Page 1

p r e s s u r e

Specification Sheet

SS-CP-2179-US

NEW SYSTEM A + B PUMPS

Certified for use in potentially

explosive environments

Model IPI

Industrial Pressure Calibrator

Pressure range

IPI030C Vacuum to 2 bar / 30 psi

IPI100C Vacuum to 7 bar / 100 psi

IPI300C Vacuum to 21 bar / 300 psi

IPI500C Vacuum to 35 bar / 500 psi

IPI015G 0 to 1 bar / 15 psi

IPI01KG 0 to 70 bar / 1,000 psi

IPI02KG 0 to 140 bar / 2,000 psi

IPI03KG 0 to 200 bar / 3,000 psi

IPI05KG 0 to 350 bar / 5,000 psi

IPI10KG 0 to 700 bar / 10,000 psi

High accuracy

±0.05% of F.S. for positive pressure

Vacuum ranges to 500 psi (35 bar)

High flexibility

Easily disassemble the test system and

use the indicator for other tasks

True field indicator

Lightweight and portable with full temperature-compensation, long battery life and

large display for easy visibility

Record min and max readings

Capture the min and max pressure

readings for safety valve applications

Complete marine program

Part of a complete program of marine

approved temperature, pressure and signal

calibrators; including temperature sensors

See more at www.jofra.com

ATEX and CSA certification

The IPI Indicator is ATEX and CSA

certified and designed for use in

potentially explosive environments

PRODUCT DESCRIPTION

JOFRA IPI indicators bring

together the ease of an analog

gauge with the accuracy and

easy-to-read display of a digital calibrator.

Use the JOFRA IPI in applications from safety valve checks

to system pressure verification.

Furthermore the IPI indicator

is ATEX and CSA certified for

use in potentially explosive

environments such as oil refineries, chemical plants and offshore platform, where there is

a risk of inflammable gases.

Features

This series is designed to meet your pressure measurement applications

and make the tasks easier. The IPI offers 18 different pressure units,

long battery life, high accuracy, and even serial communications. The

accuracy of the IPI rivals that of a pressure calibrator and is temperature

compensated for shop or in process applications. This versatile unit is

available as a stand alone indicator or in a complete test system.

You can perform a calibration locally without returning the IPI unit to the

manufacturer. All you need is an accurate pressure reference. If you do

require factory calibration, the pump and indicator are independent and

only the indicator needs to be returned.

The JOFRA IPI is available as an indicator or in one of 6 test ready systems that are complete and equipped to meet your pressure measuring

or testing needs.

CSA

ISO 9001 Manufacturer

ATEX

Page 2

Model IPI

Industrial Pressure Calibrator

Specification Sheet

SS-CP-2179-US

The JOFRA IPI digital pressure indicator takes the concept

of an analog test gauge, and brings it to a new level. The

IPI combines the accuracy of digital technology with the

simplicity of an analog gauge, and achieves performance,

ease-of-use, and a feature set unmatched in the pressure

measurement world. Setup of the IPI is fast and straightforward, through a menu-driven display, with minimal text,

and intuitive functions, that is simple enough to allow the

indicator to be used anywhere in the world, without the

need for multilingual displays.

ON / OFF

The IPI is delivered with the auto-shutoff active and set

to 30 minutes: like many of our other instruments.

This feature can be reduced from 30 minutes

down to 1 minute in 1 minute increments. In

cases where a constant reading is necessary, this can also be turned completely

off to allow for continuous operation.

ZERO

Keep the high accuracy:

ZERO the instrument before

every test.

MAX / MIN

A MIN/MAX function reads

the maximum and minimum

pressure that have been automatically stored. Monitor a

safety valve or look for pressure

spikes in the process. The IPI

also have the ability to check the

minimum and maximum readings

during the ransient.

Protective boot

Standard configuration IPI units and

those supplied with systems are

delivered with a protective boot.

Units with back mounting and the

24 VDC power supply are not delivered with the protective boot due

to design limitations.

Clear dual line display

The IPI display does more than

just show a pressure reading. The

user can check temperature and

exact battery voltage through

the use of the keypad. The

large, 5 1/2 digit, 0.65 in

(1.65 cm) character display

is large and easy-to-read;

even from a distance.

Icons are also included

to indicate battery life,

engineering units, and

there is a bar graph that

shows the percentage of

scale reading. All of this

information can be read

in low light with the use of

the backlight.

ENTER

Save selections and turn

the backlight on and off.

Pressure connections

1/4” NPT male lower connection is standard. A 1/4” BSP male

adapter is included. The IPI may be

ordered with a back mounting configuration.

This design has the 1/4 in. NPT male connection on the back of the case vice the lower manifold

connection. This allows for use in panel mounted applications or in applications where flat mounting is necessary

such as in an overhead. This configuration is not delivered

with a protective boot.

External power

Sometimes it is more convenient to take advantage of an

existing power source rather than using batteries. The IPI

may be ordered with a 24 VDC power supply option. The unit

has terminals to accept the positive and negative leads to

allow for easy connection to the power supply. These units

will not be supplied with batteries and batteries should not

be installed when the unit is connected to 24 VDC power.

2 www.jofra.com

CONFIG

This is the key to access all user-settable functions. The

CONFIG key is used in conjunction with the ▼ and ▲

functions on the ZERO and MAX/MIN keys to select and

change different functions.

You can set one of 20 engineering units, change the autoshutoff function setting, display the actual battery voltage,

display the actual temperature (in °C or °F), turn the dampening on or off, change the sample rate, and set the Tare

value. In addition to the 20 available engineering units on the

IPI, you can create your own unit to meet your measurement

need. For example, if you need to take a level measurement,

simply determine the pressure that equates to one unit of

that measurement and set that as your engineering unit. The

application may require gallons, feet, inches, meters, liters, or

similar; with the IPI you can take the measurement.

Serial communications

The IPI has a serial port that is accessible though the back

of the case. This feature uses standard ASCII commands to

allow for extraction of data from the IPI while taking readings.

This requires the optional serial cable.

Page 3

Model IPI

Industrial Pressure Calibrator

Specification Sheet

SS-CP-2179-US

Hazard location information / approvals

An explosive atmosphere is defined as a ”mixture with air,

under atmospheric conditions, of flammable substances in

the form of gases, vapours, mists or dusts in which, after

ignition has occurred, combustion spreads to the entire

unburned mixture”.

The standard in the European Union has been set

with the 9/94/EC Directive, commonly called ATEX

(“Atmosphères Explosibles,” French for explosive

atmospheres).

The JOFRA IPI Industrial Pressure Indicator is ATEX

approved by KEMA as complying with the Essential Health

and Safety Requirements related to the design and construction of equipment and protective systems intended

for use in potentially explosive atmospheres given in

Annex II in the directive, and with the following rating: II 3

G EEx nA IIB T6 (Ta=–10°C... +55°C).

The JOFRA IPI Industrial Pressure Indicator is

also certified by CSA as conforming to relevant

Canadian and USA standards with the following

rating: Class 1, Div. 2, Groups A-D.

See the definitions regarding hazardous locations in NFPA

70, Article 500 or CSA C22.1 Section 18. NFPA 70, Article

500 and CSA C22.1 Section 18.

