Page 1

Internal GPIB-M Interface:

Multichannel Functionality

for Programmable

DC Power Supplies

Operation Manual

GPIB-M-XPD

GPIB-M-XT

GPIB-M-HPD

GPIB-M-XHR

GPIB-M-XFR

GPIB-M-XFR3

TM-MCOP-01XN Rev C www.programmablepower.com

Page 2

Page 3

Page 4

Page 5

About AMETEK

AMETEK Programmable Power, Inc., a Division of AMETEK, Inc., is a global leader in the design

and manufacture of precision, programmable power supplies for R&D, test and measurement,

process control, power bus simulation and power conditioning applications across diverse

industrial segments. From bench top supplies to rack-mounted industrial power subsystems,

AMETEK Programmable Power is the proud manufacturer of Elgar, Sorensen, California

Instruments and Power Ten brand power supplies.

AMETEK, Inc. is a leading global manufacturer of electronic instruments and electromec hanical

devices with annualized sales of $2.5 billion. The Company has over 11,000 colleagues working

at more than 80 manufacturing facilities and more than 80 sales and service centers in the United

States and around the world.

Trademarks

AMETEK is a registered trademark of AMETEK, Inc. Sorensen is a trademark owned by AMETEK,

Inc. Other trademarks, registered trademarks, and product names are the property of their

respective owners and are used herein for identification purposes only.

Notice of Copyright

Internal GPIB-M Interface: Multichannel Functionality for Programmable DC Power Supplies

Operation Manual

© 2007 AMETEK Programmable Power, Inc. All rights reserved.

Exclusion for Documentation

UNLESS SPECIFICALLY AGREED TO IN WRITING, AMETEK PROGRAMMABLE POWER, INC.

(“AMETEK”):

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY

TECHNICAL OR OTHER INFORMATION PROVIDED IN ITS MANUALS OR OTHER

DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSSES, DAMAGES, COSTS OR

EXPENSES, WHETHER SPECIAL, DIRECT, INDIRECT, CONSEQUENTIAL OR INCIDENTAL,

WHICH MIGHT ARISE OUT OF THE USE OF SUCH INFORMATION. THE USE OF ANY SUCH

INFORMATION WILL BE ENTIRELY AT THE USER’S RISK, AND

(c) REMINDS YOU THAT IF THIS MANUAL IS IN ANY LANGUAGE OTHER THAN ENGLISH,

ALTHOUGH STEPS HAVE BEEN TAKEN TO MAINTAIN THE ACCURACY OF TH E

TRANSLATION, THE ACCURACY CANNOT BE GUARANTEED. APPROVED AMETEK CONTENT

IS CONTAINED WITH THE ENGLISH LANGUAGE VERSION, WHICH IS POSTED AT

WWW.PROGRAMMABLEPOWER.COM.

Date and Revision

March 2010 Revision C

Part Number

TM-MCOP-01XN

Contact Information

Telephone: 800 733 5427 (toll free in North America)

858 450 0085 (direct)

Fax: 858 458 0267

Email: sales@programmablepower.com

service@programmablepower.com

Web: www.programmablepower.com

i

Page 6

This page intentionally left blank.

ii

Page 7

G

G

Important Safety Instructions

Before applying power to the system, verify that your product is configured properly for your

particular application.

WARNIN

WARNIN

Only qualified personnel who deal with attendant hazards in power supplies, are allowed to perform

installation and servicing.

Ensure that the AC power line ground is connected properly to the Power Rack input connector or

chassis. Similarly, other power ground lines including those to application and maintenance

equipment must be grounded properly for both personnel and equipment safety.

Always ensure that facility AC input power is de-energized prior to connecting or disconnecting any

cable.

In normal operation, the operator does not have access to hazardous voltages within the chassis.

However, depending on the user’s application configuration, HIGH VOLTAGES HAZARDOUS TO

HUMAN SAFETY may be normally generated on the output terminals. The customer/user must

ensure that the output power lines are labeled properly as to the safety hazards and that any

inadvertent contact with hazardous voltages is eliminated.

Guard against risks of electrical shock during open cover checks by not touching any portion of the

electrical circuits. Even when power is off, capacitors may retain an electrical charge. Use safety

glasses during open cover checks to avoid personal injury by any sudden component failure.

Neither AMETEK Programmable Power Inc., San Diego, California, USA, nor any of the subsidiary

sales organizations can accept any responsibility for personnel, material or inconsequential injury,

loss or damage that results from improper use of the equipment and accessories.

Hazardous voltages may be present when covers are removed. Qualified

personnel must use extreme caution when servicing this equipment.

Circuit boards, test points, and output voltages also may be floating above

(below) chassis ground.

The equipment used contains ESD sensitive parts. When installing

equipment, follow ESD Safety Procedures. Electrostatic discharges might

cause damage to the equipment.

SAFETY SYMBOLS

iii

Page 8

This page intentionally left blank.

iv

Page 9

Product Family: Internal GPIB-M Interface: Multichannel Functionality for

Programmable DC Power Supplies

Warranty Period: Five Years

WARRANTY TERMS

AMETEK Programmable Power, Inc. (“AMETEK”), provides this written warranty covering the

Product stated above, and if the Buyer discovers and notifies AMETEK in writing of any defect in

material or workmanship within the applicable warranty period stated above, then AMETEK may,

at its option: repair or replace the Product; or issue a credit note for the defective Product; or

provide the Buyer with replacement parts for the Product.

The Buyer will, at its expense, return the defective Product or parts thereof to AMETEK in

accordance with the return procedure specified below. AMETEK will, at its expense, deliver the

repaired or replaced Product or parts to the Buyer. Any warranty of AMETEK will not apply if the

Buyer is in default under the Purchase Order Agreement or where the Product or any part

thereof:

• is damaged by misuse, accident, negligence or failure to maintain the same as

specified or required by AMETEK;

• is damaged by modifications, alterations or attachments thereto which are not

authorized by AMETEK;

• is installed or operated contrary to the instructions of AMETEK;

• is opened, modified or disassembled in any way without AMETEK’s consent; or

• is used in combination with items, articles or materials not authorized by AMETEK.

The Buyer may not assert any claim that the Products are not in conformity with any warranty

until the Buyer has made all payments to AMETEK provided for in the Purchase Order Agreement.

PRODUCT RETURN PROCEDURE

1. Request a Return Material Authorization (RMA) number from the repair facility (must be

done in the country in which it was purchased):

• In the USA, contact the AMETEK Repair Department prior to the return of the

product to AMETEK for repair:

Telephone: 800-733-5427, ext. 2295 or ext. 2463 (toll free North America)

858-450-0085, ext. 2295 or ext. 2463 (direct)

• Outside the United States, contact the nearest Authorized Service Center

(ASC). A full listing can be found either through your local distributor or our

website, www.programmablepower.com, by clicking Support and going to the

Service Centers tab.

2. When requesting an RMA, have the following information ready:

• Model number

• Serial number

• Description of the problem

NOTE: Unauthorized returns will not be accepted and will be returned at the shipper’s expense.

