Page 1

Series 956

Series 955

INSTALLATION M

L

INEAR

D

ISPLACEMENT

T

RANSDUCERS

ANUAL

955DQ BRIK

GEN III WITH QUADRATURE OUTPUT

ABSOLUTE PROCESS CONTROL

KNOW WHERE YOU ARE... REGARDLESS

Includes 955DQ

Programming & Maintenance

Instructions Plus Accessory Guide

Page 2

Preface

This manual is divided into three chapters. Chapter 1

provides the hardware overview for the 955DQ Linear

Displacement Transducers (LDT). Chapter 2 provides

instructions for installing the LDT to a mounting bracket.

Chapter 3 provides an overview and wiring instructions.

To further assist you, a glossary is provided at the back of

the manual.

!

CAUTION

Disconnect Power Before Servicing. The

Gemco 955DQ LDT Contains No Serviceable

Components. Consult Factory for Repair or

Replacement.

AMETEK Automation & Process Technologies has

checked the accuracy of this manual at the time it was

approved for printing. However, this manual may not

provide all possible ways of installing and maintaining

the LDT. Any errors found in this manual or additional

possibilities to the installation and maintenance of

the LDT will be added in subsequent editions. Any

comments you may have for the improvement of this

manual are welcomed.

AMETEK reserves the right to revise and redistribute

the entire contents or selected pages of this manual.

All rights to the contents of this manual are reserved

by AMETEK. The BRIK is a registered trademark of

AMETEK.

2

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • 248.435.0700 • Fax 248.435.8120 • www.AMETEKAPT.com

Page 3

Table of Contents

Chapter 1 Hardware Overview .......................................4

Chapter 2 Installing the LDT........................................... 6

2.1 Mounting Instructions ............................................................6

2.2 Mounting the Magnet Assembly ...........................................6

Chapter 3 Programming & Maintenance ........................7

3.1 Quadrature Output ................................................................7

3.2 Signal Connection Application Note ......................................7

3.3 Quadrature Output Resolution & Speed................................ 8

3.4 955DQ Wiring Connections...................................................9

3.5 Features ................................................................................16

3.6 955DQ ...................................................................................17

3.7 Troubleshooting for 955DQ ...................................................18

3.8 Catalog Numbering System ..................................................19

3.9 Specifications for 955DQ....................................................... 20

3.10 Accessories ..........................................................................21

Glossary ..........................................................................22

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • 248.435.0700 • Fax 248.435.8120 • www.AMETEKAPT.com

3

Page 4

Chapter 1 Hardware Overview

Overview

The Series 955DQ BRIK with Quadrature Output is an

accurate, auto-tuning, non-contact, Linear Displacement

Transducer in an economical, low profile package. The

transducer utilizes our field proven magnetostrictive

technology to give absolute position, repeatable to .006%

of the sensing distance. The streamlined anodized

aluminum extrusion houses the sensing element and

electronics. The magnet moves over the sensing

element that determines the position and converts it to

incremental outputs.

Features

The 955DQ has a truly unique feature. This LDT has

auto-tuning capability, the ability to sense a magnet other

than the standard slide magnet and adjust its signal

strength accordingly.

There is an indicator LED that is located at the connector

end of the probe and provides visual status information

regarding the operation of the probe. Green indicates

proper or normal operation. Red indicates the loss of

the magnetic signal or a probe failure. When the probe

is in the normal mode of operation, the LED with remain

illuminated continuously.

encoder input or counter card, eliminating costly absolute

encoder converters and special PLC interface modules.

This model can be ordered with 1 to 9999 cycles per inch

of output resolution. The transducer features an input to

re-zero the probe “on the fly”. Another unique feature is

the “Burst” mode. An input on the transducer triggers a

data transfer of all the incremental position data relative

to the transducer’s absolute zero position. This is how

the incremental output can provide absolute functionality.

The “Burst” input can be used to achieve absolute

position updates when power is restored to the system

or anytime an update is needed to re-zero or home the

machine without having to move the machine.

LED Colors

Green Magnet is present and within the active range.

Red Fault, the LDT has lost its signal from the magnet or the

Yellow Used when in the communication/program mode.

magnet has moved into the Null or Dead zone.

Note: The series number on your LDT is a record of all

the specific characteristics that make up your unit. This

includes what interface type it is, its output signal and

range, the type of connector the unit uses, and stroke

length. For a translation of the model number, see

Section 3.8 Catalog Numbering System.

The 955DQ BRIK with Quadrature Output provides an

A quad B digital output signal that is proportional to the

position of the slide magnet assembly along the length

of the probe. The quadrature output makes it possible

to have a direct interface to virtually any incremental

4

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • 248.435.0700 • Fax 248.435.8120 • www.AMETEKAPT.com

Page 5

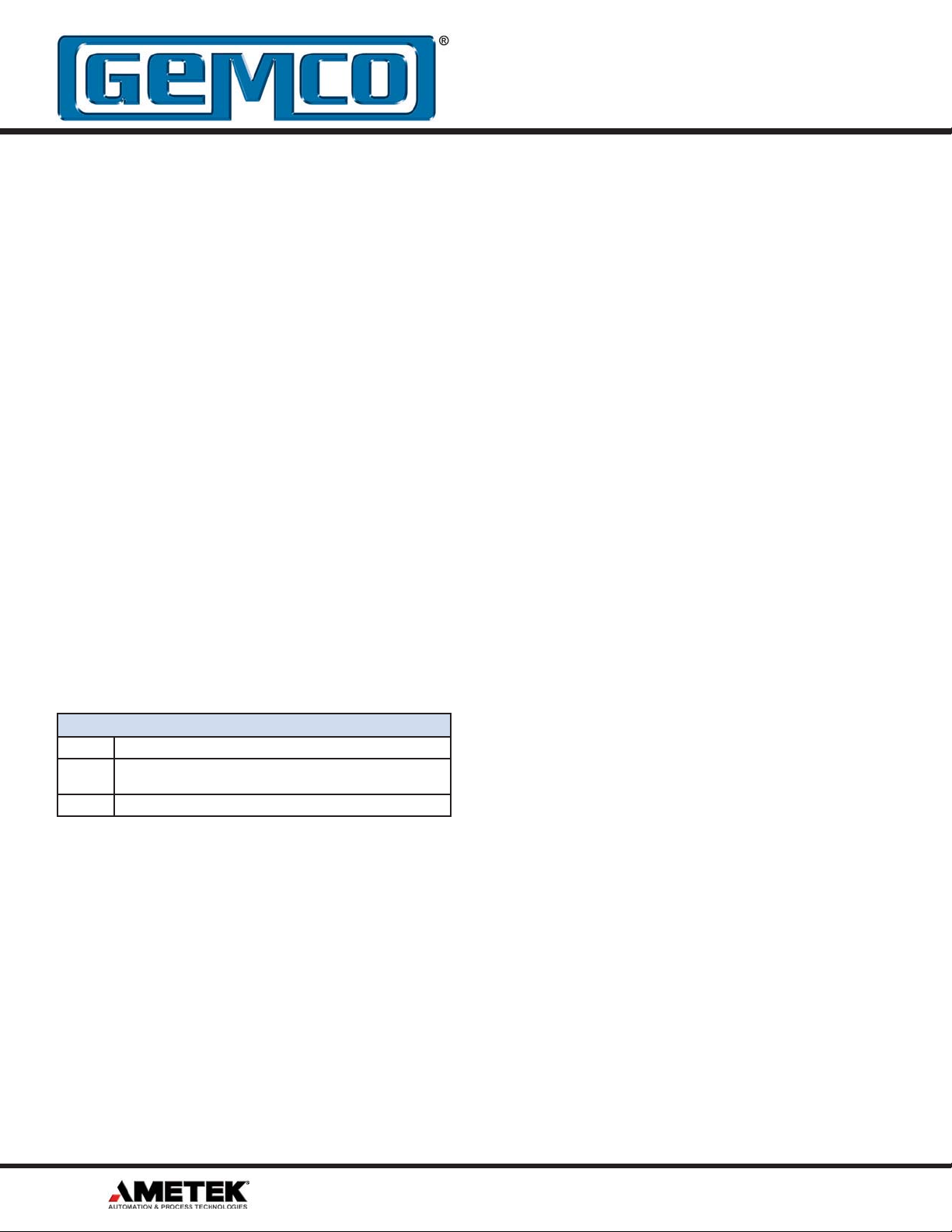

Figure 1.1 Dimension Drawing

Accessories

Item Part Number

Slide Magnet SD0521800

Float Magnet SD0522100

Mounting Foot SD0522000

6 Ft. Cable (Option H) SD0527700L6

12 Ft. Cable (Option H) SD0527700L12

25 Ft. Cable (Option H) SD0527700L25

6 Ft. 12 Pin

(Option E Connector)

12 Ft. 12 Pin

(Option E Connector)

Control Arm 955ARMXX (X = Inches)

2.06

1.19

.55

949023L6

949023L12

M5 X .56 DEEP

ALTERNATE MTG.

