Page 1

Reference Manual

Industrial Pressure Indicator

AMETEK JOFRA IPI

Copyright 2005 AMETEK Denmark A/S

Page 2

1

Introduction

The IPI combines the high accuracy of digital electronics with the

convenience and ease of use of an analog test gauge. Accurate to ±

0.05% FS, the IPI can be used as a calibration reference, or in any

application where high accuracy pressure measurement is required.

Many user configurable functions have been designed into the IPI

including sampling rate, TARE, damping, auto shut off, and min-max.

Once the gauge is configured, settings can be locked and password

protected to prevent unauthorized changes to configuration.

1.1 Contacting Ametek

US, Canada, Latin America AMETEK TCI at 1-800-527-9999

Europe, Africa, Middle East AMETEK Denmark A/S at

+ 45 4816 8000

Asia AMETEK Singapore Pte. Ltd. at

+ 65 (64) 842 388

1.2 Standard Equipment

Check to see that your IPI has arrived intact. Batteries are factory installed

unless you have purchased the optional 24V powered version, in which

case batteries are not supplied or installed. Save the packing materials at

least until you have verified that there is no concealed damage.

1.3 Safety information

A Warning identifies conditions and actions that pose hazard(s) to the user;

a Caution identifies conditions and actions that may damage the Calibrator

or the equipment under test.

Page 3

2

Symbols Used

The following table lists the International Electrical Symbols. Some or all of

these symbols may be used on the instrument or in this manual.

Symbol Description

Power OFF

Power ON

Earth ground

Risk of Danger. Important information. Refer to manual.

Battery

Hazardous Voltage

Conforms to ATEX requirements

Certified by CSA as conforming to relevant Canadian and USA standards

Conforms to relevant European Union directives.

Wheeled bin, conforms to EC directive 2002/96/EC

Hazard Location Information

Ex Hazardous Areas

An Ex-hazardous area as used in this manual refers to an area made

hazardous by the potential presence of flammable or explosive vapors.

These areas are also referred to as hazardous locations, see NFPA 70

Article 500 or CSA C22.1 Section 18.

Certification

This product is certified by CSA with the following rating:

Class I, Div. 2, Groups A-D

Misuse

Should the BetaGauge be exposed to overpressure or sudden physical

shock (i.e. being dropped) it should be examined for any damage that may

Page 4

cause a safety concern. If in doubt please return the unit for evaluation to

Ametek. Please refer to the Customer Service Section for contact

information.

Caution

To avoid possible damage to calibrator or to equipment under test:

• If the message changes to "OL" the range limit is exceeded and the

pressure source must immediately be removed from the IPI to prevent

damage to the pressure transducer inside.

• Maximum torque allowed is 13,5 Nm = 10 ftlbs. NEVER exceed the torque

allowed.

