Page 1

T555740

TOWNSQUARE

Installation

Instructions

M 9 6 8 6 5 9

Thank you for selecting American-Standard...the benchmark

of fine quality for over 100 years.

To ensure that your installation proceeds smoothly--please

read these instructions carefully before you begin.

Certified to comply with ANSI A112.18.1M

ASSE 1016

ROUGHING-IN DIMENSIONS

Recommended Tools

Flat Blade Screwdriver

Phillips Screwdriver

Remove as much surface dirt and film using clear

water and soft cotton cloth (as described above).

Use any of the following to remove tough surface

film and build-up:

Mild liquid detergents

Clear ammonia free liquid glass cleaners

Non-acidic, non-abrasive gentle liquid or fully

dissolved powder cleansers mixed according to

manufacturers directions.

Non-abrasive liquid polishers

Once clean, rinse faucet again with clear water to

thoroughly remove cleaner or polish and blot dry with

a soft cotton cloth.

To keep your new faucet looking new, please follow

these simple care instructions:

DO: Simply rinse the faucet clean with clear water.

Dry the faucet with a soft cotton cloth.

DO NOT:

Do not use any abrasive cleaners, cloths, or

paper towels.

Do not use any cleaning agents containing

acids, polish abrasives, or harsh cleaners or

soaps.

Regular and routine cleaning will reduce the need for

heavy cleaning and polishing. If heavy cleaning is

required, the following procedures are recommended:

CARE INSTRUCTIONS:

Failure to follow these care instructions may

damage the Faucet's finish.

CENTRAL THERMOSTAT

WITH VOLUME CONTROL

TRIM KIT

186mm

(7-3/8)

100mm

(3-7/8)

230mm

(9)

230mm

(9)

48mm to 68mm

(2 to 2-5/8)

150mm

(6)

NOTE: FITTING

MUST BE INSTALLED

WITH VOLUME CONTROL

ON TOP.

R520

1/2" NPT INLETS

or

R540

3/4" NPT INLETS

25mm

(1)

FINISHED

WALL

190mm

(7-1/2)

