Page 1

p r e s s u r e

Specification Sheet

SS-2110-HL

Presure Range

100 to 22,500 kPa (10 to 3,000 psi)

Accuracy

to ±0.05% of Indicated Reading

Available units

psi, kg/cm2, bar, kPa

Interchangeable Weights

Models are available with dual piston/cylinder assemblies that utilize one

weight set.

Compact Design and Portability

The HydraLite is designed for use in the

field and is completely self-contained

within the cover of the unit.

Includes Compact Screw Pump

with Ratchet Handle

The tester models are supplied with a

convenient screwpump as a pressure

source. This pump has a ratchet feature

that prevents the unit from depressurizing unexpectedly.

The gauge model can be retrofitted with

the pump as an accessory.

Model HL

®

Hydraulic and Gauge

Deadweight Tester

PRODUCT DESCRIPTION

The HydraLite Hydraulic Deadweight Tester is a primary standard

that features a re-entrant type measuring piston and cylinder assembly that helps maintain accuracy as the test pressure increases.

The HL Series tester is designed for rapid interchanging between

high and low pistons and is NIST traceable and accurate to ±0.05%

using non-magnetic die-cast alloy or aluminum weights calibrated

to international standard gravity at 9.80665 m/s2. A compact screw

pump with ratchet handle is easy-to-use. The unit is also available

as a deadweight gauge for accurate measurements and use as a

comparison standard.

Low center of gravity

he HL tester is an easy-to-use and portable primary standard capable

of offering laboratory accuracy in the field. The unit is designed to be

self-contained with all necessary components stored under the cover.

A screwpump pressure source on the tester model offers a convenient

method to raise and lower pressure for rapid testing.

Overhung Weight Carrier

Reduces side thrust and friction on the

measuring piston and cylinder assembly, thus improving measurement accuracy

Positive Over-pressure Protection

Prevents Piston Damage

NIST Traceable

All units are supplied with certifications

that are traceable to NIST.

ISO 9001 Manufacturer

Page 2

Model HL

®

Hydraulic Deadweight Tester

Specification Sheet

SS-2110-HL

FEATURES

Two accuracies available

These instruments are available in ±0.100% and ±0.050%

of reading. The accuracy stated is the overall accuracy of

the tester. The accuracy takes into account linearity, hysteresis, and repeatability. It would also account for intrinsic

corrections. Site corrections are the user’s responsibility

and the unit will not perform as specified without them.The

testers are manufactured to International Standard Gravity

and a local gravity site correction is easily performed with

a ratio correction to the output.

Easy Leveling

AMETEK floating ball testers incorporate a bulls-eye level

for reference when preparing the unit for use. The tester

also employs a 3-leg leveling system which is more con-

venient and is superior to a 4-leg system.

