Page 1

INSTALLATION MANUAL

L

INEAR

D

ISPLACEMENT

T

RANSDUCERS

™

953A VMAX

Linear Displacement Transducer

Series 953

Series 956

ABSOLUTE PROCESS CONTROL

KNOW WHERE YOU ARE... REGARDLESS

Page 2

AUTOMATION & PROCESS TECHNOLOGIES

Contents

Chapter 1: 953A Overview

Chapter 1: 953A Overview ....................................2

Chapter 2: Installing ..............................................4

2.1 Installing to a Mounting Bracket ........................4

2.2 Installing in a Hydraulic Cylinder .......................5

Chapter 3: Wiring ..................................................8

3.1 V0/V1 (Voltage) .................................................8

3.2 C4/C2 (Current) .................................................8

3.3 Setting Zero & Span Position ..........................12

Appendix A: Troubleshooting ............................13

Appendix B: Part Numbering .............................14

Appendix C: Specications ................................15

NOTE: Ametek has checked the accuracy of this

manual at the time it was approved for printing. This

manual may not provide all possible ways of installing

and maintaining the LDT. Any errors or additional

possibilities to the installation and maintenance of the

LDT will be added in subsequent editions. Comments

for the improvement of this manual are welcome.

Ametek reserves the right to revise and redistribute

the entire contents or selected pages of this manual.

All rights to the contents of this manual are reserved

by Ametek. VMAX is a registered trademark of Gemco.

Unpacking

Carefully remove the contents of the shipping carton

and check each item on the packing slip before

destroying the packing materials. Any damage must be

reported to the shipping company. If you do not receive

all of the parts, contact Ametek at 800-635-0289 (US

and Canada) or 248-435-0700 (International).

Most probes are shipped

in a Tube. To remove the

metal end cap, use a large,

at blade screw driver or

a metal rod and tap on the

inner edge of the cap until

it pivots. Grab the cap and

pull it out. Use caution as

the edge of the metal cap may be sharp.

The 953A VMAX is a magnetostrictive Linear

Displacement Transducer (LDT) for highly accurate

continuous machine positioning in a variety of

industrial applications.

This sensor is built to withstand the most severe

environmental conditions and is completely absolute.

This means that power loss will not cause the unit to

lose position information or require re-zeroing. The

non-contact design allows this device to be used in

highly repetitive applications without mechanical wear.

The 953A VMAX has a few truly unique features. One

feature is the LDT’s auto-tuning capability, the ability to

sense a magnet other than the standard magnet and

adjust its signal strength accordingly. Another feature

is that the analog output is programmable over the

entire active stroke length. The active stroke area lies

between the Null Zone and Dead Band.

There is a diagnostic LED located at the connector

end of the probe that remains green while a good

magnet signal is present and when the magnet is in

the programmed stroke area. The LED turns yellow

when the magnet is out of the programmed active

range, but still within the active stroke area. The LED

turns RED if there is a loss of magnet and the output

will go to 0 volts on a voltage unit and 3.8mA on

current model units.

The 953A VMax LDT with a 4 to 20mA output offers a

unique diagnostic capability. The normal 4 to 20mA

output indicates the position of the magnet within the

programmed span. If the position of the magnet is

outside the set span, the output is either 3.9mA or

20.1mA. If the magnet moves into the Null or Dead

Zones or there is a loss of magnet the output will be

3.8mA. This feature is only available on units with a

current output. On voltage units the voltage output

will be 0 volts below the programmed zero point and

10volts above the programmed Span.

All units can easily be changed in the eld from a

0-10VDC to a 10-0VDC or a 4-20mA to a 20-4mA.

NOTE: The part number on the LDT is a record of the

characteristics that make up your specic unit. For a

translation of the part number, see Appendix B.

If you have an RMA warranty claim, pack the probe in

a shipping tube or with stiff reinforcement to prevent

the probe from being bent in transit.

2

®

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • Phone 248.435.0700 • Fax 248.435.8120 • www.ametekapt.com

