Page 1

User’s Information Guide

32- 5034- 2

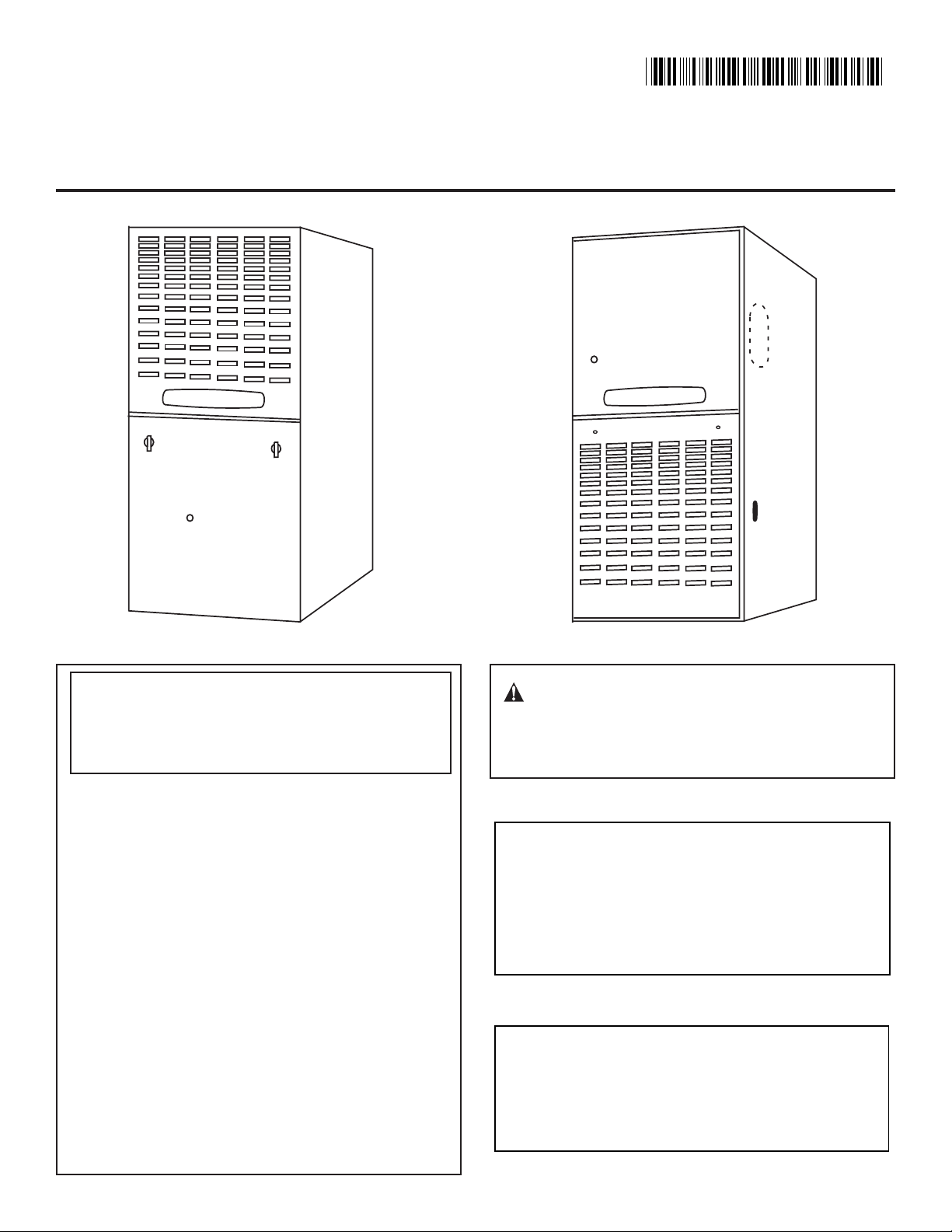

Noncondensing Gas Furnaces

Upflow / Horizontal and Downflow / Horizontal

WARNING: If the information in this manual

is not followed exactly, a fire or explosion may

result causing property damage, personal injury or loss of life.

— Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch;

do not use any phone in your building.

• Immediately call your gas supplier

from a neighbor’s phone. Follow the

gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

— Installation and service must be per-

formed by a qualified installer, service

agency or the gas supplier.

© American Standard Inc. 2001

WARNING: Disconnect power to the

unit before removing the blower door. Failure to

follow this warning could result in property damage,

personal injury or death.

▲

WARNING:

HIGH VOLTAGE ELECTRICAL COMPONENTS, FAST MOVING FANS,

AND COMBUSTIBLE GAS. FOR PROTECTION FROM THESE

INHERENT HAZARDS DURING INSTALLATION AND SERVICING,

THE ELECTRICAL SUPPLY MUST BE DISCONNECTED AND THE

MAIN GAS VALVE MUST BE TURNED OFF. IF OPERATING CHECKS

MUST BE PERFORMED WITH THE UNIT OPERATING, IT IS THE

TECHNICIANS RESPONSIBILTY TO RECOGNIZE THESE HAZARDS

AND PROCEED SAFELY.

▲

WARNING:

ANY PART HAS BEEN UNDER WATER. IMMEDIATELY

CALL A QUALIFIED SERVICE TECHNICIAN TO

INSPECT THE FURNACE AND TO REPLACE ANY

PART OF THE CONTROL SYSTEM AND ANY GAS

CONTROL WHICH HAS BEEN UNDER WATER.

BODILY INJURY CAN RESULT FROM

DO NOT USE THIS UNIT IF

Pub. No. 32-5034-02

Page 2

WARNING:

FIRE OR EXPLOSION HAZARD

Failure to follow the safety warnings exactly could

result in serious injury, death or property damage.

Improper servicing could result in dangerous operation, serious injury, death, or property damage.

Never store gasoline, combustible materials, or other

flammable liquids or vapors near your furnace.

If you have a problem, check the "Problem Solver" section

of this manual before you call for a possibly unneeded

service call.

Parts and controls of this furnace are unique. Should

service or modification be required, be sure your servicer

uses only factory authorized parts, kits, or accessories for

this furnace.

GENERAL INFORMATION

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause injury

or property damage. Refer to the installation instructions provided with the furnace and this

manual. For assistance or additional information

consult a qualified installer, service agency or the

gas supplier.

This information is intended for use by individuals possessing adequate backgrounds of electrical and mechanical experience. Any attempt to repair a central air conditioning product may result in personal injury and/or property damage. American Standard Inc. or seller cannot be

responsible for the interpretation of this information, nor

can it assume any liability in connection with its use.

Safety signal words are used to designate a degree or

level of seriousness associated with a particular hazard.

The signal words for safety markings are DANGER,

WARNING, and CAUTION.

a. DANGER indicates an imminently hazardous

situation which, if not avoided, will result in death

or serious injury. This signal word is limited to the

most extreme situations.

b. WARNING indicates a potentially hazardous situa-

tion which, if not avoided, could result in death or

serious injury.

c. CAUTION indicates a potentially hazardous situa-

tion which, if not avoided, may result in minor or

moderate injury. It is also used to alert against

unsafe practices and hazards involving only property damage.

There must be a free flow of fresh air sufficient for efficient

combustion and safe ventilation of your furnace. Do not

allow the louvers on the front panels of your furnace to

become blocked as this will restrict the flow of fresh air.

The combustion air for your furnace must be fresh uncontaminated air. Paints, varnishes, laundry bleaches, detergents, many household cleaners, water softening salts,

adhesives, and all such products release fumes containing

compounds which could lead to early heat exchanger and

vent system deterioration. Do not store these type of

products near your furnace and consider fresh air for your

furnace during construction or remodeling.

WARNING:

These furnaces are not approved or intended for

installation in manufactured (mobile) housing, trailers,

or recreational vehicles. Failure to follow this warning

could result in property damage, personal injury, or

death.

WARNING:

Do not touch igniter. It is extremely hot. Failure to

follow this warning could result in severe burns, other

injury, property damage, or death.

CAUTION:

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and dangerous operation.

Verify proper operation after servicing.

WARNING:

CARBON MONOXIDE POISONING HAZARD

Failure to follow the installation and operation instructions for the venting system's operation could result in

carbon monoxide poisoning or death.

Page 2 Pub. No. 32-5034-02

Page 3

Filter maintenance reduces energy use.