Page 2

M 9 6 8 6 5 9 M 9 6 8 6 5 9 M 9 6 8 6 5 9

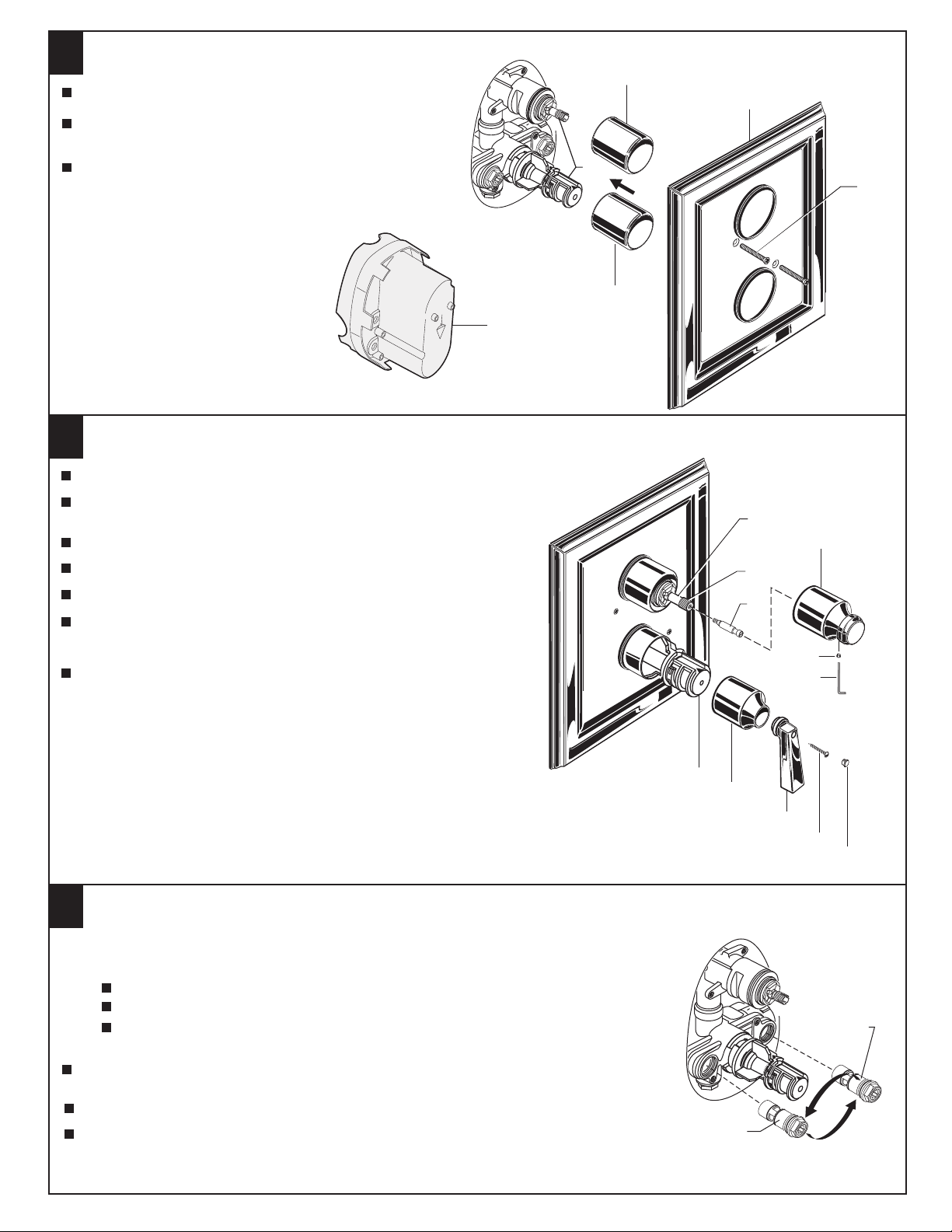

1

Remove PLASTER GUARD (1) if attached.

Push CAPS (2 & 2a) as shown onto CONTROL

VALVES (3).

Push ESCUTCHEON (4) over CAPS (2, 2a) and

flush against finished wall. Attach with the two

SCREWS (5) provided.

1

TRIM INSTALLATION

2

INSTALL HANDLES

Should the hot and cold water supply pipes have been transposed making

adjustment impossible, proceed as follows:

TRANSPOSED SUPPLY PIPING

OR BACK TO BACK INSTALLATION

3

Remove check stops and re-install them transposed.

Shut off water supply.

Remove handle and rim. (Reverse steps 1 and 2.

CHECK STOP

(RED TO BLUE)

Turn the water supply back on and perform the temperature adjustment in step 4.

Assemble HANDLES and TRIM.

CHECK STOP

(BLUE TO RED)

Important note: RED CHECK STOP is now on the right of the mixer body and the BLUE

CHECK STOP is now on the left.

1

8

5

9

10

11

3

4

6

2

2a

3

TO

P

1

5

7

Align HANDLE BASE (1) and push onto KNOB MOUNT (2).

Install LEVER HANDLE (3) as shown. Install HANDLE SCREW (4) and

tighten with screwdriver.

Push INDEX CAP (5) into HANDLE (3).

Install HANDLE ADAPTER (6) onto VALVE STEM (7).

Install HANDLE SCREW (8) and tighten.

Push VOLUME CONTROL KNOB (9) onto HANDLE ADAPTER (6).

Use HEX WRENCH (10) supplied and tighten set screw to secure

VOLUME CONTROL KNOB (9).

Push in PLUG BUTTON (11).