HOLE FOR LINKAGE

M5 X .40 DEEP

LINKAGE MTG. HOLE

.40

.98

.36

10 PIN MALE

CONNECTOR

A standard female swivel mounting arm is

provided with the slide magnet assembly.

For extensions and other options contact

AMETEK at 800-635-0289.

.22 MTG. HOLES

2 PER MTG. FOOT

.36

.30

1.97

1.372.68

1.80

1.45

.82

.10

Male Connector

.22

SLIDE MAGNET ASSEMBLY

P/N SD0521800

.60

.30

.87

.08

.28

3.00 NULL

R.87

360 ROTATION

Mounting Brackets (SD0522000) slide in the grooves on the

side of the extruded housing. When tightened down with

fastening hardware the mounting bracket clamps the unit into

place. It is recommended to use one mounting bracket on each

end and every three feet between.

R.87

360 ROTATION

1.00

1.50

.56

.25 TO CENTERLINE MAGNET SENSOR

2.00

L = NULL + STROKE + DEAD ZONE

STROKE

FLOATING MAGNET ASSEMBLY

P/N SD0522100

1.31

.34

1.50

DEADZONE

.50

1.00

TO CENTERLINE

OF MAGNET

.34

.75

2.00

1.31

.25

OF MAGNET SLUG

1.30

1.37

1.04

.08

.68

.28

.69

.87

1.50

.56

.25 TO CENTERLINE

OF MAGNET SENSOR

Note: The North Pole of the magnet

should be pointed towards the probe.

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • 248.435.0700 • Fax 248.435.8120 • www.AMETEKAPT.com

.25

.20 THRU

.359 C’BORE

.21 DEEP

OTHER END

2 PLACES

.20 THRU

2 PLACES

.50

5

Page 6

Chapter 2 Installing the LDT

2.1 Mounting Instructions

The Series 955DQ can be mounted vertically or

horizontally using SD0522000 mounting brackets. The

mounting brackets slide in the grooves on the lower part

of the extrusion and clamp down when tightened. It is

recommended to use one mounting bracket on each end

and every three feet in between.

Ferro-magnetic material, (material readily magnetized)

should be placed no closer than .25” from the sensing

surface of the LDT.

2.2 Mounting the Magnet Assembly

Before mounting the magnet assembly, you should

consider the following

• Ferromagnetic material should not be placed closer

that 0.25” from the LDT’s sensing surface. Failure

to do so could cause erratic operation. Non-ferrous

materials, such as brass, copper, aluminum,

nonmagnetic stainless steel or plastics, can be

in direct contact with the magnet assembly and

sensing surface without producing any adverse

results.

• Make sure that the magnet is located within

the LDT’s active stroke area. Captive magnet

assemblies should be positioned so that they can

move freely over the entire area of the active stroke

without binding or pushing on the extrusion. Noncaptive magnet assemblies should be situated so

that the magnet is no further than 3/8” from the

sensing surface at any point in the floating magnet

assembly’s movement.

• When using the Floating Magnet assembly

(SD0522100), the magnet should be installed within

3/8” of the sensing surface. The magnet assembly

should also be installed in such a manner that

it remains an even distance from the aluminum

extrusion throughout the entire stroke. Improperly

installed magnets can result in output signal non-

linearity.

6

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • 248.435.0700 • Fax 248.435.8120 • www.AMETEKAPT.com

Page 7

Chapter 3 Programming & Maintenance

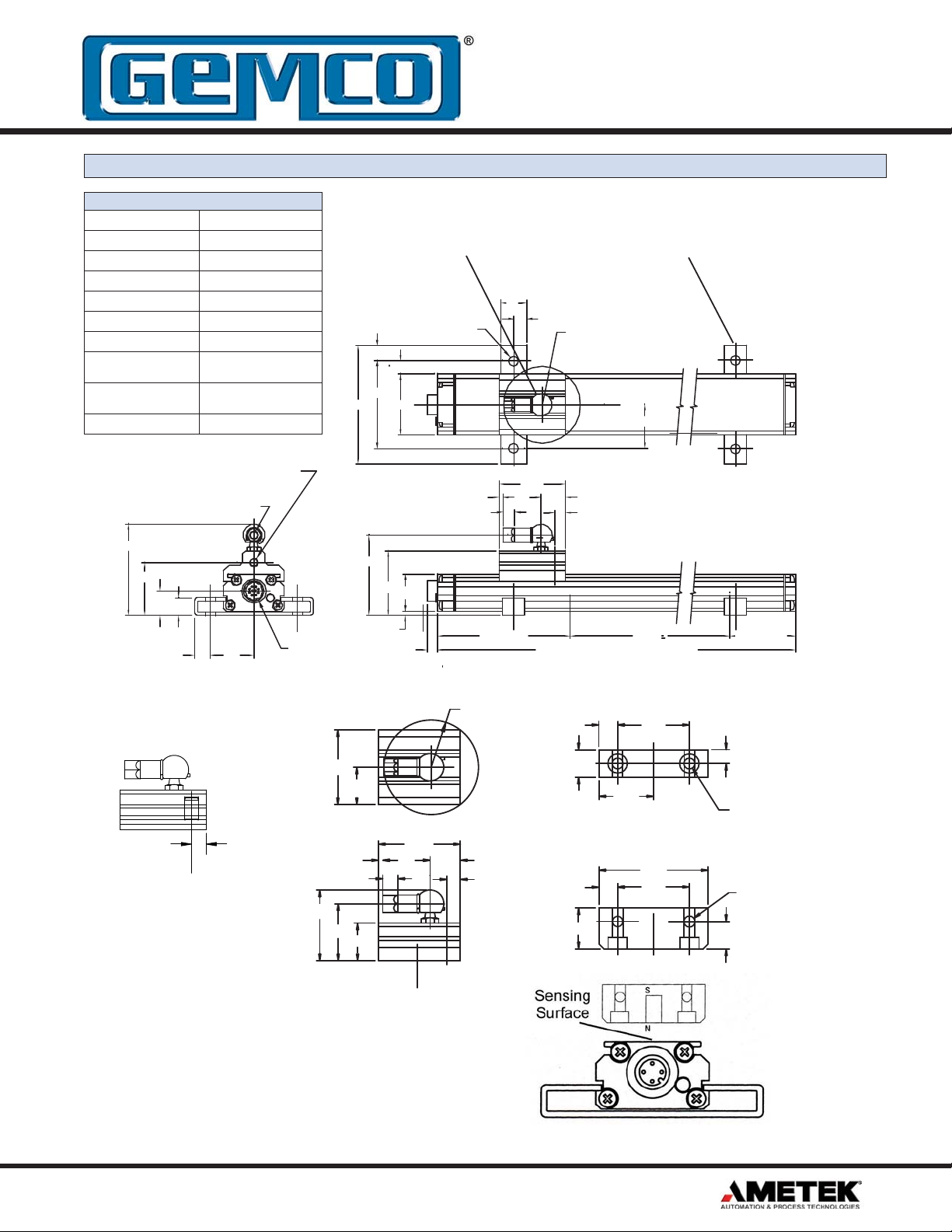

3.1 Quadrature Output

A new method of interfacing magnetostrictive transducers

offers customers an interface as common as analog

with the speed and accuracy of pulsed type signaling.

The GEMCO 955DQ LDT provides quadrature output

directly from the transducer to the controller (see drawing

below). The output from the transducer can be wired

directly to any incremental encoder input card, without

the need for a special converter module or PLC interface

card designed specifically for use with a pulsed output

magnetostrictive transducer.

