Page 1

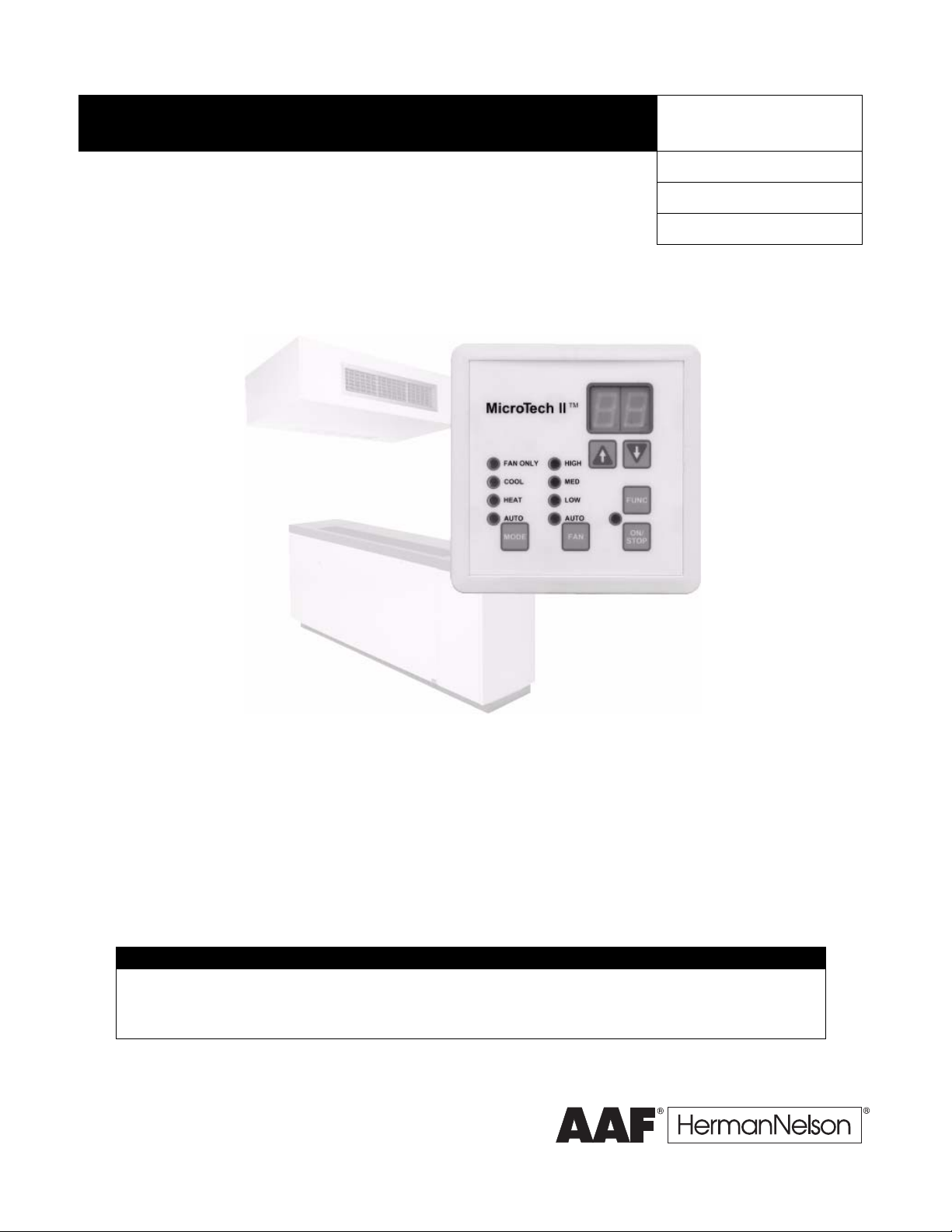

Operation Maintenance Manual OM 751-1

MicroTech II® Unit Ventilator Controls

for AAF®-HermanNelson® Classroom Unit Ventilators

Group: Applied Systems

Part Number: OM 751

Date: November 2006

DX Cooling Only-

Software Model UV05

Used with AAF-HermanNelson Classroom Unit Ventilator

Model AVV - Floor Mounted

Model AHV - Ceiling Mounted

Model AZV, AZU - Floor Mounted Self Contained Air Conditioner

IMPORTANT

Before unit commissioning, please read this publication in its entirety.

Develop a thorough understanding before starting the commissioning procedure.

This manual is to be used by the commissioner as a guide. Each installation is unique, only general topics are covered.

The order in which topics are covered may not be those required for the actual commissioning.

© 2006 McQuay International

Page 2

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Acronyms/Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Using the Keypad/Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Display Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Keypad Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Using the Keypad/Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Menu Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Description of Operation . . . . . . . . . . . . . . . . . . . . 12

State Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

UVC Unit Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

OFF Mode (State 9) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Night Purge Mode (State 8) . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Fan Only Mode (State A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Emergency Heat Mode (Super State) . . . . . . . . . . . . . . . . . . . 16

Auto Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Cool Mode (Super State) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Special Purpose Unit Modes. . . . . . . . . . . . . . . . . . . . . . . . . . 21

Unit Mode Priority . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Occupancy Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Occupied Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Unoccupied Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Standby Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Bypass Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Additional Occupancy Features . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Networked Occupancy Sensor Capability. . . . . . . . . . . . . . . . 25

Unit-Mounted Time-Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Unit-Mounted Tenant Override Switch . . . . . . . . . . . . . . . . . . 25

Remote Wall-Mounted Sensor Tenant Override Switch . . . . . 25

Remote Wall-Mounted Sensor Status LED. . . . . . . . . . . . . . . 25

Space Temperature Set Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Networked Set Point Capability. . . . . . . . . . . . . . . . . . . . . . . . 26

Networked Set Point Offset Capability . . . . . . . . . . . . . . . . . . 26

Networked Set Point Shift Capability . . . . . . . . . . . . . . . . . . . 26

Networked Space Temperature Sensor Capability . . . . . . . . . 26

Remote Wall-Mounted Sensor with +/–3°F

Adjustment (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Remote Wall-Mounted Sensor with 55°F to 85°F

Adjustment (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Effective Set Point Calculations . . . . . . . . . . . . . . . . . . . . . . .27

Proportional Integral (PI) Control Loops . . . . . . . . . . . . . . . . . . . . . 29

Discharge Air Temperature Control . . . . . . . . . . . . . . . . . . . . 29

PI Control Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Proportional Band . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Integral Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Indoor Air Fan Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Auto Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Occupied, Standby, and Bypass Operation . . . . . . . . . . . . . .31

Unoccupied Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Cycle Fan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Off Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Outdoor Air Damper Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Minimum Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Economizer Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Networked Space Humidity Sensor Capability . . . . . . . . . . . 34

Networked Outdoor Humidity Sensor Capability . . . . . . . . . . 34

Demand Controlled Ventilation (optional) . . . . . . . . . . . 34

CO

2

Networked Space CO

ASHRAE Cycle II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Compressor Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Compressor Envelope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Compressor Cooling Lockout . . . . . . . . . . . . . . . . . . . . . . . . 35

Compressor Minimum On and Off Timers . . . . . . . . . . . . . . . 36

Compressor Start Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Outdoor Air Fan Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Floating-Point Actuator Auto-Zero, Overdrive and Sync . . . . . . . . 36

External Binary Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

External Binary Input 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

External Binary Input 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

External Binary Input 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

External Binary Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

External Binary Output 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

External Binary Output 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

External Binary Output 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Sensor Capability . . . . . . . . . . . . . . . 34

2

UVC Input and Output Table . . . . . . . . . . . . . . . . . 40

Diagnostics and Service. . . . . . . . . . . . . . . . . . . . . 41

Alarm and Fault Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Space Temp Sensor Failure (F0). . . . . . . . . . . . . . . . . . . . . . 42

DX Pressure Fault (F1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Compressor Envelope Fault (F2) . . . . . . . . . . . . . . . . . . . . . . 42

Discharge Air DX Cooling Low Limit Indication (F3) . . . . . . . 42

Condensate Overflow Indication (optional) (F4). . . . . . . . . . . 43

Space Coil DX Temp Sensor Failure (F5) . . . . . . . . . . . . . . . 43

Outdoor Temp Sensor Failure (F6) . . . . . . . . . . . . . . . . . . . . 43

Discharge Air Temp Sensor Failure (F7) . . . . . . . . . . . . . . . . 43

Outdoor Coil DX Temp Sensor Failure (F8). . . . . . . . . . . . . . 43

Space Humidity Sensor Failure (optional) (FA) . . . . . . . . . . . 44

Outdoor Humidity Sensor Failure (optional) (Fb) . . . . . . . . . . 44

Space CO2 Sensor Failure (optional) (FC). . . . . . . . . . . . . . . 44

Change Filter Indication (FF) . . . . . . . . . . . . . . . . . . . . . . . . . 44

EPROM Memory Indicator (EE) . . . . . . . . . . . . . . . . . . . . . . . 44

Configuration Display (--) . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Troubleshooting Temperature Sensors . . . . . . . . . . . . . . . . . . . . . 44

Troubleshooting Humidity Sensors . . . . . . . . . . . . . . . . . . . . . . . . 45

Troubleshooting Carbon Dioxide (CO

) Sensors. . . . . . . . . . . . . . 46

2

UVC Configuration Parameters . . . . . . . . . . . . . . . 47

Page 3

Introduction

Introduction

This manual provides information on the MicroTech II® control system used in the AAF®-

®

HermanNelson

Unit Ventilator product line. It describes the MicroTech II components, input/

output configurations, field wiring options and requirements, and service procedures.

For installation and general information on the MicroTech II Unit Ventilator Controller, refer

to IM 747, MicroTech II Unit Ventilator Controller.

For installation, commissioning instructions, and general information on a particular unit

ventilator model, refer to the appropriate manual (Table 1), as well as accompanying software

operating instruction manual (Table 4), and possible accessory manuals that may pertain to the

unit (Table 3).

For installation and maintenance instructions on a plug-in communications card, refer to the

appropriate protocol-specific installation and maintenance manual (Table 2). For a description

of supported network variables for each protocol, refer to Protocol Data Packet bulletin ED

15065.