2

4

Page 3

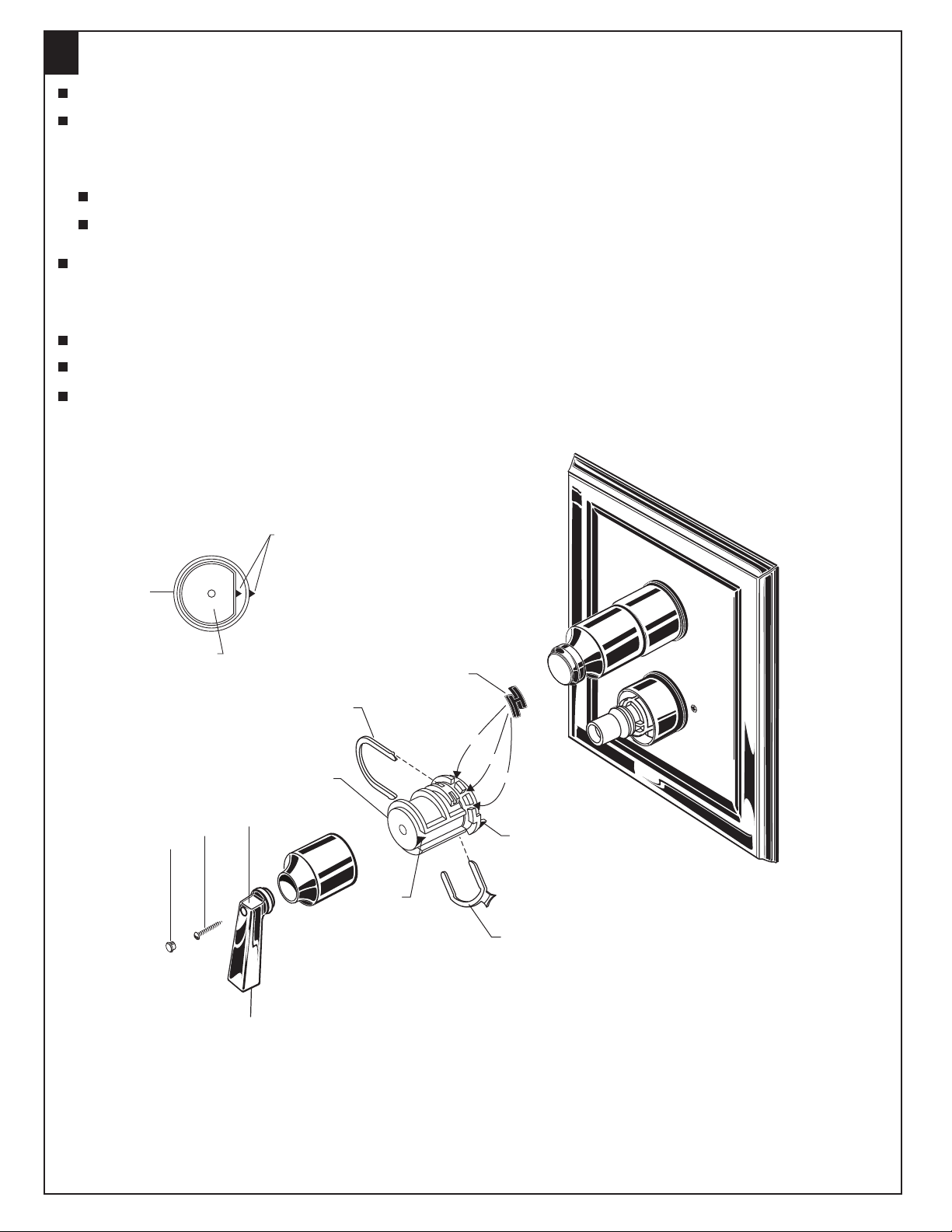

4

4

4

TEMPERATURE ADJUSTMENT

SET HOT LIMIT STOP

Check that arrow marking B points to the 3 o'clock position. If not, push the BLACK CLAMP on the SECURING RING to

the right, pull off KNOB MOUNT (4) and reinstall KNOB MOUNT (4) with arrow "B" 3 o'clock position. See Figure 1.

For 100˚F adjustment, turn the water supply on. Turn KNOB MOUNT (4) until the spout temperature is 100˚F. Check

that arrow "A" on the KNOB MOUNT (4) still points 3 o'clock position after adjusting the thermostat to 100˚F.

If not, pull out the RED LOCKING DEVICE. Remove KNOB MOUNT (4) by pulling it towards you while standing directly in

front of the valve.

Reinstall the KNOB MOUNT (4) with arrow "A" 3 o'clock position.

The maximum mixed water temperature is set at 109˚F at the factory. This setting can be changed if desired.

Remove the TEMPERATURE LIMIT STOP (H shaped Black Plastic part). Reinstall it at the desired notch as indicated in

the diagram to limit the maximum mixed water temperature to 104˚F or 112˚F.

