Page 1

INSTALLATION MANUAL

L

INEAR

D

ISPLACEMENT

T

RANSDUCERS

955D BRIK

GEN III WITH DIGITAL OUTPUT

955 Series

Series 956

ABSOLUTE PROCESS CONTROL

KNOW WHERE YOU ARE... REGARDLESS

Includes 955D

Programming & Maintenance

Instructions Plus Accessory Guide

Page 2

Preface

This manual is divided into three chapters. Chapter 1

provides the hardware overview for the 955D Linear

Displacement Transducers (LDT). Chapter 2 provides

instructions for installing the LDT to a mounting bracket.

Chapter 3 provides an overview and wiring instructions.

To further assist you, a glossary is provided at the back of

the manual.

!

CAUTION

Disconnect Power Before Servicing. The

Gemco 955D LDT Contains No Serviceable

Components. Consult Factory for Repair or

Replacement.

AMETEK Automation & Process Technologies has

checked the accuracy of this manual at the time it was

approved for printing. However, this manual may not

provide all possible ways of installing and maintaining

the LDT. Any errors found in this manual or additional

possibilities to the installation and maintenance of

the LDT will be added in subsequent editions. Any

comments you may have for the improvement of this

manual are welcomed.

U

Table of Contents

Chapter 1 Hardware Overview .........................3

Chapter 2 Installing the LDT ............................ 3

2.1 Mounting Instructions .............................3

2.2 Mounting the Magnet Assembly ............. 3

Chapter 3 955D Outputs ...................................5

3.1 CP (Control Pulse) .................................5

3.2 VP (Variable Pulse) ................................5

3.3 RS (Start/Stop) ....................................... 6

3.4 955D Wiring Connections ......................6

3.5 Features ........................ ........................7

3.6 Troubleshooting for 955D .......................8

3.7 Catalog Numbering System ...................9

3.8 Specifi cations for 955D .......................... 10

3.9 Accessories ............................................ 10

955D Glossary ...................................................11

AMETEK reserves the right to revise and redistribute

the entire contents or selected pages of this manual.

All rights to the contents of this manual are reserved

by AMETEK. The BRIK is a registered trademark of

AMETEK.

2

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • 248.435.0700 • Fax 248.435.8120 • www.AMETEKAPT.com

Page 3

Chapter 1 Hardware Overview

Chapter 2 Installing the LDT

Overview

The Series 955D BRIK with Digital Output is an

accurate, auto-tuning, non-contact, Linear Displacement

Transducer in an economical, low profi le package. The

transducer utilizes our fi eld proven magnetostrictive

technology to give absolute position, repeatable to .006%

of the sensing distance. The streamlined anodized

aluminum extrusion houses the sensing element and

electronics. The magnet moves over the sensing

element that determines the position and converts it to a

digital output.

Features

The 955D has a truly unique feature. This LDT has autotuning capability, the ability to sense a magnet other than

the standard slide magnet and adjust its signal strength

accordingly.

There is an indicator LED that is located at the connector

end of the probe and provides visual status information

regarding the operation of the probe. Green indicates

proper or normal operation. Red indicates the loss of the

magnetic signal or a probe failure. The LED turns Yellow

if no interrogation signal detected. When the probe is

in the normal mode of operation, the LED with remain

illuminated continuously.

LED Colors

Green Magnet is present and within the active range.

Red Fault, the LDT has lost its signal from the magnet or the

magnet has moved into the Null Zone or Dead Band.

Yellow No external interrogation pulse detected.

Note: The series number on your LDT is a record of all

the specifi c characteristics that make up your unit. This

includes what interface type it is, its output signal and

range, the type of connector the unit uses, and stroke

length. For a translation of the model number, see

Section 3.7 Catalog Numbering System.

The 955D BRIK with Digital Output is a Linear

Displacement Transducer. It provides a Control Pulse,

Start/Stop or Variable Pulse output signal that is

proportional to the position of the slide magnet assembly

along the length of the probe.

2.1 Mounting Instructions

The Series 955D can be mounted vertically or

horizontally using SD0522000 mounting brackets. The

mounting brackets slide in the grooves on the lower part

of the extrusion and clamp down when tightened. It is

recommended to use one mounting bracket on each end

and every three feet in between.

Ferro-magnetic material, (material readily magnetized)

should be placed no closer than .25” from the sensing

surface of the LDT.

