American Standard 2862.016, 2862.056, 2862.128, 2862.058 Installation Manual

INSTALLATION INSTRUCTIONS

FAIRFIELD

1.6 GPF ONE-PIECE TOILET, MODELS 2862.016 AND 2862.056

1.28 GPF ONE-PIECE TOILET, MODELS 2862.128 AND 2862.058

Thank you for selecting American Standard – the benchmark of fine quality for over 100 years. To ensure this product is installed properly,

please read these instructions carefully before you begin. (Certain installations may require professional help.) Also be sure your

installation conforms to local codes.

CAUTION: PRODUCT IS FRAGILE. TO AVOID BREAKAGE AND POSSIBLE INJURY HANDLE WITH CARE!

!

NOTE: Pictures may not exactly define contour of china and components.

RECOMMENDED TOOLS AND MATERIALS

Putty Knife Regular Screwdriver Adjustable Wrench Sealant Tape Measure

Hacksaw Wax Ring/Gasket Flexible Supply Tube Closet Bolts Carpenters Level

1 REMOVE OLD TOILET

a. Close toilet supply valve and flush tank completely. Towel or sponge remaining water from tank and bowl.

b. Disconnect and remove supply line. NOTE: If replacing valve, first shut off main water supply!

c. Remove old mounting hardware, remove toilet and plug floor waste opening to prevent escaping sewer gases.

d. Remove closet bolts from flange and clean away old wax, putty, etc. from base area.

NOTE: Mounting surface must be clean and level before new toilet is installed!

