Page 1

Installation

Instructions

SERIN

BATH AND SHOWER TRIM KIT

Thank you for selecting American-Standard...the benchmark

of fine quality for over 100 years.

To ensure that your installation proceeds smoothly--please

read these instructions carefully before you begin.

™

T064.50X

To ensure that your installation proceeds smoothly-please read these

instructions carefully before you begin.

Recommened Tools

Phillips Screwdriver

Plumbers' Putty or Caulking

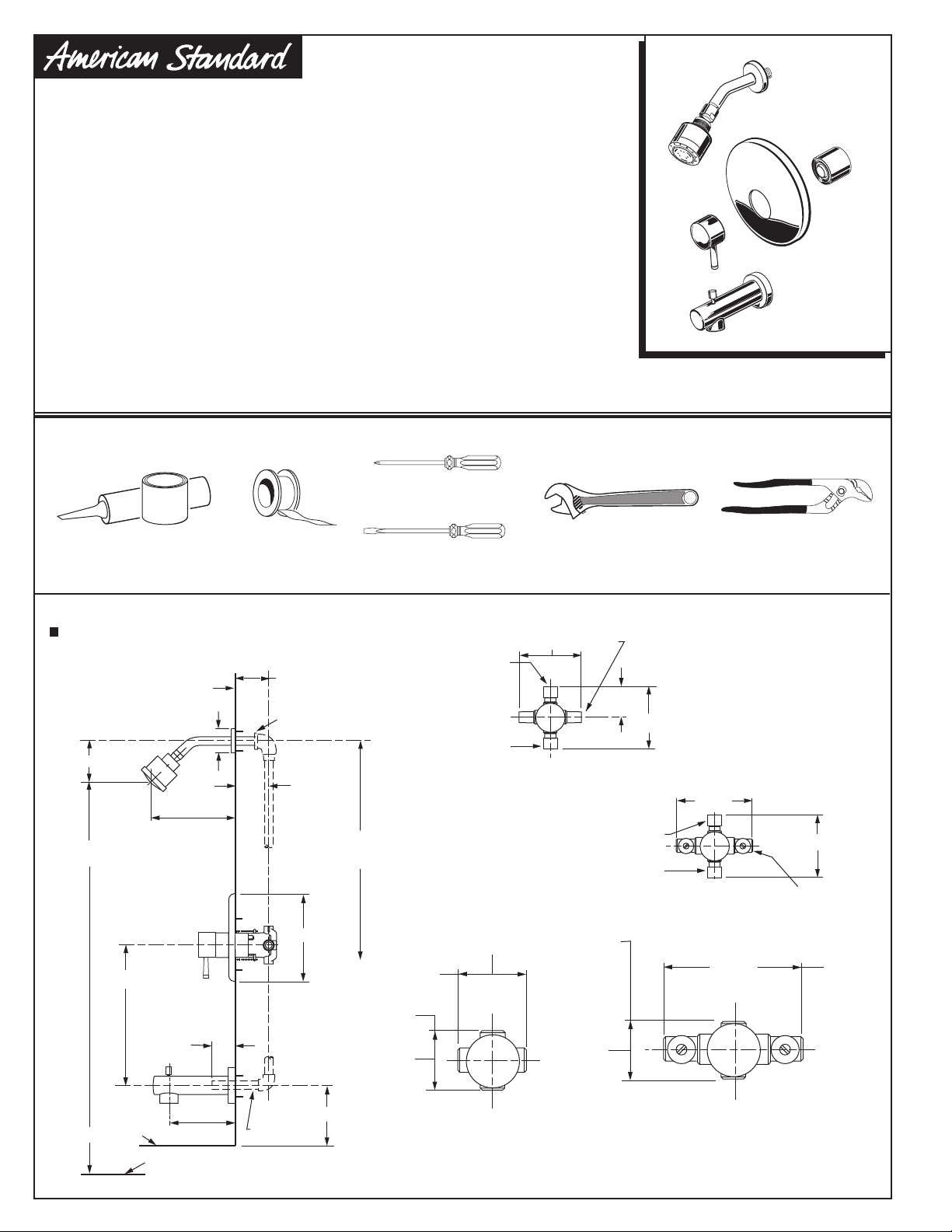

ROUGHING-IN DIMENSIONS

To assure proper positioning in relation to wall,

note roughing-in dimensions.