2.2 Mounting the Magnet Assembly

Before mounting the magnet assembly, you should

consider the following

• Ferromagnetic material should not be placed closer

than 0.25” from the LDT’s sensing surface. Failure

to do so could cause erratic operation. Non-ferrous

materials, such as brass, copper, aluminum,

nonmagnetic stainless steel or plastics, can be

in direct contact with the magnet assembly and

sensing surface without producing any adverse

results.

• Make sure that the magnet is located within

the LDT’s active stroke area. Captive magnet

assemblies should be positioned so that they can

move freely over the entire area of the active stroke

without binding or pushing on the extrusion. Noncaptive magnet assemblies should be situated so

that the magnet is no further than 3/8” from the

sensing surface at any point in the fl oating magnet

assembly’s movement.

• When using the Floating Magnet assembly

(SD0522100), the magnet should be installed within

3/8” of the sensing surface. The magnet assembly

should also be installed in such a manner that

it remains an even distance from the aluminum

extrusion throughout the entire stroke. Improperly

installed magnets can result in output signal non-

linearity.

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • 248.435.0700 • Fax 248.435.8120 • www.AMETEKAPT.com

3

Page 4

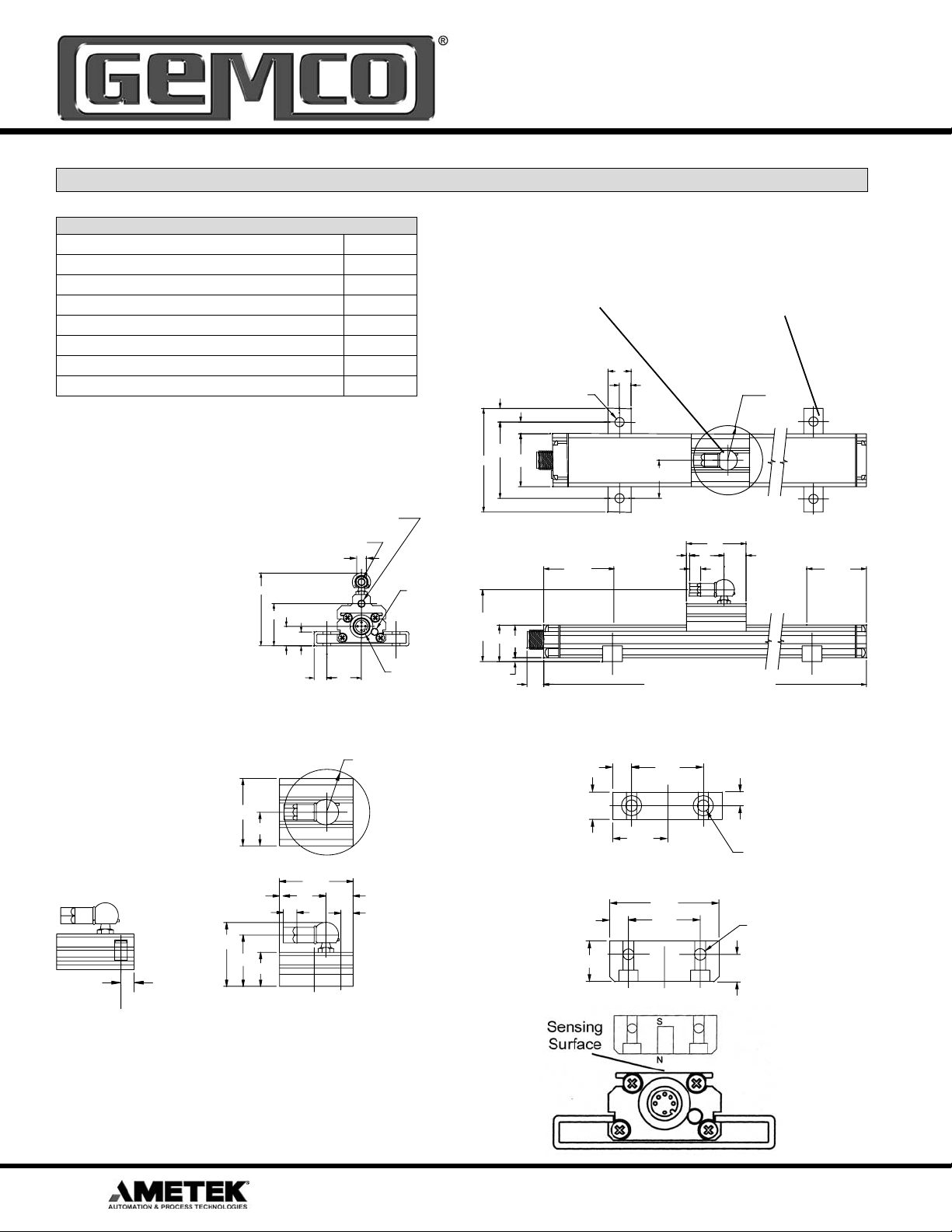

Dimension Drawing

Accessories

Item Part Number

Slide Magnet SD0521800

Float Magnet SD0522100

Mounting Foot SD0522000

6 Ft. Cable (6 Pin, Straight Micro Connector, Option E) 949021L6

12 Ft. Cable (6 Pin, Straight Micro Connector, Option E) 949021L12

6 Ft. Cable (6 Pin, Right Angle Micro Connector, Option E) 949022L6

12 Ft. Cable (6 Pin, Right Angle Straight Micro Connector, Option E) 949022L12

M5 X .56 DEEP

ALTERNATE MTG.

HOLE FOR LINKAGE

M5 X .40 DEEP

LINKAGE MTG. HOLE

.28

2.06

1.19

.55

.40

Mounting Brackets (SD0522000)

A standard female swivel

mounting arm is provided

with the slide magnet

assembly. For extensions

and other options contact

AMETEK at 800-635-0289.

slide in the grooves on the side

of the extruded housing. When

tightened down with fastening

hardware the mounting bracket

clamps the unit into place. It is

recommended to use one mounting

bracket on each end and every

three feet between.

.60

.22 MTG. HOLES

2 PER MTG. FOOT

.36

.30

1.97

2.68

1.37

NULL

LED

1.80

.92

.82

.30

1.00

1.50

.08

.87

.28

.56

R.89

360 ROTATION

DEAD

DEAD

BAND

ZONE

SLIDE MAGNET ASSEMBLY

P/N SD0521800

.25

OF MAGNET SLUG

1.30

1.37

1.04

.36 .98

.68

.08

.28

.69

1.50

.87

.56

6 Pin,12 mm EURO

MALE CONNECTOR

R.87

360 ROTATION

.25 TO CENTERLINE

OF MAGNET SENSOR

.10

.42

FLOATING MAGNET ASSEMBLY

P/N SD0522100

.50

TO CENTERLINE

.75

.34

1.00

OF MAGNET

.34

L = NULL +

1.31

2.00

1.31

STROKE + DEAD ZONE

DEAD BAND

.25

.20 THRU

.359 C’BORE

.21 DEEP

OTHER END

2 PLACES

.20 THRU

2 PLACES

.50

Note: The North Pole of the magnet

should be pointed towards the probe.

4

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • 248.435.0700 • Fax 248.435.8120 • www.AMETEKAPT.com