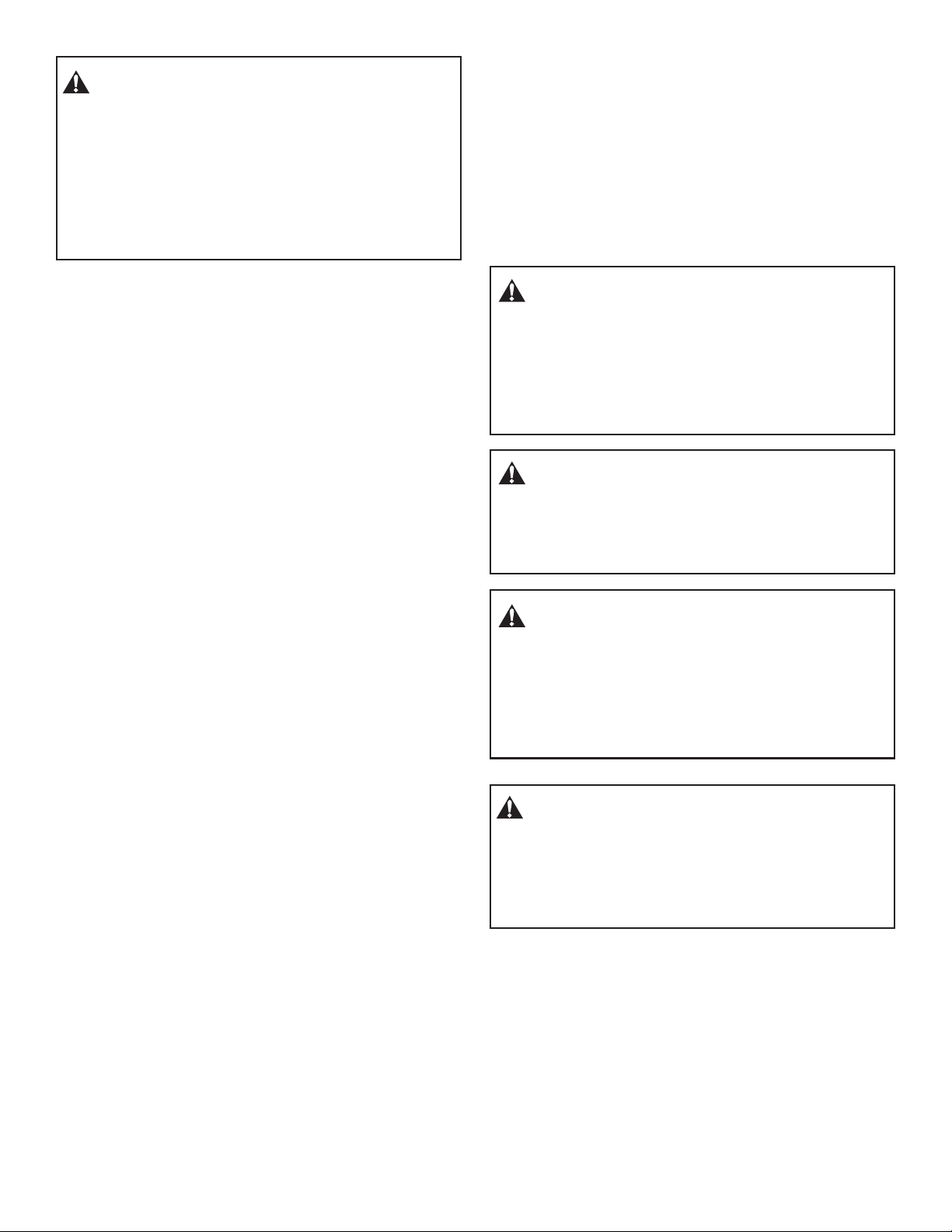

How to remove your filter.

WARNING: Disconnect power to the

unit before removing the blower door. Failure to

follow this warning could result in property damage,

personal injury or death.

A clean filter saves money.

When the furnace circulates and filters the air in your

home, dust and dirt particles build up on the filter.

Excessive accumulation can block the airflow, forcing

the unit to work harder to maintain desired temperatures.

And the harder your unit has to work, the more energy

it uses. So you pay more any time your system is running with a dirty filter.

CAUTION: Never operate your unit for either

heating or cooling with filters removed.

Help ensure top efficiency by cleaning the filter once a

month. If you have an upflow furnace, you can wash or

WARNING: Disconnect power to the

unit before removing the blower door. Failure to

follow this warning could result in property damage,

personal injury or death.

The upflow furnace blower door has a hinge at the

bottom which allows the door to tilt forward for filter

servicing or replacement without the door being removed. The furnace filter in the bottom or side configuration can be removed by simply turning the two latches

on the blower door 1/4 turn and tilting the door forward.

change the filter once a month. Clean it twice a month

during seasons when the unit runs more often.

Your furnace came from the factory with a cleanable

filter. You can clean the filter with a vacuum, OR you

can wash it with a household detergent. Good quality,

high velocity filters may be used for replacements in

upflow furnaces.

With the new patented filter rack on the upflow models,

all cleaning or replacing of filters is quick and easy.

Clean filters guarantee optimum performance of your

system.

Replacing your filter.

When replacing your furnace filters, use a high velocity

type filter. On upflow furnaces, standard size 1" thick

high velocity filters will fit into the patented filter rack

which will automatically adjust in width to fit. Filters

are available from your dealer.

Blower Door Hinge and Bottom Filter Rack Installation

The blower door may be removed if necessary by tilting the

door outward 2 to 3 inches, then pulling up. The door will

slide out of the hinge for removal. For replacement, simply

insert the blower door bottom into the space between the

furnace base front and the hinge, then tilt inward and

latch.

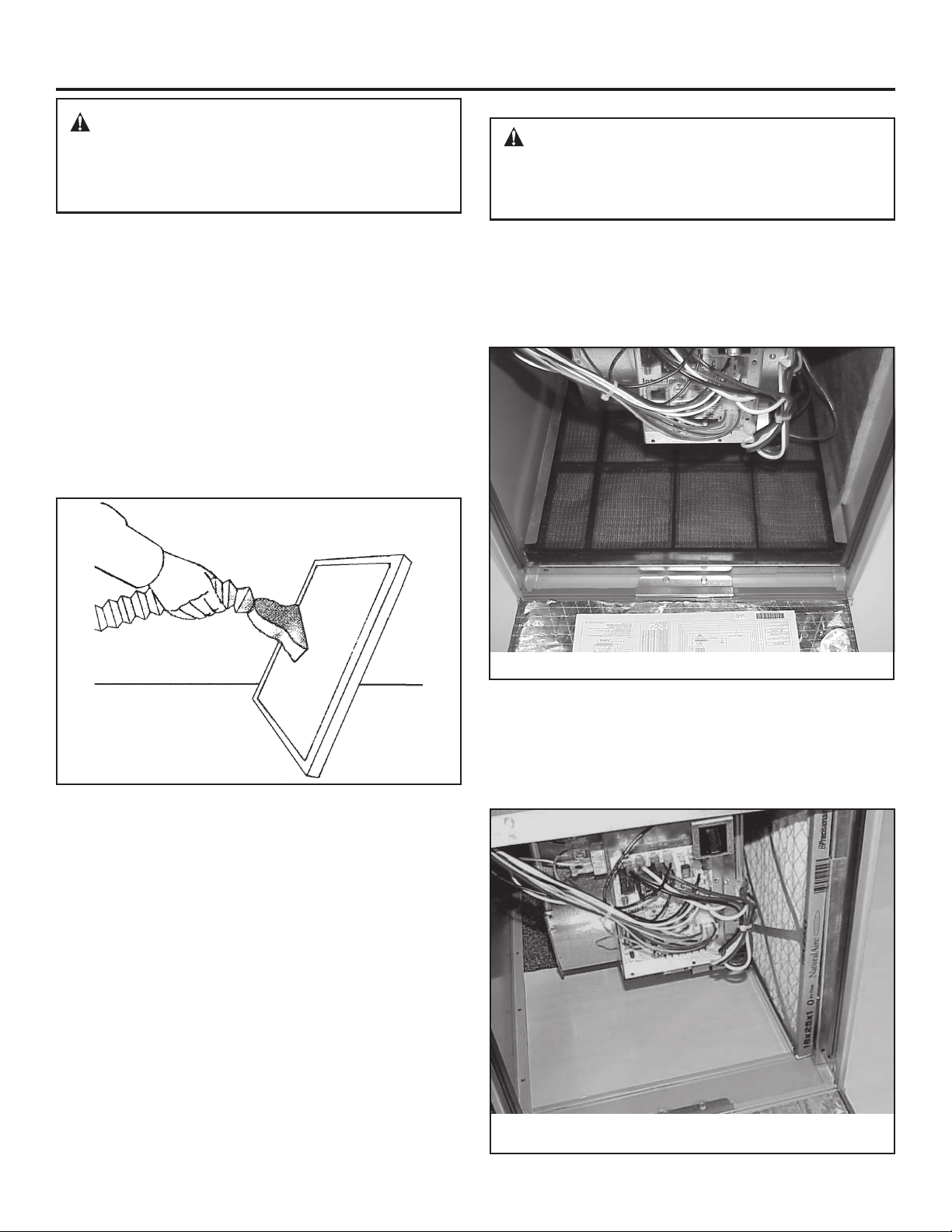

Typical Upflow Right Side Return Filter Installation

Pub. No. 32-5034-02 Page 3

Page 4

Filter Rack Assembly

The filter rails are spring loaded for automatic adjustment

to allow standard size, locally obtainable replacement

filters. The filter rack itself slides to adjust to the required

width needed for bottom or side return. Always insert the

chamfer (angle edged sides) end first.

