Page 1

Internal GPIB Interface

for XT/HPD Series

Programmable DC Power Supplies

Operation Manual

GPIB-XT

GPIB-HPD

TM-GP6H-01XN Rev B www.programmablepower.com

Page 2

Page 3

About AMETEK

AMETEK Programmable Power, Inc., a Division of AMETEK, Inc., is a global leader in the design

and manufacture of precision, programmable power supplies for R&D, test and measurement,

process control, power bus simulation and power conditioning applications across diverse

industrial segments. From bench top supplies to rack-mounted industrial power subsystems,

AMETEK Programmable Power is the proud manufacturer of Elgar, Sorensen, California

Instruments and Power Ten brand power supplies.

AMETEK, Inc. is a leading global manufacturer of electronic instruments and electromec hanical

devices with annualized sales of $2.5 billion. The Company has over 11,000 colleagues working

at more than 80 manufacturing facilities and more than 80 sales and service centers in the United

States and around the world.

Trademarks

AMETEK is a registered trademark of AMETEK, Inc. Sorensen is a trademark owned by AMETEK,

Inc. Other trademarks, registered trademarks, and product names are the property of their

respective owners and are used herein for identification purposes only.

Notice of Copyright

Internal GPIB Interface for XT/HPD Series Programmable DC Power Supplies Operation Manual

© 2007 AMETEK Programmable Power, Inc. All rights reserved.

Exclusion for Documentation

UNLESS SPECIFICALLY AGREED TO IN WRITING, AMETEK PROGRAMMABLE POWER, INC.

(“AMETEK”):

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY

TECHNICAL OR OTHER INFORMATION PROVIDED IN ITS MANUALS OR OTHER

DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSSES, DAMAGES, COSTS OR

EXPENSES, WHETHER SPECIAL, DIRECT, INDIRECT, CONSEQUENTIAL OR INCIDENTAL,

WHICH MIGHT ARISE OUT OF THE USE OF SUCH INFORMATION. THE USE OF ANY SUCH

INFORMATION WILL BE ENTIRELY AT THE USER’S RISK, AND

(c) REMINDS YOU THAT IF THIS MANUAL IS IN ANY LANGUAGE OTHER THAN ENGLISH,

ALTHOUGH STEPS HAVE BEEN TAKEN TO MAINTAIN THE ACCURACY OF TH E

TRANSLATION, THE ACCURACY CANNOT BE GUARANTEED. APPROVED AMETEK CONTENT

IS CONTAINED WITH THE ENGLISH LANGUAGE VERSION, WHICH IS POSTED AT

WWW.PROGRAMMABLEPOWER.COM.

Date and Revision

February 2009 Revision B

Part Number

TM-GP6H-01XN

Contact Information

Telephone: 800 733 5427 (toll free in North America)

858 450 0085 (direct)

Fax: 858 458 0267

Email: sales@programmablepower.com

service@programmablepower.com

Web: www.programmablepower.com

i

Page 4

This page intentionally left blank.

ii

Page 5

G

G

Important Safety Instructions

Before applying power to the system, verify that your product is configured properly for your

particular application.

WARNIN

WARNIN

Only qualified personnel who deal with attendant hazards in power supplies, are allowed to perform

installation and servicing.

Ensure that the AC power line ground is connected properly to the Power Rack input connector or

chassis. Similarly, other power ground lines including those to application and maintenance

equipment must be grounded properly for both personnel and equipment safety.

Always ensure that facility AC input power is de-energized prior to connecting or disconnecting any

cable.

In normal operation, the operator does not have access to hazardous voltages within the chassis.

However, depending on the user’s application configuration, HIGH VOLTAGES HAZARDOUS TO

HUMAN SAFETY may be normally generated on the output terminals. The customer/user must

ensure that the output power lines are labeled properly as to the safety hazards and that any

inadvertent contact with hazardous voltages is eliminated.

Guard against risks of electrical shock during open cover checks by not touching any portion of the

electrical circuits. Even when power is off, capacitors may retain an electrical charge. Use safety

glasses during open cover checks to avoid personal injury by any sudden component failure.

Neither AMETEK Programmable Power Inc., San Diego, California, USA, nor any of the subsidiary

sales organizations can accept any responsibility for personnel, material or inconsequential injury,

loss or damage that results from improper use of the equipment and accessories.

Hazardous voltages may be present when covers are removed. Qualified

personnel must use extreme caution when servicing this equipment.

Circuit boards, test points, and output voltages also may be floating above

(below) chassis ground.

The equipment used contains ESD sensitive parts. When installing

equipment, follow ESD Safety Procedures. Electrostatic discharges might

cause damage to the equipment.

SAFETY SYMBOLS

iii

Page 6

This page intentionally left blank.

iv

Page 7

Product Family: Internal GPIB Interface for XT/HPD Series Programmable DC

Power Supplies

Warranty Period: Five Years

WARRANTY TERMS

AMETEK Programmable Power, Inc. (“AMETEK”), provides this written warranty covering the

Product stated above, and if the Buyer discovers and notifies AMETEK in writing of any defect in

material or workmanship within the applicable warranty period stated above, then AMETEK may,

at its option: repair or replace the Product; or issue a credit note for the defective Product; or

provide the Buyer with replacement parts for the Product.

The Buyer will, at its expense, return the defective Product or parts thereof to AMETEK in

accordance with the return procedure specified below. AMETEK will, at its expense, deliver the

repaired or replaced Product or parts to the Buyer. Any warranty of AMETEK will not apply if the

Buyer is in default under the Purchase Order Agreement or where the Product or any part

thereof:

• is damaged by misuse, accident, negligence or failure to maintain the same as

specified or required by AMETEK;

• is damaged by modifications, alterations or attachments thereto which are not

authorized by AMETEK;

• is installed or operated contrary to the instructions of AMETEK;

• is opened, modified or disassembled in any way without AMETEK’s consent; or

• is used in combination with items, articles or materials not authorized by AMETEK.

The Buyer may not assert any claim that the Products are not in conformity with any warranty

until the Buyer has made all payments to AMETEK provided for in the Purchase Order Agreement.

PRODUCT RETURN PROCEDURE

1. Request a Return Material Authorization (RMA) number from the repair facility (must be

done in the country in which it was purchased):

• In the USA, contact the AMETEK Repair Department prior to the return of the

product to AMETEK for repair:

Telephone: 800-733-5427, ext. 2295 or ext. 2463 (toll free North America)

858-450-0085, ext. 2295 or ext. 2463 (direct)

• Outside the United States, contact the nearest Authorized Service Center

(ASC). A full listing can be found either through your local distributor or our

website, www.programmablepower.com, by clicking Support and going to the

Service Centers tab.

2. When requesting an RMA, have the following information ready:

• Model number

• Serial number

• Description of the problem

NOTE: Unauthorized returns will not be accepted and will be returned at the shipper’s expense.

NOTE: A returned product found upon inspection by AMETEK, to be in specification is subject to

an evaluation fee and applicable freight charges.

v

Page 8

This page intentionally left blank.

vi

Page 9

About This Manual

This technical manual is for the internal GPIB interface, a microprocessor-controlled

option card for XT and HPD Series DC output power supplies. This manual provides

you with descriptions and specifications, user options, and configuration

instructions, in addition to a command set which enables you to manage the power

supply from an external source. Error messages and calibration procedures are also

included.

This manual is designed for the user who is familiar with basic electrical theory

especially as it applies to the operation of power supplies. This implies a recognition

of Constant Voltage and Constant Current operation modes and the control of input

and output power, as well as the observance of safe techniques while effecting supply

or pin connections and any changes in switch settings. The user should also have

experience with a computer-based communications software package.

Refer to your power supply manual for installation, configuration, and operating

procedures for your power supply.

Main Section s

Section 1 Features and Specifications D escribes the power supply and lists

its features and specifications.

Section 2 Installation and Configuration Gives basic setup procedures.

Describes inspection, cleaning, shipping, and storage procedures. Includes

additional options for configuring the GPIB interface for operation.

Section 3 Operation Lists the complete command set, status registers, and error

codes.

Section 4 Calibration Provides detailed procedures for voltage and current

mode calibration as well as over voltage protection (OVP) calibration. Includes

calibration for programming and readback accuracy.

vii

Page 10

About This Manual

viii Operating Manual for GPIB for XT/HPD Series Power Supply

Page 11

Contents

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Section 1.

Features and

Specifications

Section 2.

Installation

and

Configuration

Section 3.

Operation

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Features and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Programmable Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Readback Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Initial Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Basic Setup Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

OVP Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

IEEE-488 Primary Address Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Remote/Local Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Remote/Local Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

LOC Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Local Mode Disable Jumper J95 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

IEEE-488 Controller Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Power On Service Request (PON SRQ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

User Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Connector J7 User Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

J7 Cable Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

GPIB Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Multiline Control Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Device Clear. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Device Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Parallel Poll . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Service Request. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Serial Poll. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Command Syntax. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Manual Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Command Format and Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Command Strings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Command Terminators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Command Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Command Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Accumulated Status, Status, and Fault Registers . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

ix

Page 12

Contents

Diagnostic LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Section 4.