Page 5

Chapter 3 955D Outputs

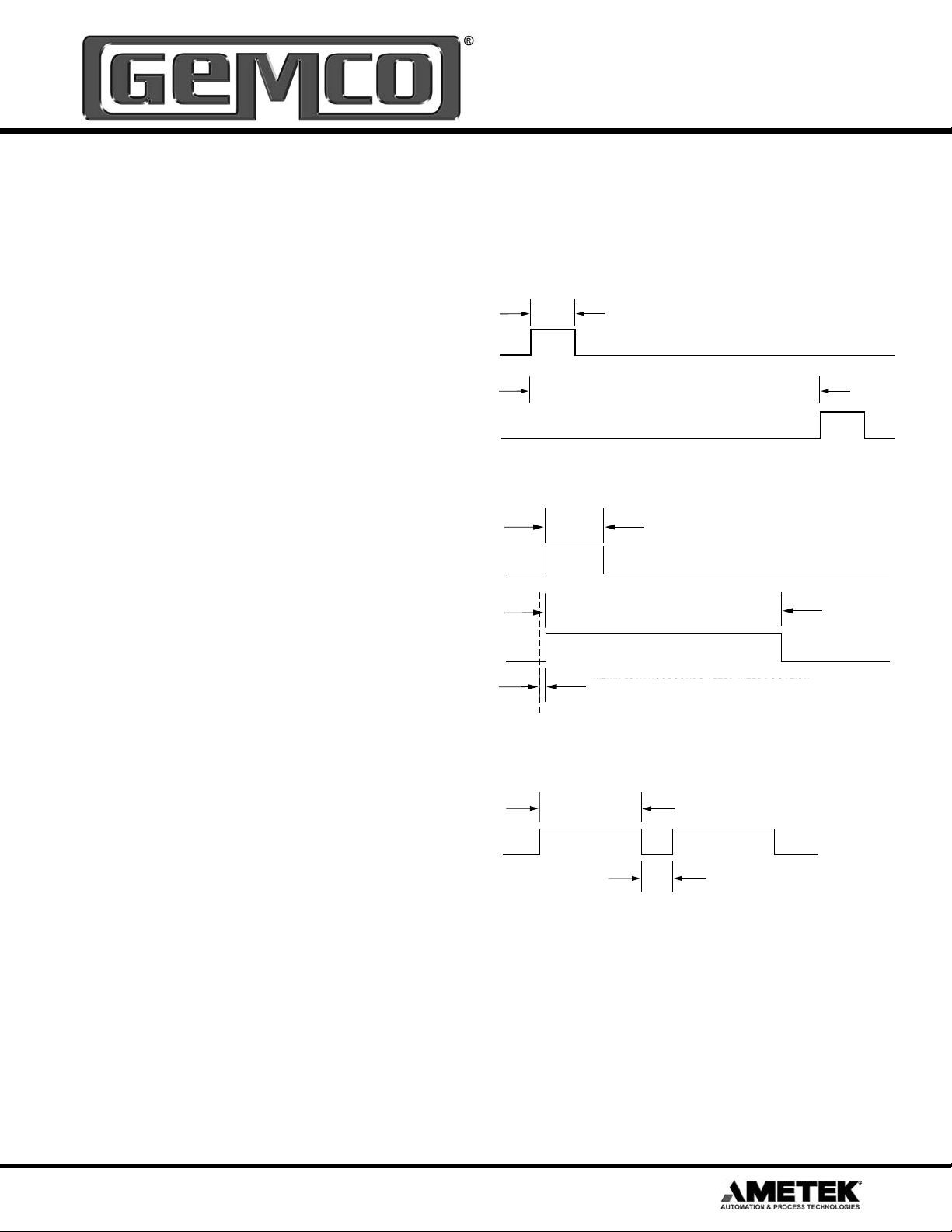

3.1 CP (Control Pulse)

The Control Pulse signal interface of the BRIK digital

output series is a differential RS-422 output. The maximum cable length for the differential digital LDT’s is 1,500

feet. To initiate a start pulse, an external device is used.

This start pulse should be 1.0 microsecond in duration.

After the start pulse is received, the LDT will generate

a stop pulse of 1.0 microsecond in duration. The time

between the leading edge of the start pulse to the leading edge of the stop pulse is proportional to the distance

from the Null Zone to the Magnet. The order of these two

pulses is illustrated in the Figure 3-1. To wire the 955DCP, see Figure 3-6. For proper grounding information,

see Section 3.4.

3.2 VP (Variable Pulse)

The Variable Pulse signal interface of the BRIK digital

output series is a pulse width modulated signal (RS-422).

The maximum cable length for the differential LDT’s is

1,500 feet. This LDT can also be confi gured for external

or internal interrogation. External interrogation is when

an external device connected to the LDT generates a

start pulse. This start pulse should be a minimum of 1.0

microsecond in duration. Within 50 nanoseconds after

the leading edge of the start pulse has been received,

the LDT will generate an output pulse. The duration of

the output pulse is proportional to the distance from

the Null Zone to the Magnet . The order of these two

pulses is illustrated in Figure 3-2. The 955D-VP can also

generate internal interrogations. This LDT will continually

output pulse width modulated signals. As with a 955DVP using an external interrogation, the duration of this

output pulse is proportional to the distance from the Null

Zone to the Magnet. This is illustrated in Figure 3-3. To

wire the 955D-VP, see Figure 3-6. For proper grounding

information, see Section 3.4.

Figure 3-1 955D-CP

1 MICROSECOND (RECOMMENDED)

0.2 MICROSECONDS (MINIMUM)

+ INPUT (START PULSE)

TIME BETWEEN PULSES IS PROPORTIONAL TO

TIME BETWEEN PULSES IS PROPORTIONAL TO

DISTANCE BETWEEN MAGNET AND NULL ZONE

DISTANCE BETWEEN MAGNET AND HEX HEAD

+ OUTPUT (STOP PULSE)

Figure 3-2 955D-VP with External Interrogation

1 MICROSECOND (RECOMMENDED)

0.2 MICROSECONDS (MINIMUM)

INPUT (INTERROGATION)

