Page 1

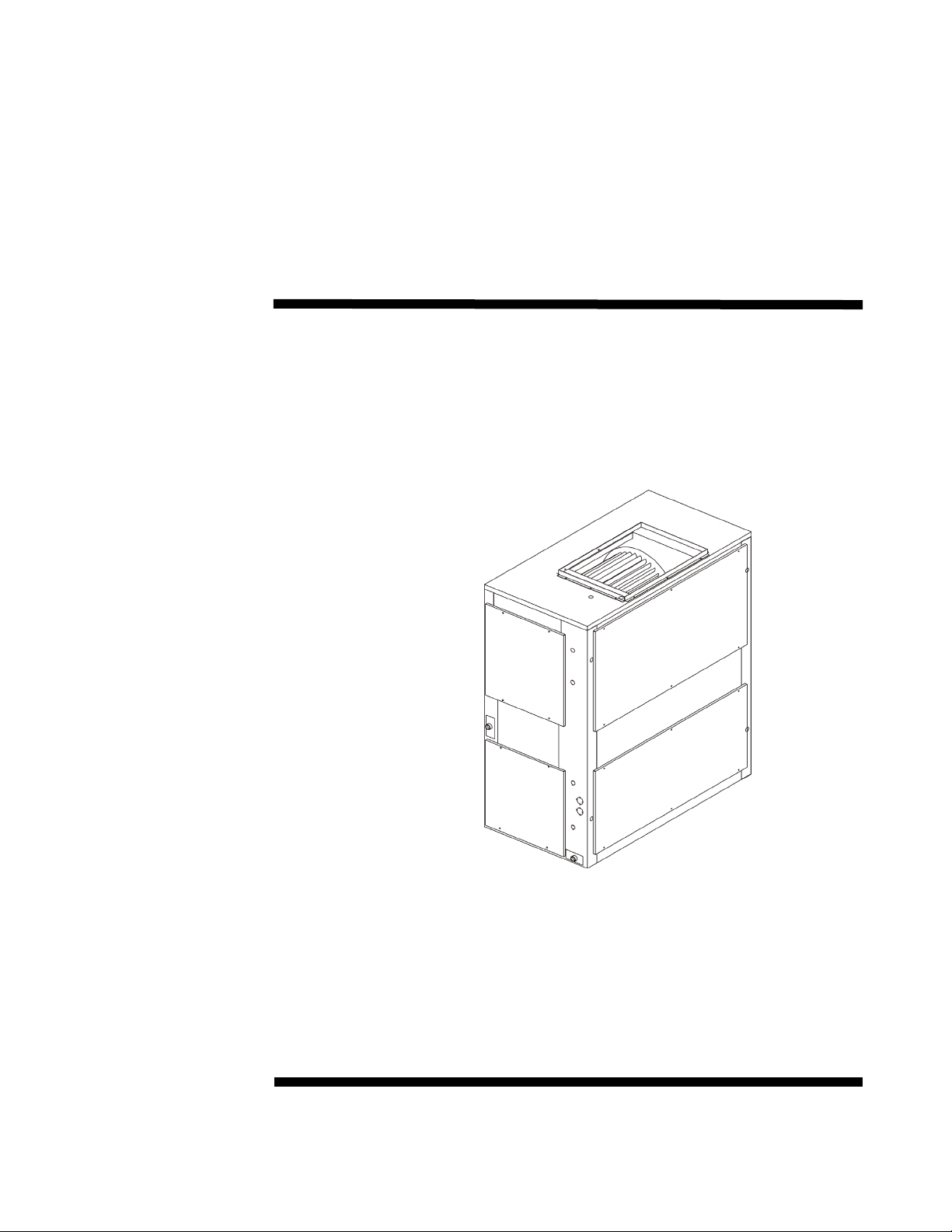

Installation

Operation

Maintenance

Split System Cooling or

Heat Pump Air Handler

7½ - 20 Tons

Model TWE

Models (60 Hz) Models (50 Hz)

TWE060A***E TWE050AD**E

TWE060B***E TWE075AD**E

TWE090A***E TWE100AD**E

TWE090B***E TWE100BD**E

TWE120A***F TWE155BD**E

TWE120B***E TWE200BD**F

TWE180B***E

TWE240B***F

October 2006 TWE-SVX03C-EN

Page 2

Preface and Warnings and Cautions

Literature Change History

TWE-SVX03A-EN (June 2003)

Implemented Global Graphics format

to IOM.

TWE-SVX03B-EN (April 2005)

Added capacitor discharge warning.

TWE-SVX03C-EN (September 2006)

Model number for 200 and 240 went

to an "F".

TWE-SVX03C-EN (October 2006)

Updated 200 and 240 unit

dimensions.

Note: One copy of this document

ships inside the control panel

of each unit and is customer

property. It must be retained

by the unit’s maintenance

personnel.

This booklet describes proper

installation, operation, and

maintenance procedures for air

cooled systems. By carefully

reviewing the information within this

manual and following the

instructions, the risk of improper

operation and/or component damage

will be minimized.

It is important that periodic

maintenance be performed to help

assure trouble free operation. A

maintenance schedule is provided at

the end of this manual. Should

equipment failure occur, contact a

qualified service organization with

qualified, experienced HVAC

technicians to properly diagnose and

repair this equipment.

Note: All phases of this installation

must comply with the

NATIONAL, STATE & LOCAL

CODES. In addition to local

codes, the installation must

conform with National

Electric Code -ANSI/NFPA

NO. 70 LATEST REVISION.

Note: Do Not release refrigerant

to the atmosphere! If

adding or removing

refrigerant is required, the

service technician must

comply with all federal,

state, and local laws.

Warnings and Cautions

Notice that warnings and cautions

appear at appropriate intervals

throughout this manual. Warnings

are provided to alert installing

contractors to potential hazards that

could result in personal injury or

death, while cautions are designed to

alert personnel to conditions that

could result in equipment damage.

Your personal safety and the proper

operation of this machine depend

upon the strict observance of these

precautions.

NOTICE:

Warnings and Cautions appear at

appropriate sections throughout this

manual. Read these carefully.

WARNING

Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury.

CAUTION

Indicates a potentially hazardous

situations which, if not avoided, may

result in minor or moderate injury. It

may also be used to alert against

unsafe practices.

CAUTION

Indicates a situation that may result

in equipment or property-damageonly accidents.

