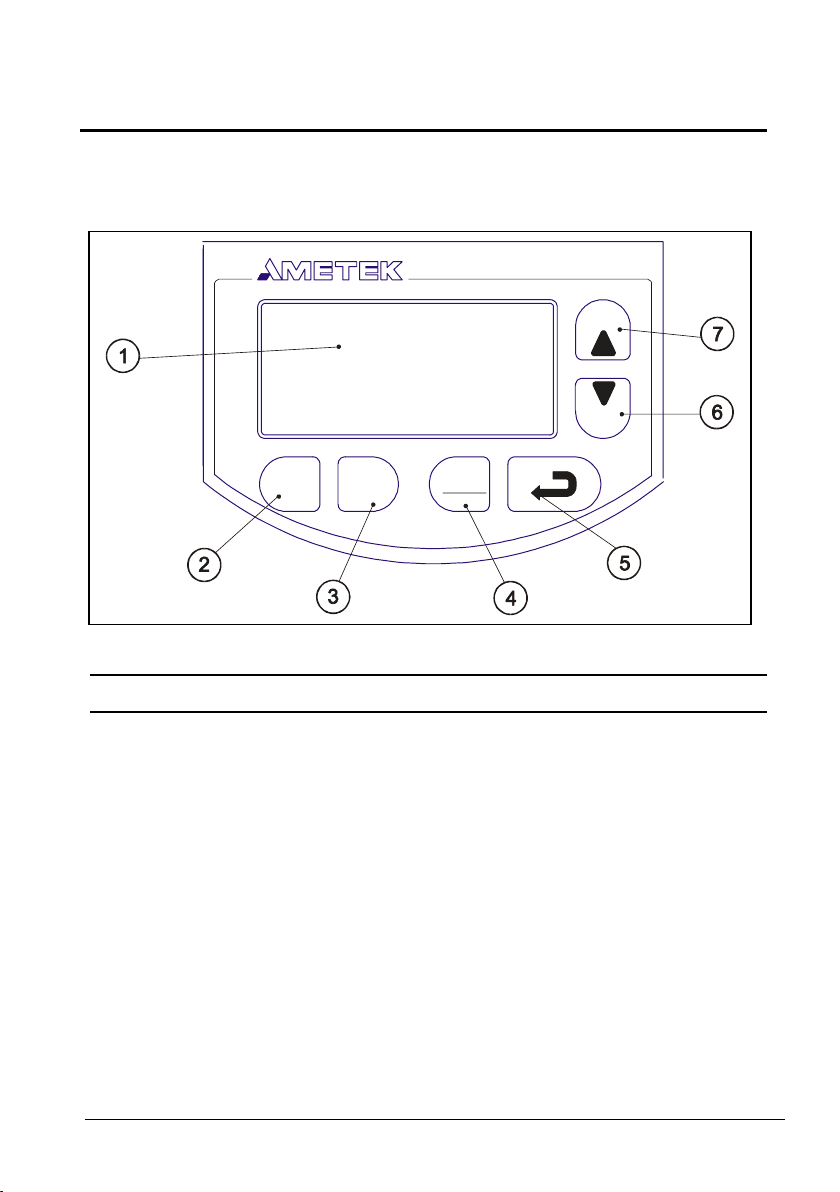

4.1 Keyboard, display and connections

Keyboard

Fig. 4

Pos. Description

CALIBRATION INSTRUMENTS

SWITCH

TEST

AUTO

STEP

ESC

MENU

LCD.

SWITCH TEST button used to activate SWITCH TEST.

The function automatically detects the opening/closing

temperatures for thermostats.

AUTO STEP button used to activate AUTO STEP.

The function is used to switch between a series of settemperatures automatically.

ESC/MENU button used as Escape key or to activate the

menu system (hold button down for min. 2 seconds).

ENTER button used to accept chosen options.

DOWN ARROW button used to adjust temperature values

(value decreases) and to select menu options.

123312 03 17-08-2004 19

Page 20

Display

Fig. 5

Pos. Description

UP ARROW button used to adjust temperature values

(value increases) and to select menu options.

20 17-08-2004 123312 03

CHECKMARK displayed when the calibrator is stable.

SWITCH TEST input open.

SWITCH TEST input closed.

AUTO STEP symbol used to indicate that the function is

active (symbol flashes repeatedly).

Used to display set-temperatures, time-until-stable and

parameter values in the menu system.

Minute time unit for bottom display.

Fahrenheit temperature unit for bottom display.

Celsius temperature unit for bottom display.

Fahrenheit temperature unit for top display.

Page 21

Celsius temperature unit for top display.

Used to display Read-temperature and parameters in the

menu system.