Page 3

AUTOMATION & PROCESS TECHNOLOGIES

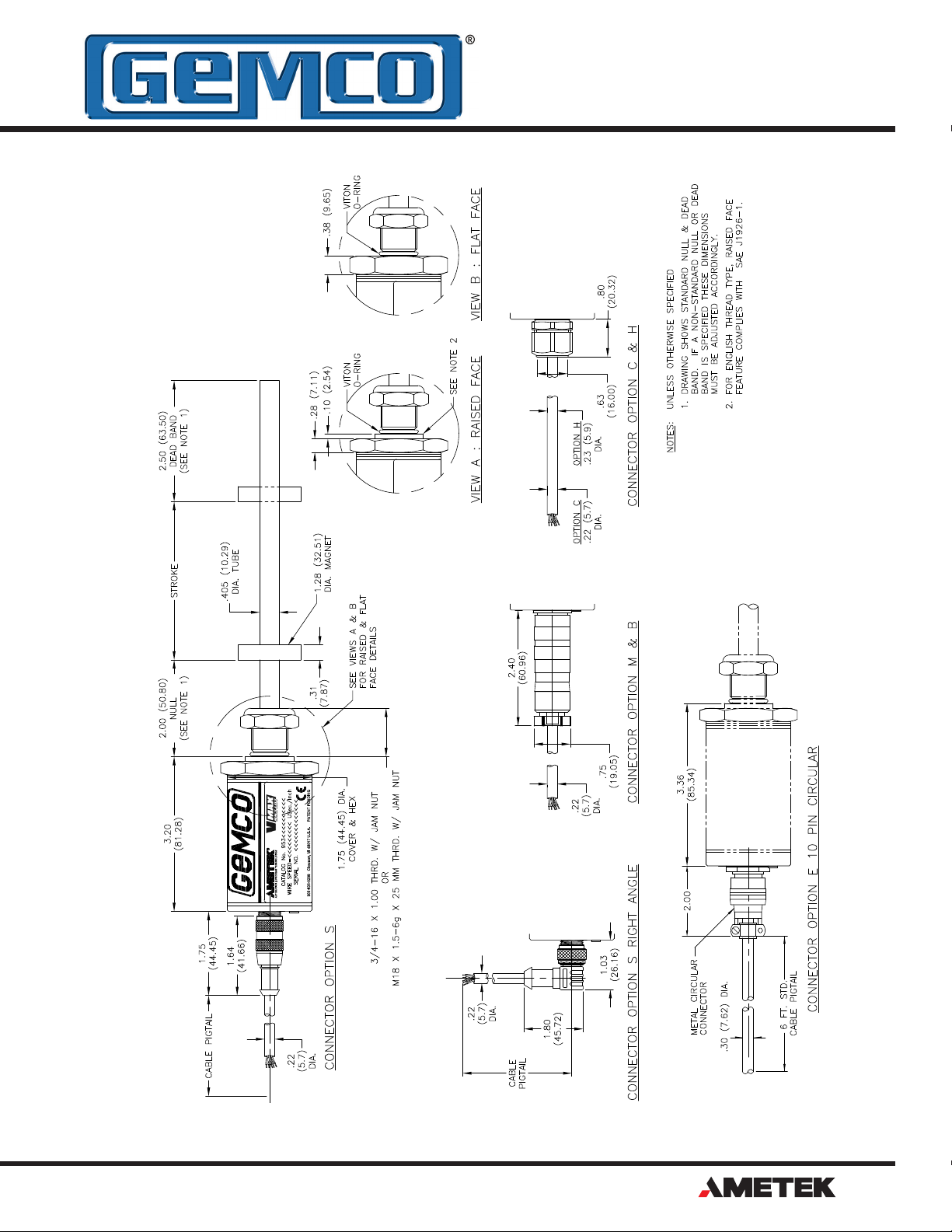

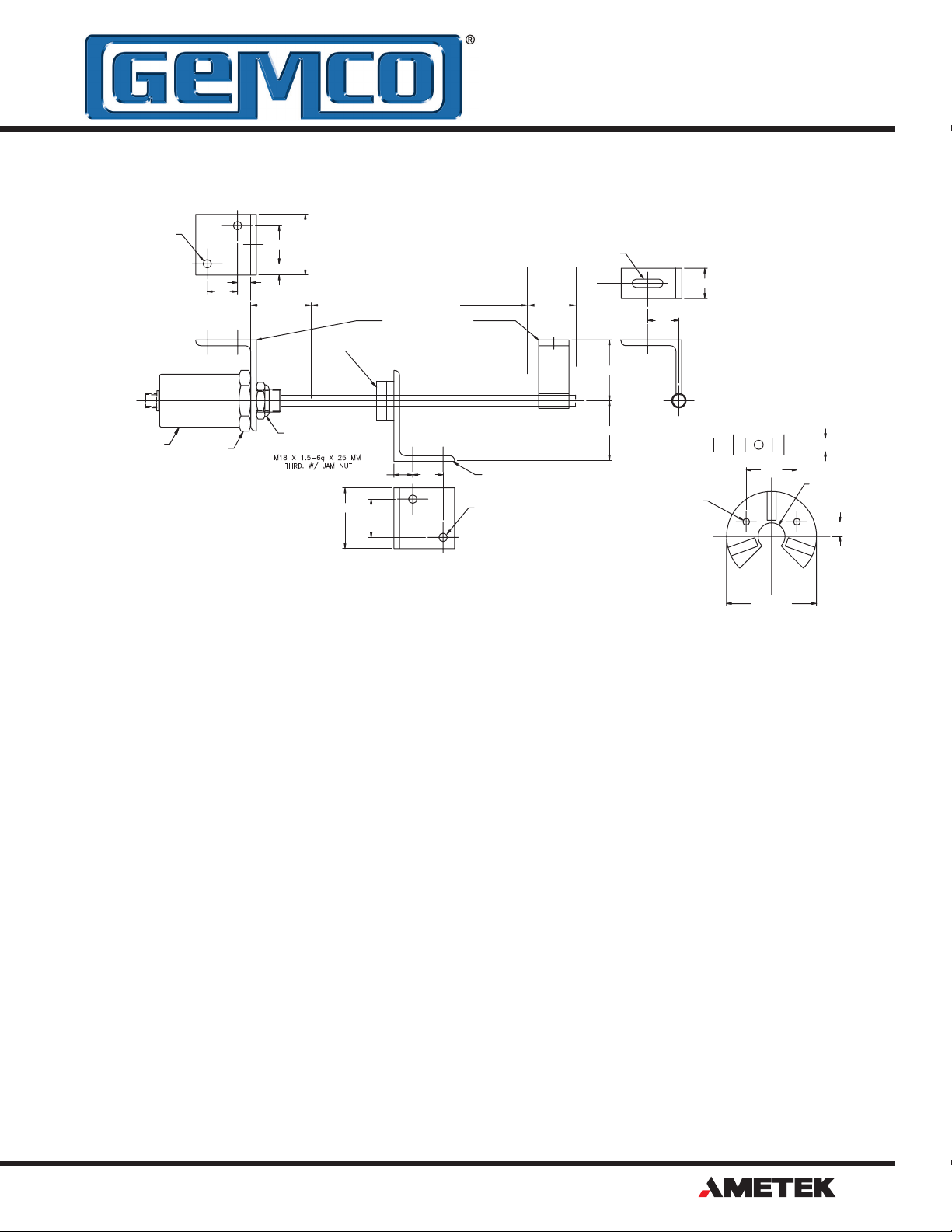

Figure 1-1 953A Dimension Drawing

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • Phone 248.435.0700 • Fax 248.435.8120 • www.ametekapt.com

®

3

Page 4

AUTOMATION & PROCESS TECHNOLOGIES

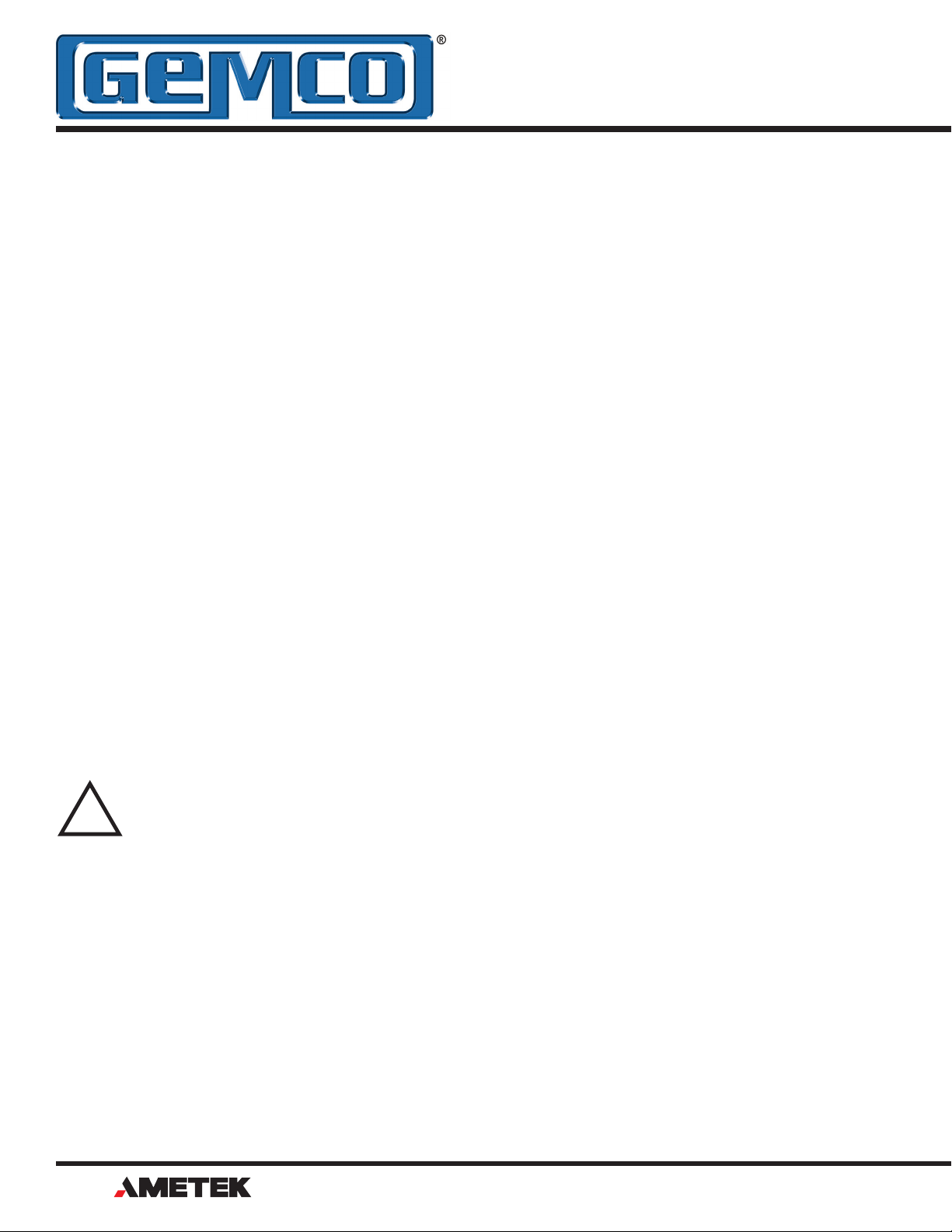

Chapter 2: Installing the LDT

!

If a mounting bracket or other part is used that is

made of ferromagnetic material (a material readily

magnetized), it should be placed no closer than 0.25"

from the LDT's rod end to minimize the effects of

magnetic ux distortion. This can cause an inaccurate

measurement of the magnet position.

Non-ferrous materials, such as brass, copper,

aluminum, non-magnetic stainless steel, or plastics,

can be in direct contact with the magnet assembly and

rod end without producing any adverse results.

