Page 1

Page 2

Principles of Operation

The Series 925 Linear Cable Reel can be used in any linear application up to 1200 inches.

The system consists of a heavy duty spring motor assembly attached to a precision

machined cable drum. As the cable is pulled off of the precision drum, the drum rotates

a shaft connected to it. This shaft is precisely geared such that the full number of

revolutions of the drum is equal to the appropriate number of revolutions required by

the chosen sensor.

Applications

The Series 925 can be used in any industrial application to monitor a linear or reciprocating machine motion.

The sensor package, along with the associated electronics (i.e. programmable logic control

ler, programmable limit switch, counter card, etc.) can sense the position of any linear

motion and can, therefore, be used to control machines.

Advantages

-

This approach to machine positioning has several advantages over traditional limit

switches. In hostile environments, such as many steel mill applications, the cable reel

sensor can be mounted remotely. This protects the sensor from excessive heat, steam,

water, chemicals and physical damage. In addition, mounting alignment is not critical

in that the cable can be mis-aligned somewhat without harm, thus saving installation

time. The variety of sensors available allows the system to be easily integrated to existing

machine controls.

Page 3

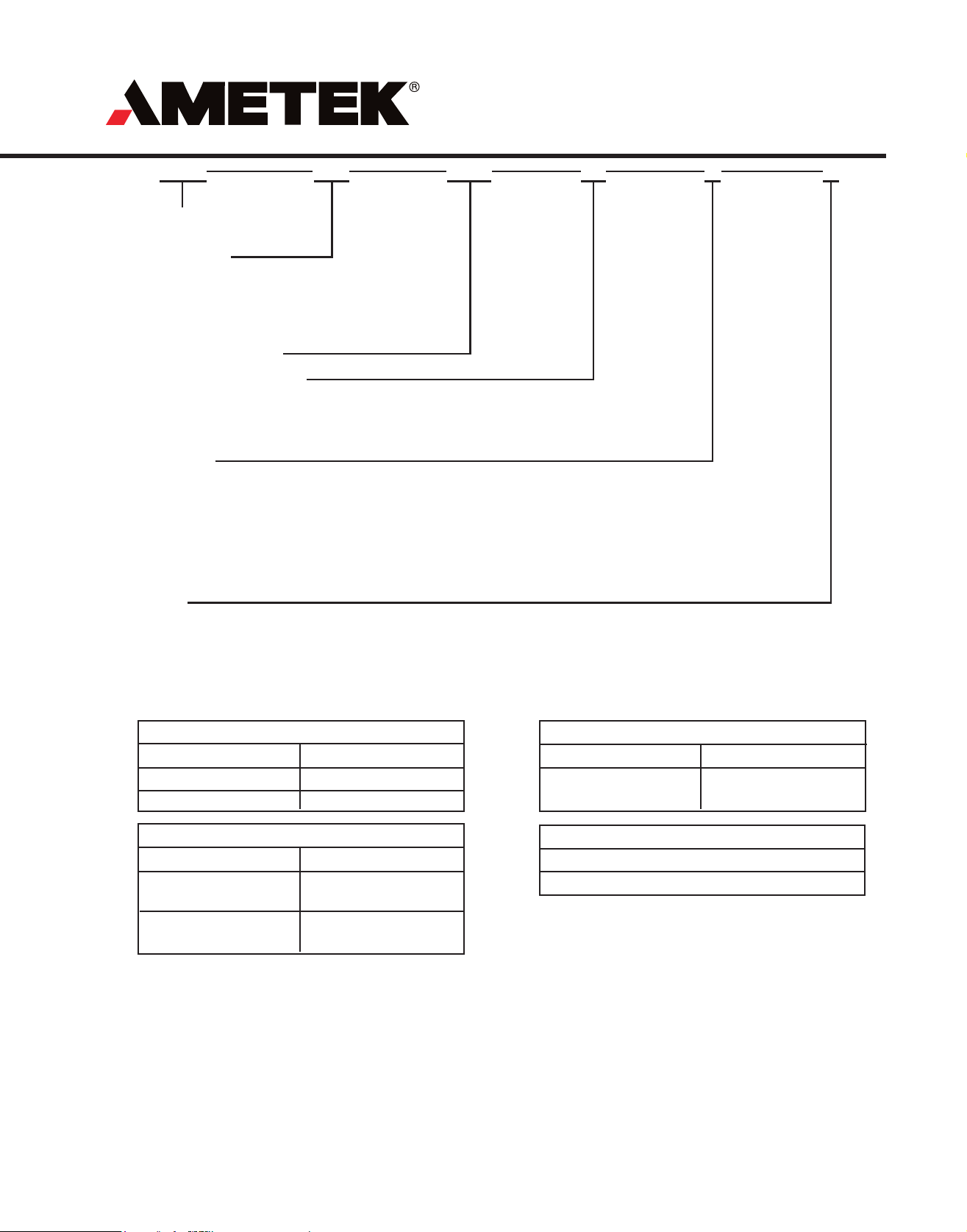

Part Numbering

925 A1

Cable Reel

Sensor

Hardware Type

A1 = 0 - 96 inch Stroke

A2 = 97 - 192 inch Stroke

B1 = 193 - 480 inch Stroke Single Spring

B2 = 193 - 480 inch Stroke Double Spring

C = 481 - 1200 inch Stroke

Active Stroke in Inches

Initial Cable Lead in Inches

First 72 inches of intial lead is no charge. Cable lead

above 72 inches an additional charge per inch.

Leave blank if no initial cable lead required.

Sensor Type

S = Single-turn Resolver

M = Multi-turn Resolver

P1 = Single-turn Potentiomenter

P2 = Multi-turn Potentiometer

E1 = Provision for an Incremental Encoder*

E2 = Provision for an Absolute Sensor*

DN = Single-turn Resolver with DeviceNet Interface

CO = 4 - 20mA Output (Resolution is 1,000 points of total stroke)

100

12

S

X

Options

X = None