Connections

Warning

• The switch-test connectors, pos. 2 on the front panel,

must NEVER be connected to a voltage source.

• Thermostats must not be connected to any other

voltage source during a test.

All connections are located on the front panel.

-

+

Switch Test

RS232

Fuse

230V 5AF/115V 10AF

115V

Fig. 6

Pos. Description

Power control switch with connection for cable and on/off

switch. Also contains the main fuse. See section 7.0 for

information on how to change the fuses.

123312 03 17-08-2004 21

Connection for thermostat test.

Connection for RS232 cable.

Page 22

C

4.2 Starting the calibrator

The instrument is initialised and the last calibration date is

The calibration date will be displayed for approx. 2 seconds.

The initialisation process has been completed and the

All settings are stored when the calibrator is switched off.

Switch the calibrator on using the power control switch (pos.

1 in Fig. 6).

displayed:

calibrator is ready for use.

When the instrument is switched back on again, the status will

be the same as when it was switched off.

4.3 Selecting the set-temperature

Press

or to adjust the set-temperature.

The current selection flashes in the bottom display:

°

°C

The starting point is the last chosen set-temperature (even if

the instrument has been switched off).

22 17-08-2004 123312 03

Press

to accept the change or to cancel.

Page 23

C

C

The calibrator will now heat up/cool down.

The top display continuously shows the read-temperature.

The bottom display shows either the set-temperature or the

estimated time in whole minutes until the calibrator will be

stable:

°

min

When the calibrator is stable the display will show the

checkmark symbol. The instrument will emit an audible alarm

and the estimated time until stable will be replaced by the settemperature:

°

°C

123312 03 17-08-2004 23

Page 24

4.4 Using the SWITCH TEST

SWITCH TEST automatically locates the switch temperature of a

thermostat.

You must enter a temperature range T

temperature is expected to be found. You must also specify the slope

rate to be used during the test in SETUP (the smaller the value, the

more accurate the results of the test and the longer the test will take).

The function can be illustrated using the following example:

min

- T

, within which the switch

max

Fig. 7

The symbols

Press

the function is active.

The function can be cancelled at any time by pressing

.

for SWITCH TEST will flash to indicate that

.

24 17-08-2004 123312 03

Page 25

C

C

Press

or to select the required T

°C

min

:

Press

Press

to accept your selection.

or to select the required T

°C

max

:

Press

to accept your selection.

The calibrator will now start working towards the T

°

°C

Once the T

has been reached and the calibrator is stable, the

min

instrument will emit an audible alarm and display the status for one

second:

°

min

:

°C

123312 03 17-08-2004 25

Page 26

The calibrator will now start working towards the T

C

C

using the slope

max

rate selected in SETUP. The flashing SWITCH TEST symbol indicates

the current status:

°

°C

The instrument will check for changes in the SWITCH TEST. If no

change has been detected by the time T

is reached, the instrument

max

will register an ERROR.

The calibrator will stabilise at this temperature, and then work towards

the T

using the slope rate selected in SETUP.

min

The flashing SWITCH TEST symbol indicates the current status:

°

°C

The instrument will check for changes in the SWITCH TEST input once

again. If no change has been detected by the time the T

has been

min

reached, the instrument will register an ERROR.

The results of the test will be displayed as 3 values: an “Open”

temperature, a “Close” temperature and a “Hyste” hysteresis

temperature (the difference between the two temperatures).

The open temperature is shown first:

°C

Press

to display the close temperature:

°C

26 17-08-2004 123312 03

Page 27

If a temperature has not been found, the instrument will

Press

display an “Error” (the “Hyste” temperature will also be shown

as an “Error”):

Press

instrument will store the T

SWITCH TEST is activated.

to display the hysteresis temperature:

°C

or to end the SWITCH TEST. The

min

and T

until the next time the

max

Note…

you can activate

temporary results.

or during the test to display the

123312 03 17-08-2004 27

Page 28

4.5 Using the AUTO STEP

AUTO STEP is used to step automatically between a range of different

calibration temperatures. This is useful when calibrating sensors in

places which are hard to reach, and when calibrating sensors for which

the output is displayed in a different location.

The function can be illustrated using the following example:

Fig. 8

The

Press

function is active.

The function can be cancelled at any time by pressing

.

symbol for AUTO STEP flashes to indicate that the

28 17-08-2004 123312 03

Page 29

Press

(minimum 2 steps, maximum 9 steps):

Press

or to select the required number of steps

to accept your selection.

Repeat the above procedure for all temperature steps.

Press

step 1:

Press

or to select the required set-temperature for

°C

to accept your selection.

123312 03 17-08-2004 29

Press

the last temperature step.