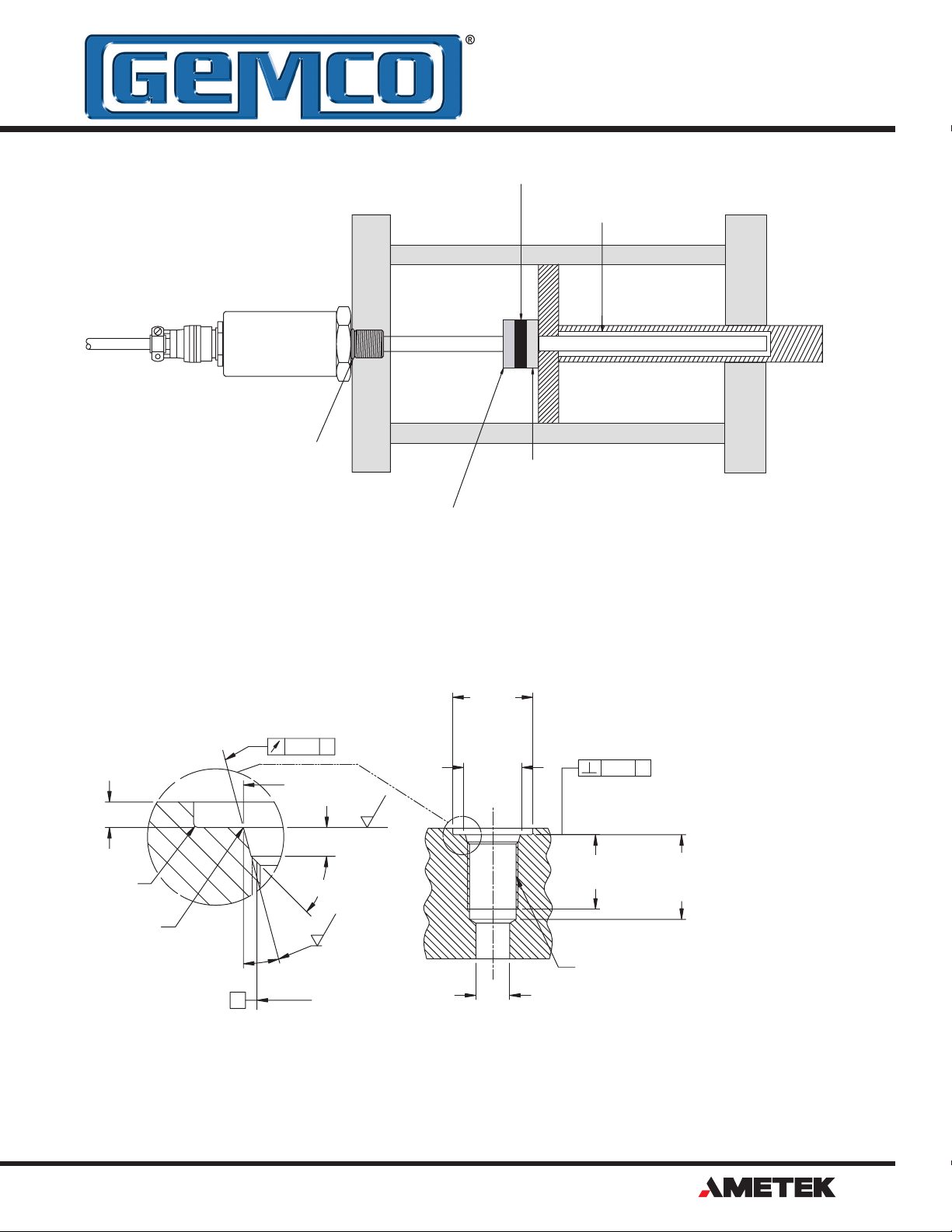

2.1: Installing the LDT to a

Mounting Bracket

Parts discussed in this section can be found in Figures

1-1 and 2-1.

1. Unscrew the LDT’s jam nut from the threads

protruding from the hex mounting base.

2. Insert the LDT’s rod end into the mounting

bracket’s hole. The mounting bracket may contain

a 3/4-16 UNF-2B or metric M18 x 1.5 threaded

hole. In this case, screw the LDT into this hole

using the threads protruding from the hex

mounting base.

3. Once the LDT is in place, screw the jam nut

back onto the threads of the hex mounting base.

Use the 1.75" hex mounting base on the head

assembly to tighten the LDT to the bracket.

WARNING: Do not use the blue

aluminum cover of the head assembly

to tighten the LDT within the bracket

(see Figure 2-1). This may damage the LDT

and will void your warranty. To tighten the

LDT within the bracket, use the 1.75" hex

mounting base on the head assembly.

If the length of the LDT’s rod end is less than 30”, skip

to the sub-section: Mounting the Magnet Assembly.

Installing Support Brackets

It is recommended that a support bracket be used

with LDTs having a rod 30”-71” in length. Supporting

the end of the rod will minimize operational errors and

protect against damage due to shock and vibration.

If the length of the LDT’s rod is 72” or longer, it is

recommended that additional support brackets be

used. These additional support brackets must be made

of a non-ferrous material. Because these additional

support brackets will interfere with the magnet’s

movement, a special split-type magnet assembly must

be used. To order a split magnet (P/N SD0411200)

and support brackets (P/N SD0411100), contact the

factory at 800-635-0289.

To install a support bracket for a LDT having a rod 30”71” in length, perform step 4a. If the rod is longer than

71”, perform step 4b.

4a. If the support bracket is made of a ferromagnetic

material (material readily magnetized), install the

support bracket no closer than 0.25” from where

the LDT’s dead band ends and the area of stroke

begins. Continue to the sub-section: Mounting

the Magnet Assembly.

To install two or more support brackets for a LDT

having a rod 72" or longer in length, perform the

following steps:

4b. Install support brackets at increments of 48”

throughout the LDT’s rod. Support brackets

placed within the Null Zone and area of stroke or

closer than 0.25” to the beginning of these areas

must be made of a non-ferrous material.

Mounting the Magnet Assembly

Before mounting the magnet assembly, the following

should be considered:

• Ferromagnetic material should not be placed

closer than 0.25” from the LDT’s magnet assembly

or rod end. Failure to do so could cause erratic

operations.

• Minimal clearance between the LDT’s rod and

the magnet assembly through the full stroke is

4

®

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • Phone 248.435.0700 • Fax 248.435.8120 • www.ametekapt.com

Page 5

AUTOMATION & PROCESS TECHNOLOGIES

2 PLACES

.406

SUPPORT BRACKET SD0411100

.2 8

.4 4

1.00

1.25

.3 7

NUL L

2.00

PROBE MOUNTING KI T

OPTIONA ORL

MAGNE T

STROK E

(P/N 949003)

.28 X 1.03 SLOT

DEAD

BAN D

2.00

C

L

1.00

1.03

3/4-16 JAM NUT

PROB E

NOTES: UNLESS OTHERWISE SPECIFIE D

1.75 HE X

1. MOUNTING KITS FURNISHED WITH

MOUNTING BOLTS.

2. MOUNTING BRACKETS ARE MADE FROM

3/16" X 2" X3" STAINLESS STEEL .

SUPPLIED W/PROB E

OPTIONAL

2.00

1.25

1.00

.6 2

Figure 2-1: Mounting the LDT

required. Stress between the magnet and the rod

can cause exing of the mounting brackets. This

may result in non-linearity.

• LDTs using a split magnet assembly must keep

the diameter of the magnet assembly around the

rod throughout the complete stroke. The diameter

of this magnet assembly should not be more than

0.2” away from the rod. Split magnet assemblies

outside of this range will cause signal loss.

To install the magnet assembly, perform the following

steps:

1. Slide the magnet assembly over the LDT rod.

2. Mount the magnet to the non-ferrous, movable

portion of the device being controlled using nonferrous screws.

MAGNET MOUNTIN G

KIT (P/N 949005)

.2 8

2 PLACES

2.00

.187 THRU

(2 PLACES)

NOTE: USE THIS MAGNET WITH ROD

S

1.407

S

N

N N

2.50 REF .

2.2: Installing the LDT in a

Hydraulic Cylinder

Before installing an LDT in a hydraulic cylinder, note

the following considerations. Items discussed in this

section are found in Figures 1-1 and 2-1.