Field recalibration

The IPI does not need to be returned to the factory for

calibration. If you have a reliable and accurate pressure

reference or a local laboratory, you may re-calibrate the

IPI locally. This feature is password protected.

Sampling rate

The IPI sampling rate is user selectable. If you want to

capture fast system transients, the IPI can take a reading

10 times per second. Conversely, you may want to conserve battery life and only need periodic samples. Then,

you can select 1 sample per every 2 seconds. This works

well for in process and panel mounted applications. You

can also choose the accepted instrument sampling rate of

3 samples per second for normal use or to allow for filtering, you can select 1 sample per second.

Damping adjustment

The damping function can be turned on or off on the IPI.

This allows for readings to be integrated, which accounts for

momentary changes such as those from pulsing sources.

JOFRACAL CALIBRATION SOFTWARE

JOFRACAL calibration software ensures easy calibration

of RTD´s, thermocouples, transmitters, thermoswithes,

pressure gauges and pressure switches. JOFRACAL can

be used with JOFRA DPC-500, APC, CPC and IPI pressure calibrators, all JOFRA temperature calibrators, as well

as JOFRA AMC910, ASC300 multi signal calibrator and

ASM-800 signal multi scanner. When used with JOFRA

ASM-800 signal multi scanner, JOFRACAL can perform a

simultaneous semi automatic calibration on up to 24 pressure and/or temperature devices under test in any combination.

JOFRACAL software controls the complete calibration

procedure, stores the results and provides a calibration

audit trail through hard-copy certificates. All calibration

data are stored for each sensor to monitor drift and optimise recalibration intervals. A scheduler feature allows

planning of future calibrations.

Please find more information about JOFRACAL calibration

software in specification sheet SS-CP-2510, which may be

found at www.jofra.com

REQUIREMENTS JOFRACAL

Minimum hardware requirements:

Intel® Pentium® lI 1.4 GHz processor.

•

•

64MB RAM (128MB recommended)

•

80MB free disk space on hard disk (120MB

recommended) prior to installation

•

Standard VGA (800x600, 256 colours). 1024x768

recommended.

CD-ROM drive for installation of program

•

•

1 or 2 free RS-232 serial ports, depending on

configuration

Minimum software equirements:

Microsoft Windows® 98,Microsoft Windows® NT 4.0,

•

Microsoft Windows® 2000, Microsoft Windows® ME,

Microsoft Windows® XP, Vista.

System fonts: MS Sans Serif and Arial

•

Tare

Beyond zeroing the IPI, you may have to account for

residual pressure. The Tare feature allows you to take care

of that error and prevent the manual calculation of the difference. This can be used in combination with the custom

engineering units to make the level measurements easier.

Temperature display and compensation

Because the IPI is designed for in-process tasks, temperature

compensation is included to make the job easier. This allows

the IPI to maintain accuracy over the measurement range. The

measured temperature may be checked from the keypad.

www.jofra.com 3

Page 4

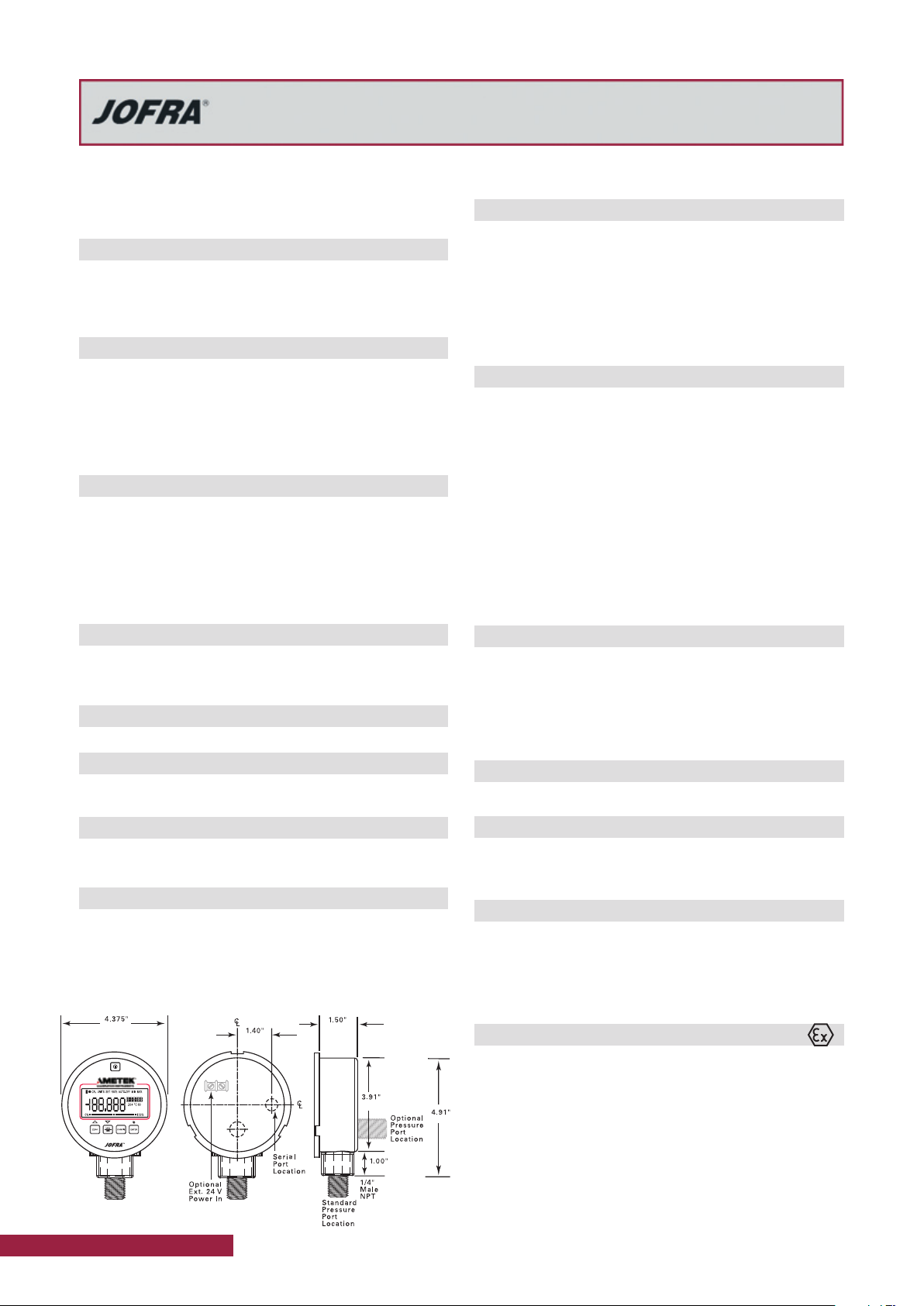

Model IPI

IPI

111 mm

36 mm

38 mm

25,4 mm

99,3 mm

125 mm

Industrial Pressure Calibrator

Specification Sheet

SS-CP-2179-US

FUNCTIONAL SPECIFICATIONS

Pressure range

psi ...........................................vacuum to 30, 100, 300, 500

bar ....................................................vacuum to 2, 7, 21, 35

psi .................... 0 to 15, 1,000, 2,000, 3,000, 5,000, 10,000

bar ........................................ 0 to 1, 70, 140, 200, 350, 700

Engineering units

User defined ................................... One user-definable unit

User selectable ........................................................ 20 units

(PSI, Bar, kg/cm2, inH2O (4 °C, 20 °C or 60 °F), ftH2O (4 °C, 20

°C or 60 °F), mmH2O (4 °C and 20 °C), cmH2O (4 °C and 20 °C),

mH2O (4 °C and 20 °C), KPa, mBAR, inHg, mmHg, Torr)

Not all units are availibale in all ranges.