Table 1: Model-specific unit ventilator installation literature

Description Manual #

Air Source Heat Pump IM 502 X

DDC Control Components AED-Q-MTII-811 X

Self-Contained IM 503 X X X X X X

Self-Contained DDC

Control Components

Vertical Split-system IM 817-1 X X X X

Horizontal Split-system IM 830 X X X X X X X X

Ceiling Vent AH IM 830 X X X X

AZS Q V U R MII

810

AEQ

AER

AHF

AHB

AHR

AVF

AVB

AHV

AVS

AVH

AVV

AVR

AZS

AZB

AZR

AZU

XXXXX

AZV

AZQ

ARQ

ERQ

Table 2: Protocol-specific communication card installation literature and protocol data

Description Manual #

Unit Ventilator Unit Controller LonWorks®

Communications Module

Unit Ventilator Unit Controller JCI N2 Open®

Communications Module

Unit Ventilator Unit Controller BACnet®

Communications Module

Protocol Data Packet ED-15065

IM 729

IM 730

IM 731

Table 3: Accessory-specific installation literature

Description Manual #

MTII Unit Ventilator Controls Installation IM 747

Room Temperature Sensors Installation IM 629-1

ATS Service Cable Installation for Unit Ventilators IM 762-0

McQuay OM 751 3

Page 4

Introduction

Table 4: Software program literature

Description Manual #

Air Source Heat Pump with Electric Heat (Software Model 00) OM 748

Water Source Heat Pump with Electric Heat (Software Model 02)

Water Source Heat Pump without Electric Heat (Software Model 03)

DX Cooling with Electric Heat (Software Model 04) OM 750

DX Cooling Only (Software Model 05) OM 751

Electric Heat Only (Software Model 06) OM 752

DX Cooling with Hydronic Heat - Valve Control (Software Model 07)

DX Cooling with Hydronic Heat - F&BP Damper Control (Software Model 08)

2-Pipe Hydronic Heat Only - Valve Control (Software Model 09)

2-Pipe Hydronic Heat Only - F&BP Damper Control (Software Model 10)

2-Pipe Chilled Water Cooling and Hot Water Heat - Valve Control (Software Model 11)

2-Pipe Chilled Water Cooling and Hot Water Heat - F&BP Damper Control (Software

Model 12)

4-Pipe Chilled Water Cooling and Hydronic Heat - Valve Control (Software Model 13)

4-Pipe Chilled Water Cooling and Hydronic Heat - F&BP Damper Control (Software

Model 14)

2-Pipe Chilled Water Cooling Only - Valve Control (Software Model 15)

2-Pipe Chilled Water Cooling Only - F&BP Damper Control (Software Model 16)

2-Pipe Chilled Water Cooling with Electric Heat - Valve Control (Software Model 17)

2-Pipe Chilled Water Cooling with Electric Heat - F&BP Damper Control (Software

Model 18)

OM 749

OM 753

OM 754

OM 755

OM 756

OM 757

OM 758

NOTICE

This equipment generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with this instruction manual, may cause interference to radio

communications. It has been tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the FCC rules. These limits are designed to provide

reasonable protection against detrimental interference when the equipment is operated in a

commercial environment. Operation of this equipment in a residential area is likely to cause

detrimental interference in which case users are required to correct the interference at their

own expense. McQuay International disclaims any liability resulting from any

interference or for the correction thereof.

WARNING

Electric shock hazard. Can cause personal injury or equipment damage.

This equipment must be properly grounded. Connections and service to the MicroTech II

control panel must be performed only by personnel that are knowledgeable in the operation

of the equipment being controlled.

CAUTION

Extreme temperature can damage system components.

The MicroTech II controller is designed to operate in ambient temperatures from -20°F to

125°F. It can be stored in ambient temperatures from -40°F to 140°F. It is designed to be

stored and operated in relative humidity up to 95% (non-condensing).

CAUTION

Static sensitive components. A static discharge while handling electronic circuit

boards can damage components.

Discharge any static electrical charge by touching the bare metal inside the main control

panel before performing any service work. Never unplug any cables, circuit board terminal

blocks, relay modules, or power plugs while power is applied to the panel.

4 McQuay OM 751

Page 5

Introduction

Acronyms/Abbreviations

The following table list acronyms and abbreviations that may or may not be used within this

manual. Other abbreviations for keypad displays and parameters can be found in Table 8 on

page 14 and Table 26 on page 47.

Table 5: Acronyms and abbreviations

Description

Air Fan AF

Auxiliary Heat End Differential AHED

Auxiliary Heat Start Differential AHSD

American Standard Code for Information Interchange ASCII

American Society of Heating, Refrigerating, and Air

Conditioning Engineers, Inc

Compressorized Cooling Lockout CCLO

Spac e C O

Chilled Water CW

Chilled Water Valve Position CWVP

Discharge Air DA

Discharge Air High Limit DAHL

Discharge Air Temperature DAT

Discharge Air Temperature Setpoint DATS

Demand Controlled Ventilation

DX Cooling Discharge Air Low Limit DXLL

Economizer Compare Differential ECD

Economizer IA/OA Enthalpy Differential EED

Economizer OA Enthalpy Setpoint EES

Emergency Heat Setpoint EHS

Exhaust Interlock OAD Min Position Setpoint EOAD

Outdoor Air Temperature Setpoint EOAT

End-of-Cycle EOC

EOC OAT Low Setpoint EOCS

Outdoor Air Humidity Output EORH

Space Humidity Setpoint ERH

Economizer IA/OA Temp Differential ETD

Economizer OA Temp Setpoint ETS

Source (water in) Temperature EWIT

Face and Bypass Damper Position FBDP

Federal Communications Commission FCC

Face and Bypass F & BP

Heating, Ventilating, Air Conditioning Refrigeration HVACR

Heating EOC Valve Setpoint HEOC

Hot Water HW

Indoor Air IA

Indoor Air Fan IAF

Indoor Air Temperature IAT

Light Emitting Diode LED

Local User Interface LUI

Mixed Air Low Limit MALL

Mechanical Cooling Low Limit Setpoint MCLL

National Electric Code NEC

Outside Air OA

Outside Air Dampers OAD

Energize Exhaust Fan OAD Setpoint OADE

OAD Min Position High-Speed Setpoint OADH

OAD Min Position Low-Speed Setpoint OADL

OAD Min Position Med-Speed Setpoint OADM

Outdoor Air Damper Position OADP

OAD Lockout Setpoint OALS

OAD Max Position Setpoint OAMX

Outside Air Temperature OAT

Setpoint CO2S

2

Acronym/

ASHRAE

DCV

Abr.

McQuay OM 751 5

Page 6

Introduction

Description

Occupied Cooling Setpoint OCS

Occupied Heating Setpoint OHS

Occupancy Override Input OOI

Occupancy Sensor Input OSI

Proportional Integral PI

Parts Per Million PPM

Positive Temperature Coefficient PTC

Relative Humidity RH

Space Humidity Setpoint

Read Only RO

Read Write RW

Standby Cooling Setpoint SCS

Standby Heating Setpoint SHS

Thermal Expansion Valve TXV

Unoccupied Cooling Setpoint UCS

Unoccupied Heating Setpoint UHS

Unit Ventilator UV

Unit Ventilator Controller UVC

UVC (Heat/Cool) Mode Output UVCM

UVC State Output UVCS

Wet Heat Valve Position VALP

Ventilation Cooling Low Limit Setpoint VCLL

Ventilation Cooling Lockout VCLO

Ventilation Cooling Setpoint VCS

Wet Heat WH

Source (water in) Temperature Differential WITD

Acronym/

RHS

Abr.

6 McQuay OM 751

Page 7

Getting Started

Getting Started

The MicroTech II Unit Vent Controller (UVC) is a self-contained device that is capable of

complete, stand-alone operation. Information in the controller can be displayed and modified

by using the keypad/display (local user interface). The following sections describe how to use

the keypad/display.

Note – Many UVC parameters are accessible both through the keypad/display and the network

interface. The shared keypad/display and the network interface variables have a “lastchange-wins” relationship.

Using the Keypad/Display

The keypad/display shown in Figure 1 is provided with all MicroTech II Applied Unit

Ventilator unit controllers. With the keypad/display, operating conditions, system alarms, and

control parameters can be monitored. Set points and other parameters also can be modified.

Figure 1: Keypad/display

MicroTechTMII

FAN ONLY

COOL

HEAT

AUTO

MODE FAN

HIGH

MED

LOW

AUTO

FUNC

ON /

STOP

Display Format

The keypad/display’s 2-digit, 7-segment display normally shows the effective heating or

cooling temperature set point (Effective Set Point Output). The display also is used to view

and modify UVC parameters as explained in the following sections.

Note – When the UVC is in the OFF mode, the effective heating set point appears in the display.

All other LEDs are switched off.

Keypad Functions

Security Levels

The keypad/display provides a 4-level password security feature that can be used to restrict

access. The available security levels are shown in Table 6.

Note – All unit ventilator controllers ship with the lowest security (level 0) enabled. To change

security levels, see Figure 2. Once a security level is changed, the keypad/display

remains at that security level until the next time it is changed.

Why can’t I use the MODE or FAN key or adjust Set Point Offset?

Most likely this is due to the security feature being used. If the security feature is set higher

than level 0, then some keypad/display functionality is locked out. To ensure this is not the

problem, enter the level 0 password then try to use the keypad/display again.

