Page 1

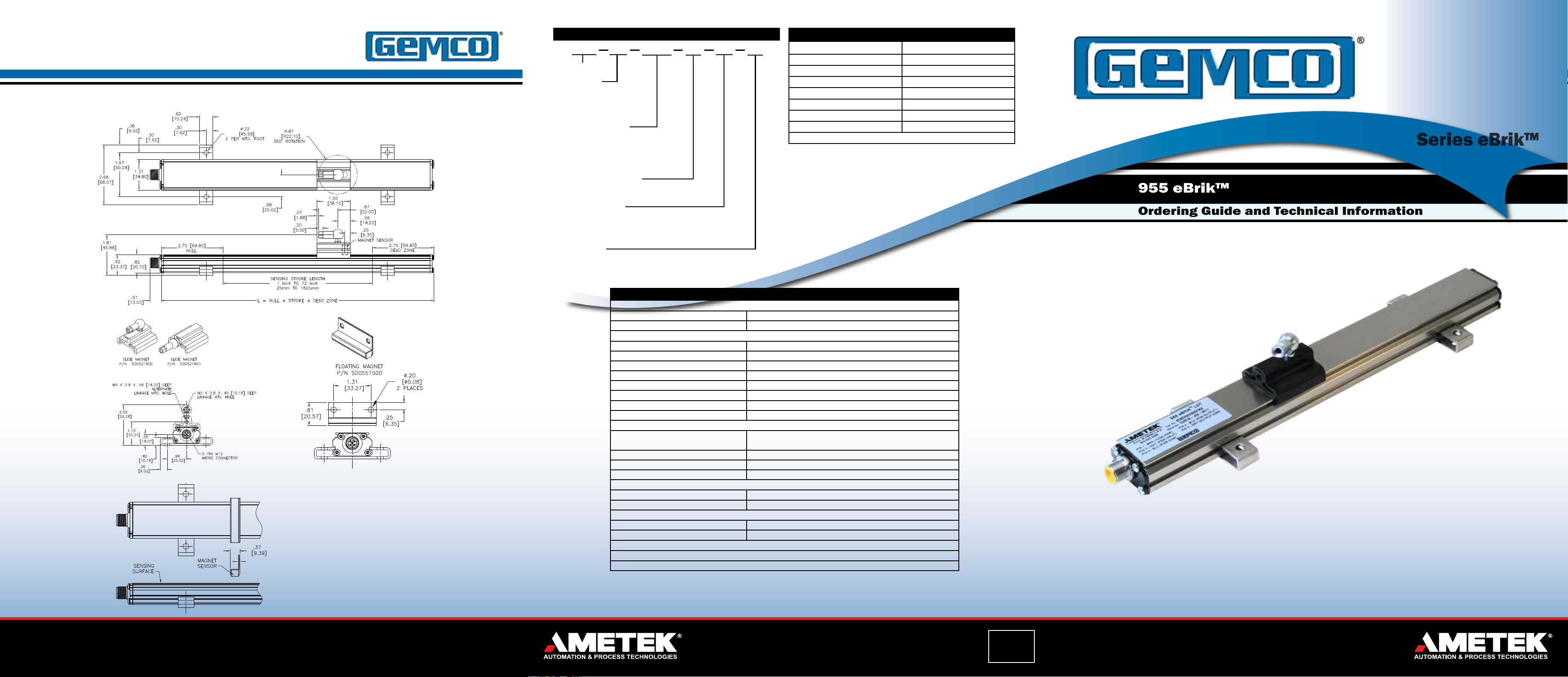

Dimensions

Part Numbering

955e V0 0120

955 eBrik™

Output

V0 = 0 to 10

V1 = 10 to 0

C2 = 20 to 4mA

C4 = 4 to 20mA

Stroke Length

Insert stroke length to 1 inch or

25mm. Enter as a four-place number.

Example: 12.0 inch stroke is entered

as 0120 (E) or 100mm is entered as

0100 (M).

Units of Measure

E = English US Inches

M = Metric

Magnet Type

FM = Floating Magnet (Standard)

SM = Slide Magnet Top Swivel

SF = Slide Magnet Front Swivel

X = No Magnet

Options

X = No Options

P= Programmable Zero and Span

Accessories

E

FM X

Item Part Number

Slide Magnet SD0521800

Large Floating Magnet SD0551500

Mounting Foot SD0522000

6 Ft, 5 Pin Straight Cable 949019L6

12 Ft, 5 Pin Straight Cable 949019L12

6 Ft, 5 Pin Right Angle Cable 949020L6

12 Ft, 5 Pin Right Angle Cable 949020L12

Consult Factory for Other Cable Length

Series eBrik™

955 eBrik™

Ordering Guide and Technical Information

All units are provided with mounting

feet and a magnet assembly. The

mounting feet (SD0522000) slide in the

grooves on the side of the extruded

housing. When tightened down with

fastening hardware, the mounting

brackets clamp the unit into place.

Specications

General Specications

Connector 5-pin 12mm Euro Micro

Displacement 1” to 72” in 1” Increments or 25mm to 1825mm in 25mm Increments

Electrical Specications

Input Voltage 24 VDC ±20%

Current Draw 1.1W (44mA typical)

Dead Band 2.75”

Null Zone 2.75”

Non-linearity Less than ± 0.03% of stroke or ± 0.013”, whichever is greater

Repeatability 0.001%

Hysteresis Less than 0.001”

Operating Temperature: -40ºC to 85ºC

Analog Output Specications

Voltage Output Minimum Load Resistance

Output Current

Analog Ripple 1 mV maximum

Current Output Maximum Load Resistance 500 Ohms

Update Time 1ms

Internal .00006”

Output 16-bit

Voltage Output 0V to 10V, 10V to 0V

Current Output 4mA to 20mA, 20mA to 4mA

Specications are subject to change without notice.