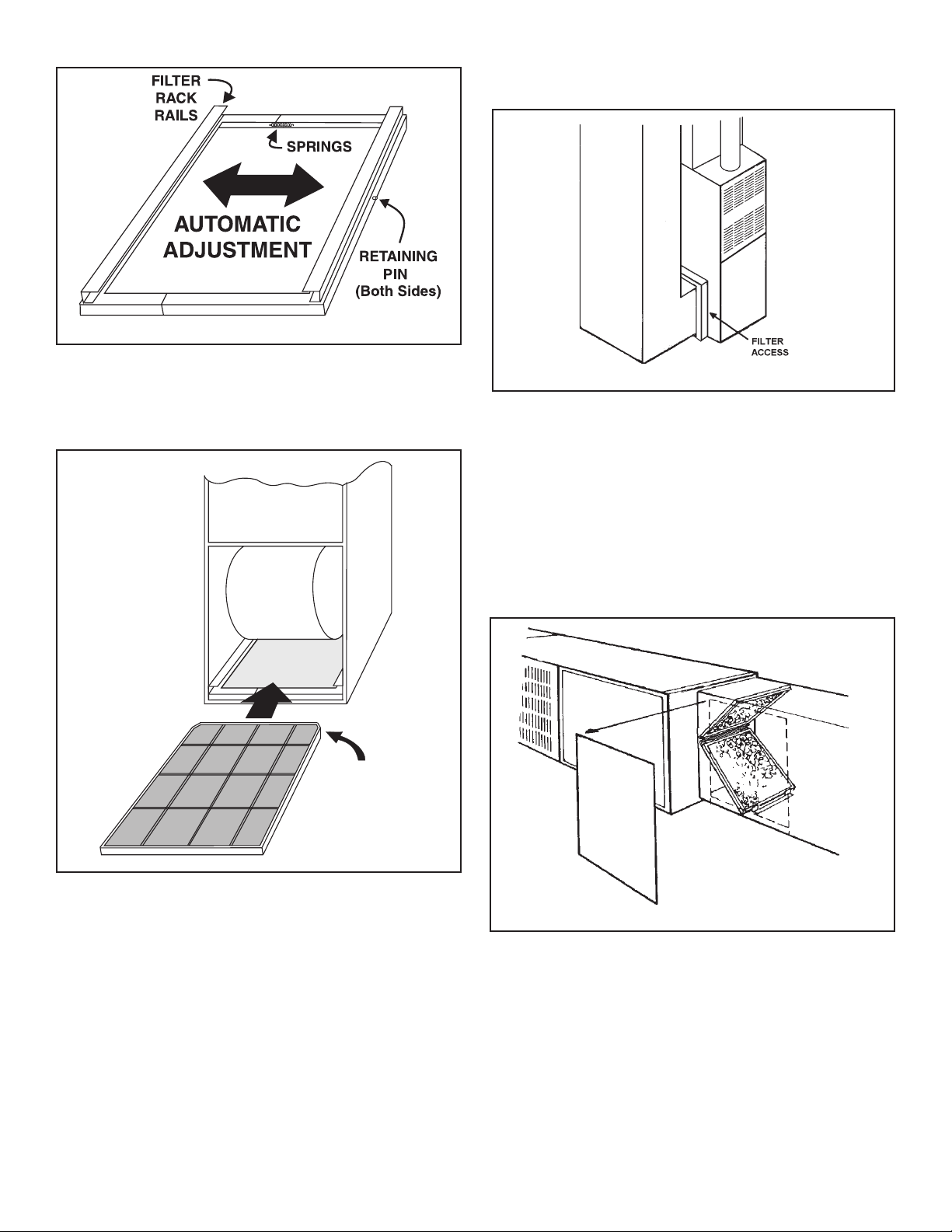

Air filters may also be located outside of the furnace

using a SIDE FILTER FRAME.

UPFLOW ONLY

Upflow / Horizontal Furnace Filters

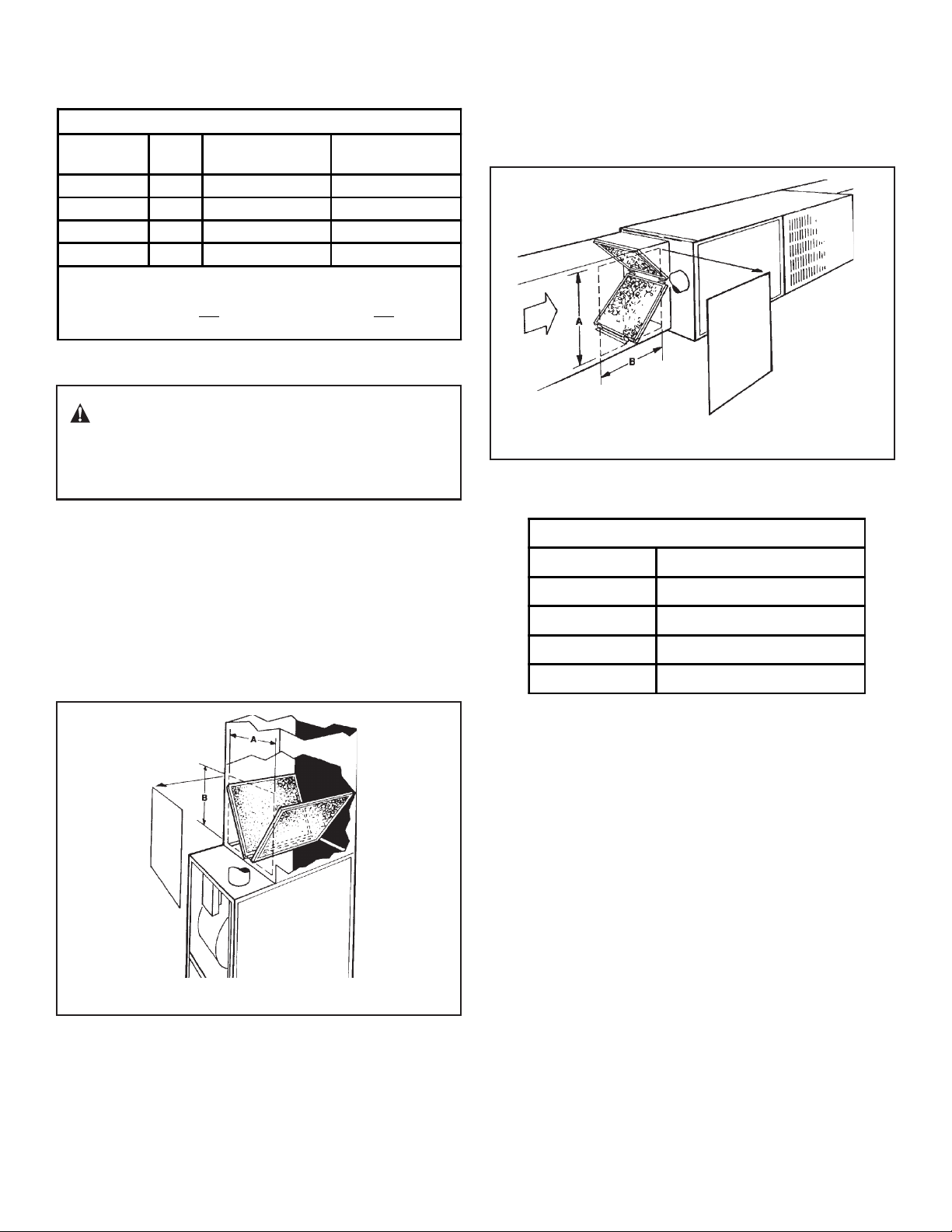

The Upflow/Horizontal furnace, when installed horizontally, requires a horizontal filter kit. The filters may be

located remote to the furnace or in the return air duct near

the furnace. Check with your dealer for the location

of your filters.

An upflow/horizontal furnace in horizontal return air filter

application, as shown, features two 14" x 20" x 1" filters in

the 14-1/2" wide furnace cabinets; or two 16" x 20" x 1"

filters in the 17-1/2", 21", and 24-1/2" wide furnace cabinets.

CHAMFER

END OF

FILTER GOES

INTO FILTER

RACK FIRST

The furnace filter may be secured with filter retaining

brackets for right side return on smaller furnaces. To

replace filters on these furnaces, remove the blower

access door, push back to flex the filter and clear the

filter retaining bracket at the front of the unit. Gently

pull the filter out. After cleaning, replace the filter in

the same manner making sure that filter is secured in

place in both front and back filter retaining brackets of

the unit. Replace blower access door.

To replace filters, remove the filter access door, lift the

filter from the lower bracket and shift the filter to the side

to free the top filter from the bracket and slide the filters

out through the filter access door. After cleaning, replace

the filters in the same manner making sure that the filters

are secured in place in both top and bottom filter brackets.

UPFLOW/HORIZONTAL WITH FILTER KIT

Replace filter access door.

Air filters may also be located outside of the furnace using

a remote filter grille. The filter grille could be in a hallway,

wall, or in the ceiling. Check with your dealer for the exact

location of your filter and the method of changing the

filters.

Page 4 Pub. No. 32-5034-02

Page 5

FACTORY SUPPLIED UPFLOW FURNACE

RETURN AIR FILTERS

UPFLOW FURNACE RETURN AIR FILTERS

CABINET

WIDTH

14-1/2" 1 14" X 25" X 1" 17-1/2" X 25" X 1"

17-1/2" 1 17" X 25" X 1" 17-1/2" X 25" X 1"

21" 1 20" X 25" X 1" 17-1/2" X 25" X 1"

24-1/2" 1 24" X 25" X 1" 17-1/2" X 25" X 1"

*NOTE - On 5 or 6 ton airflow models, if the airflow

requirement exceeds 1800 CFM, these models will require

filters on

bottom.

QTY*

both

sides; OR 1 side

CABINET

BOTTOM FILTER

and

the bottom; OR just the

CABINET

SIDE FILTER

WARNING: Disconnect power to the

unit before removing the blower door. Failure to

follow this warning could result in property damage,

personal injury or death.