Pressure accuracy

Pressure ...........................................................±0.05% F.S.

Full temperature compensation ......0 to 50°C / 32 to 122°F

Vacuum (30, 100, 300, 500 psi indicator) ........ ±0.25% F.S.

Vacuum (2, 7, 21, 35 bar indicator) ..................±0.25% F.S.

Including non-linearity, hysteresis, repeatability, and temperature

effect.

F.S. (full scale) = maximum gauge pressure in psi

Serial communication interface

Connector .......................................................... Stereo jack

Serial ......... 0-3 VDC, 9600 baud, 8 data, no parity, 1 stop

Protocol ..................................... ASCll command language

Media compatibility

Liquids and gasses compatible with 316 stainless steel.

Environmetal

Storage temperature ....................-20 to 70°C / -4 to 158°F

Operating temperature ...............-10 to 55°C / -14 to 131°F

Pressure connection

All ranges .....................................................1/4” NPT male

Adapters to 1/4” BSP male are included as standard

Pressure overload

1 to 35 bar / 15 to 500 psi…….. ............................3X range

70 to 350 bar / 1,000 to 5,000 psi ........................2X range

700 bar / 10,000 psi …………… .........................1.5X range

Overload alarm ………………………………… OL on display

Overload alarm range ……………………… …… 1.2X range

Display

Display .......................................................... Backlight, blue

Display resolution .......................... 5 digit floating decimal

Bar graph........................................ 20 segment, 0 to 100%

Display indicators ..............................Engineering units icon

...................................................Low battery indication icon

.............................. Battery life indication utilizing bar graph

............................................. Measured temperature display

Display update ......................................... twice per second

Power supply

Battery .......................................................... (3) AA Alkaline

Battery life ......... 1500 operational hours without backlight

Battery life ......... 2000 operational hours without backlight

..............................................................at low sampling rate

Battery life .................150 operational hours with backlight

Low battery indicator .............................................at 3 VDC

Optional input port .....................24 VDC connection

1) Units delivered with 24 VDC power supply connection are not

supplied with batteries

2) Batteries should not be installed when using 24 VDC power

supply as damage to the IPI may occur

3) Units with 24 VDC power supply connection cannot be ordered

with the protective boot option

1) 2) 3)

Instrument dimensions

Indicator LxWxH ..... 125 x 111 x 38 mm / 4.9 x 4.4 x 1.5 in

Indicator weight (including battery) ................1.6 lb / 0.7 kg

Input port ..........................1/4” NPT Male lower connection

Optional input port ........1/4” NPT Male back connection 1)

3) Units with back connection cannot be ordered with the protective boot option

Shipping dimensions

Indicator LxWxH ... 250 x 160 x 100 mm / 9.8 x 6.3 x 3.9 in

Indicator weight ..............................................1.8 lb / 0.8 kg

Instrument case

Rating ..........................................................NEMA 4/IP65

1) Does not apply if the serial connection is in use or if the

external 24 VDC power option is used.

1)

Approvals - IPI system

CE Conformity .............. EN61326: 1998, EN60079-0: 2006,

................................................................. EN60079-15:2005

The JOFRA IPI systems are type approved by Det Norske

Veritas. Find the certificate at www.jofra.com

Approval, Certificate no. .........................................A-10549

Ex approvals - IPI indicator only

CSA ......................................Class 1, Div. 2, Groups A-D

ATEX ................ II 3 G EEx nA IIB T6 (Ta=–10°C... +55°C)

1)

The 24 volt version is not CSA or ATEX approved

1)

1)

4 www.jofra.com

Page 5

Model IPI

Industrial Pressure Calibrator

Specification Sheet

SS-CP-2179-US

JOFRA IPI PRESSURE RANGES

This table shows the resolutions that can be obtained by the IPI indicators throughout all engineering units.