Press

the calibrator to remain at every step:

Press

to accept your choices once you have adjusted

or to set the amount of extra time you wish

min

to accept your selection.

Page 30

C

The following will be displayed for one second to indicate that the

calibrator is ready to work towards the set-temperature:

°C

The calibrator will now work towards the given set-temperature. An

audible alarm will be emitted once the calibrator is stable.

The calibrator will wait the specified amount of extra time. The

instrument indicates this by counting down the amount of time

remaining:

°

min

The calibrator will then go to the next step. The procedure is the same

as for the first step. This process will be repeated until the last step has

been executed and the function has been completed.

30 17-08-2004 123312 03

Page 31

4.6 Using the MENU

Hold down

Press

Press

parameters:

or to switch between the adjustable

for more than approx. 2 seconds:

to select SETUP.

⇑⇓

⇑⇓

⇑⇓

⇑⇓

123312 03 17-08-2004 31

Page 32

C

F

If you wish to exit SETUP, simply press

.

The instrument will ignore all changes if you press

adjusting any of the parameters.

Press

to adjust the parameter.

4.6.1 Adjusting the temperature unit

- and

Press

or to switch between °C and °F:

°

°

when

32 17-08-2004 123312 03

Press

to accept your selection.

Page 33

4.6.2 Adjusting the max-temperature

If the current set-temperature is higher than the new max-

Press

0.1°C or 0.1°F:

temperature, you will need to adjust the set-temperature. The

instrument will immediately begin to cool (if required) as soon

as the new max-temperature is accepted.

Press

If you wish to exit SETUP, simply press

or to set the max-temperature in steps of

°C

to accept your selection.

.

4.6.3 Adjusting the SWITCH TEST slope rate

123312 03 17-08-2004 33

Press

temperature between 0.1°C and 9.9°C in steps of 0.1°C (if

your chosen temperature unit is °F, the range will change to

between 0.1°F and 9.9°F in steps of 0.1°F):

Press

or to set the SWITCH TEST slope rate to a

°C

to accept your selection.

Page 34

4.6.4 Adjusting the extra stability time

The extra stability time is the amount of extra time you wish to elapse

before the checkmark symbol

stabilised.

is displayed after the calibrator has

Press

20 minutes:

Press

or to set the time to anywhere between 0 and

min

to accept your selection.

4.6.5 Adjusting the temperature resolution

- and

Press

or to select the required number of decimals:

°C

°C

34 17-08-2004 123312 03

Press

to accept your selection.

Page 35

4.7 Simulation/training

The instrument will then revert to the standard display.

The calibrator’s simulation mode is used to train personnel in the use

of the instrument, etc. The simulation setting differs from the standard

setting as follows:

• The instrument will not actually heat up or cool down the well.

• The heating and cooling processes are simulated at around 10

The calibrator will remain in simulation mode until it is switched off.

Hold down the

calibrator.

The instrument will display the following screen:

times the normal speed of these operations.

and buttons while you switch on the

123312 03 17-08-2004 35

Page 36

5.0 Storing and transporting the calibrator

Switch off the calibrator using the power control switch.

Note that the calibration procedure may be interrupted at any time

using the power control switch. Switching off the calibrator during the

calibration process will not damage either the instrument or the sensor.

Caution…

The following guidelines should always be observed when

storing and transporting the calibrator. This will ensure that

the instrument and the sensor remain in good working

order.

S

T

N

E

M

U

R

T

S

N

I

N

O

I

T

A

R

B

I

L

A

C

Fig. 9

36 17-08-2004 123312 03

Page 37

The following routine must be observed before the insertion tube is

removed and the instrument switched off:

Over 100°C/212°F

If the calibrator has been heated up to temperatures above

100°C/212°F, you must wait until the instrument reaches a

temperature below 100°C/212°F before you switch it off.

Below 0°C/32°F (applies only to the ITC-155 A models)

If the calibrator has reached a temperature below 0°C/32°F,

ice crystals may form on the insertion tube and the well.

This, in turn, may cause verdigris to form on the material.

To prevent this from happening, simply heat up the

calibrator to 50°C/122°F.

Remove the insertion tube from the calibrator using the tool for

insertion tube supplied with the instrument as shown in Fig. 9.

Caution…

• The insertion tube must always be removed from the

calibrator after use.

The humidity in the air may cause verdigris to form on the

insertion tube inside the instrument. There is a risk that

the insertion tube may become stuck if this is allowed to

happen.

• The insertion tube must be removed to avoid damage to

the instrument if the calibrator is to be transported long

distances.

Warning

Never leave hot insertion tubes which have been removed

from the calibrator unsupervised – they may constitute a fire

hazard.