The quadrature output provides absolute position data

in engineering units. This means that the need for the

calibration constant (wire speed) programming has been

removed, thereby eliminating the possibility of having an

improperly calibrated system. The output signal wires

are driven by differential line drivers, similar to the drivers

used in most magnetostrictive pulsed type transducers,

providing a high degree of noise immunity.

A unique feature of this transducer is a “burst” mode of

operation. An input on the transducer triggers a data

transfer of all the incremental position data relative to

the transducer’s absolute zero position. This can be

used to achieve absolute position updates when power

is restored to the system or anytime an update is needed

to re-zero or home the machine. Additionally, another

input to the transducer can be used to establish a “zero”

position for the transducer.

3.2 Signal Connection Application Note

Overview

This application note will clarify the input and output

signals of the 955DQ quadrature probe.

Inputs

The quadrature probe has two inputs, the “zero” and

“burst” inputs. These inputs are “single ended”. That is,

the connection for each input consists of only one wire,

the corresponding signal wire. For these (single ended)

inputs, the signal is measured with reference to the

power supply ground, which is sometimes referred to as

“common”.

The quadrature probe is available with either +24 VDC

level signal thresholds or TTL level thresholds. The

signal voltage level required to activate the input for the

+24 VDC level signal is proportional to the power supply

voltage that the customer is supplying to the probe. This

level is approximately 41% of the power supply voltage.

For example, if the power supply voltage powering the

probe is exactly 24 VDC, the threshold voltage would be

approximately 9.84 volts.The TTL level threshold signals

are activated when these inputs exceed the typical TTL

level threshold, which is 2.0 VDC.

Additionally, for the 24 VDC level signals, the customer

can specify either a “sourcing” or “sinking” type of input.

A “sourcing” input type is pulled high internal to the probe.

To activate a “sourcing” input, the customer must pull the

signal lower than the threshold voltage to activate the

input. A “sourcing” input is usually driven by a “sinking”

output or a switch connected to ground. A “sinking”

input type is pulled low internal to the probe. To activate

a “sinking” input, the customer must pull the signal

higher than the threshold voltage to activate the input. A

“sinking” input is usually driven by a “sourcing” output or

a switch connected to the power supply.

It is important that the customer drive the signal levels

much greater or lower than the threshold voltages.

Asserting a signal with a voltage level close to the

threshold voltage could induce multiple activations of that

input (or none at all) and therefore produce unexpected

results or probe readings.

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • 248.435.0700 • Fax 248.435.8120 • www.AMETEKAPT.com

7

Page 8

Outputs

The quadrature probe has three outputs, the “A”, “B”

and “Z” outputs. These outputs are “differential” (also

known as “balanced”). That is, the connection for each

output consists of two signal wires. These are typically

described as the “+” and “-” signals. For example, the

“A” channel consists of “A+” and “A-”. The same applies

to the B and Z channels. For these (differential) outputs,

the signal is measured with reference to the other

signal (i.e. the difference or differential). For example;

if the “A+” signal voltage is greater than the “A-” signal,

channel “A” is a logic “1”. Conversely, if the “A+” signal

voltage is lower than the “A-” signal, channel “A” is a

logic “0”. Again, this applies to the B and Z channels as

well. Differential type signals are much less prone to

interference caused by electrical noise or ground loops

more often found in single ended signal connections.

The differential outputs of the A, B and Z channels are

at RS-422 signal levels on option D (output drivers)

units. RS-422 is a well known TIA/EIA standard and

common interface type for incremental encoders. The

RS-422 receiver channel (on the PLC or controller side

of the connection) typically has what is referred to as

a termination resistor connected across the “+” and “-”

signal pins. The value of the termination resistor is (by

RS-422 specifications) typically 100 ohms. However,

some receivers will work with greater resistance values

and some with no termination resistor at all. For proper

signal integrity, especially at higher data rates (i.e.

quadrature pulse frequency), a termination resistor of no

greater than 1K ohm is recommended.

Driving Single Ended Inputs

When using PLS’s or controllers that are not TTL

compatible output driver option “L” should be used.

Option “L” uses a 0L7272 line driver I.C. The output from

this driver will be 1 volt less than the LDT’s input power.

When physically connecting a differential output to a

single ended input, only use the “+” signal, leaving the

“-” signal unconnected. Do NOT connect the “-”

signals to ground. The “A+, “B+” and “Z+” signals

should be connected to their corresponding inputs.

Insulate and tie back the “-” signals. See figure 3-4 or

3-5, Single Ended Interface.

3.3 Quadrature Output

Resolution & Speed

The internal resolution of the 955DQ Gemco LDT is

0.001”. This would be represented to the encoder

input device by specifying an output resolution of 1,000

cycles per inch for the transducer. Although the typical

resolution is 1,000 cycles per inch (CPI), the transducer

can be ordered with virtually any CPI setting.

For a typical rotary type shaft encoder with incremental

quadrature output, the output frequency of the pulses is

governed by the resolution of the encoder (pulses per

turn) and the rotational speed (RPM) of the encoder. The

output pulses rate from the transducer is stretched out

over the LDT internal update time. The output frequency

must be specified so that it does not exceed the

maximum pulse rate of the encoder input card the sensor

is connected to. The output pulse frequency range can

be ordered from 1KHz to 1MHz.

A differential output can also be used to drive single

ended inputs. Special consideration must be given

to these types of applications. It should be noted the

main signal requirements for an RS-422 signal is the

differential voltage of the “+” relative to the “-” signals

and not necessarily the voltage level of any one of these

signals with respect to ground (or common). To meet

the RS-422 specification, this differential voltage only

needs to be +/- 0.2 volts. However, an RS-422 driver

will typically drive either the “+” or “-” signal to around 3.8

volts with respect to ground. This voltage is more than

sufficient to drive TTL level inputs as well as other low

level inputs. The input voltage level specifications of the

PLC or controller being used should be consulted for the

actual level required.

8

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • 248.435.0700 • Fax 248.435.8120 • www.AMETEKAPT.com

Page 9

3.4 955DQ Wiring Connections

Once the LDT has been installed, wiring connections can

be made. There are two groups of connections you will

need to make. They are as follows:

• Power Supply Connections (including grounding

and shielding)

• LDT Input/Output Connections

Power Supply/Ground Connections

The 955DQ is available with two different connector

options, either Option H or Option E. Refer to the

part number labeled on your unit to determine which

connector you have. Always observe proper grounding

techniques such as single point grounding and isolating

high voltage (i.e. 120/240 VAC) from low voltage (10-30

VDC cables). Whenever possible, this cable should be

run in conduit by itself.

The power supply common, the cable shield and a

good earth ground should be connected together at the

location of the power supply common.

Figure 3.1 Power Supply Wiring

UNIPOLAR

Single ended

power supply

+13.5 to +30 VDC

+ COM

Pin 2 (red) Pin 1 (black) Connecter Option H

Pin 2 (brown) Pin 7 (blue) Connecter Option E

!

WARNING

Do not route the BRIK with Quadrature Output cable near

high voltage sources.

Option E: Uses a 12-Pin 12mm Euro Cordset with the

shield tied to the coupling nut. The 12-pin connector has

ten conductors of 24ga, with an aluminum/polyester/

aluminum foil with drain wire plus an overall braid of

tinned copper shield. Cable O.D. is .280. To reduce

electrical noise, the shield must be properly used.

Connect the cable’s shield to the controller system GND.

The connector shell on the probe is electrically connected

to the probe housing.

Option H: Uses a 10-Pin HRS connector. The 955DQ

BRIK with connector Option H uses a standard cable,

a multi-conductor Alpha 6334. It has ten conductors of

24ga, with an aluminum/polyester/aluminum foil with

drain wire plus an overall braid of tinned copper shield.

Cable O.D. is .270. To reduce electrical noise the shield

must be properly used. Connect the cable’s shield to

the controller system GND. The cable shield is not

connected at the transducer end.