Resolution obtained

by the IPI indicator

Imperial ranges

psi -12.000 30.000 -12.000 100.00 -12.000 300.00 -12.00 500.00

inH2O@4°C -332.17 830.42 -332.2 2768.1 -332.2 8304.2 -332

inH2O@20°C -332.76

inH2O@60°F -332.50 831.24 -332.5 2770.8 -332.5 8312.4 -332

ftH2O@4°C -27.681 69.202 -27.68 230.67 -27.68 692.02 -27.7

ftH2O@20°C -27.730 69.324 -27.73 231.08 -27.73 693.24 -27.7

ftH2O@60°C -27.708 69.270 -27.71 230.90 -27.71 692.70 -27.7

inHg@0°C -24.432 61.081 -24.43 203.60 -24.43 610.81 -24.4 1018.0

Torr -620.6 1551.5 -620.6 5171.5 -620 15514 -621 25858

Metric ranges

bar -0.8300 2.0000 -0.8300 7.0000 -0.8300 21.000 -0.8300 35.000

mbar -830.0 2000.0 -830.0 7000.0 -830.00 21000 -830 35000

kPa -83.00 200.00 -83.00 700.00 -83.0 2100.0 -83.0 3500.0

kg/cm2

cmH2O@4°C

cmH2O@20°C

mH2O@4°C

mH2O@20°C

mmHg@0°C -622.6 1500.1 -622.6 5250.4 -622 15751 -623 26252

IPI30C

Vacuum to 30 psi

Vacuum to 2 bar

831.89 -332.7 2773.0 -332.7 8318.9 -333 13865

-0.8464 2.0394 -0.8464 7.1380 -0.846 21.414 -0.846 35.690

-846.4 2039.5 -846.4 7138.2 -846 21415 -846 35691

-847.9 2043.1 -847.9 7150.8 -847 21452 -848 35754

-8.464 20.395 -8.464 71.382 -8.46 214.15 -8.46 356.91

-8.479 20.431 -8.479 71.508 -8.48 214.52 -8.48 357.54

IPI100C

Vacuum to 100 psi

Vacuum to 7 bar

IPI300G

Vacuum to 300 psi

Vacuum to 21 bar

IPI500G

Vacuum to 500 psi

Vacuum to 35 bar

13840

13854

1153.4

1155.4

1154.5

Resolution obtained

by the IPI indicator

Imperial ranges

psi 15.000 1000.0 2000.0 3000.0 5000.0 10000

inH2O@4°C 415.21 27681

inH2O@20°C

inH2O@60°F 415.62 27708

ftH2O@4°C

ftH2O@20°C 34.662 2310.8 4621.6 6932.4

ftH2O@60°C

inHg@0°C 30.540 2036.0 4072.1 6108.1 10180 20360

Torr 775.73 51715 N/A N/A N/A N/A

Metric ranges

bar 1.0000 70.000 140.00 200.00 350.00 700.00

mbar 1000.0 70000 N/A N/A N/A N/A

kPa 100.00 7000.0 14000 20000 35000 70000

kg/cm2

cmH2O@4°C

cmH2O@20°C 1021.5

mH2O@4°C

mH2O@20°C 10.215

mmHg@0°C 750.06 52504 N/A N/A N/A N/A

IPI015G

0 to 15 psi

0 to 1 bar

415.95 27730 55459 83189 N/A N/A

34.601 2306.7 4613.5 6920.2 11534 23067

34.635 2309.0 4618.0 6927.0 11545 23090

1.0197 71.380 142.76 203.94 356.90 713.80

1019.7 71382 N/A N/A N/A N/A

10.197 713.82 1427.6 2039.5 3569.1 7138.2

IPI01KG

0 to 1,000 psi

0 to 70 bar

71508 N/A N/A N/A N/A

715.08 1430.2 2043.1 3575.4 7150.8

IPI02KG

0 to 2,000 psi

0 to 140 bar

55361 83042 N/A N/A

55416 83124 N/A N/A

IPI03KG

0 to 3,000 psi

0 to 200 bar

IPI05KG

0 to 5,000 psi

0 to 350 bar

11554 23108

IPI10KG

0 to 10,000 psi

0 to 700 bar

www.jofra.com 5

Page 6

Model IPI

Industrial Pressure Calibrator

Specification Sheet

SS-CP-2179-US

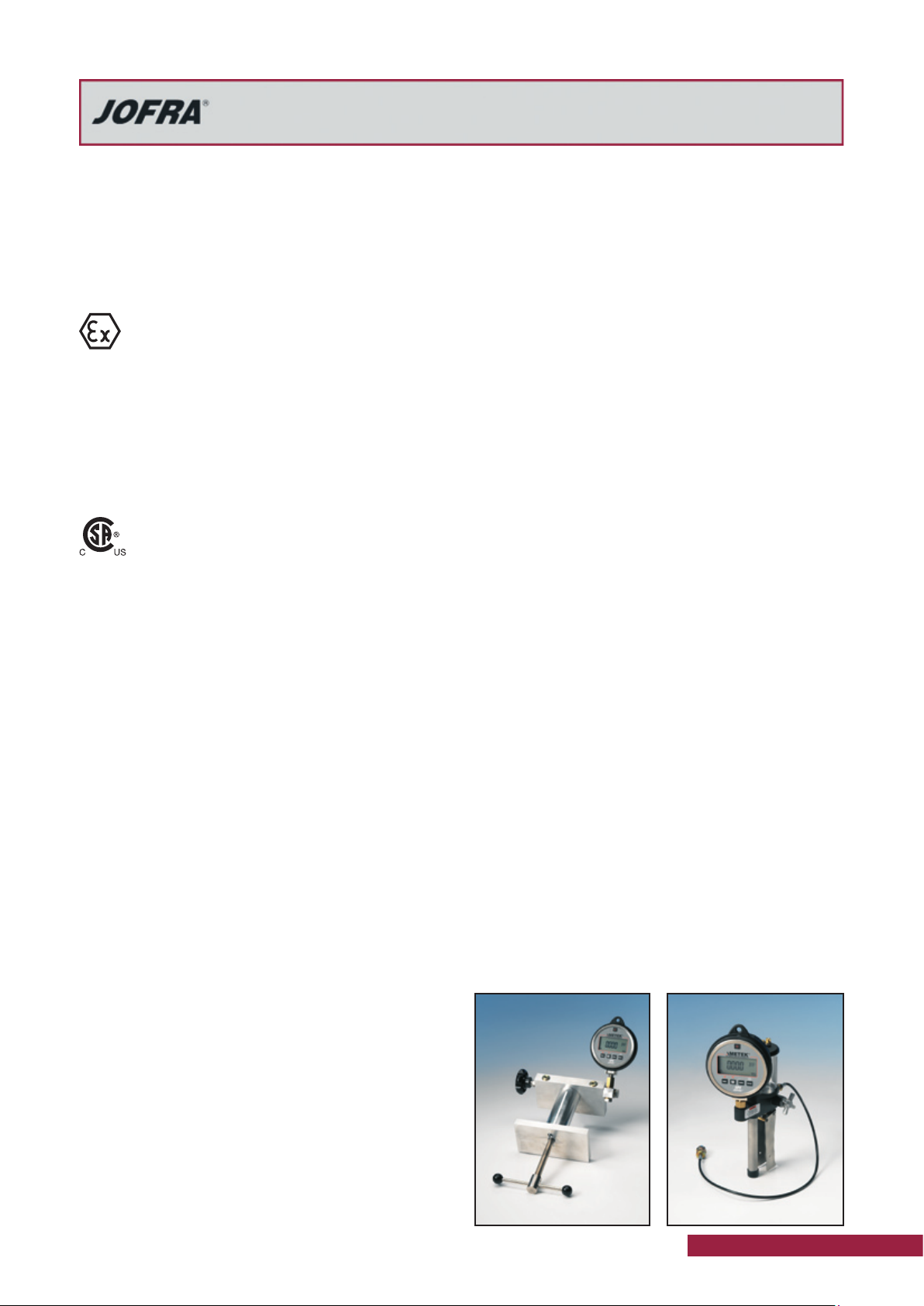

JOFRA IPI System A

•

0 to 1 bar (15 psi)

•

Vacuum to 2 bar (30 psi )

•

Vacuum to 7 bar (100 psi)

•

Vacuum to 21 bar (300 psi)

This system includes the

JOFRA IPI calibrator together

with one of the following pneumatic hand pumps: T-960 and

T-970, depending on the chosen pressure range. System A

is an easy-to-use single hand operated calibration system.

No need for a flat surface to operate the system - just hold

it in your hand.

The System A comes in an aluminium carrying case with

cutouts for fittings, hose, and the complete assembled

calibration unit - no time is required to assemble the unit

every time you need it. The calibrator (indicator) can at any

time be used separately for other pressure test tasks.

A special quick connector between the pump and the indicator makes it possible to seperate the system in seconds

and to swivel the indicator for easy viewing.

The JOFRA IPI delivery always includes a protective boot

for the indicator. All IPI indicators used in System A are

delivered calibrated in both pressure and vacuum.

Only the IPI indicator is approved for use in potentially explosive

atmospheres.

T-960 and T-970 pumps for system A

Model T-960 pneumatic pressure pump features an

extended range vernier adjustment for precisely controlling

pump pressure and comfortable pistol grip handle.

Model T-970 pneumatic pressure pump is similar to the T960, but generate pressure up to 40 bar (580 psi).

Pressure range, T-960 ..................... 0 to 2 bar / 0 to 30 psi

Pressure range, T-970 ..................0 to 40 bar / 0 to 580 psi

Type .....................................................................Pheumatic

Test medium..................................................................... Air

Operation .................................................................. Scissor

“O”-rings ..................................................................Buna-N

Wetted parts ............................ Aluminium, brass, stainless,

...................................................... steel, nylon, Nylatron GS

Connection to test object....................... Hose 0.6 m / 24 in

........................with 1/4” BSP and NPT female terminations

Size .........................21.6 x 12.1 x 6.2 cm / 8.5 x 4.8 x2.4 in

Weight ............................................................1.4 kg / 3.0 lb

Ordering

Part No. Description

T-960 Pump: 0 to 2 bar (30 psi)

T-970 Pump: 0 to 40 bar (580 psi)

Included with System A delivery

Standard delivery (see page 12)

•

Hand pump T-960 or T-970

•

3/8” BSP female adapter with 1/4” BSP and NPT

•

female terminations

0.6 m / 24 in hose with 1/4” BSP and NPT female

•

terminations

Quick connector between pump and indicator

•

1 roll of Teflon tape

•

Protective carrying case

•

Accessories

Part No. Description

75P014 Service kit for T-960 pump

75P016 Service kit for T-970 pump

T-733-2 Pressure hose for T-960/970, 0.6 meter std.