WIDTH OF PULSE IS PROPORTIONAL TO

WIDTH OF PULSE IS PROPORTIONAL TO

DISTANCE BETWEEN MAGNET AND NULL ZONE

DISTANCE BETWEEN MAGNET AND HEX HEAD

OUTPUT PULSE

WITHIN 50 NANOSECONDS AFTER INTERROGATION

WITHIN 50 NANOSECONDS AFTER INTERROGATION

PULSE WIDTH MODULATED OUTPUT SIGNAL BEGINS

TO DISTANCE BETWEEN MAGNET AND HEX HEAD

Figure 3-3 955D-VP with Internal Interrogation

WIDTH OF PULSE IS PROPORTIONAL TO

WIDTH OF PULSE IS PROPORTIONAL

DISTANCE BETWEEN MAGNET AND NULL ZONE

TO DISTANCE BETWEEN MAGNET AND HEX HEAD

OUTPUT PULSE

LOW OUTPUT VARIES DEPENDING ON THE

LOW OUTPUT VARIES DEPENDING ON LENGTH

INTERROGATION TIME AND THE POSITION

PROGRAMMED VIA DIP SW2 SWITCHES 1-6

OF THE MAGNET

Recirculations

The method used to improve the resolution of a system

using a digital LDT. The “on” Time of a pulse width

output is multiplied by a specifi c factor (from 1-127).

This multiplication provides more counting time for the

counter in the customer’s electronics, thus improving

the resolution. The only disadvantage to the higher

recirculation numbers is the time needed to process the

signal.

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • 248.435.0700 • Fax 248.435.8120 • www.AMETEKAPT.com