Calibration

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Voltage Mode Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Voltage Calibration Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Voltage Program Calibration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Voltage Readback Calibration Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Current Mode Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Current Calibration Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Current Program Calibration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Current Readback Calibration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Over Voltage Protection (OVP) Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

x

Operating Manual for GPIB for XT/HPD Series Power Supply

Page 13

Section 1. Features and Specifications

Description

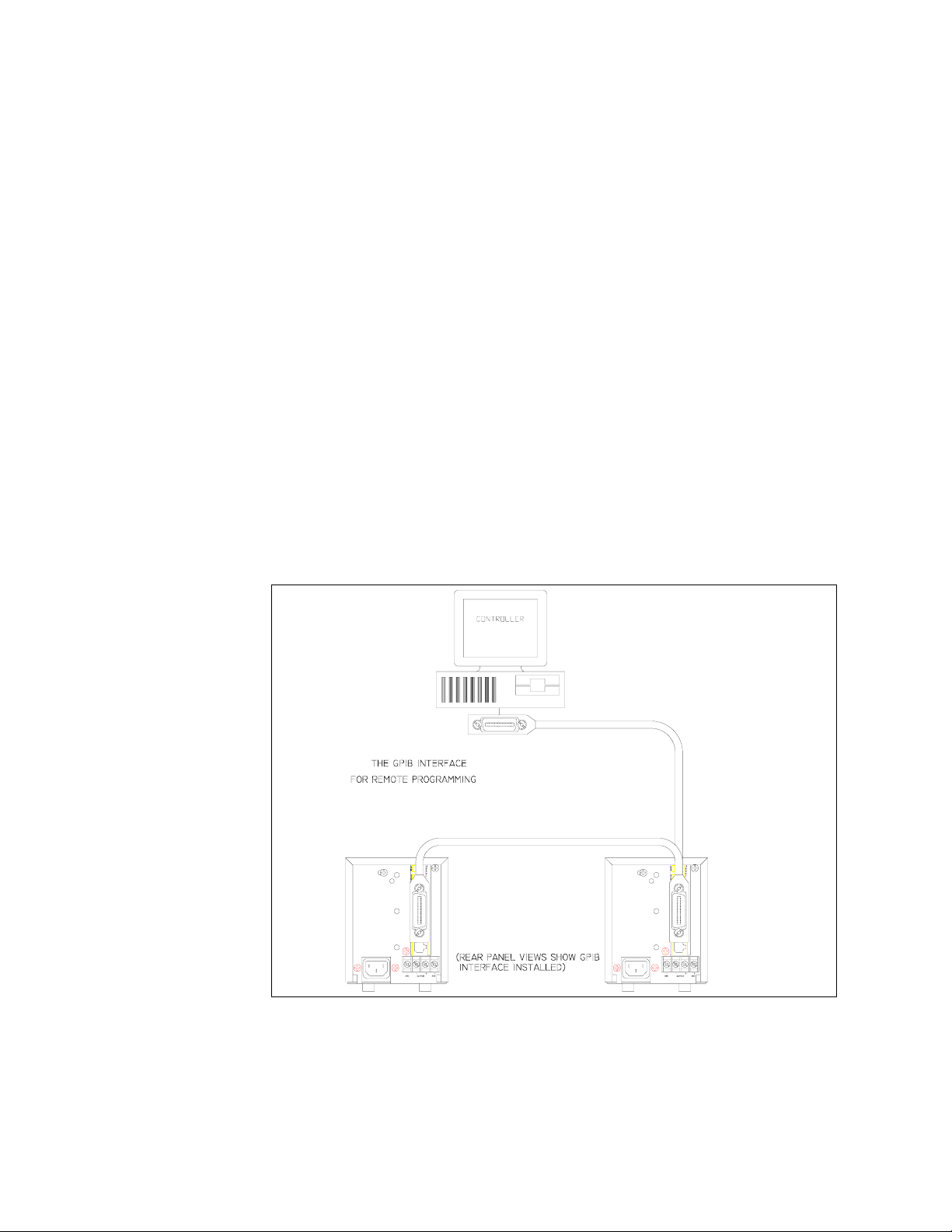

The internal GPIB interface card allows you to operate your power supply from a

computer controller via the IEEE-488 communications bus. See Figure 1.1, “Sample

Configuration using GPIB Interface”.

The GPIB interface allows complete remote programming of your power supply,

including status reporting, settings query, and interrupt generation with

user-designated fault conditions. Both the voltage and current output are precisely

programmed directly in volts and amps with 16-bit resolution. Additionally, the

built-in DVM and current shunt measure the actual power supply output and provide

16-bit readback. The programming command set is easy-to-use and includes

software calibration commands. The interface card comes standard with several

protection features such as programmable over voltage protection, foldback, load

isolation signal, and soft limits.

Figure 1.1 Sample Configuration using GPIB Interface

11

Page 14

Features and Specifications

Features and Functions

Features and Functions

Features • 16-bit programming and readback of voltage and current

• Programmable soft limits for voltage and current

• Programmable over voltage protection with reset

• Easy-to-use, self-documenting command set

• Isolated user-programmable signals such as fault, polarity, isolation, and

auxiliary signals

• LED status signals: error, addressed, service request, over voltage protection,

and remote operation

• Foldback in CV or CC mode with reset

• Software calibration

Programmable

Functions

Readback

Functions

• Output voltag e and current

• Soft limits for voltage and current

• Overvoltage protection

• Output enable/disable

• Maskable fault interrupt

• Hold and trigger

• User-programmable output relay signals

• Actual measured voltage and current

• Voltage and current settings

• Soft voltage and current limits

• Overvoltage protection setting

• Present and accumulated power supply status

• Programming error codes

• Fault codes

• Power supply model and version identification

• Firmware revision levels

12 Operating Manual for GPIB for XT/HPD Series Power Supply

Page 15

Features and Specifications

Specifications

The specifications in this section are warranted at 25°C ±5°C unless otherwise

specified. All specifications are subject to change without notice.

Table 1.1 Specifications for XT 60 W Series Supply with GPIB Interface Installed

Models 7-6 15-4 20-3 30-2 60-1 120-0.5 250-0.25

Program Resolution

Voltage

Current

OVP

Program Accuracy

Voltage

Current

OVP

Readback Resolution

Voltage

Current

Readback Accuracy

Voltage

Current

1. Apply accuracy specifications according to the following voltage program accuracy example:

Set a model XT 15-4 power supply to 10 volts.

The expected result will be within the range of 10 volts ± 20mV ± 0.1% of the set voltage of 10 volts.

1

1

1.1mV

1.0mA

1.0mV

10mV

±0.1%

110mA

±0.15%

70mV

1.1mV

1mA

10mV

±0.15%

110mA

±0.15%

2.4mV

0.6mA

2.4mV

20mV

±0.1%

70mA

±0.15%

150mV

2.4mV

1mA

10mV

±0.1%

70mA

±0.15%

3.1mV

0.5mA

3.1mV

20mV

±0.15%

50mA

±0.15%

200mV

3.1mV

1mA

10mV

±0.1%

50mA

±0.15%

4.7mV

0.3mA

4.7mV

30mV

±0.15%

40mA

±0.15%

300mV

4.7mV

1mA

15mV

±0.1%

40mA

±0.15%

9.3mV

0.2mA

9.3mV

200mV

±0.15%

26mA

±0.2%

600mV

9.3mV

1mA

35mV

±0.15%

26mA

±0.2%

17mV

0.1mA

17mV

400mV

±0.15%

13mA

±0.2%

1.2V

17mV

1mA

70mV

±0.15%

13mA

±0.2%

34mV

0.08mA

34mV

800mV

±0.15%

7mA

±0.2%

2.4V

34mV

1mA

140mV

±0.15%

7mA

±0.2%

Specifications

13

Page 16

Features and Specifications

Specifications

Table 1.2 Specifications for HPD 300 W Series Supply with GPIB Interface Installed

Models 15-20 30-10 60-5

Program Resolution

Voltage

Current

OVP

Program Accuracy

Voltage

Current

OVP

Readback Resolution

Voltage

Current

Readback Accuracy

Voltage

Current

1. Apply accuracy specifications according to the following voltage program accuracy example:

Set a model HPD 15-20 power supply to 10 volts.

The expected result will be within the range of 10 volts ± 60mV ± 0.1% of the set voltage of

10 volts.

2.4mV

2.8mA

2.4mV

1

60mV

±0.1%

75mA

±0.12%

1.5V

2.4mV

2.8mA

1

45mV

±0.3%

75mA

±0.12%

4.7mV

1.4mA

4.7mV

70mV

±0.1%

50mA

±0.12%

3V

4.7mV

1.4mA

90mV

±0.3%

40mA

±0.12%

9.3mV

0.7mA

9.3mV

90mV

±0.12%

25mA

±0.1%

6V

9.3mV

1mA

175mV

±0.3%

25mA

±0.1%

14 Operating Manual for GPIB for XT/HPD Series Power Supply

Page 17

Section 2. Installation and Configuration

!

Introduction

To use this product, you must have the following equipment:

• a compatible model of DC output power supply

• IEEE-488 connector and cable

• computer with an IEEE-488 interface card

• Computer-based communications software package

The GPIB interface is usually installed in a power supply at the factory. Your local

distributor or service center can also install the interface, especially for use in a

previously-purchased supply already on site. The GPIB interface card will be

calibrated and configured with default settings. Y ou will need to configure the supply

for your system using the “Basic Setup Procedure” on page 18. Refer also to

Figure 2.1, pg. 16, Figure 2.2, pg. 16 and Figure 2.3, pg. 17 for drawings of the front

panel, the interface subplate, and the GPIB interface printed circuit board (PCB).