© 2006 American Standard Inc. All rights reserved TWE-SVX03C-EN

Page 3

Contents

Model Number Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Unit Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Inspection Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

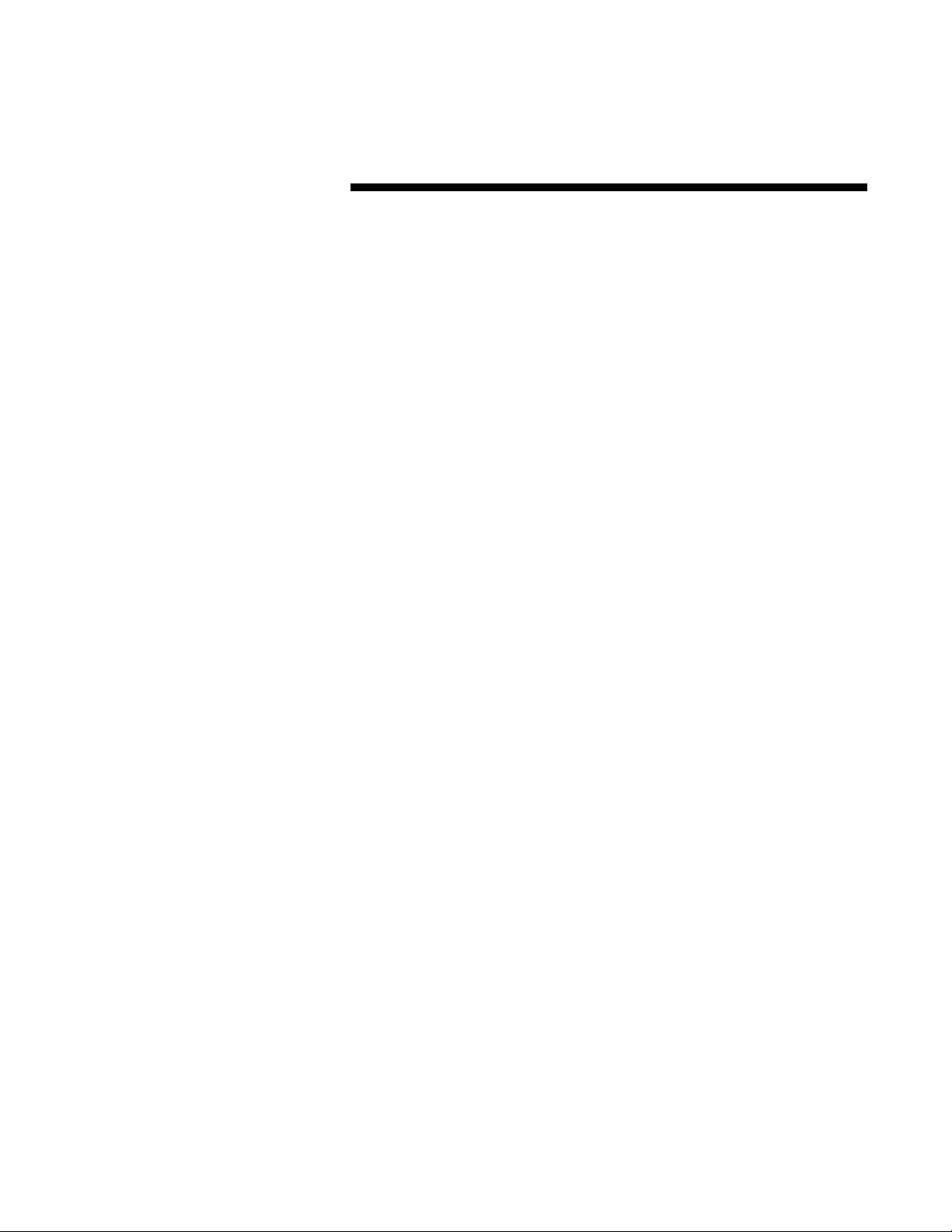

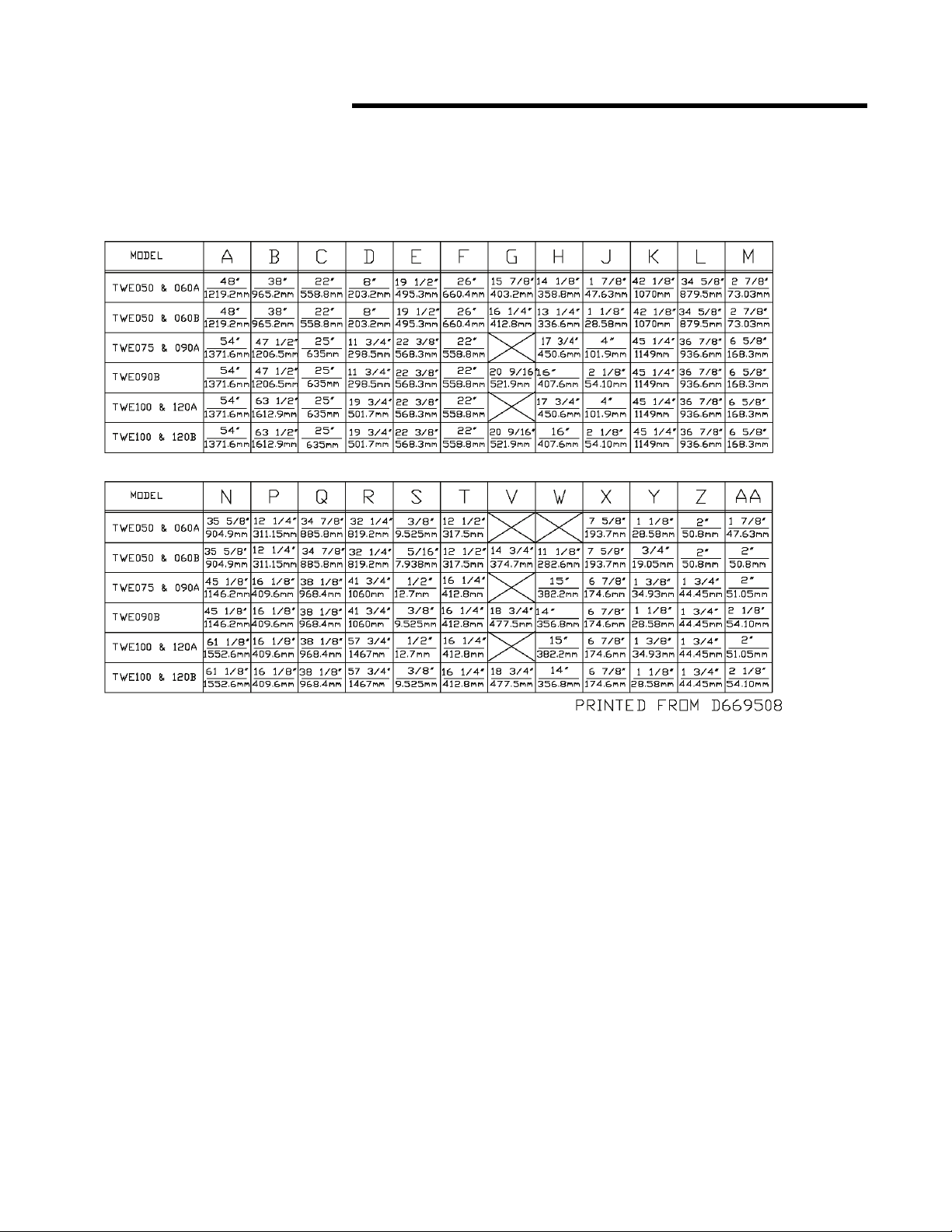

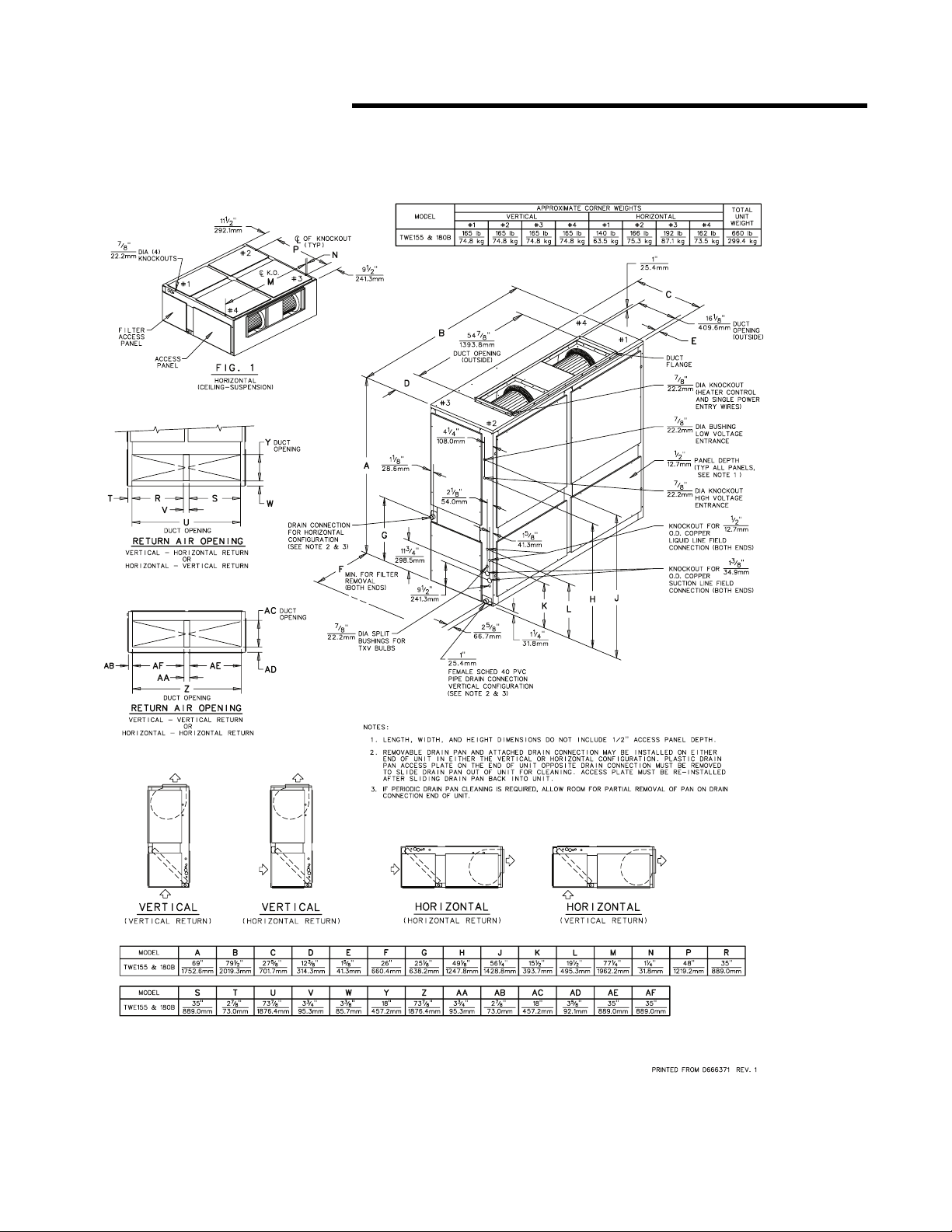

Unit Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Recommended t’stat wire size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Field Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Field Wiring Outdoor/Indoor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

TWE-SVX03C-EN 3

Page 4

Model Number Description

TWE 090 A 1 00 E A

123 456 7 8 9 10 11 12

Model Number Description

All products are identified by a

multiple-character model number

that precisely identifies a particular

type of unit. An explanation of the

alphanumeric identification code is

provided. Its use will enable the

owner/operator, installing

contractors, and service engineers to

define the operation, specific

components, and other options for

any specific unit.

When ordering replacement parts or

requesting service, be sure to refer