5

Page 6

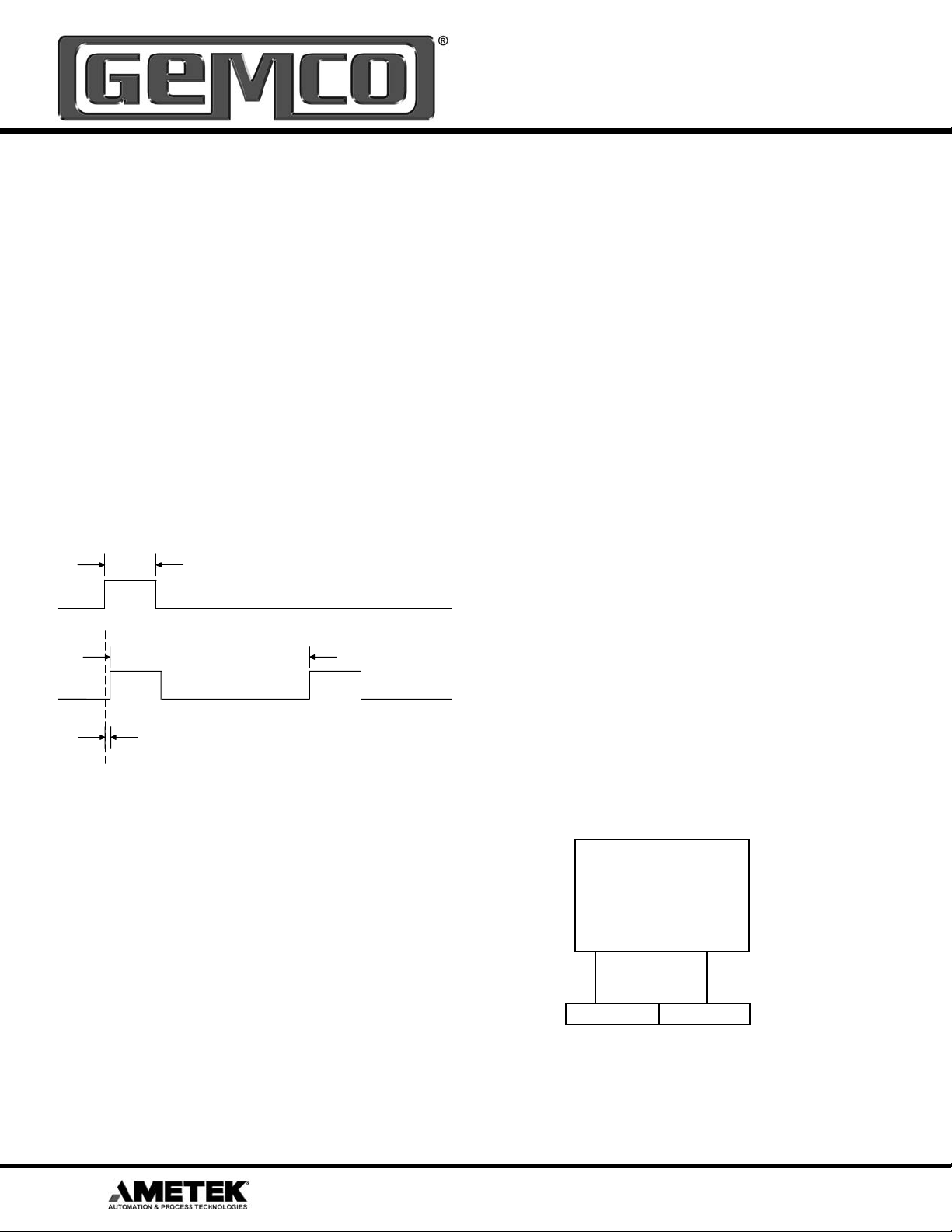

3.3 RS (Start/Stop)

The Start/Stop signal interface of the BRIK digital output

series is differential RS-422 output. The maximum cable

length for differential LDT's is 1,500 feet. To initiate a start

pulse, an external device is used. This start pulse should

be a minimum of 1.0 microsecond in duration. Within 50

nanoseconds after the leading edge of the start pulse,

the LDT will generate a start pulse of 1.0 microsecond in

duration. A stop pulse of 1.0 microsecond in duration will

follow. The time it takes from the leading edge of the start

pulse to the leading edge of the stop pulse is proportional

to the distance from the Null Zone to the Magnet . The

order of these two pulses is illustrated in Figure 3-4. To

wire the 955D-RS, see Figure 3-6. For proper grounding

information, see Section 3.4.

Figure 3-4 955D-RS

1 MICROSECOND (RECOMMENDED)

0.2 MICROSECONDS (MINIMUM)

INPUT (INTERROGATION PULSE)

OUTPUT (START PULSE) OUTPUT (STOP PULSE)

TIME BETWEEN PULSES IS PROPORTIONAL TO

TIME BETWEEN PULSES IS PROPORTIONAL TO

DISTANCE BETWEEN MAGNET AND NULL ZONE

DISTANCE BETWEEN MAGNET AND HEX HEAD

WITHIN 50 NANOSECONDS AFTER INTERROGATION

PULSE, START PULSE BEGINS

braid of tinned copper shield. Cable O.D. is .270. To

reduce electrical noise, the shield must be properly used.

Connect the cable’s shield to the controller system GND.

The connector shell on the probe is electrically connected

to the probe housing.

Always observe proper grounding techniques such as

single point grounding and isolating high voltage (i.e.

120/240 VAC) from low voltage (13.5-30 VDC cables).

Whenever possible, this cable should be run in conduit

by itself. The power supply common, the cable shield and

a good earth ground should be connected together at the

location of the power supply common.

!

WARNING

U

Do not route the BRIK output cable near high voltage

sources.

In order for the 955D to operate properly, the LDT’s