Initial Inspection

CAUTION

If you remove the unit's cover, use proper static control techniques to avoid damage

to static-sensitive components on the printed circuit board.

On first receiving your unit, perform a quick physical check.

• Ensure each package contains a power supply with its GPIB interface board

installed, and manuals for the power supply and the GPIB interface. Any

additional parts shipped with the power supply will be identified in the supply's

documentation.

• Inspect the unit for any signs of physical damage such as scratches, cracks, or

broken switches, connectors, or displays.

• Check the printed circuit board and components if you suspect internal damage.

If the unit is damaged, save all packing materials and notify the carrier immediately.

For additional information, please see the section titled, “Returning Power Supplies

to the Manufacturer” in the manual shipped with your complete unit.

15

Page 18

Installation and Configuration

Initial Inspection

Over Voltage Protection (OVP) LED

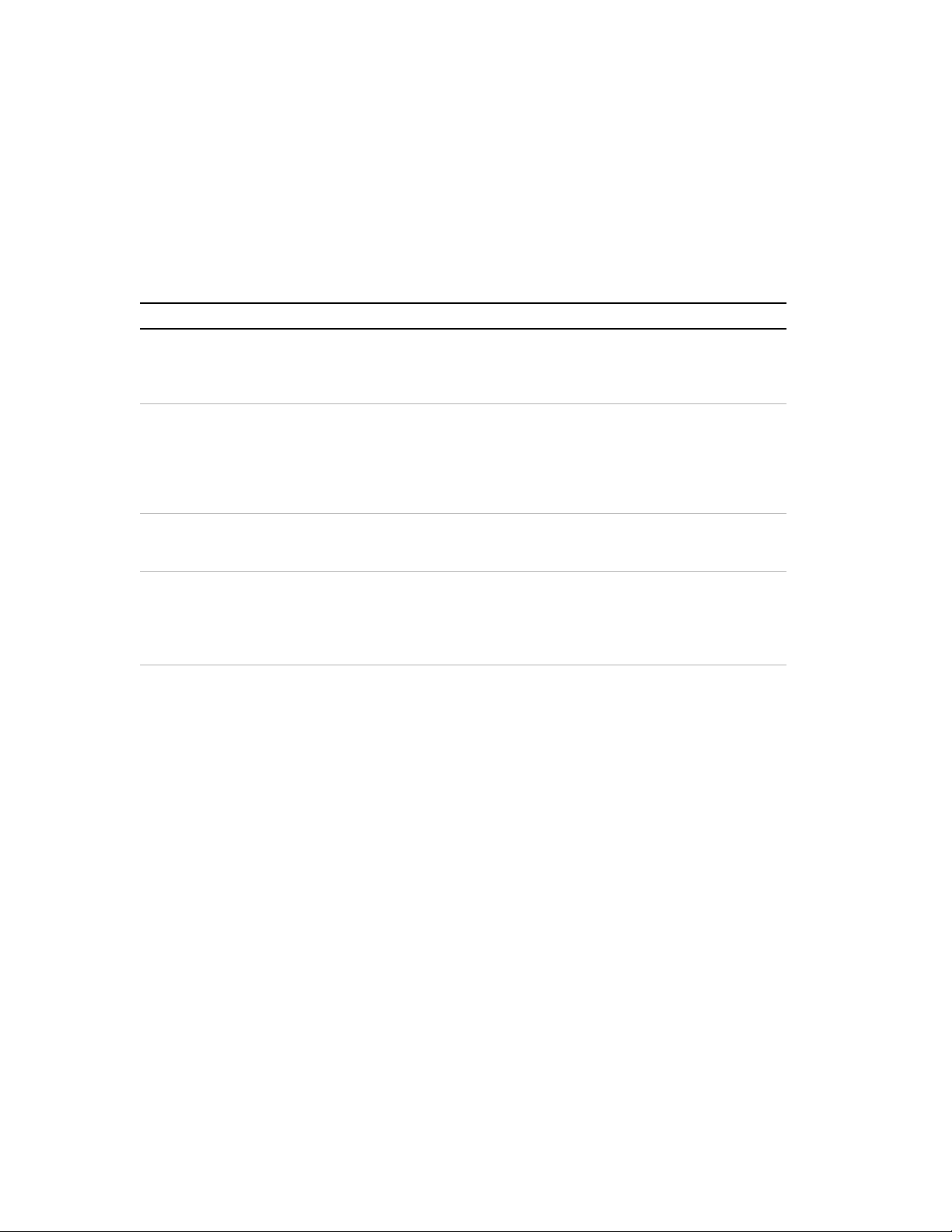

Figure 2.1 Power Supply Front Panel with GPIB Interface Installed

Remote Mode (REM) LED

Service Request (SRQ) LED

OVP Potentiometer

Error (ERR) LED

Addressed (ADR) LED

0

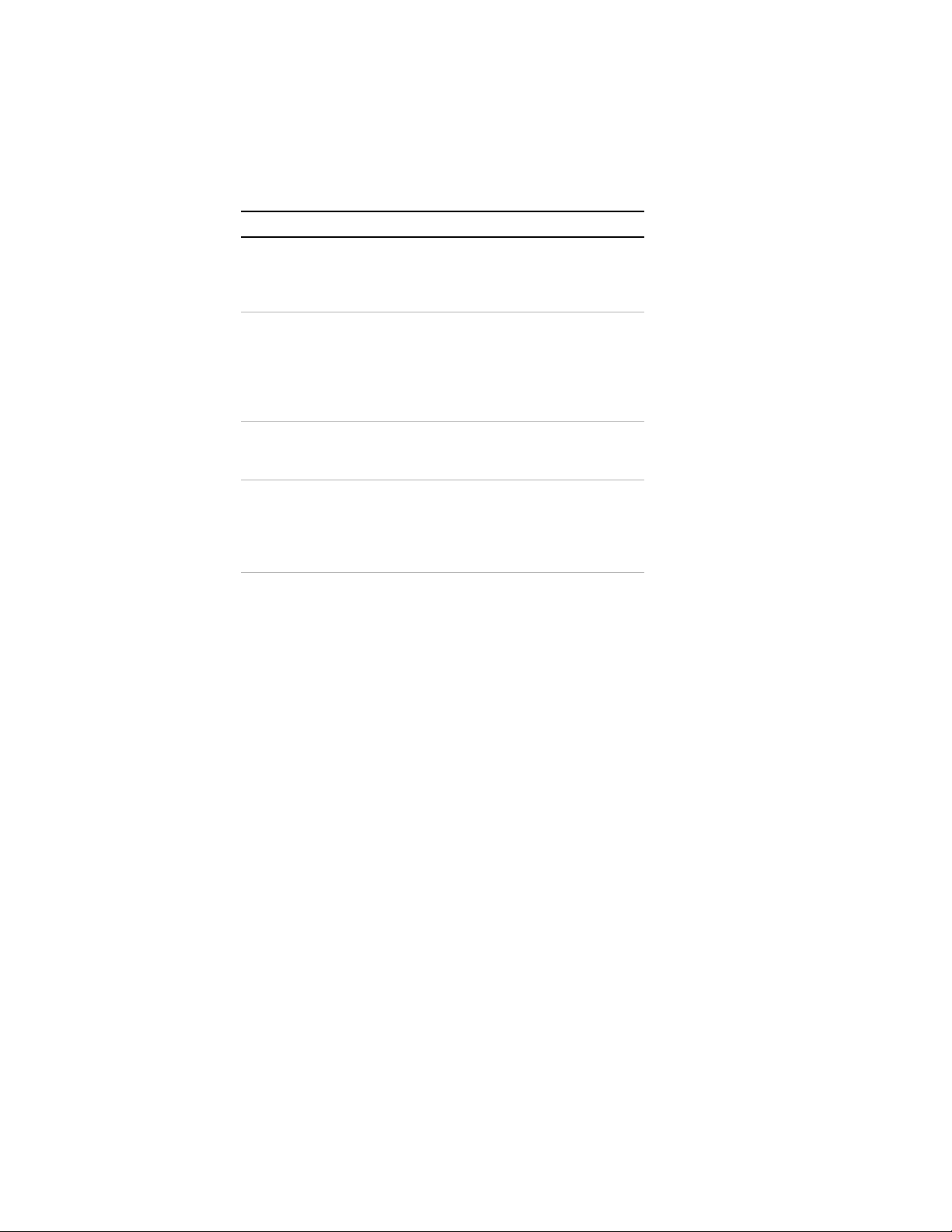

1

SW1 Switch:

1 Remote Mode Selection

2 Power ON Request (PON SRQ) Selection

4-8 A1-A5 Primary Address Selection

J8 IEEE Port

J7 User Signal Connector

Figure 2.2 Power Supply Rear Panel with GPIB Interface Installed

16 Operating Manual for GPIB for XT/HPD Series Power Supply

Page 19

Installation and Configuration

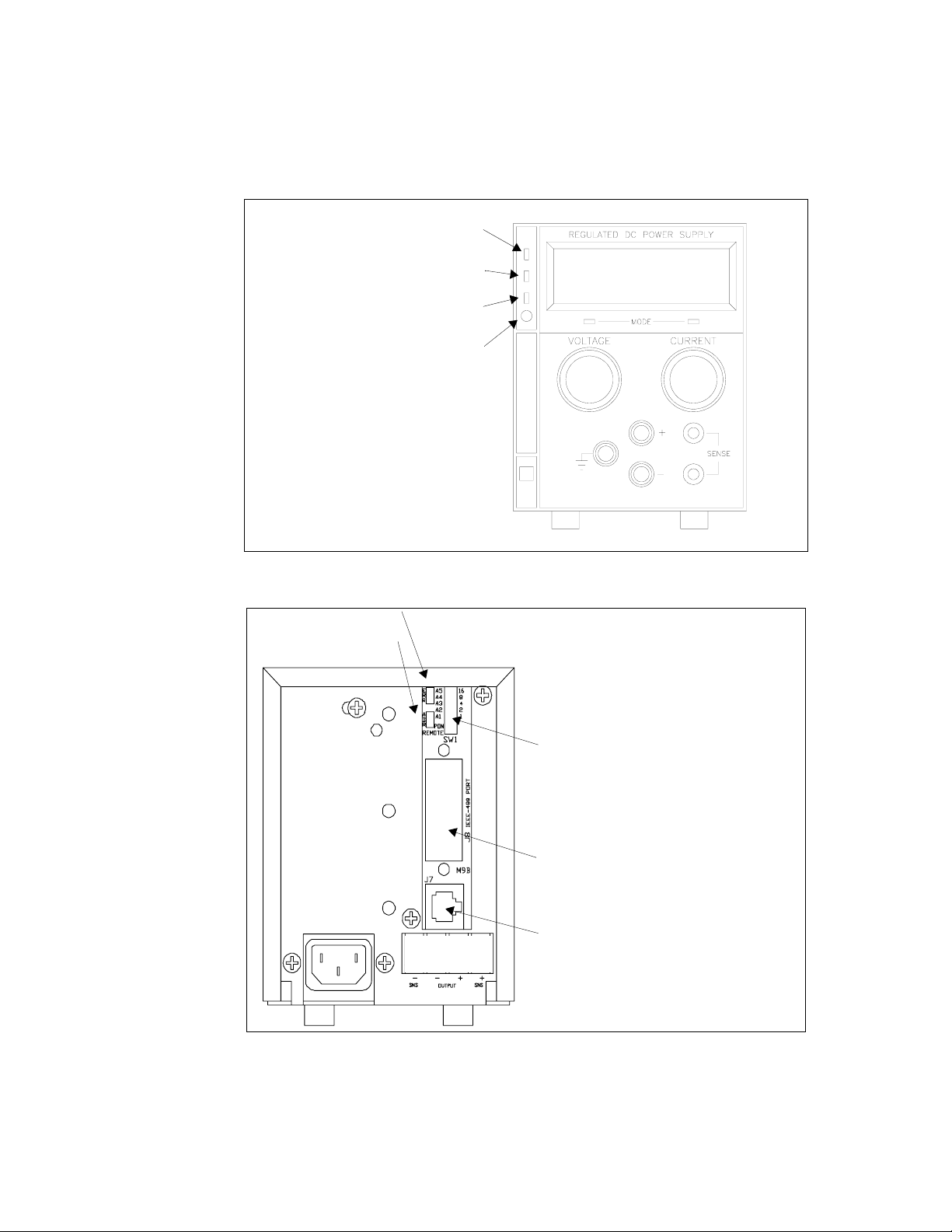

JUMPER SELECTION

J217 Local OVP control selection [closed] [default]. See page 19.

[open] Front Panel OVP Control.

J117 User TTL shutdown (S/D) selection [1-2] User TTL S/D line active low.

See page 26.

[2-3] [default] User TTL S/D line active high.

J217 Local Mode Disable Selection [closed] [default]. See page 23.

[open] Software control of power supply only

Note: All other jumpers are not user-selectable.

Initial Inspection

LED INDICATORS

CR141 Red Diagnostic LED Bus error or soft restart on Slave circuitry.

CR14 Red Diagnostic LED Soft restart on Master circuitry.

CR13 Green Diagnostic LED Bus error on Master circuitry.

EPROMS

U958 Slave EPROM See revision number stamped on EPROM.

U18 Master EPROM See revision number stamped on EPROM.

CONNECTORS

J6 IEEE 488 Bus Connector (J8 on rear panel subplate)

J10 User Signal Connector (J7 on rear panel subplate)

Figure 2.3 GPIB Interface PCB

17

Page 20

Installation and Configuration

Basic Setup Procedure

Basic Setup Procedure

This procedure can be used as a quick reference for those familiar with the

configuration requirements for the GPIB interface as installed in the DC power

supply. For those who want more information, each step refers to more detailed

procedures located in subsequent sections. Execute each step of the procedure in the

sequence given. Unless indicated otherwise, all procedures apply to the XT and HPD

series power supplies.

Table 2.1 Setup Procedure

Step # Description Action Reference

1 OVP Selection By default, you control the over voltage

protection (OVP) function via remote

operation.

2 Primary Address

Selection

3 Remote/Local

Operation

4 IEEE-488

Controller

Connection

5 Power ON Power on the unit. Before proceeding,

6 Configure

Computer

Controller

7 Test Test the link by communicating with the

* This text uses National Instruments' IBIC (Interface Bus Interactive Control) program commands

Use GPIB interface rear panel switches

SW1-4 to SW1-8 to select a unique

primary address. Setting the address

identifies the power supply to the

computer controller in a GPIB system.

Set the unit to remote mode using the

rear panel switch SW1-1 (open)

Connect the IEEE-488 bus to the supply

at connector J8.

check to ensure that the green REM

LED on the front panel is on.

Configure the controller to match the

power supply identification and

characteristics using one of the available

programs.

power supply.

developed for their GPIB interface for computer controllers as examples only.

See

“OVP Selection” on page 19

See “IEEE-488 Primary Address

Selection” on page 20

See “Remote/Local Operation” on

page 21

See “IEEE-488 Controller

Connection” on page 23

See “User Signals” on page 25 for

information about Local/Remote

OVP, TTL Shutdown, and auxiliary

connector J7 user signals.

One such program is IBCONF

(Interface Bus Configuration) from

National Instruments. This program

is used here as an example only.

Example: VSET2;ISET1

This command string sets power

supply voltage to 2V and its current

limit to 1A.

Example: ibwrt "vset2;iset1" As

above, using IBIC. *

18 Operating Manual for GPIB for XT/HPD Series Power Supply

Page 21

OVP Selection

Installation and Configuration

OVP Selection

Over voltage protection (OVP) on the GPIB Interface is set at the factory for remote

software operation. When operating the power supply in remote mode, you control

the OVP trip level using the OVSET software command. If you return the power

supply to local operation, the control of the OVP trip level switches to the front panel

potentiometer.

Jumper J217 is the OVP control jumper. Opening jumper J217 disables remote OVP

control of the power supply , limiting control of the OVP trip level to the front panel

potentiometer. The local mode disable jump er , J95, also af fects the location of OVP

control. Table 2.2 shows the jumper settings and OVP programming selection. See

“Remote/Local Operation” on page 21 for a detailed description of the local mode

disable jumper, J95

Table 2.2 OVP Control Mode Selection

PCB Jumper

J217 Position

Closed (default) Closed (default) Software or Front Panel OVP control

Closed Open Software OVP control only

Open Closed Front Panel OVP control only

Open Open Front Panel OVP control only

PCB Jumper J95

Position

OVP Programming Selection

(dependent on the power supply operating state)

19

Page 22

Installation and Configuration

IEEE-488 Primary Address Selection

IEEE-488 Primary Address Selection

1. Assign a primary address to each power supply: Choose a number between 0 and

30 which is unique to your IEEE-488 bus, that is, different from other device

addresses on the same bus.

2. Locate switch SW1 on the GPIB interface rear panel. See “Power Supply Rear

Panel with GPIB Interface Installed” on page 16 for the interface subplate

drawing.

3. Use switch positions A1 to A5 to set the primary address for the power supply.

See Table 2.3, “IEEE-488 Primary Address Selection”.

Switch 0 = (OFF, OPEN) Switch 1 = (ON, CLOSED)

Table 2.3 IEEE-488 Primary Address Selection

Address A5A4A3A2A1Address A5A4A3A2A1

0 0000016 10000

1 0000117 10001

2 0001018 10010

3 0001119 10011

4 0010020 10100

5 0010121 10101

6 0011022 10110

7 0011123 10111

8 0100024 11000

9 0100125 11001

10 0101026 11010

11 0101127 11011

12 0110028 11100

13 0110129 11101

14 0111030 11110

15 01111

Note: Ensure you assign one address to each GPIB controller board as well.

20 Operating Manual for GPIB for XT/HPD Series Power Supply

Page 23

Remote/Local Operation

You can enable or disable remote or local operation of your power supply in one of

three ways:

• Rear panel Remote/Local switch SW1-1, or

• GPIB LOC command, or

• Local Mode Disable Jumper J95 selection.

Installation and Configuration

Remote/Local Operation

Remote/Local

Switch

Use the rear panel Remote/Local switch SW1- 1 to toggle between remote and local

operation without losing programmed values. To locate the switch, refer to the

“Power Supply Rear Panel with GPIB Interface Installed” on page 16.

Rear Panel SW1-1 Position Operation Selected

Open Unit in remote mode

Closed Unit in local mode

Powering up in remote mode will result in the default operating conditions in

Table 2.4. See also “Command Reference” on page 40.