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • 248.435.0700 • Fax 248.435.8120 • www.AMETEKAPT.com

9

Page 10

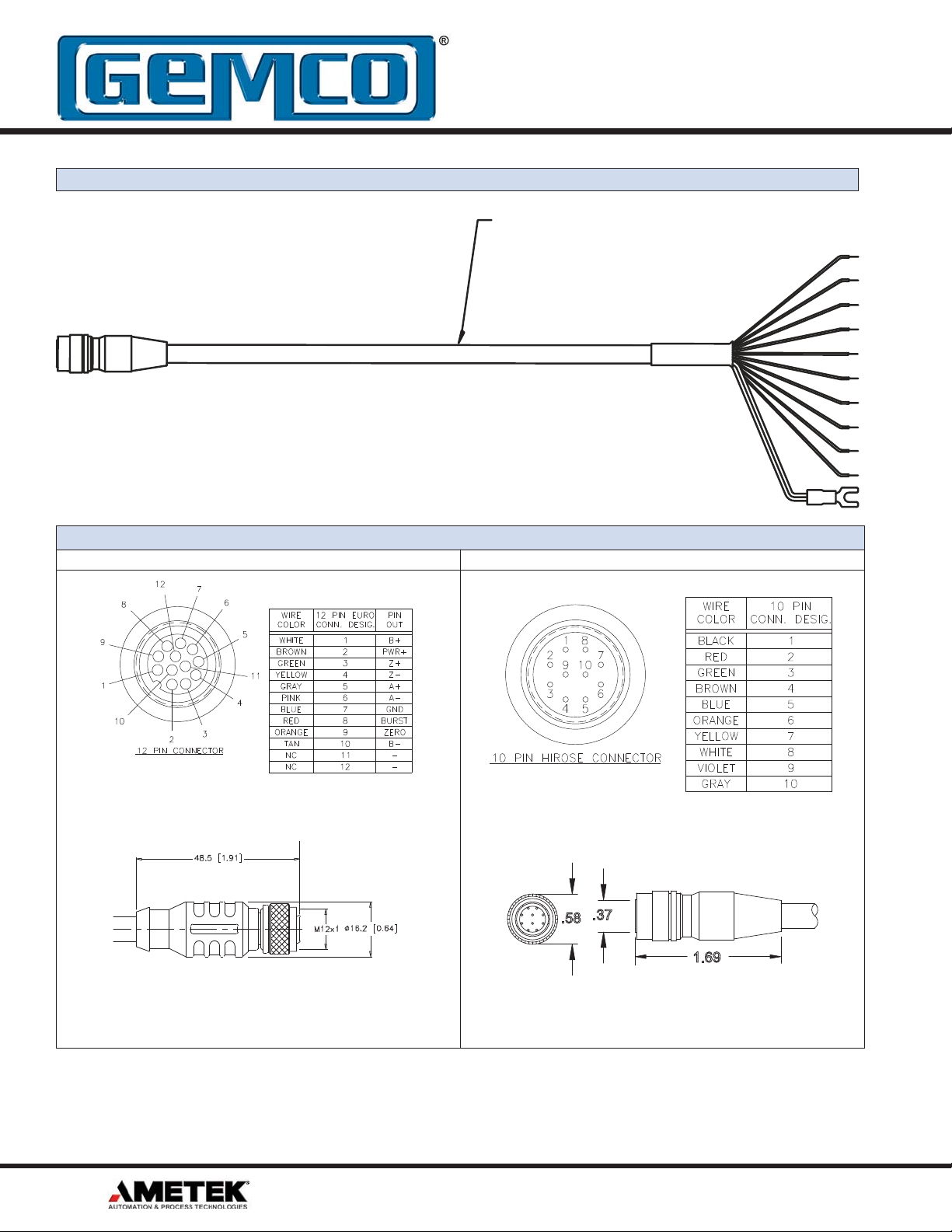

Figure 3.2 Power Supply Wiring

OPTION H

Part Number

SD0527700LXX

Wiring Diagram

Connector Option E Connector Option H

10

Connector View

12 Pin Micro 12mm

Euro Straight Cable

12 Pin Part Number: 949-023LXX

(X = Length in Feet)

Connector View

10 Pin Straight Cable

.37

.58

1.69

Part Number: SD0527700LXX

(X = Length in Feet)

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • 248.435.0700 • Fax 248.435.8120 • www.AMETEKAPT

.com

Page 11

Figure 3.3 Wiring Diagram

Connector Option E Cable Assembly

Part Number 949-023LXX (X = Length in Feet)

Connector Option H Cable Assembly

Part Number SD0527700XX (X = Length in Feet)

PIN - 1 WHITE

PIN - 2 BROWN

PIN - 3 GREEN

PIN - 4 YELLOW

PIN - 5 GRAY

PIN - 6 PINK

PIN - 7 BLUE

PIN - 8 RED

PIN - 9 ORANGE

PIN - 10 TAN

B+

POWER +

Z+

Z-

A+

A-

GND

BURST INPUT

ZERO INPUT

B-

PIN - 1 BLACK

PIN - 2 RED

PIN - 3 GREEN

PIN - 4 BROWN

PIN - 5 BLUE

PIN - 6 ORANGE

PIN - 7 YELLOW

PIN - 8 WHITE

PIN - 9 VIOLET

PIN - 10 GRAY

COMMON

POWER +

Z+

Z-

A+

A-

B+

BURST INPUT

ZERO INPUT

B-

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • 248.435.0700 • Fax 248.435.8120 • www.AMETEKAPT.com

11

Page 12

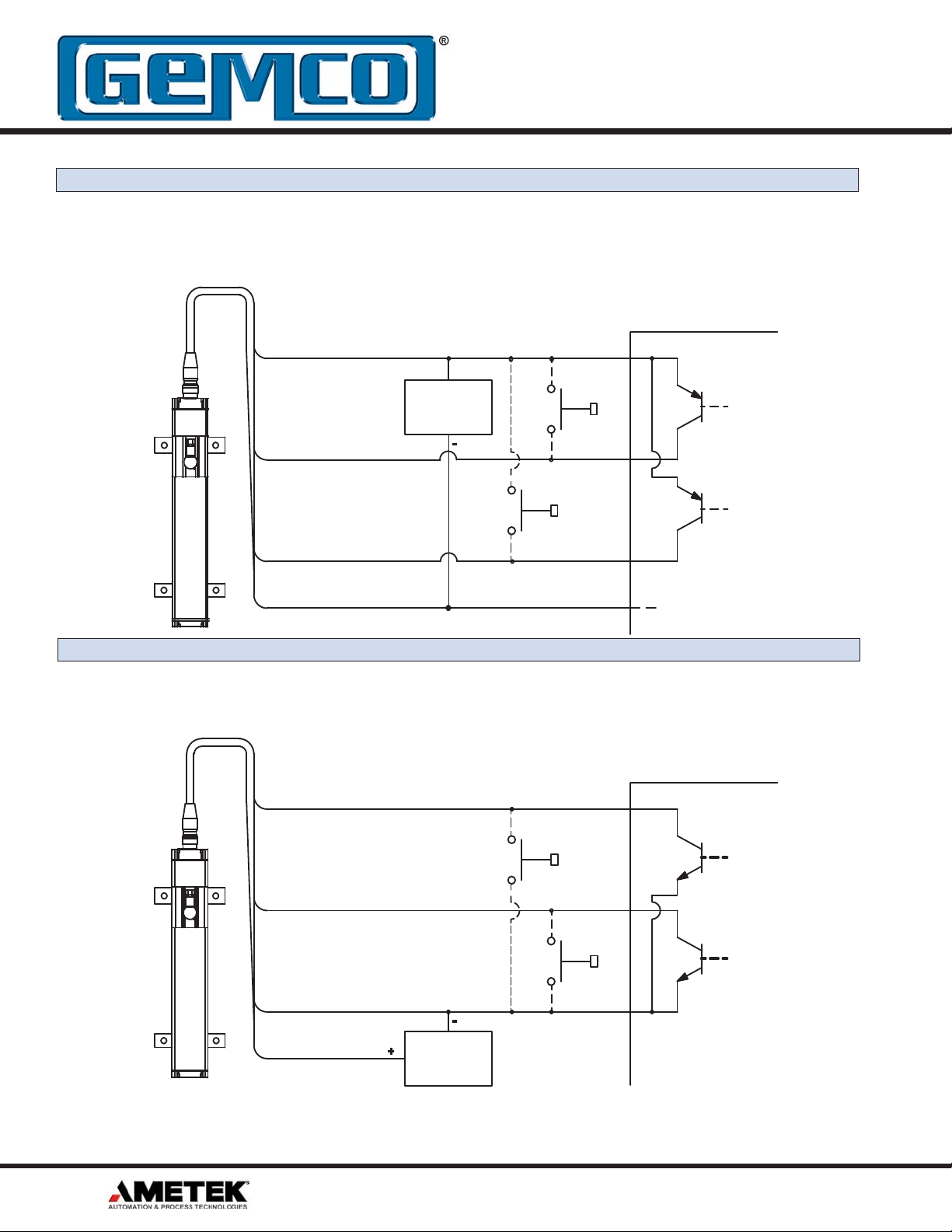

Figure 3.4a Option H Input Connections for Sinking Input

Part Number SD0527700LXX

CABLE ASSY

CABLE ASSY.