external power supply must provide a voltage between

+13.5 to +30 VDC. The power supply must be rated at

150mA minimum. The power supply should provide less

than 1% rippel and 10% regulations. (The power supply

should be dedicated to the LDT to prevent noise from

external loads from affecting the BRIK.)

3.4 955D Wiring Connections

Once the LDT has been installed, wiring connections can

be made. There are two groups of connections you will

need to make. They are as follows:

• Power Supply Connections (including ground and

shield)

• LDT Input/Output Connections

Power Supply/Ground Connections

The 955D standard cable is a 6 Pin, 12mm, Euro Style

cordset. It has 6 conductors of 24ga, with an aluminum/

polyester/aluminum foil with drain wire plus an overall

6

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • 248.435.0700 • Fax 248.435.8120 • www.AMETEKAPT.com

Figure 3.5 Power Supply Wiring

UNIPOLAR

Single ended

power supply

+13.5 to +30 VDC

+ COM

Pin 1 (brown) Pin 3 (blue)

Page 7

Figure 3.6 Wiring Diagram

Cable Assembly

Part Number 949-021LX

(X = Length in Feet)

PIN - 1 BROWN

PIN - 2 WHITE

PIN - 3 BLUE

PIN - 4 BLACK

PIN - 5 GRAY

PIN - 6 PINK

POWER +

OUT +

COMMON

OUT-

INT-

INT+

949-021LX (X = Length in Feet)

Part Number

Shield

3.5 Features

Automatic Gain Control

The Automatic Gain Control feature will automatically

search and fi nd the magnet on power up, if power is

applied without a magnet on the LDT, the LED will turn

RED indicating no magnet signal is detected. Turn power

off and place magnet within the active stroke area. Reapply power.

When using the Floating Magnet assembly (SD0522100),

the magnet should be installed within 3/8” of the sensing

surface. The magnet assembly should also be installed

so that it remains an even distance from the aluminum

extrusion throughout the entire stroke. Improperly

installed magnets can result in output signal non-linearity.