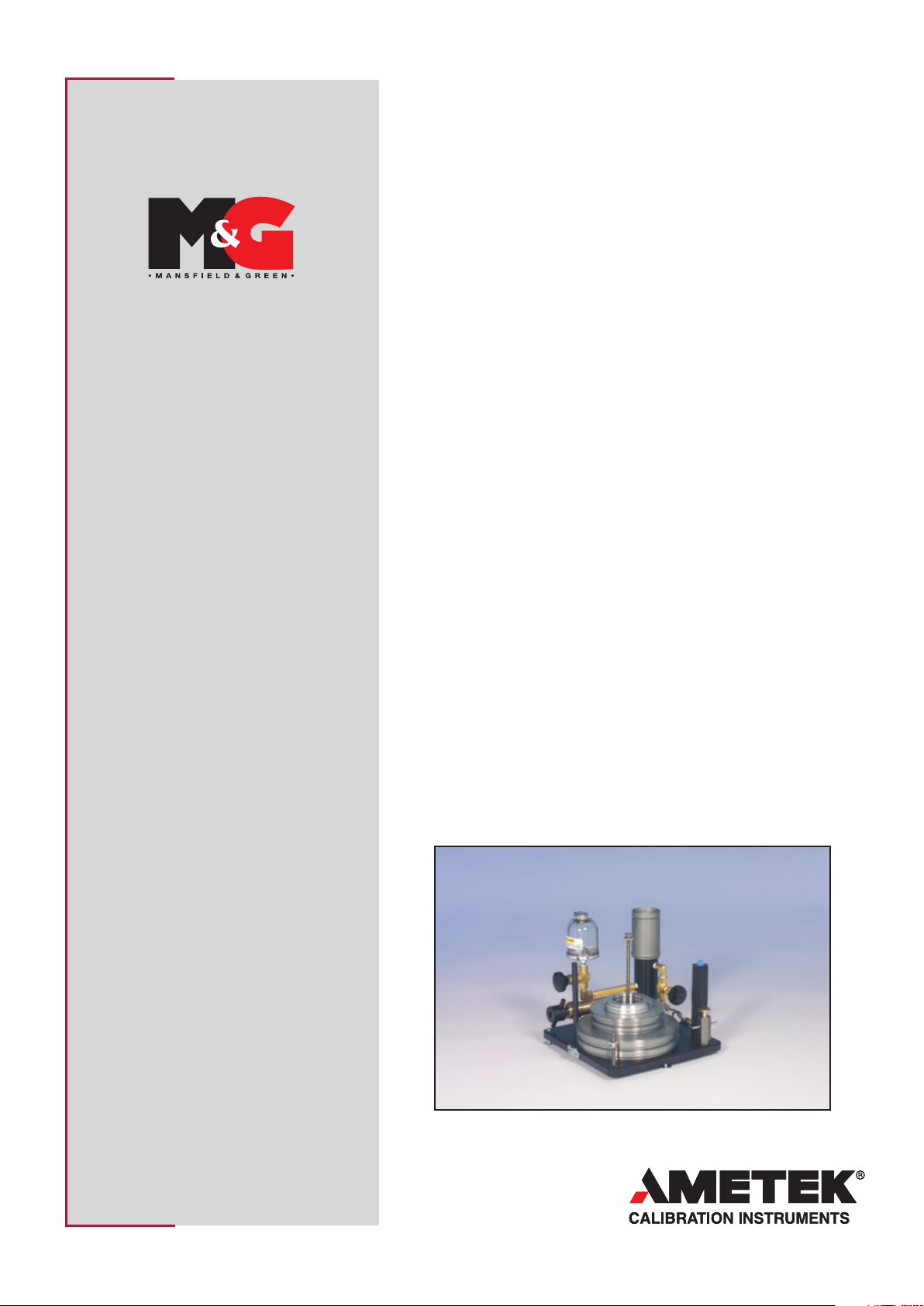

Re-entrant piston / cylinders

The HL deadweight

employs a re-entrant

type piston/cylinder

assembly. This design

applies test fluid to

the outside and inside

of the cylinder. Unlike

a simple piston/cylinder, this configuration

reduces clearance

between the piston

and cylinder as pressure increases. This

reduces the rate of

fluid leakage and

increases float time, offers the technician more time for

testing, and reduces the amount of pumping necessary to

sustain the fluid loss.

Pressure media

Because the HL is manufactured using brass and aluminum components, AAA Tester Oil is the recommended

and supplied pressure media. Other fluids compatible with

stainless steel, brass, aluminum, and Buna may be used;

however, consideration should be given to the cleanliness

of the fluid. AAA Tester Oil is triple-filtered to remove suspended solids that can harm the piston/cylinder assembly.

Overhung weight carriers

Another feature of HL deadweight tester is the way that

the weights are positioned on the carrier - an overhung

weight carrier design. This design employs a tube carrier

that is positioned over the column and onto the piston

driver, which lowers the center of gravity of the weights

reducing side thrust and friction. This design lengthens

the life of the piston and cylinder assembly thus improving

measurement accuracy.

Over-pressure protection

The measuring pistion assembly features positive overpressure protection restrivting vertical movement of the

measuring piston by a piston cap. This positive stop will

prevent the piston from damage due to accidental removal

of the weights when pressurized.