If you intend to store the calibrator in the optional aluminium

carrying case after use, you must ensure that the instrument

has cooled to a temperature below 100°C/212°F before

placing it in the carrying case.

123312 03 17-08-2004 37

Page 38

6.0 Errors

If the calibrator detects an error during operation, the instrument will

terminate all functions and display an error code:

Likely cause: Defective RTD-sensor or excessively high

temperature measured by the instrument’s internal

sensor.

Solution: The calibrator should be returned to the

manufacturer for service.

Warning

The calibrator must be switched off before any attempt to

service the instrument is made.

Note…

Ametek Denmark’s liability ceases if:

• parts are replaced/repaired using spare parts which are

not identical to those recommended by the manufacturer.

• non-original parts are used in any way when operating

the instrument.

Ametek Denmark’s liability is restricted to errors which

originated from the factory.

Likely cause: The calibration coefficients have not been accepted.

Solution: Try again. If the error message returns, the

calibrator should be returned to the manufacturer

for service.

38 17-08-2004 123312 03

Page 39

Likely cause: An error has occurred in the control circuit.

Solution: The calibrator should be returned to the

manufacturer for service.

Nothing happens when the power control switch (on/off switch)

is pressed.

Likely cause: There is no power to the calibrator.

Solution: Check that the calibrator is correctly connected.

Check the fuse.

If there are no problems with the mains cable or the

fuse, the calibrator should be returned to the

manufacturer for service.

123312 03 17-08-2004 39

Page 40

7.0 Setting the main voltage and replacing

the fuses

Fig. 10

Warning

• The fuse box must not be removed from the power

control switch until the mains cable has been

disconnected.

• The two main fuses must be identical and correspond to

the chosen voltage.

S

T

N

E

M

U

R

T

S

N

I

N

O

I

T

A

R

B

I

L

A

C

C

S

E

U

N

E

M

O

T

U

A

P

E

T

S

H

C

T

I

T

W

S

E

S

T

Locate the main fuses in the fuse box in the power control

switch and check the voltage of the power control switch

(on/off switch (230V/115V)). If the voltage of the power

control switch differs from the line voltage, you must adjust

the voltage of the power control switch.

Open the lid of the fuse box using a screwdriver.

Remove the fuse box.

40 17-08-2004 123312 03

Page 41

Remove both fuses and insert two new fuses. These must be

identical and should correspond to the line voltage.

• ITC-155: 115V, 2AT = 105014 / 230V, 1AT = 105007

• ITC-320/650: 115V, 10AF = 60B302 / 230V, 5AF = 60B301

If the fuses blow immediately after you have replaced them,

the calibrator should be returned to the manufacturer for

service.

Slide the fuse box into place with the correct voltage turning

upwards.

7.1 Returning the calibrator for service

When returning the calibrator to the manufacturer for service, please

enclose a fully completed service information form. Simply copy the

form on the following page and fill in the required information.

The calibrator should be returned in the original packing.

123312 03 17-08-2004 41

Page 42

Service info

Customer data: Date:

Customer name and address:___________________________________________

Attention and Dept.:___________________________________________________

Fax no./Phone no.:____________________________________________________

Your order no.:_______________________________________________________

Delivery address:_____________________________________________________

Distributor name:_____________________________________________________

Instrument data:

Model and Serial no.:__________________________________________________

Warranty claimed Yes:____ No:_____ Original invoice no.:_________________

___________________________________________________________________

Temp. Sensor Service request: This instrument is sent for

calibration input (please tick off):

___ Calibration as left ___ Check

___ Calibration as found and as left ___ Service

___ Accredited calibration as left ___ Repair

___ Accredited calibration as found and as left.

___________________________________________________________________

Diagnosis data/cause for return:

Diagnosis/Fault description:_____________________________________________

___________________________________________________________________

Special requests:_____________________________________________________

___________________________________________________________________

Safety precautions: if the product has been exposed to any hazardous substances, it must be

thoroughly decontaminated before it is returned to Ametek. Details of the hazardous substances

and any precautions to be taken must be enclosed.

42 17-08-2004 123312 03

Page 43

8.0 Maintenance

8.1 Cleaning

Users should/must carry out the following cleaning procedures as and

when required:

• The exterior of the instrument - Clean using water and a soft

• The insertion tube - Must always be clean and should be

• The well - Must always be clean. Dust and textile fibres should be

Caution…

Before cleaning the calibrator, you must switch it off, allow

it to cool down and remove all cables.

cloth.

The cloth should be wrung out hard to avoid any water penetrating

the calibrator and causing damage.

The keyboard may be cleaned using isopropyl alcohol when

heavily soiled.

regularly wiped using a soft, dry cloth.