to the specific model number, serial

number, and DL number (if

applicable) stamped on the unit

nameplate.

DIGITS 1-3: PRODUCT TYPE

TWE = Split System Heat Pump/

Cooling Air Handler

DIGITS 4-6: NOMINAL GROSS

COOLING CAPACITY (MBh)

060 = 5 Tons

090 = 7½ Tons

120 = 10 Tons

150 = 12½ Tons

180 = 15 Tons

240 = 20 Tons

DIGIT 7: MAJOR DEVELOPMENT

SEQUENCE

A = Single

B = Dual

DIGIT 8: ELECTRICAL

CHARACTERISTICS

1 = 208-230/60/1

3 = 208-230/60/3

4 = 460/60/3

W = 575/60/3

D = 380-415/50/3

K = 380/60/3

DIGITS 9, 10: FACTORY

INSTALLED OPTIONS

00 = Packed Stock

DIGITS 11: MINOR DESIGN

SEQUENCE

Current Design Sequence

DIGITS 12: SERVICE DIGIT

A = First

4 TWE-SVX03C-EN

Page 5

General Information

General

This manual covers installation of

the TWE050, 060, 075, 090,100 and

120A single circuit air handlers and

TWE060, 075, 090, 100, 120, 155, 180,

200 and 240B dual circuit air

handlers. These air handler models

incorporate a single slab coil

assembly, improved application

flexibility, servicing, maintenance

accessibility and an improved

accessory line. They are fully

convertible, (vertical to horizontal

discharge) without field removal or

reorientation of the coil assembly.