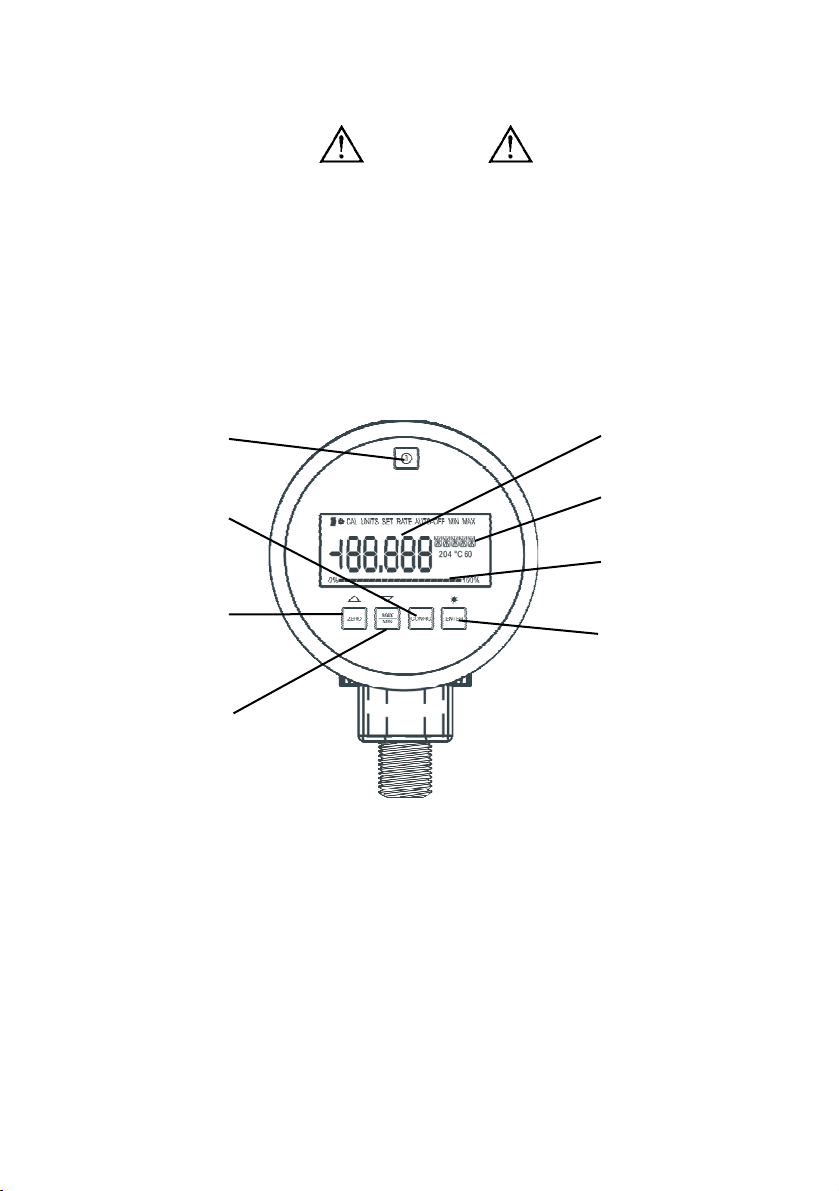

IPI Display and Controls

Operation

Power: The standard IPI is supplied with 3 AA batteries installed. If you

purchased the optional 24Volt powered version, batteries are not installed.

Connect a 24V power supply to the terminal block on the rear of the gauge,

noting proper polarity.

Do not install batteries when external power will be used.

Push the power button momentarily to turn the unit on. Push it again to turn

it off.

Set-up and configuration:

Push the CONFIG button to access the user-settable functions on the gauge.

Each time the CONFIG button is pressed; the display advances to the next

3

Pressure display

Engineering Units

0 - 100% bar graph

Selects an action in

configuration.

Also turns the

back-light on/off

Turns Power on/off

Enters set-up and

configuration menus

Zeros the display,

Scrolls forward through

menu displays

Recalls min and max

readings.

Scrolls backwards

through menu displays

Page 5

4

function. Once a function has been set, press ENTER to exit the

configuration menu, or CONFIG to continue with further configuration. In

order, the configuration menu and operation is as follows:

1. Engineering Units set. The unit is shipped configured to display

PSI. By pressing the ▲ and ▼ (ZERO and MAX/MIN) keys you can

scroll forward and backwards through the 18 standard engineering

units plus a one custom unit/scale. When the desired unit is displayed,

press ENTER or CONFIG. Pressure will now be displayed in the

chosen engineering units.

See the Specifications section of this manual for a list of available

engineering units. See the Supervisory Mode section for details on

setting up custom units.

2. Set Auto Off. The auto-shut off can be set in 1 minute increments

from 1 to 30 minutes or “off” (continuous operation). The unit is

shipped set for 30 minutes. Use the ▲ and ▼ keys to set the desired

interval. The “off” setting is at the low end of the choices, below 1

minute.

3. Display battery voltage. Actual voltage and a percent of life

bargraph indicate battery condition

4. Display actual temperature. The IPI is temperature compensated,

this displays the temperature measured by the internal sensor. The

value can be set to degrees F or degrees C using the arrow keys.

5. Set damping. Choices are “on” and “off” set with the ▲ and ▼ keys.

Turning damping on will smooth readings from pulsating pressure

sources.

