Installation

Instructions

3808.101

Centerset Lavatory Faucet with

Speed Connect™ Drain

Congratulations on purchasing your American Standard

faucet with Speed Connect drain, a feature found only on

American Standard faucets.

Speed Connect™ Drain*

• Fewer parts, installs in less time

• Never needs adjustment

• Guaranteed to seal properly the first time, every time.

To ensure that your installation proceeds smoothly-please read these instructions carefully before you begin.

Recommended tools

Certified to comply with ANSI A112.18.1

51314 Rev.1.3

Adjustable Wrench Screwdriver Channel Locks

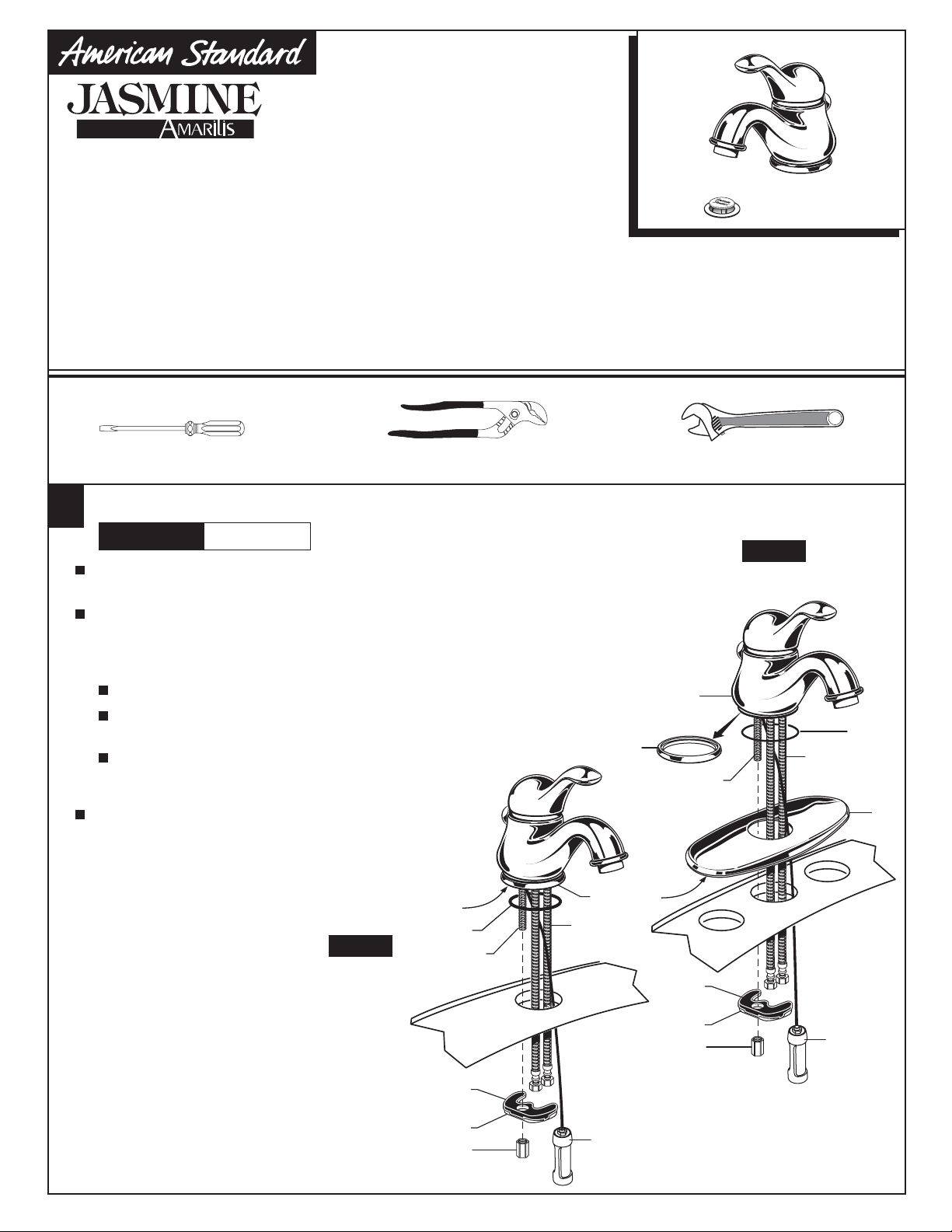

INSTALL FAUCET

1

1

CAUTION

For single hole installation. Fig. A.