They are shipped ready for

horizontal installation.

The TWE090A300C, TWE090B300C,

TWE120A300D, TWE120B300D

models are shipped from the factory

wired for 208-230V/3ph/60 Hz, but

may be field converted for 460V/3ph/

60 Hz applications by changing

voltage plug on the motor. For

voltage change plug instructions,

refer to Figure 9.

All units (both single and dual

circuit), have one drain pan that can

be installed in any one of four

positions. This allows for vertical or

horizontal applications and right or

left exit.

Note: The TWE060B, TWE090B,

TWE100B, and TWE120B

dual circuit air handlers have

a split face coil. When they

are installed in either

position, the lower half of the

coil is designated as “Circuit

A” and should always wet

first.

The TWE155B, TWE180B, TWE200B

dual circuit units have a mixed face

coil.

Note: Note: The TWE050, 060, 075,

090, 100 and 120 air handlers

have structural provisions to

allow 180 degree rotation of

discharge panel/blower

assembly at installation. A

reversible discharge wiring

kit, BAYWRKT001A is

available with instructions.

Installation procedures should be

performed in the sequence that they

appear in this manual. Do not

destroy or remove the manual from

the unit.

The manual should remain weatherprotected with the unit until all

installation procedures are

complete.

Note: It is not the intention of this

manual to cover all possible

variations in systems that

may occur or to provide

comprehensive information

concerning every possible

contingency that may be

encountered during an

installation. If additional

information is required or if

specific problems arise that

are not fully discussed in this

manual, contact your local

sales office.

Note: "Warnings" and "Cautions"

appear at appropriate places

in this manual. Your personal

safety and the proper

operation of this machine

require that you follow them

carefully. The Company

assumes no liability for

installations or servicing

performed by unqualified

personnel.

Installation Checklist

An "Installation Checklist" is

provided at the end of the

installation section of this manual.

Use the checklist to verify that all

necessary installation procedures

have been completed. Do not use the

checklist as a substitute for reading

the information contained in the

manual. Read the entire manual

before beginning installation

procedures.

Unit Inspection

Inspect material carefully for any

shipping damage. If damaged, it

must be reported to, and claims

made against the transportation

company. Compare the information

that appears on the unit nameplate

with ordering and submittal data to

insure the proper unit was shipped.

Available power supply must be

compatible with electrical

characteristics specified on

component nameplates. Replace

damaged parts with authorized parts

only.

Inspection Checklist

To protect against loss due to

damage incurred in transit, complete

the following checklist upon receipt

of the unit.

[ ] Inspect individual pieces of the

shipment before accepting the unit.

Check for obvious damage to the

unit or packing material.

[ ] Inspect the unit for concealed

damage before it is stored and as

soon as possible after delivery.

Concealed damage must be reported

within 15 days. If concealed damage

is discovered, stop unpacking the

shipment. Do not remove damaged

material from the receiving location.

Take photos of the damage if

possible. The owner must provide

reasonable evidence that the

damage did not occur after delivery.

[ ] Notify the carrier’s terminal of

damage immediately by phone and

by mail. Request an immediate joint

inspection of the damage by the

carrier and the consignee.

[ ] Notify the sales representative

and arrange for repair. Do not repair

the unit until the damage is

inspected by the carrier’s

representative.

TWE-SVX03C-EN 5

Page 6

Unit Dimensions

Unit Dimensions

Figure 1.

6 TWE-SVX03C-EN

Page 7

Unit Dimensions

Figure 1. (continued from previous page)

TWE-SVX03C-EN 7

Page 8

Unit Dimensions

Figure 2.

8 TWE-SVX03C-EN

Page 9

Unit Dimensions

Figure 3.

TWE-SVX03C-EN 9

Page 10

Installation

Installation Preparations

The final position for the air handler

must be dictated by required service

access to it, weight distribution over

structural supports, and by the

locations of electrical, refrigerant

and condensate drainage

connections. After this is

determined, the following

preparations should be made.

Repositioning Drain Pan

These air handlers come with one

drain pan that can be installed in any

one of four positions; this allows for

vertical or horizontal application and

right or left condensate line

connection. The drain pan can also

be easily removed for periodic

cleaning.

Note: Important! All air handlers

are shipped with the drain

pan installed in the

horizontal position and the

connection on the left side

(as shown in Figure 4). If an

alternate position is required,

the drain pan should be

repositioned before setting

the air handler.

Figure 4.

Process for Drain Pan Relocation

1. Remove the access plate at the

opposite end of the drain

connection. This plate secures

and lifts the back end of the

drain pan for sloping. It must be

removed before the drain pan

can be removed. This is done as

follows:

a. Remove the screw

b. Lift the access plate up

c. Pull the plate out. If the drain

pan is to be moved to the

vertical position also remove

the other two access plates.

2. Remove the screw securing the

drain pan.

a. Lift the pan up

b. Slide the pan out

3. Install the drain pan into the new

position.

a. Slide the drain pan into the

opening

b. Lift the drain pan up

c. Push it in all the way

d. Drop it down over the lip of

the opening, secure with

screw

4. Install the access plate on the

opposite end of the drain pain.

a. Slide the edge of the access

plate under the drain pan

b. Lift the access plate and

drain pan up

c. Push the access plate in

d. Drop the access plate down

over the lip of the opening,

secure with screw. If the

drain pan is being moved to

the vertical position, install

the other access plates over

the horizontal position

opening.

Figure 5.

10 TWE-SVX03C-EN

Page 11

Installation

Refrigerant Piping Preparation

The air handler is designed so that

refrigerant piping can enter from

either the right or left hand side. It is

shipped with the intent that the

refrigerant lines will enter from the

left hand side. To convert to right

hand entry, unbraze the elbow on the

suction line and rotate 180° and

rebraze.

Note: Important! Access to

refrigerant lines is limited in

all horizontal and some

vertical applications.

Therefore, refrigerant lines

should be stubbed out and

temporarily capped prior to

setting the air handler.

Protect adjacent surfaces

from heat damage when

brazing in and around the air

handler.

Caution

System Component Damage!

