American Metal Ware 74110E, 7000, 8000, 9000 User Manual

1204 Form # AM-301-03

Part # 090-082

American Metal Ware®Midline & Space Saver Urns

Operation and Instruction Manual

For

7000, 8000, 9000

and Chinese Tea Urn Series

American Metal Ware Midline and Space

Saver Models: 7000, 8000, 9000, and

Chinese Tea Urn Series.

•

•

•

•

Your model number is found on the nameplate of the urn below the

controls.

Electric heated models have suffix (E).

Steam heated models have suffix (S).

Heat exchange urns start in 74, 80, 81, 84,

91 or 99, all without suffix (P).

Pump models begin in 72, 73, 77, 82, 83,

87, 93, CH, or Models 81 and/or 91 with the

second suffix (P).

© Grindmaster Corporation™, 1996

PRINTED IN USA

Grindmaster Corporation™

4003 Collins Lane

Louisville, Kentucky 40245 USA

(502) 425-4776

(800) 695-4500 (USA and Canada only)

(800) 568-5715 (technical service only)

FAX: (502) 425-4664

www.grindmaster.com

TABLE OF CONTENTS

Installation........................................................................................................2-3

Operation and Start-up........................................................................................4

How to Brew........................................................................................................5

Urn Adjustments...............................................................................................5-6

Care and Cleaning..............................................................................................7

Liquid Level Control System................................................................................8

Service

Access Controls.................................................................................9

Drain Tank.........................................................................................10

Remove Liner....................................................................................10

Replace Liner....................................................................................10

Replace Heater.................................................................................11

Replace Thermostat..........................................................................11

Convert Between Single/3 PH...........................................................11

Replace Sprayover Pump.................................................................11

Troubleshooting...........................................................................................12-15

Parts Illustrations

High Volume Urns.............................................................................16

7700 Series Urns..............................................................................17

7400 Series Urns..............................................................................18

8000 Series Urns..............................................................................19

Rough in Specifications

High Speed Brew Urns (090-999).....................................................20

Sgl. 7700, 7400 or Chinese Tea Urn Series (A-1184)........................21

Twin 7700, 7400 or Chinese Tea Urn Series (A-890)........................22

Twin 1.5 Gallon Urn (090-749)..........................................................23

8000 Single Space Saver Urn (090-305)...........................................24

8000 Twin Space Saver Urn (090.779)..............................................25

8000 Triple Space Saver Urn (091-780)............................................26

Wiring Diagrams

All series urns with Air Agitation (091-537)........................................27

All series urns with low temp no brew (091-538)...............................28

All series urns with no air agitation (091-541)....................................29

Diagram for optional seven day timer (A-987)...................................30

Diagram for optional high speed fill jug (A-1001)...............................31

208V 240V 2 or 3 heating element wiring, all urns (091-227) .........32

380V-480V 3PH, 3 element wiring, all urns (091-027).......................33

Prior authorization must be obtained

from Grindmaster Corporation for all

warranty claims.

Installation

WARNING! ELECTRIC SHOCK HAZARD!

INSTALLATION OF THIS APPLIANCE SHOULD BE PERFORMED BY QUALIFIED

SERVICE PERSONNEL ONLY. IMPROPER INSTALLATION COULD CAUSE

ELECTRIC SHOCK.

See the rough-in drawings for this model for dimensions and locations of electric, steam, and water input.

Positioning

1) Position urn so that the faucets drip into a drip trough or drain receptacle of some type.

2) Level urn both front to back and left to right. The feet are adjustable for this purpose.

IMPORTANT:

THE PERSON INSTALLING THIS COFFEE URN IS RESPONSIBLE FOR ENSURING

THAT THE ELECTRIC AND WATER CONNECTIONS MEET THE REQUIREMENTS OF

THE NATIONAL ELECTRIC CODE, THE NATIONAL PLUMBING CODE, AND ANY

LOCAL ORDINANCES.

DO NOT RUN TUBING, PIPES, CONDUIT OR CABLE UNDER CENTER PORTION OF

SPACE SAVER URN. THIS AREA MUST BE KEPT CLEAR FOR SERVICING URN

CONTROLS.

Water

1) Cold or hot water (160 degrees F. maximum) may be used. Heat input capacity is ample

for the coldest water, and cold water should be used for best brewing results.

2) Provide shut-off valve and union in supply line near urn.

3) Minimum operating pressure at urn should be 30 PSI.

4) Maximum pressure recommended at urn is 70 PSI.