Make sure that O-RING (1) is installed into base of FAUCET (2).

For installation with DECORATIVE RING (3) (single hole installation) feed faucet

SUPPLIES (4) and CABLE CONNECTOR (5) through sink or mounting surface hole.

For installation with ESCUTCHEON PLATE (6) (for 3 hole, 4" centers installation)

use the following steps:

Unscrew and remove DECORATIVE RING (3) from FAUCET BODY (2).

Apply putty to underside of ESCUTCHEON PLATE (6) and

place over mounting holes.

Feed faucet tubes through O-RING (1) supplied with

ESCUTCHEON PLATE (6) and through the hole in the

ESCUTCHEON (6) and through SINK or DECK.

From below, push GASKET (7) and RETAINER PLATE (8)

over STUD (9) and secure with NUT (10) Before final

tightening, adjust faucet so that it is centered over

mounting hole.

Turn off water at

main supply.

Fig. B.

Fig. A.

SINGLE HOLE

INSTALLATION

2

1

9

Fig. B.

INSTALLATION WITH

ESCUTCHEON PLATE

2

1

3

4

9

6

3

PUTTY

4

7

7

8

10

8

10

5

1

5

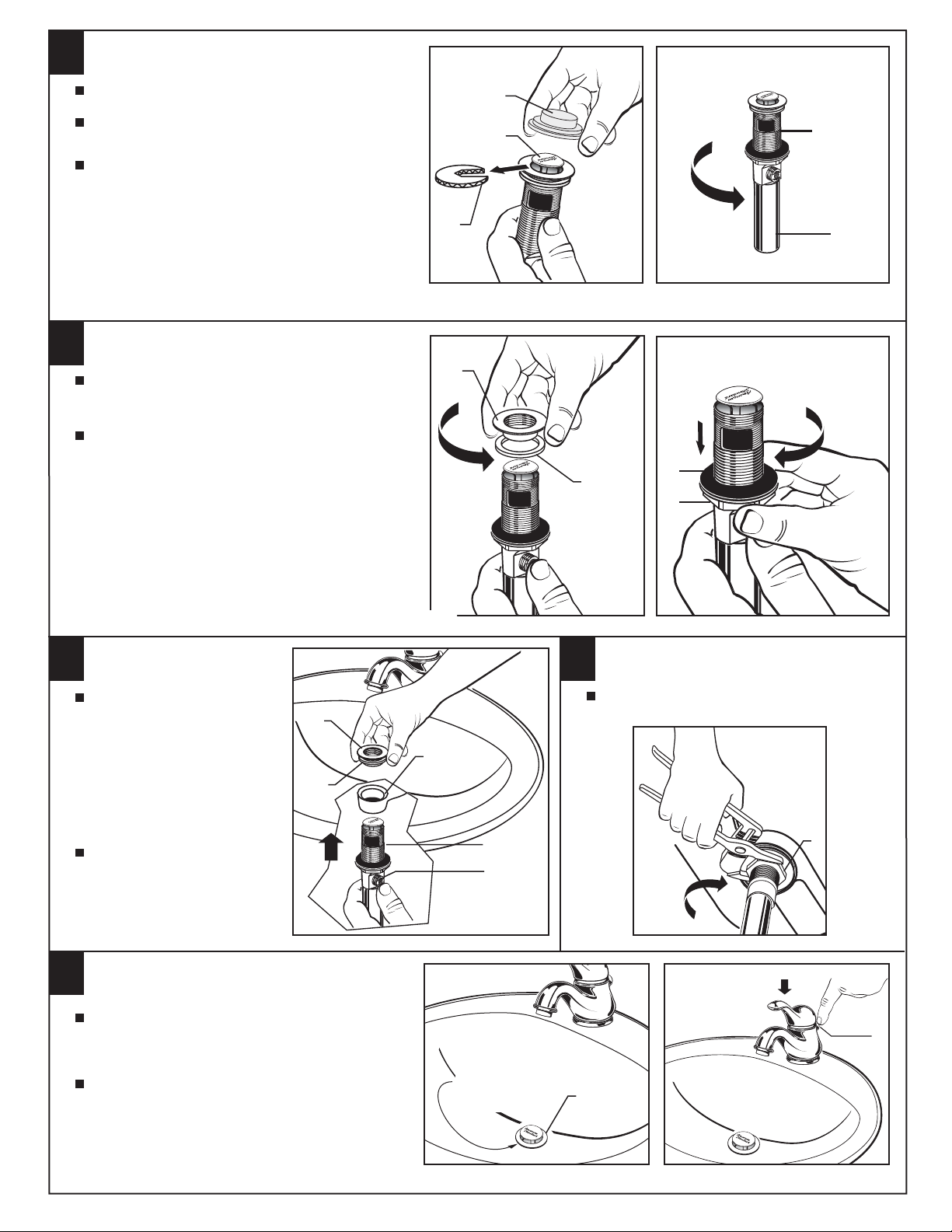

POP-UP DRAIN

2

Fig. A. Fig. B.

Remove CLEAR PLASTIC COVER (1).

Remove CARDBOARD SPACER (2) from under

DRAIN POP-UP (3).

Tighten TAILPIECE (4) on DRAIN BODY before

installing DRAIN BODY.

REMOVE FLANGE

3

Thread FLANGE (1) counter-clockwise and

remove FLANGE (1) and FOAM GASKET (2)