21

Page 24

Installation and Configuration

Remote/Local Operation

Table 2.4 Remote Mode Power On Conditions

Condition Default Settings 7.5-140 Model Example

Voltage 0 V VSET 0

Current 0 A ISET 0

Soft Voltage Limit VMAX (see models) VMAX 7.5

Soft Current Limit IMAX (see models) IMAX 140

OVP Trip Voltage Model VMAX + 10% OVSET 8.25

Delay 0.5 s DLY 0.5S

Foldback Protection OFF FOLD OFF

Output ON OUT ON

Hold OFF HOLD OFF

Unmask NONE UNMASK NONE

Service Request Capability OFF SRQ OFF

LOC

Command

AUXA OFF AUXA OFF

AUXB OFF AUXB OFF

The LOC command overrides the Remote/Local switch. Use LOC to enable or

disable one or all slave supplies to operate in local mode. See “Command Reference”

on page 40.

22 Operating Manual for GPIB for XT/HPD Series Power Supply

Page 25

Installation and Configuration

!

Remote/Local Operation

Local Mode

Disable

Jumper J95

IEEE-488

Controller

Connection

You can disable local control of the power supply by removing jumper J95 on the

PCB. We recommend that you remove jumper J95 only if you never plan to control

the power supply from the front panel. When the Local Mode Disable Jumpe r J95 is

closed, you can select between operating the power supply in either local mode or

remote mode by using the rear panel remote/local switch or by using the software

commands. With jumper J95 open, you can only operate the power supply in remote

mode. Opening the J95 jumper disables the rear panel remote/local switch and the

front panel voltage and current limit potentiometers. Y ou cannot return to local mode

using software commands without closing jumper J95.

Table 2.5 Local Mode Disable Jumper J95 Selection

Jumper J95 Position Operating State

Closed Remote or Local control of Power Supply

Open Software Control Only

Note: The location of over voltage protection control is dependent on the position of

jumper J95 and of OVP control jumper J217. Table 2.2, on page 19 shows how

jumper position affects the location of OVP control.

CAUTION

Do not operate power supplies at different chassis potentials. The interface

connection system is not capable of handling the resulting excessive ground

currents.

Use an approved IEEE-488 connector and cable when connecting the GPIB Interface

to your IEEE-488 GPIB network. Refer to Figure 2.2, “Power Supply Rear Panel

with GPIB Interface Installed” on page 16 for the location of the power supply

mating connector, J8.

23

Page 26

Installation and Configuration

Remote/Local Operation

Power On

Service

Request

(PON SRQ)

Setting the rear panel PON SRQ switch SW1-2 to open causes the power supply to

send a service request to the computer controller when the power supply is turned on

or when it re initializes after a momentary power interrupt. When a service request

is sent, the front panel SRQ LED will also turn on. Y ou can clear the service request

and turn off the SRQ LED by performing a serial poll. See also “Command

Reference” on page 40 for information about the SRQ command.

Table 2.6 Enable Switch Selection

Rear Panel Switch SW1-2 PON SRQ State

Open PON SRQ Enabled

Closed PON SRQ Disabled

24 Operating Manual for GPIB for XT/HPD Series Power Supply

Page 27

User Signals

Installation and Configuration

User Signals

Connector J7

User Signals

Auxiliary connector J7, located on the GPIB interface rear panel, provides several

signals to increase your operating control of the supply. These signals are dependent

on the operator's design and uses. The operation of the J7 signal requires that you

provide external Vcc and ground. T o locate the connector, refer to the GPIB interface

subplate drawing in Figure 2.2, on page 21. See Figure 2.4, “User Signals J7

Connector” on page 25 for pin descriptions.

J7-1 External TTL shutdown input signal

J7-2 Polarity signal, open collector

(asserted by VSET -x)

J7-3 Isolation signal, open collector

(asserted by OUT OFF)

J7-4 Fault signal, open collector

(asserted when bit set in fault register)

J7

J7-5 External Vcc, 18V maximum

(supplied by connecting and operating an external source)

J7-6 External ground and shutdown return

(supplied by connecting and operating an external source)

J7-7 Open collector user signal

(asserted by AUXA ON)

J7-8 Open collector user signal

(asserted by AUXB ON)

Figure 2.4 User Signals J7 Connector

25

Page 28

Installation and Configuration

User Signals

J7 Cable

Connection

R96

R96

R96

R96

R96

VCCS

5

C

U72

4N35

E

4

VCCS

/E

/C

/A

/B

7

U75

4N35

8

9

10

5

6

1

2

3

4

6

1

A

KB

2

6

1

U74

2

3

MCT6

45

1

2

MCT6

3

45

U73

1

A

KB

CR62

2

C

5

E

4

8

7

6

8

7

6

1

6

1

5

1

4

1

R61

3

1

2

R61

10k

R61

10k

R61

10k

10k

R61

10k

R63

511

/E

/D

/C

/B

/A

SHUTDOWN

EXT_VCC

AUXB

FAULT

AUXA

POLARITY

ISOLATION

EXT_GND

J7- 1

J7- 5

J7- 8

J7- 4

J7- 11

J7- 12

J7- 7

J7- 2

J7- 3

J7- 6

Figure 2.5 J7 User Signal Connector Circuit Block Diagram

Use a standard 8-position RJ45 connector and data cable to connect to J7. Add a

ferrite block to reduce radiated emission. The one inch square ferrite block with

built-in housing clip is packaged and shipped with the power supply interface card.

To install the ferrite block:

1. Position the block no more than 5 cm (2 in.) from the power supply end of the

J7 user cable.

2. Open the ferrite block housing.

3. Loop the cable through the ferrite block. See Figure 2.6, “J7 User Cable with

Ferrite Block” on page 27.

4. Close the housing clip.

The ferrite block ensures that the power supply system meets radiated emission

requirement 89/336/EEC for CE mark approval. See the power supply's operating

manual for noise specifications.

26 Operating Manual for GPIB for XT/HPD Series Power Supply

Page 29

Ferrite Block

Figure 2.6 J7 User Cable with Ferrite Block

Installation and Configuration

User Signals

J7 User Cable

To User Custom InterfaceTo J7 Connector

27

Page 30

Installation and Configuration

User Signals

28 Operating Manual for GPIB for XT/HPD Series Power Supply

Page 31

Section 3. Operation

Introduction

This section covers GPIB interface programming, starting with IEEE-488 functions,

continuing with an extensive set of GPIB commands, error codes, and status and

fault register information.

GPIB Operation

A GPIB interface controller card enables you to control an IEEE-488 bus system via

computer, identifying which of its interconnected devices are to send and receive

data. Interconnected devices could include programmable AC or DC power supplies,

oscilloscopes, signal generators, digital voltmeters, universal counters, readouts,

relays, and printers.

Use the GPIB interface to relay GPIB instructions from a computer controller to a

power supply located at a selected IEEE-488 address and then to return responses

from the power supply to the computer. You will also use the computer controller to

issue commands such as output voltage level and status queries.

Note: This text employs National Instruments' IBIC (Interface Bus Interactive

Control) program commands developed for their GPIB interface for computer

controllers as examples only.

29

Page 32

Operation

GPIB Operation

Table 3.1 IEEE-488.1 Interface Functions Implemented

Mnemonic Capability Description

SH1 Source Handshake Device must properly transfer a multiline message.

Multiline

Control

Functions

Interface

Functions

AH1 Acceptor Handshake Device must properly receive remote multiline

messages.

T6 Talker Device must be able to transmit.

L4 Listener Device must receive commands and data.

DC1 Device Clear Device can be initialized to a previously determined

state.

DT1 Device Trigger A device function can be initiated by a talker on the

bus.

E1 Open Collector Drivers Describes the type of electrical drivers in a device.

PP1 Parallel Poll Upon controller request, device must uniquely

identify itself if it requires service.

RL1 Remote/Local Device must be able to operate from front panel and

via remote information from bus.

SR1 Service Request Device can asynchronously request service from

controller.

SP1 Serial Poll All talkers on the bus assume a serial poll mode.

Each device when addressed will provide an 8-bit

word of status information.

Multiline

Control

Functions

The GPIB interface and the computer controller implement the Acceptor Handshake,

Source Handshake, Listener, and Talker functions. No user action is required. The

unit's ADR (Addressed) LED turns on when the power supply is addressed to listen

or talk.

Device Clear The power supply will implement Device Clear regardless of whether it is in local or

remote control. Device Clear is typically used to send all or selected devices to a

known state with a single command. The power supply will be set to Initial (Power

On) Conditions after Device Clear.

Example:

ibclr Low level command directed to entire bus, or

ibwrt"clr" Device-dependent command directed to a

specific device.

30 Operating Manual for GPIB for XT/HPD Series Power Supply

Page 33

Operation

GPIB Operation

Device

Trigger

Device Trigger will implement the most recently programmed values whether the

unit is in local or remote control. If the power supply is in local mode, the new values

will be implemented when it is switched from local to remote control. Device

Trigger is typically used to synchronize the operation of a number of addressed

devices.

Example: Use HOLD Command to set values to be executed when triggered. See

“Command Reference” on page 40.

Then use:.

ibtrg Command directed to entire bus, or

ibwrt"trg" Command directed to a specific device.

Parallel Poll Parallel Poll allows the computer controller to determine quickly which of a number

of instruments on the bus requested service. The parallel poll response corresponds

to bit 7 of the serial poll status byte. Parallel Poll does not reset the service request.

The power supply must be configured remotely to respond to a parallel poll with

either a "1" or "0" on one of the DIO lines if the unit is requesting service.