McQuay OM 751 7

Page 8

Getting Started

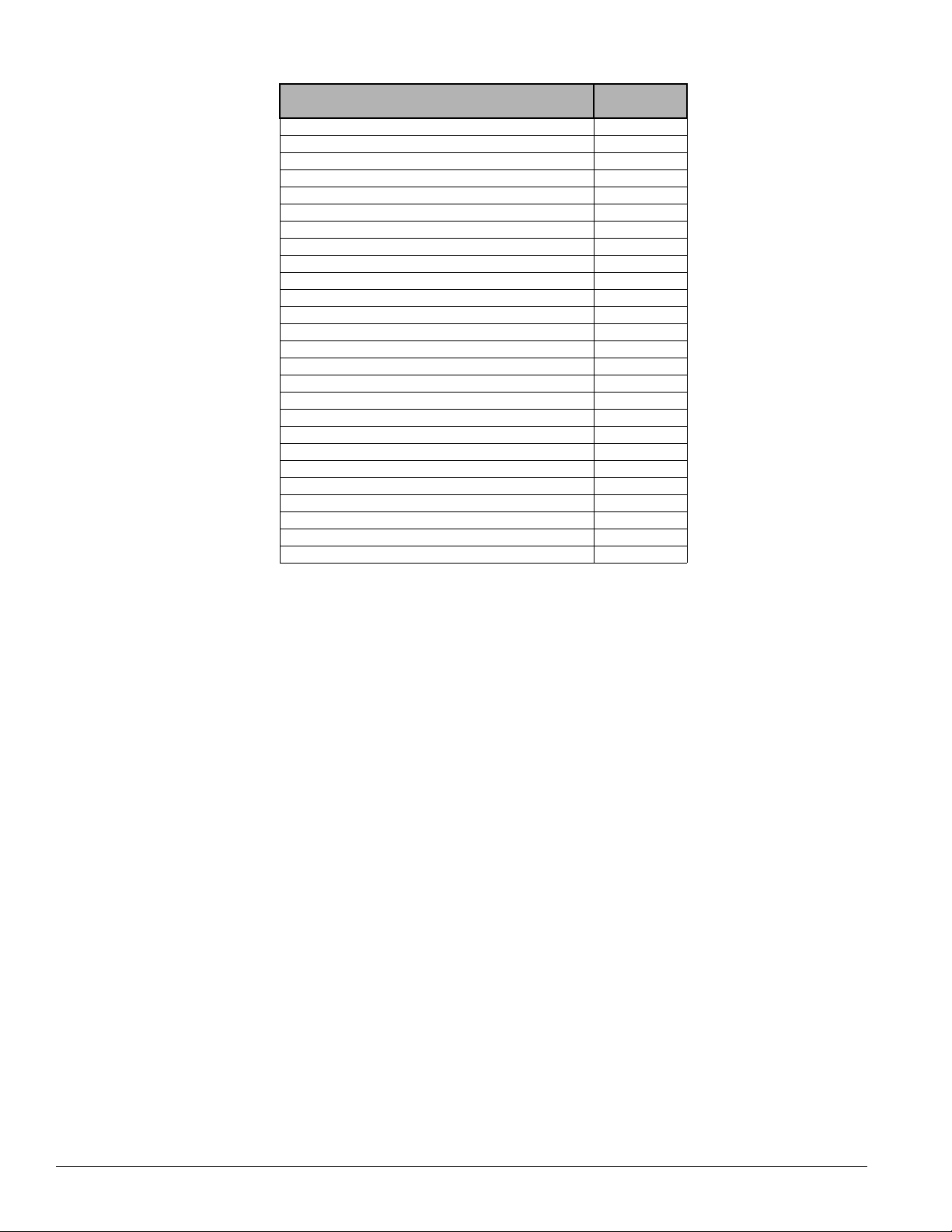

Table 6: Keypad/display security levels

Level Display What is restricted? Password

0

1

2

3

U0

Default level (access all) 10

Does not allow set point offset changes;

U1

also locks out keypad/display menu

access.

Does not allow set point offset changes

nor MODE key changes; also locks out

U2

keypad/display menu access.

Does not allow set point offset changes

U3

nor MODE and FAN key changes; also

locks out keypad/display menu access.

21

32

43

Figure 2: Changing keypad/display security levels

ON/STOP Key and LED

Use the ON/STOP key to toggle the UVC between OFF mode and running (Application Mode

Input). The ON/STOP LED is off when the UVC is in the OFF mode.

Note – When the UVC is in the OFF mode, the effective heating set point appears in the display.

All other LEDs are switched off.

– The UVC archives each change to the keypad/display FAN and MODE keys. When the

ON/STOP key is used to bring the unit out of OFF mode, the UVC implements the last

active fan and unit modes.

– Each time the UVC power cycles, the UVC is in the auto fan and auto unit modes when

power is returned.

WARNING

Off mode is a “stop” state for the unit ventilator. It is not a “power

off” state. Power may still be provided to the unit.

FAN Key

Use the FAN key to toggle through each of the fan speeds (Fan Speed Command Input): Auto,

Low, Medium, and High.

MODE Key

Use the MODE key to toggle through the keypad/display accessible unit modes (Heat/Cool

Mode Input): Auto, Heat, Cool, and Fan Only.

Arrow Keys

Use the arrow keys to scroll between parameters and to adjust parameters.

FUNC Key

Use the Func key to view the actual space temperature or to confirm selection and changes to

user-adjustable parameters.

8 McQuay OM 751

Page 9

Getting Started

Using the Keypad/Display

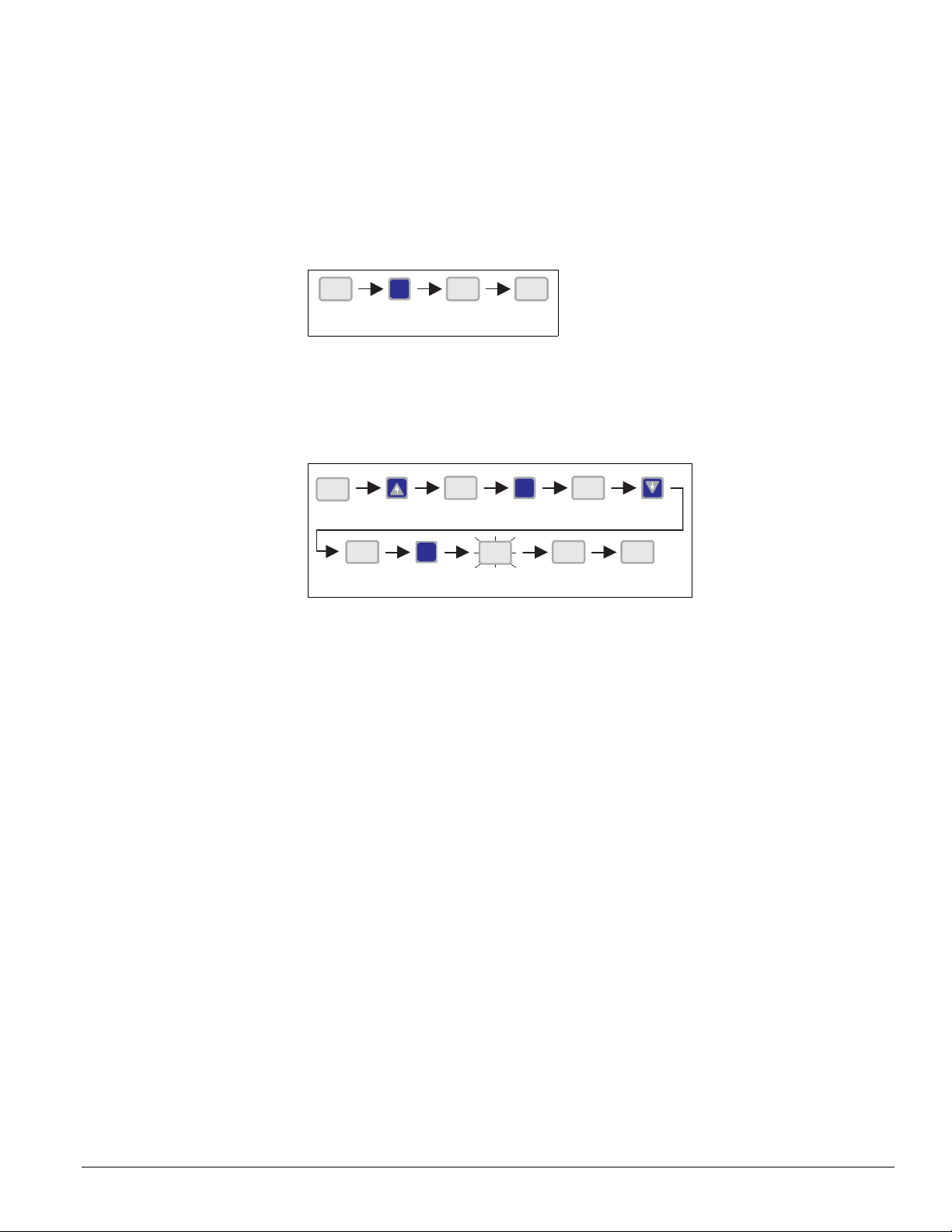

Viewing Actual Indoor Air Temperature (IAT)

Normally, the effective set point temperature appears on the keypad/display. You also can use

the keypad/display to view the indoor air temperature (IAT). See Figure 3.

Note – When the actual indoor air temperature (Effective Space Temp Output) equals the

effective set point temperature (Effective Set Point Output), you there is no change to the

keypad/display when you view space temperature.

Figure 3: Viewing indoor air temperature

70 71 70

Effective

set point

Changing Set Points

The keypad/display can be used to make a +/–5°F (+/–3°C) offset adjustment to the effective

temperature set point. See Figure 4. Also see “Space Temperature Set Points” on page 26 to

learn more about temperature set points.

Figure 4: Adjusting the set point offset

FUNC

Enter

(5-sec)

Actual space

temperature

Effective

set point

-1

Flash

value

FUNC

Enter

0

0

Current

offset

So 69

Effective

set point

70

Effective

set point

-1

Adjusted

offset

FUNC

Save

change

So

Set point

offset

Note – The set point offset clears whenever UVC power is cycled. When you change the set point

offset after a power cycle, or for the very first time, this cleared value shows as the highest

allowed value (5°F/3°C) but is not an actual offset value.

– When using the +/–3°F (+/–1.7°C) remote wall sensor, any set point offset adjustment

made at the keypad/display causes the UVC to override and ignore the remote wall

sensor set point adjustment knob. To use the remote wall sensor set point adjustment

knob after you changed the set point offset on the keypad/display, clear the keypad/

display set point offset by cycling UVC power.

– When using the 55°F to 85°F remote wall sensor, the UVC ignores any LUI set point offset

adjustments.

Menu Reference

The keypad/display menu eases troubleshooting and simplifies UVC configuration. The user

can access the most common parameters and system status values without a PC or network

interface.

The keypad/display menu is accessed via an unmarked, hidden key. This hidden key is located

approximately behind the letter “h” in the MicroTech II logo on the keypad/display face.

The keypad/display menu consists of two levels. The first level is the keypad/display Menu

Item List containing alphanumeric characters representing each parameter. The second level is

where the parameter’s value is viewed and adjusted if the parameter is adjustable. After 15seconds, an inactivity timer automatically causes the display to back out of the menu levels,

returning to the effective set point display.