Reinstall RED LOCKING DEVICE.

See step 3 for HANDLE (3) installation.

Pull out index CAP (1) and remove HANDLE SCREW (2). Pull off HANDLE ASSEMBLY (3).

ARROW

"A"

BLACK

CLAMP

ARROW

"B"

RED LOCKING

DEVICE

TEMPERATURE

LIMIT STOP

ARROWS AT 3 O'CLOCK

POSITION

Figure 1

KNOB MOUNT

112

109

104

1

2

3

Page 4

M962636-YYY0A

VOLUME CONTROL HANDLE

TOWNSQUARE

MODEL NUMBER

CHROME

BLACKENED BRONZE (PVD)

SATIN NICKEL (PVD)

002

068

295

Replace the "YYY" with

appropriate finish code

HOT LINE FOR HELP

For toll-free information and answers to your questions, call:

1-800 442-1902

Weekdays 8:00 a.m. to 8:00 p.m. EST

IN CANADA 1-800-387-0369 (TORONTO 1-905-306-1093)

Weekdays 8:00 a.m. to 7:00 p.m. EST

Pr od uc t na me s li st ed h ere in a re t ra de ma rk s of A me ri ca n St an da rd I nc .

A907090-YYY0A

CAP

M962635-YYY0A

ESCUTCHEON AND SCREWS

A918434-YYY0A

ESCUTCHEON SCREWS

M962633-YYY0A

HANDLE SCREW

AND INDEX BUTTON

M908587-YYY0A

HANDLE BASE

M916815-YYY0A

LEVER HANDLE

© AS A me ri ca , In c. 2 00 7

CENTRAL THERMOSTAT

WITH VOLUME CONTROL

TRIM KIT

T555740

Page 5

Installation

Instructions

R520

CENTRAL THERMOSTAT

WITH VOLUME CONTROL

Thank you for selecting American-Standard...the benchmark

of fine quality for over 100 years.

To ensure that your installation proceeds smoothly--please

read these instructions carefully before you begin.

ROUGHING-IN DIMENSIONS

CONNECTIONS ARE: 1/2" NPT

1/2" NPT

SHOWER

3-15/16

1/2" NPT

INLET

II II

3-5/8

1/2" NPT

TUB

5-7/8

1/2" NPT

INLET

7

1-5/8 - 2-1/2

OP

T

Certified to comply with ANSI A112.18.1M

ASSE 1016

M968255Rev.1.1

6-1/4

THERMOSTATIC BATH/

SHOWER INSTALLATION

USING A TWIN ELL, DIVERTER

SPOUT AND FIXED SHOWER

C/L

80"-86"

18"

(OPTIONAL)

TWIN

ELL

TOP OF TUB RIM

BOTTOM OF TUB

IMPORTANT: WHEN NOT USING A

DIVERTER SPOUT A SEPARATE

DIVERTER VALVE MUST BE USED.

TUB PORT

MUST BE

PLUGGED

4"

THERMOSTATIC SHOWER INSTALLATION

USING A DIVERTER VALVE, FIXED

SHOWER HEAD AND ADJUSTABLE HAND

HELD SHOWER

DIVERTER

VALVE

HOT

1/2" 1/2"

TUB PORT MUST

BE PLUGGED

COLD

THERMOSTATIC SHOWER INSTALLATION USING A

DIVERTER VALVE, FIXED SHOWER HEAD, ADJUSTABLE

HAND HELD SHOWER, ON/OFF VALVE AND TWO

BODY SPRAYS

DIVERTER

VALVE

ON/OFF

VALVE

HOT

1/2" 1/2"

TUB PORT MUST

BE PLUGGED

NOTE: MINIMUM FLOWING PRESSURE REQUIRED FOR

THIS SYSTEM OPERATING WITH ONE SHOWER HEAD

AND 2 BODY SPRAYS IS 40 PSI

COLD

Page 6

ROUGHING-IN THE VALVE

1

Prepare water supplies per ROUGHING-IN DIMENSIONS. Make sure the finished wall is between

the minimum and maximum rough dimension.

Install VALVE at indicated height and depth. Make sure the "TOP" marking on the PLASTER

GUARD is up.