These air handlers are shipped with a

dry nitrogen holding charge in the

coil. Cut the process tube or

puncture the cap to bleed off the

nitrogen prior to any brazing.

Temporarily cap off tubes if the

refrigerant line connections are to be

made later.

Installations, Limitations and

Recommendations

The general location of the air

handler is normally selected by the

architect, contractor and/or buyer. For

proper installation the following

items must be considered.

a. Available power supply must

agree with electrical data on

component nameplate.

b. Air Handlers shipped wired

for 208-230 volt applications

can be converted for 460 volt

by rewiring the blower motor

(See Figure 9).

c. If external accessories are

installed on the unit,

additional clearances must be

provided.

d. All duct work should be

properly insulated to prevent

condensation and heat loss.

e. Refrigerant gas piping must

be insulated.

Caution

System Component Damage!

Properly insulate all refrigerant gas

piping to prevent possible water

damage due to condensation and to

prevent capacity loss and possible

compressor damage.

It is recommended that the outline

drawings (pages 3 and 4) be studied

and dimensions properly noted and

checked against the selected

installation site. By noting in advance

which knockouts are to be used,

proper clearance allowances can be

made for installation and possible

future service.

Note: Important! When installing

these units "free standing"

with discharge grills and

isolators, a top support with

isolator should be added to

prevent tipping. Support and

isolator can be attached to a

wall or other appropriate

structure.

Note: Important! If adding external

accessories to the unit,

additional clearances must be

considered for the overall

space needed.

For installation of accessories

available for this air handler, follow

the instructions packed with each

accessory.

Lifting Recommendations

WARNING

Improper Unit Lift!

Test lift unit approximately 24 inches

to verify proper center of gravity lift

point. To avoid dropping of unit,

reposition lifting point if unit is not

level. Failure to properly lift unit

could result in death or serious injury

or possible equipment or propertyonly damage.

Before preparing the unit for lifting,

the center of gravity should be

determined for lifting safety. Because

of the placement of external

components, the unit weight may be

unevenly distributed. Approximate

total unit weight and corner weights

are given in Figure 1- Figure 3.

The crated unit can be moved using a

forklift of suitable capacity. For lifting

the unit into an elevated mounting

position, run lifting straps or slings

under the unit and attach securely to

the lifting device. Use spreader bars

to protect the unit casing from

damage. Test lift the unit to

determine proper balance and

stability.

Caution

Equipment Damage!

Use spreader bars to prevent straps

from damaging the unit. Install the

bars between lifting straps, both

underneath the unit and above the

unit. This will prevent the straps

from crushing the unit cabinet or

damaging the unit finish.

Horizontal Suspension

If the air handler will be suspended,

use a suspension mounting kit to

isolate the unit from the structure.

This is usually accomplished through

the use of spring or rubber isolators,

which are offered as an accessory.

Mounting rods must be field

supplied. Isolator selection is

dependent upon total unit weight

including accessories. Approximate

unit weights are provided in Table 1.

TWE-SVX03C-EN 11

Page 12

Installation

Caution

Equipment Damage!

Before hanging the unit on

suspension rods, reinforce the

cabinet around the knockouts by

using a large washer inside the

cabinet. Washers should be between

the skin of the air handler and the

nut on the suspension rod.

Align holes (knockouts) in the cabinet

with structural supports and secure

suspension rods to the structure,

then to the air handler cabinet. If

knockout locations do not permit

proper alignment with existing

structure, it may be necessary to field

fabricate cross members on existing

structural beams.

Note: When other than bottom

return is to be used, side

panel removed for return

duct installation must be

secured over the bottom

opening.

Leveling

This air handler has a double sloped

drain pan. In order to assure proper

drainage along the length of the

drain pan, it is important to have the

unit properly leveled. Be sure the air

handler is level or slightly sloped in

the direction of the condensate

connection.

Auxiliary Drain Pan

A field fabricated, auxiliary drain pan

should be installed under the unit for

all horizontal applications and when

air handlers are installed above

ceilings or in other locations where

condensate overflow may cause

damage. This drain pan will eliminate

any excess condensation that may be

due to extreme humidity or an

obstructed drain in the primary drain

pan. Drain lines from this pan must

be installed, but should not be

connected to the primary drain line

from the unit. Isolate the auxiliary

drain pan from both the air handler

and the structure.

WARNING

Fiberglass Wool!

Product contains fiberglass wool.

Disturbing the insulation in this

product during installation,

maintenance or repair will expose

you to airborne particles of glass

wool fibers and ceramic fibers

known to the state of California to

cause cancer through inhalation.

Glass wool fibers may also cause

respiratory, skin or eye irritation.

Precautionary Measures

• Avoid breathing fiberglass dust.

• Use a NIOSH approved dust/mist

respirator.

• Avoid contact with the skin or

eyes. Wear long-sleeved, loosefitting clothing, gloves, and eye

protection.

• Wash clothes separately from

other clothing: rinse washer

thoroughly.

• Operations such as sawing,

blowing, tear-out, and spraying

may generate fiber

concentrations requiring

additional respiratory protection.

Use the appropriate NIOSH

approved respirator in these

situations.

First Aid Measures

Eye Contact - Flush eyes with water

to remove dust. If symptoms persist,

seek medical attention.

Skin Contact - Wash affected areas

gently with soap and warm water

after handling.

Refrigerant Piping

Installation, brazing, leak testing and

evacuation of refrigerant lines are

covered in the installation

instructions packaged with the

outdoor unit. Read the instructions

before beginning installation of

refrigerant lines.

Locate cloth bag(s) attached to the

refrigerant tube of the coil that

contains two (2) brass clamps

(straps) and cork impregnated

insulation material approximately 9"

long by 4" wide. This is for attaching

and insulating the expansion valve

bulb(s) to the suction line(s).

On air handlers that will have

refrigerant lines entering the cabinet

from the left side, remove the split

rubber grommet from the knockout

in the end of the air handler. Uncoil

the cap tub with the bulb attached at

the expansion valve and place the

grommet on the cap tube. With the

grommet around the tube, push the

bulb through the hole and position

the grommet back into its original

position (one bulb and cap tube on

single circuit units and two bulbs and

cap tubes on dual circuit units).

Attach the bulb(s) approximately 45°

off vertical, 10 to 12 inches outside of

the air handler.

On air handlers that will have

refrigerant lines entering the cabinet

from the right side, the bulb(s)

should be attached to the suction

tube(s) inside the cabinet in the same

manner as above, approximately 10"

from the right end of the unit.