6. Set sample rate: This determines how often pressure is sampled and

the display is updated. Choices are 0.5, 1, 3, and 10 samples/

second. Note that 10/sec provides the fastest response time.

7. Set TARE. This allows you to set a constant offset value, which is

then subtracted from the measured pressure. For example if a TARE is

set at 30 PSI, and the measured pressure is 37 PSI, the displayed

value will be 7 PSI.

A pressure of 27 PSI would be displayed as –3 PSI.

The tare value is set manually with the ▲ and ▼ keys, and is based on

the engineering units and resolution selected for display. TARE value

can be set to the maximum range of the gauge.

The bar graph will always display the actual pressure based on the full

range of the gauge regardless of the tare setting. This is done for

safety to insure that even with a “0” reading that pressure is being

applied to the gauge.

Page 6

8. Function Lock: Access to each of the settable parameters above can

be turned “off” once set, to prevent unauthorized changes to

configuration. This is accomplished through a password protected

“supervisory mode”. Press ENTER to access the supervisory mode, or

CONFIG to return to normal operation.

Supervisory Mode

Push the CONFIG button to access the user-settable functions on the

indicator. Each time the CONFIG button is pressed; the display advances

to the next function. Press CONFIG repeatedly until “FUnC LOCK” is

displayed.

Press ENTER when “FUnC LOCK” is displayed, 0

PWRD

will be displayed on

the gauge. The password to enter supervisory mode is 101, set using the

▲ and ▼ keys. Holding a key continuously will cause the display to

advance more quickly for faster setting. The password is factory set and

cannot be changed.

1. Your IPI is shipped from the factory with all setting access “unlocked”

or available to be changed.

2. In supervisory mode each of the parameters can be locked or

unlocked using the ▲ and ▼ keys. Select LOC (lock) for those

parameters you do not want to be accessible, and UnLOC (unlock) for

those can be accessed.

3.

In order, the functions that can be unlocked, locked or accessed are:

• Zero function (enable/disable)

• Set pressure units (enable/disable)

• Auto shutdown adjustment (enable/disable)

• Damping settings (enable/disable)

• Sample rate setting (enable/disable)

• Tare setting (enable/disable)

• Custom engineering units (set scale factor)

4. Use the CONFIG key to scroll through the above choices, and the ▲

and ▼ keys to lock and unlock features. Press CONFIG to continue

scrolling through the parameters, pressing ENTER at any point saves

your settings and returns the gauge to normal operation.

When a function is “locked”, it cannot be accessed or changed from

its current state. To change a locked function, enter the supervisory

mode, and unlock the function. Once it is changed, you may enter

supervisory mode to lock access again.

5. Setting a custom engineering unit or scale: The last menu choice in

supervisory mode is SET FACTR. This allows you to set a multiplier

5

Page 7

6

factor from 0.001 to 100, creating a custom scale. The set factor will

be multiplied by the PSI measured, the result will be displayed.

For example: 40 PSI is the equivalent of 1000 lbs of product in a tank.

You want to display the product weight , using a 100 PSI gauge. By

setting a factor of 25, a 40 PSI pressure would display as 1000 (40 x

25). The engineering unit displayed on the IPI will be “Cust”.

Normal Operation

Turning the backlight on and off: Press the ENTER button.

Zeroing the display: Press and hold the ZERO button.

MAX/MIN: The IPI stores minimum and maximum pressure values in

memory. Pressing the MAX/MIN button once will display the minimum

pressure from memory. Pressing the MAX/MIN button again will display

the maximum pressure from memory. After about 2 seconds, the gauge

returns to normal (live display) operation. To clear the MAX/MIN memory

registers, press and hold the MAX/MIN button for 2 or more seconds until

“CLr” is displayed.

The analog bar graph at the bottom of the display indicates the applied

pressure level relative to the full range of the gauge. Keep in mind that if a

TARE value has been programmed into the gauge, the displayed pressure

will not reflect the true pressure applied.

Changing the Batteries

WARNING

Explosion hazard

Batteries must only be changed in an area known

to be non-hazardous.