T-733-3 Pressure hose for T-960/970, 0.5 meter

T-733-4 Pressure hose for T-960/970, 1.0 meter

T-733-5 Pressure hose for T-960/970, 2.0 meter

T-733-6 Pressure hose for T-960/970, 5.0 meter

65R191 Set of BSP female fittings, teflon tape, packings

* Fitting size : 1x1/8”, 1x3/8”, 1x1/2”

65R192 Set of NPT female fittings, teflon tape, packings

* Fitting size : 1x1/8”, 1x1/4”, 1x3/8” 1x1/2”

60R191 1 set of packing and seals for 65R191 and 65R192

123958 RS232 cable with stereo Jack connector, 2m/6ft

124716 4x 1,5 Volt rechargeable batteries

124718 Charger for rechargeable batteries - 115/230 VAC

SPK-HPC-005 Quick connector set for IPI system A / B

Ordering information System A

Order no. Description

Pressure indicator

IPI Industrial Pressure Indicator

Indicator pressure range

015G 0 to 1 bar (15 psi)

030C Vacuum to 2 bar (30 psi)

100C Vacuum to 7 bar (100 psi)

300C Vacuum to 21 bar (300 psi)

NONE Pump system only (no calibrator)

Boot

B With boot (standard for indicator with

battery power and lower mounting –

and on all system kits)

Power supply

X Batteries (standard)

Mounting

X Lower mount (standard)

Base model number

AXX IPI System A (pump T-960)

AHX IPI System A (pump T-970)

Certification

G NIST traceable certificate (standard)

H Accredited certificate

(optional quotation basis)

IPI030CBXXAXXG Sample order number

JOFRA IPI 2 bar (30 psi) indicator with boot and in pres

sure System A with pneumatic pressure handpump and

NIST traceable calibration certificate.

-

6 www.jofra.com

Page 7

Model IPI

Industrial Pressure Calibrator

Specification Sheet

SS-CP-2179-US

JOFRA IPI System B

Vacuum to 2 bar (30 psi )

•

Vacuum to 7 bar (100 psi)

•

•

Vacuum to 21 bar (300 psi)

Vacuum to 35 bar (500 psi)

•

This system includes the dual

function pneumatic hand

pump. With this pump you

can calibrate both vacuum

and pressure applications. It

takes just a few seconds to

switch between vacuum and pressure, just push one button (valve) on the T-975 handpump.

The System B comes in an aluminium carrying case with cutouts for fittings, hose and the complete assembled calibration unit - no time required to assemble the unit every time.

The indicator and the pump are fitted with a special quick

connector that makes it possible to separate the system

in seconds without any tool. This quick connector also

makes it possible to use the assembled system with the

indicator twisted to any angle.

Only the IPI indicator is approved for use in potentially explosive

atmospheres.

Included with System B delivery

Standard delivery (see page 12)

•

Hand pump T-975 for all ranges

•

3/8” BSP female adapter with 1/4” BSP and NPT

•

female terminations

0.6 m / 24 in hose with 1/4” BSP and NPT female

•

terminations

Quick connector between pump and indicator

•

1 roll of Teflon tape

•

Protective carrying case

•

Accessories

Part No. Description

75P017 Service kit for T-975 pump

T-733-2 Pressure hose for T-975, 0.6 meter std.

T-733-3 Pressure hose for T-975, 0.5 meter

T-733-4 Pressure hose for T-975, 1.0 meter

T-733-5 Pressure hose for T-975, 2.0 meter

T-733-6 Pressure hose for T-975, 5.0 meter

65R191 Set of BSP female fittings, teflon tape, packings

* Fitting size : 1x1/8”, 1x3/8”, 1x1/2”

65R192 Set of NPT female fittings, teflon tape, packings

* Fitting size : 1x1/8”, 1x1/4”, 1x3/8” 1x1/2”

60R191 1 set of packing and seals for 65R191 and 65R192

123958 RS232 cable with stereo Jack connector, 2m/6ft

124716 4x 1,5 Volt rechargeable batteries

124718 Charger for rechargeable batteries - 115/230 VAC

SPK-HPC-005 Quick connector set for IPI system A / B

T-975 hand pump for system B

Model T-975 pneumatic pressure pump features both

vacuum and pressure generation. A button (valve) makes

it easy to switch from vacuum to pressure measurements.

Built-in release valve, vernier valve for fine adjustment and

dual pressure output enable safe and simple operation.

The unit offers both metric and imperial threads on the reference connection and the hose.

Pressure range ...........-0.91 to 40 bar / -27 inHg to 580 psi

Type .....................................................................Pheumatic

Test medium..................................................................... Air

Operation .................................................................. Scissor

“O”-rings ..................................................................Buna-N

Wetted parts .......Anodized aluminium, nickel-plated brass,

............................................................ stainless steel, Nylon

Connection to test object....................... Hose 0.6 m / 24 in

........................with 1/4” BSP and NPT female terminations

Size .........................21.6 x 12.1 x 6.2 cm / 8.5 x 4.8 x2.4 in

Weight ............................................................1.4 kg / 3.0 lb

Ordering

Part No. Description

T-975 Pump: -0.91 to 40 bar / -27 inHg to 580 psi

Ordering information System B

Order No. Description

Pressure indicator

IPI Industrial Pressure Indicator

Indicator pressure range

030C Vacuum to 2 bar (30 psi)

100C Vacuum to 7 bar (100 psi)

300C Vacuum to 21 bar (300 psi)

500C Vacuum to 35 bar (500 psi)

NONE Pump system only (no calibrator)

Boot

B With boot (standard for indicator with

battery power and lower mounting –

and on all system kits)

Power supply

X Batteries (standard)

Mounting

X Lower mount (standard)

Base model number

BXX IPI System B (pump T-975)

Certificate

G NIST traceable certificate (standard)

H Accredited certificate

(optional quotation basis)

IPI300CBXXBXXG Sample order number

JOFRA IPI 21 bar (300 psi) indication with boot and in

pressure System B kit with pneumatic combination handpump and NIST traceable calibration certificate.

www.jofra.com 7

Page 8

Model IPI

Industrial Pressure Calibrator

Specification Sheet

SS-CP-2179-US

JOFRA IPI System C

0 to 35 bar (500 psi)

•

0 to 70 bar (1,000 psi)

•

•

0 to 140 bar (2,000 psi)

•

0 to 200 bar (3,000 psi)

0 to 350 bar (5,000 psi)

•

This system consists of an

IPI indicator together with a

hydraulic, high pressure hand

pump T-620 or T-620H, which features an oil reservoir to

prime the system. System C is an easy-to-use single-hand

operated test system. No need for a flat surface (table)

to operate the system. The system includes release valve

and vernier valve for fine adjustment to enable safe and

simple operation of the pump.