* In instances where provisions for a customer supplied sensor are required, the following points must be covered:

A. A detailed dimension drawing of the sensor to be coupled must be supplied

B. A custom dimension/approval drawing will be made prior to manufacturing.

C. Special gearing of sensor may require an additional charge.

Sheave Assemblies

Description Part Number

Horizontal

Vertical

PSD0102600

PSD0102500

Description

Resolver & Mating

Connector

Replacement Spring Assembly

Description

Spring motor for A1&

A2 Style Units

Spring motor for B &

C Style Units

Points to note when ordering a linear cable reel sensor:

1. Hardware types determine the maximum capable stroke of each style. The actual stroke is customer specified. Three

initial wraps minimum remain on cable drum after the stroke length is reached. Pulling the cable out to its physical

maximum length may damage the unit.

Part Number

M0352900

SD039220

Resolver

Part Number

SD0308900

Cable Assembly

Part Number

SD0414600L__

2. Standard gearing of single-turn sensors is such that the active stroke of the cable reel will rotate the sensor 350 degrees.

Multi-turn sensors will rotate the maximum number of turns over the active stroke. Requests for gearing other than the

above must be called out clearly on order.

3. Mounting of customer supplied sensors is done in the most expedient way possible. Special mounting requirements

must be specified clearly on order.

Page 4

1.86

.42

THROAT

CLEAR

VIEW "A"

.19

Dimensions

“A” Version (stroke 96” or less)

2.50

.20

2.11

SEE VIEW "A"

1.50

.26

5.94

6.46

.50

.38 SLOT

4 PLACES

ACTIVE

STROKE

AS SPECIFIED

6.13

5.08

1.86

.42

THROA

CLEAR

VIEW "A"

.19

T

SPECIFY INITIAL

CABLE LEAD

.20

2.11

CABLE

REPLACEMENT

ACCESS

1.48

5.06

8.04

“A” Version (stroke 97” to 192”)

2.50

1.50

SEE VIEW "A"

.26

6.48

5.94

.50

.38 SLOT

4 PLACES

GEAR REDUCER ACCESS

CONNECTOR

(MS-3102E-16S-1P)

ACTIVE

STROKE

AS SPECIFIED

6.13

5.08

GEAR REDUCER ACCESS

SPECIFY INITIAL

CABLE LEAD

E

CABL

REPLACEMENT

ACCESS

9.25

5.06

CONNECTOR

(MS-3102E-16S-1P)

Page 5

3.12

Dimensions

“B” Version

16.00

15.00

INITIAL CABLE LEAD

2.00

STANDARD

7 PIN

CONNECTOR

3.12

1.89

5.18

12.82

.41

4 PLACES

SEE VIEW "A"