Grasp the face ring on the IPI, turn it approximately ¼ turn

counterclockwise and remove. The face of the gauge can now be lifted to

expose the battery holder. Take off the battery hold clip and remove the

batteries. Install three AA batteries noting proper polarity. Note: Use ONLY

AA size batteries and be sure to reinstall the battery holder retaining clip.

Reassemble the case making certain that the face is properly oriented.

If you purchased the optional 24 Volt powered version, the terminals for

power input are located on the rear of the gauge. To apply power simply

connect 24 volts to the rear terminal block taking care to observe proper

polarity.

Page 8

WARNING

Gauges ordered with the external power option will not come with

batteries installed. Batteries MUST NOT be installed when

operating on external power. External power option gauges are not

approved for hazardous location use.

Battery life

Battery life is about 1500 hours (60 days) of continuous use with the

backlight off. With intermittent use, batteries could last a year or more.

There is a low battery icon in the upper left of the display. It will appear

when battery level is low. Replace batteries per recommendations found in

the specifications section of this manual.

RS-232 Interface

An RS-232 interface is standard on the IPI. Serial communication can be

used for configuration, calibration, and to transfer measurement data from

the gauge. For detailed specifications on the interface and software

communication, contact the factory at 603-434-1433 and request a copy of

our interface manual.

WARNING

The RS-232 interface must not be used in hazardous areas.

CLEANING

To clean the BetaGauge use a cloth with a mild cleaning solution.

7

Page 9

8

Specifications

All specifications cover the temperature range from 0°C to +50°C, unless otherwise noted.

Available Input Ranges

See page 14 for a table of available ranges in PSI plus equivalent ranges

and resolution for all engineering units

Accuracy

Positive Pressure: ±0.05% FS

Vacuum: ±0.25% FS (500 PSI gauge ranges and below)

0.1% FS for 15/30 PSI compound/vacuum versions

For gauges with full scale ranges equal to, or less than 30 psi (2 BAR),

vacuum operation is limited to -5psi (-350 mBAR). The exception is the 30

PSI compound/vacuum model which will operate to –14.7 PSI.

Over Pressure Protection:

Ranges from 15 PSI to 500 PSI/1 to 35 bar: 3X input pressure range

1,000, 3,000, and 5,000 PSI/70 to 350 bar ranges: 2X input pressure range

10,000 PSI/700 bar: 1.5X input pressure range

Overload Alarm (indicate OL on display): 1.2X input pressure range

Temperature Compensation

0 °C to +50 °C (32 °F to +122 °F) to rated accuracy

Note: For temperatures from –10 °C to 0 °C and 50 °C to 55 °C add .005%

F.S./°C

Standard Engineering Units

PSI, Bar, kg/cm

2

, inH2O (4 °C, 20 °C or 60 °F),

ftH2O (4 °C, 20 °C or 60 °F), cmH2O (4 °C and 20 °C), mH2O (4 °C and 20 °C),

KPa, mBAR, inHg, mmHg, Torr

One custom unit (user programmable)

Media Compatibility

Liquids and gases compatible with 316 stainless steel

Environmental

Operating Temperature -10 °C to +55 °C

Storage -20 °C to +70 °C (-4 °F to +158 °F)

Humidity 10% to 95% RH Non-condensing

Pollution Degree II

Page 10

Mechanical

Dimensions 4.5” (diameter) x 2.2” (depth) x 5” (height)

Pressure Connection: ¼” NPT Male

Housing: Stainless steel, meets NEMA 4/IP65

Display

5-1/2 Digits, 0.65” (16.53 mm) high

20-Segment bar graph, 0 to 100%

Power

Battery three (3), size AA alkaline batteries, optional 24 VDC power.

Battery Life 1,500 hours without backlight, 2,000 hours at slow sample rate

Low Battery Indicator icon is displayed near the end of battery life

Approvals

Class I, Div. 2, Groups A-D CE approved

Appendix 1: IPI Calibration Procedure

Overview

Calibration adjustment of the IPI is performed electronically via internal

software with the case closed. There are no mechanical adjustments; all

calibration commands and adjustments are done via the keypad, using the

display to guide the user through the calibration process.