The System C comes in a protective carrying case with

cutouts for fittings, hose, and the complete assembled

test unit - no time adder to assemble the unit every time.

Easy and fast connection between pump and indicator

makes it easy to use the pressure indicator separately for

other pressure test tasks.

Only the IPI indicator is approved for use in potentially explosive

atmospheres.

Included with System C delivery

Standard delivery (see page 12)

•

•

Hand pump T-620 or T-620H

•

0.6 m (24 in) hose with 1/4” NPT female and 1/4” BSP

terminations

1 roll of Teflon tape

•

Protective carrying case

•

Accessories

Part No. Description

T-656 Service kit for T-620 and T-620H pumps

T-649 Pressure hose for T-620/T-620H pumps

65P175 1 m hose with 1/4” BSP female termination

Max. pressure 350 bar (5,000 psi)

65P180 2 m hose with 1/4” BSP female termination

Max. pressure 350 bar (5,000 psi)

123958 RS232 cable with stereo Jack connector, 2m/6ft

124716 4x 1,5 Volt rechargeable batteries

124718 Charger for rechargeable batteries - 115/230 VAC

MGAAA/GL Oil for T-620 & T-1 pump AAA OIL in

1-GALLON CAN

MGAAA/QT Oil for T-620 & T-1 pump AAA OIL in 1-

QUART CAN

AMETEK hydraulic handpump

This easy-to-use hand pump is specially designed for high

pressure applications. The pump has a built-in reservoir,

vent valve, and vernier valve for fine adjustment. The

pump has a dual pressure output - one for the test object

and one for the IPI indicator.

Pressure range, T-620 .................... 0 to 200 bar / 3,000 psi

Pressure range, T-620H .................

Type .......................................................................Hydraulic

Test medium..................................................................... Oil

Reservoir capacity .......................................200 cl / 0.5 pint

Operation ..............................................................Pistol-grip

“O”-rings ..................................................................Buna-N

Wetted parts ..........Aluminum, brass, stainless steel, Lexan

Connection to test object....................... Hose 0.6 m / 24 in

........................with 1/4” BSP and NPT female terminations

Size ........................21.6 x 12.1 x 6.2 cm / 8.5 x 4.8 x 2.4 in

Weight ............................................................1.4 kg / 3.0 lb

0 to 350 bar / 5,000 psi

Ordering

Part No. Description

T-620 Pump: 0 to 200 bar (3,000 psi)

T-620H Pump: 0 to 350 bar (5,000 psi)

Ordering information IPI System C

Order No. Description

Pressure indicator

IPI Industrial Pressure Indicator

Indicator pressure range

500C Vacuum to 35 bar (500 psi)

01KG 0 to 70 bar (1,000 psi)

02KG 0 to 140 bar (2,000 psi)

03KG 0 to 200 bar 3,000 psi)

05KG 0 to 350 bar 5,000 psi)

NONE Pump system only (no calibrator)

Boot

B With boot (standard for indicator with

battery power and lower mounting –

and on all system kits)

Power supply

X Batteries (standard)

Mounting

X Lower mount (standard)

Base model number

CXX IPI System C (pump T-620 / T-620 H)

Certificate

G NIST traceable certificate (standard)

H Accredited certificate

(optional quotation basis)

IPI01KGBXXCXXG Sample order number

JOFRA IPI 70 bar (1,000 psi) indicator with boot and in

pressure System C with hydraulic pressure handpump and

NIST traceable calibration certificate.

8 www.jofra.com

Page 9

Model IPI

Industrial Pressure Calibrator

Specification Sheet

SS-CP-2179-US

JOFRA IPI System D

0 to 35 bar (500 psi)

•

0 to 70 bar (1,000 psi)

•

•

0 to 140 bar (2,000 psi)

•

0 to 200 bar (3,000 psi)

0 to 350 bar (5,000 psi)

•

This system consists of an IPI indicator together with a

rugged, hydraulic, high pressure screwpump. System D

is an easy-to-use test system. Place the pump on a flat

surface and turn the handle to generate pressure. You can

adjust the indicator to fit the best viewing angle. The system includes a manifold for connection of the test device,

a fine adjustment vernier valve (optional), and a reservoir

for extra oil or water (optional).

The System D comes in a protective carrying case with

cutouts for fittings and the complete assembled test unit

- no time adder to assemble the unit every time. Easy

and fast connection between pump and indicator makes

it easy to use the pressure calibrator separately for other

pressure test tasks.

Only the IPI indicator is approved for use in potentially explosive

atmospheres.

Accessories

Part No. Description

60P013 Vernier valve fine adjustment for 65-P016/017

60P016 Packing set for screw pump oil part no. 65-P016

60P017 Packing set for screw pump water part no. 65-P017

65-R975 Reservoir set with seals, valve and bonded seal

60R135 Valve for oil reservoir

65P175 1 m. Pressure hose, (Max. 350 bar / 5,000 psi)

* 1/4” BSP female to 1/4” BSP male

65P180 2 m. Pressure hose, (Max. 350 bar / 5,000 psi)

* 1/4” BSP female to 1/4” BSP male

60I156 1.5 m. Pressure hose, (Max. 700 bar/10,000 psi)

* 1/4” BSP female to 1/4” BSP male

60I157 5 meter, Pressure hose, (Max. 700 bar / 10,000 psi)

* 1/4” BSP female to 1/4” BSP male

65N000 Extension tube, 120 mm (Max. 350 bar / 5.000 psi)

* 1/4” BSP female to 1/4” BSP male

123958 RS232 cable with stereo Jack connector, 2m/6ft

124716 4x 1,5 Volt rechargeable batteries

124718 Charger for rechargeable batteries - 115/230 VAC

50-REP 615 Quick connector set, female 1/4”BSP

to 1/4” BSP

AMETEK screwpump

The 65-P016 and 65-P017 screwpumps are designed

for very easy generation of high pressure. The screwpumps has a 4 connection manifold. Fine adjustment,

vernier valve, liquid reservoir, and fittings are optional. The

AMETEK screwpump may be delivered for 2 different test

media: hydraulic oil or water.