Example:

ibrpp Conduct a parallel poll.

Service

Request

Service request is a uniline message asserted by the power supply at power on and

for fault conditions. Six (6) power supply conditions are defined as faults: CV, CC,

OV, SD, FOLD, and ERR. See “Accumulated Status, Status, and Fault Registers” on

page 48 for more information. Power ON (PON) can also be flagged in the fault

register if the supply's rear panel power on service request (PON SRQ) switch is set

to ON. See “Power On Service Request (PON SRQ)” on page 24.

Enabling or disabling a condition from asserting service request does not affect the

condition within the power supply, nor the external status indicators.

31

Page 34

Operation

GPIB Operation

Serial Poll In a serial poll, the controlle r polls each device.

Example:

ibrsp Return serial poll byte.

The power supply responds with a 8-bit status byte defined as follows:

Table 3.2 Serial Poll St atus Register

Bit

Position

0 (LSB) 1 Fault - Set when any bit in the fault

Decimal

Weight

Description Reset By

register is set by a fault condition in the

supply. See also

Status, Status, and Fault Registers”

on page 48

1 2 Not used

2 4 Not used

3 8 Not used

416Ready - Set when power supply is

ready to accept commands.

532Error (ERR) - Set when ERR bit

asserted in status register. See also

.

“Accumulated Status, Status, and

Fault Registers” on page 48

664Request Service (SRQ) - Set when

power supply requests service.

7 (MSB) 128 Power On (PON) - Set when unit

initializes at power on.

FAULT? query to reset

“Accumulated

Power supply, during

command processing

period

ERR? query or a new

error-free command

.

Serial Poll

CLR or Device Clear

32 Operating Manual for GPIB for XT/HPD Series Power Supply

Page 35

Command Syntax

Operation

Command Syntax

Manual

Conventions

The manual uses these conventions when displayi ng co mmand info rmatio n. These

characters are not part of the command but are used to denote parameters used with

the command.

< > (angle brackets) Angle brackets enclose a parameter. Do not include

the angle brackets in the command line you send to

the computer.

/ (slash) Separates two alternative parameters. When a slash

separates two parameters, you can use either

parameter to achieve the same result.

Example:

Entering

COMPUTER ENTRY Words typed on the computer are shown in Arial

text, full capitals.

<1/ON>

1 or ON will achieve the same result.

33

Page 36

Operation

Command Syntax

Command

Format and

Parameters

The device-dependent language for the GPIB Interface consists of commands and

parameters. A command is a one word code which either gives instructions to the

interface or asks for information from the interface. A command may be followed by

one or more parameters, a short code that changes the state of the power supply or

the state of the bit register. Table 3.3, “Command Parameters” lists the parameters

that affect the command set.

Format:

COMMAND or

COMMAND <parameter> or

COMMAND <parameter>,<parameter>

• You can enter commands in upper or lower case lettering.

Example: MASK FOLD = mask fold

• Do not further abbreviate command names or parameters.

Example: MASK FOLD ≠ MK FOLD

MASK FOLD ≠ MASK FD

• Use a space between the command and the first parameter. Any number of

consecutive spaces is treated as one space. Numeric data may contain leading

spaces. Embedded spaces between digits or between a digit and a decimal point

are not accepted.

Example: MASK FOLD = MASK FOLD

VOUT 3.4 = VOUT 3.4

VOUT 3.4 ≠ VOUT 3. 4

• Use commas between parameters in those commands with more than one

parameter, and between mnemonic para meters as in the MASK and UNMASK

commands. Only one comma is allowed and it may be preceded or followed by

any number of spaces.

Example: MASK CV, OV, FOLD

34 Operating Manual for GPIB for XT/HPD Series Power Supply

Page 37

Command Syntax

Table 3.3 Command Parameters

Parameter Description Form

<current> The current in amps or milliamps. If no unit is

given, the default unit is amps.

<seconds> The time in seconds or milliseconds. If no unit

is given, the default unit is seconds.

<voltage> The voltage in volts or millivolts. If no unit is

given, the default unit is volts.

<fault mask> A combination of CV, CC, CV, OV, SD and

FOLD. See MASK and UNMASK commands

in the command reference for use of the ALL

and NONE parameters.

<status mask> A combination of CV, CC, OV, SD, FOLD,

ERR, and REM. See MASK and UNMASK

commands in the command reference for use

of the ALL and NONE parameters.

<other> Command-specific parameters such as 1, 0,

ON, OFF, ALL or NONE.

<float>

<float>A

<float>mA

<float>

<float>s

<float>ms

<float>

<float>V

<float>mV

See registers

on page 48.

See registers

on page 48.

Operation

Floating Point Number <float> Variables sent with command parameters are

floating point numbers. T able 3.4 defines the structure of floating point numbers for

use with the software commands.

Table 3.4 Floating Point Numbers

Floating Number Definition Example

The floating point number has four significant figures. It can be of either sign, positive or negative.

A floating point number can have a decimal point. 0.123

Scientific Notation

Use E or e after the number for a base ten exponent.

An integer of either sign must follow an exponent.

1.234

-1.234

+1.234

1.2

123.4

123.0E-1

1.2E-1

10.00E+1

35

Page 38

Operation

Command Syntax

Command

Strings

Command

Terminators

If you send more than one command line, separate the commands with a semicolon.

The semicolon may be preceded or followed by spaces.

Example:

ISET 2.0A ; VSET 5V

ISET 2.0A ; VSET 5V

Terminators indicate the end of a command string and tell the power supply to

execute the command. The termination character is LF (Line Feed).

Format:

COMMAND1 <parameter1>; COMMAND2 <parameter1>, <parameter2><LF>

Most computer controllers automatically send LF with output statements.

You may also terminate commands by asserting EOI on the GPIB concurrently with

the last byte of the command.

Example:

VMAX 5.25

E

O

I

All data sent by the power supply to the computer controller is terminated by a

carriage return and a line feed character. EOI is asserted concurrently with a linefeed.

Example:

VMAX 5.250<CR><LF>

E

O

I

Order You may send commands in any order, keeping in mind that only those commands

received after a HOLD and before a TRG (trigger) will be released by the TRG

command. In addition, only these commands received after a supply disable and

before a RST (reset) or OUT ON command will be released by the RST command

or the OUT command. Commands are executed in the order they are received.

36 Operating Manual for GPIB for XT/HPD Series Power Supply

Page 39

Command Summary

Use these commands to control the operation of the supply. They are listed here by

function: PROGRAMMING , QUER Y, CALIBRATION, and ST ATUS commands.

See “Command Reference” on page 40 for more detailed information about each

command and its use.

Table 3.5 Programming Commands

Command Description

AUXA Selects the state of the AUXA output signal on the J7-7 connector.

AUXB Selects the state of the AUXB output signal on the J7-8 connector.

CLR Initializes the power supply to its Power ON (PON) state.

DLY Sets a programmable time delay which is executed by the supply

FOLD Sets foldback mode for the supply.

HOLD Enables or disables voltage/current setting hold mode for the supply.

IMAX Sets an upper soft limit on the programmed output current for the

ISET Sets the output current of the supply in amps (default) or in milliamps.

LOC Enables or disables the supply to operate in local mode.

OUT Enables or disables voltage/current output for the supply.

OVSET Sets the over voltage protection trip point for the supply in volts

RST Resets the supply to the present voltage and current settings if the

SRQ Enables or disables the power su pply's ability to generate a service

TRG Implements programmed voltage and current settings which had been

VMAX Sets an upper soft limit on the supply’s programmed output voltage.

VSET Sets the output voltage of the power supply in volts (default) or in

Operation

Command Summary

before reporting fault conditions after a new output voltage or current is

specified.

supply.

(default) or in millivolts.

output is disabled by OVP or foldback protection.

request.

in hold mode.

millivolts.

37

Page 40

Operation

Command Summary

Table 3.6 Query Commands

Command Description

AUXA? Asks for the state of the set value for the AUXA command

AUXB? Asks for the state of the set value for the AUXB command

CMODE? Asks for the power supply’s calibration mode status.

DLY? Asks for the programmable time delay setting before the supply

reports fault conditions.

ERR? Asks for the most recent remote programming error which occurred in

the supply since the last time the error query command (ERR?) was

used.

FOLD? Asks for the supply’s present foldback setting.

HOLD? Asks for the present hold mode setting.

ID? Asks for the power supply’s model name and master EPROM version.

IMAX? Asks for the supply’s soft current limit setting.

IOUT? Measures the supply’s actual current output.

ISET? Asks for the supply’s present output current limit setting.

LOC? Queries the present enabled/disabled status of local mode operation

for the supply.

OUT? Asks for the present enabled/disabled status of the supply’s output.

OVSET? Asks for the supply’s present over voltage protection limit.

ROM? Asks for the version number of the master and slave EPROMs on the

interface PCB.

SRQ? Asks for the present enabled/disabled status of the IEEE-488 Service

Requests generated by the supply.

VMAX? Asks for the supply’s soft voltage limit setting.

VOUT? Measures the supply’s actual voltage output.

VSET? Asks for the supply’s present output voltage setting.

38 Operating Manual for GPIB for XT/HPD Series Power Supply

Page 41

Command Summary

Table 3.7 Calibration Commands

Command Description

CMODE Places the supply into calibration mode.

IDATA Calculates the slope and intercept for current programming.

IHI Sets the current output to the high calibration point.