NOTE: A returned product found upon inspection by AMETEK, to be in specification is subject to

an evaluation fee and applicable freight charges.

v

Page 10

This page intentionally left blank.

vi

Page 11

About This Manual

This operating manual is for the internal Multichannel Interface (GPIB-M), a

microprocessor-controlled option card for your DC output power supply. This

manual provides you with descriptions and specifications, user options, and

configuration instructions, in addition to a command set which enables you to

manage the power supply from an external source. Error messages and calibration

procedures are also included.

This manual is designed for the user who is familiar with basic electrical theory

especially as it applies to the operation of power supplies. This implies a recognition

of Constant Voltage and Constant Current operation modes and the control of input

and output power, as well as the observance of safe techniques while effecting supply

or pin connections and any changes in switch settings. The user should also have

experience with a computer-based communications software package.

Refer to your power supply manual for installation, configuration, and operating

procedures for your power supply.

Main Section s

Section 1 Features and Specifications Describes the power supply and lists

its features and specifications.

Section 2 Installation and Configuration Gives basic setup procedures.

Describes inspection, cleaning, shipping, and storage procedures. Includes

additional options for configuring the GPIB-M interface for operation.

Section 3 Operation Describes operation of each feature.

Section 4 Status Registers Details status registers and how to use them to

monitor the power supply status.

Section 5 Current Sharing Explains how to configure the power supply for

current sharing among units connected in parallel.

Appendix A GPIB Describes the General Purpose Interface Bus (GPIB)

commands and lines supported by specific products with the Multichannel Interface

installed.

vii

Page 12

About This Manual

Appendix B SCPI Command Reference Describes the Standard Commands

for Programmable Instruments (SCPI) commands supported by various products

with the Multichannel Interface installed.

Appendix C Error Messages Describes the error messages that could appear

during operation.

Appendix D Calibration Provides the calibration procedures and parameters.

viii Operating Manual for Multichannel Functionality (GPIB-M)

Page 13

Table of Contents

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

List of Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xiii

List of Figures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Section 1. Features and Specifications

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Features and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Programmable Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Readback Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Section 2. Installation and Configuration

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Initial Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Basic Setup Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Setup Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Power On Service Request . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Configure for GPIB Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Change Remote Control Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Set GPIB Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Configure for Multichannel Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Multichannel Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Multichannel Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

CANbus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

CANbus Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Configuration of CAN-only Interface Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Using Multichannel Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Multichannel Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Broadcasting Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

User Lines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

User Lines Connection (XT, HPD, XPD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Section 3. Operation

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Power Supply Operating States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Powering ON the Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Power-On. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Output Shutdown. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Soft Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Normal Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

ix

Page 14

Power Supply Regulation Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Constant Voltage (CV) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Constant Current (CC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Automatic Mode Crossover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Remote Control Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Front Panel LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Power Supply Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Change Remote/Local Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Power On Remote State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Enable Output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Set Voltage and Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Readback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Configure Output Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

OVP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Fold Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Additional Protections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Set Shutdown Recovery for AC Off. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

AC Off Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Over Temperature Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Clear Protection Event . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Shutdown vs Protection Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

User Settings (Save and Recall). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Set Up Power ON Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Power On Output State. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Reset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Read Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Clear Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Configure Auxiliary Status Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Auto Sequencing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Programming a Sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Deleting a Sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Using Auto Sequencing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Set V, I, and P Limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Triggered Setpoints. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Triggering Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Slew Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Identification Query. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Option Identification Query . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

SCPI Version Query . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Section 4. Status Registers

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Condition Register. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Event Register. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Enable Register. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Transition Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

OPERation Status Register. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

REGulating Sub-Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

x Operating Manual for Multichannel Functionality (GPIB-M)

Page 15

SHUTdown Sub-Register. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Protection SHUTdown Sub-Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Remote CONtrol Sub-Register. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Current SHare Sub-Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

QUEStionable Status Register. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

VOLTage Sub-Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

CURRent Sub-Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Standard Event Status Register. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Status Byte. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Master Summary Status (MSS). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Request Service (RQS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Status Register Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

SCPI Status Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

IEEE 488.2 Status and Event Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

Operation Status Register Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Regulating Sub-Register Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Shutdown Sub-Register Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Protection Shutdown Sub-Register Commands. . . . . . . . . . . . . . . . . . . . . . . . .86

Remote Control Sub-Register Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

Current Share Sub-Register Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

Questionable Status Register Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

Voltage Sub-Register Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

Current Sub-Register Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

Section 5. Current Sharing

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

Theory of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

Configure Current Share . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

Setup Current Sharing Network. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

Appendix A. GPIB

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

Codes and Standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

Message Terminators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

Address Range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

Primary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

Secondary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

Service Request and Polling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

Protocol Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

Multiline Control Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

Interface Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

Driver Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

Mechanical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

xi

Page 16

Appendix B. SCPI Command Reference

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Codes and Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

IEEE 488.2 Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

SCPI Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

IEEE-488.2/SCPI Syntax and Style. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Understanding SCPI Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

SCPI Command Hierarchy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Using SCPI Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Parameter Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

SCPI Command Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Notations Used in the Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Expressions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Appendix C. Error Messages

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Command Error List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Execution Error List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Device-Specific Error List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Query Error List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

User Request Event. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Operation Complete Event. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Front Panel Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

CPU Error Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Analog Programming Interface Error codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Auto Sequencing Error Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

CANbus Error Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Multichannel Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Current Share Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Appendix D. Calibration

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Entering Calibration Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Security code. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Setup and Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Calibration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Output Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Output Current. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Exit calibration mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Restore Factory Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

xii Operating Manual for Multichannel Functionality (GPIB-M)

Page 17

List of Tables

Table 1.1 Specifications for HPD 300 W with GPIB-M or CANbus . . . . . . . . . . .19

Table 1.2 Specifications for XFR 1200 W with GPIB-M or CANbus . . . . . . . . . .20

Table 1.3 Specifications for XFR 2800 W with GPIB-M or CANbus . . . . . . . . . .21

Table 1.4 Specifications for XHR 1000 W with GPIB-M or CANbus . . . . . . . . . .22

Table 1.5 Specifications for XPD 500 W with GPIB-M or CANbus . . . . . . . . . . . 23

Table 1.6 Specifications for XT 60 W with GPIB-M or CANbus . . . . . . . . . . . . .23

Table 2.1 Remote Mode Power On Conditions. . . . . . . . . . . . . . . . . . . . . . . . . .33

Table 2.2 CANbus Pins. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Table 2.3 User Line Pins. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Table 3.1 Power Supply Factory Defaults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Table 3.2 Features Affected by Reset (*RST) Command . . . . . . . . . . . . . . . . . .57

Table 4.1 OPERation Status Register. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

Table 4.2 REGulating Sub-Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

Table 4.3 SHUTdown Sub-Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Table 4.4 Protection SHUTdown Sub-Register. . . . . . . . . . . . . . . . . . . . . . . . . .73

Table 4.5 Remote CONtrol Sub-Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

Table 4.6 Current SHare Sub-Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

Table 4.7 QUEStionable Status Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

Table 4.8 VOLTage Sub-Register. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