McQuay OM 751 9

Page 10

Getting Started

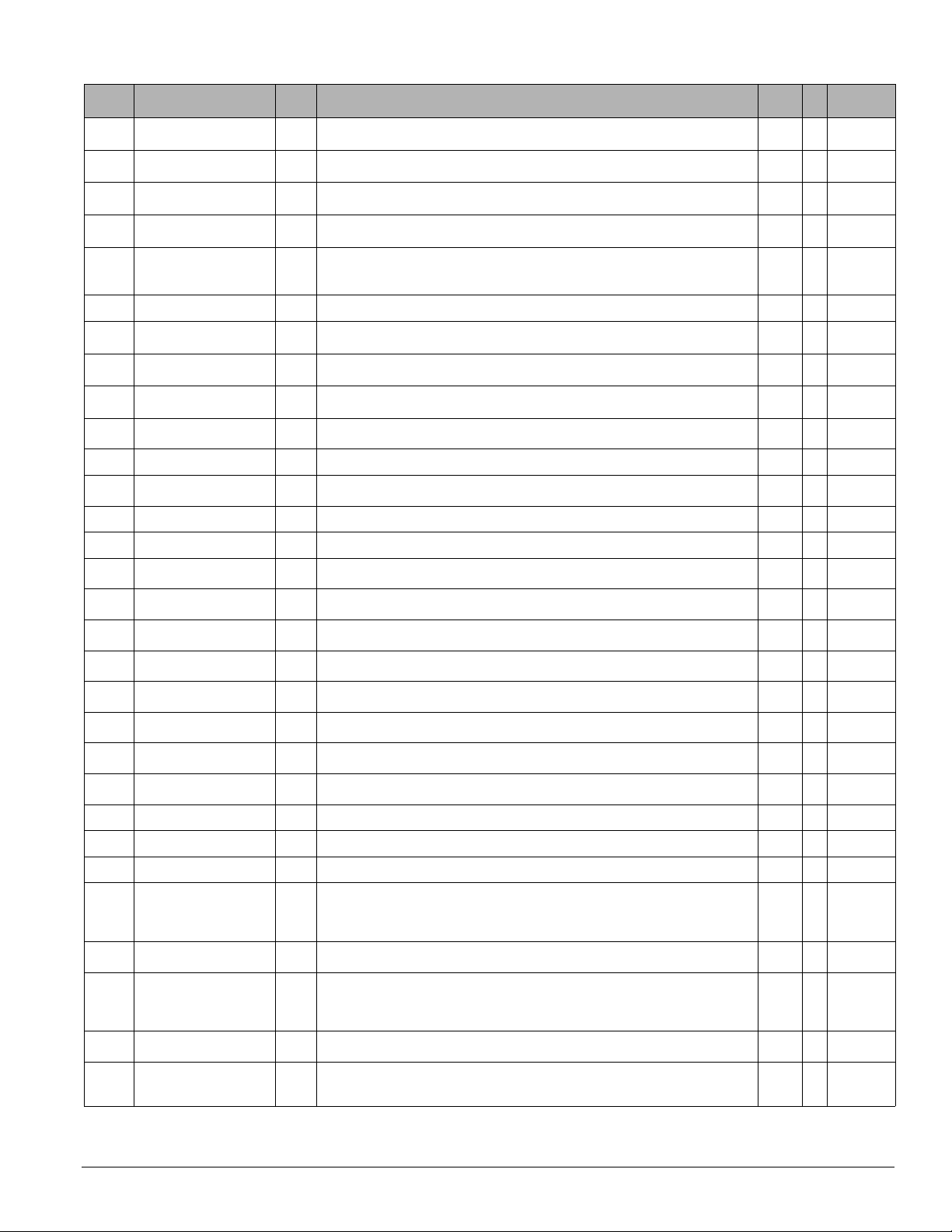

Figure 5: Changing a keypad/display menu item

Table 7: Keypad/display menu item list

Display Keypad menu item list Abr. Description

Reset Alarm Input Enter 1 to clear alarms (clears all inactive alarms, except filter alarm). To enable

rA

UVC (Heat/Cool) Mode

HC

Output

UVC State Output

St

Discharge Air Temp Set

d0

point Output

Discharge Air Temp

d1

Output

Ventilation Cooling Low

d2

Limit set point

Mechanical Cooling Low

d3

Limit set point

Slave Type Configuration Set slave type: 0 = Independent (slave uses own sensors), 1 = Dependent (slave

SL

Effective Occupancy

Eo

Output

Occupancy Override

Input

o(

Occupied Cooling set

(o

point

Standby Cooling Set

(S

point

Unoccupied Cooling Set

(U

point

Occupied Heating Set

ko

point

Standby Heating Set

kS

point

Unoccupied Heating Set

kU

point

Wall Sensor Type

rS

Outside Air Damper

o1

Position Output

OAD Min Position High-

o2

Speed Set point

OAD Min Position MedSpeed Set point OADM

o3

OAD Min Position LowSpeed Set point OADL

o4

the alarm again, enter 0.

Display current UVC mode. 1 = Heat, 3 = Cool, 4 = Night Purge, 6 = Off, 8 = Emerg.

UVCM

Heat, 9 = Fan Only

Display current UVC state. 1 = EconMech, 2 = Mech, 3 = Econ, 4 = DA Heat, 5 =

Heat, 6 = ActiveDehum, 7 = Full Heat, 8 = Night Purge, 9 = Off, 10 = Fan Only, 11

UVCS

= Heat Mode Cant Heat, 12 = CantCool, 13 = Emerg Heat Mode Cant Heat, 14 =

Heat Mode Low Limit, 15 = Cool Mode Low Limit

DATS Display current DA temperature set point. RO x

DAT Display current DA temperature. RO x

VCLL Adjust economizer cooling DA temperature low limit. RW x

MCLL Adjust mechanical cooling DA temperature low limit. RW x

follows master). This feature requires a network over which the master and slave

UVCs can communicate.

Display current occupancy. RO x

Set occupancy: 0 = occupied, 1 = unoccupied, 2 = bypass, 3 = standby. Adjusting

this variable is intended only for troubleshooting. Once you are done, cycle unit

power to clear this variable and return the UVC to normal operation.

OCS Adjust occupied cooling set point. RW x

SCS Adjust standby cooling set point. RW x

UCS Adjust unoccupied cooling set point. RW x

OHS Adjust occupied heating set point. RW x

SHS Adjust standby heating set point. RW x

UHS Adjust unoccupied heating set point. RW x

Set wall sensor type: 0 = +/–3F, 1 = 55°F to 85°F. RW x 0

OADP Display OA damper position. RO x

Adjust OA damper minimum position with IAF at high speed. (This variable is

OADH

factory set to 5% open when the unit is ordered with optional

Adjust OA damper minimum position with IAF at medium speed. (This variable is

not used when the optional

damper minimum regardless of fan speed.)

Adjust OA damper minimum position with IAF at low speed. (This variable is not

used when the optional

damper minimum regardless of fan speed.)

CO2 DCV is enabled. Only OADH is active as the OA

CO2 DCV is enabled. Only OADH is active as the OA

CO2 DCV.)

RO

05

1

RW

RW x

RO x

RO x

RW x 0

RW x

RW x 20%

RW x 25%

RW x 30%

Default

//

54°F

(12°C)

45°F

(7°C)

//

73.4°F

(23°C)

77°F

(25°C)

82.4°F

(28°C)

69.8°F

(21°C)

66.2°F

(19°C)

60.8°F

(16°C)

2

2

10 McQuay OM 751

Page 11

Display Keypad menu item list Abr. Description

Exhaust Interlock OAD

o5

Min Position set point

Energize Exhaust Fan

o6

OAD Set point

OAD Max Position Set

o7

point

OAD Lockout Enable

o8

OAD Lockout Set point OALS

o9

Economizer Enable Set economizer status: 0 = disable, 1 = enable. RW x 1

E1

Economizer OA Temp

E2

Set point

Economizer IA/OA Temp

E3

Differential

Economizer OA Enthalpy

E5

Set point

Economizer IA/OA

E6

Enthalpy Differential

Space Humidity Output ERH Display room humidity (optional). 00 = No sensor connected. RO x

r1

Outdoor Air Humidity

r3

Output

Outdoor Air Temp Output EOAT Display OA temperature. RO x

ot

Emergency Heat Enable Set emergency heat status: 0 = disable, 1 = enable. RW x 1

k1

Emergency Heat Set

k2

point

Emergency Heat

k3

Shutdown Configuration

Auxiliary Heat Start

A1

Differential

Auxiliary Heat End

A2

Differential

Auxiliary Heat

A3

Configuration

External BI-3

b3

Configuration

External BO-3

b6

Configuration

Fan Cycling

(F

Configuration

Filter Alarm Enable Set filter alarm status: 0 = disable, 1 = enable. RW x 0

(E

Reset Filter Alarm Input Enter 1 to clear filter alarm. RW x

(r

Compressor Enable Set compressor status: 0 = disable, 1 = enable. RW x 1

(1

Compressor Cooling

(2

Lockout Set point

Compressor Heating

(3

Lockout Set point

Compressor Start Delay

(6

Space Temp Sensor

SP

Offset

Keypad/display

Un

Temperature Units

1. RW = read and write capable, RO = read only.

2. If a menu value is greater than 2-digits (higher than 99), then

Adjust OA damper position above which the exhaust fan output will be energized.

EOAD

There is a fixed –5% differential associated with this set point.

Adjust OA damper minimum position when the exhaust interlock input is

OADE

energized.

OAMX Adjust OA damper maximum position. RW x 99%

Set OA damper lockout feature status: 0 = disable, 1 = enable. (This variable is

factory set to 1 when the unit is ordered as a recirc unit with no OAD.)

Adjust OA temperature below which the OA damper closes if the OA damper

lockout is enabled. (This variable is factory set to –99°C when the unit is ordered

as a recirc unit with no OAD.)

Adjust economizer OA temperature set point. DO NOT lower this set point below

ETS

CCLO or you risk creating a deadband where no cooling occurs.

ETD Adjust economizer IA/OA temperature differential. RW x 1.8°F (1°C)

EES Adjust economizer OA enthalpy set point. RW x

EED Adjust economizer IA/OA enthalpy differential. RW x

EORH Display OA humidity (optional). 00 = No sensor connected. RO x

EHS Adjust emergency heat set point. RW x

Set emergency heat operation during shutdown, 0 = no emergency heat during

shutdown: 1 = allow emergency heat during shutdown.

AHSD Adjust auxiliary heat start differential. RW x 1.8°F (1°C)

AHED Adjust auxiliary heat stop differential. RW x 1.8°F (1°C)

Set auxiliary heat type: 0 = N.O. device, 1 = N.C. device. RW x 0

Set the function external binary Input 3: 0 = ventilation lockout, 1 = exhaust

interlock.

Set the function of external binary output 3: 0 = exhaust fan on/off signal, 1 =

auxiliary heat.