Pressure range ............................... 350 bar / 0 to 5,000 psi

Type .......................................................................Hydraulic

Test media ............................................. Hydraulic oil, water

Operation ..........................................................Screw pump

“O”-rings ..................................................................Buna-N

Wetted parts ..................... Aluminum, brass, stainless steel

Connections to test objects ................ 4 x 1/4” BSP female

Size ....................36.6 x 19.5 x 10.5 cm / 14.4 x 7.7 x 4.1 in

Weight ............................................................3.7 kg / 8.2 lb

Ordering

Part No. Description

65-P016 Screw pump oil: 0 to 350 bar (5000 psi) 1)

65-P017 Screw pump water: 0 to 350 bar (5000 psi) 1)

1) 25 ml (0.85 oz) reservoir

Included with System D delivery

Standard delivery (see page 12)

•

Screwpump 65-P016 for hydraulic oil or 65-P017 for

•

water

1 roll of Teflon tape

•

10 bonded seals

•

6 mm Allen key

•

Protective carrying case

•

Ordering information IPI System D

Order No. Description

Pressure indicator

IPI Industrial Pressure Indicator

Indicator pressure range

500C Vacuum to 35 bar (500 psi)

01KG 0 to 70 bar (1,000 psi)

02KG 0 to 140 bar (2,000 psi)

03KG 0 to 200 bar (3,000 psi)

05KG 0 to 350 bar (5,000 psi)

NONE Pump system only (no calibrator)

Boot

B With boot (standard for indicator with

battery power and lower mounting –

and on all system kits)

Power supply

X Batteries (standard)

Mounting

X Lower mount (standard)

Base model number

DOX IPI System D (pump 65-P016)

DWX IPI System D (pump 65-P017)

Certificate

G NIST traceable certificate (standard)

H Accredited certificate

(optional quotation basis)

IPI01KGBXXDOXG Sample order number

JOFRA IPI 70 bar (1,000 psi) indicator with boot and in

pressure System D with hydraulic oil screwpump and NIST

traceable calibration certificate.

www.jofra.com 9

Page 10

Model IPI

Industrial Pressure Calibrator

Specification Sheet

SS-CP-2179-US

JOFRA IPI System E

0 to 70 bar (1,000 psi)

•

•

0 to 140 bar (2,000 psi)

•

0 to 200 bar (3,000 psi)

0 to 350 bar (5,000 psi)

•

0 to 700 bar (10,000 psi)

•

This system consists of an IPI

indicator together with a rugged, hydraulic, high pressure pump.

System E is an easy-to-use test system. The hydraulic

pump makes it very easy to prime the system. You can

adjust the indicator to fit the best viewing angle. The system includes a manifold for connection of two test devices

and the fine adjustment vernier valve is standard.

The System E comes in a protective carrying case with

cutouts for fittings and the complete assembled test unit

- no time adder to assemble the unit every time. Easy

and fast connection between pump and indicator makes

it easy to use the pressure calibrator separately for other

pressure test tasks.

Only the IPI indicator is approved for use in potentially explosive

atmospheres.

Included with System E delivery

Standard delivery (see page 12)

•

Hydraulic pump 65-P014 for hydraulic oil

•

Vernier valve

•

1 roll of Teflon tape

•

10 bonded seals

•

6 mm Allen key

•

Protective carrying case

•

Accessories

Part No. Description

60P013 Vernier valve for fine adjustment

60P014 Packing set for Jack pump part no. 65-P014

60I156 1.5 m. Pressure hose, (Max. 700 bar/10,000 psi)

* 1/4” BSP female to 1/4” BSP male

60I157 5 meter, Pressure hose, (Max. 700 bar / 10,000 psi)

* 1/4” BSP female to 1/4” BSP male

123958 RS232 cable with stereo Jack connector, 2m/6ft

124716 4x 1,5 Volt rechargeable batteries

124718 Charger for rechargeable batteries - 115/230 VAC

50-REP 615 Quick connector set, female 1/4”BSP

to 1/4” BSP

AMETEK high pressure hydraulic oil pump

The 65-P014 hydraulic pump is designed for high pressure applications. The pump has a 4 connection output

manifold. Fine adjustment vernier valve and fittings are

optional.

Pressure range ............................. 0 to 700 bar / 10,000 psi

Type .......................................................................Hydraulic

Test media ........................................................................Oil

Operation ............................................................ Jack pump

“O”-rings ..................................................................Buna-N

Wetted parts ..................... Aluminum, brass, stainless steel

Connections to test objects ................ 4 x 1/4” BSP female

Size ....................36.5 x 20.0 x 14.2 cm / 14.4 x 7.9 x 5,6 in

Weight ........................................................5.3 kg / 11.6 lbs

Ordering

Part No. Description

65-P014 Hydraulic pump for oil: 0 to 700 bar (10,000 psi) 1)

1) 450 ml (15.22 oz) reservoir

Ordering information IPI System E

Order No. Description

Pressure indicator

IPI Industrial Pressure Indicator

Indicator pressure range

01KG 0 to 70 bar (1,000 psi)

02KG 0 to 140 bar (2,000 psi)

03KG 0 to 200 bar (3,000 psi)

05KG 0 to 350 bar (5,000 psi)

10KG 0 to 700 bar (10,000 psi)

NONE Pump system only (no calibrator)

Boot

B With boot (standard for indicator with

battery power and lower mounting –

and on all system kits)

Power supply

X Batteries (standard)

Mounting

X Lower mount (standard)

Base model number

EXX IPI System E (pump 65-P014)

Certificate

G NIST traceable certificate (standard)

H Accredited certificate

(optional quotation basis)

IPI01KGBXXEXXG Sample order number

JOFRA IPI 70 bar (1,000 psi) indicator with boot an in

pressure system System E with high pressure pump for

hydraulic oil and NIST traceable calibration certificate.

10 www.jofra.com

Page 11

Model IPI

Industrial Pressure Calibrator

Specification Sheet

SS-CP-2179-US

JOFRA IPI System F

0 to 35 bar (500 psi)

•

0 to 70 bar (1,000 psi)

•

•

0 to 140 bar (2,000 psi)

•

0 to 200 bar (3,000 psi)

0 to 350 bar (5,000 psi)

•

0 to 700 bar (10,000 psi)

•

System F is an easy-to-use test system. The hydraulic pump

makes it very easy to prime the system. The pump contains

75 in3 / 1.23 l of liquid. The system includes a manifold for

connection of two test devices and the fine adjustment vernier valve is standard. The System F comes in a protective

carrying case with cutouts for fittings. Easy and fast connection between pump and calibrator makes it easy to use the

pressure calibrator separately for other pressure test tasks.

Only the IPI indicator is approved for use in potentially explosive

atmospheres.

AMETEK Type T hydraulic oil or water pump

The type T pump is designed for high pressure applications up to 15,000 psi (1,000 bar). The pump and system

may be ordered with either oil or a water/alcohol mixture

as the pressure medium. The pump is constructed of 300

series stainless steel and Monel allowing for the use of

other hydraulic media. There are three available seal packages for the system: Buna-N, Viton®, and EPT. 1)

The Type T pump features a dual pressure output manifold, fine adjustment vernier valve, relief valve, and dual

volume control for rapid pressure increase at lower pressures and easier pumping at higher pressures.

Pressure range .......................... 0 to 1,000 bar / 15,000 psi

Type .......................................................................Hydraulic

Test media ............................................. Hydraulic oil, water

Reservoir capacity ...........................................1.23 l / 75 in

Operation ............................................................ Jack pump

“O”-rings ......... Buna-N (standard) or EPT / Viton (optional)

Wetted part ....................................... Stainless steel, Monel

Connections to test objects ................... 1/4” and 1/2” BSP

............ terminations; 1/4” and 1/2” PT female terminations

Size ................................ 79.4x22.9x50.8 cm / 31.3x9x20 in

Weight ...........................................................9.1 kg / 20 lbs

Ordering

Part No. Description Seals

T-1 0 to 1,000 bar (15,000 psi) water - Buna N

T-1/VITON 0 to 1,000 bar (15,000 psi) water - Viton

T-1/EPT 0 to 1,000 bar (15,000 psi) water - EPT

T-1/OIL 0 to 1,000 bar (15,000 psi) oil - Buna N

T-1/OIL/VITON 0 to 1,000 bar (15,000 psi) oil - Viton

T-1/OIL/EPT 0 to 1,000 bar (15,000 psi) oil - EPT

1) Customer must verify compatibility of seals and pump materials with

pressure medium. Viton is a registered trademark.