FINISHED WALL

5-5/8" REF.

2-3/8"

8-1/8" REF.

74" FOR HEAD

CLEARANCE

18" OPTIONAL

Teflon Tape

1-5/8" TO 3-1/4"

1/2" NPT

1-5/8"

to

3-1/4"

OPTIONAL TO FINISHED

BETWEEN 65'' AND 80''

7-1/4"

FLOOR USUALLY

Flat Blade Screwdriver

SHR. 1/2" NOM.

COPPER SWEAT

SWEAT

INLETS

TUB 1/2" NOM.

COPPER SWEAT

INLETS 1/2" NPT

3-3/8"

INLETS

4-1/16"

Adjustable Wrench

INLETS

1/2" NOM.

COPPER

SWEAT

2"

4-1/16"

SHR. 1/2" NOM.

COPPER SWEAT

TUB 1/2" NOM.

COPPER SWEAT

OUTLETS

1/2" NPT

Certified to comply with ANSI A112.18.1

M968837 Rev.1.5

Channel Locks

SWEAT

INLETS (STOPS)

5-7/8"

4-1/16"

INLETS

1/2" NOM.

COPPER

SWEAT

5-7/8"

INLETS

1/2" NPT

TOP OF TUB RIM

1 -3/4"

4-7/8" REF.

BOTTOM OF TUB

1/2" COPPER

3-3/8"

OUTLETS

1/2" NPT

4"

THREADED INLETS

3-3/8"

THREADED INLETS (STOPS)