Set space fan cycles (switches off) during occupied, bypass, and standby mode: 2

= continuous, 3 = cycling.

Adjust compressor cooling lockout set point. When the OA temperature falls below

this set point, compressor cooling is not allowed. DO NOT make this setting lower

CCLO

than the factory default. There is a fixed +3.6°F (2°C) differential associated with

this set point.

Adjust compressor heating lockout set point. When the OA temperature falls below

CHLO

this set point, compressor heating is not allowed and only electric heat will be used.

Adjust compressor start delay. Where several units (inductive loads) are

connected to the same electrical supply, make this set point unique for every UVC

to prevent multiple compressors from energizing at the same time after a power

failure or occupancy change.

Adjust this setting to bias the UVC measured space temperature. RW x 0

Set keypad/display temperature units in English or SI. This set point also effects

which unit types displayed over Metasys N2 and BACnet MS/TP networks using

the appropriate optional communications modules.

// will be displayed on the keypad/display.

Getting Started

RO

05

1

RW

RW x 99%

RW x 12%

RW x 0

RW x

RW x

RW x 0

RW x 0

RW x 0

RW x 2

Default

35.6°F

(2°C)

68°F

(20°C)

25 Btu/lb

(58 kJ/kg)

1.3 Btu/lb

(3 kJ/kg)

53.6°F

(12°C)

//

RW x

RW x

RW x 0 sec

RW x F

63.5°F

(17.5°C)

25°F

(-4°C)

2

McQuay OM 751 11

Page 12

Description of Operation

Description of Operation

State Programming

The MicroTech II UVC takes advantage of “state” machine programming to define and

control unit ventilator operation. “State” defines specific states or modes of operation for each

process within the unit ventilator (e.g., heating, cooling, etc.) and contain the specific logic for

each state. This eliminates some of the most common problems associated with control

sequences such as the possibility of simultaneous heating and cooling, rapid cycling, etc.

State machine programming, and the unique nature of state diagrams, can be easily used to

describe operation. It can simplify sequence verification during unit commissioning, as well as

simplify troubleshooting. With the unique combination of state machine programming and the

keypad/display’s ability to allow a technician to easily determine the active UVC state,

troubleshooting the UVC can be very simple.

The state diagrams presented in the following sections consist of several “elements” including

super states, states, conditional jumps (also called transitions) and transition points. Super

states are used as a means to group two or more related states into a single control function

such as cooling, or heating, etc. States are where all the actual work takes place, within each

state the UVC enables PI-loops and other logic sequences required to control unit ventilator

operation within that particular state, while other functions and PI-loops not needed during

that state may be disabled. Conditional jumps, or transitions, are the logic paths used by the

UVC to determine which state should be made active, these are the “questions” the UVC

continually considers. The transition point is simply a point through which a number of

conditional jumps meet. Think of it as a point where a number of questions must be

considered from which the UVC then determines which path is followed and which state is

then made active.

The UVC states and super states are used to define the “normal” unit modes, such as Off,

Night Purge, Fan Only, Emergency Heat, Auto, Cool, and Heat. The UVC also supports

several “special purpose” unit modes such as Purge, Pressurize, De-pressurize, and Shutdown,

which can be forced via a network connection and override typical UVC operation.

Note – Not all states or modes are available for all UV configurations, and some states (such as

Active Dehum) are optional.

– In the state descriptions below the terms, saturated high and saturated low, indicate that

the heating or cooling function being described has reached 100% or 0%, respectively.

12 McQuay OM 751

Page 13

Figure 6: Complete UVC—state diagram

Description of Operation

CantHeat

B

EmergencyHeat

ModeSuperState

FullHeat

7

CantHeat

D

HeatMode

SuperState

Off

Heat

5

LowLimit

E

NightPurge

Econ

Mech

8

FanOnly

A

AutoMode

3

1

2

DAHeat

4

LowLimit

F

9

CoolMode

SuperState

CantCool

C

EconMech

UVC Unit Modes

The UVC provides several “normal” modes of unit operation. These include: Off, Night

Purge, Fan Only, Cool, Emergency Heat, Auto, Heat, and Cool.

Normal UVC modes can contain a single state or several states depending upon the

functionality required for each particular mode. Each UVC state is assigned a number, which

can be very helpful when trying to understand which state is currently active within the UVC.

To view the current UVC state number, use the keypad/display.

McQuay OM 751 13

Page 14

Description of Operation

F

Table 8: UVC state names and numbers

Normal UVC modes State names

OFF OFF 9 9 57

Night purge Night Purge 8 8 56

Fan only Fan Only 10 A 65

Emergency heat

Heat

Auto

Cool

Full Heat 7 7 55

Cant Heat 13 D 68

Heat 5 5 53

Cant Heat 11 B 66

Low Limit 14 E 69

EconMech 1 1 49

Mech 2 2 50

Econ 3 3 51

DA Heat 4 4 52

Cant Cool 12 C 67

Low Limit 15 F 70

Decimal ASCII Hex

State numbers

WARNING

Off mode is a “stop” state for the unit ventilator. It is not a “power

off” state. Power may still be provided to the unit.

OFF Mode (State 9)

Off mode is provided so that the UVC can be forced into a powered OFF condition. OFF mode

is a “stop” state for the unit ventilator; it is not a power off state. OFF mode consists of a

single UVC state: OFF [9].

When OFF mode becomes active, the UVC stops all normal heating, cooling, and ventilation

(OA damper is closed), and fan operation ends. The UVC continues to monitor space

conditions, indicate faults, and provide network communications (if connected to a network)

in the OFF mode while power is maintained to the unit.

While in OFF mode, the UVC does not maintain DA temperatures. If the space temperature

drops below EHS while in the OFF mode, the UVC is forced into the Emergency Heat mode

(see “Emergency Heat Mode (Super State)” on page 16).

The space lighting output continues to operate based upon the current occupancy mode.

Note – Special purpose unit modes such as Purge, Pressurize, and De-pressurize can force the

UVC to perform “special” functions during which the display appears to be in the OFF

mode.

Figure 7: Off state diagram

OFF

9

UVC Mode

UVC Mode ≠ OFF

=

OF

Transition

point

14 McQuay OM 751

Page 15

Description of Operation

Night Purge Mode (State 8)

Night Purge mode is provided as a means to more easily and quickly ventilate a space. Night

purge can be useful in helping to remove odor build up at the end of each day, or after

cleaning, painting, or other odor generating operations occur within the space. Night Purge

mode consists of a single UVC state: Night Purge [8].

Night Purge is a full ventilation with exhaust mode, during which room comfort is likely to be

compromised. Therefore, McQuay strongly recommends using Night Purge only when the

space is unoccupied.

When Night Purge mode becomes active, the UVC stops all normal heating and cooling. Since

any new energy used to treat the incoming air would be wasted in the purge process. In the

Night Purge mode, the space fan is set to high speed, the OA damper is set to 100% open, and

the Exhaust Fan binary output (see “External Binary Outputs” on page 38) is set to ON. If the

UVC is not set to another mode within 1 hour (fixed), the UVC automatically switches to the

Fan Only mode (see “Fan Only Mode (State A)” on page 15).

While in Purge mode, the UVC does not maintain DA temperatures. If the space temperature

drops below the EHS, the UVC is forced into the Emergency Heat mode (see “Emergency

Heat Mode (Super State)” on page 16).

Figure 8: Night purge state diagram

Night Purge

8

UVC Mode ≠

Night purge

=

Transition

point

UVC Mode

Night purge

Fan Only Mode (State A)

The Fan Only mode is provided so that the UVC can be forced into a Fan Only operation via a

keypad/display or a network connection. Fan Only mode consists of a single UVC state: Fan

Only [A].

When Fan Only mode becomes active, the UVC stops all normal heating and cooling.

While in Fan Only mode, the UVC does not maintain DA temperatures. If the space

temperature drops below the EHS, the UVC is forced into the Emergency Heat mode (see

“Emergency Heat Mode (Super State)”).

Figure 9: Fan only state diagram

UVC Mode ≠

Fan Only

Fan Only

A

Transition

point

UVC Mode

Fan Only

=

McQuay OM 751 15

Page 16

Description of Operation

Emergency Heat Mode (Super State)

The Emergency Heat mode is provided for situations where the UVC is in a mode that does

not normally allow heating, such as OFF, Cool, Night Purge, or Fan Only. If Emergency Heat

mode is enabled, the UVC can automatically force itself into the Emergency Heat mode from

OFF, Cool, Night Purge, Fan Only, Purge, Pressurize, De-pressurize, and Shutdown.

Emergency Heat mode consists of UVC states: Full Heat [7] and Cant Heat [D].

Software model 05 does not have the primary or secondary heating devices. The UVC uses

auxiliary heat (if field provided and field connected) when emergency heat is required.

When the Emergency Heat mode becomes active, the UVC automatically determines which

state to make active, Full Heat [7], or Cant Heat [D], based on the transitions for each of those

states.

Figure 10: Emergency heat state diagram

Emergency Heat Mode

Super State

Full Heat

≠

Heat

Available

7

Heat

Available

UVC Mode

Emergency Heat

=

UVC Mode ≠

Emergency Heat

=

Transition

point

Cant Heat

D

Full Heat State (State 7)

The Full Heat [7] state is the “normal” state that the UVC goes into when Emergency Heat

mode is active. It is activated when the space temperature is lower than the EHS.

When Emergency Heat mode becomes active, the UVC goes into 100% heating until the space

temperature raises to the EHS plus a fixed differential (5.4°F/3°C). In the Emergency Heat

mode, the space fan is set to high speed, and the OA damper operates normally.

If the UVC automatically forces itself into the Emergency Heat mode from another mode

(e.g., Cool, Fan Only, etc.), then the UVC returns to the appropriate unit mode once the space

temperature rises to the EHS plus a fixed differential (5.4°F/3°C).

The UVC monitors the DAT to ensure it does not exceed DAHL. If the DAT does exceed

DAHL, then heating is set to 0% for a minimum of 2-minutes (fixed) and until the DAT drops

36°F (20°C) fixed differential below DAHL.

Cant Heat State (State D)

The Cant Heat [D] state is a “non-normal” state that the UVC can go into when Emergency

Heat mode is active. An IAT or DAT sensor fault during Emergency Heat mode causes the

UVC to make this state active.

When the Cant Heat state becomes active, the space fan remains at high speed as set during

the Full Heat state.

The UVC will remain in the Cant Heat state until heat becomes available.