Table 4.9 CURRent Sub-Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Table 4.10 Standard Event Status Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

Table 4.11 Status Byte Summary Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Table 4.12 Preset Values of User Configurable Registers . . . . . . . . . . . . . . . . . .81

Table A.1 Multiline Control Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

Table A.2 Interface Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

Table A.3 Driver Types for Interface Lines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

Table B.1 IEEE 488.2 Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104

Table B.2 Readback Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .105

Table B.3 Commands for Output Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106

Table B.4 Commands for Current Share . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107

Table B.5 Commands for Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107

Table B.6 Command to Clear all Protection Mechanisms . . . . . . . . . . . . . . . . .107

Table B.7 Commands for Fold Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

Table B.8 Commands for Triggering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

Table B.9 System Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

Table B.10 Status Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

xiii

Page 18

List of Tables

Table B.11 Protection Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Table B.12 User Lines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Table B.13 Output State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Table B.14 Auto Sequence Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Table B.15 Expressions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Table C.1 Command Error List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Table C.2 Execution Error List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Table C.3 Device-Specific Error List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Table C.4 Query Error List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Table C.5 User Request Event . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Table C.6 Operation Complete Event . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Table C.7 Front Panel Error Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Table C.8 CPU Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Table C.9 Analog Programming Interface Error code. . . . . . . . . . . . . . . . . . . . 122

Table C.10 Auto Sequencing Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Table C.11 CANbus Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Table C.12 Multichannel Error Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Table C.13 Current Share Error Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

xiv

Operating Manual for Multichannel Functionality (GPIB-M)

Page 19

List of Figures

Figure 2.1 XFR and XHR Power Supply Front Panel with GPIB-M Interface. . . .26

Figure 2.2 XPD Power Supply Front Panel with GPIB Interface. . . . . . . . . . . . . .27

Figure 2.3 XT and HPD Power Supply Front Panel with GPIB Interface . . . . . . .27

Figure 2.4 XFR 2800 Watt Power Supply Rear Panel with GPIB-M Interface . . . 28

Figure 2.5 XFR 1200 Watt Power Supply Rear Panel with GPIB-M Interface . . . 28

Figure 2.6 XHR Power Supply Rear Panel with GPIB-M Interface. . . . . . . . . . . . 29

Figure 2.7 XPD Power Supply Rear Panel with GPIB-M Interface. . . . . . . . . . . .29

Figure 2.8 XT/HPD Power Supply Rear Panel with GPIB-M Interface. . . . . . . . .30

Figure 2.9 XFR GPIB Cable with Ferrite Block. . . . . . . . . . . . . . . . . . . . . . . . . . .31

Figure 2.10 Connections for Multichannel Operation . . . . . . . . . . . . . . . . . . . . . . .37

Figure 2.11 User Signals Connector (XT, HPD and XPD) . . . . . . . . . . . . . . . . . . .41

Figure 2.12 XT, HPD, XPD User Cable with Ferrite Block . . . . . . . . . . . . . . . . . . .41

Figure 2.13 Schematic For User Line Interface . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Figure 4.1 Operation Status Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Figure 4.2 Questionable Status Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Figure 4.3 IEEE 488.2 Status Register and Status Byte. . . . . . . . . . . . . . . . . . . .77

Figure 5.1 Example of Current Share Operation . . . . . . . . . . . . . . . . . . . . . . . . .89

xv

Page 20

List of Figures

xvi

Operating Manual for Multichannel Functionality (GPIB-M)

Page 21

Section 1. Features and Specifications

Description

The internal GPIB-M interface card allows you to operate your power supply from

a computer controller via the IEEE-488 communications bus.

The GPIB-M interface allows complete remote programming of your power supply,

including status reporting, settings query, and service request generation with

user-designated conditions. Both the voltage and current output are precisely

programmed directly in volts and amps with 16-bit resolution. Additionally, the

16-bit readbacks measure the actual power supply output. The programming

command set is easy to use and includes software calibration commands. The

interface card comes with several protection features such as programmable over

and under voltage protection, and soft limits.

Multichannel addressing via CANbus allows up to 50 power supplies to be

controlled from one GPIB address. This manual covers operation of both the

GPIB-M and CAN-only interface cards.

Features and Functions

Features • 16-bit programming and readback of voltage and current

• Programmable soft limits for voltage and current

• LED status signals: remote operation, serv ice request and shutdown; (XFR and

XHR only) error, addressed, over voltage protection, auxiliary status bits

• Software calibration

• Automatic voltage/current mode crossover

• Shutdown or warning for over- and under-programmed trip points

• Programmable auxiliary status lines for monitoring power supply conditions

• Remote interlock and trigger lines

• Selectable standby, programmed sequence and other power-on defaults

• Active current sharing with parallel connected units for higher power

requirements

• CANbus communications link for multichannel addressing, and master/slave

current sharing

• Extensive SCPI command set for control and status monitoring

17

Page 22

Features and Specifications

Features and Functions

Programmable

Functions

Readback

Functions

• Output voltage and current

• Soft limits for voltage and current

• Overvoltage protection

• Output enable/disable

• Ten, 99-step auto sequences for easy programming of complex test routines

• Ten stored settings

• Five load protection mechanisms including fold protection in CV or CC mode

• Actual measured voltage and current

• Voltage and current settings

• Soft voltage and current limits

• Overvoltage protection setting

• Programming error codes

• Power supply model and version identification

• Firmware revision levels

18 Operating Manual for Multichannel Functionality (GPIB-M)

Page 23

Specifications

Features and Specifications

Specifications

The specifications in this section are warranted at 25°C ±5°C unless otherwise

specified. All specifications are subject to change without notice.

Table 1.1 Specifications for HPD 300 W with GPIB-M or CANbus

Models 15-20 30-10 60-5

Program Resolution

Voltage

Current

Program Accuracy

1

Voltage

Current

Readback Resolution

Voltage

Current

Readback Accuracy

Voltage

Current

1. Apply accuracy specifications according to the following voltage program accuracy example:

Set a model HPD 15-20 power supply to 10 volts.

The expected result will be within the range of 10 volts ± 60mV ± 0.1% of the set voltage of

10 volts.