You must ensure there are no textile fibres on the insertion tube

when it is inserted in the well. The fibres may adhere to the well

and damage it.

removed from the well using e.g. compressed air.

Warning

REMEMBER! Wear goggles when using compressed

air!

123312 03 17-08-2004 43

Page 44

8.2 Adjusting and calibrating the instrument

You are advised to return the calibrator to Ametek Denmark A/S or an

accredited laboratory at least once a year for calibration and

adjustment.

Alternatively, you can calibrate/adjust the calibrator yourself. You will

need a reference thermometer and a reference sensor with a traceable

certificate. Please follow the instructions given below.

Connect the calibrator to an external precision instrument (e.g. a DTI)

as shown in Fig. 11:

Fig. 11

S

T

N

E

M

U

R

T

S

N

I

N

O

I

T

A

R

B

I

L

A

C

Hold down the

button while pressing the on/off power

control switch.

The instrument is now in adjustment/service mode.

44 17-08-2004 123312 03

Page 45

Press

or to toggle between the different options:

⇑⇓

⇑⇓

⇑⇓

To exit the adjustment/service mode, switch the instrument off

123312 03 17-08-2004 45

Press

and on again using the power control switch.

to accept your selection.

Page 46

8.2.1 Adjusting the calibration date

Adjust the date by toggling through the available days, months and

years. Begin by selecting the required day as shown below:

Press

31.

Press

Press

FEB / MAR / APR / MAY / JUN / JUL / AUG / SEP /

OCT / NOV / DEC.

Press

or to select the required day in the interval 1-

to accept your selection.

or to select the required month from JAN /

to accept your selection.

46 17-08-2004 123312 03

Press

or to select a year between 2001–2025.

Page 47

or

Press

adjusted if necessary to ensure the legality of the date.

Finally, the day, month and year will flash:

Press

press

to accept your selection. The day will be

to accept the date.

to cancel the whole selection.

8.2.2 Calibrating/adjusting the instrument

The internal calibration/adjustment is a complex function which is

divided into a number of different steps:

The instrument will disclose the first calibration temperature by

displaying the text “TEMP.1 XXX°C” for approx. 1 second:

Calibration temperature for calibrators:

ITC-155 A 1. -23°C / -9.4°F

2. 20°C / 68°F

3. 60°C / 140°F

4. 100°C / 212°F

5. 155°C / 311°F

123312 03 17-08-2004 47

Page 48

ITC-320 A 1. 50°C / 122°F

C

2. 120°C / 248°F

3. 180°C / 356°F

4. 250°C / 482°F

5. 320°C / 608°F

ITC-650 A 1. 50°C / 122°F

2. 200°C / 392°F

3. 350°C / 662°F

4. 500°C / 932°F

5. 650°C / 1202°F

The instrument will now heat up/cool down to reach the first calibration

temperature:

°

°C

Once the calibrator is stable, you need to enter the reference

temperature found using the reference thermometer. The

calibration temperature is suggested as a reference point:

°C

This procedure is repeated for TEMP.2, TEMP.3, TEMP.4 and

TEMP.5.

All five calibration temperatures and associated reference

temperatures have now been entered.

The instrument will now check whether the reference temperatures

which have been entered are within the permitted tolerances.

Permitted tolerances:

• ITC-155 A : ±0,1°C / 0.18°F

• ITC-320 A : ±0,15°C / 0.27°F

• ITC-650 A : ±0,20°C / 0.36°F

48 17-08-2004 123312 03

Page 49

If the instrument detects excessive deviations for one or more steps, it

will show a screen reading =ERR. in the top of the display. The text

AdJ. will flash in the bottom of the display to indicate that an

adjustment is required (accept by pressing

If the calibrator is found to be within the permitted tolerances, the

instrument will display the text =OK at the top of the display. The text

Cont. will flash in the bottom of the display to indicate that you may

continue without adjustments:

Press

Press

to repeat an adjustment step when it is shown on the display.

Press

to cancel the adjustment function.

to go back to a previous screen and press

to toggle between AdJ. and Cont. on the display.

:

)

123312 03 17-08-2004 49

Press

coefficients. Next, repeat the entire calibration/adjustment

procedure.

when AdJ. is flashing to calculate a new set of

Page 50

If the new coefficients deviate by more than 4% from the

standard values, the instrument will display an ERROR 2 in

the display. The calculated coefficients will be ignored:

Press

procedure.

Press

calibration/adjustment procedure and enter a new calibration

date (see section 8.2.1).

to repeat the entire calibration/adjustment

when Cont. is flashing to end the

50 17-08-2004 123312 03

Page 51

9.0 Technical specifications

The illustration below shows the setup which forms the basis for the

technical specifications.