ILO Sets the current output to the low calibration point.

IRDAT Calculates the slope and intercept for current readback.

IRHI Sets the current output to the high readback point.

IRLO Sets the current output to the low readback point.

OVCAL Calibrates the over voltage protection (OVP).

VDATA Calculates the slope and intercept for voltage programming.

VHI Sets the voltage output to the high calibration point.

VLO Sets the voltage output to the low calibration point.

VRDAT Calculates the slope and intercept for voltage readback.

VRHI Sets the voltage output to the high readback point.

VRLO Sets the voltage output to the low readback point.

Operation

Table 3.8 Status Commands

Command Description

ASTS? Asks for the supply’s accumulated status register.

FAULT? Asks for the supply’s fault register for the status preset operating

conditions.

MASK Prevents the supply's previously unmasked operating conditions from

setting bits in the fault register.

STS? Asks for the supply’s present status register.

UNMASK Enables you to select those supply's operating conditions that you are

most interested in monitoring for fault occurrence.

UNMASK? Asks for the supply's fault conditions which are currently enabled

(unmasked).

39

Page 42

Operation

Command Reference

Command Reference

Table 3.9 Command Reference

Command Description

ASTS? Returns the supply’s accumulated status register. The accumulated status

register stores any bit that was entered in the status register since the

accumulated status query command (ASTS?) was last used, regardless of

whether the condition still exists. Bits in the accumulated status register

represent the bits and conditions of the bits in the status register . A bit in the

accumulated status register will be set at 1 if the corresponding bit in the

status register has been 1 (TRUE) at any time since the register was last

read. See

The ASTS? query clears the accumulated status register.

Response: ASTS <status mask> where status mask is the decimal

equivalent of the total bit weights for the operating conditions as listed in the

status register.

AUXA <1/ON>,<0/OFF> Sets the AUXA output signal level at rear panel connector J7-7. Active low.

Initial value: AUXA 0

AUXA? Returns the present set value of the AUXA output signal.

Response: AUXA 0 (OFF)

AUXB <1/ON>,<0/OFF> Sets the AUXB output signal level at rear panel connector J7-8. Active low.

Initial value: AUXB 0

AUXB? Returns the present set value of the AUXB output signal.

Response: AUXB 0 (OFF)

CLR Initializes the power supply to its power ON condition. If issued while in local

mode, CLR will force power supply settings to register default values as in

but these default settings will not come into effect until the power supply is

switched to remote mode operation. The CLR commands will clear faults

from the fault register. CLR will not reset CMODE.

CMODE <1/ON>,<0/OFF> CMODE ON places the power supply into calibration mode for processing

calibration commands.

Initial value: CMODE OFF or CMODE 0

CMODE? Returns the power supply’s calibration mode status.

Response: CMODE 0 (disabled)

“Accumulated Status, Status, and Fault Registers” on page 48.

AUXA 1 (ON)

AUXB 1 (ON)

CMODE 1 (enabled)

40 Operating Manual for GPIB for XT/HPD Series Power Supply

Page 43

Operation

Command Reference

Command Description

DLY <seconds> Sets a programmable time delay employed by the supply before reporting

fault conditions. The power supply uses the time delay after receiving a new

output voltage or current setting via VSET or ISET, or after receiving RST,

TRG, or OUT ON commands. During the time delay, the power supply

disables CV, CC, and FOLD conditions from generating faults, preventing

possible nuisance foldback if the supply momentarily switches modes while

changing an output setting.

Range: 0 to 32 seconds, with 32ms resolution

Initial value: 0.5 second

DLY? Returns the setting of the programmable time delay before the supply

reports fault conditions.

Response: DLY <seconds>

ERR? Returns the most recent remote programming error. When the power supply

detects a programming error, it lights the ERR LED and sets the ERR bit in

the accumulated status and fault registers. If the error bit has been masked

using the MASK command, then the ERR bit in the registers will not set.

Once an error is detected, the remaining portion of the command line is

discarded. An error query clears the ERR bit in the accumulated status

register. See

Response: ERR <error number> Example: ERR 0 (if no error)

FAULT? Returns the state of the fault register. A bit is set in the fault register when a

fault arises for that condition. Lists the conditions which activate a fault bit.

You can use the MASK command to disable bits from being set in the fault

register.

When a bit is set in the fault register it also asserts a signal on the J7-4 user

signal line. You can tie the J7-4 fault line signal to the power supply's own

External Shutdown user line, J7-1, so that the shutdown signal goes low

(active) in the case of a user-defined fault.

The FAULT? query clears bits in the supply's fault register and fault line.

Response: FAULT <fault mask> where fault mask is the decimal equivalent

of the total bit weights for the operating conditions as listed in the fault

register. See

.

48

FOLD

<2/CC>, <1/CV>,

<0/OFF>

Sets foldback mode for the supply. Foldback protection disables the power

supply output when the output enters the fold condition. Reset with the RST

command.

Example: Specify FOLD 1 or FOLD CV (Constant Voltage) when you want

the supply to operate in Constant Current mode and have foldback

protection disable the output if the supply switches to Constant Voltage

mode.

Initial value: FOLD 0/OFF

“Error Codes” on page 49.

“Accumulated Status, Status, and Fault Registers” on page

41

Page 44

Operation

Command Reference

Command Description

FOLD? Returns the supply’s present foldback setting.

Response: FOLD <mode> where mode is:

0 (OFF) or

1 (CV or Constant Voltage mode) or

2 (CC or Constant Current mode)

HOLD <1/ON>,<0/OFF> Enables or disables voltage/current setting hold mode for the supply. When

HOLD ON is specified, hold mode is enabled so that all voltage and current

settings which would normally be applied immediately are held until a TRG

(trigger) command is received. This feature allows you to synchronize the

operation of several supplies.

Initial value: HOLD OFF or HOLD 0

HOLD? Returns the present hold mode setting.

Response: HOLD 0 (OFF or disabled) or

HOLD 1 (ON or enabled)

ID? Returns the power supply model and the master EPROM version.

Response: ID <model name><version>

IDATA <Ilo>,<Ihi> Calculates and records the slope and offset for programmed current using

ILO and IHI data. Set CMODE ON before using this command. See also the

calibration procedures in Section 4.

<Ilo> and <Ihi> are in <current> format.

IHI In response to this command, the power supply sends a programmed

current value to the output terminal. This value is at the high end of the

power supply’s current range and is read by an external device connected

as part of the calibration procedure. Refer to this value as IHI and record it

to use as input with the IDA TA command. Set CMODE ON before using this

command. See also the calibration procedures in Section 4.

ILO In response to this command, the power supply sends a programmed

current value to the output terminal. This value is at the low end of the

power supply’s current range and is read by an external device connected

as part of the calibration procedure. Refer to this value as ILO and record it

to use as input with the IDA TA command. Set CMODE ON before using this

command. See also the calibration procedures in Section 4.

IMAX <current> Sets an upper soft limit on the supply’s programmed output current. If the

soft limit is exceeded, or if the soft limit value is lower than the present

output current setting, the supply will ignore the command, turn on the

ERR LED, and set the ERR bit in the bit registers.

Range: 0 to model maximum output current (IMAX)

Initial value: model IMAX

IMAX? Returns the supply’s soft current limit setting.

Response: IMAX <current>

IOUT? Measures and returns the supply’s actual current output using the built-in

current readback circuitry.

Response: IOUT <current>

42 Operating Manual for GPIB for XT/HPD Series Power Supply

Page 45

Operation

Command Reference

Command Description

IRDAT <Ilo>,<Ihi> Calculates and records the slope and offset for readback voltage using

IRLO and IRHI data. Set CMODE ON before using this command. See also

the calibration procedures in Section 4.

<Ilo> and <Ihi> are in <current> format.

IRHI The power supply outputs a current value to an external device connected

as part of the calibration procedure and records a current readback value

internally. These values are at the high end of the programmed current

range. Refer to the output value as IRHI and record it to use as input with

the IRDAT command. Set CMODE ON before using this command. See

also the calibration procedures in Section 4.

IRLO The power supply outputs a current value to an external device connected

as part of the calibration procedure and records a current readback value

internally. These values are at the low end of the programmed current

range. Refer to the output value as IRLO and record it to use as input with

the IRDAT command. Set CMODE ON before using this command. See

also the calibration procedures in Section 4.

ISET <current> Sets the power supply’s output current in amps (default) or in milliamps.

This programmed current is the actual output in CC mode or the current

limit in CV mode.

Range: 0 to model maximum output current (IMAX)

Initial value: 0 amps

ISET? Returns the supply’s present output current setting. Does not apply to

current settings which are being held. See HOLD command.

Response: ISET <current>

MASK <mnemonics> Disables the supply's previously unmasked operating conditions from

setting bits in the fault and status registers. See

“Accumulated Status,

Status, and Fault Registers” on page 48. Mnemonics are separated from

each other by commas and may be sent in any order.

Mnemonics: CV, CC, OV, SD, FOLD, ERR, PON, ALL, NONE

Note: UNMASK NONE = MASK ALL (Initial value)

MASK NONE = UNMASK ALL

43

Page 46

Operation

Command Reference

Command Description

OUT <1/ON>,<0/OFF> Enables or disables the supply’s voltage/current output. The supply will

continue to accept new commands while the output is disabled but these

will not be implemented until OUT ON or OUT 1 is received. OUT ON is the

default setting. When you start the supply in remote mode, the output is

enabled.