Connect the hot and cold water supplies. Assemble all connecting pipes. Flush lines to

remove any dirt. Connections are 1/2" NPT.

Assemble the connection pipe to one of the MIXED OUTLETS of the VALVE.

Cap the other MIXED OUTLET. (Tub port is fitted with a plug at the factory).

WARNING

DO NOT SOLDER DIRECTLY TO THE VALVE BODY; THIS WILL DAMAGE

THE TEMPERATURE CONTROL ELEMENT AND CHECK STOP VALVES.

WOOD

BRACE

HOT

MIXED

COLD

OP

T

IMPORTANT! INSTALL ANY REQUIRED SHUT OFF OR DIVERTER VALVES

INTO THE PIPING SYSTEM.

If the CHECK STOPS (4, 5) were removed during installation,

ensure the hot and cold CHECK STOPS (4, 5) are not reversed. The

hot CHECK STOP (4) has a red top and the cold CHECK STOP (5)

has a blue top.

CHECK STOPS (4,5) are supplied in the open position.

Closing using 5/32" (4 mm) hex wrench to pressure

test and to check for leaks.

To flush lines, remove the CHECK STOPS (4,5)

and run water. If desired, the TEMPERATURE

CONTROL UNIT can be removed. Reinstall CHECK

STOPS (4,5) and CONTROL UNIT (6), if it was

removed.

Remove PLASTER GUARD (2) if still installed.

Turn on water supplies and check for leaks.

Reassemble PLASTER GUARD (2) and FINISH

WALL.

Beware of Freezing. No water should remain

in the MIXING VALVE if freezing is a possibility.

Remove the CHECK STOPS (4,5) to completely

drain the MIXER UNIT (1).

TEMPERATURE ADJUSTMENT

2

Unscrew PLASTER GUARD SCREWS and remove PLASTER GUARD.

Check that arrow marking B points vertically upwards. If not, push the BLACK

CLAMP on the SECURING RING to the right, pull off KNOB MOUNT and reinstall

KNOB MOUNT with arrow "B" pointing upwards.

The maximum mixed water temperature is set at 109 F at the factory.

This setting can be changed if desired.

Remove the TEMPERATURE LIMIT STOP (H shaped Black Plastic part). Reinstall it

at the desired notch as indicated in the diagram to limit the maximum mixed water

temperature to 104 F or 112 F.

For 100 F adjustment, turn the water supply on. Turn KNOB MOUNT until the spout

temperature is 100 F. Check that arrow marking A on the KNOB MOUNT still points

upward after adjusting the thermostat to 100 F. If not, pull out the RED LOCKING DEVICE.

Remove KNOB MOUNT by pulling it towards you while standing directly in front of the valve.

HOT

1

3

PLUG TUB

PORT

CHECK STOP

(HOT RED)

6

4

TEMPERATURE

LIMIT STOP

COLD

2

104

109

112

SECURING

RING

RED LOCKING

DEVICE

ARROW

"B"

5

CHECK STOP

(COLD BLUE)

PLUG TUB

PORT

BLACK

CLAMP

TOP

ARROW

"A"

KNOB

MOUNT

Reinstall the KNOB MOUNT so that the arrow marking A points upwards.

Reinstall RED LOCKING DEVICE.

TRANSPOSED SUPPLY PIPING

OR BACK TO BACK INSTALLATION

3

Should the hot and cold water supply pipes have been transposed making

adjustment impossible, proceed as follows:

Shut off water supply.

Remove handle and rim

Remove check stops and re-install them transposed.

Important note: RED CHECK STOP is now on the right of the mixer body and the BLUE

CHECK STOP is now on the left.

Turn the water supply back on and perform the temperature adjustment in step 2.