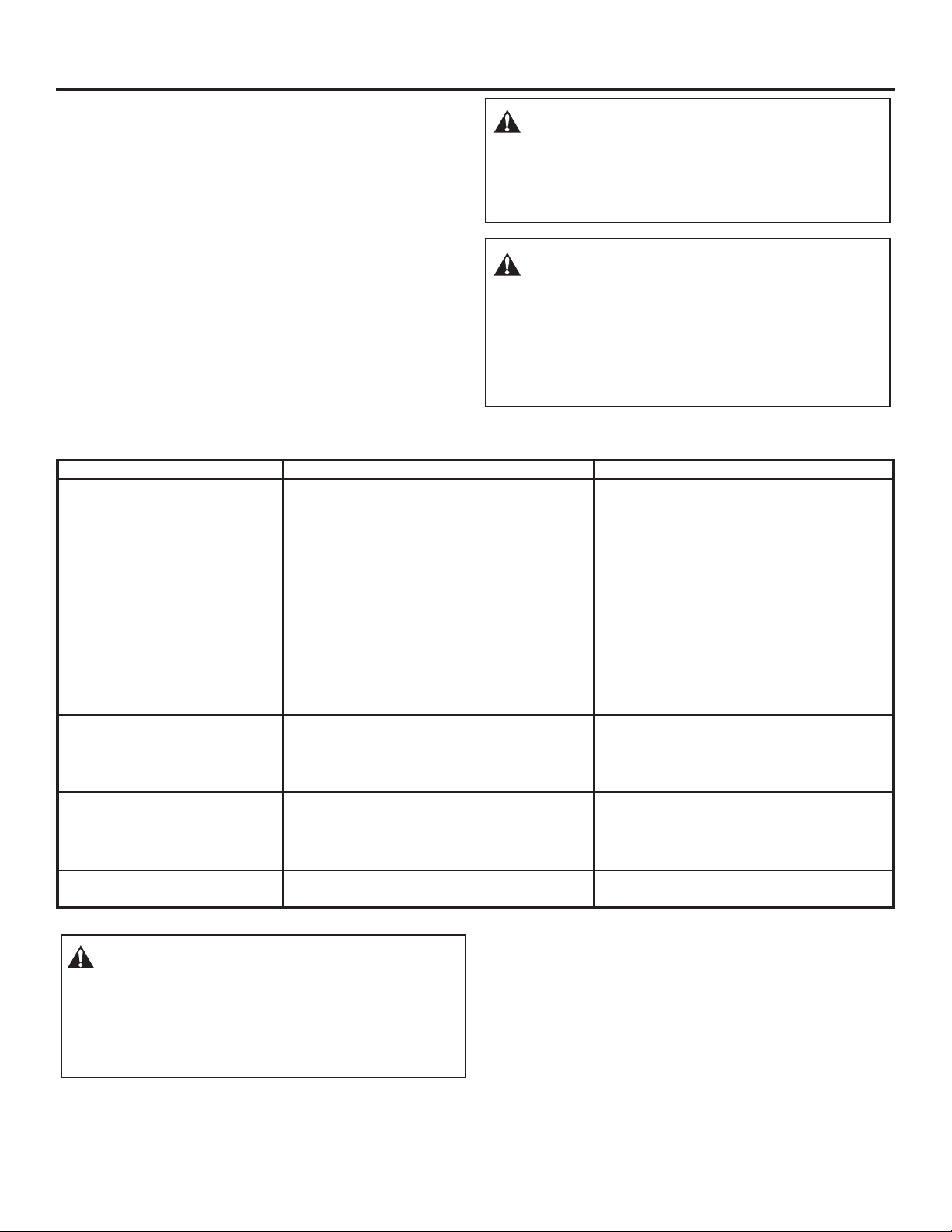

A downflow/horizontal furnace with horizontal return air

filter application, as shown, features two 14" x 20" x 1"

filter in the 14-1/2" wide furnace cabinets; or two 16" x 20"

x 1" filter in the 17-1/2", 21", and 24-1/2" wide furnace

cabinets.

DOWNFLOW/HORIZONTAL FILTER

DOWNFLOW FILTER TABLE

Downflow Furnace Filters

Downflow/Horizontal furnaces use 2 standard size permanent type air filters which may be located remote to the

furnace or in the return air duct. Check with your dealer

for the location of your filters.

A downflow/horizontal furnace vertical return air filter

application, as shown, features two 14" x 20" x 1" filter in

the 14-1/2" wide furnace cabinets; or two 16" x 20" x 1" filter

in the 17-1/2", 21", and 24-1/2" wide furnace cabinets.

REQUIRED FILTERS - DOWNFLOW

CABINET WIDTH FILTER QUANTITY & SIZE

14-1/2" 2 - 14" X 20" X 1"

17-1/2" 2 - 16" X 20" X 1"

21" 2 - 16" X 20" X 1"

24-1/2" 2 - 16" X 20" X 1"

DOWNFLOW FILTER

Pub. No. 32-5034-02 Page 5

Page 6

The problem solver.

A furnace is not a household appliance. It is complex and

requires professional maintenance and repair.

That’s why attempts at “do-it-yourself” repairs on an inwarranty unit may void the remainder of your warranty.

Other than performing the simple maintenance recommended in this manual, you should not attempt to make

any adjustments to your furnace. Your dealer will be able

to take care of any questions or problems you may have. A

periodic inspection of your furnace should be made by a

qualified service agency at the start of each heating season.

Keep your furnace looking like new for years.

Clean the enamel finish of your furnace with ordinary soap

and water. For stubborn grease spots, use a household

detergent. Lacquer thinner or other synthetic solvents may

damage the finish.

Save time and money. Before calling for service, check the following:

Problem Possible Trouble Possible Remedy

No Heating - Blower 1. Thermostat set incorrectly. 1. Adjust thermostat See operating

Does not operate instructions

2. Blown fuse or tripped circuit breaker. 2. Replace or reset protective device

3. Defective component. 3. Most controls are automatic and will

4. Burner does not ignite. 4. Call servicer.

5. Main gas line turned off. 5. Have gas company check.

6. Blower door removed or ajar. 6. Close door securely to restore power

7. Lockout 7. Turn power on-off-on-off twice

Insufficient Heating - 1. Dirty air filters. 1. Clean or replace filters.

Blower operates

continuously 2. Blocked supply or 2. Make sure registers are open and

return registers. No obstacles blocking off the air.

No Heat - Vent motor Restricted or plugged furnace 1. Remove drain clamps to condensate

is running condensate drain. trap and drain pan outlet

Unusual Noise Call your servicer

WARNING:

Do not touch igniter. It is extremely hot. Failure to

follow this warning could result in severe burns, other

injury, property damage, or death.

CAUTION:

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and dangerous operation.

Verify proper operation after servicing.

or call for servicer.

recycle. If your unit still does not

operate call for servicer.

to blower and gas valve.

in 30 secs.

2. Flush or clear drain blockage.

3. Reinstall clamps.

WARNING:

CARBON MONOXIDE POISONING HAZARD

Failure to follow the installation and operation instructions for the venting system's operation could result in

carbon monoxide poisoning or death.

Page 6 Pub. No. 32-5034-02

Page 7

Maintenance information.

Never stop the cooling system by shutting off the

main power.

If the main power to your air conditioner is ever disconnected for more than three hours, turn off the thermostat.

Then wait for at least three more hours after the power has

been restored before turning the thermostat back on.

Failure to follow this procedure could result in damage to

your air conditioning system.

1. GENERAL INSPECTION - Examine the furnace installation for the following items:

a. All flue product carrying areas external to the furnace (i.e. chimney, vent connector) are clear and free of

obstruction.

b. The vent connector is in place, slopes upward and is

physically sound without holes or excessive corrosion.

c. The return air duct connection(s) is physically sound,

is sealed to the furnace and terminates outside the

space containing the furnace.

d. The physical support of the furnace should be sound

without sagging, cracks, gaps, etc., around the base so

as to provide a seal between the support and the base.

e. There are no obvious signs of deterioration of the

furnace.

WARNING:

NOTE: On LP (propane) units, some light yellow tipping of

the outer mantle is normal. Inner mantle should be bright

blue.

Natural gas units should not have any yellow tipped

flames. This condition indicates that a service call is

required. For best operation, burners must be cleaned

annually using brushes and vacuum cleaner.

NOTE: On LP (propane) units, due to variations in BTU

content and altitude, servicing may be required at shorter

intervals.

Do not touch igniter. It is extremely hot. Failure to

follow this warning could result in severe burns.

2. BLOWERS - The blower size and speed determine the

air volume delivered by the furnace. The blower motor

bearings are factory lubricated and under normal operating conditions usually do not require servicing. Annual

cleaning of the blower wheel and housing is recommended

for maximum air output, and this must be performed only

by a qualified servicer or service agency.

3. IGNITER - This unit has a special hot surface direct

ignition device that automatically lights the burners. Please

note that it is very fragile and should be handled with care.

CAUTION: Do not touch igniter. It is extremely hot.

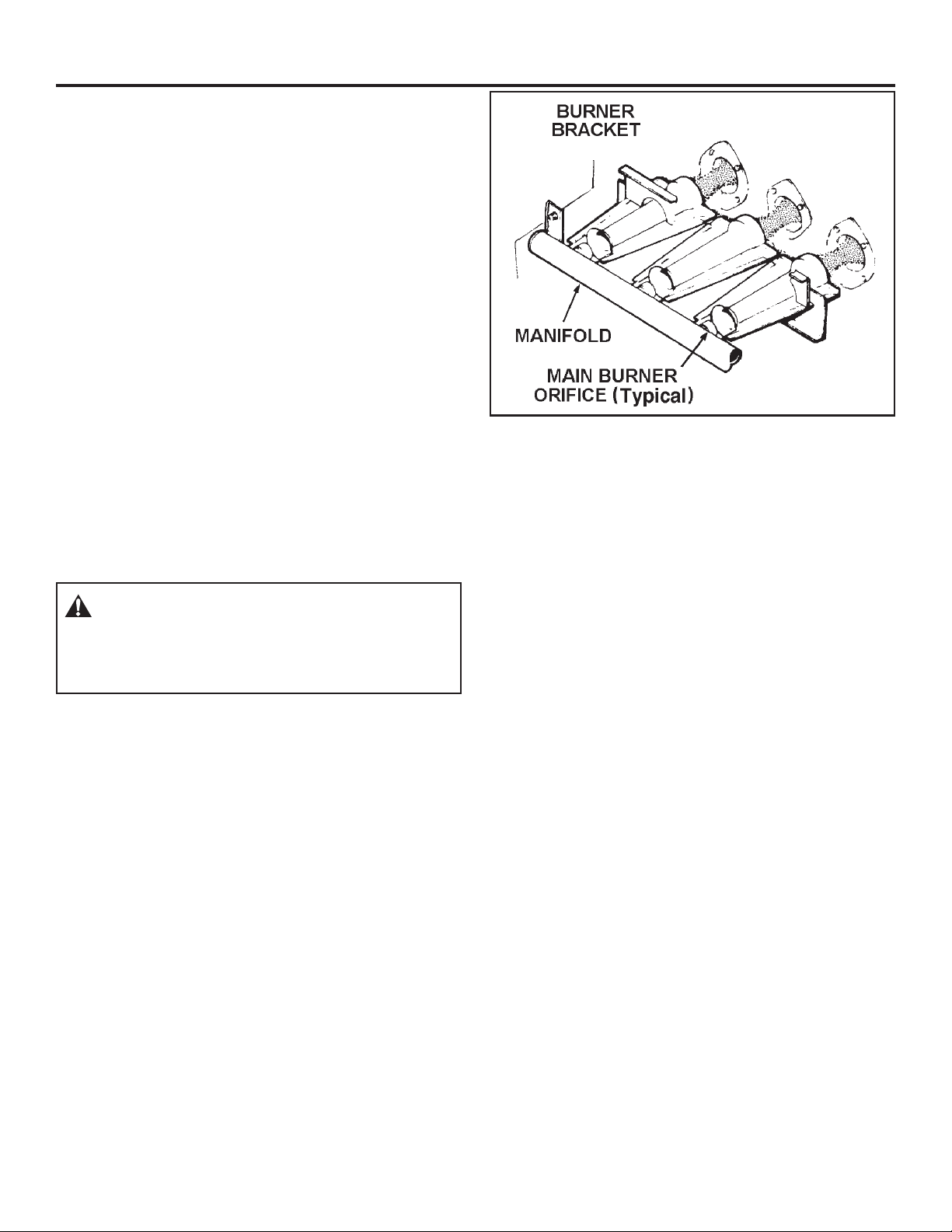

4. BURNER - Gas burners do not normally require scheduled servicing, however, accumulation of foreign material

may cause a yellowing flame or delayed ignition. Either

condition indicates that a service call is required. For best

operation, burners must be cleaned annually using brushes

and vacuum cleaner.