Fig. 12

3

4

2

S

T

N

E

M

U

R

T

S

N

I

N

I

O

T

A

R

B

I

L

A

C

1

123312 03 17-08-2004 51

Page 52

Pos. Description

Calibrator

Ø4.2 mm insertion tube

Ø4 mm Pt 100 sensor with traceable certificate

DTI 1000 reference precision thermometer with traceable

certificate

TECHNICAL SPECIFICATIONS – ALL MODELS

All specifications are given with an ambient temperature of

23°C/73.4°F ± 3°C/5.4°F

GENERAL SPECIFICATIONS

MECHANICAL SPECIFICATIONS

Dimensions l × w × h 241 × 139 × 375mm / 9.5 × 5.5 × 14.8 inch

Weight

Bore diameter/depth of well ITC-155 A: ø 20 mm / 150 mm

Weight non-drilled insert ITC-155 A: 130 g / 4.6 oz

POWER SUPPLY

Line voltage/frequency ITC-155/320A:

Power consumption ITC-155 A: 150 VA

ITC-155 A: 7.6 kg / 16.8 lb

ITC-320 A: 6.5 kg / 14.3 lb

ITC-650 A: 8.5 kg / 18.7 lb

ø 0.79 inch / 5.9 inch

ITC-320/650 A: ø 30 mm / 160 mm

ø 1.18 inch / 6.3 inch

ITC-320/650A: 940 g / 33.2 oz

90-127VAC / 180-254VAC 45-65 Hz

ITC-650 A:

100-127VAC / 200-254VAC 45-65 Hz

ITC-320/650A: 1150 VA

52 17-08-2004 123312 03

Page 53

RS232 COMMUNICATION INTERFACE

Type of connection IEC320

ENVIRONMENT

Ambient operating temperature range 0-40°C / 32-104°F

Storage temperature range -20-50°C / -4-122°F

Humidity range 0-90% RH.

Protection class IP10

READOUT SPECIFICATIONS

Resolution 0.1°C / 0.1°F

Temperature units °C / °F

THERMAL SPECIFICATIONS ITC-155 A

Maximum temperature 155°C / 311°F

Minimum temperature -39°C / -38.2°F @ ambient temperature 0°C /

Well specifications 40 mm / 1.57 inch axial homogeneity :

32°F

-23°C / -9.4°F @ ambient temperature 23°C /

73.4°F

-10°C / 14°F @ ambient temperature 40°C /

104°F

0.10°C / 0.18°F @155°C / 311°F

0.05°C / 0.09°F @-20°C / -4°F

50 mm / 1.97 inch axial homogeneity :

0.10°C / 0.18°F @155°C / 311°F

0.10°C / 0.18°F @-20°C / -4°F

60 mm / 2.36 inch axial homogeneity :

0.20°C / 0.36°F @155°C / 311°F

0.15°C / 0.27°F @-20°C / -4°F

70 mm / 2.76 inch axial homogeneity :

0.40°C / 0.72°F @155°C / 311°F

0.35°C / 0.63°F @-20°C / -4°F

123312 03 17-08-2004 53

Page 54

THERMAL SPECIFICATIONS ITC-155 A

80 mm / 3.15 inch axial homogeneity :

0.8°C / 1.44°F @155°C / 311°F

0.5°C / 0.9°F @-20°C / -4°F

Difference between holes :

0.03°C / 0.05°F

Influence from load :

0.15°C / 0.27°F @155°C / 311°F

0.10°C / 0.18°F @-20°C / -4°F

Influence from load with

ext. reference :

0.02°C / 0.03°F @155°C / 311°F

0.02°C / 0.03°F @-20°C / -4°F

Difference between inserts :

0.08°C / 0.14°F

Long term drift (1 year) :

±0.10°C / ±0.18°F

Calibration accuracy (test limit) ±0.10°C / ±0.18°F

Temperature coefficient 0.02°C/°C (0-40°C) / 0.03°F/°F (32-104°F)

Stability ±0.03°C / ±0.05°F

Reference accuracy ±0.10°C / ±0.18°F

Total accuracy ±0.25°C / 0.45°F

Heating time incl. insert -20°C / -4°F to 23°C / 73.4°F : 4 min.

23°C / 73.4°F to 155°C / 311°F : 14 min.

-20°C / -4°F to 155°C / 311°F : 18 min.

Additional stabilisation time 10 min.

Cooling time incl. insert 155°C / 311°F to 100°C / 212°F : 4 min.

155°C / 311°F to 23°C / 73.4°F : 14 min.

23°C / 73.4°F to -20°C / -4°F : 23 min.

155°C / 311°F to -20°C / -4°F : 37 min.