OUT OFF (or OUT 0) also sets the isolation signal on the rear panel J7

connector, line 3. Y ou can use the to trip external relays to isolate the power

supply from the load.

Initial value: OUT ON (or OUT 1) for output enabled

OUT? Returns the present enabled/disabled status of the supply’s output

voltage/current.

Response: OUT 1 output enabled or

OUT 0 output disabled

OVCAL Causes the master controller to perform automatic calibration of the

supply’s over voltage protection circuitry. Set CMODE ON before using this

command. Ensure jumper J217 on the GPIB Interface PCB is connected for

remote operation.

OVSET <voltage> Sets the supply’s over voltage protection trip point in volts (default) or in

millivolts. If the trip point is exceeded, or if the trip point value is lower than

the present output voltage setting, the supply will ignore the command, turn

on the ERR LED, and set the ERR bit in the accumulated status register.

Reset with the RST command.

Range: 0 to 110% of model maximum output voltage (VMAX)

Initial value: 110% of model VMAX

OVSET? Returns the supply’s present over voltage protection limit.

Response: OVSET <voltage>

ROM? Returns the version number of the master and slave EPROMs located on

the interface PCB.

Response: ROM M:<version> S:<version>

RST Resets the supply to present voltage and current settings if the output is

disabled by over voltage or foldback protection. Output values may be

changed via VSET, ISET, and OVSET while the unit is disabled, but those

values will not take effect until RST is applied.

44 Operating Manual for GPIB for XT/HPD Series Power Supply

Page 47

Operation

Command Reference

Command Description

SRQ <1/ON>,<0/OFF> SRQ ON enables the supply to respond to a variety of fault conditions with a

request for service to the IEEE-488 bus controller. With SRQ ON, the SRQ

line will be asserted true whenever the FAULT bit in the supply's serial poll

register changes from 0 to 1. Therefore, the mask register, in addition to

specifying which conditions set the FAULT bit, also determines which

conditions can generate service requests. Ten power supply conditions are

defined as faults: CB, CC, OV, OTP, SD, ERR, FOLD, ACF, OPF, SNSP.

Use the FAULT? query to discover which condition caused the service

request. See

. A request for service at Power ON (PON SRQ) is set via a rear panel

48

switch on the supply. See

page 24

is cleared by a FAULT? query.

SRQ? Returns the supply's present ability to generate service requests.

Response: SRQ 0 (disabled)

STS? Returns the supply’s present status register. Status conditions are stored in

the status register. Each bit represents a separate condition. When the

condition is true, the corresponding bit is 1 (true). Bits remain set in the

status register as long as the condition is true. See

“Accumulated Status, Status, and Fault Registers” on page

“Power On Service Request (PON SRQ)” on

. SRQ remains disabled until the FAULT bit in the serial poll register

SRQ 1 (enabled)

“Accumulated Status,

Status, and Fault Registers” on page 48.

Response: STS <status mask> where status mask is the decimal equivalent

of the total bit weights for the operating conditions as listed in the status

register.

TRG Causes programmed voltage and current settings which had been in hold

mode to be applied. The supply operates with previous values until the TRG

(trigger) command is sent.

UNMASK <mnemonics> Selects the supply operating conditions that you are most interested in

monitoring for fault occurrence. Mnemonics describing the conditions are

separated from each other by commas, and may be sent in any order.

Specifying one or more mnemonics which describe the conditions (or the

decimal equivalent of their total bit weight) enables the selected conditions

to set bits in the supply’s fault and status registers during operation. A bit is

set in the fault register when the corresponding bit in the status register

changes from 0 to 1 and the corresponding bit in the mask register is 1. See

“Accumulated Status, Status, and Fault Registers” on page 48.

Mnemonics: CV, CC, OV, SD, FOLD, ERR, PON, ALL, NONE

Initial value: UNMASK NONE

UNMASK? Returns the supply's fault conditions which are currently enabled

(unmasked).

Response: UNMASK <fault mask> where fault mask is the decimal

equivalent of the total bit weights for the operating conditions as listed in the

status and fault registers See

Registers” on page 48

“Accumulated Status, Status, and Fault

.

45

Page 48

Operation

Command Reference

Command Description

VDATA <Vlo>,<Vhi> Calculates and records the slope and offset for programmed voltage using

VLO and VHI data. Set CMODE ON before using this command. See also

the calibration procedures in Section 4.

<Vlo> and <Vhi> are in <voltage> format.

VHI In response to this command, the power supply sends a programmed

voltage value to the output terminal. This value is at the high end of the

power supply’s voltage range and is read by an external device connected

as part of the calibration procedure. Refer to this value as VHI and record it

to use as input with the VDATA command. Set CMODEON before using

this command. See also the calibration procedures in Section 4.

VLO In response to this command, the power supply sends a programmed

voltage value to the output terminal. This value is at the low end of the

power supply’s voltage range and is read by an external voltmeter

connected as part of the calibration procedure. Refer to this value as VLO

and record it to use as input with the VDATA command. Set CMODE ON

before using this command. See also the calibration procedures in

Section 4.

VMAX <voltage> Sets an upper soft limit on the supply’s programmed output voltage. If the

soft limit is exceeded, or if the soft limit value is lower than the present

output voltage setting, the supply will ignore the command, turn on the

ERR LED, and set the ERR bit in the accumulated status register.

Range: 0 to model maximum output voltage (VMAX)

Initial value: model VMAX

VMAX? Returns the supply’s soft voltage limit setting.

Response: VMAX <voltage>

VOUT? Measures and returns the supply’s actual voltage output using the built-in

voltage readback circuitry.

Response: VOUT <voltage>

VRDAT <Vlo>,<Vhi> Calculates and records the slope and offset for readback voltage using

VRLO and VRHI data. Set CMODE ON before using this command. See

also the calibration procedures in Section 4 .

<Vlo> and <Vhi> are in <voltage> format.

VRHI The power supply outputs a voltage value to an external voltmeter

connected as part of the calibration procedure and records a voltage

readback value internally. These values are at the high end of the

programmed voltage range. Refer to the output value as VRHI and record it

to use as input with the VRDAT command. Set CMODE ON before using

this command. See also the calibration procedures in Section 4.

46 Operating Manual for GPIB for XT/HPD Series Power Supply

Page 49

Operation

Command Reference

Command Description

VRLO The power supply outputs a voltage value to an external voltmeter

connected as part of the calibration procedure and records a voltage

readback value internally. These values are at the low end of the

programmed voltage range. Refer to the output value as VRLO and record it

to use as input with the VRDAT command. Set CMODE ON before using

this command. See also the calibration procedures in Section 4.

VSET <voltage>

or

VSET <-voltage>

Sets the power supply’s output voltage in volts (default) or in millivolts. This

programmed voltage is the actual output in CV (constant voltage) mode or

the voltage limit in CC (constant current) mode.

If you enter a negative voltage value, the power supply will assert a signal

on the J7-4 user signal line. You can use the user signal to trip external

relays to switch the output polarity.

Range: 0 to model maximum output voltage (VMAX)

Initial value: 0 volts

VSET? Returns the power supply’s present output voltage setting. Does not apply

to voltage settings which are being held. See HOLD command.

Response: VSET <voltage>

47

Page 50

Operation

Accumulated Status, Status, and Fault Registers

Accumulated Status, Status, and Fault Registers

The GPIB option card uses three separate registers which are always active. They

are the accumulated status, status, and fault registers. You can use the status

commands shown in Table 3.8, “Status Commands” to activate the registers. The

bit register has eight conditions, each assigned a bit weight. When querying a

register, the controller returns a response which is the sum of the weights of all

relevant conditions.

Example:

ASTS? Query the Accumulated Status register.

ASTS 771 Controller response.

771 = 512 + 256 + 2 + 1 = PON + REM + CC + CV

The accumulated status register shows that PON, REM, CC and CV have all been

active since the last accumulated register query.

T able 3.10 shows the mnemonics and bit weights which correspond to each register

condition. You can control conditions in the fault and status register by using the

MASK and UNMASK commands.

Table 3.10 Accumulated Status, Status, and Fault Registers

Condition Mnemonic Bit Position Bit Weight

Constant voltage operation CV 0 1

Constant current operation CC 1 2

Not used – 2 4

Overvoltage protection tripped OV 3 8

Not used – 4 16

Supply external shutdown active (J7-1) SD 5 32

Foldback mode operation FOLD 6 64

Remote programming error ERR 7 128

Power ON (accumulated status, status

registers only)

Remote mode (accumulated status, status

registers only)

PON 8 256

REM 9 512

Notes:

1. Only CV, CC, OV, SD, ERR, PON and FOLD can be masked or unmasked.

2. The error (ERR) bit is reset in the accumulated status, status, and serial poll registers with an

error query (ERR?).

3. The accumulated status register is cleared with an accumulated status query (ASTS?).

4. A fault is cleared with a fault query (FAULT?).

48 Operating Manual for GPIB for XT/HPD Series Power Supply

Page 51

Error Codes

Operation

Error Codes

If the ERR flag in the accumulated status or fault registers has been activated, an

ERR? query will return an error number which corresponds to an event described

in the following table. The ERR? query will also clear the ERR bit in the register.

Table 3.11 Error Codes

ERROR # ERROR IDENTIFICATION EXPLANATION

0No Errors

4 Unrecognized Character Received a character such as @,*,$.

Improper Number Received a numeric character but the