3.19

* *

“C” Version

ADD 1.75 (FOR

"B2" STYLE UNITS

11.47

1.86

8.50

VIEW "A"

2.11

.19

.42

THROAT

CLEARANCE

.20

18.60

19.60

N

7 PI

CONNECTOR

2.00

1.89

6.34

15.22

.41

4 PLACES

SEE VIEW "A"

4.94

1.86

.42

THROAT

CLEAR

10.69

VIEW "A"

2.11

.19

.20

Page 6

Sensor Type

Single Turn Resolver

Cable reel sensor with single turn resolvers are

setup so that the full stroke of the cable reel is

equal to approximately 350 degrees rotation of

the resolver. The resolver signal is fed to a converting device, like the Gemco Series 2500 PLS.

The Series 2500 can be scaled to display the

linear motion of the cable reel sensor. Example:

A 20 ft.. stroke cable reel sensor is specified

to be used with our Series 2500 PLS. Desired

accuracy is .01 ft. By calculating a scale factor

based on 360 degrees rotation of the resolver

such that 2000 counts or (20.00 ft.) is obtained

at 350 degrees, full linear display is achieved.

Stroke Range

Mechanical Accuracy

Speed Range

Cable Tension

Cable Material

Housing Material

Seal

Temperature Range

Specifications

Up to 1200 inches (100 ft.) standard

0.05% of active stroke

Variable

Type A unit 2.5 lbs. to 4.2 lbs. (stroke to 96”)

Type A unit 1.25 lbs. to 4.2 lbs. (stroke to 192”)

Type B unit 1.6 lbs. to 14.27 lbs.

Type C unit .75 lbs. to 16.30 lbs.

.056” (actual) stainless steel aircraft grade

10 gauge cold rolled sheet steel with baked enamel

paint finish

Splash Proof

Sensor dependent (most encoders and potentiometers

are around 0° to 180° F standard, resolvers are

typically -50° to 250° F). Check manufacturers specs

Multi-Turn Resolvers

In instances where a high degree of accuracy

or a long stroke is required, it may be advantageous to use a multi-turn resolver. The multiturn resolver can generate many counts per

revolution of the cable drum (up to 16,384 with

our Series 2500 electronics) and will accumulate these counts per revolution to track the

total linear travel. By using the linear travel per

revolution of the drum we can formulate a scale

factor for the electronic package that will display

linear cable travel throughout the full stroke.

Encoder and Potentiometer Sensors

When encoders or potentiometers are used we

can formulate the outputs to most any customer

specification. As standard packages potentiometers would be geared so that the full stroke of

the cable reel sensor was equal to approximately

90% of the active rotation on a single turn pot

and approximately 90% of the last turn on a 10

turn pot.

Incremental encoders can be directly driven

off the cable drum to give a known number of

pulses per revolution.

Absolute encoders can be geared so that the

maximum number of counts would equal the

specified linear stroke. If maximum stroke is

exceeded, the encoder will roll through to zero.

Page 7

MOVING

MEMBER

SHEAVE

ASSEMBLIES

CABLE REEL

SENSOR

CABLE REEL

SENSOR

Mounting & Sheave Assemblies

SHEAVE ASSEMBLY

CABLE REEL

SENSOR

G

MOVIN

MEMBER

SHEAVE

ASSEMBLIES

CABLE REEL

SENSOR

MOVIN

DEVICE

G

MOVING

DEVICE

2.00

3.00

1.03

SHEAVE ASSEMBLIES

HORIZONTAL MOUNT

P/N PSD-0102600

.38 DIA. MTG.

HOLES (4 PLACES)

5.47

6.22

VERTICAL MOUNT

P/N PSD-0102500

3.38 DIA.

2.00

0.25

0.70

3.15

2.37

.38 DIA. MTG.

HOLES (4 PLACES)

2.06

2.95

4.05

2.36

0.19

Page 8

AUTOMATION & PROCESS TECHNOLOGIES

®

1080 N. Crooks Road, Clawson, MI 48017-1097

Phone: 248-435-0700 Toll Free: 800-635-0289

Fax: 248-435-8120 www.AMETEKAPT.com

925.B2R

10/05.Z12

Loading...

Loading...