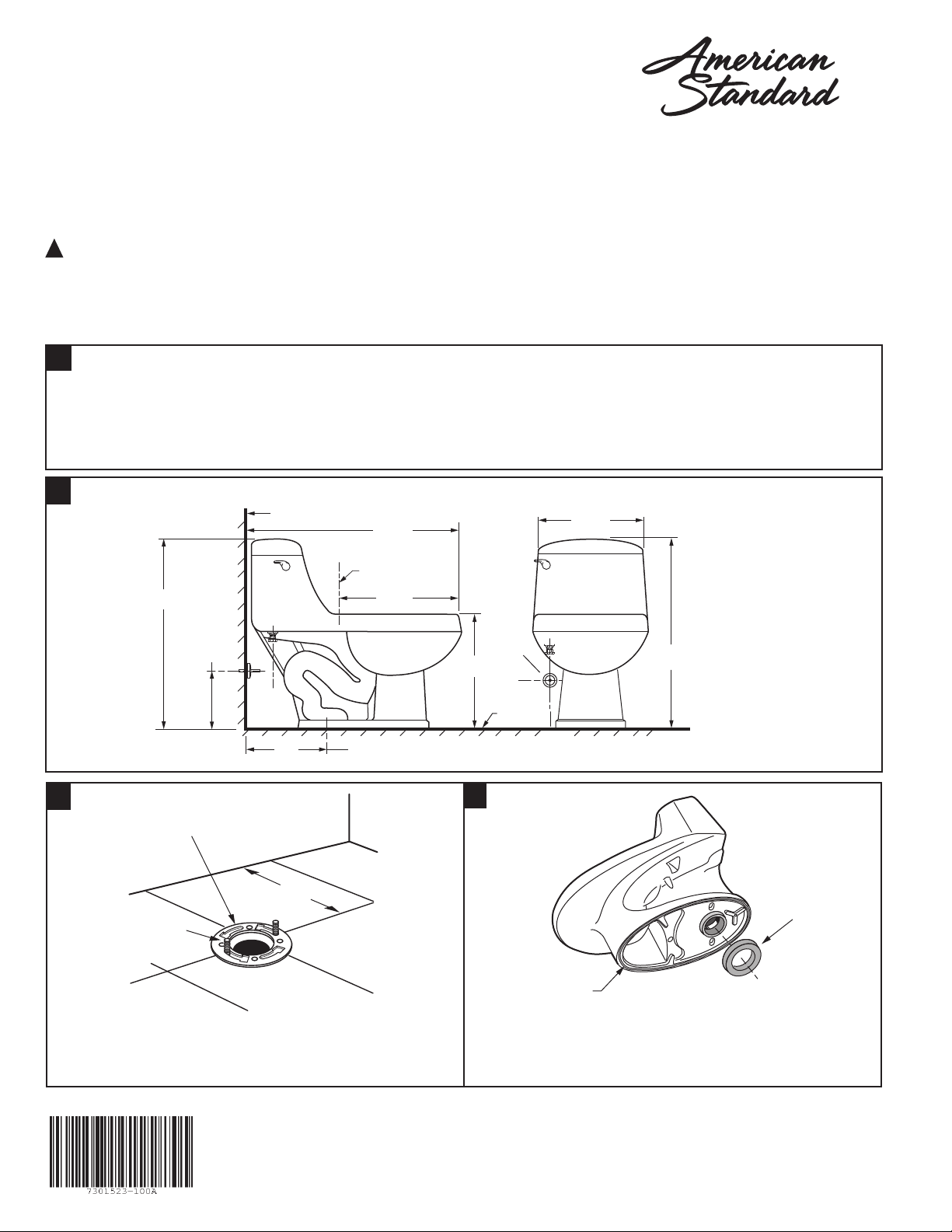

ROUGHING-IN DIMENSIONS NOTE: Distance from wall to closet flange centerline must be as listed below:

2

26-1/4"

(667mm)

FINISHED WALL

29-1/4"

(743mm)

C/L OF SEAT

POST HOLES

140mm (5-1/2)

CENTERS

18-3/4"

(476mm)

16-1/8"

(410mm)

I.P.S.

SUPPLY

12"

(305mm)

3

CLOSET FLANGE

A

CLOSET BOLTS

INSTALL CLOSET BOLTS

Install closet bolts in flange channel, turn 90°, and slide

into place 6" (152 mm) apart and parallel to wall.

C/L OUTLET

SUPPLY

AS

16"

(406mm)

REQ'D

FINISHED

FLOOR

26-3/16"

(665mm)

4

SEALANT

INSTALL WAX SEAL

Invert toilet on floor (cushion to prevent damage), and install wax

ring evenly around waste flange (horn), with tapered end of ring

facing toilet. Apply a thin bead of sealant around toilet base.

SAVE FOR FUTURE USE

WAX RING

Product names listed herein are trademarks of AS America, Inc.