Eight calibration points are used in the adjustment program, working from

full scale to zero at pressures equaling 100%, 87.5%, 75%, 62.5%, 50%,

37.5%, 25%, 12.5%, and 0% of full scale plus vacuum.

Note: This is an ambient temperature calibration, and should be performed

at an ambient temperature of 23 °C ± 3 °C (72 °F ± 5 °F). Calibration

outside this temperature range will invalidate the temperature

compensation program in the IPI.

Calibration Interval

You should check performance of the PI at the interval required by your

calibration program. We recommend adjustment when measurement

deviates by more than 75% of the specified accuracy, or 0.04%

Test Equipment

Verification and calibration of the IPI requires pressure and/or vacuum

standards able to produce and indicate pressures from vacuum to the fullscale range of the unit under test. In order to maintain the specified

accuracy of the IPI, standards should have a TUR of 4:1 or better.

9

Page 11

10

Connections:

The PI uses a 1/4 NPT male connection in the pressure input port. Various

adapters may or may not be needed to connect to the pressure standard.

Always make sure the hose, tubing, and fittings etc have a rated working

pressure at or above the pressure of the unit. Also it is important that there

be no leaks when performing calibration; use Teflon tape where

appropriate.

Entering Calibration Mode:

After you have made your connections, turn the power on while holding the

CONFIG key. Use the arrow keys to enter the password. The password is

101. If you have entered calibration mode correctly the display should look

as shown below. The pressure value displayed will be the full-scale value

of the gauge.

Procedure:

Screens shown in this manual represent the displays shown with a 500 psi

Gauge. The IPI will prompt the technician for the appropriate pressure at

each calibration point.

Use the Pressure Standard to output 500.00 psi (100%). After the output

has stabilized, press the ENTER key to continue. As the unit takes

readings, the screen will show ———-. When the readings are complete

the screen should look as shown in the illustration that follows.

Use the Pressure Standard to output 437.50 psi (87.5%). After the output

has stabilized, press the ENTER key to continue. As the unit takes

readings, the screen will show ———-. When the readings are complete

the screen should look as shown below.

PSI

437.50

CAL MODE

PSI

375.00

CAL MODE

PSI

500.00

CAL MODE

Page 12

Use the Pressure Standard to output 375.00 psi (75%). After the output

has stabilized, press the ENTER key to continue. As the unit takes

readings, the screen will show ———-. When the readings are complete

the screen should look as shown below.

Use the Pressure Standard to output 312.50 psi (62.5%). After the output

has stabilized, press the ENTER key to continue. As the unit takes

readings, the screen will show ———-. When the readings are complete

the screen should look as shown below.

Use the Pressure Standard to output 250.00 psi (50%). After the output

has stabilized, press the ENTER key to continue. As the unit takes

readings, the screen will show ———-. When the readings are complete

the screen should look as shown below.

Use the Pressure Standard to output 187.50 psi (37.5%). After the output

has stabilized, press the ENTER key to continue. As the unit takes

readings, the screen will show ———-. When the readings are complete

the screen should look as shown below.

Use the Pressure Standard to output 125.00 psi (25%). After the output

has stabilized, press the ENTER key to continue. As the unit takes

11

PSI

250.00

CAL MODE

PSI

187.50

CAL MODE

PSI

125.00

CAL MODE

PSI

312.50

CAL MODE

Page 13

12

readings, the screen will show ———-. When the readings are complete the

screen should look as shown below.

Use the Pressure Standard to output 62.50 psi (12.5%). After the output has

stabilized, press the ENTER key to continue. As the unit takes readings, the

screen will show ———-. When the readings are complete the screen

should look as shown below.

Use the Pressure Standard to output 0.00 psi. After the output has

stabilized, press the ENTER key to continue. As the unit takes readings, the

screen will show ———-. When the readings are complete the screen

should look as shown below.

Note: Only some ranges use vacuum calibration. If your gauge is not one,

than this step will be automatically skipped and calibration will be complete.

Use the Pressure Standard to output -12.00 psi. After the output has

stabilized, press the ENTER key to continue. As the unit takes readings, the

screen will show ———-. When the readings are complete the unit will

reset and power up in normal mode.