Worldwide engineering units

The HL deadweight tester and HLG gauge can be manufactured in four different engineering units: psi, bar, kg/

cm2, and kPa. All of the different engineering units are

available in any of the configurations.

HydraLite HLG Gauge

The AMETEK HydraLite HLG Gauge is a precision, portable instrument used to accurately measure pressure in

field conditions. The HydraLite HLG gauge may be used

as a primary standard instrument where a high accuracy reference measurement is needed. Simply connect

the gauge to the process and add weights until there

is a proper float. Standard accuracy is ±0.1% of indicated pressure traceable to the U.S. National Institute of

Standards and Technology (NIST). The instrument may

also be specified with +0.05% accuracy.

If you initially need a gauge and later find that you need a

full tester, an accessory kit is available to incorporate the

screwpump into the gauge.

2 www.ametekmg.com

Page 3

Model HL

®

Hydraulic Deadweight Tester

Specification Sheet

SS-2110-HL

ORDERING INFORMATION

Base model

HL- Single piston/cylinder assembly, imperial engineering units, 0.100%

accuracy, standard accessories, NIST traceable certificate

HLG- Single piston/cylinder assembly, imperial engineering units, 0.100%

accuracy, standard accessories, NIST traceable certificate

Range options

Model Operating range Increment Piston area Weight set

2 10 to 200 psi 0.1 psi 0.05 in² 1

4 10 to 400 psi 0.1 psi 0.05 in² 2

6 10 to 600 psi 0.1 psi 0.05 in² 3

10 50 to 1,000 psi 0.5 psi 0.01 in² 1

20 50 to 2,000 psi 0.5 psi 0.01 in² 2

30 50 to 3,000 psi 0.5 psi 0.01 in² 3

Base model

HL- Single piston/cylinder assembly, metric engineering units, ±0.100%

accuracy, standard accessories, NIST traceable certificate

HLG- Single piston/cylinder assembly, metric engineering units, ±0.100%

accuracy, standard accessories, NIST traceable certificate

Range options

Model Operating range Increment Piston area Weight set

15M 1 to 15 kg/cm² 0.005 kg/cm² 0.05 in² 1M

30M 1 to 30 kg/cm² 0.005 kg/cm² 0.05 in² 2M

45M 1 to 45 kg/cm² 0.005 kg/cm² 0.05 in² 3M

75M 5 to 75 kg/cm² 0.025 kg/cm² 0.01 in² 1M

150M 5 to 150 kg/cm² 0.025 kg/cm² 0.01 in² 2M

225M 5 to 225 kg/cm² 0.025 kg/cm² 0.01 in² 3M

15B 1 to 15 bar 5 mbar 0.05 in² 1N

30B 1 to 30 bar 5 mbar 0.05 in² 2N

45B 1 to 45 bar 5 mbar 0.05 in² 3N

75B 5 to 75 bar 25 mbar 0.01 in² 1N

150B 5 to 150 bar 25 mbar 0.01 in² 2N

225B 5 to 225 bar 25 mbar 0.01 in² 3N

1500N 100 to 1,500 kPa 0.5 kPa 0.05 in² 1N

3000N 100 to 3,000 kPa 0.5 kPa 0.05 in² 2N

4500N 100 to 4,500 kPa 0.5 kPa 0.05 in² 3N

7500N 500 to 7,500 kPa 2.5 kPa 0.01 in² 1N

15000N 500 to 15,000 kPa 2.5 kPa 0.01 in² 2N

22500N 500 to 22,500 kPa 2.5 kPa 0.01 in² 3N

ORDERING INFORMATION

Base model

HL- Dual piston/cylinder assembly, imperial engineering units, ±0.100%

accuracy, standard accessories, NIST traceable certificate

HLG- Dual piston/cylinder assembly, imperial engineering units, ±0.100%

accuracy, standard accessories, NIST traceable certificate

Range options

Model Operating range Increment Piston area Weight set

12 10 to 200 psi 0.1 psi 0.05 in² 1

50 to 1,000 psi 0.5 psi 0.01 in²

24 10 to 400 psi 0.1 psi 0.05 in² 2

50 to 2,000 psi 0.5 psi 0.01 in²

36 10 to 600 psi 0.1 psi 0.05 in² 3

50 to 3,000 psi 0.5 psi 0.01 in²

Base model