X = Length in Feet

P/N SD0527700LXX

Pin-2 RED

955QD

LDT

Pin-9 VIOLET

Pin-8 WHITE

Pin-1 BLACK

Figure 3.4b Option H Input Connections for Sourcing Input

+

POWER

POWER

SUPPLY

SUPPLY

13.5 TO 30V

10 TO 30V

-

TYPICAL SOURCING

OUTPUT INTERFACE

VSOURCE

ZERO

BURST

COMMON

Part Number SD0527700LXX

CABLE ASSY

CABLE ASSY.

X = Length in Feet

P/N SD0527700LXX

Pin-9 VIOLET

955QD

LDT

Pin-8 WHITE

Pin-1 BLACK

Pin-2 RED

+

-

POWER

POWER

SUPPLY

SUPPLY

13.5 TO 30V

10 TO 30V

TYPICAL SINKING

OUTPUT INTERFACE

ZERO

BURST

COMMON

12

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • 248.435.0700 • Fax 248.435.8120 • www.AMETEKAPT

.com

Page 13

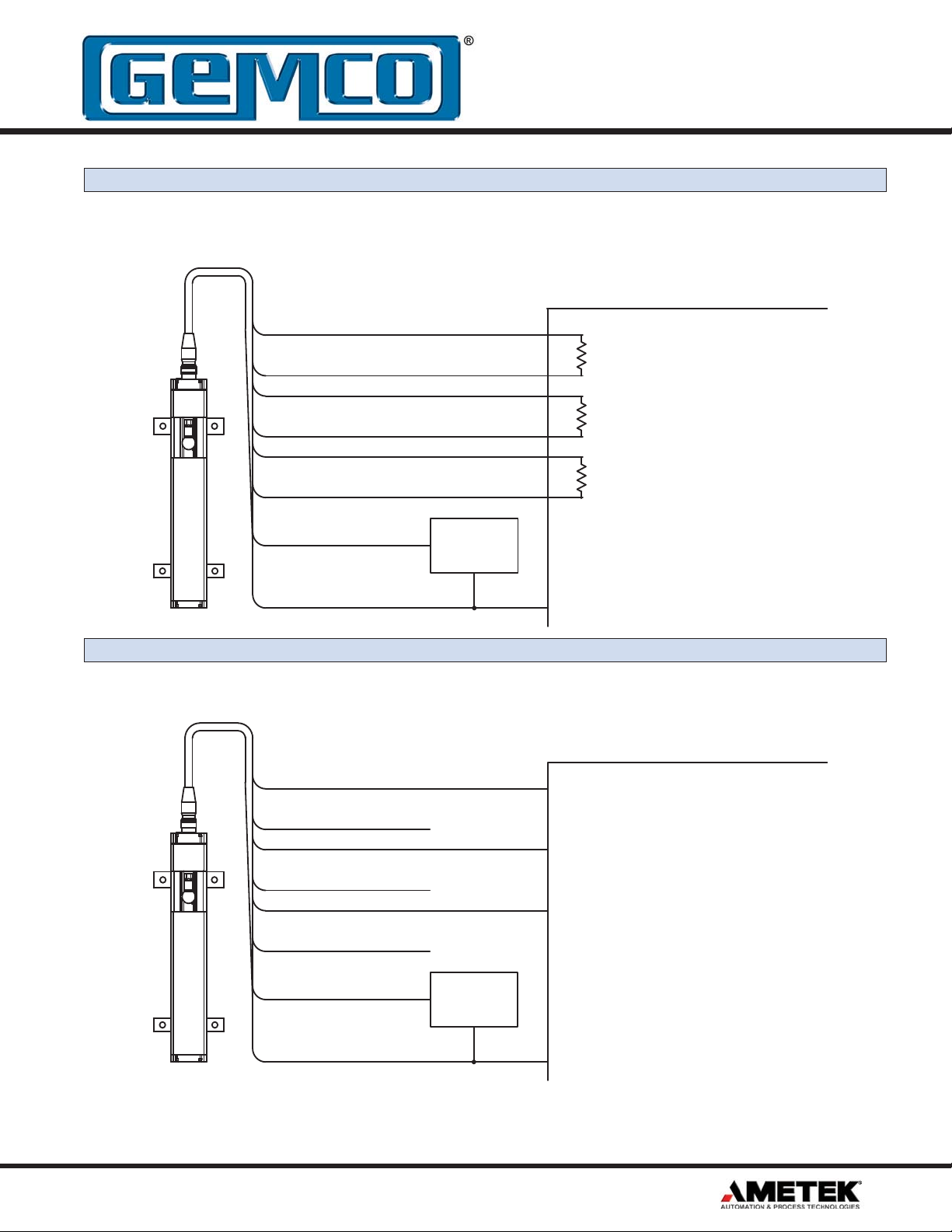

Figure 3.4c Option H Output Connections for Differential Interface

Part Number SD0527700LXX

X = Length in Feet

Pin-5 BLUE

CABLE ASSY

955QD

LDT

Pin-6 ORANGE

Pin-7 YELLOW

Pin-10 GRAY

Pin-3 GREEN

Pin-4 BROWN

Pin-2 RED

Pin-1 BLACK

Figure 3.4d Option H Output Connections for Single Ended Interface

Part Number SD0527700LXX

CABLE ASSY

X = Length in Feet

VSOURCE

COMMON

POWER

SUPPLY

13.5 TO 30V

TYPICAL DIFFERENTIAL INTERFACE

A+

*

COMMON

Rt

*

Rt

Rt

*

*

Rt is the termination resistor

Note:

typically used for RS-422 differential

connections. If these termination

resistors are not internal to the

controller, they should be installed

externally at the connector. If

these are not specified or included

with the controller, use 1K OHM

resistors.

A-

B+

B-

Z+

Z-

TYPICAL SINGLE ENDED INTERFACE

Pin-5 BLUE

**

A-

**

B-

**

Z-

N.C.

N.C.

N.C.

POWER

SUPPLY

13.5 TO 30V

955QD

LDT

Pin-6 ORANGE

Pin-7 YELLOW

Pin-10 GRAY

Pin-3 GREEN

Pin-4 BROWN

Pin-2 RED

Pin-1 BLACK

VSOURCE

COMMON

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • 248.435.0700 • Fax 248.435.8120 • www.AMETEKAPT.com

A+

B+

Z+

**

COMMON

Tie back and insulate unused

Note:

A-, B- and Z- wires.

13

Page 14

Figure 3.5a Option E Input Connections for Sinking Input

CABLE ASSY

Part Number 949-023LXX

X = Length in Feet

Figure 3.5b Option E Input Connections for Sourcing Input

CABLE ASSY

Part Number 949-023LXX

X = Length in Feet

14

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • 248.435.0700 • Fax 248.435.8120 • www.AMETEKAPT

.com

Page 15

Figure 3.5c Option E Output Connections for Differential Interface

CABLE ASSY

Part Number 949-023LXX

X = Length in Feet

Figure 3.5d Option E Output Connections for Single Ended Interface

CABLE ASSY

Part Number 949-023LXX

X = Length in Feet

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • 248.435.0700 • Fax 248.435.8120 • www.AMETEKAPT.com

15

Page 16

3.5 Features

Automatic Gain Control

The Automatic Gain Control feature will automatically

search and find the magnet on power up, if power is

applied without a magnet on the LDT, the LED will turn

RED indicating no magnet signal is detected. Turn power

off and place magnet within the active stroke area. Reapply power.

When using the Floating Magnet assembly (SD0522100),

the magnet should be installed within 3/8” of the sensing

surface. The magnet assembly should also be installed

Burst Mode

so that it remains an even distance from the aluminum

extrusion throughout the entire stroke. Improperly

installed magnets can result in output signal non-linearity.

LED Colors

Green Magnet is present and within the active programmed

range.