CHECK STOP

(RED TO BLUE)

CHECK STOP

(BLUE TO RED)

M968255Rev.1.1

Page 7

953950-0070A

CHECK STOP (COLD BLUE)

994053-0070A

CARTRIDGE

A918572-0070A

CARTRIDGE SCREW

923348-0070A

HANDLE ADAPTER

CENTRAL THERMOSTAT

WITH VOLUME CONTROL

MODEL NUMBER

R520

953960-0070A

THERMOSTAT

CARTRIDGE

953951-0070A

CHECK STOP (HOT RED)

963434-YYY0A DEEP ROUGH KIT

(SOLD SEPARATELY)

912647-0070A

O-RING

953963-0070A

HANDLE EXTENSION

953957-0070A

TEMPERATURE

CALIBRATION UNIT

For toll-free information and answers to your questions, call:

IN CANADA 1-800-387-0369 (TORONTO 1-905-306-1093)

Product names listed herein are trademarks of American Standard Inc.

© American Standard Inc. 2003

HOT LINE FOR HELP

1-800 442-1902

Weekdays 8:00 a.m. to 8:00 p.m. EST

Weekdays 8:00 a.m. to 7:00 p.m. EST

M968255Rev.1.1

Page 8

T

O

P

3/4" CENTRAL THERMOSTAT

WITH VOLUME CONTROL

Installation

Instructions

M 9 6 8 4 8 0

R540

Thank you for selecting American-Standard...the benchmark

of fine quality for over 100 years.

To ensure that your installation proceeds smoothly--please

read these instructions carefully before you begin.

Certified to comply with ANSI A112.18.1M

ASSE 1016

ROUGHING-IN DIMENSIONS

CONNECTIONS ARE: 3/4" NPT

5-7/8

II II

3-15/16

7

3-5/8

3/4" NPT

TUB

3/4" NPT

INLET

3/4" NPT

INLET

3/4" NPT

SHOWER

IMPORTANT: WHEN NOT USING A

DIVERTER SPOUT A SEPARATE

DIVERTER VALVE MUST BE USED.

NOTE: MINIMUM FLOWING PRESSURE REQUIRED FOR

THIS SYSTEM OPERATING WITH ONE SHOWER HEAD

AND 2 BODY SPRAYS IS 40 PSI

TUB PORT MUST

BE PLUGGED

HOT

3/4" 3/4"

COLD

TUB PORT MUST

BE PLUGGED

HOT

3/4" 3/4"

COLD

THERMOSTATIC BATH/

SHOWER INSTALLATION

USING A TWIN ELL, DIVERTER

SPOUT AND FIXED SHOWER

THERMOSTATIC SHOWER INSTALLATION

USING A DIVERTER VALVE, FIXED

SHOWER HEAD AND ADJUSTABLE HAND

HELD SHOWER

THERMOSTATIC SHOWER INSTALLATION USING A

DIVERTER VALVE, FIXED SHOWER HEAD, ADJUSTABLE

HAND HELD SHOWER, ON/OFF VALVE AND TWO

BODY SPRAYS

TWIN

ELL

TOP OF TUB RIM

BOTTOM OF TUB

TUB PORT

MUST BE

PLUGGED

DIVERTER

VALVE

DIVERTER

VALVE

ON/OFF

VALVE

C/L

4"

18"

(OPTIONAL)

80"-86"

6-1/4

1-5/8 - 2-1/2

Page 9

T

O

P

TEMPERATURE ADJUSTMENT

2

WARNING

Prepare water supplies per ROUGHING-IN DIMENSIONS. Make sure the finished wall is between

the minimum and maximum rough dimension.

1

ROUGHING-IN THE VALVE

Install VALVE at indicated height and depth. Make sure the "TOP" marking on the PLASTER

GUARD is up.

Connect the hot and cold water supplies. Assemble all connecting pipes. Flush lines to

remove any dirt. Connections are 3/4" NPT.

Assemble the connection pipe to one of the MIXED OUTLETS of the VALVE.

Cap the other MIXED OUTLET. (Tub port is fitted with a plug at the factory).

IMPORTANT! INSTALL ANY REQUIRED SHUT OFF OR DIVERTER VALVES

INTO THE PIPING SYSTEM.

DO NOT SOLDER DIRECTLY TO THE VALVE BODY; THIS WILL DAMAGE

THE TEMPERATURE CONTROL ELEMENT AND CHECK STOP VALVES.

Unscrew PLASTER GUARD SCREWS and remove PLASTER GUARD.

Check that arrow marking B points vertically upwards. If not, push the BLACK

CLAMP on the SECURING RING to the right, pull off KNOB MOUNT and reinstall

KNOB MOUNT with arrow "B" pointing upwards.