LED Colors

Green Magnet is present and within the active programmed

Red Fault, the LDT has lost its signal from the magnet or the

Yellow No external interrogation signal detected.

range.

magnet has moved into the Null Zone or Dead Band.

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • 248.435.0700 • Fax 248.435.8120 • www.AMETEKAPT.com

7

Page 8

3.6 Troubleshooting for 955D

Troubleshooting describes common problems that

may occur when installing the LDT and offers possible

solutions to these problems. If, after reading this

appendix, you are unable to resolve a problem, contact

our technical support department at 1-800-635-0289.

General Checks

Make sure that the magnet is located within the LDT’s

active stroke area. Captive magnet assemblies should

be positioned so that they can move freely over the entire

area of the active stroke without binding or pushing on

the extrusion. Non-captive magnet assemblies should be

situated so that the magnet is no further than 3/8” from

the sensing surface at any point in the fl oating magnet

assembly’s movement.

Note: Ferromagnetic material (material readily

magnetized) should be located no closer than 0.25” from

the sensing surface of the LDT. This includes mounting

brackets, magnet spacers, magnet brackets, and

mounting screws. Ferromagnetic material can distort the

magnetic fi eld, causing adverse operation or failure of the

LDT.

Check all LDT wires for continuity and/or shorts. It

is preferable that the cable between the LDT and the

interface device be one continuous run. If you are using

a junction box, it is highly recommended that the splice

junction box be free of AC and/or DC transient-producing

lines. The shield should be carried through the splice

and terminated at the interface device end.

Power Supply Check

the LDT wattage by the input voltage. For example, 2.5

watts divided by 24 VDC equals 105mA.

If your LDT is not operating properly, the LDT’s cable

may have an open or short, or the power supply is not

supplying suffi cient power. To verify this, perform the

following steps:

1. Turn the power supply off.

2. Remove the mating connector from the LDT.

3. Turn the power supply on.

4. Using a digital voltmeter, check pins 3 (GND) and

1 (+) from the mating end of the cable for a level

between +13.5 and +30 VDC.

If reading is between 13.5 and 30 VDC, turn power

supply off and go to step 7. If reading is below 13.5 VDC,

either your power supply is not providing enough power

or the LDT’s cable possibly has a short/open. Readings

of no voltage or minimal voltage (less than 5 volts) may

be due to short/open in the cable. If reading is NOT

between 13.5 and 30 VDC, go to step 5. If reading is

above 30 VDC, adjust power supply or replace.

5. Turn the power supply off.

6. Check the continuity of the individual wires of the

cable between the power supply and the LDT. Check

for continuity from one end of the cable to the other.

Also verify that no shorts exist between pins.

7. Reconnect the mating connector to the LDT.

8. Turn power supply on.

9. Using a digital voltmeter, check the power supply’s “+”

and “-” terminals for a voltage between

13.5 and 30 VDC.

This section will help you to determine if your power

supply is adequate for the LDT to operate properly, or if

the LDT’s cable has a short or open.

In order for the 955D to operate properly, the external

power supply must provide a level between 13.5 to

30 VDC. A power supply providing voltage above this

specifi ed range may damage the LDT. A power supply

providing power below this specifi ed range will not be

suffi cient to power the LDT. When powering more than

one BRIK on a single power supply, remember that each

BRIK requires 2.5 watts of power maximum. The amount

of current draw will vary based on the input voltage used.

To calculate the current draw for a particular LDT, divide

8

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • 248.435.0700 • Fax 248.435.8120 • www.AMETEKAPT.com

Low voltage readings may indicate a power supply with

a wattage (current) rating that is too low. (Each LDT

requires 2.5 watts). If the cabling checks out in step 6

and your voltage is below 13.5 VDC, check your power

supply current rating. If voltage is between 13.5 to 30

VDC and the LDT is still inoperative, contact factory.

Page 9

3.7 Catalog Numbering System

Variable Pulse

955D 0120 EVP 001 X

955D BRIK with

Variable Pulse Output

Output Mode

VP = Variable Pulse

Stroke Length

Insert stroke length to 0.1 inch. Enter as

a four-place number. Example A 12.0”

stroke enters as 0120. To convert a metric

stroke in millimeters, multiply millimeter

Options

X = None

E = Wet environment.

Electronics sealed to IP68 Rating.

value by 0.03937 to arrive at inch value.

Interrogation Mode

I = Internal Interrogation

E = External Interrogation

Number of Recirculations

001 (Standard) to 127

Control Pulse or Stop/Start Pulse

955D 0120XX X

955D BRIK with

Control Pulse or

Stop/Start Output

Stroke Length

Insert stroke length to 0.1 inch. Enter as

a four-place number. Example A 12.0”

stroke enters as 0120. To convert a metric

Options

X = None

E = Wet environment.