Red Fault, the LDT has lost its signal from the magnet or the

magnet has moved into the Null or Dead zone.

Yellow Factory use only. Used to determine when the LDT is in

the programming mode.

This feature enables the system to be absolute even

though data transfer is through an “incremental” method.

In the event of power failure, the controller can be

programmed to automatically send a signal to the probe,

Zero Pulse

By sending a signal to the probe at any point in the

stroke, a new zero point can be established. When using

the burst input, the absolute position provided will be

relative to the programmed zero position. In probes with

volatile storage the zero point will be kept until a new

which will then respond with the current position data.

An input signal to the probe will cause a “burst” of data,

representing the absolute position, to be fed back to the

controller.

zero pulse is sent or until the probe loses power. Probes

with nonvolatile storage will store the zero position even if

you lose power. The nonvolatile zero can be set 100,000

times; the volatile zero can be set an infinite number of

times.

16

Signal Types Needed for Burst & Zero Inputs

E = Sinking (PLC Sourcing Outputs)

C = Sourcing (PLC Sinking Outputs)

T = TTL

See section 3.9 Specifications, for more information.

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • 248.435.0700 • Fax 248.435.8120 • www.AMETEKAPT

.com

Page 17

3.6 955DQ

Frequency or Pulse Rate

Selecting the proper frequency in the LDT’s part number

is very important. The 955DQ has an internal update

time of 1 millisecond on LDT’s less than 60” in length and

approximately 2 milliseconds on the units greater than

60” in length. The LDT will stretch the amount of pulses

travelled over the update rate. All incremental pulses

must be transmitted before the LDT will interrogate itself

again. The frequency or pulse rate of the 955DQ is factory set from 1KHz - 1.00MHz, consult part number for

your model. The input for the PLC or display will determine the frequency needed.

Example: If your PLC High Speed counter card or display accepts a 1MHz encoder input, the choices are

A1 = 1KHz

A2 = 2KHz

A3 = 5KHz

F1 = 10KHz

F2 = 25KHz

F3 = 50KHz

F4 = 75KHz

F6 = 150KHz

F7 = 250KHz

F8 = 500KHz

F9 = 1.00MHz

F5 = 100KHz

Output Drivers

The 955DQ BRIK uses a 0L7272 line driver IC. Your LDT

was configured at the factory for either a TTL level output

or a 13.5 - 30 VDC level output. Refer to label on LDT for

your output type.

D = Differential RS-422 line driver, TTL compatible

L = Differential line driver 13.5 - 30VDC

V out = V in (LDT Power) -1 volt

Option D has a 5 volt TTL level output regardless of input

power.

Option L has an output of 1 volt less than probe input

power. This option is used when driving higher voltage

input cards and is not TTL compatible.

Note: If your controller’s maximum input frequency falls

between two available frequencies, choose the lower

frequency.

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • 248.435.0700 • Fax 248.435.8120 • www.AMETEKAPT.com

17

Page 18

3.7 Troubleshooting for 955DQ

Troubleshooting describes common problems that

may occur when installing the LDT and offers possible

solutions to these problems. If, after reading this

appendix, you are unable to resolve a problem, contact

our technical support department at 1-800-635-0289.

General Checks

Make sure that the magnet is located within the LDT’s

active stroke area. Captive magnet assemblies should

be positioned so that they can move freely over the entire

area of the active stroke without binding or pushing on

the extrusion. Non-captive magnet assemblies should be

situated so that the magnet is no further than 3/8” from

the sensing surface at any point in the floating magnet

assembly’s movement.

Note: Ferromagnetic material (material readily

magnetized) should be located no closer than 0.25” from

the sensing surface of the LDT. This includes mounting

brackets, magnet spacers, magnet brackets, and

mounting screws. Ferromagnetic material can distort the

magnetic field, causing adverse operation or failure of the

LDT.

Check all LDT wires for continuity and/or shorts. It

is preferable that the cable between the LDT and the

interface device be one continuous run. If you are using

a junction box, it is highly recommended that the splice

junction box be free of AC and/or DC transient-producing

lines. The shield should be carried through the splice

and terminated at the interface device end.

Power Supply Check

This section will help you to determine if your power

supply is adequate for the LDT to operate properly, or if

the LDT’s cable has a short or open.

In order for the 955DQ to operate properly, the external

power supply must provide a level between 13.5 to

30 VDC. A power supply providing voltage above this

specified range may damage the LDT. A power supply

providing power below this specified range will not be

sufficient to power the LDT. When powering more than

one BRIK on a single power supply, remember that each

BRIK requires three (2.5) watts of power maximum (2

watts typical). The amount of current draw will vary

based on the input voltage used. To calculate the current

draw for a particular LDT, divide the LDT wattage by the

input voltage. For example, 2 watts divided by 24 VDC

equals 104 mA.

If your LDT is not operating properly, the LDT’s cable

may have an open or short, or the power supply is not

supplying sufficient power. To verify this, perform the

following steps:

1. Turn the power supply off.

2. Remove the mating connector from the LDT.

3. Turn the power supply on.

4. Using a digital voltmeter, check from power supply

common (GND) and Power Supply + (Vsource) from

the mating end of the cable for a level between +13.5

and +30 VDC.

If reading is between 13.5 and 30 VDC, turn power

supply off and go to step 7. If reading is below 13.5 VDC,

either your power supply is not providing enough power

or the LDT’s cable possibly has a short/open. Readings

of no voltage or minimal voltage (less than 5 volts) may

be due to short/open in the cable. If reading is not

between 13.5 and 30 VDC, go to step 5. If reading is

above 30 VDC, adjust power supply or replace.

5. Turn the power supply off.

6. Check the continuity of the individual wires of the

cable between the power supply and the LDT. Check

for continuity from one end of the cable to the other.

Also verify that no shorts exist between pins.

7. Reconnect the mating connector to the LDT.

8. Turn power supply on.

9. Using a digital voltmeter, check the power supply’s “+”

and “-” terminals for a voltage between

13.5 and 30 VDC.

Low voltage readings may indicate a power supply with

a wattage (current) rating that is too low. (Each LDT

requires 2.5 watts). If the cabling checks out in step 6

and your voltage is below 13.5 VDC, check your power

supply current rating. If voltage is between 13.5 to 30

VDC and the LDT is still inoperative, contact factory.

18

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • 248.435.0700 • Fax 248.435.8120 • www.AMETEKAPT