Service Center Calibration or Repair

Only qualified service personnel should perform calibration, repairs, or

servicing not covered in this manual. If the calibrator fails, check the

batteries first, and replace them if needed.

Verify that the calibrator is being operated as explained in this manual. If the

calibrator is faulty, send a description of the failure with the calibrator. Be

sure to pack the calibrator securely, using the original shipping container if it

is available.

PSI

-12.00

CAL MODE

PSI

62.50

CAL MODE

PSI

0.00

CAL MODE

Page 14

13

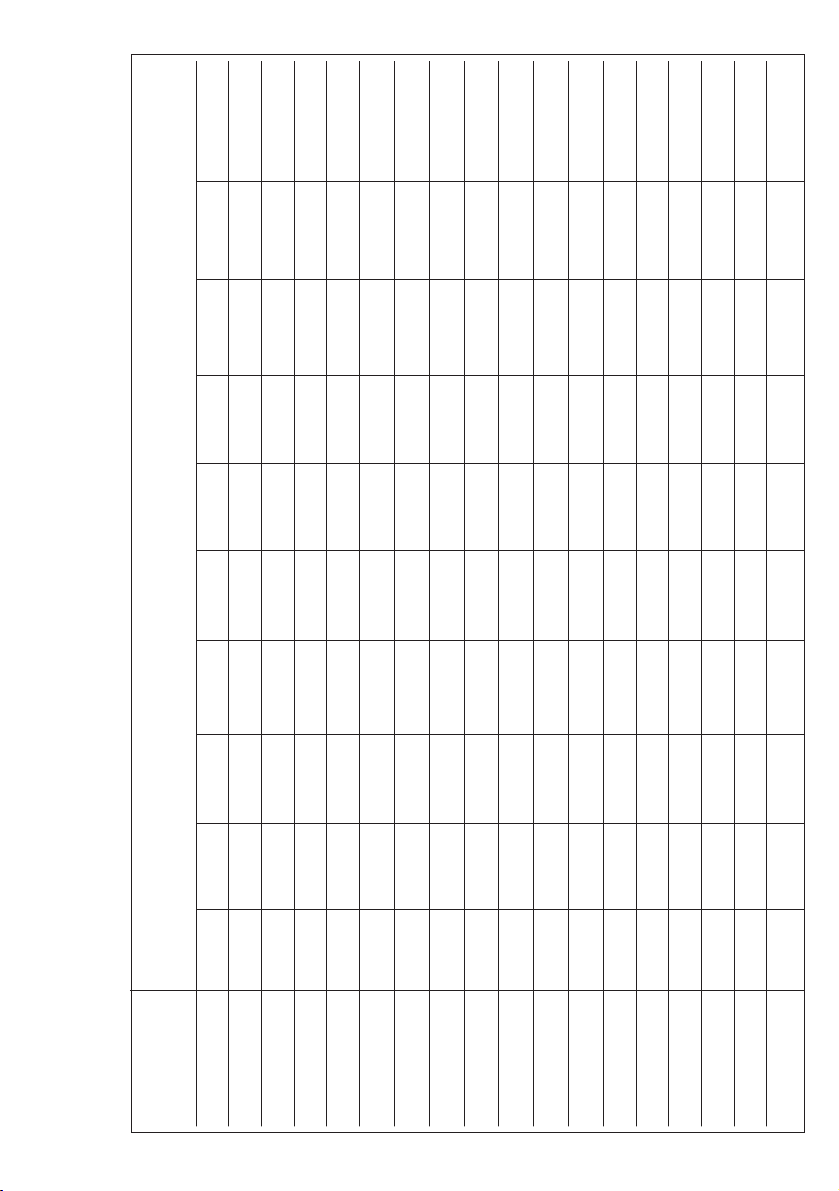

PSI Ranges

Eng. Units 15 30 100 300 500 1000 2000 3000 5000 10000

psi 15.000 30.000 100.00 300.00 500.00 1000.0 2000.0 3000.0 5000.0 10000

bar 1.0342 2.0684 6.8947 20.684 34.474 68.947 137.89 206.84 344.74 689.47

mbar 1034.2 2068.4 6894.8 20684 34474 68948 NA NA NA NA

kPa 103.42 206.84 689.48 2068.4 3447.4 6894.8 13790 20684 34474 68948

kg/cm

2

1.0546 2.1092 7.0307 21.092 35.153 70.307 140.61 210.92 351.53 703.07

cmH

2

O@4°C 1054.6 2109.3 7030.9 21093 35154 70309 NA NA NA NA

cmH

2

O@20°C 1056.5 2113.0 7043.4 21130 35217 70434 NA NA NA NA

mH

2

O@4°C 10.546 21.093 70.309 210.93 351.54 703.09 1406.2 2109.3 3515.4 7030.9

mH

2

O@20°C 10.565 21.130 70.434 211.30 352.17 704.34 1408.7 2113.0 3521.7 7043.4

inH

2

O@4°C 415.21 830.42 2768.1 8304.2 13840 27681 55361 83042 NA NA

inH

2

O@20°C 415.95 831.89 2773.0 8318.9 13865 27730 55460 83189 NA NA

inH

2

O@60°F 415.61 831.23 2770.8 8312.3 13854 27708 55415 83123 NA NA

mmHg@0°C 775.73 1551.5 5171.5 15515 25858 51715 NA NA NA NA

inHg@0°C 30.540 61.081 203.60 610.81 1018.0 2036.0 4072.0 6108.1 10180 20360

ftH2O@4°C 34.601 69.202 230.67 692.02 1153.4 2306.7 4613.5 6920.2 11534 23067

ftH2O@20°C 34.662 69.324 231.08 693.24 1155.4 2310.8 4621.6 6932.4 11554 23108

ftH2O@60°F 34.634 69.269 230.90 692.69 1154.5 2309.0 4617.9 6926.9 11545 23090

Torr 775.73 1551.5 5171.5 15515 25858 51715 NA NA NA NA

Available Ranges and Resolution by Engineering Unit