After attaching to the suction line(s),

either inside or outside of the

cabinet, wrap the cork impregnated

insulation around the bulb(s) and

suction tube(s). Refrigerant piping

should be insulated.

Note: Important! Ensure that the

refrigerant lines passing

through the cabinet are not

resting on sharp sheet metal

edges.

Condensate Piping

The drain pan condensate

connection is a female slip joint type

for 1" Schedule 40 PVC pipe. Use PVC

cement and tubing as required (field

supplied) to construct a trap. A union

or flexible tubing and clamps may be

installed if the drain pan is to be

removed periodically for cleaning.

12 TWE-SVX03C-EN

Page 13

Installation

Note: Important! When air handler

.

Figure 6.

is installed in the vertical

position and close proximity

trapping of condensate is

required, use of a subbase

accessory to raise the air

handler for clearance of the

drain trap is recommended.

See Figure 6 for a typical

drain trap assembly

Filters

Air handlers are shipped with

throwaway filters installed. For

replacement filters consult the air

handler service facts for correct size

and number. To replace filters from

the end of the unit, remove lower

access panel (either end) and slide

old filters out and replace with new

ones. To replace from the front of the

unit, remove one "L" shaped angle.

Remove and replace filters and

reinstall "L" shaped angle. See

Figure 7.

.

filter track to increase the width of the

filter opening.

Duct Connections

The supply and return ducts should

be connected to the unit with flame

retardant duct connectors to reduce

vibration transmission. The return

duct should be sized to the same

dimensions as the return inlet of the

unit.

Note: Important! Duct flanges are

provided for attachment of

the duct work. On TWE060,

090, and 120 the flanges are

not installed but are shipped

inside the air handler. While

facing the air handler with the

control box to your left,

remove the upper access

panel. The duct flanges will

be attached to the belly band

of the air handler nearest

you. Remove the screws

securing flanges in place.

Position the four flanges

around the supply opening.

Secure with field supplied

screws, using the predrilled

holes. On TWE180 and 240,

the duct flanges are packaged

on the outside of the cabinet.

Air Flow Settings

Unit is shipped for nominal airflow

with nominal static pressure. Please

refer to fan performance table in

either the product catalog or unit

service facts and select the proper

drive package for each application.

Failure to do so could result in

improper airflow causing coil

frosting or condensate management

problems. Condensate management

problems such as water drip off or

water blow off could be the result of

too great of air face velocity across

the coil.

WARN ING

Hazardous Voltage

w/Capacitors!

Disconnect all electric power,

including remote disconnects and

discharge all motor start/run

capacitors before servicing. Follow

proper lockout/tagout procedures to

ensure the power cannot be

inadvertently energized. Verify with

an appropriate voltmeter that all

capacitors have discharged. Failure

to disconnect power and discharge

capacitors before servicing could

result in death or serious injury.

Note: For additional information

regarding the safe discharge

of capacitors, see

PROD-SVB06A-EN or

PROD-SVB06A-FR.

Figure 7.

To convert from 1" filter to a 2" filter

on units so equipped, remove lower

access panels from both ends of the

air handler. Remove screws and

reposition the "L" shaped angles

from both the top and bottom of the

TWE-SVX03C-EN 13

Page 14

Installation

WARNING

Hazardous Voltage!

Disconnect all electric power,

including remote disconnects before

servicing. Follow proper lockout/

tagout procedures to ensure the

power can not be inadvertently

energized. Failure to disconnect

power before servicing could result

in death or serious injury.

Electrical Connections

1. All electrical lines, sizing,

protection, and grounding must

be in accordance with the

National Electric Code and local

codes.

2. If conduit is used, isolate

whenever vibration transmission

may cause a noise problem

within the building structure.

3. Ensure all connections are tight

and no wires exposed.

4. All accessories must be installed

and wired according to the

instructions packaged with that

accessory.

For air handler power entry only, or

for dual power entry (power entry for

air handler and power entry for

electric heats), the electrical

connections are made in the fan

control box located in the left side of

the air handler and electric heater

respectively. Wiring entrance is

through holes provided in the end of

the air handler cabinet, see Figure 8.

Breaker or fuse size can be selected

using the nameplates attached to the

unit and electric heater. See pages 13

through 22 for typical

interconnecting wiring diagrams.

Table 1. Recommended t’stat wire size

Wire Size

(Gauge)

22 30 Feet

20 50 Feet

18 75 Feet

16 125 Feet

14 200 Feet

Maximum Wire Length

Physical distance between Unit & T’stat

Figure 8.

Checkout Procedure

Complete the following “installation

checklist” once installation of field

wiring connections is complete. All

operational checks (unit running)

must be made after the outdoor unit

is installed and system

interconnection is complete.

Installation Checklist

Complete this checklist once the unit

is installed to verify that all

recommended procedures have been

accomplished before the system is

started. Operational checks cannot be

performed until the outdoor unit is

installed and system interconnection

is complete.

• Verify that the unit electrical

power is disconnected.

• Inspect all field wiring

connections. All connections

should be clean and tight.

• Inspect unit ground

connection(s). Ground must

comply with all applicable codes.

• Inspect unit suspension

arrangement (if used). Unit

position must be secure. Remove

any tools or debris found in or

near the unit.

• Inspect duct outlets. Outlets

must be open and unrestricted.

• Inspect unit drain lines. Pipe

connections must be tight and

drain line unrestricted.

• Inspect fan assembly to insure all

moving parts move freely.

• If unit is horizontally mounted,

make sure secondary drain pan

has been installed.

• Inspect unit for proper filters,

securely installed. All cabinet

panels must be secure.

• Instruct owner/operator on

proper system operating and

maintenance procedure.

Figure 9.

14 TWE-SVX03C-EN

Page 15

Thermostat and Control

Connections

1. Observe all notes on the

diagrams.

2. Mount the thermostat in the

desired location.

3. Install color coded low voltage

cables between outdoor unit,

indoor unit and thermostat.

4. Connect low voltage control

wiring to the low voltage

terminal board located on the

side of the fan control box per

the typical interconnecting

wiring diagrams on pages 13

through 22.

TTA090A/TWE090A

TTA120A/TWE120A

Field Wiring:

a. 3 power wires. Line voltage.

b. 3 power wires. Line voltage

for 3 phase; 2 wires for single

phase.

c. Cooling only thermostat: 3

wires, 24 volts.

i. One stage Electric heat:

add 1 additional wire, 24

volts.

ii. Two Stage Electric heat:

add 2 additional wires, 24

volts.

d. 4 wires, 24 volts.