.com

Page 19

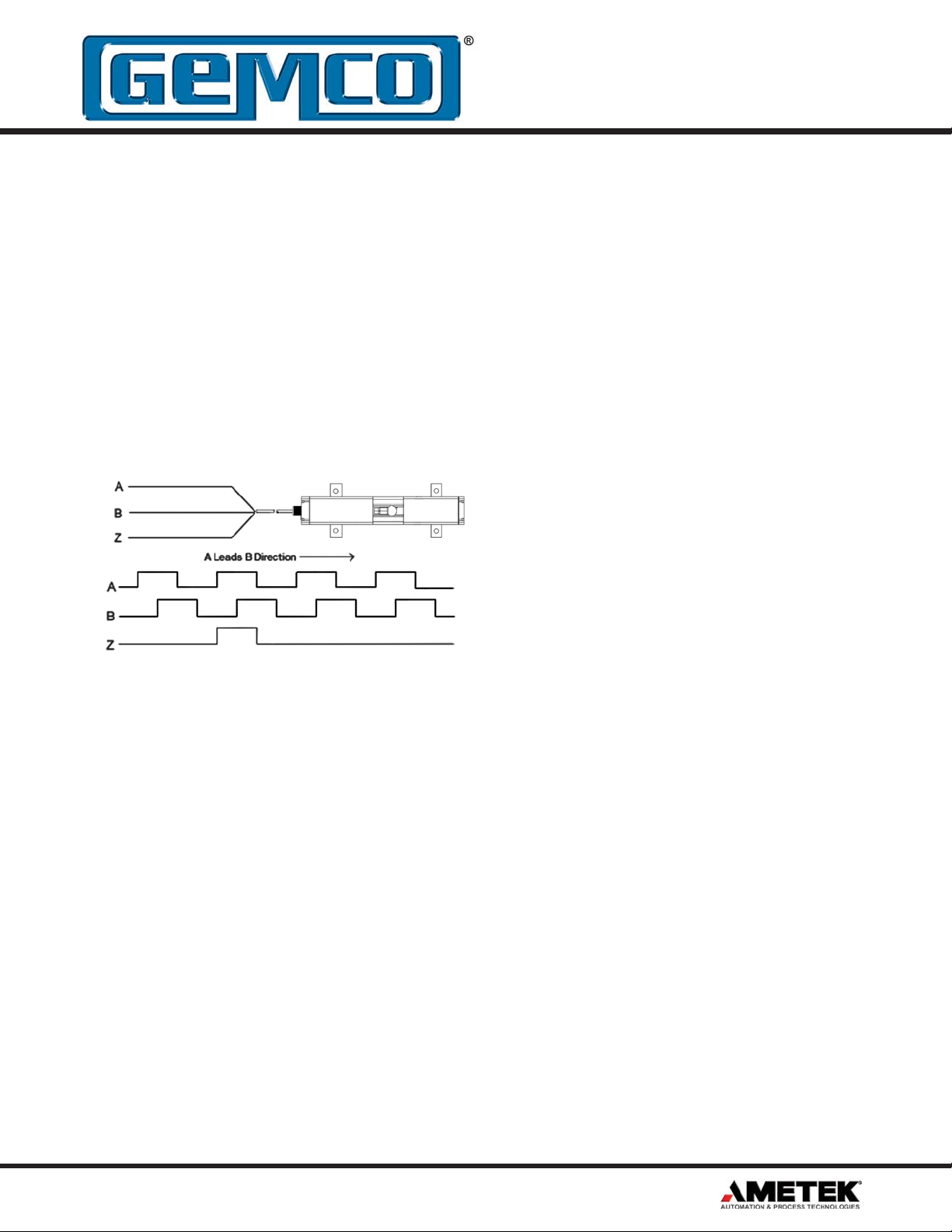

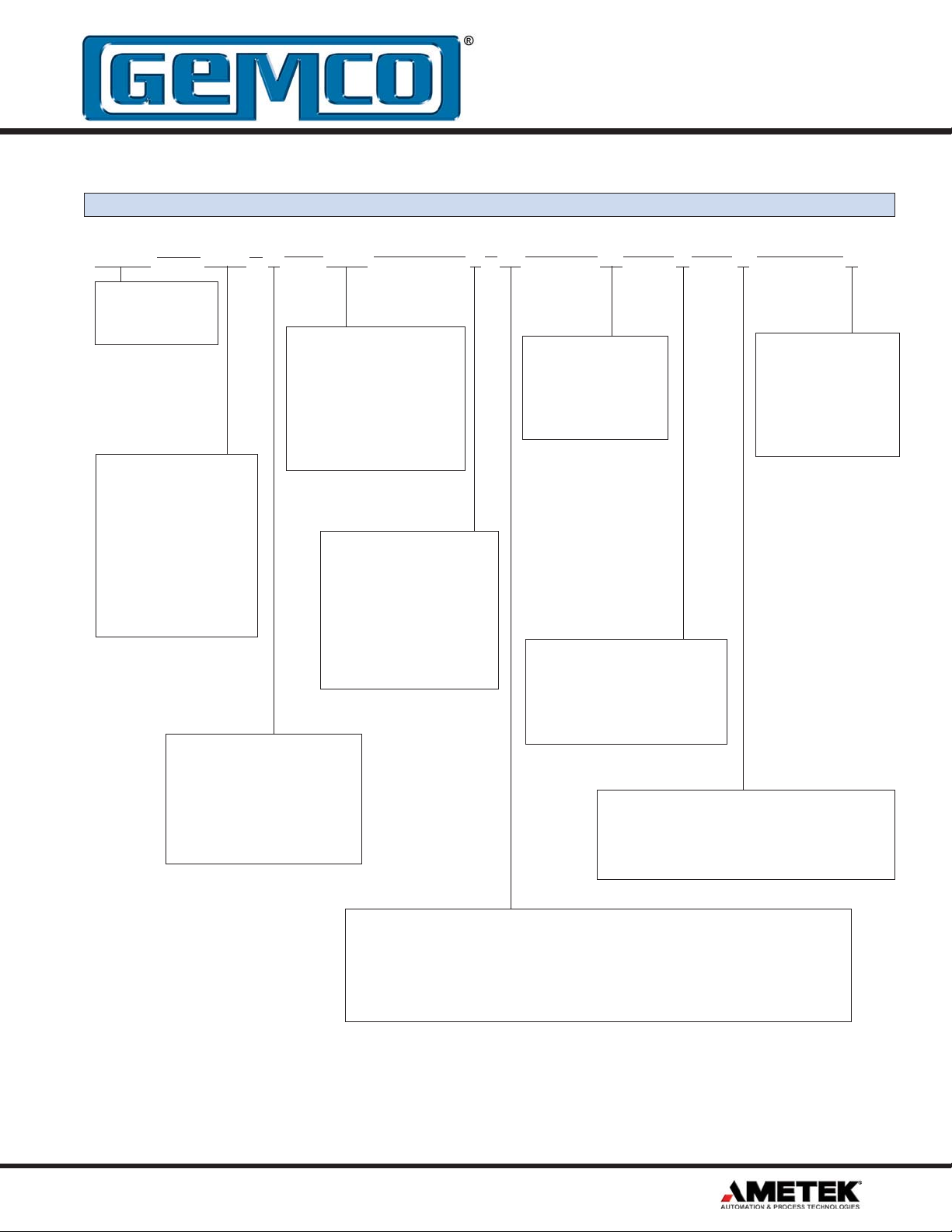

3.8 Catalog Numbering System

Part Numbering

955DQ 0120 E 1000 E F7 X1 N D X

955DQ BRIK

Quadrature

Output

Stroke Length

Insert stroke length to 0.1

inch. Enter as a four-place

number. Example A 12.0”

stroke enters as 0120. To

convert a metric stroke in

millimeters, multiply millimeter value by 0.03937

to arrive at inch value.

Connector Style

H = HRS

Environmental Connector

E = Euro 12 Pin,

12mm Connector.

Consult factory for others.

Output Resolution

Cycles per inch, maximum

internal resolution is .001

inches. 1000 standard (Available range is 0001 through

9999). Consult factory for for

ranges above 9999.

Input Type

E = Sinking

(Typically used with sourcing

output type)

C = Sourcing

(Typically used with sinking

output type)

T = TTL Level

Output Mode

X1 = X1 Quadrature

D1 = Dual Magnet,

Difference between

magnets.

Zero Offset Storage

V = Volatile (nonretentive)

N = Nonvolatile

(retentive, 100,000 storage cycles

maximum)

Output Drivers

D = Differential RS422 line driver, TTL compatible.

L = Differential line driver 13.5 to 30 VDC,

V out = V in (LDT Power) - 1 Volt.

Options

X = None

E = Wet environment.

Electronics sealed to

IP68 Rating. Connector

Option E only.

Quadrature Cycle Output

Frequency Range

A1 = 1 KHz

A2 = 2 KHz

A3 = 5 KHz

F1 = 10 KHz

F2 = 25 KHz

F3 = 50 KHz

F4 = 75 KHz

F5 = 100 KHz

F6 = 150 KHz

F7 = 250 KHz

F8 = 500 KHz

F9 = 1.0 MHz

Note: Contact our Technical Support at 1-800-635-0289

for custom configurations.