Turn off gas and electric power supply. To clean burners,

remove top burner bracket and lift burner from orifice.

NOTE: Be careful not to break igniter when removing burners. Clean burners with brush and/or vacuum

cleaner. Reassemble parts by reversal of the above procedure.

Pub. No. 32-5034-02 Page 7

5. HEAT EXCHANGER / FLUE PIPE - These items must

be inspected for signs of corrosion, and/or deterioration at

the beginning of each heating season by a qualified service

technician and cleaned annually for best operation.

6. CIRCUIT PROTECTION - If blower or gas valve fail to

operate, the cause could be the circuit breaker or a loose or

blown fuse. Replace fuse or reset circuit breaker.

7. OPERATION - Your warm air furnace should not be

operated in a corrosive atmosphere. Paint solvents, cleaning chemicals, spray propellants, and bleaches should not

be used in the vicinity of the furnace during normal

operation.

8. COOLING COIL CONDENSATE DRAIN - If you have

a cooling coil installed with your furnace, condensate

drains should be checked and cleaned periodically to assure that condensate can drain freely from coil to drain. If

condensate cannot drain freely water damage could occur.

9. AIR CIRCULATION - To ensure increased comfort,

blower on this unit may be operated continuously for both

heating and cooling. This will result in constantly filtered

air and aid in maintaining more even temperatures by

avoiding temperature stratification throughout the conditioned area. To accomplish constant air circulation, set

your thermostat fan switch to "ON".

Page 8

WARNING: Disconnect power to the

unit before removing the blower door. Failure to

follow this warning could result in property damage,

personal injury or death.

▲

WARNING:

ANY PART HAS BEEN UNDER WATER. IMMEDIATELY

CALL A QUALIFIED SERVICE TECHNICIAN TO

INSPECT THE FURNACE AND TO REPLACE ANY

PART OF THE CONTROL SYSTEM AND ANY GAS

CONTROL WHICH HAS BEEN UNDER WATER.

For your safety.

Furnace area must be kept clear and free of combustible

materials, gasoline, and other flammable vapors and liquids.

Air for combustion and ventilation.

The flow of combustion and ventilating air must not be

obstructed from reaching the furnace. Air openings provided in the casing of furnace must be kept free of obstructions which would restrict airflow, thereby affecting efficiency and safe operation of your furnace.

Also, air openings provided to the area in which the

furnace is installed and the space around the furnace shall

not be blocked or obstructed. Keep this in mind should you

choose to remodel the area which contains your furnace.

Furnaces must have air for proper performance.

If additional insulation is added after the furnace is installed, the area around the furnace must be inspected to

ensure it is free and clear of insulation. If this furnace is

installed in an attic or other insulated space it must be kept

free and clear of all insulating materials as some insulating materials are combustible.

DO NOT USE THIS UNIT IF

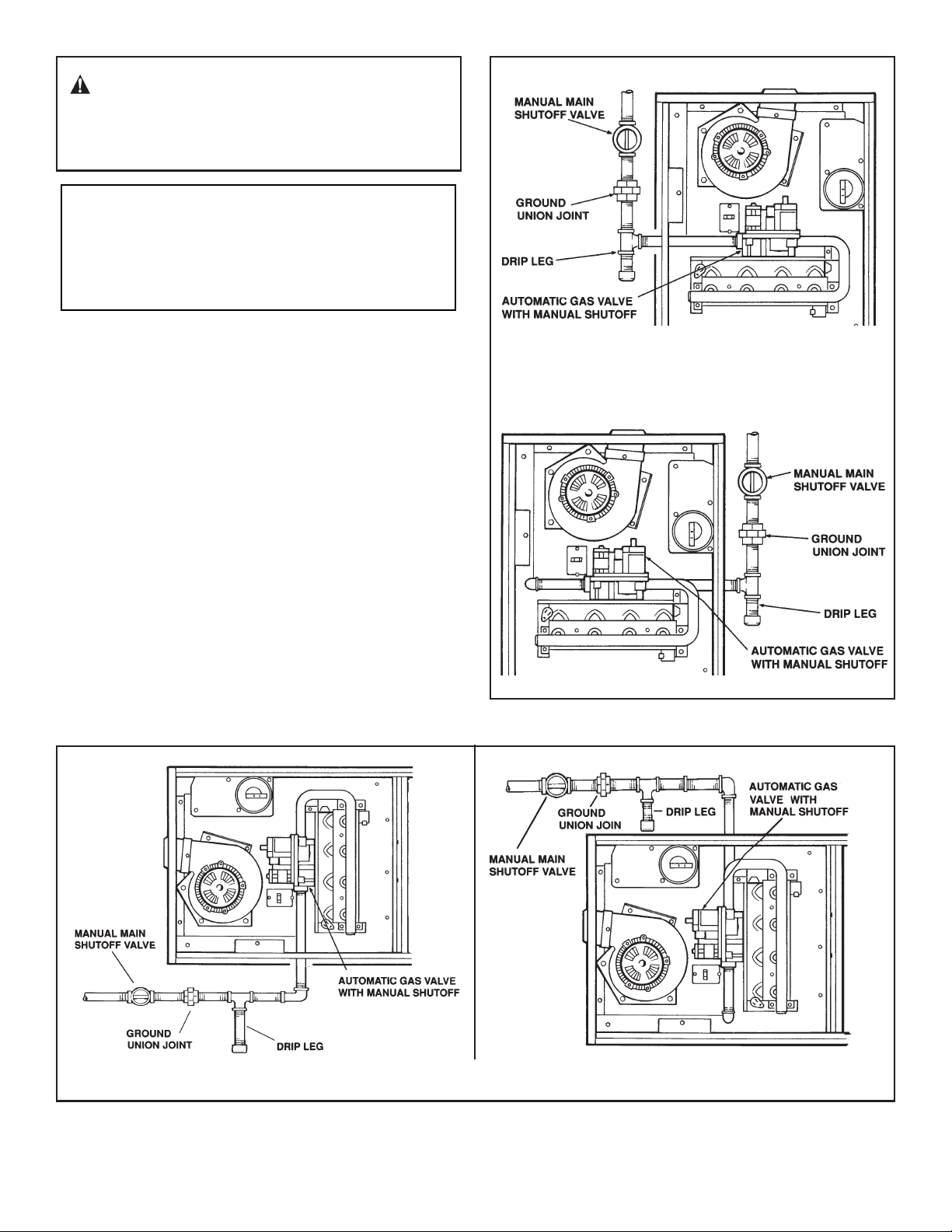

Manual Main Gas Shut-off Valve May Be

Located on the Left or Right Side

Manual Main Gas Shut-off Valve May Be Located on the Top or Bottom Side

NOTE THE LOCATION OF THE MANUAL MAIN GAS SHUTOFF VALVE FOR YOUR FUR-

NACE.

Have your installer or servicer show you the location if you have any questions.

Page 8 Pub. No. 32-5034-02

Page 9

To light furnace.

WARNING:

FIRE OR EXPLOSION HAZARD

Failure to follow the safety warnings exactly could result in

serious injury, death or property damage.

Never test for gas leaks with an open flame. Use a com-

mercially available soap solution made specifically for the

detection of leaks to check all connections. A fire or

explosion may result causing property damage, personal

injury, or loss of life.

Lighting instructions.

Your furnace is equipped with a hot surface direct ignition

device.

WARNING.

Do not attempt to manually light the furnace.

1. Please read all safety information in this book before operating

furnace.

2. Set thermostat to lowest setting. Turn off all electric power to

furnace.

3. Remove control access panel.

4. Turn gas cock knob on main gas valve with unit clockwise to

“OFF” position. If external gas cock is used, turn to “OFF”

position. Allow 5 minutes for any gas within the unit to escape.

LP gas being heavier than air may require forced ventilation. If

you smell gas STOP! Follow the “What To Do If You Smell Gas”

instructions on the front cover of this book. If you don’t smell gas,

go to next step.

5. Turn gas cock knob counterclockwise to “ON” marker.

6. Replace control access panel.

7. Turn on main electrical supply and set thermostat to desired

setting. Combustion blower will start and ignition device will

start to heat up. After approximately 15 seconds main gas valve

will open and burners will ignite.

8. When thermostat is satisfied, main burners will extinguish.

9. If main burners fail to ignite, lower thermostat setting or

disconnect electrical supply, wait 5 minutes, raise thermostat

setting above indicated temperature.

10. If furnace will not light, turn “OFF” all gas and electricity to

unit and call servicer or gas supplier.

For complete shutdown.

Turn gas cock knob on main gas valve to “OFF” position. Disconnect electrical supply to unit.

CAUTION: If this is done during the cold weather months,

provisions must be taken to prevent freeze-up of all water pipes

and water receptacles.

Whenever your house is to be vacant, arrange to have someone

inspect your house for proper temperature. If your furnace

should fail to operate, damage could result, such as frozen water

pipes.

Safety cutoff device (thermal limit).

All models are equipped with a fusible link behind gas valve.

In case of main gas valve malfunction and consequent

overheating, link will open and close off flow of all gas. See

instruction label on front panel of heat exchanger.