• A non-ferrous spacer must be used to separate the

magnet assembly from the head of the piston rod.

See Figure 2-2.

• The magnet should not be closer than 2.0” from the

base of the LDT’s hex head when the piston rod is

fully retracted. In instances where space restraints

exist, it may be required to countersink the magnet

into the piston rod. Two magnets are available

for mounting to the piston: the standard 1.29"

in diameter (P/N SD0400800) four-hole magnet

and the 1.0" magnet (P/N SD0410300) designed

exclusively for countersunk mounting applications.

The 1.0" magnet must be secured with a snap ring.

.38

.75 THRU

S S

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • Phone 248.435.0700 • Fax 248.435.8120 • www.ametekapt.com

®

5

Page 6

AUTOMATION & PROCESS TECHNOLOGIES

• An O-ring is provided at the base of the LDT’s

!

mounting hex for pressure sealing. The O-ring seal

was designed to meet Mil-Std-MS33656. Refer to

SAE J514 or SAE J1926/1 for machining of mating

surfaces.

• A chamfered rod bushing in front of the magnet

may be required. It is recommended that a

chamfered rod bushing be used with LDTs having

a rod 60.0” or longer. This bushing will prevent

wear on the magnet assembly (wear occurs as the

piston retracts from extended lengths). This rod

bushing should be manufactured from a high wear

polymer, such as Teon®.

• It is recommended the bore for the cylinder

piston rod have an inside diameter of at least

0.50”. The LDT rod has an outside diameter of

0.405”. Use standard practices for machining and

mounting these components. Consult the cylinder

manufacturer for details on applicable SAE or

military specications.

It may be necessary to perform machining and

mounting operations on the hydraulic cylinder before

installing the LDT. Consult the information and

specications provided by the cylinder manufacturer

before beginning the following steps:

1. Unscrew the LDT’s jam nut from the threads

protruding from the hex mounting base.

2. Position the non-ferrous spacer against the

piston face, followed by the magnet, and then the

chamfered rod bushing if the LDT’s rod is 60.0” or

longer in length.

If the leading edge of the magnet will come closer

than 2.0” from the base of the LDT’s hex head

when the piston rod is fully retracted, it will be

necessary to counterbore the magnet assembly

into the piston rod. Both the standard 1.29” fourhole magnet assembly (P/N SD0400800) and

the 1.0” magnet assembly (P/N SD0410300) are

designed for counterbored mounting applications.

If it has a 1.0” magnet assembly, a snap ring will

be needed to hold it in place.

4. Insert the LDT’s rod into the hole of the hydraulic

cylinder’s mounting bracket.

The protective Plug may need to be removed from

the hydraulic cylinder before inserting the LDT. The

end cap should contain a 3/4-16 UNF-2B threaded

hole. Screw the LDT into this hole using the

threads protruding from the LDT’s hex mounting

base.

WARNING: Do not use the blue

aluminum cover of the head assembly

to tighten the LDT within the bracket

(see Figure 2-1). This may damage

the LDT and will void your warranty. To tighten

the LDT within the bracket, use the 1.75" hex

mounting base on the head assembly.

With the LDT properly installed inside the hydraulic

cylinder, it may be necessary to assemble parts of the

hydraulic cylinder. For assistance in this task, refer to

the information provided by the cylinder manufacturer.

3. Insert non-ferrous screws through the chamfered

rod bushing (if used), magnet, and non-ferrous

spacer. Secure items by tightening screws.

6

®

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • Phone 248.435.0700 • Fax 248.435.8120 • www.ametekapt.com

Page 7

AUTOMATION & PROCESS TECHNOLOGIES

S EE N O TE 4

.094 MAX.

1.18

3

4

S TANDARD 4-H O LE MA G NET

0.5” BORE MINIMUM

O-RING SEAL

MAGNET SPACER

O PTI O NAL R O D B US HIN G

Figure 2-2: Mounting LDT in a Hydraulic Cylinder

R.015

MAX.

R

.008

.004

15°

RECOMMENDE D

MIN. SPOTFAC E

DIAMETER

.004

.813

+/-.002

A

SEE NOTE 1

.866

MINIMU M

SEE NOTE 2

.008

A

125

.106

+/-.008

1.250

SEE NOTE

SEE NOTE

45°

1.100

SEE NOTE 4

125

3/4-16 UNF-2B THREAD

A

PITC H

DIA.

Figure 2-3: Port Detail (SAE J1926/1)

.500

REF.

NOTES:

1. IF FACE OF PORT IS ON A

MACHINED SURFACE,

DIMENSIONS 1.180 AND .094

NEED NOT APPLY AS LONG

AS R.008/.0004 IS

MAINTAINED TO AVOID

DAMAGE TO THE O-RING

DURING ASSEMBLY.

2. MEASURE PERPENDICULARITY TO A AT THIS

DIAMETER.

3. THIS DIMENSION APPLIES

WHEN TAP DRILL CANNOT

PASS THROUGH ENTIRE

BOSS.

4. THIS DIMENSION DOES

NOT CONFORM TO SAE

J1926-1.

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • Phone 248.435.0700 • Fax 248.435.8120 • www.ametekapt.com

®

7

Page 8

AUTOMATION & PROCESS TECHNOLOGIES

Chapter 3: Wiring

!

!

Once the LDT has been installed, wiring connections

can be made. The VMAX has four different connector

options. Please refer to the part number label to help

identify which wiring diagram is correct. There are two

groups of connections that will need to be made. They

are as follows:

• Power Supply Connections

(including grounding and shielding)

• LDT Input/Output Connections

Power Supply/Ground Connections

The 953A VMAX is available with many different connector/wiring options. Refer to part numbering on unit

in question for proper wiring. See Appendex B for part

numbering grid and qures 3.3 - 3.9 for wiring details.

Connector option S is an industry standard 5 pin

12mm Euro style cordset with a shield. Option B is an

8 pin DIN with a shield, and option M is a 6 pin DIN

with a shield. To reduce electrical noise, the shield

must be properly used. Connect the cable’s shield to

the controller system GND. The cable shield is NOT

connected at the transducer rod. Always observe

proper grounding techniques such as single point

grounding and isolating high voltage (i.e. 120/240

VAC) from low voltage (7-30 VDC cables).

Diagnostic LED

LED Color Description

None No power to LDT

Green Magnet signal detected and within programmed

range.

Yellow Magnet signal detected, but magnet is outside of

programmed range.

NOTE: Magnet can be programmed in this range

if desired.

Red No magnet signal detected. Make sure magnet

is on the rod and within the active area. Move

magnet back into the range and cycle power.

WARNING: Do not use molded cordsets

with LEDs!

It is preferable that the cable between the LDT and

the interface device be one continuous run. If you are

using a junction box, it is highly recommended that the

splice junction box be free of AC and/or DC transientproducing lines. The shield should be carried through

the splice and terminated at the interface device end.

NOTE: When grounding the LDT, a single earth

ground should be connected to the Power Supply

Common (circuit ground). The LDT Power Supply

Common should be connected to the Power Supply

Common (-) terminal. The LDT power supply (+VDC)

should be connected to the power supply positive

terminal (+). The LDT cable shield should be tied to

earth ground at the power supply. The LDT analog

common should not be connected to earth ground and

should be used for connection to interface devices

only. For assistance, refer to your LDT’s wiring drawing

in this chapter.

In order for the VMAX to operate properly, the external

power supply must provide a voltage between 7-30

VDC. The power supply must be rated at one watt

minimum. The power supply should provide less than

1% ripple with 10% regulation.

Single ended

power supply

WARNING: Do not

route the VMAX

cable near high

voltage sources.

Pin 1 (brown) Pin 3 (blue)

7-30 VDC

+ COM

Figure 3-1: Power Supply Wiring

The power supply should be dedicated to the

VMAX to prevent noise and external loads from

affecting it. When powering up more than one

VMAX on a single power supply, each unit will draw

approximately one watt.