HL- Dual piston/cylinder assembly, metric engineering units, ±0.100%

accuracy, standard accessories, NIST traceable certificate

HLG- Dual piston/cylinder assembly, metric engineering units, ±0.100%

accuracy, standard accessories, NIST traceable certificate

Range options

Model Operating range Increment Piston area Weight set

90M 1 to 15 kg/cm² 0.005 kg/cm² 0.05 in² 1M

5 to 75 kg/cm² 0.025 kg/cm² 0.01 in²

180M 1 to 30 kg/cm² 0.005 kg/cm² 0.05 in² 2M

5 to 150 kg/cm² 0.025 kg/cm² 0.01 in²

270M 1 to 45 kg/cm² 0.005 kg/cm² 0.05 in² 3M

5 to 225 kg/cm² 0.025 kg/cm² 0.01 in²

90B 1 to 15 bar 5 mbar 0.05 in² 1N

5 to 75 bar 25 mbar 0.01 in²

180B 1 to 30 bar 5 mbar 0.05 in² 2N

5 to 150 bar 25 mbar 0.01 in²

270B 1 to 45 bar 5 mbar 0.05 in² 3N

5 to 225 bar 25 mbar 0.01 in²

9000N 100 to 1,500 kPa 0.5 kPa 0.05 in² 1N

500 to 7,500 kPa 2.5 kPa 0.01 in²

18000N 100 to 3,000 kPa 0.5 kPa 0.05 in² 2N

500 to 15,000 kPa 2.5 kPa 0.01 in²

27000N 100 to 4,500 kPa 0.5 kPa 0.05 in² 3N

500 to 22,500 kPa 2.5 kPa 0.01 in²

Calibration Options (all models and ranges)

Model Accuracy Gravity Data

NONE ±0.100% rdg (standard) 9.80665 m/s

/C ±0.100% rdg (standard) 9.80665 m/s

-1/C ±0.050% rdg (optional) 9.80665 m/s

2

(standard) None

2

(standard) Yes

2

(standard) Yes

Accessories

Order no. Description

T-536 Overall rebuild kit - HL/HLG Buna N (standard material)

MGAAA/QT Tester oil - 0.95 l (1 qt)

MGAAA/GL Tester oil - 3.79 l (1 gal)

99-90019 Oil dispenser

11-90009 Adapter (1/4” NPT male x 1/2” NPT female)

T-786 Adapter (1/4” NPT male x 1/4” BSP female)

T-787 Adapter (1/4” NPT male x 1/2” BSP female)

60I104 Roll of Teflon tape

101549 Bonded seal (1/2”)

60R120 Bonded seal (1/4”)

60R122 Bonded seal (1/8”)

K-1562 Tripod for convenient field use

www.ametekmg.com 3

Page 4

FUNCTIONAL SPECIFICATIONS

Model: .................................................................... HydraLite HL and HLG

Type: ......................................................................Hydraulic, piston gauge

Pressure range: ...................to 22,500 kPa / 3,000 psi (model dependent)

Accuracy (12 months): ...................................................... to ±0.050% rdg

Increments (low - min): ..................0.1 psi, 0.005 kg/cm2, 5 mbar, 0.5 kPa

Increments (high - min): ..............0.5 psi, 0.025 kg/cm2, 25 mbar, 2.5 kPa

Gravity: .............................................9.80665 m/s2 (international standard)

Piston/cylinders: ............................................... Single or dual (as ordered)

Columns: ........................................................................................... Single

Weight sets:...................................................................Single (as ordered)

Pressure source: ...........................................Screwpump, hand-actuated,

........................................................... hydraulic pump (tester models only)

Medium: .......................................................................................... AAA oil

Reservoir capacity: .............................. 0.24 l /14.4 in3 (tester models only)

Wetted surfaces: ....................300 series stainless steel, brass, aluminum

O-rings: ............................................................................................Buna N