2.4mV

2.8mA

60mV

±0.1%

75mA

±0.12%

2.4mV

2.8mA

1

45mV

±0.3%

75mA

±0.12%

4.7mV

1.4mA

70mV

±0.1%

50mA

±0.12%

4.7mV

1.4mA

90mV

±0.3%

40mA

±0.12%

9.3mV

0.7mA

90mV

±0.12%

25mA

±0.1%

9.3mV

0.7mA

175mV

±0.3%

25mA

±0.1%

19

Page 24

Features and Specifications

Specifications

Table 1.2 Specifications for XFR 1200 W with GPIB-M or CANbus

Models 7.5-140 12-100 20-60 35-35 40-30

Program Resolution

Voltage

Current

Program Accuracy

Voltage

Current

1

1.16mV

19.6mA

10mV

±0.12%

500mA

±0.1%

1.8mV

14mA

50mV

±0.12%

460mA

±0.1%

3.08mV

8.4mA

75mV

±0.12%

250mA

±0.1%

5.4mV

5.4mA

75mV

±0.3%

200mA

±0.1%

6.2mV

4.2mA

75mV

±0.3%

150mA

±0.15%

Readback Resolution

Voltage

Current

Readback Accuracy

Voltage

Current

1

1.16mV

19.6mA

30mV

±0.12%

500mA

±0.1%

1.8mV

14mA

60mV

±0.12%

460mA

±0.1%

3.08mV

8.4mA

75mV

±0.12%

250mA

±0.1%

5.4mV

5.4mA

75mV

±0.3%

200mA

±0.1%

6.2mV

4.2mA

75mV

±0.3%

150mA

±0.15%

Models 60-20 100-12 150-8 300-4 600-2

Program Resolution

Voltage

Current

Program Accuracy

Voltage

Current

1

9.2mV

2.8mA

150mV

±0.25%

120mA

±0.1%

15.4mV

1.68mA

150mV

±0.35%

80mA

±0.1%

23.1mV

1.12mA

225mV

±0.35%

80mA

±0.1%

46.2mV

0.56mA

225mV

±0.35%

80mA

±0.1%

92.4mV

0.28mA

250mV

±0.35%

50mA

±0.1%

Readback Resolution

Voltage

Current

Readback Accuracy

Voltage

Current

1. Apply accuracy specifications according to the following voltage program accuracy example:

Set a model XFR 20-60 power supply to 10 volts.

The expected result will be within the range of 10 volts ± 75mV ± 0.12% of the set voltage of 10 volts.

1

9.2mV

2.8mA

150mV

±0.25%

120mA

±0.1%

15.4mV

1.68mA

150mV

±0.35%

80mA

±0.1%

23.1mV

1.12mA

225mV

±0.35%

80mA

±0.1%

46.2mV

0.56mA

225mV

±0.35%

80mA

±0.1%

92.4mV

0.28mA

250mV

±0.35%

50mA

±0.1%

20 Operating Manual for Multichannel Functionality (GPIB-M)

Page 25

Features and Specifications

Table 1.3 Specifications for XFR 2800 W with GPIB-M or CANbus

Models 7.5-300 12-220 20-130 33-85 40-70

Program Resolution

Voltage

Current

Program Accuracy

Voltage

Current

1.16mV

42.0mA

1

10mV

±0.12%

900mA

±0.1%

1.8mV

30.8mA

50mV

±0.12%

750mA

±0.1%

3.08mV

18.2mA

75mV

±0.12%

500mA

±0.1%

5.1mV

13.0mA

75mV

±0.3%

425mA

±0.1%

6.2mV

9.8mA

75mV

±0.3%

350mA

±0.15%

Readback Resolution

Voltage

Current

1.16mV

42.0mA

1.8mV

30.8mA

3.08mV

18.2mA

5.1mV

13.0mA

6.2mV

9.8mA

Readback Accuracy

Voltage

Current

30mV

±0.12%

900mA

±0.1%

60mV

±0.12%

750mA

±0.1%

75mV

±0.12%

500mA

±0.1%

75mV

±0.3%

425mA

±0.1%

75mV

±0.3%

350mA

±0.1%

Specifications

Models 60-46 100-28 150-18 300-9 600-4

Program Resolution

Voltage

Current

Program Accuracy

Voltage

Current

9.2mV

6.44mA

1

150mV

±0.25%

250mA

±0.1%

15.4mV

3.92mA

150mV

±0.35%

140mA

±0.1%

23.1mV

2.52mA

225mV

±0.35%

120mA

±0.1%

46.2mV

1.26mA

225mV

±0.35%

80mA

±0.1%

92.4mV

0.56mA

250mV

±0.35%

80mA

±0.1%

Readback Resolution

Voltage

Current

Readback Accuracy

Voltage

Current

1. Apply accuracy specifications according to the following voltage program accuracy example:

Set a model XFR 20-130 power supply to 10 volts.

The expected result will be within the range of 10 volts ± 75mV ± 0.12% of the set voltage of 10 volts

1

9.2mV

6.44mA

150mV

±0.25%

250mA

±0.1%

15.4mV

3.92mA

150mV

±0.35%

140mA

±0.15%

23.1mV

2.52mA

225mV

±0.35%

120mA

±0.1%

46.2mV

1.26mA

225mV

±0.35%

80mA

±0.1%

92.4mV

0.56mA

250mV

±0.35%

80mA

±0.1%

21

Page 26

Features and Specifications

Specifications

Table 1.4 Specifications for XHR 1000 W with GPIB-M or CANbus

Models 7.5-130 20-50 33-33 40-25 60-18

Program Resolution

Voltage

Current

Program Accuracy

Voltage

Current

1

1.16mV

42.0mA

10mV

±0.12%

900mA

±0.1%

1.8mV

30.8mA

50mV

±0.12%

750mA

±0.1%

3.08mV

18.2mA

75mV

±0.12%

500mA

±0.1%

6.2mV

9.8mA

75mV

±0.3%

350mA

±0.1%

9.2mV

6.44mA

150mV

±0.25%

250mA

±0.1%

Readback Resolution

Voltage

Current

Readback Accuracy

Voltage

Current

1

1.16mV

42.0mA

30mV

±0.12%

900mA

±0.1%

1.8mV

30.8mA

60mV

±0.12%

750mA

±0.1%

3.08mV

18.2mA

75mV

±0.12%

500mA

±0.1%

6.2mV

9.8mA

75mV

±0.3%

350mA

±0.1%

9.2mV

6.44mA

150mV

±0.25%

250mA

±0.1%

Models 100-10 150-7 300-3.5 600-1.7

Program Resolution

Voltage

Current

Program Accuracy

Voltage

Current

1

15.4mV

3.92mA

150mV

±0.35%

140mA

±0.15%

23.1mV

2.52mA

225mV

±0.35%

120mA

±0.1%

46.2mV

1.26mA

225mV

±0.35%

80mA

±0.1%

92.4mV

0.56mA

250mV

±0.35%

80mA

±0.1%

Readback Resolution

Voltage

Current

Readback Accuracy

Voltage

Current

1. Apply accuracy specifications according to the following voltage program accuracy example:

Set a model XHR 20-50 power supply to 10 volts.

The expected result will be within the range of 10 volts ± 50mV ± 0.12% of the set voltage of 10 volts.