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • 248.435.0700 • Fax 248.435.8120 • www.AMETEKAPT.com

19

Page 20

3.9 Specifications for 955DQ

Null Zone

Dead Zone

Extrusion Assembly

Connector

Sensor Length

Agency Approval

Shock & Vibration

Input Voltage

Current Draw

Nonlinearity

Repeatability

Hysteresis

Operating Temperature

Storage Temperature

Drivers

Option D

General Specifications

3.00”

2.00”

Anodized Aluminum with gasket seals, IP 67, IP 68 Optional

Option H - HRS-Style Standard (quick connect/disconnect) Connector

Option E - 12 Pin, 12mm Euro Style Connector

5” to 180”

CE

Random Vibration MIL-STD 810E, 10Grms random, 20Hz - 2K Hz

Shock Tested to 40G

Electrical Specifications

Unipolar 13.5 to 30 VDC

2.5 watts maximum

+/- 0.05% of full stroke

+/- 0.006% of full stroke

+/- 0.02% of full stroke

-20° to 70° C

-40° to 85° C

1. Quadrature A RS-422 differential

2. Quadrature B RS-422 differential

3. Zero (index) position RS-422 differential

Maximum 5 volts, minimum 2 volts into a 50 ohm load (TTL compatible)

Option L

Digital Input

Update Time

1. Quadrature A differential line driver

2. Quadrature B differential line driver

3. Zero (index) position differential line driver

Maximum 30 VDC, min 13.5 VDC, driver 0L7272

V out = V in (LDT Power) - 1 volt

1. Zero position set 5 - 30 volts Source or Sink

2. Burst mode input 5 - 30 volts Source or Sink

Input impedance 5 K ohms

Sink threshold Input < 0.41 * Power Supply Voltage

i.e. 0.41 x 24 VDC Power Supply = < 9.84 VDC

Source threshold Input > 0.41 * Power Supply Voltage

i.e. 0.41 x 24 VDC Power Supply = > 9.84 VDC

TTL threshold Input > 2.1 Volts

40” or less

4

1” to 100” 2mS (Stroke Lengths 41” to 100”)

101” to 150” 3mS (Stroke Lengths 101” to 150”)

151” to 180” 4mS (Stroke Lengths 151” to 180”)

Specifications are subject to change and are based on a typical 36” LDT

1mS (Stroke Lengths 5” to 40”)

20

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • 248.435.0700 • Fax 248.435.8120 • www.AMETEKAPT

.com

Page 21

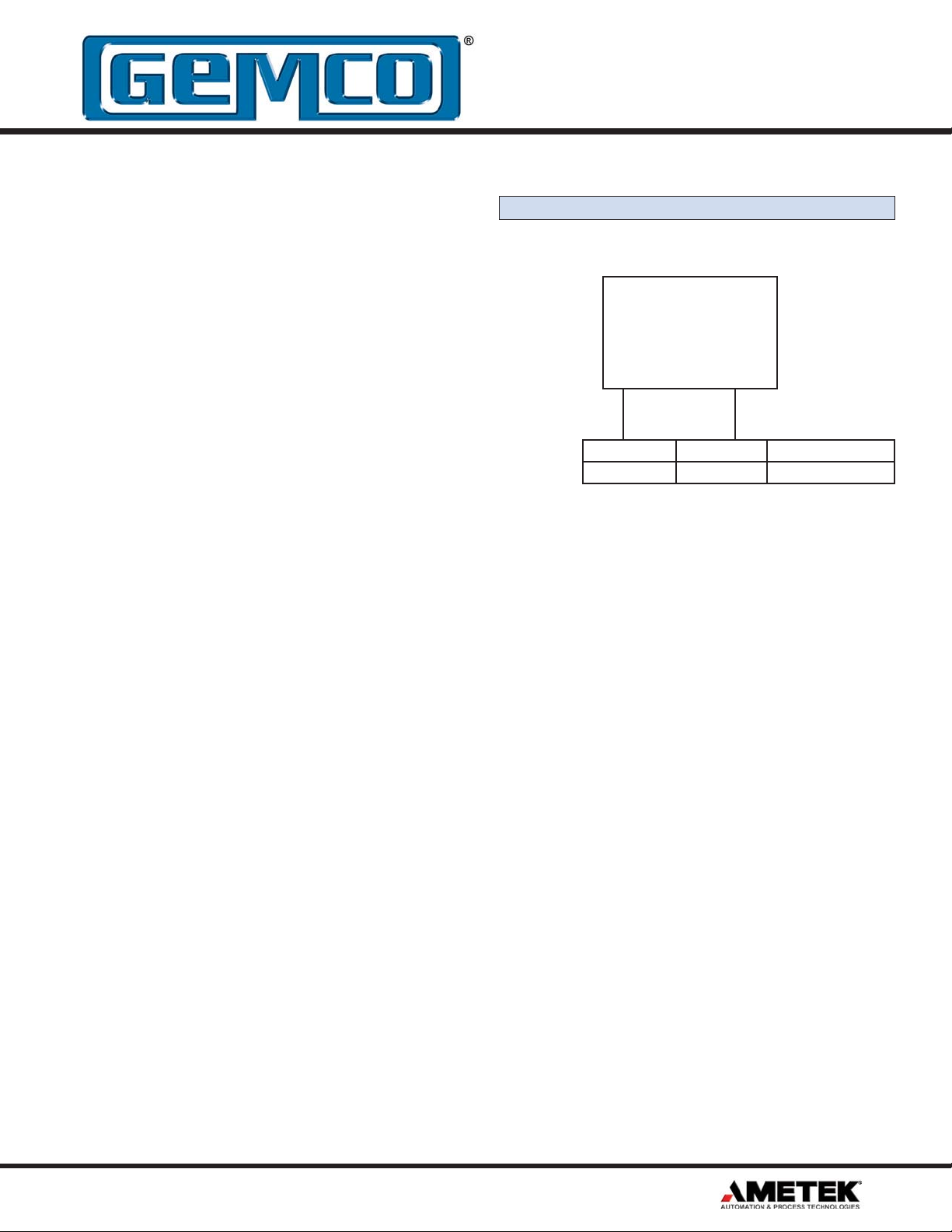

3.10 Accessories

OF MAGNET SLUG

Mounting Foot

Part Number SD0522000

0.2

(4 Holes)

.6

.3

Slide Magnet Assembly

Part Number SD0521800

1.37

.68

.25

.08

.28

1.30

1.04

.69

.87

R.87

360 ROTATION

1.50

.56

.25 TO

CENTERLINE

OF MAGNET

SENSOR

Cable Option H

Part Number SD0527700LXX

X = Length in Feet

.34

.50

1.00

TO CENTERLINE

OF MAGNET

.34

.75

Floating Magnet Assembly

Part Number SD0522100

1.31

.25

.20 THRU

.359 C’BORE

.21 DEEP

OTHER END

2 PLACES

2.00

1.31

.50

.20 THRU

2 PLACES

Cable Option E

Part Number 949-023LXX

X = Length in Feet

1.9

.4

2.6

.58

.37

1.69

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • 248.435.0700 • Fax 248.435.8120 • www.AMETEKAPT.com

21

Page 22

955DQ Glossary

Active Stroke Area The area on the extrusion between the Null and Dead Zone on which the magnet assembly

Burst Input An input signal to the probe will cause a “burst” of data, representing the absolute position to be

Dead Zone

Floating Magnet

Incremental

Input Type

Non-volatile

Null Zone

Output Driver

Output Resolution Used to determine amount of pulses per inch.

Quadrature

Quadrature Cycle Output Frequency

RS-422 Differential

Slide Magnet Assembly

moves.

fed to the controller.

An area usually 2” from the end of the extrusion where sensing of the magnet is not possible.

A non-ferrous assembly that contains the magnet that moves across the LDT’s sensing surface

in a non-contact manner.

A relative position feedback device whose signal is always referenced to the zero position. The

LDT produces a digital, square wave pulse train that is fed into an up/down counter chip or

clock to derive position.

Used to determine input type for “burst” and “zero” modes. i.e.; sinking, sourcing or TTL.

Position is held in memory and will not be lost on power down.

An area usually covering 3.00” on the extrusion beginning at the connector end.

Used to determine output type of A, B and Z.

Two output channels out of phase by 90 electrical degrees.

The maximum frequency at which the pulse rate is transmitted out of the probe.

Differential line driver.

A non-ferrous assembly that moves across the LDT’s sensing surface.

Unipolar

Volatile

Wire Speed

Zero Pulse

A power supply that provides a single voltage.

Position held in memory that is lost on power down.

The average time it takes a pulse to travel one inch on the LDT’s wire.

By sending a signal to the probe at any time in the stroke a new zero point can be established.

22

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • 248.435.0700 • Fax 248.435.8120 • www.AMETEKAPT

.com

Page 23

Notes:

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • 248.435.0700 • Fax 248.435.8120 • www.AMETEKAPT.com

23

Page 24

Other Products

Copyright 2004 by AMETEK AUTOMATION & PROCESS TECHNOLOGIES.

All Rights Reserved. Made in the USA.

1080 N. Crooks Road, Clawson, MI 48017-1097

Phone 248-435-0700 Toll Free 800-635-0289

Fax 248-435-8120 www.AMETEKAPT.com

955DQ.M1R1

3/08.Z169

PQ

Loading...

Loading...