Your furnace may have a "Knob Switch" or a "Toggle Switch" to turn the gas ON or OFF.

Pub. No. 32-5034-02 Page 9

Page 10

Limited Warranty

High Efficiency Induced Draft Gas Furnace

UE, DE, UD-R, DD-R, UD-RV, DD-RV,

UD-C, DD-C, CUB and CDB

Models Less Than 20 Tons for Residential Use*

(Parts Only)

This limited warranty is extended by American Standard Inc., to the original purchaser and to any succeeding

owner of the real property to which the Gas Furnace is originally affixed, and applies to products purchased and

retained for use within the U.S.A. and Canada.

If any part of your Gas Furnace fails because of a manufacturing defect within five years from the date of the

original purchase, Warrantor will furnish without charge the required replacement part. Any local transportation,

related service labor, air filters, and diagnosis calls, are not included.

In addition, if the steel heat exchanger fails because of a manufacturing defect within the sixth through twentieth

year from the date of original purchase, Warrantor will furnish without charge a replacement heat exchanger. Any

local transportation, related service labor, air filters, and diagnosis calls, are not included.

This limited warranty does not cover failure of your gas furnace if it is damaged while in your possession, failure

attributable or caused by unreasonable use of the gas furnace and/or failure to properly maintain the gas furnace

as set forth in the Use and Care manual.

This limited warranty applies to product installed on or after 10/1/2001 where product is manufactured after

1/1/2000. This limited warranty is not retroactive to any installations prior to 10/1/2001 or on product produced

prior to 2000.

THE LIMITED WARRANTY AND LIABILITY SET FORTH HEREIN ARE IN LIEU OF ALL OTHER

WARRANTIES AND LIABILITIES, WHETHER IN CONTRACT OR IN NEGLIGENCE, EXPRESS OR

IMPLIED, IN LAW OR IN FACT, INCLUDING IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR PARTICULAR USE, AND IN NO EVENT SHALL WARRANTOR BE LIABLE FOR ANY

INCIDENTAL OR CONSEQUENTIAL DAMAGES.

Some states do not allow limitations on how long an implied limited warranty lasts or do not allow the exclusion

or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

This limited warranty gives you specific legal rights, and you may also have other rights which vary from state to

state.

Parts will be provided by our factory organization through an authorized service organization in your area listed

in the yellow pages. If you wish further help or information concerning this limited warranty, contact:

American Standard Inc.

Troup Highway

Tyler, TX 75711-9010

Attention: Manager, After Sales Support

GW-615-4001

* This limited warranty is for residential usage of this equipment and not applicable when this equipment is used

for a commercial application. A commercial use is any application where the end purchaser uses the product for

other than personal, family or household purposes.

Warranty Information

It’s always a good idea to keep records which will save you time

and money. If it’s necessary to have your FURNACE repaired,

the service man will want to know if your unit is still under

Warranty. To save time, take a few minutes to record the

following information here:

Model Number:_____________________________________

Serial Number: _____________________________________

Date of Purchase:___________________________________

Service Information

Call your installing dealer if the unit is inoperative. Before

you call, always check the following to be sure service is

really required:

a. Be sure the main switch that supplies power to the unit is

in the “ON” position.

b. Replace any burned-out fuses or reset circuit breakers.

c. Be sure the thermostat is properly set.

Extended warranties are available from the manufacturer through your dealer. The limited warranty is backed by the

manufacturer and any representations made about extending the limited warranty would be backed by the manufacturer if and

only if an extended warranty agreement was received from the manufacturer.

Page 10 Pub. No. 32-5034-02

Page 11

The following warning complies with State of California law, Proposition 65.

WARNING: This product contains fiberglass wool insulation! Fiberglass dust and ceramic fibers are be-

lieved by the state of California to cause cancer through inhalation. Glasswool fibers may also cause respiratory, skin,

or eye irritation.

PRECAUTIONARY MEASURES

• Avoid breathing fiberglass dust.

• Use a NIOSH approved dust/mist respirator.

• Avoid contact with the skin or eyes. Wear long-sleeved,

loose fitting clothing, gloves, and eye protection.

• Wash clothes separately from other clothing; rinse washer

thoroughly.

• Operations such as sawing, blowing, tear-out, and spraying may generate fiber concentrations requiring additional

respiratory protection. Use the appropriate NIOSH approved respirator in these situations.

FIRST AID MEASURES

Eye Contact - Flush eyes with water to remove dust. If

symptoms persist, seek medical attention.

Skin Contact - Wash affected areas gently with soap

and warm water after handling.

Pub. No. 32-5034-02 Page 11

Page 12

American Standard Inc.

6200 Troup Highway

Tyler, TX 75711-9010

Since the manufacturer has a policy of continuous product and product data improvement, it reserves the right

to change design and specifications without notice.

Page 12 Pub. No. 32-5034-02

Page 13

User’s Information Guide

32- 5034- 2

Noncondensing Gas Furnaces

Upflow / Horizontal and Downflow / Horizontal

WARNING: If the information in this manual

is not followed exactly, a fire or explosion may

result causing property damage, personal injury or loss of life.

— Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch;

do not use any phone in your building.

• Immediately call your gas supplier

from a neighbor’s phone. Follow the

gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

— Installation and service must be per-

formed by a qualified installer, service

agency or the gas supplier.

© American Standard Inc. 2001

WARNING: Disconnect power to the

unit before removing the blower door. Failure to

follow this warning could result in property damage,

personal injury or death.

▲

WARNING:

HIGH VOLTAGE ELECTRICAL COMPONENTS, FAST MOVING FANS,

AND COMBUSTIBLE GAS. FOR PROTECTION FROM THESE

INHERENT HAZARDS DURING INSTALLATION AND SERVICING,

THE ELECTRICAL SUPPLY MUST BE DISCONNECTED AND THE

MAIN GAS VALVE MUST BE TURNED OFF. IF OPERATING CHECKS

MUST BE PERFORMED WITH THE UNIT OPERATING, IT IS THE

TECHNICIANS RESPONSIBILTY TO RECOGNIZE THESE HAZARDS

AND PROCEED SAFELY.

▲

WARNING:

ANY PART HAS BEEN UNDER WATER. IMMEDIATELY

CALL A QUALIFIED SERVICE TECHNICIAN TO

INSPECT THE FURNACE AND TO REPLACE ANY

PART OF THE CONTROL SYSTEM AND ANY GAS

CONTROL WHICH HAS BEEN UNDER WATER.

BODILY INJURY CAN RESULT FROM

DO NOT USE THIS UNIT IF

Pub. No. 32-5034-02

Page 14

WARNING:

FIRE OR EXPLOSION HAZARD

Failure to follow the safety warnings exactly could

result in serious injury, death or property damage.

Improper servicing could result in dangerous operation, serious injury, death, or property damage.

Never store gasoline, combustible materials, or other

flammable liquids or vapors near your furnace.

If you have a problem, check the "Problem Solver" section

of this manual before you call for a possibly unneeded

service call.

Parts and controls of this furnace are unique. Should

service or modification be required, be sure your servicer

uses only factory authorized parts, kits, or accessories for

this furnace.

GENERAL INFORMATION

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause injury

or property damage. Refer to the installation instructions provided with the furnace and this

manual. For assistance or additional information

consult a qualified installer, service agency or the

gas supplier.

This information is intended for use by individuals possessing adequate backgrounds of electrical and mechanical experience. Any attempt to repair a central air conditioning product may result in personal injury and/or property damage. American Standard Inc. or seller cannot be

responsible for the interpretation of this information, nor

can it assume any liability in connection with its use.

Safety signal words are used to designate a degree or

level of seriousness associated with a particular hazard.

The signal words for safety markings are DANGER,

WARNING, and CAUTION.

a. DANGER indicates an imminently hazardous

situation which, if not avoided, will result in death

or serious injury. This signal word is limited to the

most extreme situations.

b. WARNING indicates a potentially hazardous situa-

tion which, if not avoided, could result in death or

serious injury.

c. CAUTION indicates a potentially hazardous situa-

tion which, if not avoided, may result in minor or

moderate injury. It is also used to alert against

unsafe practices and hazards involving only property damage.

There must be a free flow of fresh air sufficient for efficient

combustion and safe ventilation of your furnace. Do not

allow the louvers on the front panels of your furnace to

become blocked as this will restrict the flow of fresh air.

The combustion air for your furnace must be fresh uncontaminated air. Paints, varnishes, laundry bleaches, detergents, many household cleaners, water softening salts,

adhesives, and all such products release fumes containing

compounds which could lead to early heat exchanger and

vent system deterioration. Do not store these type of

products near your furnace and consider fresh air for your

furnace during construction or remodeling.

WARNING:

These furnaces are not approved or intended for

installation in manufactured (mobile) housing, trailers,

or recreational vehicles. Failure to follow this warning

could result in property damage, personal injury, or

death.

WARNING:

Do not touch igniter. It is extremely hot. Failure to

follow this warning could result in severe burns, other

injury, property damage, or death.

CAUTION:

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and dangerous operation.

Verify proper operation after servicing.

WARNING:

CARBON MONOXIDE POISONING HAZARD

Failure to follow the installation and operation instructions for the venting system's operation could result in

carbon monoxide poisoning or death.

Page 2 Pub. No. 32-5034-02

Page 15

Filter maintenance reduces energy use.

How to remove your filter.

WARNING: Disconnect power to the

unit before removing the blower door. Failure to

follow this warning could result in property damage,

personal injury or death.

A clean filter saves money.

When the furnace circulates and filters the air in your

home, dust and dirt particles build up on the filter.

Excessive accumulation can block the airflow, forcing

the unit to work harder to maintain desired temperatures.

And the harder your unit has to work, the more energy

it uses. So you pay more any time your system is running with a dirty filter.

CAUTION: Never operate your unit for either

heating or cooling with filters removed.