5) Copper tubing should be used for flexibility.

6) To insure pressure at the urn of at least 30 PSI, use 3/8" OD tubing for short runs, 1/2" OD tubing for

longer runs, and larger size tubing for unusually long runs. Be sure other appliances will not reduce

water pressure excessively.

7) Turn on the water supply line and check for leaks.

American Metal Ware Midline & Space Saver Urns Page 2

Page 3 American Metal Ware Midline & Space Saver Urns

Heat Input

Electric Heated Urns, Models with suffix (E):

1) Check rating marking on urn nameplate to be sure electric lines match voltage, phase, and amperage

requirements of urn. Select the proper cord and cord grip for electrical rating of the urn. The cord must

be an oil resistant type such as SO, SOO, STO, STOO, SEO, SJO, SJOO, SJTO, SJTOO, SJEO, HSO,

HSOO, HSJO, or HSJOO. Alternatively, flexible metal conduit and type THHN wires may be used.

2) The terminal block and ground screw are located behind a cover plate on the front, right side of the urn,

or inside the control box mounted on right hand side of mid line equipment.

3) A neutral wire is normally required on all single phase and on 208 Volt, 3 phase power supplies to

operate 120 VAC control circuit. In the case of single phase, 2 wire service (no neutral), or 3 phase

3 wire service (no neutral), a separate 120 VAC cord and plug (NEMA 5-15P) supplies 120 VAC power

to the control circuit (or for use of transformer on heat exchange urns). This cord must be ordered

separately.

WARNING:

NEVER USE THE GROUND CONDUCTOR AS A NEUTRAL. THIS COULD CAUSE

ELECTROCUTION.

4) A fused disconnect switch should be installed near urn.

5) Urn body MUST be grounded. A grounding terminal is provided for this purpose.

7) Use only copper wire to connect this urn.

Steam Heated Urns, Models with suffix (S):

1) Steam supply line should have a shut-off valve ahead of the urn. (A strainer and control valve are

located in the urn's control compartment.)

2) Steam return lines should be connected to a high-quality steam trap. Also, we recommend including a

bypass and test valve to check trap operation while in service.

3) Use unions and/or copper tubing on both the supply and return connections to avoid strain on the urn.

4) A cord and plug (NEMA-5-15P), are attached for electrical control power. Plug cord into a nearby 115

volt, 15 amp, grounded wall outlet, only after the water line is turned on.

American Metal Ware Midline & Space Saver Urns Page 4

Operation and Start-Up

1) Open water supply line valve to urn.

2) Turn on or plug in the power supply to the urn. Water compartment will begin to fill automatically.

Do not power up the urn when the water line is off.

3) Pump urns have a fast fill feature. Pump urns have model numbers beginning in 72, 73, 77, 82, 83, 87,

93, and CH with any suffix, or may be any model with second suffix (P). To fill the urn in only ten

minutes on these models:

a) Disconnect power to the urn.

b) Remove the control drawer in the center, underneath the urn. On triple urns, remove the left

drawer. On Midline and Chinese Tea Urns, remove the cover on the side of the control box.

Leave the drawer sitting under the urn, making certain no uninsulated live parts are touching

the urn body.

c) Locate the FAST FILL VALVE which is a labeled screw type valve on the water inlet

assembly - left side facing the urn.

d) Open the valve completely.

e) Leave the control drawer disconnected and restore power. The urn should fill in about ten

minutes.

f) Disconnect power.

g) Close the valve until it is snug. There is no need to tighten.

h) Reattach the control drawer to the urn. Restore power.

4) Turn the thermostat knob in front of housing to BREW position. Pilot light on top of thermostat bezel will

illuminate. Water in urn will heat up, and thermometer pointer will rise to high end of BREW zone on

thermometer dial. It will take approximately 45 minutes to heat water, depending on inlet water

temperature, and urn heater wattage. Pilot light on top of thermostat bezel will go out when water in urn

is at brew temperature.

5) Brew and discard at least one batch of water into each liner. Check that the level is

correct. See the adjustments section if changes are needed.

Page 5 American Metal Ware Midline & Space Saver Urns

How to Brew in an Automatic Urn

1) Place filter paper in brew basket with designated amount of coffee grounds. Coffee experts recommend

from 6.4 to 8 ounces of coffee per gallon of water. Make certain you have a level bed of coffee.