16 McQuay OM 751

Page 17

Description of Operation

Auto Mode

Auto mode is provided so that the UVC can be set to automatically determine if heating or

cooling is required. Auto mode is the default power-up UVC mode. Auto mode is made up of

the Heat and Cool modes. When the UVC is set to auto mode, the UVC automatically

determines which mode (Heat or Cool) to use.

Heat Mode (Super State)

When in Heat mode, the UVC will use auxiliary heat (if field provided and field connected to

the unit) as needed to maintain the effective heating setpoint (see “Space Temperature Set

Points” on page 26). The keypad/display or a network connection can be used to force the unit

into the Heat mode. Additionally, the UVC when set to Auto mode can automatically force the

unit into the Heat mode as needed. When the UVC is in Auto mode, it is “normal” for the

UVC to “idle” in Heat mode when there is no need to switch to another mode.

The Heat mode super state consists of UVC states: Heat [5], Low Limit [E], and Cant Heat

[B].

When the Heat mode super state becomes active, the UVC automatically determines which of

the Heat Mode states to make active based upon the transitions for each state.

Figure 11: Heat mode super state diagram

Transition

point

UVC Mode = Heat

OR

=

Space

Auto AND

≠

Warm

UVC Mode ≠ Heat AND

UVC Mode

UVC Mode

Warm AND Heat Pl = Sat Low

≠

Auto

OR

=

Auto AND Space =

Heat Mode

Super State

UVC Mode

Heat

≠

Cant Heat

B

Heat

Available

Heat = Available

AND

Low Limit = Inactive

Heat = Available

AND

Low Limit = Inactive

≠

Available

Heat Pl = Sat Hi

(2 minutes)

DAT<VCLL

AND

DAT<(VCLL + 1.8F)

Low Limit

Heat

5

LLPl = Sat Lo

(2 minutes)

AND

E

Heat State (State 5)

The Heat state is the “normal” state during Heat mode. When the Heat state becomes active,

the UVC will (within State) continually calculate the DATS (“Discharge Air Temperature

Control” on page 29) required to maintain the effective heat setpoint (see “Space Temperature

Set Points” on page 26). The calculated DATS will not be allowed to go above DAHL. The

UVC will use auxiliary heat (if field provided and field connected to the unit) as needed to

maintain the current DATS.The auxiliary heat binary output will be used as needed. The Heat

Timer (3-minutes fixed) will begin counting. The CO

will be active, if the unit is equipped for CO

control (see “CO2 Demand Controlled

2

demand controlled ventilation function

2

Ventilation (optional)” on page 34), and the OA damper will be adjusted as needed to maintain

the CO

setpoint. The UVC will remain in this state until one of the transition out conditions

2

become true, or until one of the super state transition out conditions becomes true.

McQuay OM 751 17

Page 18

Description of Operation

Note – The OAD is considered to be in “alarm” when the OAD is forced below the active minimum

position in the Low Limit state. This is not an actual unit “alarm” or “fault” condition, but

only a condition used for the purpose of transition arguments.

Low Limit State (State E)

The Low Limit state is a “non-normal” state the UVC can go into while Heat mode is active

when the unit reaches 100% heating and still cannot meet the current DATS (see “Discharge

Air Temperature Control” on page 29) required to maintain the effective heating set point (see

“Space Temperature Set Points” on page 26). This is likely to occur only if the OA

temperature is very cold, the OA damper minimum position is set too high, the unit ventilator

is oversized for the application, or if the electric heating has failed, or is set incorrectly.

When the Low Limit state becomes active, the Low Limit PI-loop can override the OA

damper position (see “Outdoor Air Damper Operation” on page 32) and adjust the OA damper

toward closed as necessary to maintain the current DATS (see “Discharge Air Temperature

Control” on page 29).

Cant Heat State (State B)

The Cant Heat state is a “non-normal” state the UVC can go to when Heat mode is active. An

IAT or DAT sensor fault during the Heat mode causes the UVC to make this state active.

When the Cant Heat state becomes active, no heating or ventilation takes place. The OA

damper goes to the minimum position unless it is forced closed by other functions such as

freezestat (T6) or morning warm-up.

Cool Mode (Super State)

When in Cool mode the UVC uses primary cooling (economizer) and secondary cooling

(mechanical, DX) as needed to maintain the effective cooling set point (see “Space

Temperature Set Points” on page 26). The keypad/display or network connection can be used

to force the unit into the Cool mode. When the UVC is in Auto mode, it is “normal” for the

UVC to “idle” in Cool mode when there is no need to switch to another mode. The Cool mode

super state consists of the following UVC states: Econ Mech [1], Mech [2], Econ [3], DA Heat

[4], Low Limit [F], and Cant Cool [C].

When the Cool mode super state becomes active, the UVC will automatically determine which

UVC state to make active based upon the transitions for each state.

If the space temperature drops below EHS, and the Emergency Heat function is enabled, the

UVC will be forced into the Emergency Heat mode (see “Emergency Heat Mode (Super

State)” on page 16).

18 McQuay OM 751

Page 19

Figure 12: Cool mode super state diagram

Econ

EconMech

Mech

3

1

2

CantCool

C

CoolMode

SuperState

DAHeat

LowLimit

4

F

LLPI=SatLow (2min)

AND

DAT>(VCLL+1.8F)

HeatPI=SatHi(2min)

AND DAT<VCLL

Space≠HighCO2

AND

HeatPI=SatLow

AND

DAT>VCLL

Space=HighCO2

OR

DAT<VCLL

UVCMode≠Cool AND UVCMode≠Auto

OR

UVCMode=Auto AND Space=Cold AND

MechPI=SatLow(3min) AND

EconPI=SatLow

UVCMode=Cool

OR

UVCMode=Auto AND Space=Warm

Econ≠Available

AND

MechCool

≠

Available

Econ = Available

AND

MechCool

≠

Available

Econ≠Available

AND

MechCool=Available

MechPI=SatLow (3min) AND

EconMechTimer=Expired

(3 minutes) OR

MechCool

≠

Available

Econ≠Available

Econ=Available

MechCool≠Available

Econ≠Available

AND

MechCool=Available

Transition

Point

EconTimer=Expired

(3 minutes) AND

EconPI=SatHi AND

MechCool=Available

Description of Operation

Econ State (State 3)

The Econ state is a “normal” state during Cool mode. The Econ state typically is active in the

Cool mode when primary cooling (economizer) is available and adequate to meet the cooling

requirements.

When the Econ state becomes active, the UVC uses economizer cooling (see “Economizer

Operation” on page 32) as needed to maintain the effective cooling set point (see “Space

Temperature Set Points” on page 26). If cooling is not required while in the Econ state, the

UVC can “idle” in the Econ state until cooling is required or until there is a call to switch to

another mode or state.

The UVC monitors the DAT to ensure it does not fall below VCLL.

The CO

Controlled Ventilation (optional)” on page 34) and the OA damper is adjusted as needed to

maintain the CO

demand controlled ventilation function (optional) will be active (see “CO2 Demand

2

set point.

2

McQuay OM 751 19

Page 20

Description of Operation

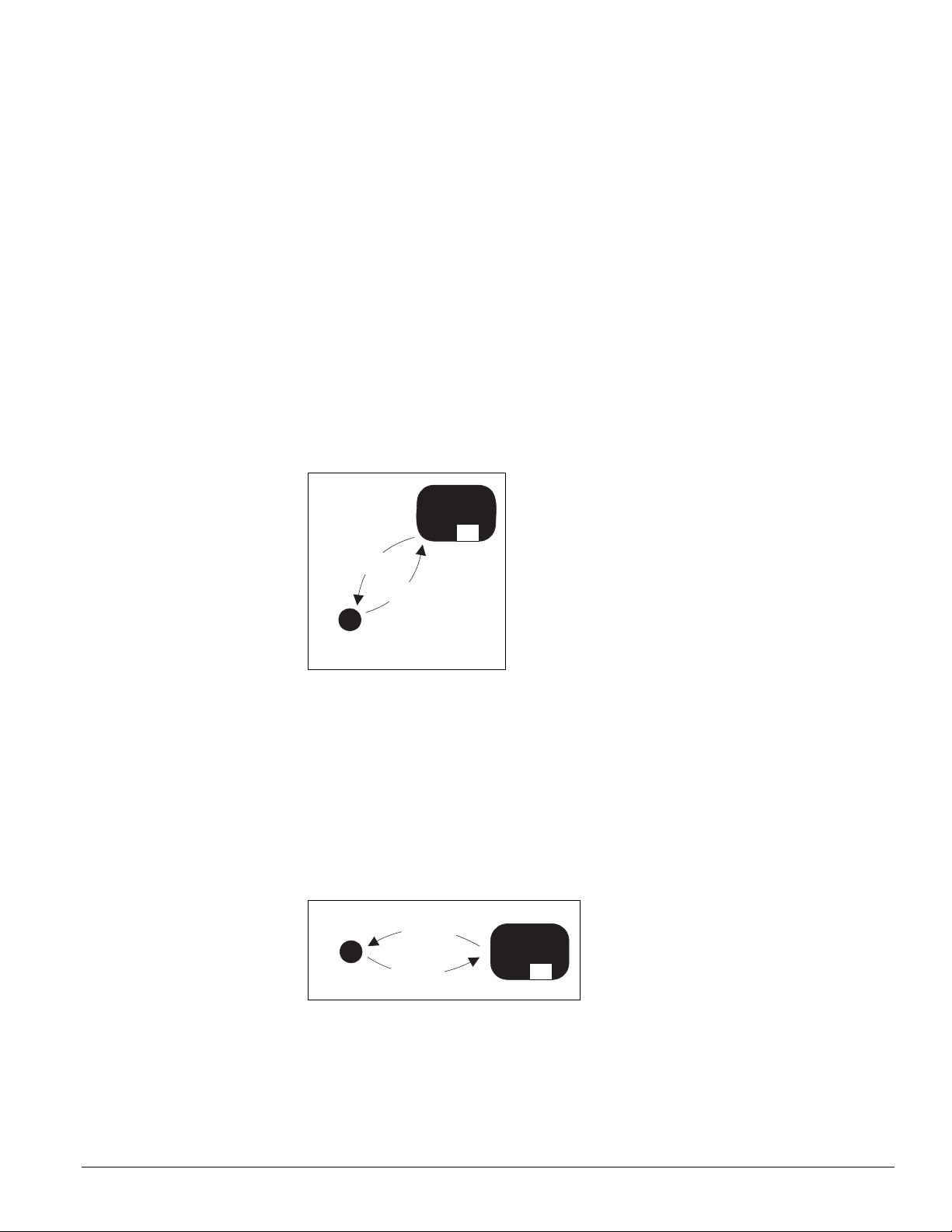

Figure 13: Econ state operation (occupied mode and auto fan)

Econ Mech State (State 1)

The Econ Mech state is a “normal” state during Cool mode. The Econ Mech state typically is

active in the Cool mode when primary cooling (economizer) alone is not adequate to meet the

cooling requirements and both primary cooling and secondary cooling (compressor) are

available.