Help ensure top efficiency by cleaning the filter once a

month. If you have an upflow furnace, you can wash or

WARNING: Disconnect power to the

unit before removing the blower door. Failure to

follow this warning could result in property damage,

personal injury or death.

The upflow furnace blower door has a hinge at the

bottom which allows the door to tilt forward for filter

servicing or replacement without the door being removed. The furnace filter in the bottom or side configuration can be removed by simply turning the two latches

on the blower door 1/4 turn and tilting the door forward.

change the filter once a month. Clean it twice a month

during seasons when the unit runs more often.

Your furnace came from the factory with a cleanable

filter. You can clean the filter with a vacuum, OR you

can wash it with a household detergent. Good quality,

high velocity filters may be used for replacements in

upflow furnaces.

With the new patented filter rack on the upflow models,

all cleaning or replacing of filters is quick and easy.

Clean filters guarantee optimum performance of your

system.

Replacing your filter.

When replacing your furnace filters, use a high velocity

type filter. On upflow furnaces, standard size 1" thick

high velocity filters will fit into the patented filter rack

which will automatically adjust in width to fit. Filters

are available from your dealer.

Blower Door Hinge and Bottom Filter Rack Installation

The blower door may be removed if necessary by tilting the

door outward 2 to 3 inches, then pulling up. The door will

slide out of the hinge for removal. For replacement, simply

insert the blower door bottom into the space between the

furnace base front and the hinge, then tilt inward and

latch.

Typical Upflow Right Side Return Filter Installation

Pub. No. 32-5034-02 Page 3

Page 16

Filter Rack Assembly

The filter rails are spring loaded for automatic adjustment

to allow standard size, locally obtainable replacement

filters. The filter rack itself slides to adjust to the required

width needed for bottom or side return. Always insert the

chamfer (angle edged sides) end first.

Air filters may also be located outside of the furnace

using a SIDE FILTER FRAME.

UPFLOW ONLY

Upflow / Horizontal Furnace Filters

The Upflow/Horizontal furnace, when installed horizontally, requires a horizontal filter kit. The filters may be

located remote to the furnace or in the return air duct near

the furnace. Check with your dealer for the location

of your filters.

An upflow/horizontal furnace in horizontal return air filter

application, as shown, features two 14" x 20" x 1" filters in

the 14-1/2" wide furnace cabinets; or two 16" x 20" x 1"

filters in the 17-1/2", 21", and 24-1/2" wide furnace cabinets.

CHAMFER

END OF

FILTER GOES

INTO FILTER

RACK FIRST

The furnace filter may be secured with filter retaining

brackets for right side return on smaller furnaces. To

replace filters on these furnaces, remove the blower

access door, push back to flex the filter and clear the

filter retaining bracket at the front of the unit. Gently

pull the filter out. After cleaning, replace the filter in

the same manner making sure that filter is secured in

place in both front and back filter retaining brackets of

the unit. Replace blower access door.

To replace filters, remove the filter access door, lift the

filter from the lower bracket and shift the filter to the side

to free the top filter from the bracket and slide the filters

out through the filter access door. After cleaning, replace

the filters in the same manner making sure that the filters

are secured in place in both top and bottom filter brackets.

UPFLOW/HORIZONTAL WITH FILTER KIT

Replace filter access door.

Air filters may also be located outside of the furnace using

a remote filter grille. The filter grille could be in a hallway,

wall, or in the ceiling. Check with your dealer for the exact

location of your filter and the method of changing the

filters.

Page 4 Pub. No. 32-5034-02

Page 17

FACTORY SUPPLIED UPFLOW FURNACE

RETURN AIR FILTERS

UPFLOW FURNACE RETURN AIR FILTERS

CABINET

WIDTH

14-1/2" 1 14" X 25" X 1" 17-1/2" X 25" X 1"

17-1/2" 1 17" X 25" X 1" 17-1/2" X 25" X 1"

21" 1 20" X 25" X 1" 17-1/2" X 25" X 1"

24-1/2" 1 24" X 25" X 1" 17-1/2" X 25" X 1"

*NOTE - On 5 or 6 ton airflow models, if the airflow

requirement exceeds 1800 CFM, these models will require

filters on

bottom.

QTY*

both

sides; OR 1 side

CABINET

BOTTOM FILTER

and

the bottom; OR just the

CABINET

SIDE FILTER

WARNING: Disconnect power to the

unit before removing the blower door. Failure to

follow this warning could result in property damage,

personal injury or death.

A downflow/horizontal furnace with horizontal return air

filter application, as shown, features two 14" x 20" x 1"

filter in the 14-1/2" wide furnace cabinets; or two 16" x 20"

x 1" filter in the 17-1/2", 21", and 24-1/2" wide furnace

cabinets.

DOWNFLOW/HORIZONTAL FILTER

DOWNFLOW FILTER TABLE

Downflow Furnace Filters

Downflow/Horizontal furnaces use 2 standard size permanent type air filters which may be located remote to the

furnace or in the return air duct. Check with your dealer

for the location of your filters.

A downflow/horizontal furnace vertical return air filter

application, as shown, features two 14" x 20" x 1" filter in

the 14-1/2" wide furnace cabinets; or two 16" x 20" x 1" filter

in the 17-1/2", 21", and 24-1/2" wide furnace cabinets.

REQUIRED FILTERS - DOWNFLOW

CABINET WIDTH FILTER QUANTITY & SIZE

14-1/2" 2 - 14" X 20" X 1"

17-1/2" 2 - 16" X 20" X 1"

21" 2 - 16" X 20" X 1"

24-1/2" 2 - 16" X 20" X 1"

DOWNFLOW FILTER

Pub. No. 32-5034-02 Page 5

Page 18

The problem solver.

A furnace is not a household appliance. It is complex and

requires professional maintenance and repair.

That’s why attempts at “do-it-yourself” repairs on an inwarranty unit may void the remainder of your warranty.

Other than performing the simple maintenance recommended in this manual, you should not attempt to make

any adjustments to your furnace. Your dealer will be able

to take care of any questions or problems you may have. A

periodic inspection of your furnace should be made by a

qualified service agency at the start of each heating season.

Keep your furnace looking like new for years.

Clean the enamel finish of your furnace with ordinary soap

and water. For stubborn grease spots, use a household

detergent. Lacquer thinner or other synthetic solvents may

damage the finish.

Save time and money. Before calling for service, check the following:

Problem Possible Trouble Possible Remedy

No Heating - Blower 1. Thermostat set incorrectly. 1. Adjust thermostat See operating

Does not operate instructions

2. Blown fuse or tripped circuit breaker. 2. Replace or reset protective device

3. Defective component. 3. Most controls are automatic and will

4. Burner does not ignite. 4. Call servicer.

5. Main gas line turned off. 5. Have gas company check.

6. Blower door removed or ajar. 6. Close door securely to restore power

7. Lockout 7. Turn power on-off-on-off twice

Insufficient Heating - 1. Dirty air filters. 1. Clean or replace filters.

Blower operates

continuously 2. Blocked supply or 2. Make sure registers are open and

return registers. No obstacles blocking off the air.

No Heat - Vent motor Restricted or plugged furnace 1. Remove drain clamps to condensate

is running condensate drain. trap and drain pan outlet

Unusual Noise Call your servicer

WARNING:

Do not touch igniter. It is extremely hot. Failure to

follow this warning could result in severe burns, other

injury, property damage, or death.

CAUTION:

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and dangerous operation.

Verify proper operation after servicing.

or call for servicer.

recycle. If your unit still does not

operate call for servicer.

to blower and gas valve.

in 30 secs.

2. Flush or clear drain blockage.

3. Reinstall clamps.

WARNING:

CARBON MONOXIDE POISONING HAZARD

Failure to follow the installation and operation instructions for the venting system's operation could result in

carbon monoxide poisoning or death.

Page 6 Pub. No. 32-5034-02

Page 19

Maintenance information.

Never stop the cooling system by shutting off the

main power.

If the main power to your air conditioner is ever disconnected for more than three hours, turn off the thermostat.

Then wait for at least three more hours after the power has

been restored before turning the thermostat back on.

Failure to follow this procedure could result in damage to

your air conditioning system.

1. GENERAL INSPECTION - Examine the furnace installation for the following items:

a. All flue product carrying areas external to the furnace (i.e. chimney, vent connector) are clear and free of

obstruction.

b. The vent connector is in place, slopes upward and is

physically sound without holes or excessive corrosion.

c. The return air duct connection(s) is physically sound,

is sealed to the furnace and terminates outside the

space containing the furnace.

d. The physical support of the furnace should be sound

without sagging, cracks, gaps, etc., around the base so

as to provide a seal between the support and the base.

e. There are no obvious signs of deterioration of the

furnace.

WARNING:

NOTE: On LP (propane) units, some light yellow tipping of

the outer mantle is normal. Inner mantle should be bright

blue.

Natural gas units should not have any yellow tipped

flames. This condition indicates that a service call is

required. For best operation, burners must be cleaned

annually using brushes and vacuum cleaner.

NOTE: On LP (propane) units, due to variations in BTU

content and altitude, servicing may be required at shorter

intervals.

Do not touch igniter. It is extremely hot. Failure to

follow this warning could result in severe burns.

2. BLOWERS - The blower size and speed determine the

air volume delivered by the furnace. The blower motor

bearings are factory lubricated and under normal operating conditions usually do not require servicing. Annual

cleaning of the blower wheel and housing is recommended

for maximum air output, and this must be performed only

by a qualified servicer or service agency.

3. IGNITER - This unit has a special hot surface direct

ignition device that automatically lights the burners. Please

note that it is very fragile and should be handled with care.

CAUTION: Do not touch igniter. It is extremely hot.

4. BURNER - Gas burners do not normally require scheduled servicing, however, accumulation of foreign material

may cause a yellowing flame or delayed ignition. Either

condition indicates that a service call is required. For best

operation, burners must be cleaned annually using brushes

and vacuum cleaner.

Turn off gas and electric power supply. To clean burners,

remove top burner bracket and lift burner from orifice.