Consult your coffee supplier for exact brewing specifications. Filter paper sizes are:

Liner size

Filter size American Part #

1.5 gallon 13 x 5 BB1.5WP

3 gallon 18 x 6 BB3WP

6 gallon 21 x 9 BB6WP

10 gallon 25 x 11 BB810WP

2) Replace cover. Lift and rotate the spray arm to position the nozzle in the hole on the basket cover.

3) Set the batch size toggle for a full or half batch. Press the start button on timer.

4) The brew cycle takes from 2 to 15 minutes depending on the size of the urn. When the brew is finished,

allow one to two minutes for the coffee to drip from the basket.

5) When the drip period is complete, center the spray arm and remove the basket to throw away the

grounds. Replace the liner cover to keep the coffee hot.

6) Coffee is ready to serve.

7) Hold brewed coffee at 185 to 190 degrees F by turning to the HOLD setting on thermostat knob.

Urn Adjustments

Brew Volume: Sprayover Time and Rate

Timer and sprayover rate are factory set. If other volumes of water or a faster or slower sprayover rate is

desired, see following instructions:

Urn should be up to temperature before making adjustments of the brew system.

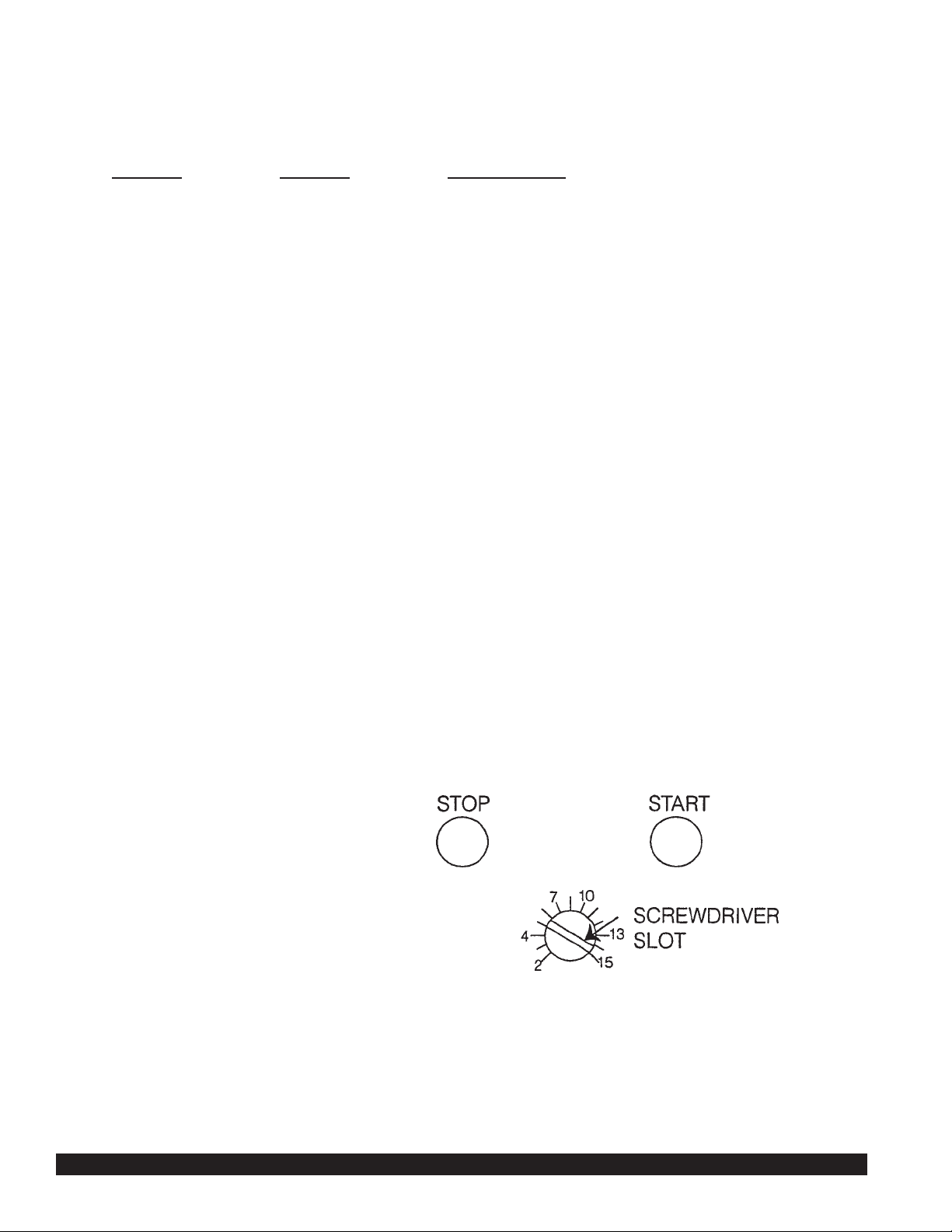

Timer Adjustment

The brew timer's full batch may be adjusted.