3.1: V0/V1 (Voltage)

The LDT generates a voltage output based on position.

The 953 VMAX offers 16 Bits of resolution, and is

fully programmable over the entire active stroke

length. Keep in mind that there is a 2” Null Zone at the

connector end of the LDT and a 2.5” Dead Band at the

other end of the LDT that the magnet must stay out

of at all times. The units come fully programmed from

the factory and do not require re-programming unless

desired.

The analog output is referenced to the analog common

terminal and should not be referenced to any of the

other common terminals. For wiring, see Figure 3-2.

For programming Zero and Span, See Section 3.3.

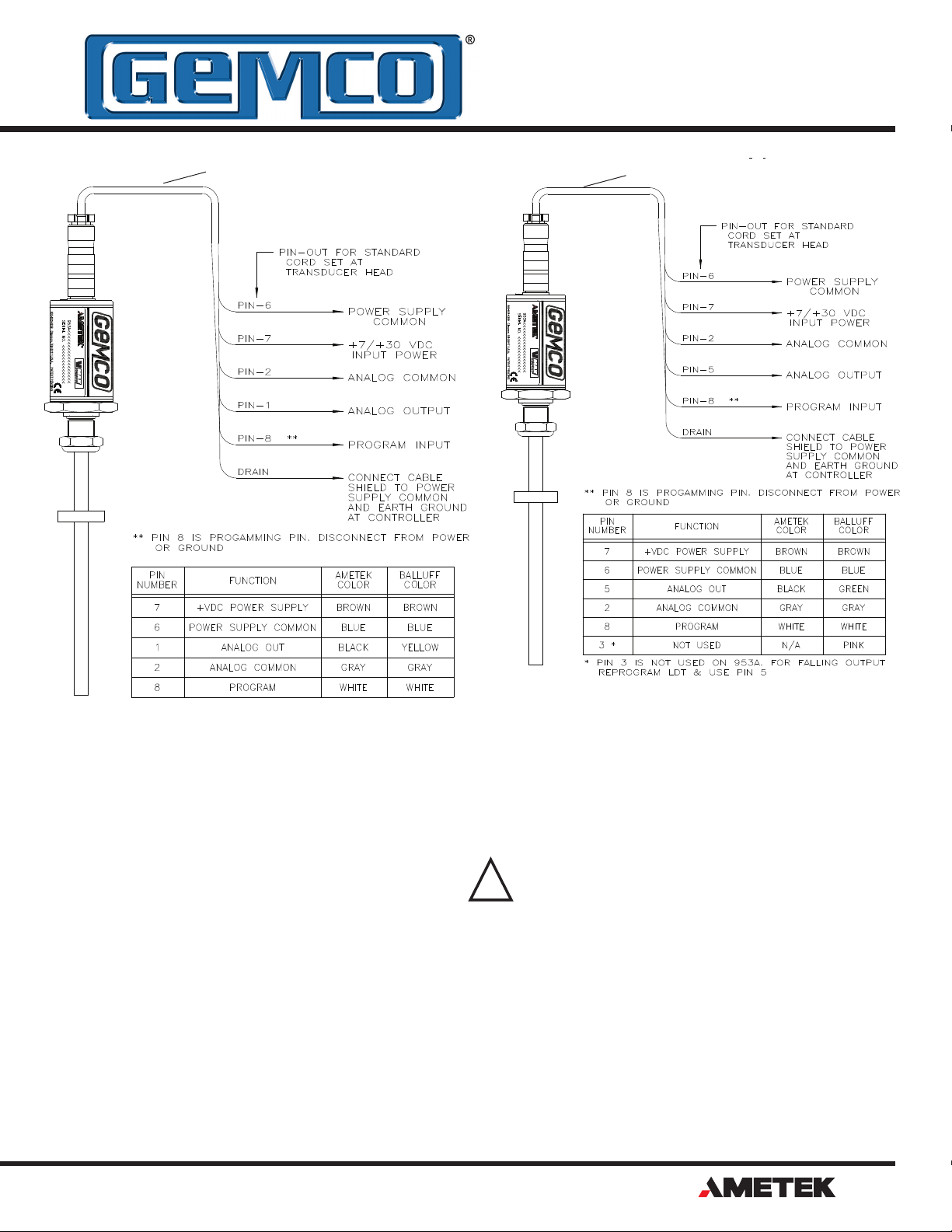

3.2: C4/C2 (Current)

The LDT generates a current output based on position.

The 953 VMAX offers 16 Bits of resolution, and is fully

programmable over the entire active stroke length of

the LDT. Keep in mind that there is a 2” Null Zone at

the connector end of the LDT and a 2.5” Dead Band at

the other end of the LDT that the magnet must stay out

of at all times. The units come fully programmed from

the factory and do not require re-programming unless

desired.

8

®

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • Phone 248.435.0700 • Fax 248.435.8120 • www.ametekapt.com

Page 9

AUTOMATION & PROCESS TECHNOLOGIES

Typical Wiring

Figure 3-2 shows two common methods for wiring the

953A to a customer supplied interface device, such

as a PLC or panel meter. The two different methods

are commonly referred to as Single Ended Input or

Differential Input. Differential Input is the preferred

wiring method.

With the Differential Input, the Analog Common wire is

connected to the customer supplied input device and

the Power Supply Common is wired separately to the

customers supplied power source. When wired using

the Differential method, the electrical noise and

voltage offset errors produced by the currents running

through the Power Supply Common are eliminated.

The Power Supply Common and Analog Common are

internally connected inside of the 953A VMAX LDT.

Cable # 949011LXX

NOTE: XX= Length in feet

AUTOMATION & PROCESS TECHNOLOGIES

TM

Power

Supply

7-30 VDC

Customer

Supplied Power

+

Power

Supply Common

_

Program Input

953A

LDT

Position

Output

Position

Common

+ Input

- Input

Differential Input

Power

Supply

7-30 VDC

Customer

Supplied Power

+

Power

Supply Common

_

Program Input

953A

LDT

Position

Output

+ Input

Common

Single Ended Input

Figure 3-2: Current Sourcing

The 953A-C is current sourcing which allows

the current to ow from the LDT into the users

equipment.

1

2

5

4

3

LDT

Connector

View

Figure 3-3: Wiring for Connector

Option "S", 5 Pin Micro

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • Phone 248.435.0700 • Fax 248.435.8120 • www.ametekapt.com

®

9

Page 10

AUTOMATION & PROCESS TECHNOLOGIES

AUTOMATION & PROCESS TECHNOLOGIES

TM

10

Figure 3-4:

Wiring for Connector

Option "C", Integral Cable Assembly

®

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • Phone 248.435.0700 • Fax 248.435.8120 • www.ametekapt.com

Figure 3-5:

Wiring for Connector

Option "H", High Temp Integral Assembly

Page 11

AUTOMATION & PROCESS TECHNOLOGIES

!

Cable # SD0553400LXX

NOTE: XX= Length in feet

Cable # SD0553300LXX

NOTE: XX= Length in feet

AUTOMATION & PROCESS TECHNOLOGIES

TM

AUTOMATION & PROCESS TECHNOLOGIES

TM

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • Phone 248.435.0700 • Fax 248.435.8120 • www.ametekapt.com

Figure 3-6:

Wiring for Connector

Option "B", 8 Pin DIN,

Current Output

CAUTION: Pinout is different for

voltage vs. current models with

connector option "B"

Figure 3-7:

Wiring for Connector

Option "B", 8 Pin DIN,

Voltage Output

®

11

Page 12

AUTOMATION & PROCESS TECHNOLOGIES

Cable # SD0439700LXX

NOTE: XX= Length in feet

AUTOMATION & PROCESS TECHNOLOGIES

AUTOMATION & PROCESS TECHNOLOGIES

TM

TM

Cable # SD0553200LXX

NOTE: XX= Length in feet

12

Figure 3-8:

Wiring for Connector

Option "E", 10 Pin MS Connector

®

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • Phone 248.435.0700 • Fax 248.435.8120 • www.ametekapt.com

Figure 3-9:

Wiring for Connector

Option "M", 6 Pin DIN

Page 13

AUTOMATION & PROCESS TECHNOLOGIES

!