Electronics sealed to IP68 Rating.

stroke in millimeters, multiply millimeter

Output Mode

value by 0.03937 to arrive at inch value.

CP = Control Pulse

RS = RS-422 Start/Stop Pulse

Note: Contact our Technical Support at 1-800-635-0289 for custom confi gurations.

3.8 Specifi cations for 955D

General Specifi cations

Null Zone

Dead Band

Extrusion Assembly

Connector

Sensor Length

Agency Approval

Shock & Vibration

Random Vibration

Shock

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • 248.435.0700 • Fax 248.435.8120 • www.AMETEKAPT.com

3.00”

2.00”

Anodized Aluminum with gasket seals,

IP 67, IP 68 Optional

6 Pin, 12mm Euro Style Connector

5” to 180”

CE

MIL-STD 810E, 10Grms random,

20Hz - 2K Hz

Tested to 40G

Input Voltage

Current Draw

Nonlinearity

Repeatability

Hysteresis

Operating Temperature

Storage Temperature

Update Time

Electrical Specifi cations

Specifi cations are subject to change

and are based on a typical 36” LDT.

Unipolar 13.5 to 30 VDC

2.5 watts maximum

+/- 0.05% of full stroke

+/- 0.006% of full stroke

+/- 0.02% of full stroke

-20° to 70° C

-40° to 85° C

Controller Dependent

9

Page 10

3.9 Accessories

Slide Magnet Assembly

Part Number SD0521800

1.37

.68

.25

OF MAGNET SLUG

.08

.28

1.30

1.04

.69

Mounting Foot

Part Number SD0522000

0.2

(4 Holes)

Floating Magnet Assembly

Part Number SD0522100

R.87

360 ROTATION

1.50

.87

.56

.25 TO

CENTERLINE

OF MAGNET

SENSOR

.34

.50

1.00

TO CENTERLINE

OF MAGNET

.34

.75

1.31

2.00

1.31

.25

.20 THRU

.359 C’BORE

.21 DEEP

OTHER END

2 PLACES

.20 THRU

2 PLACES

.50

6 Pin Micro 12mm Euro Straight Cable

Part Number 949-021LXX

X = Length in Feet

.6

.3

1.9

.4

2.6

6 Pin Micro 12mm Euro Right Angle Cable

Part Number 949-022LXX

X = Length in Feet

10

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • 248.435.0700 • Fax 248.435.8120 • www.AMETEKAPT.com

Page 11

955D Glossary

Active Stroke Area The area on the extrusion between the Null Zone and Dead Band on which the magnet assembly

Dead Band

Floating Magnet

External Device

External Interrogations

Null Zone

LDT

RS-422 Differential

Slide Magnet Assembly

Unipolar

Wire Speed

Recirculations

Return (Stop) Pulse

Start Pulse

moves.

An area usually 2.0” from the end of the extrusion where sensing of the magnet is not possible.

A non-ferrous assembly that contains the magnet that moves across the LDT’s sensing surface in a

non-contact manner.

A device wired to the LDT which generates external interrogations.

Pulses sent from an external device to the LDT, usually to initiate a pulse sequence.

An area usually covering 3.00” on the extrusion beginning at the connector end.

Linear Displacement Transducer.

Differential line driver.

A non-ferrous assembly that moves across the LDT’s sensing surface.

A power supply that provides a single voltage.

The average time it takes a pulse to travel one inch on the LDT’s wire.

The method used to improve the resolution of a system using a digital LDT. The “on” Time of a

pulse width output is multiplied by a specifi c factor (from 1-127). This multiplication provides more

counting time for the counter in the customer’s electronics, thus improving the resolution. The only

disadvantage to the higher recirculation numbers is the time needed to process the signal.

A pulse generated by the BRIK to determine the location of the magnet assembly on the extrusion.

A pulse generated by either an external device or the LDT to start a pulse sequence.

Stop Pulse

(See Return Pulse)

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • 248.435.0700 • Fax 248.435.8120 • www.AMETEKAPT.com

11

Page 12

Other Products

Copyright 2004 by AMETEK AUT OMATION & PROCESS TECHNOLOGIES.

All Rights Reserved. Made in the USA.

1080 N. Crooks Road, Clawson, MI 48017-1097

Phone 248-435-0700 Toll Free 800-635-0289

Fax 248-435-8120 www.AMETEKAPT.com

955D.M1RO

10/04.Z167

Loading...

Loading...