The adjustment screw is located behind the

plug under the start and stop buttons. See

the figure at right. Since the sprayover rate

is constant, the length of brew time sets the

brew volume. The half batch is exactly 1/2

of the full batch.

American Metal Ware Midline & Space Saver Urns Page 6

Urn Adjustments (con't.)

Sprayover Rate Adjustment

Pump Urns: models starting in 72, 73, 77, 82, 83, 87, 93, CH, or suffix (P).

A fixed orifice is located in top of spray arm swivel post. The only way to adjust the rate of flow from the spray arm is

to drill a larger hole for more sprayover water or replace the existing orifice with a smaller hole size for less

sprayover water.

Heat Exchange Urns: models beginning in 74, 80, 81, 84, 91, 99, without suffix (P).

Heat exchange urns have a regulator which adjusts the sprayover rate. The adjustment screw is located under urn in

the back of the control drawer on the left side, or inside the control box on the Midline Urns. Loosen, CCW, the screw

to decrease flow and tighten, CW, the screw to increase the flow. The spray pattern should touch the weld line near

the top of the liner.

To set the sprayover rate, follow these steps:

1) Divide the desired brew size by the desired brew time. This is your sprayover rate in

gallons per minute.

2) Operate the brew timer for one minute and measure the amount of water. If the volume is higher than your

sprayover rate from step 1, decrease the flow. Increase the flow if the volume is too low.

3) Continue the adjustment until the desired rate is achieved.