1

15.4mV

3.92mA

150mV

±0.35%

140mA

±0.15%

23.1mV

2.52mA

225mV

±0.35%

120mA

±0.1%

46.2mV

1.26mA

225mV

±0.35%

80mA

±0.1%

92.4mV

0.56mA

250mV

±0.35%

80mA

±0.1%

22 Operating Manual for Multichannel Functionality (GPIB-M)

Page 27

Features and Specifications

Specifications

Table 1.5 Specifications for XPD 500 W with GPIB-M or CANbus

Models 7.5-67 18-30 33-16 60-9 120-4.5

Program Resolution

Voltage

Current

Program Accuracy

Voltage

Current

1.2mV

5.2mA

1

10mV

±0.12%

250mA

±0.1%

4.6mV

3.6mA

75mV

±0.12%

140mA

±0.1%

5.1mV

2.9mA

75mV

±0.12%

115mA

±0.15%

9.3mV

1.3mA

150mV

±0.3%

80mA

±0.15%

18.6mV

0.7mA

180mV

±0.25%

80mA

±0.1%

Readback Resolution

Voltage

Current

Readback Accuracy

Voltage

Current

1. Apply accuracy specifications according to the following voltage program accuracy example:

Set a model XPD 18-30 power supply to 10 volts.

The expected result will be within the range of 10 volts ± 75mV ± 0.12% of the set voltage of 10 volts.

1

1.2mV

5.2mA

30mV

±0.12%

250mA

±0.1%

4.6mV

3.6mA

75mV

±0.12%

140mA

±0.1%

5.1mV

2.4mA

75mV

±0.2%

115mA

±0.15%

9.3mV

1.3mA

150mV

±0.3%

80mA

±0.15%

18.6mV

0.7mA

180mV

±0.25%

80mA

±0.1%

Table 1.6 Specifications for XT 60 W with GPIB-M or CANbus

Models 7-6 15-4 20-3 30-2 60-1 120-0.5 250-0.25

Program Resolution

Voltage

Current

Program Accuracy

Voltage

Current

1.1mV

1.0mA

1

10mV

±0.1%

110mA

±0.15%

2.4mV

0.6mA

20mV

±0.1%

70mA

±0.15%

3.1mV

0.5mA

20mV

±0.15%

50mA

±0.15%

4.7mV

0.3mA

30mV

±0.15%

40mA

±0.15%

9.3mV

0.2mA

200mV

±0.15%

26mA

±0.2%

17mV

0.1mA

400mV

±0.15%

13mA

±0.2%

17mV

0.1mA

400mV

±0.15%

13mA

±0.2%

Readback Resolution

Voltage

Current

Readback Accuracy

Voltage

Current

1. Apply accuracy specifications according to the following voltage program accuracy example:

Set a model XT 15-4 power supply to 10 volts.

The expected result will be within the range of 10 volts ± 20mV ± 0.1% of the set voltage of 10 volts.

1.1mV

1.0mA

1

10mV

±0.15%

110mA

±0.15%

2.4mV

0.6mA

10mV

±0.1%

70mA

±0.15%

3.1mV

0.5mA

10mV

±0.1%

50mA

±0.15%

4.7mV

0.3mA

15mV

±0.1%

40mA

±0.15%

9.3mV

0.2mA

35mV

±0.15%

26mA

±0.2%

17mV

0.1mA

70mV

±0.15%

13mA

±0.2%

17mV

0.1mA

70mV

±0.15%

13mA

±0.2%

23

Page 28

Features and Specifications

Specifications

24 Operating Manual for Multichannel Functionality (GPIB-M)

Page 29

Section 2. Installation and Configuration

!

Introduction

To use this product, you must have the following equipment:

• a compatible model of DC output power supply

• IEEE-488 connector and cable

• computer with an IEEE-488 interface card

• Computer-based communications software package

• parallel CANbus cables (to connect power supply for multichannel operation)

The GPIB

Your local distributor or service center can also install the interface, especial ly for

use in a previously-purchased supply already on site. The interface card will be

calibrated and configured with default settings. Y ou will need to configure the supply

for your system using the “Basic Setup Procedure” on page 31. Refer also to

Figure 2.1, pg. 26, Figure 2.2, pg. 27 and Figure 2.3, pg. 27 for drawings of the front

panels. The interface subplate is different for each product. Please check Figure 2.4

to Figure 2.7.

Initial Inspection

On first receiving your unit, perform a quick inspection.

• Ensure each package contains a power supply with its GPIB interface board

• Inspect the unit for any signs of physical damage such as scratches, cracks, or

• Check the printed circuit board and components if you suspect internal damage.

or CANbus interface is usually installed in a power supply at the factory.

CAUTION

If you remove the unit's cover, use proper static control techniques to avoid damage

to static-sensitive components on the printed circuit board.

installed, and manuals for the power supply and the GPIB interface. A custom

CANbus cable and a terminator are also supplied with each GPIB-M or

CAN-only interface. Any additional parts shipped with the power supply will be

identified in the supply's documentation.

broken switches, connectors, or displays.

If the unit is damaged, save all packing materials and notify the carrier immediately.

For additional information, please see the section titled, “Returning Power Supplies

to the Manufacturer” in the manual shipped with your complete unit.

25

Page 30

Installation and Configuration

!

Initial Inspection

CAUTION

Use proper static control techniques to avoid damage to static-sensitive components

on the printed circuit board.

Remote Programming LEDs:

Local Switch (LOCAL)Remote LED (REM)

Address LED (ADR)

Indicates that the master controller is ad dressing the unit.

Service Request LED (SRQ)

Comes on at power up if the PON SRQ is set to on.

Error LED (ERR)

Indicates when a programming error has occurred. You

can clear the ERR LED with an error query command.

Fault LED (FLT )

Used to indicate AUX B status is TRUE.

Polarity LED (POL)

Used to indicate AUX A status is TRUE.

Figure 2.1 XFR and XHR Power Supply Front Panel with GPIB-M Interface

(XFR 1200 Watt model shown)

26 Operating Manual for Multichannel Functionality (GPIB-M)

Page 31

Installation and Configuration

Service Request LED (SRQ)

Remote LED (REM)

Shutdown LED (S/D)