from drain body.

Thread LOCKNUT (3) clock-wise to bottom of

drain body. Push GASKET (4) down against

LOCKNUT (3).

Fig. B.

Fig. B.

Fig. A.

1

3

2

Fig. A. Fig. B.

1

2

4

3

DRAIN

BODY

4

INSTALL DRAIN FROM

4

BELOW FIXTURE

From under side of SINK

install DRAIN BODY (1) up

through drain outlet.

Note: No plumber’s putty

or caulk is required.

The CABLE ATTACHMENT

POINT (2) must face towards

the rear of the SINK.

Install FOAM GASKET (3)

and FLANGE (4) onto drain

body from above SINK and

tighten FLANGE (4) firmly.

FLANGE GASKET AND POP-UP KNOB

6

Check DRAIN FLANGE in SINK to ensure that

WHITE FOAM GASKET (3) is fully compressed

and not visible. Fig. A.

POP-UP KNOB (1) must be fully down. Fig. B.

4

3

TIGHTEN LOCKNUT

REAR

OF SINK

DRAIN

OUTLET

1

2

Fig. A. Fig. B.

WHITE FOAM

GASKET

NOT VISIBLE

5

Tighten LOCKNUT (1) firmly with Adjustable

Wrench or Channel Locks.

DRAIN

FLANGE

1

DOWN

1

51314 Rev.1.3

2

ATTACH CABLE CONNECTOR

2

1

7

Thread CABLE CONNECTOR (1) clockwise

onto DRAIN BODY CONNECTION (2) and

hand tighten. Fig. A.

Your new POP-UP DRAIN installation is

now complete. Fig. B.

Note: Tailpeice on pop-up drain is 1-1/4” O.D.

Fig. B.

Fig. A.

Fig. B.

1

CHECK OPERATION OF POP-UP

8

Operate LIFT KNOB (1) to verify that STOPPER (2) opens and

closes.