2K Ohms

Guaranteed 5mA minimum for voltage units

Resolution

Output Type

Enclosure Rating - IP-67

Approvals - CE (EMC)

ABSOLUTE PROCESS CONTROL

KNOW WHERE YOU ARE... REGARDLESS

6380 Brockway Rd, Peck, MI 48466

Phone: 248-435-0700 Toll Free: 800-635-0289

Fax: 248-435-8120 www.ametekapt.com

955e.B1R

2/12.Z390

Page 2

The need for automation is greater today than ever before

Typical Industries

The 955 eBrik™

Linear Displacement Transducers (LDT) play an important role in factory automation. They provide

accurate, reliable, absolute position feedback to help automate today’s sophisticated machinery.

Sensors must deliver value, be easy to set up, and interface easily into the host controller.

The 955 eBrik™ Linear Displacement Transducer (LDT) is an ideal alternative to the traditional

low-cost Linear Potentiometer. The advantages of the 955 eBrik over the traditional potentiometer

are that the 955 eBrik™ is an accurate, programmable zero & span, auto-tuning, non-contact

position sensor in an economical low profile package, that uses our field proven Magnetostrictive

technology to give absolute analog feedback.

Potentiometers are electro-mechanical devices that consist of a moveable wiper and resistive

element to provide a voltage feedback. Potentiometers are subject to wear from repetitive

operation and vibration, not to mention that they also drift with temperature. Contaminants are

also a problem as they can enter into the sensors housing and interrupt the contact from the wiper

to the resistive element, causing premature failure or erratic position signals.

With no moving parts and the IP67 rating the 955 eBrik™ is an ideal alternative. The 5 pin connector

simplifies wiring and allows for quick replacement. Programmability allows you to scale the LDT

exactly for your application, or fine tune it in the field. Diagnostics are built into every unit and

are transmitted to the host controller via the analog output. If there is ever a fault, the eBrik™ will

transmit a fault voltage or current warning the host controller that there is a problem.

• Plastic Injection Molding

• Hydro Power Generation

• Material Handling

• Packaging Machinery

• Pulp & Paper

• Factory Automation

• Sawmill & Woodworking

• Tire & Rubber

• Hydraulic Presses

Benets

• Non-contact technology (Magnetostrictive)

• Absolute analog feedback (Voltage or Current) – 16-Bit resolution

• Longevity – Nothing to wear out

• Economically priced

• Programmable Zero & Span points

• Industry standard mating cordset- 5 pin 12mm Micro

• Floating or Slide magnet option for easy integration to the host controller

• Wide operation temperature range with low drift

The 955 eBrik™ is an accurate, programmable zero and span, auto-tuning, non-contact linear position sensor in an

economical, low-profile package. The sensor utilizes our field-proven Magnetostrictive technology to provide absolute

position, repeatable to .001% of the sensing distance.

The 955 eBrik™ is a cost effective linear sensing solution. The streamlined anodized aluminum extrusion houses

the sensing element and electronics. The magnet moves over the sensing element that determines the position and

converts it to a readable output. The 955 eBrik™ is a self-contained unit and does not have a “can” or head assembly.

All of the electronics are incorporated in the transducer, which is less than one inch tall.

Units can be ordered in span lengths up to 72 inches long in 1 inch or 25mm increments. The slide magnet is, designed

to move effortlessly along the transducer in guide tracks, or a floating magnet assembly can be positioned above

the unit. A variety of hardware is available for attaching the magnet slide to the moving portion of the process. The

transducer can be ordered with 0 to 10 VDC or 4 to 20 mA output.

All units are provided with our standard 5 pin 12mm Euro Micro connector, mounting feet and magnet assembly.

Mating cables are sold in various lengths and must be ordered separately.

The 955 eBrik™ has some truly unique features. One feature is the LDT’s auto-tuning capability, the ability to sense the

distance between the magnet and the sensing surface and adjust its signal strength accordingly. As a bonus feature,

the 955 eBrik™ offers programmability, the ability to rescale the zero and span positions or invert the positions in the

field. This is an optional feature and must be called out at time of order under the “Options” field. All units come fully

programmed from the factory, are 100% absolute, and do not require reprogramming unless desired. There is a unique

diagnostic that is built into the analog output on every unit. If there is a loss of magnet, or if the magnet assembly

moves beyond the programmed range, the analog output will transmit a fault voltage or current, warning the host

controller that it is out of range.

The transducer can be mounted vertically or horizontally using our mounting feet which slide on the lower part of the

extrusion and clamp down when tightened. This packaging provides a compact and easy method of mounting for

machine builders.

The 955 eBrik™ is designed for applications where economical continuous feedback is necessary. The sensor can be

a cost effective replacement to linear potentiometers, limit and proximity sensors. Applications include presses, blow

molding, injection molding, extruding, roll positioning, tire press, material handling, web tensioning, sawmill, hydro

power generation and many more.

955 eBrik™ Linear Displacement Transducer

Absolute Control In The World Of Automation

Loading...

Loading...