2) Buna N are the standard ”O” ring material for the hydraulic testers. They

are used with water/alcohol or non corrosive oils.

3) Viton ”O” ring material is used for all corrosive oils other than Skydrol.

4) EPT ”O” ring material is specifically for Skydrol Oil used for hydraulic

systems in airplanes, it is very corrosive.

2)

3)

4)

2)

3)

4)

Included with System F delivery

Standard delivery (see page 12)

•

Type T Hydraulic pump

•

1 roll of Teflon tape

•

Protective carrying case

•

Accessories

Part No. Description

T-250 Service kit for T pump with Buna N O-rings

T-250 Service kit for T pump with VITON N O-rings

T-250 Service kit for T pump with EPT N O-rings

60I156 1.5 m. Pressure hose, (Max. 700 bar/10,000 psi)

* 1/4” BSP female to 1/4” BSP male

60I157 5 meter, Pressure hose, (Max. 700 bar / 10,000 psi)

* 1/4” BSP female to 1/4” BSP male

123958 RS232 cable with stereo Jack connector, 2m/6ft

124716 4x 1,5 Volt rechargeable batteries

124718 Charger for rechargeable batteries - 115/230 VAC

MGAAA/GL Oil for T-620 & T-1 pump AAA OIL in

1-GALLON CAN

MGAAA/QT Oil for T-620 & T-1 pump AAA OIL in 1-

QUART CAN

Ordering information IPI System F

Order No. Description

Pressure indicator

IPI Industrial Pressure Indicator

Indicator pressure range

500C Vacuum to 35 bar (500 psi)

01KG 0 to 70 bar (1,000 psi)

02KG 0 to 140 bar (2,000 psi)

03KG 0 to 200 bar (3,000 psi)

05KG 0 to 350 bar (5,000 psi)

10KG 0 to 700 bar (10,000 psi)

NONE Pump system only (no calibrator)

Boot

B With boot (standard for indicator with

battery power and lower mounting –

3

and on all system kits)

Power supply

X Batteries (standard)

Mounting

X Lower mount (standard)

Base model number

FWB IPI System F (pump T-1)

FWV IPI System F (pump T-1/VITON)

FWE IPI System F (pump T-1/EPT)

FOB IPI System F (pump T-1/OIL)

FOV IPI System F (pump T-1/OIL/VITON)

FOE IPI System F (pump T-1/OIL/EPT)

Certificate

G NIST traceable certificate (standard)

H Accredited certificate

(optional quotation basis)

IPI10KGBXXFOEG Sample order number

JOFRA IPI 700 bar (10,000 psi) indicator with boot and in

pressure System F with Type T pump for oil, EPT seals

and NIST traceable calibration certificate.

www.jofra.com 11

Page 12

ORDERING INFORMATION - JOFRA IPI INDICATOR

Order No. Description

Pressure indicator

IPI Industrial Pressure Indicator

Indicator pressure range

030C Vacuum to 2 bar (30 psi)

100C Vacuum to 7 bar (100 psi)

300C Vacuum to 21 bar (300 psi)

500C Vacuum to 35 bar (500 psi)

015G 0 to 1 bar (15 psi)

01KG 0 to 70 bar (1,000 psi)

02KG 0 to 140 bar (2,000 psi)

03KG 0 to 200 bar (3,000 psi)

05KG 0 to 350 bar (5,000 psi)

10KG 0 to 700 bar 10,000 psi ()

Boot

B With boot (standard for indicator with battery power

and lower mounting - and on all system kits)

X No boot (standard for indicators with back mounting

and/or 24 VDC powers supply connection)

Power supply

X Batteries (standard)

1)

E Connection for external 24 VDC power supply

Mounting

X Lower mount (standard)

B Back mount

Base model number

IND IPI indicator with standard accessories for configuration

Certification

G NIST traceable certificate (standard)

H Accredited certificate (optional – on quotation basis)

IPI030CBXXINDG Sample order number

JOFRA IPI 2 bar (30 psi) indicator with boot, standard accessories, and

NIST traceable calibration certificate.

1)

The 24 volt version is not CSA or ATEX approved

STANDARD DELIVERY

IPI indicator

•

Calibration certification

•

performance traceable to NIST

(3) AA batteries

•

Adapter to 1/4” BSP male

•

User manual

•

Protective boot

•

is one of the world’s leading manufacturers and

AMETEK Calibration Instruments

developers of calibration instruments for

temperature, pressure and process signals

as well as for temperature sensors both from

a commercial and a technological point of view.

JOFRA Temperature Instruments

Portable precision thermometers. Dr y-block and

liquid bath calibrators: 4 series, with more than

25 models and temperature ranges from

-90° to 1205°C / -130° to 2200°F. All featuring speed,

portabilit y, accuracy and advanced documenting

functions with JOFRACAL calibration software.

JOFRA Pressure Instruments

Convenient electronic systems ranging from

-1 to 1000 bar (25 inHg to 14,500 psi) -

multiple choices of pressure ranges, pumps and

accuracies, fully temperature-compensated

for problem-free and accurate field use.

JOFRA Signal Instruments

Process signal measurement and simulation for

easy control loop calibration and measurement

tasks - from handheld field instruments to

laboratory reference level bench top instruments.

JOFRA / JF Marine Instruments

A complete range of calibration equipment

for temperature, pressure and signal,

approved for marine use.

FP Temperature Sensors

A complete range of temperature sensors

for industrial and marine use.

M&G Pressure Testers

Pneumatic floating-ball or hydraulic piston dead

weight testers with accuracies to 0.015% of reading.

M&G Pumps

Pressure generators from small pneumatic

“bicycle” style pumps to hydraulic pumps

generating up to 1,000 bar (15,000 psi).

.. .becau s e cali bratio n is

a m a tter o f conf idence

Headquarters:

AMETEK Denmark A/S

Gydevang 32-34 • 3450 Allerød • Denmark

Tel: +45 4816 8000 • ametek@ametek.dk

Sales & Service:

Europe, Asia, Africa, Middle East and South America

Information in this document is subject to change without notice.

©2008, by AMETEK, Inc., www.ametek.com. All rights reserved.

Pub code SS- CP-21 79-US Issue 08 08

12 www.jofra.com

www.ametekcalibration.com

www.jofra.com

Sales & Service Offices:

AMETEK Mansfield & Green (North America)

Tel: +1 800 527 9999 • cal.info@ametek.com

AMETEK Singapore Pte. Ltd. (Singapore)

Tel: +65 6 484 2388 • aspl@ametek.com.sg

AMETEK Inc. Beijing Rep. Office (China)

Tel: +86 10 8526 2111 • jofra@ametek.com.cn

AMETEK GmbH (Germany)

Tel: +49 2159 91360 • info@ametek.de

AMETEK Lloyd Instruments (UK)

Tel: +44 (0) 1489 486 404 • jofra@ametek.co.uk

Loading...

Loading...