© AS America, Inc. 2013

7301523-100 Rev. A

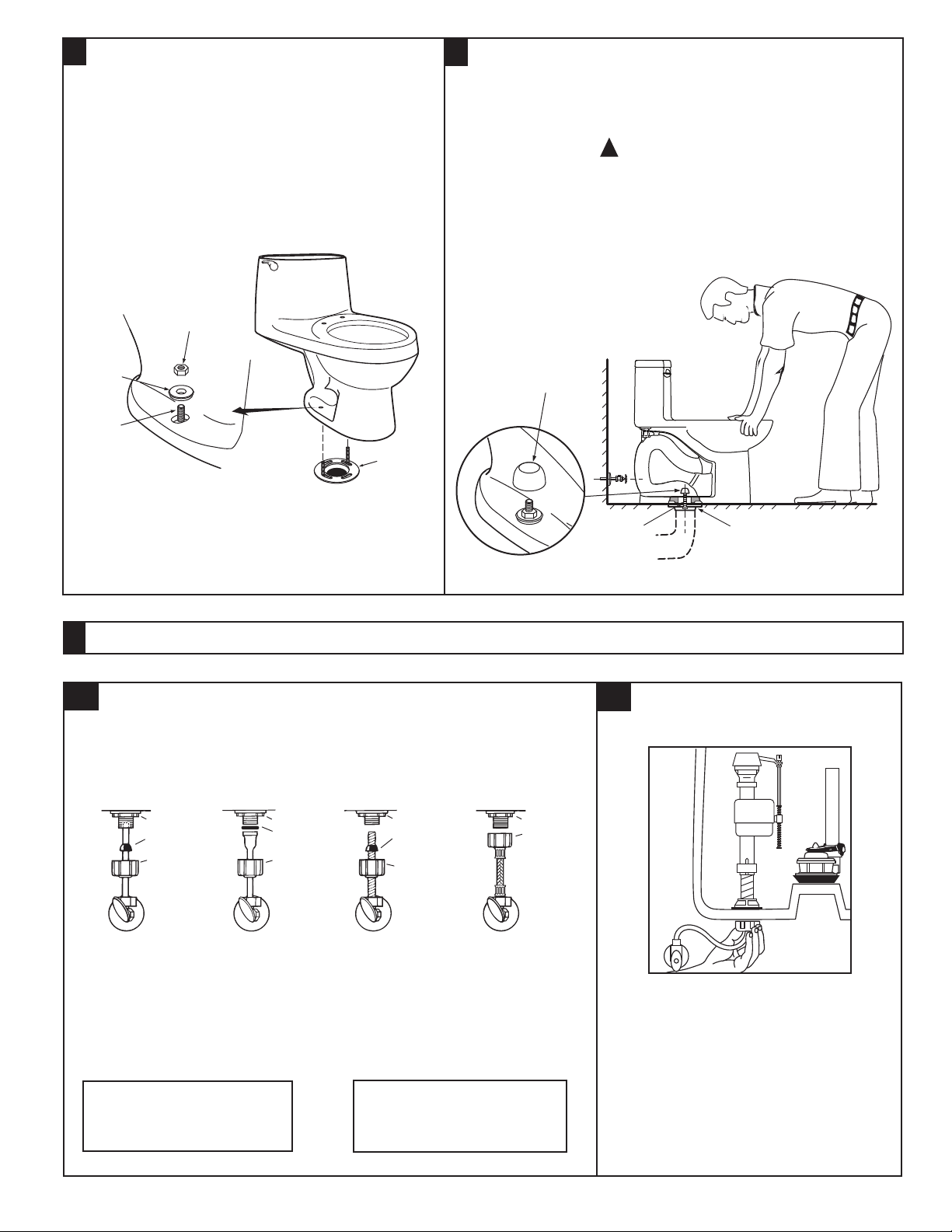

5

POSITION TOILET ON FLANGE

a. Unplug floor waste opening and install toilet on closet

flange so bolts project through mounting holes.

b. Loosely install retainer washers and nuts. Side of

washers marked "THIS SIDE UP" must face up!

NUT

INSTALL TOILET

6

a. Position toilet squarely to wall and, with a rocking

motion, press bowl down fully on wax ring and flange.

Alternately tighten nuts until toilet is firmly seated on floor.

!

CAUTION:

DO NOT OVERTIGHTEN NUTS

OR BASE MAY BE DAMAGED!

b. Install caps on washers. (If necessary, cut bolt height to

size before installing caps.)

c. Smooth off the bead of sealant around base. Remove

excess sealant.

WASHER

BOLT

INSTALL TOILET SEAT Install toilet seat in accordance with manufacturer's directions.

7

T

H

P

I

S

U

S

E

I

D

FLANGE

8a

Before continuing, determine the type of water supply connection you have from

the chart below and use the appropriate assembly parts required to properly

reconnect the water supply. DO NOT use plumber's putty to seal these fittings.

METAL/COPPER

FLARED TUBING

CONE

WASHER

COUPLING

NUT

WATER

SHUT-OFF

METAL FLANGED

TUBING

EXISTING

WASHER

EXISTING

COUPLING

NUT

WATER

SHUT-OFF

METAL SPIRAL

TUBING

WATER

SHUT-OFF

EXISTING

CONE

WASHER

COUPLING

NUT

VINYL/BRAIDED

CONNECTOR

BOLT CAP

LOCK NUTLOCK NUT LOCK NUT LOCK NUT

COUPLING

NUT

WATER

SHUT-OFF

BOLTS

8b

CLOSET FLANGE

These parts must be used as

illustrated to insure water-tight

connection. Use of existing

coupling nut may result in

water leakage. Water supply

tube or pipe must extend at

least 1/2" inside threaded

shank of valve (does not apply

to flanged tubing).

Use existing

coupling nut

and washer.

CAUTION: DO NOT USE

CONE WASHER WITH

PLASTIC SUPPLY LINE.

Use existing spiral

cone washer.

Fluidmaster cone

washer may not

seal completely on

spiral type supply

line.

Captive cone

washers already

included. No

additional washers

needed.

CAUTION: Overtightening of

LOCK NUT or COUPLING NUT

could result in breakage and

potential flooding.

- 2 -

With correct washers in place

(see Step 8a), tighten COUPLING

NUT 1/4 turn beyond hand tight.

DO NOT OVERTIGHTEN.

7301523-100 Rev. A

Loading...

Loading...