Field Wiring

Figure 10. Field Wiring

TWA090A/TWE090A

TWA120A/TWE120A

Field Wiring:

a. 3 power wires. Line voltage.

b. 3 power wires. Line voltage

for 3 phase; 2 wires for single

phase.

c. Heat pump thermostat: 6

wires, 24 volts.

i. Electric heat: add 2

additional wire, 24 volts.

d. 6 wires, 24 volts.

i. Outdoor thermostat; add

1 additional wire, 24

volts.

ii. Electric heat: add 1

additional wires, 24 volts.

TTA120B/TTE120B

TTA120C/TWE120C

TTA120B/TWE120B

Field Wiring:

a. 3 power wires. Line voltage.

b. 3 power wires. Line voltage

for 3 phase; 2 wires for single

phase.

c. Cooling only thermostat: 4

wires, 24 volts.

i. One Stage Electric heat:

add 1 additional wire, 24

volts.

ii. Two Stage Electric heat:

add 2 additional wires, 24

volts.

d. 5 wires, 24 volts.

TT_060/TWE060A

Field Wiring:

a. 3 power wires. Line voltage.

b. 3 power wires. Line voltage

for 3 phase; 2 wires for single

phase.

c. Cooling only thermostat: 3

wires, 24 volts.

i. One Stage Electric heat:

add 1 additional wire, 24

volts.

ii. Two Stage Electric heat:

add 2 additional wires, 24

volts.

d. 2 wires, 24 volts.

TW_060A/TWE060A

Field Wiring:

a. 3 power wires. Line voltage

for 3 phase; 2 wires for single

phase.

TWE-SVX03C-EN 15

Page 16

Field Wiring

b. 3 power wires. Line voltage

for 3 phase; 2 wires for single

phase.

c. Heat pump thermostat: 6

wires, 24 volts.

i. Electric heat: add 2

additional wire, 24 volts.

d. 2 wires, 24 volts.

i. Outdoor thermostat; add

1 additional wire, 24 volts.

ii. Electric heat: add 1

additional wire, 24 volts.

(2) TT_060/TTE120B

(2) TT_060/TWE120B

(2) TT_030/TWE060B

Field Wiring:

a. 3 power wires. Line voltage

for 3 phase; 2 wires for single

phase.

b. 3 power wires. Line voltage

for 3 phase; 2 wires for single

phase.

c. Cooling only thermostat: 4

wires, 24 volts.

i. One Stage Electric heat:

add 1 additional wire, 24

volts.

ii. Two Stage Electric heat:

add 2 additional wires, 24

volts.

d. 2 wires, 24 volts to outdoor

section A.

i. 2 wires, 24 volts to

outdoor section B.

(2) TW_030/TWE060B

(2) TW_060/TWE120B

Field Wiring:

a. 3 power wires. Line voltage

for 3 phase; 2 wires for single

phase.

b. 3 power wires. Line voltage

for 3 phase; 2 wires for single

phase.

c. Heat pump thermostat: 7

wires, 24 volts.

i. Electric heat: add 2

additional wire, 24 volts.

d. 5 wires, 24 volts to outdoor

section A.

i. 2 wires, 24 volts to

outdoor section B.

ii. 2 wires, 24 volts between

outdoor sections A and B.

iii. Outdoor thermostat; add

1 additional wire, 24 volts.

iv. Electric heat: add 1

additional wires, 24 volts.

16 TWE-SVX03C-EN

Page 17

Field Wiring

Figure 11. TTA090A, 120A/TWE090A, 120A; TTA075A, 100A/TWE075A, 100A

Figure 12. TTA120B/TWE120B; TTA120C/TWE120A; TTA100B/TWE100B; TTA100C/TWE100A

TWE-SVX03C-EN 17

Page 18

Field Wiring

Figure 13. TWA090A, 120A/TWE090A, 120A; TWA075A, 100A/TWE075A, 100A

Figure 14. TTA120B/TWE120B; TTA120C/TWE120A; TTA100B/TWE100B; TTA100C/TWE100A

18 TWE-SVX03C-EN

Page 19

Field Wiring

Figure 15. TTA090A, 120A/TWE090A, 120A; TTA075A, 100A/TWE075A, 100A

Figure 16. TW_060/TWE060; TW_050/TWE050

TWE-SVX03C-EN 19

Page 20

Field Wiring

Figure 17. TW_060/TWE060; TW_050/TWE050

Figure 18. TW_060/TWE060; TW_050/TWE050

20 TWE-SVX03C-EN

Page 21

Field Wiring

Figure 19. TW_030/TWE060B; TW___/TWE090B; TW_060/TWE120B; TW_050/TWE100B

Figure 20. TW_030/TWE060B; TW___/TWE090B; TW_060/TWE120B; TW_050/TWE100B

TWE-SVX03C-EN 21

Page 22

Figure 21. Field Wiring Outdoor/Indoor

Note: Wiring shown with dashed

lines is to be furnished and

installed by the customer. All

customer-supplied wiring

must be copper only and

must conform to NEC and

local electrical codes. Codes

may require line of sight

between the disconnect

switch and the unit.

Note: When electric heater

accessory is used, single

point power entry or dual

point power entry is field

optional. Single point power

entry option is through the

electric heater only.

Field Wiring

TTA150B/TWE150B

TTA180B/TWE180B

TTA240B/TWE240B

TTA180C/TWE180B

Field Wiring:

a. 3 power wires. Line voltage.

b. 3 power wires. Line voltage

for 3 phase; 2 wires for single

phase.

c. Cooling only thermostat: 4

wires, 24 volts.

i. One Stage Electric heat:

add 1 additional wire, 24

volts.

ii. Two Stage Electric heat:

add 2 additional wires, 24

volts.

d. 5 wires, 24 volts.

TWA180B/TWE180B

TWA240B/TWE240B

Field Wiring:

a. 3 power wires. Line voltage.

b. 3 power wires. Line voltage

for 3 phase; 2 wires for single

phase.

c. Heat pump thermostat: 7

wires, 24 volts.

i. Electric heat: add 2

additional wire, 24 volts.

d. 7 wires, 24 volts.

i. Outdoor thermostat; add

1 additional wire, 24 volts.

ii. Electric heat: add 4

additional wires, 24 volts.