Page 2

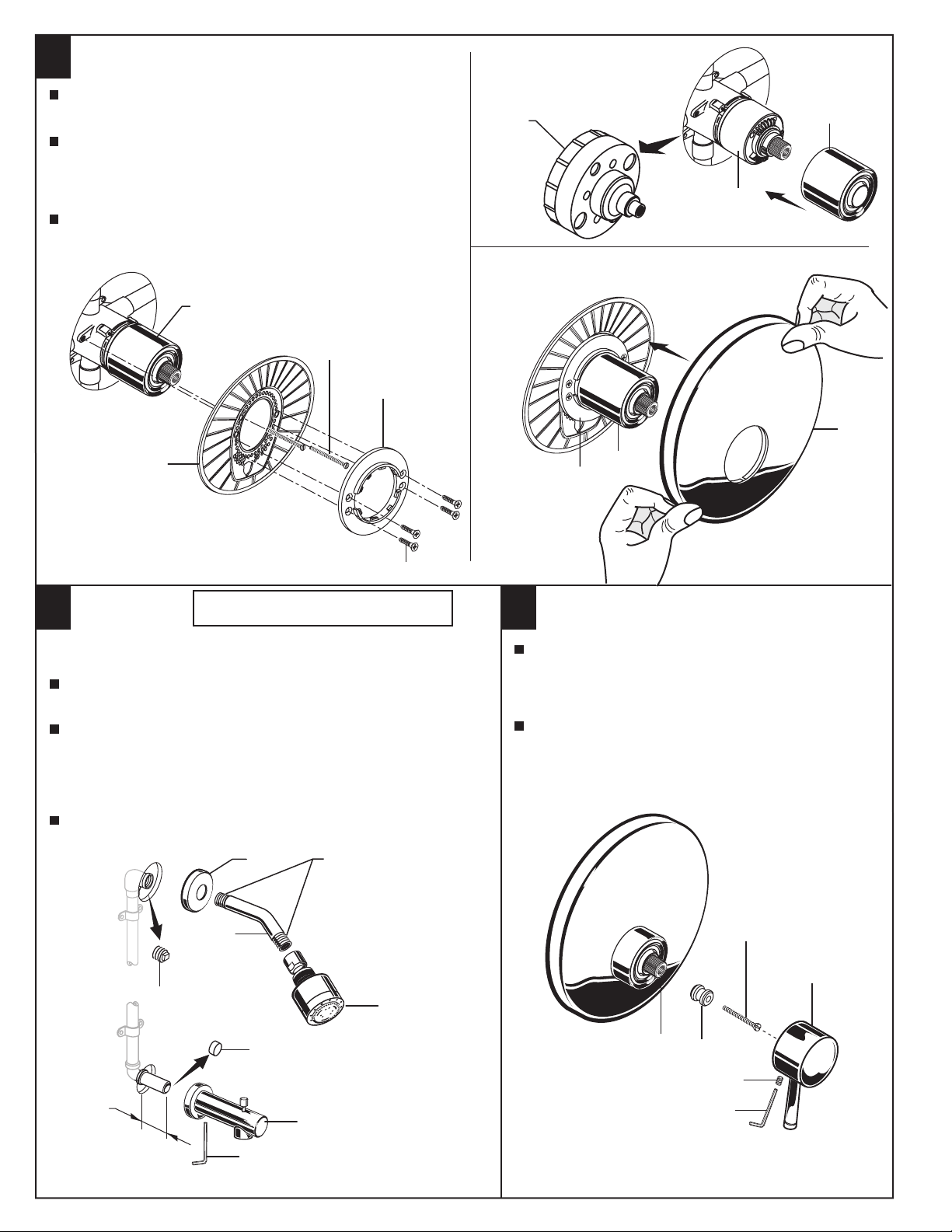

INSTALL VALVE TRIM

1

Figure 1. Remove plaster guard from valve. Push CAP (1)

over VALVE CARTRIDGE (2) until seated against stop.

Figure 2. Push ESCUTCHEON HOLDER (3) onto CAP (1)

and attach to valve body with LONG SCREWS (4). Mount

ESCUTCHEON SUPPORT (5) to ESCUTCHEON HOLDER (3)

with 4 SHORT SCREWS (6).

Figure 3. Install ESCUTCHEON (7) onto CAP (1) and push

flush against finished wall. Escutcheon (7) will snap fit onto

ESCUTCHEON SUPPORT (5).

1

4

5

PLSTER

GUARD

Figure 1.

1

2

7

3

Figure 2.

6

INSTALL TRIM

2

Note: Apply sealant or Teflon Tape to shower arm.

Remove PIPE PLUG and CAP (1, 2) from shower pipe and tub

filler pipe.

Install SHOWER ESCUTCHEON (3) onto SHOWER

ARM (4). Apply sealant or Teflon tape to threads on

both ends of SHOWER ARM (4) and thread longer

leg of SHOWER ARM (4) into shower elbow.

Thread SHOWER HEAD (5) onto SHOWER ARM (4).

Install TUB SPOUT (6). Tighten with HEX WRENCH supplied.

CAUTION: Protect finish on SHOWER

HEAD and TUB SPOUT when installing.

3

APPLY SEALANT OR

TEFLON TAPE TO THREADS

1

5

Figure 3.

INSTALL HANDLE

3

Hold ADAPTER (1) onto VALVE STEM (2) and install

ADAPTER SCREW (3) through ADAPTER (1) into

VALVE STEM (2).Tighten ADAPTER SCREW (3) to

secure ADAPTER (1) to VALVE STEM (2).

Install HANDLE BASE (4) onto ADAPTER (1). Insert

SET SCREW (5) into HANDLE BASE (4). Align

HANDLE BASE (4) and tighten with HEX WRENCH

(6) supplied.