Note: If STOPPER (2) does not open and close properly then

refer to the “troubleshooting section” of these instructions.

MAKE WATER SUPPLY AND WASTE CONNECTIONS

9

Connect FLEXIBLE SUPPLIES (1, 2) directly to wall supplies.

Connection on fitting supplies are 3/8" compression. Connect

left SUPPLY (1) to Hot (Marked with a Red Band) and right supply

to COLD (2) wall supply.

2

1-1/4” O.D.

Faucet supplies are 20" long from faucet base.

Note: If additional supply length is required, installer must

purchase additional parts separately.

Important: If SUPPLY HOSES (1, 2) are to long, loop as

illustrated to avoid kinking.

Connect 1-1/4” O.D. tailpiece on POP-UP DRAIN to

waste outlet.

APPROX. 20"

3

2

1

RED

BAND

HOT

BLUE

BAND

3/8" COMPRESSION

COLD

51314 Rev.1.3

10

TEST INSTALLED FITTING

11

With HANDLE (1) in OFF position, turn on WATER

SUPPLIES (2) and check all connections for leaks.

Remove AERATOR (3).

Operate HANDLE (1) to flush water lines thoroughly.

Replace AERATOR (3).

CHECK DRAIN CONNECTIONS

Operate POP-UP KNOB (4) and fill lavatory with water.

Check that DRAIN STOPPER (5) makes a good seal

and retains water in SINK. If DRAIN STOPPER (5)

does not seal properly, please refer to Troubleshooting

section in these instructions.

Release POP-UP KNOB (4) down and check all drain

connections and "P" trap for leaks. Tighten

if necessary.

SERVICE

4

1

3

5

WASTE

OUTLET

2

2

“P” TRAP

IF FAUCET DRIPS

If faucet drips, operate handle several times from

"off" to "on". Do not apply excessive force.

Clogged CARTRIDGE (5) inlets may cause reduced

flow in "full on" hot or cold. To clean inlets, first

turn off water supply, then:

Remove HANDLE (1), CAP (2) CARTRIDGE

SCREWS (3) RETAINER (4) and CARTRIDGE (5).

Clean inlets on CARTRIDGE (5).

Reassemble CARTRIDGE (5), RETAINER (4)

alternately tightening SCREWS (3), CAP (2)

and HANDLE (1). Check flow.

3

4

5

HOT LIMIT SAFETY STOP

By restricting handle rotation and limiting the amount of hot

water allowed to mix with the cold, the HOT LIMIT SAFETY

STOP reduces risk of accidental scalding. To set the maximum

hot water temperature of your faucets, all you need

to do is adjust the setting on the HOT LIMIT SAFETY STOP.

Remove necessary trim parts. Use a flat blade screwdriver or

pull forward with your fingers to rotate red HOT LIMIT SAFETY

STOP. Follow Step "A" or "B" to adjust max./min. discharge

temperature. "0" being the hottest to "7" the coldest

temperature setting.

"A"

ADJUSTMENT WHEN

POINTER ON

HOT LIMIT STOP

"B"

ADJUSTMENT WHEN

WATER IS TOO COLD

1

PRY RED RING FORWARD

AND ROTATE CLOCKWISE

"B"

WATER IS TOO HOT

0

1

2

3

4

5

PRY RED RING FORWARD

AND ROTATE COUNTER-

CLOCKWISE ONE CLICK

2

"A"

RED RING HOT

LIMIT SAFETY

STOP

12

CARE INSTRUCTIONS:

DO: SIMPLY RINSE THE PRODUCT CLEAN WITH CLEAR WATER. DRY WITH A SOFT COTTON FLANNEL CLOTH.

DO NOT: DO NOT CLEAN THE PRODUCT WITH SOAPS, ACID, POLISH, ABRASIVES, HARSH CLEANERS, OR A

CLOTH WITH A COARSE SURFACE.

51314 Rev.1.3

4

Loading...

Loading...