Test connections: ..................................................1/4” NPT and 1/2” NPT

Weight material: ......................... Hard, non-magnetic alloy and aluminum

Engineering units: ...................................................... psi, kg/cm2, bar, kPa

Cases: ............................................................................. 1 (self-contained)

PHYSICAL SPECIFICATIONS

Tester size (L x W x H): .................... 22.9 x 22.9 x 25.4 cm / 9 x 9 x 10 in

Weight: .................................................................................20.4 kg / 45 lb

Configuration: ............................................... Single or dual piston/cylinder

............................................single column hydraulic deadweight or gauge

Delivery: ......................... Pump (tester), piston(s), weight set, tools, gauge

...........................post, adapters, manual, and NIST traceable certification

General Process Information for Calibrated Parts

Include serial number, accuracy, gravity, and model number of

•

deadweight tester when ordering weight sets or calibrated parts.

•

Masses for weights ordered seperately, including tolerance, must be

supplied by customer; unless combined with tester on same order.

Calibrated parts may be made to archival data if requested on the

•

purchase order.

•

Calibrated parts are certified for physical dimension only (mass or

area) and not for accuracy unless ordered with a new tester or the

tester is returned for proper calibration of parts.

Certification of Accuracy and Traceability

A Certification of Accuracy and Traceability to NIST is included with

every AMETEK floating ball-type deadweight tester. An optional

Certification of Accuracy with area, mass and intrinsic correction factors

is available.

is one of the world’s leading manufacturers and

AMETEK Calibration Instruments

developers of calibration instruments for

temperature, pressure and process signals

as well as for temperature sensors both from

a commercial and a technological point of view.

JOFRA Temperature Instruments

Portable precision thermometers. Dry-block and

liquid bath calibrators: 4 series, with more than

25 models and temperature ranges from

-90° to 1205°C / -130° to 2200°F. All featuring speed,

portability, accuracy and advanced documenting

functions with JOFR ACAL calibration software.

JOFRA Pressure Instruments

Convenient electronic systems ranging from

-1 to 1000 bar (25 inHg to 14,500 psi) -

multiple choices of pressure ranges, pumps and

accuracies, fully temperature- compensated

for problem-free and accurate field use.

JOFRA Signal Instruments

Process signal measurement and simulation for

easy control loop calibration and measurement

tasks - from handheld field instruments to

laboratory reference level bench top instruments.

JOFRA / JF Marine Instruments

A complete range of calibration equipment

for temperature, pressure and signal,

approved for marine use.

FP Temperature Sensors

A complete range of temperature sensor s

for industrial and marine use.

M&G Pressure Testers

Hydraulic floating-ball or hydraulic piston dead

weight testers with accuracies to 0.015% of reading.

M&G Pumps

Pressure generators from small Hydraulic

“bicycle” style pumps to hydraulic pumps

generating up to 1,000 bar (15,000 psi).

.. .b ec au se c al ib ra tion is

a ma tter of confidence

Headquarter:

AMETEK Denmark A/S

Gydevang 32-34 • 3450 Allerød • Denmark

Tel: +45 4816 8000 • ametek@ametek.dk

Sales & Service:

Europe, Asia, Africa, Middle East and South America

Information within this document is subject to change without notice.

©2007, by AMETEK, Inc., www.ametek.com. All rights reserved.

Pub code SS -2110-HL Iss ue 0710

4 www.jofra.com

www.ametekcalibration.com

www.jofra.com

Sales & Service Offices:

AMETEK Mansfield & Green (North America)

Tel: +1 800 527 9999 • cal.info@ametek.com

AMETEK Singapore Pte. Ltd. (Singapore)

Tel: +65 6 484 2388 • aspl@ametek.com.sg

AMETEK Inc. Beijing Rep. Office (China)

Tel: +86 10 8526 2111 • jofra@ametek.com.cn

AMETEK GmbH (Germany)

Tel: +49 2159 91360 • info@ametek.de

AMETEK Lloyd Instruments (UK)

Tel: +44 (0) 1489 486 404 • jofra@ametek.co.uk

Loading...

Loading...