1-3/4"

4

3

4

1

2

5

2

1

5

6

HEX WRENCH

6

M968837 Rev.1.5

Page 3

ADJUST HOT LIMIT STOP

4

By restricting HANDLE rotation and limiting the amount of hot

water allowed to mix with the cold, the HOT LIMIT SAFETY

STOP (1) reduces risk of accidental scalding. To set the maximum

2

7

9

5

1

3

1

1

3

0

1

4

5

1

3

5

1

hot water temperature of your faucet, all you need to do

is adjust the setting on the HOT LIMIT SAFETY STOP (1).

Turn CARTRIDGE STEM (2) to the OFF position (coldest setting) before

3

making adjustment to HOT LIMIT STOP (1). Use aflat blade screwdriver to pry

free the HOT LIMIT SAFETY STOP (1). Pull forward and rotate counterclockwise

one number to limit hot water temperature. Use ARROW (3) on CARTRIDGE (4)

and NUMBERS (5) on HOT LIMIT STOP (1) for indication.

TO GAIN ACCESS TO VALVE FOR SERVICING

5

Remove HANDLE (see step 3 and reverse).

Remove ESCUTCHEON and CARRIDGE CAP (see step 1 and reverse).

Shut off water supply by either closing off main water supply, or closing off

the hot and cold CHECK STOPS on valve.

1

5

1

3

1

1

9

7

5

3

1

4

COLDER

(Larger Numbers)

0 1 3 5 7 9 11 13 15

2

HOTTER

(Smaller Numbers)

0 1 3 5 7 9 11 13 15

1

5

1

3

1

1

9

7

5

3

1

5

1

VALVE LEAKS WHEN SHUT OFF

Remove CARTRIDGE (1) by removing CARTRIDGE SCREWS (2). Remove three SCREWS (3) from FIXATION RING (4) and

pull out PRESSURE BALANCING (5) unit.

Clean SEALS (9) on base of CARTRIDGE (1). Check base of PRESSURE BALANCING UNIT (5) and clean O-RINGS (6). Remove

CAPS (7) and check O-RINGS on inside of CAPS (7). Clean inside sealing surfaces of VALVE BODY (8).

Re-assemble PRESSURE BALANCING UNIT (5) and CARTRIDGE (1). Tighten all screws.

Turn on water supply and see above for installing TRIM and HANDLE.

UNABLE TO MAINTAIN CONSTANT TEMPERATURE

Remove PRESSURE BALANCE UNIT (5).

Remove CAPS (7) and clean valve thoroughly.

Examine balancing unit and check condition of O-ring on end of piston. Piston should move back and forth. Order Repair

Part M952100-0070A if balancing unit is defective.

Replace CAPS (7) and install PRESSURE BALANCE UNIT (5). Make sure inlets line up with two holes in bottom of casting.

Top flange should butt-up against top of casting.

BACK TO BACK INSTALLATION

Remove PRESSURE BALANCE UNIT (5). Rotate PRESSURE BALANCE UNIT (5) 180˚ so that the inlets face up and the

large outlet port faces down.

Push PRESSURE BALANCE UNIT (5) in casting make sure inlets line up with holes in bottom of casting. Top flange should

butt up against top of casting.

Reassemble FIXATION RING (4) and CARTRIDGE (1).

4

1

LARGE OUTLET

ROTATE 180˚

8

7

6

CARE INSTRUCTIONS:

6

5

3

9

2

5

INLETS

BACK TO BACK INSTALLATION

DO: SIMPLY RINSE THE PRODUCT CLEAN WITH CLEAR WATER. DRY WITH A SOFT COTTON FLANNEL CLOTH.

DO NOT: DO NOT CLEAN THE PRODUCT WITH SOAPS, ACID, POLISH, ABRASIVES, HARSH CLEANERS, OR A

CLOTH WITH A COARSE SURFACE.

M968837 Rev.1.5

Loading...

Loading...