When the Econ Mech state becomes active, the OA damper is set to 100% open, and the UVC

uses the units mechanical cooling capabilities as needed to maintain the effective cooling set

point (see “Space Temperature Set Points” on page 26).

The UVC monitors the DAT to ensure it does not fall below MCLL.

Figure 14: Econ mech state operation (occupied mode and auto fan)

Mech State (State 2)

The Mech state is a “normal” state during Cool mode. The Mech state typically is active in the

Cool mode when primary cooling (economizer) is not available and secondary cooling

(compressor) is available.

When the Mech state becomes active, the UVC uses the unit’s mechanical cooling capabilities

as needed to maintain the effective cooling set point (see “Space Temperature Set Points” on

page 26). If cooling is not required while in the Mech state, the UVC can “idle” in the Mech

state until cooling is required or until there is a call to switch to another mode or state.The

UVC monitors the DAT to ensure it does not fall below MCLL.

20 McQuay OM 751

Page 21

Description of Operation

The CO2 demand controlled ventilation function (optional) is active (see “CO2 Demand

Controlled Ventilation (optional)” on page 34), and the OA damper is adjusted as needed to

maintain the CO

Figure 15: Mech state operation (occupied mode and auto fan)

set point.

2

Discharge Air (DA) Heat State (State 4)

The DA Heat state is a “normal” state during Cool mode. The DA Heat state typically is active

when reheat is required to maintain DATS while maintaining the required OA damper

position. The DA Heat state can also be made active if the optional CO

provided and CO

levels are high, requiring the OA damper to open beyond what is required

2

DCV feature is

2

for economizer cooling.

When DA Heat state is active, the UVC uses the units heating capability as needed to maintain

VCLL. The CO

Demand Controlled Ventilation (optional)” on page 34), and the OA damper is adjusted as

needed to maintain the CO

demand controlled ventilation function (optional) is active (see “CO2

2

set point.

2

Low Limit State (State F)

The Low Limit state is a “non-normal” state during Cool mode. The Low Limit state typically

follows the DA Heat state when the UVC reaches 100% heat and still cannot maintain VCLL.

When the Low Limit state becomes active, the Low Limit PI-loop overrides the OAD

minimum position (see “Outdoor Air Damper Operation” on page 32) and adjusts the OAD

toward closed as necessary to maintain the DAT set point (see “Discharge Air Temperature

Control” on page 29).

Cant Cool State (State C)

The Cant Cool state is a “non-normal” state during Cool mode. The Cant Cool state typically

becomes active when both primary (economizer) and secondary (compressor) cooling are not

available (or they are disabled) or when an IAT, DAT or OAT sensor failure occurs.

When the Cant Cool state becomes active, no cooling is available.

Special Purpose Unit Modes

There are some additional UVC modes that are considered special purpose unit modes. These

special purpose modes include Pressurize, Depressurize, Purge, Shutdown, and Energy Hold

Off. These modes force the UVC to perform very specific and limited functions. Use these

with caution and only for short periods as needed.

McQuay OM 751 21

Page 22

Description of Operation

In each of these special purpose UVC modes, if the space temperature drops below EHS and

the Emergency Heat function is enabled, the UVC is forced into the Emergency Heat mode

(see “Emergency Heat Mode (Super State)” on page 16) and then return once the Emergency

Heat function is satisfied.

Table 9: Actions during special purpose unit modes

Action

Pressurize High 100% Open Off

Depressurize Off Closed On

Purge High 100% Open On

Shutdown Off Closed Off

Energy hold off Off Closed Off

Indoor air fan

(IAF)

Outdoor air

damper (OAD)

Exhaust fan

output

Pressurize Mode

When in Pressurize mode, the UVC uses the IAF, OAD, and exhaust output as needed to

pressurize the space. The UVC stops all normal heating and cooling but does allow emergency

heat if required. The pressurize mode can only be accessed via a network connection.

Depressurize Mode

When in Depressurize mode the UVC will use the IAF, OAD, and exhaust output as needed to

depressurize the space. The UVC stops all normal heating and cooling but does allow

emergency heat if required. The de-pressurize mode can only be accessed via a network

connection or with ServiceTools for MicroTech II Applied Terminal Unit Controllers (ATS).

Purge Mode

When in Purge mode, the UVC uses the IAF, OAD, and exhaust output as needed to purge the

space. The UVC stops all normal heating and cooling but does allow emergency heat if

required. The purge mode can only be accessed via a network connection or with ServiceTools

for MicroTech II Applied Terminal Unit Controllers (ATS).

Shutdown Mode

Shutdown mode is the equivalent of the Off mode, but is an Off mode forced by a network

connection. When in Shutdown mode, the UVC stops all normal heating, cooling, ventilation

(OA damper is closed), and fan operation. By default emergency heat is not be used during the

shutdown mode, however, the UVC can be configured (Emergency Heat Shutdown

Configuration) to allow emergency heat operation during shutdown mode. The shutdown

mode can be accessed via a network connection, a binary input to the UVC, or with

ServiceTools for MicroTech II Applied Terminal Unit Controllers (ATS).

WARNING

Shutdown mode and energy hold off mode are a “stop” state for

the unit ventilator. It is not a “power off” state.

Energy Hold Off Mode

The UVC supports an energy hold off state, which when active forces the UVC to stop all

normal heating, cooling and ventilation. Typically used by a network connection to force the

UVC to cease heating, cooling and ventilation when conditions exist where heating, cooling

and ventilation are not required or desired. Energy hold off mode is very similar to shutdown

mode except that energy hold off always allows emergency heat if required. The energy hold

off mode can only be accessed via a network connection or with ServiceTools for

MicroTech II Applied Terminal Unit Controllers (ATS).

22 McQuay OM 751

Page 23

Description of Operation

Unit Mode Priority

The UVC uses the network variables and binary inputs listed in Table 10 and Table 11 to

determine the current unit mode. Special purpose UVC unit modes have higher priority than

the normal UVC unit modes as shown in the tables.

Each table lists the highest priority items on the left to the lower priority items to the right. The

right-most columns indicate unit operation as a result of the left-most columns. The term

“Don’t care” in these tables implies that another network variable or binary input to the left

has a higher priority.

Table 10: Special purpose UVC unit mode priority

Priority result

Emergency override

input

Normal

1

3

Pressurize Don’t care Don’t care Don’t care Off Pressurize

De-pressurize Don’t care Don’t care Don’t care Off De-pressurize

Purge Don’t care Don’t care Don’t care Off Purge

Shutdown Don’t care Don’t care Don’t care Off Off

1. Network input.

2. Network output.

3. Normal indicates the UVC power-up condition.

4. De-energized indicates that the contacts connected to this binary input are open.

5. Energized indicates that the contacts connected to this binary input are closed.

Remote shutdown

binary input

De-energized

Energized

4

5

Energy hold

off input

1

Normal Normal

Energy hold

off output

2

Unit mode

output

2

See the normal

UVC mode priority (Table 11)

Energy hold off Energy hold off Off Off

Don’t care Energy hold off Off Off

Actual UVC action

Table 11: Normal UVC mode priority

Priority result

Application override

input

1

Normal (Auto)

Heat Don’t care Heat

Cool Don’t care Cool

Night purge Don’t care Night purge

Off Don’t care Off

Emergency heat Don’t care Emergency heat

Fan only Don’t care Fan only

1. Network input.

2. Network output.

3. Normal (Auto) is the normal UVC power-up state.

Unit mode override

Normal (Auto)

3

Night purge Night purge

Emergency heat Emergency heat

input

1

Unit mode output

3

Heat

Cool

Emergency heat

Heat Heat

Cool Cool

Off Off

Fan only Fan only

2

McQuay OM 751 23

Page 24

Description of Operation

Occupancy Modes

The UVC is provided with four occupancy modes: Occupied, Standby, Unoccupied, and

Bypass. The occupancy mode affects which heating and cooling temperature set points are

used, affects IAF operation, and affects OAD operation. The Manual Adjust Occupancy and

Networked Occupancy Sensor network variables, along with the Unoccupied and Tenant

Override binary inputs, are used to determine the Effective Occupancy. The term “Don’t care”

in Table 12 implies that another network variable or binary input to the left has a higher

priority.

Note – The Occupancy Override Input is provided as a way for a network connection to manually

force the UVC into a particular occupancy mode. The Occupancy Override Input can

override the tenant override feature. For example, if the network uses the Occupancy

Override Input to force the unit into unoccupied mode, then the tenant override switch

does not operate as expected. Therefore, McQuay strongly recommends using the

Occupancy Sensor Input to control occupancy modes over a network and only using the

Occupancy Override Input if there is reason to ensure tenant override does not occur.

Table 12: Occupancy mode priority

Priority result

Occupancy

Override input

Occupied Don’t care Don’t care Occupied

Unoccupied Don’t care Don’t care Unoccupied

Bypass

Standby Don’t care Don’t care Standby

Null (default)

1. Network input.

2. Network output.

3. Typical operation is defined in this row of the table.

4. The tenant override switch (unit or wall sensor mounted) can be used here to force the UVC

into bypass.

Occupancy

sensor input

Occupied Don’t care Occupied

Unoccupied Don’t care Bypass

Null (default)

Occupied Don’t care Occupied

Unoccupied Don’t care Unoccupied

3

Null (default)

Unoccupied binary input

1

Contacts open (Occupied) Occupied

Contacts Closed (Unoccupied) Bypass

Contacts open (Occupied) Occupied

Contacts closed (Unoccupied) Unoccupied

Effective

occupancy

output

2

4

4

Occupied Mode

The occupied mode is the normal day time mode of UVC operation. During occupied mode

the UVC uses the occupied heating and cooling set points, the OAD operates normally, and by

default the IAF remains on.