3.3: Features

Automatic Gain Control

The Automatic Gain Control feature will automatically

search and nd the magnet on power up, if power is

applied without a magnet on the LDT, the LED will turn

RED indicating no magnet signal is detected. Turn

power off and place magnet within the active stroke

area. Re-apply power.

Diagnostic LED

LED Color Description

None No power to LDT

Green Magnet signal detected and within programmed

range.

Yellow Magnet signal detected, but magnet is outside of

programmed range.

NOTE: Magnet can be programmed in this range

if desired.

Red No magnet signal detected. Make sure magnet

is on the rod and within the active area. Move

magnet back into the range and cycle power.

Accessories

P/N Description

949011L6 6 Foot, 5 Pin, Straight, 12mm, Euro Connector

949012L6 6 Foot, 5 Pin, Right Angle, 12mm, Euro Connector

SD0439700LXX 10 Pin, Straight Connector, 6 Foot Standard

SD0439700LXX 10 Pin, Right Angle Connector, 6 Foot Standard

SD0553200LXX

SD0553300LXX

SD0553400LXX

SD0400800 Standard 4 Hole Magnet

Consult factory for complete accessory offerings.

MTS-6 Pin, "M" Option, (Voltage or Current Outputs)

Balluff-8 Pin, "B" Option, (Voltage Outputs Only)

Balluff-8 Pin, "B" Option, (Current Outputs Only)

3.4: Setting Zero & Span Position

The units come fully programmed from the factory and

do not require re-programming unless desired. The

units are 100% absolute and will not lose programmed

parameters on power loss. The Zero and Span points

can be programmed in any order and anywhere within

the LDT's active sensor area.

NOTE 1: Zero or Span can be adjusted individually

without setting the other.

NOTE 2: Zero = 0V on 0-10 VDC units and 4mA

on 4-20mA units.

There is a timing sequence that is used to unlock the

probe for programming. This is to insure that the Span

cannot be accidentally re-programmed by someone in

the eld.

Before programming the Zero or Span, the program

input must be connected to the Power Supply

Common for a minimum of 2 seconds and no more

than 6 seconds, then released for 1 second. The

LTD programming sequence is now unlocked and

will remain an unlocked unit until either the Zero or

Span is programmed or the 10 second programming

sequence times out. During the unlock mode either

the Zero or Span can be programmed by momentarily

connecting the Program Input to either the Power

Supply Common or Power Supply +.

NOTE: The LDT must be unlocked to program the

Zero and unlocked again to program the Span. Once

either the Zero or Span is programmed the LDT will go

back into the locked mode.

To program the Zero or Span, the program input must

be connected to the Power Supply Common for 4

seconds, then released for 1 second. Within the next 5

seconds, you can program either the Zero or the Span

by momentarily connecting the Program Input to either

the Power Supply Common or Power Supply +VDC.

WARNING: During normal operation,

electrically insulate the White

Program wire to prevent accidental

setting of Span.

Manual Setting of Zero & Span

To set the Zero and Span position, follow these steps:

1. Apply power to the LDT.

2. Place magnet assembly where Zero is to be

located, but within the active region of the probe.

3. Short the Program Input pin to the Power Supply

Common for 4 seconds. Remove the short for 1

second. Within 5 seconds, short the Programming

Input pin to the Power Supply Common. This

completes the Zero programming process.

4. Place magnet assembly where Span is to be

located, but within the active region of the probe.

5. Short the Program Input pin to the Power Supply

Common for 4 seconds. Remove the short for 1

second. Within 5 seconds, short the Programming

Input pin to the Power Supply +VDC.

This completes the programming process.

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • Phone 248.435.0700 • Fax 248.435.8120 • www.ametekapt.com

®

13

Page 14

AUTOMATION & PROCESS TECHNOLOGIES

Optional Remote Tester & Programmer

Optional In-Line Programmer

The battery operated remote tester / programmer is

available in either a voltage or current model. P/N

SD0528810 is designed for voltage

units while SD0528811 is for current

units. Both units are designed to

work with connector option S only.

These units are typically used to

demonstrate the functionality of the

LDT in the eld, however, they can

be used as a handy troubleshooting

/ programming device.

1. Attach the 5 pin Euro connector

to the VMAX.

2. Push the toggle switch to the ON position to power

the LDT.

3. Place magnet assembly where Zero is to be

located, but within the active region of the probe.

4. Push the black Zero button for 4 seconds,

release for 1 second. Within 5 seconds, push

the Zero button again. This completes the Zero

programming process.

5. Place magnet assembly where Span is to be

located, but within the active region of the probe.

6. Push the black Zero button for 4 seconds, release

for 1 second. Within 5 seconds, push the Span

button.

NOTE: This time the Span button is pushed for the

nal programming step.

This completes the programming process.

The 955-1409 is a remote

programmer that can help

simplify the programming

process. The programmer

is a portable device

that can be temporarily or permanently

installed in series with the VMAX with

connector option S.

1. Remove the 5 pin cordset to the LDT.

2. Attach the existing cordset to the 955-1409

programmer.

3. Attach the other end to the LDT.

4. Apply power to the LDT.

5. Place magnet assembly where Zero is to be

located, but within the active region of the probe.

6. Push the Zero button for 4 seconds. Release the

button for 1 second. Within 5 seconds, push the

Zero button again.

7. Place magnet assembly where Span is to be

located, but within the active region of the probe.

8. Push the Zero button for 4 seconds. Release the

Zero button for 1 second. Within 5 seconds, push

the Span button.

Appendix A: Troubleshooting

A Tri-color LED is conveniently located next to the

connector to help with set-up and diagnostics.

Diagnostic LED

LED Color Description

None No power to LDT

Green Magnet signal detected and within programmed

range.

Yellow Magnet signal detected, but magnet is outside of

programmed range.

NOTE: Magnet can be programmed in this range

if desired.

Red No magnet signal detected. Make sure magnet

is on the rod and within the active area. Move

magnet back into the range and cycle power.

If a problem exists after reading this section, please

contact our technical support department.

General Checks

Make sure that the magnet is located within the

LDT’s active stroke area. Keep in mind that the LDT

is programmable over the entire active stroke area.

Captive magnet assemblies should be positioned

so that they can move freely over the entire area of

the active stroke without binding or pushing on the

rod end. Non-captive magnet assemblies should be

situated so that the magnet is no farther than 0.2”

from the rod at any point in the magnet assembly’s

movement.

14

®

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • Phone 248.435.0700 • Fax 248.435.8120 • www.ametekapt.com

NOTE: Ferromagnetic material (material readily

magnetized) should be located no closer than 0.25”

from the magnet or LDT rod end. This includes

mounting brackets, magnet spacers, magnet brackets,

and mounting screws. Ferromagnetic material can

distort the magnetic eld, causing adverse operation or

even failure of the LDT.

Check all LDT wires for continuity and/or shorts. It

is preferred that the cable between the LDT and the

interface device be one continuous run. If you are

using a junction box, it is highly recommended that the

splice junction box be free of AC and/or DC transientproducing lines. The shield should be carried through

the splice and terminated at the interface device end.

Power Supply Checks

This section will help you to determine if your power

supply is adequate for the LDT to operate properly, or

if the LDT’s cable has a short or open.

In order for the VMAX to operate properly, the external

power supply must provide a level between 7-30 VDC.