54 17-08-2004 123312 03

Page 55

THERMAL SPECIFICATIONS ITC-320 A

Maximum temperature 320°C / 608°F

Minimum temperature 10°C / 50°F @ ambient temperature 0°C / 32°F

33°C / 91°F @ ambient temperature 23°C / 73.4°F

50°C / 122°F@ ambient temperature 40°C /

104°F

Well specifications 40 mm / 1.57 inch axial homogeneity :

0.60°C / 1.08°F @320°C / 608°F

0.30°C / 0.54°F @155°C / 311°F

0.10°C / 0.18°F @50°C / 122°F

50 mm / 1.97 inch axial homogeneity :

0.90°C / 1.62°F @320°C / 608°F

0.50°C / 122°F @155°C / 311°F

0.15°C / 0.27°F @50°C / 122°F

60 mm / 2.36 inch axial homogeneity :

1.20°C / 2.16°F @320°C / 608°F

0.60°C / 1.08°F @155°C / 311°F

0.20°C / 0.36°F @50°C / 122°F

70 mm / 2.76 inch axial homogeneity :

1.50°C / 2.7°F @320°C / 608°F

0.80°C / 1.44°F @155°C / 311°F

0.25°C / 0.45°F @50°C / 122°F

80 mm / 3.15 inch axial homogeneity :

2.0°C / 3.60°F @320°C / 608°F

1.0°C / 1.80°F @155°C / 311°F

0.30°C / 0.54°F @50°C / 122°F

Difference between holes :

0.07°C / 0.13°F

123312 03 17-08-2004 55

Page 56

THERMAL SPECIFICATIONS ITC-320 A

Influence from load :

0.2°C / 0.36°F @320°C / 608°F

Influence from load with

ext. reference :

0.03°C / 0.05°F @320°C / 608°F

Difference between inserts:

0.10°C / 0.18°F

Long term drift (1 year) :

±0.10°C / ±0.18°F

Calibration accuracy (test limit) ±0.15°C / ±0.27°F

Temperature coefficient 0.03°C/°C (0-40°C) / 0.05°F/°F (32-104°F)

Stability ±0.03°C / ±0.05°F

Reference accuracy ±0.10°C / ±0.18°F

Total accuracy ±0.30°C / ±0..54°F

Heating time incl. insert 50°C / 122°F to 320°C / 608°F : 7 min.

Additional stabilisation time 10 min.

Cooling time incl. insert 320°C / 608°F to 100°C / 212°F: 30 min.

320°C / 608°F to 50°C / 122°F : 60 min.

THERMAL SPECIFICATIONS ITC-650 A

Maximum temperature 650°C / 1202°F

Minimum temperature 10°C / 50°F @ ambient temperature 0°C / 32°F

33°C / 91°F @ ambient temperature 23°C / 73.4°F

50°C / 122°F@ ambient temperature 40°C /

104°F

56 17-08-2004 123312 03

Page 57

THERMAL SPECIFICATIONS ITC-650 A

Well specifications 40 mm / 1.57 inch axial homogeneity :

0.50°C / 122°F @650°C / 1202°F

0.25°C / 0.45°F @320°C / 608°F

0.05°C / 0.09°F @50°C / 122°F

50 mm / 1.97 inch axial homogeneity :

0.85°C / 1.53°F @650°C / 1202°F

0.40°C / 0.72°F @320°C / 608°F

0.07°C / 0.13°F @50°C / 122°F

60 mm / 2.36 inch axial homogeneity :

1.3°C / 2.34°F @650°C / 1202°F

0.60°C / 1.08°F @320°C / 608°F

0.10°C / 0.18°F @50°C / 122°F

70 mm / 2.76 inch axial homogeneity :

1.80°C / 3.24°F @650°C / 1202°F

0.90°C / 1.62°F @320°C / 608°F

0.15°C / 0.27°F @50°C / 122°F

80 mm / 3.15 inch axial homogeneity :

2.50°C / 4.5°F @650°C / 1202°F

1.10°C / 1.98°F @320°C / 608°F

0.20°C / 0.36°F @50°C / 122°F

Difference between holes :

0.10°C / 0.18°F

Influence from load :

0.20°C / 0.36°F @650°C / 1202°F

Influence from load with

ext. reference :

0.05°C / 0.09°F @650°C / 1202°F

123312 03 17-08-2004 57

Page 58

THERMAL SPECIFICATIONS ITC-650 A

Difference between inserts:

0.25°C / 0.45°F

Long term drift (1 year) :

±0.2°C / ±0.36°F

Calibration accuracy (test limit) ±0.20°C / ±0.36°F

Temperature coefficient 0.05°C/°C (0-40°C) / 0.09°F/°F (32-104°F)

Stability ±0.04°C / ±0.07°F

Reference accuracy ±0.10°C / ±0.18°F

Total accuracy ±0.50°C / 0.9°F

Heating time incl. insert 50°C / 122°F to 650°C / 1202°F : 25 min.