Unoccupied Mode

The unoccupied occupancy mode is the normal night time mode of UVC operation. During

unoccupied mode the UVC uses the unoccupied heating and cooling set points, the OAD

remains closed, and the IAF cycles as needed for heating or cooling. The IAF remains off

when there is no need for heating or cooling.

Standby Mode

The standby mode is a special purpose daytime mode of UVC operation. During standby,

mode the UVC uses the standby heating and cooling set points, the OAD remains closed, and

by default the IAF remains on.

24 McQuay OM 751

Page 25

Description of Operation

Bypass Mode

The bypass mode (also called Tenant Override) is the equivalent of a temporary occupied

mode. Once the bypass mode is initiated, it remains in effect for a set period of time (120

minutes, default). During the bypass mode, the UVC uses the occupied heating and cooling set

points, the OAD operates normally, and by default the IAF remains on.

Additional Occupancy Features

Networked Occupancy Sensor Capability

A networked occupancy sensor can be interfaced with the Occupancy Sensor Input variable to

select occupancy modes. When the Occupancy Sensor Input variable is used, it automatically

overrides any hard-wired unoccupied binary input signal.

Unit-Mounted Time-Clock

An optional unit-mounted factory-installed electronic 24-hour/7-day time clock can be

provided on stand-alone unit ventilator configurations. It is factory wired to the UVC

unoccupied binary input and can be set to automatically place the unit into occupied and

unoccupied modes based upon its user configured schedule.

Unit-Mounted Tenant Override Switch

A tenant override switch is factory installed in all floor mounted units and is located near the

LUI on the unit. This switch provides a momentary contact closure that can be used by room

occupants to temporarily force the UVC into the bypass occupancy mode from unoccupied

mode.

Note – The Occupancy Override Input can override the tenant override feature. For example, if

the network uses the Occupancy Override Input to force the unit into unoccupied mode,

then the unit-mounted tenant override switch does not operate as expected. Therefore,

McQuay strongly recommends using the Occupancy Sensor Input to control occupancy

modes over a network and only using the Occupancy Override Input if there is reason to

ensure tenant override does not occur.

Remote Wall-Mounted Sensor Tenant Override Switch

The optional remote wall-mounted sensors include a tenant override switch. This switch

provides a momentary contact closure that can be used by room occupants to temporarily force

the UVC into the bypass occupancy mode from unoccupied mode.

Note – The Occupancy Override Input can override the tenant override feature. For example, if

the network uses the Occupancy Override Input to force the unit into unoccupied mode,

then the wall sensor tenant override switch does not operate as expected. Therefore,

McQuay strongly recommends using the Occupancy Sensor Input to control occupancy

modes over a network and only using the Occupancy Override Input if there is reason to

ensure tenant override does not occur.

Remote Wall-Mounted Sensor Status LED

The optional remote wall-mounted sensors each include a UVC status LED. This status LED

aids diagnostics by indicating the UVC occupancy mode and fault condition.

Table 13: Remote wall-mounted sensor status LED

Indication LED operation

Occupied On continually

Unoccupied On 1 second/off 9 seconds

Bypass On continually

Standby On 9 seconds/off 1 second

Fault On 5 seconds/off 5 seconds

McQuay OM 751 25

Page 26

Description of Operation

Space Temperature Set Points

The UVC uses the six occupancy-based temperature set points as the basis to determine the

Effective Set point Output. The effective set point is calculated based on the unit mode, the

occupancy mode, and the values of several network variables. The effective set point then is

used as the temperature set point that the UVC maintains.

Table 14: Default occupancy-based temperature set points

Temperature set point Abbreviation Defaults

Unoccupied cool UCS 82.4°F (28.0°C)

Standby cool SCS 77.0°F (25.0°C)

Occupied cool OCS 73.4°F (23.0°C)

Occupied heat OHS 69.8°F (21.0°C)

Standby heat SHS 66.2°F (19.0°C)

Unoccupied heat UHS 60.8°F (16.0°C)

Networked Set Point Capability

The Space Temp Setpoint Input variable is used to allow the temperature set points for the

occupied and standby modes to be changed via the network; the unoccupied set points are not

affected by this variable.

Networked Set Point Offset Capability

The Networked Set Point Offset Input variable is used to shift the effective occupied and

standby temperature set points by adding the value of the Setpoint Offset Input variable to the

current set points; the unoccupied points are not affected by this variable. This variable is

typically set bound to a supervisory network controller or to a networked wall module having

a relative set point knob.

Use the keypad/display to make adjustments to the value of the Setpoint Offset Input variable.

See “Changing Set Points” on page 9.

Note – The keypad/display and the network both affect the Set Point Offset Input variable. Keep

in mind that changes to this variable are last-one-wins.

Networked Set Point Shift Capability

The Set Point Shift Input variable is used to shift the effective heat/cool set points. It typically

is bound to a networked supervisory controller or system that provides functions such as

outdoor air temperature compensation. All occupied, standby, and unoccupied set points are

shifted upward (+) or downward (

–) by the corresponding value of the Set Point Shift Input

variable.

Note – The Set Point Shift Input capability is not available through the BACnet® interface.

Networked Space Temperature Sensor Capability

A networked space temperature sensor can be interfaced with the Space Temp Input variable.

When the Space Temp Input variable is used (valid value), it automatically overrides the hardwired space temperature sensor.

26 McQuay OM 751

Page 27

Description of Operation

Remote Wall-Mounted Sensor with +/–3°F

Adjustment (optional)

When the optional remote wall-mounted sensor with +/–3°F adjustment dial is used, the UVC

effectively writes the value of the set point adjustment dial to the Set Point Offset Input

variable.

Note – If a network connection is used to adjust the Set Point Offset Input variable, you must not

use the optional remote wall-mounted sensor with +/–3°F adjustment.

– If the keypad/display is used by room occupants to adjust the Set Point Offset, do not use

the optional remote wall-mounted sensor with +/–3°F adjustment.

If you have the optional remote wall-mounted sensor with +/–3°F adjustment and an

occupant uses the keypad to make Set Point Offset adjustments, this overrides any

+/–3°F adjustment on the optional remote wall-mounted sensor since the keypad/display

has higher priority. If you find that changes to the +/–3°F adjustment on the remote wallmounted sensor have no effect, it is likely that an occupant used the keypad/display to

make a Set Point Offset change. Cycle unit power to clear this situation and restore the

ability to change the Set Point Offset from the +/–3°F adjustment on the remote

wall-mounted sensor.

Remote Wall-Mounted Sensor with 55°F to 85°F

Adjustment (optional)

When the optional remote wall-mounted sensor with 55°F to 85°F adjustment dial is used, the

UVC will effectively write the value of the set point dial to the Space Temp Set Point Input

variable.

Note – If a network connection is using the Space Temp Set Point Input variable, do not use the

optional remote wall-mounted sensor with 55°F to 85°F adjustment.

– If it is intended that the LUI will be used by room occupants to adjust the Setpoint Offset,

then you must not use the optional remote wall-mounted sensor with 55

adjustment. When using the optional remote wall-mounted sensor with 55

adjustment, the UVC will ignore any Setpoint Offset changes made at the LUI.

°F to 85°F

°F to 85°F

Effective Set Point Calculations

The UVC calculates the effective set point (Effective Set Point Output) based on several

factors. These factors include the six occupancy set points for heating and cooling (Occupancy

Temperature Set Point), occupancy mode, the value of the network variables Space Temp Set

Point Input, Set Point Offset Input, and the Set Point Shift Input as well as the optional wallmounted sensor’s set point adjustment knob. As always, network inputs have priority over

hardwired connections.

The UVC determines if heating or cooling is required based on the current unit mode (Heat/

Cool Mode Output) and then calculates the required set point for heating or cooling. After

calculating, the Effective Set Point Output network variable is set equal to the calculated set

point. The Effective Set Point Output is the temperature set point that the UVC maintains,

which normally appears on the keypad/display.

McQuay OM 751 27

Page 28

Description of Operation

Figure 16: Effective set point calculations

Occupancy Temperature Setpoints

(network configuration variables)

Occupied Cooling Set Point (OCS)

Standby Cooling Set Point (SCS)

Unoccupied Cooling Set Point (UCS)

Occupied Heating Set Point (OHS)

Standby Heating Set Point (SHS)

Unoccupied Heating Set Point (UHS)

Space Temp

Set Point Input

(network input)

WallSensorType

Config. Value

Set Point

Offset Input

(network input)

SetptShift (network inputs)

Occupied Cooling Set Point Shift (OCSS)

Standby Cooling Set Point Shift (SCSS)

Unoccupied Cooling Set Point Shift (UCSS)

Occupied Heating Set Point Shift (OCSS)

Standby Heating Set Point Shift (SHSS)

Unoccupied Heating Set Point Shift (UHSS)

Network Value

55°F/85°F

Wall Sensor

1

0

+3°F/–3°F

Wall Sensor

Local User

Interface

+5°F/–5°F

Network Value

Set Point

SetptOffset

Effective Set Point Calculations for each Occupancy Mode

AbsOffsetOccupied = Setpoint - (OCS + OHS)/2

AbsOffsetStandby = Setpoint - (SCS + SHS)/2

Occupied and Bypass Modes

EffectiveCoolSetpoint = OCS + AbsOffsetOccupied + SetptOffset + OCSS

EffectiveHeatSetpoint = OHS + AbsOffsetOccupied + SetptOffset + OHSS

Standby Mode

EffectiveCoolSetpoint = SCS + AbsOffsetStandby + SetptOffset + SCSS

EffectiveHeatSetpoint = SHS + AbsOffsetStandby + SetptOffset + SHSS

Unoccupied Mode

EffectiveCoolSetpoint = UCS + UCSS

EffectiveHeatSetpoint = UHS + UHSS

If both entering paths have

valid values, then the network

value has priority.

If both entering paths have

valid values, then the keypad/display value

has priority.

Table 15: Set point calculation examples

Given

OccupancyMode = Occupied or BypassHeat/CoolMode = Heat

SpaceTempSetpoint = (not used)

SetpointOffset = (not used) = 0.0°F

SetpointShift = (not used) = 0.0°F

OHS = 69.8°F

Example A

Effective set point calculations

EffectiveSetpoint = OHS + SetpointOffset + SetpointShift = 69.8 + 0.0 + 0.0 = 69.8°F

Given

OccupancyMode = Occupied or BypassHeat/CoolMode = Heat

SpaceTempSetpoint = 71.0°F

SetpointOffset = -1.0°F (occupant adjustment on remote wall sensor, or LUI)

SetpointShift = (not used) = 0.0°F