TTA090A/TWE180B

TTA120A/TWE240B

Field Wiring:

a. 3 power wires. Line voltage.

b. 3 power wires. Line voltage

for 3 phase; 2 wires for single

phase.

c. Cooling only thermostat: 4

wires, 24 volts.

i. One Stage Electric heat:

add 1 additional wire, 24

volts.

ii. Two Stage Electric heat:

add 2 additional wires, 24

volts.

d. 6 wires, 24 volts.

(2) TWA090A/TWE180B

(2) TWA120A/TWE240B

Field Wiring:

a. 3 power wires. Line voltage.

b. 3 power wires. Line voltage.

c. Heat pump thermostat: 7

wires, 24 volts.

i. Electric heat: add 2

additional wire, 24 volts.

d. 9 wires, 24 volts.

i. Outdoor thermostat; add

3 additional wire, 24 volts.

ii. Electric heat: add 2

additional wires, 24 volts.

22 TWE-SVX03C-EN

Page 23

Field Wiring

Figure 22. TTA150B, 180B, 240B/TWE180B, 240B; TTA125B, 155B, 200B/TWE155B, 200B; TTA155C/TWE155B;

TTA180C/TWE180B

Figure 23. TTA150B, 180B, 240B/TWE 180B, 240B; TTA125B, 155B, 200B/TWE155B, 200B; TTA155C/TWE155B;

TTA180C/TWE180B

TWE-SVX03C-EN 23

Page 24

Field Wiring

Figure 24. TWA180B, 240B/TWE 180B, 240B; TWA155B, 200B/TWE 155B, 200B

Figure 25. TWA 090A, 120A/TWE 180B, 240B; TWA075A, 100A/TWE 155B, 200B

24 TWE-SVX03C-EN

Page 25

Field Wiring

Figure 26. TTA090A, 120A/TWE 180B, 240B; TTA075A, 100A/TWE155B, 240B

Figure 27. TTA090A, 120A/TWE 180B, 240B; TTA075A, 100A/TWE155B, 200B

TWE-SVX03C-EN 25

Page 26

Field Wiring

Figure 28. TW_030A/TWE060B; TW___/TWE090B; TW_060/TWE120B; TW_050/TWE100B

26 TWE-SVX03C-EN

Page 27

Warranty

TTA, TTN, TTP, TTR, TTB, TTX, TTY and TTZ (parts only)

This warranty is extended by

American Standard to the original

purchaser and to any succeeding

owner of the real property to which

the Air Conditioner is originally

affixed, and applies to products

purchased and retained for use

within the U.S.A. and Canada. There

is no warranty against corrosion,

erosion or deterioration.

If any part of your Air Conditioner

fails because of a manufacturing

defect within one year from the date

of original purchase, Warrantor will

furnish without charge the required

replacement part.

In addition, if the sealed motorcompressor(s) fail(s) because of a

manufacturing defect within the

second through fifth year from the

date of original purchase, Warrantor

will furnish without charge a

replacement compressor(s).

Warrantor’s obligations and

liabilities under this warranty are

limited to furnishing F.O.B. Warrantor

factory or warehouse replacement

parts for Warrantor’s products

covered under this warranty.

Warrantor shall not be obligated to

pay for the cost of lost refrigerant.

No liability shall attach to Warrantor

until products have been paid for

and then liability shall be limited

solely to the purchase price of the

equipment under warranty shown to

be defective.

THE WARRANTY AND LIABILITY

SET FORTH HEREIN ARE IN LIEU

OF ALL OTHER WARRANTIES

AND LIABILITIES, WHETHER IN

CONTRACT OR IN NEGLIGENCE,

EXPRESS OR IMPLIED, IN LAW

OR IN FACT, INCLUDING

IMPLIED WARRANTIES OF

MERCHANTABILITY AND

FITNESS FOR PARTICULAR USE,

AND IN NO EVENT SHALL

WARRANTOR BE LIABLE FOR

ANY INCIDENTAL OR

CONSEQUENTIAL DAMAGES.

Some states do not allow limitations

on how long an implied warranty

lasts or do not allow the exclusion or

limitation of incidental or

consequential damages, so the

above limitation or exclusion may

not apply to you. This warranty gives

you specific legal rights, and you

may also have other rights which

vary from state to state.

American Standard Inc.

2701 Wilma Rudolph Blvd.

Clarksville, TN 37040-1008

Attention: Manager, Product Service

TW-338-0597

* This warranty is for commercial

usage of said equipment and not

applicable when the equipment is

used for a residential application.

Commercial use is any application

where the end purchaser uses the

product for other than personal,

family or household purposes.

Commercial Equipment Rated 20 Tons and Larger and Related Accessories (Parts Only)

PRODUCTS COVERED — This

warranty is extended by American

Standard Inc., and applies only to

commercial equipment rated 20 tons

and larger and related accessories

purchased and retained for use

within the U.S.A. and Canada.

Warrantor warrants for a period of 12

months from initial start-up or 18

months from date of shipment,

whichever is less, that the products

covered by this warranty (1) are free

from defects in material and

manufacture, and (2) have the

capacities and ratings set forth in

catalogs and bulletins; provided, that

no warranty is made against

corrosion, erosion or deterioration.

Warrantor’s obligations and

liabilities under this warranty are

limited to furnishing, F.O.B. factory

replacement parts (or equipment at

the option of Warrantor) for all

Warrantor’s products not conforming

to this warranty.

Warrantor shall not be obligated to

pay for the cost of lost refrigerant.

No liability whatever shall attach to

Warrantor until said products have

been paid for and then said liability

shall be limited to the purchase price

of the equipment shown to be

defective.

The Warranty and Liability set forth

herein are in lieu of all other

warranties and liabilities, whether in

contract or in negligence, express or

implied, in law or in fact, including

implied warranties of

merchantability and fitness for

particular use, and in no event shall

warrantor be liable for any incidental

or consequential damages.

Some states do not allow limitations

on how long an implied warranty

lasts or do not allow the exclusion or

limitation of incidental or

consequential damages, so the

above limitation or exclusion may

not apply to you. This warranty gives

you specific legal rights, and you

may also have other rights which

vary from state to state.

American Standard Inc.—Warrantor

2701 Wilma Rudolph Blvd.

Clarksville, TN 37040

GW-598-4799

TWE-SVX03C-EN 27

Page 28

Literature Order Number TWE-SVX03C-EN

Date October 2006

Supersedes TWE-SVX03C-0906

Stocking Location WebbMason

The manufacturer has a policy of continuous product and product data improvement and reserves

the right to change design and specifications without notice.

Loading...

Loading...