Figure 2.2 XPD Power Supply Front Panel with GPIB Interface

Initial Inspection

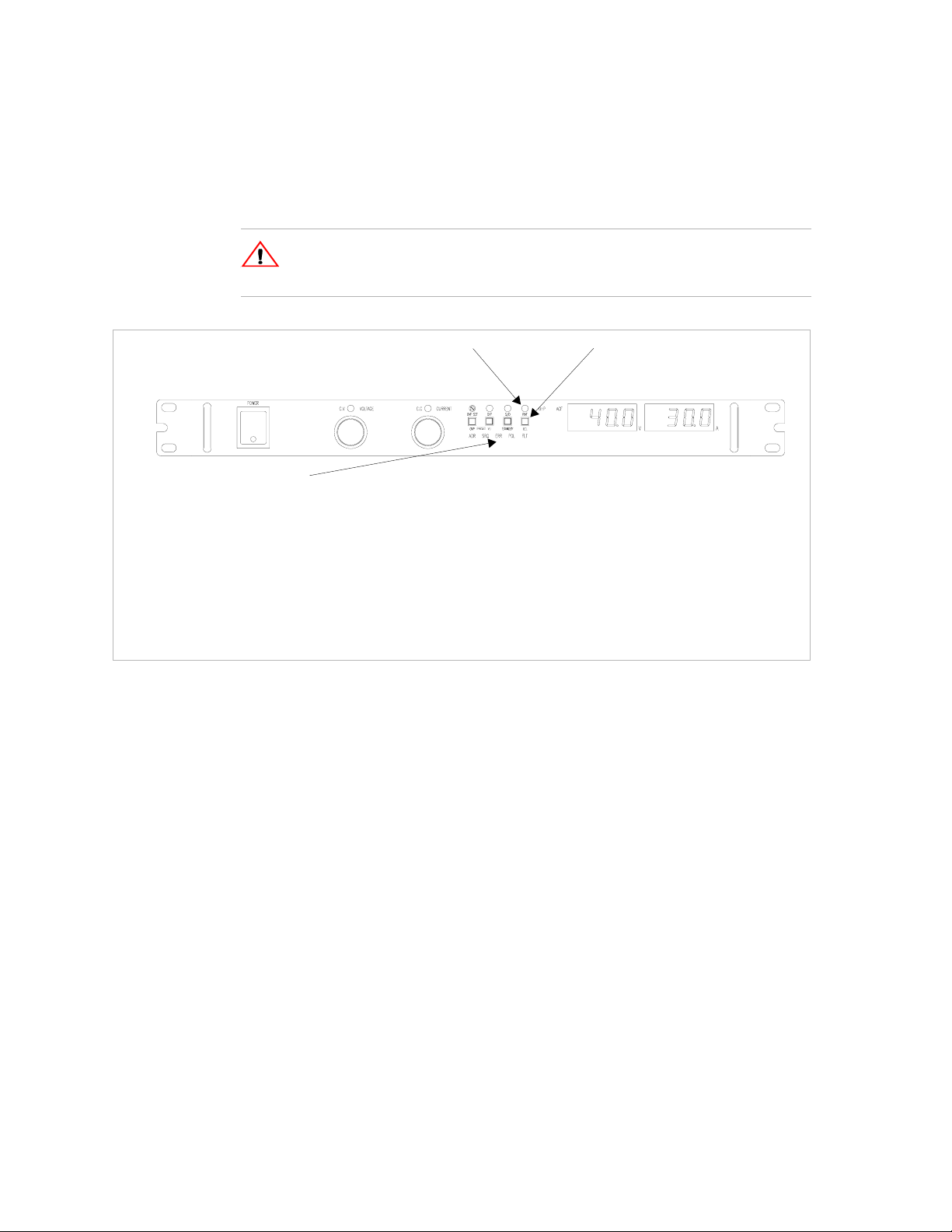

Remote Mode (REM) LED

Service Request (SRQ) LED

Over Voltage Protection (OVP) LED

OVP Potentiometer

Figure 2.3 XT and HPD Power Supply Front Panel with GPIB Interface

27

Page 32

Installation and Configuration

Initial Inspection

Figure 2.4 XFR 2800 Watt Power Supply Rear Panel with GPIB-M Interface

GPIB CANBUS USER LINES

1

CANBUS GPIBUSER LINES

1

Figure 2.5 XFR 1200 Watt Power Supply Rear Panel with GPIB-M Interface

28 Operating Manual for Multichannel Functionality (GPIB-M)

Page 33

Installation and Configuration

GPIB CANBUS USER LINES

Figure 2.6 XHR Power Supply Rear Panel with GPIB-M Interface

Initial Inspection

USER LINES

CANBUS

GPIB

Figure 2.7 XPD Power Supply Rear Panel with GPIB-M Interface

29

Page 34

Installation and Configuration

!

Initial Inspection

USER LINES

CANBUS

GPIB

Figure 2.8 XT/HPD Power Supply Rear Panel with GPIB-M Interface

CAUTION

Use proper static control techniques to avoid damage to static-sensitive components

on the printed circuit board

30 Operating Manual for Multichannel Functionality (GPIB-M)

Page 35

Basic Setup Procedure

This procedure can be used as a quick reference for those familiar with the

configuration requirements for the GPIB-M interface as installed in the DC power

supply.

IEEE-488 Controller Connection

Connect the GPIB cable to the supply at connector on the rear panel. Use an approved

IEEE-488 connector and cable when connecting the GPIB Interface to your IEEE-488

GPIB network. Refer to Figure 2.4, Figure 2.5, Figure 2.6 or Figure 2.7.

Add a ferrite block to reduce radiated emissions. The one inch square ferrite block

with built-in housing clip is packaged and shipped with the power supply interface

card.

To install the ferrite block:

1. Position the block no more than 5 cm (2 in.) from the power supply end of the

user cable.

2. Open the ferrite block housing.

3. Run the cable through the ferrite block. See Figure 2.9, “XFR GPIB Cable with

Ferrite Block” on page 31.

Installation and Configuration

Basic Setup Procedure

4. Close the housing clip.

The ferrite block ensures that the power supply system meets radiated emission

requirements for CE Mark.

Figure 2.9 XFR GPIB Cable with Ferrite Block

31

Page 36

Installation and Configuration

Basic Setup Procedure

Setup

Procedure

For those who want more information, each step refers to more detailed procedures

located in subsequent sections.

1. Power ON

Power on the unit.

2. Configure Computer Controller

Configure the controller to match the power supply characteristics. The unit is

shipped with default GPIB address 2. Configure your controller to talk to

address 2.

3. Test

Test the link by communicating with the power supply.

Example: Send the ID query “*IDN?” and ensure you get a response. Send the

command ":VOLT 2;:CURR 1" to set voltage to 2V and current limit to 1A.

(Using IBIC

1

this would be ‘ibwrt ":volt 2;:curr 1"’)

See “Change Remote/Local Mode” on page 48 for information about changing

about Local/Remote modes.

4. Configure power supply

If desired, configure the power supply with the desired power on settings or a

different GPIB address. (Be sure to change the controller address to match.)

See “Power On Remote State” on page 49, “Set Up Power ON Defaults” on page

56, and “Power On Output State” on page 57.

1. This text uses National Instruments' IBIC (Interface Bus Interactive Control) program commands

developed for their GPIB interface for computer controllers as examples only.

32 Operating Manual for Multichannel Functionality (GPIB-M)

Page 37

Installation and Configuration

!

Basic Setup Procedure

Table 2.1 Remote Mode Power On Conditions

Feature Factory Preset Value

Voltage setpoint 0.0V

Current setpoint 0.0A

Triggered voltage setpoint Disabled (DEFault)

Triggered current setpoint Disabled (DEFault)

Trigger source None

Low voltage setpoint limit 0.0V

High voltage setpoint limit 103% of voltage rating

Low current setpoint limit 0.0A

High current setpoint limit 103% of current rating

Over voltage protection Disabled (0.0V)

Under voltage protection Disabled (0.0V) and not shutdown when tripped

Over current protection Disabled (0.0A) and not shutdown when tripped

Under current protection Disabled (0.0A) and not shutdown when tripped

Fold shutdown protection None and delay 0.5s

AC OFF shutdown recovery Auto recover

OTP shutdown recovery Latched

Aux line configuration None and active low

Power On

Service

Request

CAUTION

Ensure the power supply chassis is properly connected to ground. The interface

connection system is not capable of handling the resulting excessive ground currents

that may flow through the connection to the controlling computer if the chassis is not

at ground potential.