Additional stabilisation time 10 min.

Cooling time incl. insert 650°C / 1202°F to 100°C / 212°F : 56 min.

650°C / 1202°F to 50°C / 122°F : 95 min.

STANDARDS – ALL MODELS

The following standards are observed

according to the EMC-directive (89/336)

The following standards are observed

according to the low voltage-directive

(73/23)

EN61326-1:1997/A1:1998 : Electrical

equipment for measurement, control and

laboratory use – EMC requirements

EN61010-1:1993/A2:1995 : Safety requirements

for electrical equipment for measurement, control

and laboratory use, part 1: general requirement

INPUT SPECIFICATIONS – ALL MODELS

Signal range on : 0-10kΩ / off : >100kΩ

Internal power supply 5 V (open) / 2.5 mA (closed)

Type of connection 4 mm safety sockets

58 17-08-2004 123312 03

Page 59

10.0 List of accessories

All parts listed in the list of accessories can be obtained from the

factory through our dealers.

Please contact your dealer for assistance if you require parts which do

not appear on the list.

List of accessories

Accessories Part no.

Fuse 115V, 10AF (ITC-320/650 A) 60B302

Fuse 230V, 5AF

Fuse 63mAT

Cover for fuse holder

Fuse 500mAT

Fuse 115V, 2AT

Fuse 230V, 1AT

Fuse 4AT

User manual 123311

Reference manual 123312

Protocol manual 105402

Tool for insertion tube 60F170

Heat protection shield 104216

Alu. carrying case incl. carton 123396

Mains cable, 115V, US, type B 60F135

Mains cable, 240V, UK, type C 60F136

Mains cable, 220V, South Africa, type D 60F137

Mains cable, 220V, Italy, type E 60F138

Mains cable, 240V, Australia, type F 60F139

Mains cable, 230V, Europe, type A 60F140

Mains cable, 230V, Denmark, type G 60F141

Mains cable, 220V, Switzerland, type H 60F142

Mains cable, 230V, Israel, type I 60F143

Cleaning brush, 4mm 122832

Cleaning brush, 6mm 60F174

(ITC-320/650 A) 60B301

(ITC-320/650 A) 105333

(ITC-320/650 A) 105332

(ITC-320/650 A) 123448

(ITC-155 A) 105014

(ITC-155 A) 105007

(ITC-155 A) 105334

123312 03 17-08-2004 59

Page 60

Cleaning brush, 8mm 122822

Set of insulation plugs

(ITC-155 A only) 123374

Set of test cables 104203

Certificate, National 99-C-T

RS232 serial cable 105366

JofraCal PC software 124915

PART NO. FOR STANDARD INSERTION TUBES

Sensor

size

undrilled

undrilled

only with

ref. hole

1/8”

3/16”

1/4”

5/16”

3/8”

7/16”

1/2”

9/16”

5/8”

3 mm

4 mm

5 mm

6 mm

7 mm

8 mm

9 mm

10 mm

11 mm

12 mm

13 mm

14 mm

15 mm

16 mm

ITC-155 A

123286

123285

123279

123280

123281

123282

123283

123301**

123302**

-

-

123270

123271

123272

123273

123274

123275

123276

123277

123278

123299**

123300**

-

-

-

ITC-320 A

122719

122721

105676

105678

105680

105682

105684

105686

105688

105690

105692

105622

105624

105626

105628

105630

105632

105634

105636

105638

105640

105642

105644

105646

105648

ITC-650 A

122719

122721

105676

105678

105680

105682

105684

105686

105688

105690

105692

105622

105624

105626

105628

105630

105632

105634

105636

105638

105640

105642

105644

105646

105648

60 17-08-2004 123312 03

Page 61

** Inserts are delivered without 4 mm reference hole, but with matching insulation plugs.

Description

(metric)

Type 1

Type 2

Type 3

Type 4

Description

(inch)

Type 4

Type 5

Type 6

NOTE:

All multi-hole insertion tubes (metric and inches) for ITC-155 are supplied with a

matching insulation plug.

PART NO. FOR STANDARD INSERTION TUBES – MULTI-HOLE

ITC-155 A

123294

123295

123296

PART NO. FOR STANDARD INSERTION TUBES – MULTI-HOLE

-

ITC-155 A

123297

123298

-

ITC-320 A

122750

122752

122754

122756

ITC-320 A

-

122758

122760

ITC-650 A

122750

122752

122754

122756

ITC-650 A

122758

122760

-

123312 03 17-08-2004 61

Loading...

Loading...