A power supply providing voltage above this specied

range may damage the LDT. A power supply providing

power below this specied range will not be sufcient

Page 15

AUTOMATION & PROCESS TECHNOLOGIES

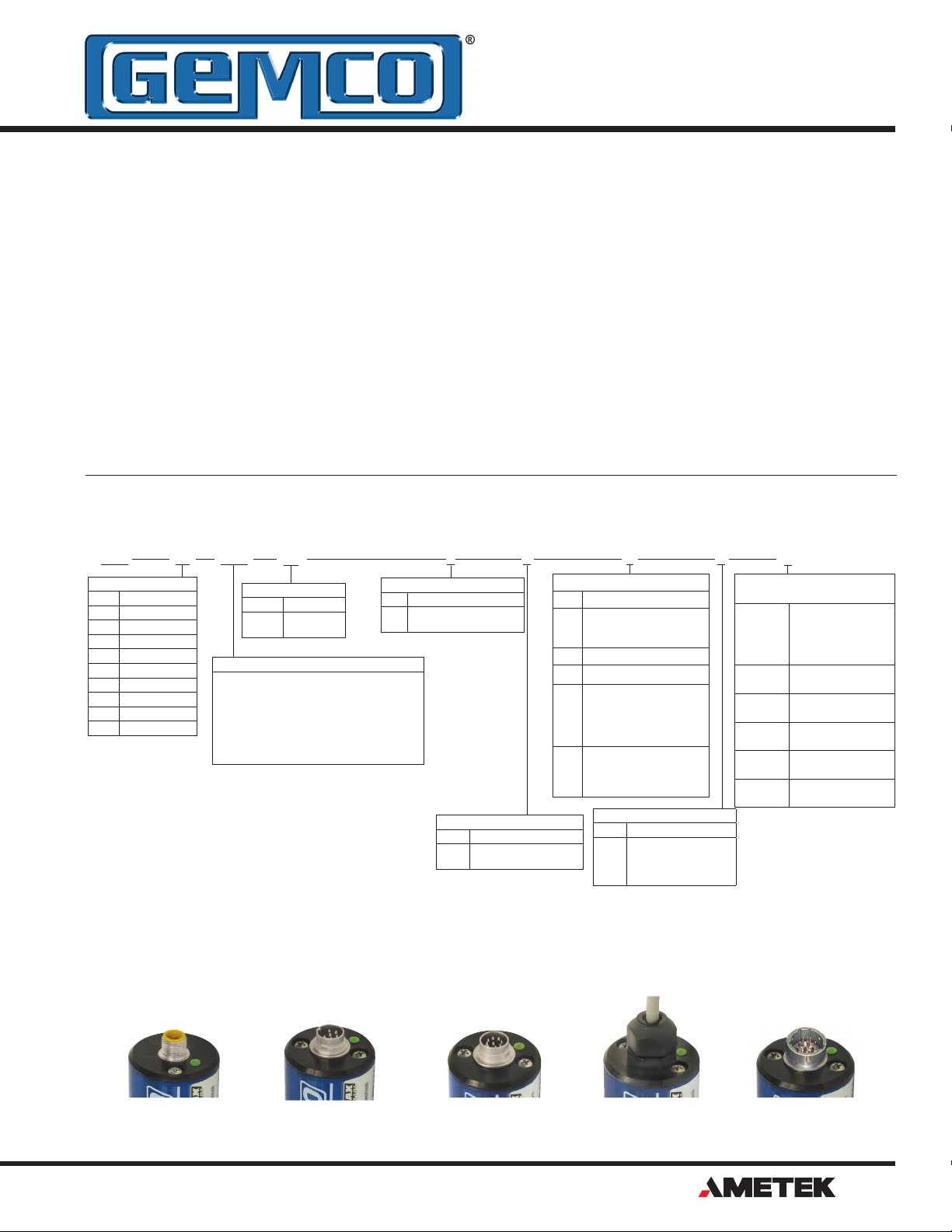

Appendix B: Part Numbering

to power the LDT. When powering more than one

VMAX on a single power supply, remember that each

unit requires approximately one watt of

power. The amount of current draw will vary based on

the input voltage used. To calculate the current draw

for a particular LDT, divide the LDT wattage by the

input voltage. For example, 1 watt divided by 24 VDC

equals 41.6mA.

NOTE: LDT’s with integral cable assemblies

should be checked for proper voltage at the power

supply terminals. This cable assembly cannot be

removed from the LDTIf the reading is between 7

and 30 VDC, turn power supply off and go to step

7. If the reading is below 7 VDC, either the power

supply is not providing enough power or the LDT’s

cable possibly has a short or open. A reading of

no voltage or minimal voltage (less than 5 volts)

may be due to a short or open in the cable. If the

If the LDT is not operating properly, the LDT’s cable

may have an open or short, or the power supply is not

supplying sufcient power. To verify this:

1. Turn the power supply off.

2. Remove the mating connector from the LDT.

3. Turn the power supply on.

4. Using a digital voltmeter, check across Power Supply

Common and customer supplied power (+VDC) on

the mating end of the cable for a level between 7 and

30 VDC.

reading is not between 7 and 30 VDC, go to step

5. If the reading is above 30 VDC, adjust power

supply or replace.

5. Turn the power supply off.

6. Check the continuity of the individual wires of

the cable between the power supply and the

LDT. Check for continuity from one end of the

cable to the other. Also, verify that no shorts

exist between pins.

7. Reconnect the mating connector to the LDT.

Appendix B: Part Numbering

953A 0120V0 X

Output

V0

0 to 10 VDC

V1

10 to 0 VDC

V2

-10 to 10 VDC

V3

10 to -10 VDC

V4

0 to 5 VDC

V5

5 to 0 VDC

V6

-5 to 5 VDC

V7

5 to -5 VDC

C4

4 to 20mA

C2

20 to 4mA

NOTE 1: On unsupported stroke

lengths greater

than 4 feet, rod support bracket(s)

and a special magnet

should be used.

NOTE 2: Specify magnet as separate line item.

Standard magnet is SD0400800.

Insert stroke length to 0.1 inch. Enter as a fourplace number. Example: A 12.0” stroke enters as

0120.

OR

Insert stroke in millimeters to 1mm. Enter as a

four-place number. Example: 305mm stroke entered

as 0305M. Metric length includes metric mounting,

M18x1.5. Unless specified otherwise.

Units

Blank

M

VP

Inches

Metric Base

and Threads

Stroke Length

Null Zone

X

Standard 2 inches.

Insert non-standard Null

N_

Zone (1.5" Minimum).

D_

Dead Band

X

Standard 2.5 inches.

Insert non-standard Dead

Band (2.25" Minimum).

S

C_

M

B

E

H_

SXX

Connector Option

Standard 5 Pin, 12mm Euro

Integral Cable Assembly.

Insert length in feet. Example:

C6 = 6 foot cable.

6 Pin DIN, MTS Style D60

8 Pin DIN, Balluff S32

Environmental 10 Pin MS

Connector compatible w/951 &

952 LDTs

w/connector option “E”.

o

High Temp., Integral cable

assembly 200 C Teflon Cable.

Insert length in feet. Example: H6=

6 foot High Temp Teflon Cable.

Options

X

None

Stainless Steel cover and

connector. Only available

S

with connector options S,

C and H.

Optional Housing Style

Mounting Threads

Raised face hex base

Blank

(Standard) - Threads will

be the same as "Units

of Measure" unless

specified otherwise.