NOTE: Be careful not to break igniter when removing burners. Clean burners with brush and/or vacuum

cleaner. Reassemble parts by reversal of the above procedure.

Pub. No. 32-5034-02 Page 7

5. HEAT EXCHANGER / FLUE PIPE - These items must

be inspected for signs of corrosion, and/or deterioration at

the beginning of each heating season by a qualified service

technician and cleaned annually for best operation.

6. CIRCUIT PROTECTION - If blower or gas valve fail to

operate, the cause could be the circuit breaker or a loose or

blown fuse. Replace fuse or reset circuit breaker.

7. OPERATION - Your warm air furnace should not be

operated in a corrosive atmosphere. Paint solvents, cleaning chemicals, spray propellants, and bleaches should not

be used in the vicinity of the furnace during normal

operation.

8. COOLING COIL CONDENSATE DRAIN - If you have

a cooling coil installed with your furnace, condensate

drains should be checked and cleaned periodically to assure that condensate can drain freely from coil to drain. If

condensate cannot drain freely water damage could occur.

9. AIR CIRCULATION - To ensure increased comfort,

blower on this unit may be operated continuously for both

heating and cooling. This will result in constantly filtered

air and aid in maintaining more even temperatures by

avoiding temperature stratification throughout the conditioned area. To accomplish constant air circulation, set

your thermostat fan switch to "ON".

Page 20

WARNING: Disconnect power to the

unit before removing the blower door. Failure to

follow this warning could result in property damage,

personal injury or death.

▲

WARNING:

ANY PART HAS BEEN UNDER WATER. IMMEDIATELY

CALL A QUALIFIED SERVICE TECHNICIAN TO

INSPECT THE FURNACE AND TO REPLACE ANY

PART OF THE CONTROL SYSTEM AND ANY GAS

CONTROL WHICH HAS BEEN UNDER WATER.

For your safety.

Furnace area must be kept clear and free of combustible

materials, gasoline, and other flammable vapors and liquids.

Air for combustion and ventilation.

The flow of combustion and ventilating air must not be

obstructed from reaching the furnace. Air openings provided in the casing of furnace must be kept free of obstructions which would restrict airflow, thereby affecting efficiency and safe operation of your furnace.

Also, air openings provided to the area in which the

furnace is installed and the space around the furnace shall

not be blocked or obstructed. Keep this in mind should you

choose to remodel the area which contains your furnace.

Furnaces must have air for proper performance.

If additional insulation is added after the furnace is installed, the area around the furnace must be inspected to

ensure it is free and clear of insulation. If this furnace is

installed in an attic or other insulated space it must be kept

free and clear of all insulating materials as some insulating materials are combustible.

DO NOT USE THIS UNIT IF

Manual Main Gas Shut-off Valve May Be

Located on the Left or Right Side

Manual Main Gas Shut-off Valve May Be Located on the Top or Bottom Side

NOTE THE LOCATION OF THE MANUAL MAIN GAS SHUTOFF VALVE FOR YOUR FUR-

NACE.

Have your installer or servicer show you the location if you have any questions.

Page 8 Pub. No. 32-5034-02

Page 21

To light furnace.

WARNING:

FIRE OR EXPLOSION HAZARD

Failure to follow the safety warnings exactly could result in

serious injury, death or property damage.

Never test for gas leaks with an open flame. Use a commercially available soap solution made specifically for the

detection of leaks to check all connections. A fire or

explosion may result causing property damage, personal

injury, or loss of life.

Lighting instructions.

Your furnace is equipped with a hot surface direct ignition

device.

WARNING.

Do not attempt to manually light the furnace.

1. Please read all safety information in this book before operating

furnace.

2. Set thermostat to lowest setting. Turn off all electric power to

furnace.

3. Remove control access panel.

4. Turn gas cock knob on main gas valve with unit clockwise to

“OFF” position. If external gas cock is used, turn to “OFF”

position. Allow 5 minutes for any gas within the unit to escape.

LP gas being heavier than air may require forced ventilation. If

you smell gas STOP! Follow the “What To Do If You Smell Gas”

instructions on the front cover of this book. If you don’t smell gas,

go to next step.

5. Turn gas cock knob counterclockwise to “ON” marker.

6. Replace control access panel.

7. Turn on main electrical supply and set thermostat to desired

setting. Combustion blower will start and ignition device will

start to heat up. After approximately 15 seconds main gas valve

will open and burners will ignite.

8. When thermostat is satisfied, main burners will extinguish.

9. If main burners fail to ignite, lower thermostat setting or

disconnect electrical supply, wait 5 minutes, raise thermostat

setting above indicated temperature.

10. If furnace will not light, turn “OFF” all gas and electricity to

unit and call servicer or gas supplier.

For complete shutdown.

Turn gas cock knob on main gas valve to “OFF” position. Disconnect electrical supply to unit.

CAUTION: If this is done during the cold weather months,

provisions must be taken to prevent freeze-up of all water pipes

and water receptacles.

Whenever your house is to be vacant, arrange to have someone

inspect your house for proper temperature. If your furnace

should fail to operate, damage could result, such as frozen water

pipes.

Safety cutoff device (thermal limit).

All models are equipped with a fusible link behind gas valve.

In case of main gas valve malfunction and consequent

overheating, link will open and close off flow of all gas. See

instruction label on front panel of heat exchanger.

Your furnace may have a "Knob Switch" or a "Toggle Switch" to turn the gas ON or OFF.

Pub. No. 32-5034-02 Page 9

Page 22

Limited Warranty

High Efficiency Induced Draft Gas Furnace

UE, DE, UD-R, DD-R, UD-RV, DD-RV,

UD-C, DD-C, CUB and CDB

Models Less Than 20 Tons for Residential Use*

(Parts Only)

This limited warranty is extended by American Standard Inc., to the original purchaser and to any succeeding

owner of the real property to which the Gas Furnace is originally affixed, and applies to products purchased and

retained for use within the U.S.A. and Canada.

If any part of your Gas Furnace fails because of a manufacturing defect within five years from the date of the

original purchase, Warrantor will furnish without charge the required replacement part. Any local transportation,

related service labor, air filters, and diagnosis calls, are not included.

In addition, if the steel heat exchanger fails because of a manufacturing defect within the sixth through twentieth

year from the date of original purchase, Warrantor will furnish without charge a replacement heat exchanger. Any

local transportation, related service labor, air filters, and diagnosis calls, are not included.

This limited warranty does not cover failure of your gas furnace if it is damaged while in your possession, failure

attributable or caused by unreasonable use of the gas furnace and/or failure to properly maintain the gas furnace

as set forth in the Use and Care manual.

This limited warranty applies to product installed on or after 10/1/2001 where product is manufactured after

1/1/2000. This limited warranty is not retroactive to any installations prior to 10/1/2001 or on product produced

prior to 2000.

THE LIMITED WARRANTY AND LIABILITY SET FORTH HEREIN ARE IN LIEU OF ALL OTHER

WARRANTIES AND LIABILITIES, WHETHER IN CONTRACT OR IN NEGLIGENCE, EXPRESS OR

IMPLIED, IN LAW OR IN FACT, INCLUDING IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR PARTICULAR USE, AND IN NO EVENT SHALL WARRANTOR BE LIABLE FOR ANY

INCIDENTAL OR CONSEQUENTIAL DAMAGES.

Some states do not allow limitations on how long an implied limited warranty lasts or do not allow the exclusion

or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

This limited warranty gives you specific legal rights, and you may also have other rights which vary from state to

state.

Parts will be provided by our factory organization through an authorized service organization in your area listed

in the yellow pages. If you wish further help or information concerning this limited warranty, contact:

American Standard Inc.

Troup Highway

Tyler, TX 75711-9010

Attention: Manager, After Sales Support

GW-615-4001

* This limited warranty is for residential usage of this equipment and not applicable when this equipment is used

for a commercial application. A commercial use is any application where the end purchaser uses the product for

other than personal, family or household purposes.

Warranty Information

It’s always a good idea to keep records which will save you time

and money. If it’s necessary to have your FURNACE repaired,

the service man will want to know if your unit is still under

Warranty. To save time, take a few minutes to record the

following information here:

Model Number:_____________________________________

Serial Number: _____________________________________

Date of Purchase:___________________________________

Service Information

Call your installing dealer if the unit is inoperative. Before

you call, always check the following to be sure service is

really required:

a. Be sure the main switch that supplies power to the unit is

in the “ON” position.

b. Replace any burned-out fuses or reset circuit breakers.

c. Be sure the thermostat is properly set.

Extended warranties are available from the manufacturer through your dealer. The limited warranty is backed by the

manufacturer and any representations made about extending the limited warranty would be backed by the manufacturer if and

only if an extended warranty agreement was received from the manufacturer.

Page 10 Pub. No. 32-5034-02

Page 23

The following warning complies with State of California law, Proposition 65.

WARNING: This product contains fiberglass wool insulation! Fiberglass dust and ceramic fibers are be-

lieved by the state of California to cause cancer through inhalation. Glasswool fibers may also cause respiratory, skin,

or eye irritation.

PRECAUTIONARY MEASURES

• Avoid breathing fiberglass dust.

• Use a NIOSH approved dust/mist respirator.

• Avoid contact with the skin or eyes. Wear long-sleeved,

loose fitting clothing, gloves, and eye protection.

• Wash clothes separately from other clothing; rinse washer

thoroughly.

• Operations such as sawing, blowing, tear-out, and spraying may generate fiber concentrations requiring additional

respiratory protection. Use the appropriate NIOSH approved respirator in these situations.

FIRST AID MEASURES

Eye Contact - Flush eyes with water to remove dust. If

symptoms persist, seek medical attention.

Skin Contact - Wash affected areas gently with soap

and warm water after handling.

Pub. No. 32-5034-02 Page 11

Page 24

American Standard Inc.

6200 Troup Highway

Tyler, TX 75711-9010

Since the manufacturer has a policy of continuous product and product data improvement, it reserves the right

to change design and specifications without notice.

Page 12 Pub. No. 32-5034-02

Loading...

Loading...