For 100 F adjustment, turn the water supply on. Turn KNOB MOUNT until the spout

temperature is 100 F. Check that arrow marking A on the KNOB MOUNT still points

upward after adjusting the thermostat to 100 F. If not, pull out the RED LOCKING DEVICE.

Remove KNOB MOUNT by pulling it towards you while standing directly in front of the valve.

Reinstall the KNOB MOUNT so that the arrow marking A points upwards.

The maximum mixed water temperature is set at 109 F at the factory.

This setting can be changed if desired.

Remove the TEMPERATURE LIMIT STOP (H shaped Black Plastic part). Reinstall it

at the desired notch as indicated in the diagram to limit the maximum mixed water

temperature to 104 F or 112 F.

Reinstall RED LOCKING DEVICE.

KNOB

MOUNT

ARROW

"A"

BLACK

CLAMP

ARROW

"B"

RED LOCKING

DEVICE

SECURING

RING

104

109

112

TEMPERATURE

LIMIT STOP

T

O

P

CHECK STOP

(HOT RED)

PLUG

TUB

PORT

CHECK STOP

(COLD BLUE)

COLD

HOT

3

2

4

WOOD

BRACE

5

6

If the CHECK STOPS (4, 5) were removed during installation,

ensure the hot and cold CHECK STOPS (4, 5) are not reversed. The

hot CHECK STOP (4) has a red top and the cold CHECK STOP (5)

has a blue top.

CHECK STOPS (4,5) are supplied in the open position.

Closing using 5/32" (4 mm) hex wrench to pressure

test and to check for leaks.

Reassemble PLASTER GUARD (2) and FINISH

WALL.

Beware of Freezing. No water should remain

in the MIXING VALVE if freezing is a possibility.

Remove the CHECK STOPS (4,5) to completely

drain the MIXER UNIT (1).

Remove PLASTER GUARD (2) if still installed.

Turn on water supplies and check for leaks.

To flush lines, remove the CHECK STOPS (4,5)

and run water. If desired, the TEMPERATURE

CONTROL UNIT can be removed. Reinstall CHECK

STOPS (4,5) and CONTROL UNIT (6), if it was

removed.

MIXED

PLUG TUB

PORT

COLD

Should the hot and cold water supply pipes have been transposed making

adjustment impossible, proceed as follows:

TRANSPOSED SUPPLY PIPING

OR BACK TO BACK INSTALLATION

3

Remove check stops and re-install them transposed.

Shut off water supply.

Remove handle and rim

CHECK STOP

(RED TO BLUE)

Important note: RED CHECK STOP is now on the right of the mixer body and the BLUE

CHECK STOP is now on the left.

Turn the water supply back on and perform the temperature adjustment in step 2.

CHECK STOP

(BLUE TO RED)

HOT

1

Page 10

3/4" CENTRAL THERMOSTAT

WITH VOLUME CONTROL

MODEL NUMBER

M 9 6 8 4 8 0M 9 6 8 4 8 0

R540

HOT LINE FOR HELP

For toll-free information and answers to your questions, call:

1-800 442-1902

Weekdays 8:00 a.m. to 8:00 p.m. EST

IN CANADA 1-800-387-0369 (TORONTO 1-905-306-1093)

Weekdays 8:00 a.m. to 7:00 p.m. EST

Pr od uc t na me s li st ed h ere in a re t ra de ma rk s of A me ri ca n St an da rd I nc .

© Am er ic an S ta nd ar d In c. 20 03

923348-0070A

HANDLE ADAPTER

A994352-0070A

CARTRIDGE

954040-0070A

THERMOSTAT

CARTRIDGE

912647-0070A

O-RING

953963-0070A

HANDLE EXTENSION

953957-0070A

TEMPERATURE

CALIBRATION UNIT

A953971-0070A

CHECK STOP (COLD BLUE)

A953972-0070A

CHECK STOP (HOT RED)

918428-0070A

CARTRIDGE SCREW

9 6 3 4 3 4 - Y Y Y 0 A D E E P R O U G H K I T

( S O L D S E PA R A T E LY )

912647-0070A

O-RING

Loading...

Loading...