US Threads with raised

R

face hex base

US Threads with flat

F

face hex base

Metric Threads with

M

raised face hex base

Metric Threads with flat

N

face hex base

Sensor cartridge only

C

No hex base

5 Pin Micro, 12mm Euro

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • Phone 248.435.0700 • Fax 248.435.8120 • www.ametekapt.com

S Connector Style

M Connector Style

6 Pin DIN, Fits MTS D60

B Connector Style

8 Pin DIN, Fits Balluff S32

C Connector Style

Integral Cable Assembly

E Connector Style

10 Pin MS Connector,

Fits Gemco 951 & 952 Wiring

®

15

Page 16

AUTOMATION & PROCESS TECHNOLOGIES

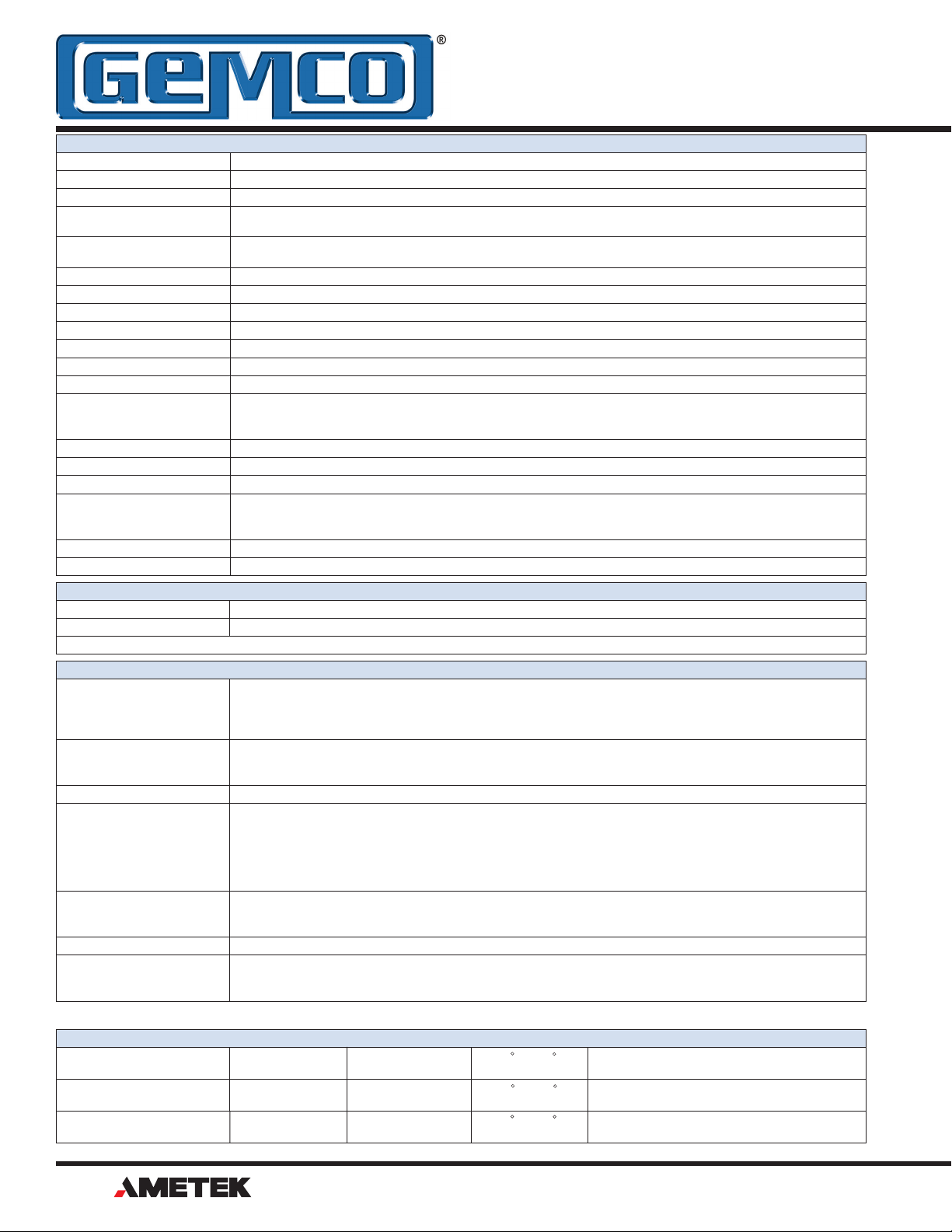

Appendix C: Specications

General Specications

Rod End 316 Stainless Steel, 0.405" (10.29 mm) outer diameter

Mounting Hex 316 Stainless Steel, 1.75" (44.45 mm) across ats, IP68

Mounting Threads 3/4" (19.05 mm) x 16 x 1.00" (25.4 mm) with ESNA jam nut and O-ring seal. Optional M 18x 1.5 Metric threads

Head Assembly Thick wall aluminum cover with Viton O-ring standard, gasket seal at the base and connector exit, IP68 IEC

Head Enclosure 3.2" (81.3 mm) long with 1.75" (44.45 mm) diameter- Note: See pg. 3 for connector option "E" Head enclosure

Connector 5 pin 12mm Euro/Micro standard. Intergrated cable assembly, 6 pin or 8 pin DIN & 10 pin MS optional.

Displacement 1" to 300"

Dead Band 2.50" (63.5 mm) standard (cannot be less than 2.25")

Null Zone 2.00" (50.8 mm) standard (cannot be less than 1.5")

Linearity Less than +/- 0.01% or +/- 0.005", whichever is greater. (+/- 0.002" typical)

Repeatability Equal to Resolution

Hysteresis 0.001"

Operating Temperature

Head (Electronics)

Guide Tube

Storage Temperature -40° to 221° F (-40° to 105° C)

Operating Pressure 3,000 psi constant, 8,000 psi spike

Guide Tube Pressure 5,000 psi constant, 10,000 psi spike

Shock & Vibration

Shock

Vibration

Zero & Span Adjustability Factory set at Null Zone & Dead Band locations. Field re-settable at any location within active stroke.

Approvals CE, 89/336/EEC (EMC)

Input Voltage 7-30 VDC

Current Draw One watt, 40mA at 24 VDC typical

Temperature Drift

Position

Output

Analog Output Loading Voltage output minimum load resistance: 2K ohms

Analog Ripple <1 mV maximum (position output)

Update Time Stroke Length

Resolution

Internal

Output

Position Output 0-10 VDC, 16 Bits (65,535) resolution 4-20mA, 16 Bits (65,535) resolution

Output Type

Voltage

Current

Cable Type Gauge Jacket Temp Bend Radius

Connector Options

"S", "M", "B", "C"

High Temp Integral Cable

"H" option

Connector Option "E" 22 Polyurethane -50 to 105 C Moving Applications - 2.3"

Fixed applications - 1.2"

600529, stainless steel cover optional

dimensions.

-40° to 185° F ( -40° to 85° C)

-40° to 221° F (-40° to 105° C)

1,000Gs (lab tested) IEC 60068-2-27

30Gs (lab tested) IEC 60068-2-6

Electrical Specications

Specications are subject to change and based on a typical 48" stroke length.

Analog Specications

3.1 ppm/° F/in. of stroke2

3.1 ppm/° F for Voltage output

9.2 ppm/° F for Current output

Current output: Guaranteed 5mA minimum for voltage units

Maximum load resistance: 500 ohms

L ≤ 2”

2” < L ≤ 12”

12” < L ≤ 30”

30” < L ≤ 50”

50” < L ≤ 100”

0.00006" (1.524 microns)

16-Bit

V0- 0 to 10 VDC, V1- 10 to 0 VDC, V2- -10 to 10 VDC, V3- 10 to -10 VDC, V4- 0 to 5 VDC, V5- 5 to 0 VDC,

V6- -5 to 5 VDC, V7- 5 to -5 VDC, C4- 4 to 20mA, C2- 20 to 4mA

22 PVC -50 to 105 C Moving Applications - 2.36"

Fixed applications - 1.18"

22 Teon -70 to 200 C Moving Applications - 4.6"

Fixed applications - 2.3"

Update Time

0.5 ms

1 ms

2 ms

3 ms

4 ms

Stroke Length

100” < L ≤ 150”

150” < L ≤ 180”

180” < L ≤ 250”

250” < L ≤ 300”

Cable Specications

Update Time

5 ms

6 ms

7 ms

8 ms

16

®

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • Phone 248.435.0700 • Fax 248.435.8120 • www.ametekapt.com

Page 17

Part Number

Serial Number

Purchase Order Number

Sales Order Number

Comments

NOTES:

Page 18

AUTOMATION & PROCESS TECHNOLOGIES

®

Other Products

Copyright 2012 by AMETEK Automation & Process Technologies. All Rights Reserved. Made in the USA.

®

1080 N. Crooks Road, Clawson, MI 48017-1097

Phone: 248.435.0700 Toll Free: 800.635.0289

953A.M3R

4/12.Z191

Fax: 248.435.8120 www.ametekapt.com

Loading...

Loading...