The Power On Service Request setting causes the power supply to send a service

request to the computer controller when the power supply is turned on or when it

re-initializes after a momentary power interrupt if the following conditions are also

met:

• *PSC (power on status clear) is set to 0, and

• bit 5 in the Service Request Enable register has been set (*ESE) prior to power

off.

When a service request is sent, the front panel SRQ LED will also turn on. You can

clear the service request and turn off the SRQ LED by performing a serial poll. See

also “Status Byte” on page 79 for information about the SRQ command.

33

Page 38

Installation and Configuration

Configure for GPIB Operation

Configure for GPIB Operation

The power supply is ready for GPIB communication when it leaves the factory, but

you may change any of the control settings. The default remote control setting is

GPIB, address 2.

Change

Remote

Control

Source

Set GPIB

Address

Select an interface for remote control.

SYST:REM:SOUR [GPIB|MCHannel]

where

• GPIB: control via GPIB interface

• MCHannel: multichannel operation using the CANbus interface

Change the GPIB address.

SYST:COMM:GPIB:ADDR <GPIB-address>

where

<GPIB-address> may be a value from 1 to 30.

Be sure to make a note of the GPIB address. If the address is unknown, use a feature

such as “Scan for Instruments” on National Instruments’ Measurement and

Automation Explorer.

34 Operating Manual for Multichannel Functionality (GPIB-M)

Page 39

Configure for Multichannel Operation

Installation and Configuration

Configure for Multichannel Operation

Multichannel

Connections

Multichannel

Configuration

Y ou may remotely control up to 50 power supplies from one GPIB interface by using

multichannel addressing via the CANbus.

One power supply will be connected to a PC via GPIB. All other power supplies are

connected via CANbus (Controller Area Network) to that unit. SCPI commands that

include a channel address will be sent via the CANbus to the other power supplies.

(Commands with the local address will be executed locally and will not be sent).

The multichannel address must be appended to the program mnemonic. If no

multichannel address is appended to the program mnemonic, the command is

executed by the local (directly connected) power supply.

Each unit of the network can send and receive commands to and from other units on

the network. It is highly recommended that only one command be sent at a time. Any

GPIB timeout settings should be increased when using multichannel commands.

If a second power supply that has the same multichannel address as another is

connected to the bus, it will automatically increment its address until it finds a unique

address. If it fails to find a unique address, it will disconnect itself from the bus and

you will not be able to communicate with it until you disconnect the other power

supplies and cycle the power. Therefore, when configuring a network of supplies,

you can make all connections, and power on one supply at a time. They will

configure their addresses in the order that they were powered on. Be sure to note the

address of each power supply for future reference or in case you want to reorganize

the network.

Example:

Connect 3 power supplies for multichannel operation. Y ou have one GPIB-M supply

and 2 CAN-only supplies. The GPIB-M supply's multichannel address is set to 1 at

the factory. Both CAN-only supplies are set to 2.

Connect all units as described in “Basic Setup Procedure” on page 31.

Power on the GPIB-M supply, then one of the CAN-only supplies. Check that you

can communicate with both. Send the *IDN? query to return the identification string

from the GPIB-M supply . Send "SYST2:IDEN?" to return the ID string from the

CAN-only unit.

Power on the last unit. Since multichannel address 2 already exists on the bus, it will

automatically configure itself to address 3. Check that this is the case by sending the

command "SYST3:IDEN?"

35

Page 40

Installation and Configuration

Configure for Multichannel Operation

CANbus The CANbus port consists of two 4-pin modular “handset” jacks to support daisy

chain connections. The CAN (Controller Area Network) is an ISO standard

(ISO11898) for a serial communication network. Table 2.2 describes the pin

functions. The CANbus is used for communications in multichannel operation or

current sharing (master/slave) operation.

Table 2.2 CANbus Pins

Pin # Function

1CANLO

2 Ground

3CANHI

4 Ground

CANbus

Cables

Configuration

of CAN-only

Interface

Cards

The custom CANbus cables shipped with your unit are parallel 4-connector cables

with 4-pin modular “handset” connectors.

The CAN-only interface cards must be configured via the CANbus with another

GPIB-M card. The CAN-only interface cards are set to multichannel address 2 at the

factory . Ensure the multichannel address on the GPIB-M is set to an unused address,

for example, address 1. Connect the two power supplies as shown in Figure 2.10,

“Connections for Multichannel Operation” on page 37.

Send the query to the CAN-only power supply:

SYST2:REM:SOUR?

and ensure the response is “MCH” for multichannel.

If necessary, set the power supply to accept control via multichannel commands

(the CANbus interface) with the SCPI command:

SYST2:REM:SOUR MCH

Set each slave's unique multichannel address using the command:

SYST2:COMM:MCH:ADDR <multichannel-address>

where multichannel-address is an integer in the range of 1-50.

This procedure can be repeated separately with each power supply to assign a unique

address to each. Once all power supplies are configured, they can be connected to the

CANbus network.

Note See “Broadcasting Commands” on page 39 for additional information on

configuring CAN-only units.

36 Operating Manual for Multichannel Functionality (GPIB-M)

Page 41

Setup See Figure 2.10.

1. Connect power supplies to be controlled via the CANbus network. Connect the

power supplies in a daisy chain by linking the first power supply to the second

using one cable, and then the second to the third using a second cable and the

second CAN port. Continue making connections in this fashion until all the

power supplies are connected. T erminate the bus at both ends, using the unused

CAN ports, with 120 ohm, 1/4 Watt resistors (included) across the CAN HI and

CAN LO signals (Pins 1 and 3). See Table 2.2, “CANbus Pins,” on page 36.

2. At least one power supply must be connected to a PC via GPIB for multichannel

functionality. Configure each of the power supplies with a unique address, as

described in the configuration section. Addresses may be in the range 1 to 50

inclusive. Record the address of each unit for future reference.

3. Turn the power supplies on one at a time.

Installation and Configuration

Configure for Multichannel Operation

Using

Multichannel

Operation

GPIB

Connection

Figure 2.10Connections for Multichannel Operation

Once the power supplies have been configured and connected, you may power them

on.

Power supplies controlled via multichannel have full capabilities, including

changing REM/LCL modes and calibration.

Any power supply may send multichannel commands, if they are connected to a PC

via GPIB.

37

Page 42

Installation and Configuration

Configure for Multichannel Operation

A power supply will attempt to connect to the network:

• on power up, and

• when the multichannel address is changed.

The power supply will successfully connect if there are no other power supplies on

the network with the same address.

Error 1702, “Multichannel address taken” is queued if the power

supply fails to connect.

SCPI Remote Control (RCONtrol) subregister will indicate the status of the

connection. A power supply that has been disabled will not have any bits set. Use the

SCPI command:

STAT:OPER:RCON:COND?

to query the condition of the multichannel interface.

See T a ble 4.5, “Remote CONtrol Sub-Register,” on page 74 for a description of the

bits in this register.