Page 15

P/N 0219225 Rev. B 08/05

Page 16

AMETEK is a leading global manufacturer of electrical and electromechanical products for niche markets. Listed on the New York Stock Exchange (AME)

since 1930. AMETEK’s annual sales exceed $1 billion. Operations are in North America, Europe, and Asia, with about one third of sales to markets outside

the United States.

CALIBRATION INSTRUMENTS

AMETEK Test & Calibration Instruments • Florida, USA (Western Hemisphere)

Tel: +1 727-536-7831 • Tel: +1 800-527-9999 • calinfo.us@ametek.com

AMETEK Denmark A/S • Denmark (Europe and the Middle East)

Tel: +45 4816 8000 • ametek@ametek.dk

AMETEK Precision Instruments Europe GmbH • Germany (Germany only)

Tel: +49 2159 91360 • info@ametek.de

AMETEK Singapore Pte. Ltd. • Singapore (Asia)

Tel: +65 6 484 2388 • aspl@ametek.com.sg

w ww.ame tekca libra tion. com

w ww.jof ra.co m

Information within this document is

subject to change without notice.

All rights reserved.

...because calibration is

a matter of condence

AMETEK

Calibration Instruments

offers a complete range of calibration equipment for

pressure, temperature, and signal - including software.

JOFRA Temperature standards

Portable precision thermometer. Dry-block calibrators:

4 series, more than 20 models - featuring speed,

portability, accuracy, and advanced documenting functions.

M&G Primary pressure standards

Pneumatic floating-ball or hydraulic piston deadweight testers

- easy-to-use with accuracies up to 0.015% of reading.

JOFRA Pressure standards

Convenient electronic systems ranging from -1 to 700 bar

(25 inHg to 10,000 psi) - multiple choices of pressure ranges,

pumps, and accuracies, fully temperature-compensated

for problem-free and accurate field use.

JOFRA Signal calibration

Process signal measurement and simulation

for easy control loop calibration and measurement tasks -

from handheld field instruments for multi or single

signals to laboratory reference level bench top instruments.

Loading...

Loading...