Multichannel

Commands

To send a command to a multichannel power supply, attach the channel address to

the command. If no channel number is specified, the command will be executed by

the directly connected power supply.

For example, the command:

SOURce12:VOLT 10.0

will set the power supply with address 12 to 10V output. The master receives the

command and puts in on the CANbus.

Appendix B. “SCPI Command Reference” lists all commands.

[<channel>]indicates where the multichannel address is to be inserted into the

command.

IEEE488.2 commands have been given an alias that is SCPI compliant if the

command is applicable to a power supply in multichannel operation. These

commands include *CLS, *IDN?, *OPT?, *RST, *TST?, *RCL, *SAV, *SDS, and

*WAI. See Table B.1, “IEEE 488.2 Commands,” on page 104.

Note The multichannel interface can not handle multiline response messages.

38 Operating Manual for Multichannel Functionality (GPIB-M)

Page 43

Installation and Configuration

Configure for Multichannel Operation

Broadcasting

Commands

You can specify a channel address of "0" to broadcast a command to all power

supplies connect via CANbus. Broadcast commands are useful in set up and

operation.

Example:

Set all power supplies to remote mode:

SYST0:REM:STAT REM

Turn output on:

OUTP0 ON

Set voltage output to maximum:

SOUR0:VOLT MAX

Attempting to broadcast any query will generate an error.

Note Broadcasting may be useful in configuring a CAN-only power supply when its

address is unknown. Connect the unit to a GPIB-M power supply. Broadcast the set

multichannel command to change the CAN-only supply's address. The command has

no effect on the GPIB controlled unit.

Example:

"SYST0:COMM:MCH:ADDR 2" will set the CAN-only unit to address 2.

Note that there will be a lag in execution time between the local unit and all other

units of up to a maximum of 20 ms.

Specifications

Max connected units 50

Max cable length 40 m

Bus speed 700 kbits/sec

Termination 120 ohm 1/4 W

Connectors

Addresses 1 to 50

modular handset 4-position, 4-contact jacks

39

Page 44

Installation and Configuration

User Lines

User Lines

The user lines connector, located on the GPIB-M interface rear panel, provides

several signals to increase your operating control of the supply. These signals are

dependent on the operator's design and uses. The operation of the auxiliary status

lines requires that you provide external Vcc and ground. To locate the connector,

refer to Figure 2.4, Figure 2.5, Figure 2.6 and Figure 2.7. See Figure 2.13,

“Schematic For User Line Interface” on page 42 and T able 2.3, “User Line Pins,” on

page 40 for pin descriptions.

The user lines are optically isolated, open collector configuration. The input lines are

capable of sinking 10mA (with recommended 5V at input) up to a maximum of

90mA.

XT/HPD and XPD: The connector for the user lines is a standard 8-conductor RJ45

jack. The cable is supplied by the user.

XFR or XHR: The connectors are removable “wire clamp” terminal block style

connectors. Use shielded twisted pairs of 22-24 AWG wire for connections. Strip

0.2” (5mm) of insulation from the wires and clamp securely at the appropriate pin.

Table 2.3 User Line Pins

Pin # Function Input/Output

1 Aux Status Line A Output

2 Aux Status Line B Output

3 External Trigger 4-12V Input

4 Safety Interlock (Shutdown) 4-12V Input

5 Safety Interlock (Shutdown) GND) Input

6 User Power, 5-12Vdc Input

7 User Ground Input

40 Operating Manual for Multichannel Functionality (GPIB-M)

Page 45

User Lines

Connection

(XT, HPD,

XPD)

Installation and Configuration

User Lines

Figure 2.11User Signals Connector (XT, HPD and XPD)

Use a standard 8-connector RJ45 connector and data cable to connect to the user

lines.

Add a ferrite block to reduce radiated emission. The one inch square ferrite block

with built-in housing clip is packaged and shipped with the power supply interface

card.

To install the ferrite block:

1. Position the block no more than 5 cm (2 in.) from the power supply end of the

user cable.

2. Open the ferrite block housing.

3. Loop the cable through the ferrite block. See Figure 2.12, “XT , HPD, XPD User

Cable with Ferrite Block” on page 41.

4. Close the housing clip.

The ferrite block ensures that the power supply system meets radiated emission

requirements for CE mark.

J7 User Cable

Ferrite Block

To User Custom InterfaceTo J7 Connector

Figure 2.12XT , HPD, XPD User Cable with Ferrite Block

41

Page 46

Installation and Configuration

S

User Lines

CHASSIS POTENTIAL ISOLATED USER LINES

CNY17-2

CNY17-2

CNY17-2

508 Ohm

0.4W

508 Ohm

0.4W

USER LINE

CNY17-2

Vf = 1.3V TYP, 1.5V MAX

If = 10mA Recommended, 90mA MAX

Figure 2.13Schematic For User Line Interface

42 Operating Manual for Multichannel Functionality (GPIB-M)

Page 47

Section 3. Operation

Overview

Once you have installed the power supply and connected both the AC input power

and the load as explained in Section 2, the power supply is in its default

configuration and is ready for operation.

One power supply must be connected via GPIB. Additional units may be controlled

via the CANbus port which enables multichannel addressing. The multichannel

addressing also supports the current sharing feature for parallel-connected units. Any

unit may be toggled between remote and local control modes.

Section 3 provides information about operating the power supply remotely via the

GPIB-M or CAN-only optional interface.

In addition, brief descriptions are provided of Constant V oltage and Constant Current

modes. See “Power Supply Operation” on page 48.

Powering ON

the Power

Supply

WARNING- Shock Hazard

The factory setting for Power ON is 0V and 0A with the output OFF. These settings

can be customized by end users. If you suspect that the power supply has been used

by someone else since it was received from the factory, be prepared for the unit to

power ON with a live DC output.

To power on the power supply:

1. Ensure that the AC power switch is OFF.

2. Connect the unit to an AC outlet.

3. Turn on the front panel AC power switch.

After a short power-on delay, the digital meters on the front panel and the CV LED

illuminate.

43

Page 48

Operation

Power Supply Operating States

Power Supply Operating States

The power supply has 5 operating states:

• Power-On

• Output Shutdown

• Soft Start

• Normal Operation

• Calibration

Power-On This is the period between the time that AC power is applied to the supply (AC

breaker turned on) and the time that the power supply is ready for operation. During

this period, the internal circuits are powering up and performing self-tests. At the end

of the Power-On period, the supply is normally in its default Power-On mode with

the output OFF, V

SET

=0 and I

SET

=0.

Output

Shutdown

In this state, the output is disabled and there is no output regardless of power settings.

The power supply can be placed in the Output Shutdown state by a command (or the

the front panel - XFR, XHR only), via the Interlock signal, or from a protection

mechanism. This is also called the Standby mode.

Soft Start In this state, the output power is ramping up gradually towards its target load. This

reduces equipment stress. This state occurs whenever the supply output is enabled

by the software (a command or a protection is cleared), and is approximately 2