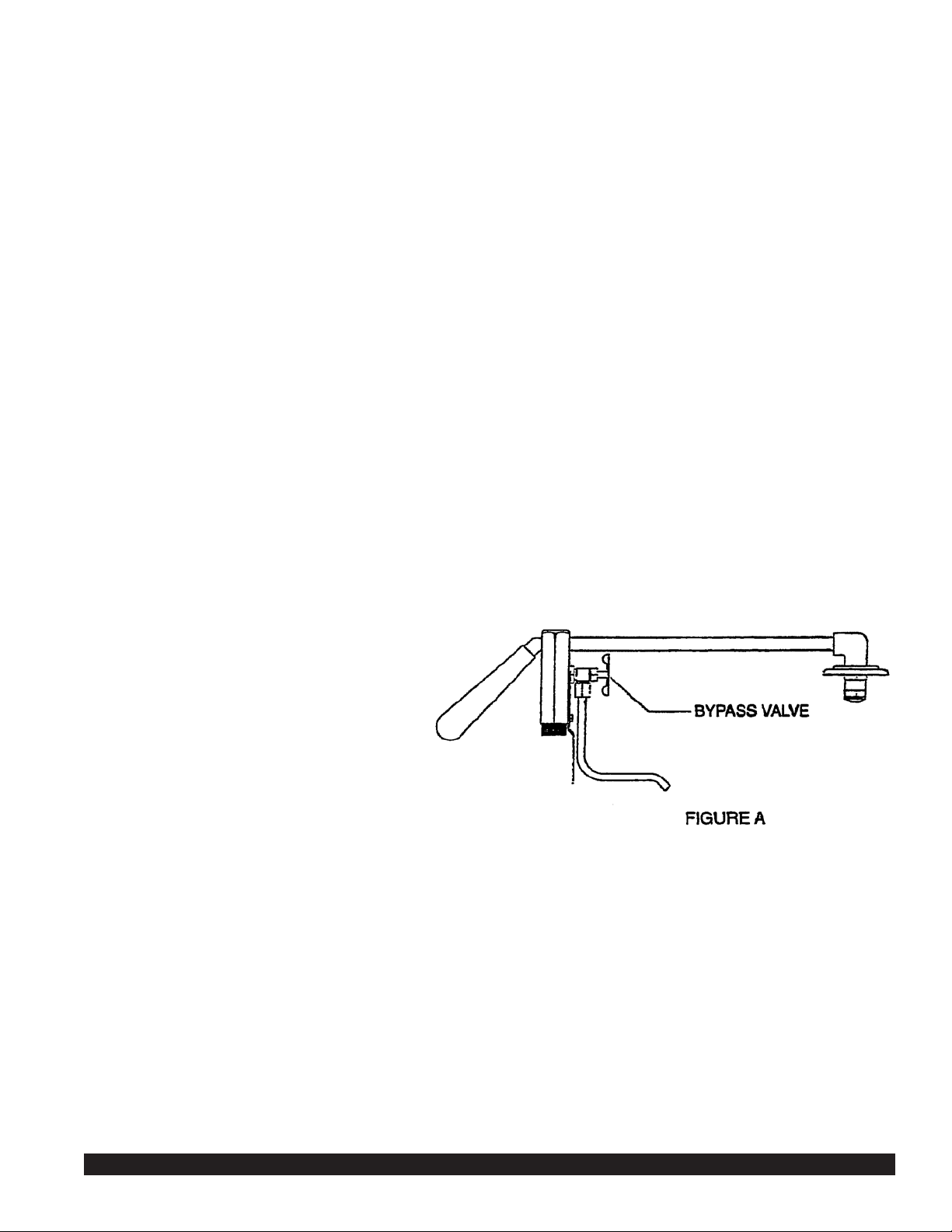

Bypass Adjustment (Refer to Figure A)

The bypass adjustment controls the

amount of water which bypasses the

coffee during the brew. This water

dilutes the final brew. If bypass is

desired, open red handle on bypass

valve. This opening will bypass up

to about 40% of total sprayover water.

Each complete turn is approximately

equal to 5% bypass.

Thermostat Adjustment

The thermostat is factory set so that the maximum temperature is about 204 degrees F in heat exchange urns and

195 degrees F in pump urns. This is the high end of brew range on the thermometer and corresponds to the BREW

position on the thermostat. The HOLD position is the low end of the brew range on the thermometer, or

185 degrees F.

Water should never boil in the urn. If you need to adjust the maximum setting of the thermostat, do the following:

1) Remove the thermostat knob.

2) Insert small screwdriver into the center of the shaft. Turn the screw slightly clockwise to decrease the

temperature.

3) Check the setting by adding cold water to make sure the temperature reaches the high end of the

BREW range.

Page 7 American Metal Ware Midline & Space Saver Urns

Care and Cleaning of Coffee Urns

WARNING: THE URN SURFACES AND WATER INSIDE ARE VERY HOT. USE CAUTION

WHEN CLEANING THIS URN.

NEVER USE CHLORINE BASED CLEANERS SUCH AS BLEACH TO CLEAN STAINLESS

STEEL. DO NOT USE SCOURING CLEANERS ON THE URN'S SURFACES.

After Each Brew

1) Discard grounds and rinse brew basket.

Every Day

1) Clean liners by rinsing and scrubbing with large, plastic bristle brush.

2) Wipe outside surfaces of the urn with a damp cloth.

3) Clean the brew basket. Remove wire basket insert if needed.

4) Wipe clean the liner covers.

5) Fill the liners with about one gallon of water to prevent coffee oil burn-in.

Weekly or Bi-Weekly Depending on Use

1) Fill the urn liners with about one gallon of hot water. Leave the thermostat on BREW.

2) Pour into the liner the recommended concentration of urn cleaner. Excessive amounts of cleaner will

attack the stainless steel.

Urn cleaners which have been used successfully:

DIP-IT manufactured by Economics Laboratories, Inc.

4 Corporate Park Drive, White Plains, NY 10604

OXYLITE manufactured by Avril, Inc., Syndet Division

601 N. Third Street, Reading, PA 19601

3) Scrub the liner interior with a large plastic bristle brush. Drain the liner.

4) Clean the gauge glasses with a long narrow brush. Rinse.

5) With the liners empty, remove the coffee faucets by unscrewing the large plastic wing-nuts

which fasten the faucets. Scrub from the opening into the center of the urn with a long brush.

WARNING: THE HOT WATER FAUCET SHOULD NOT BE REMOVED FOR CLEANING.

HOT WATER WILL EMPTY FROM JACKET, CAUSING BURNS. TO CLEAN WATER

GAUGE, CLOSE SHUT-OFF VALVE AT BASE OF GAUGE ASSEMBLY.

6) Unscrew the top of the faucet from its body. Scrub faucet body. Clean the silicone seat cup with a soft cloth

and soapy water.

7) Reassemble faucets. Fill the liners with hot water and drain until the liner and all parts are completely

rinsed.

American Metal Ware Midline & Space Saver Urns Page 8

Liquid Level Control System

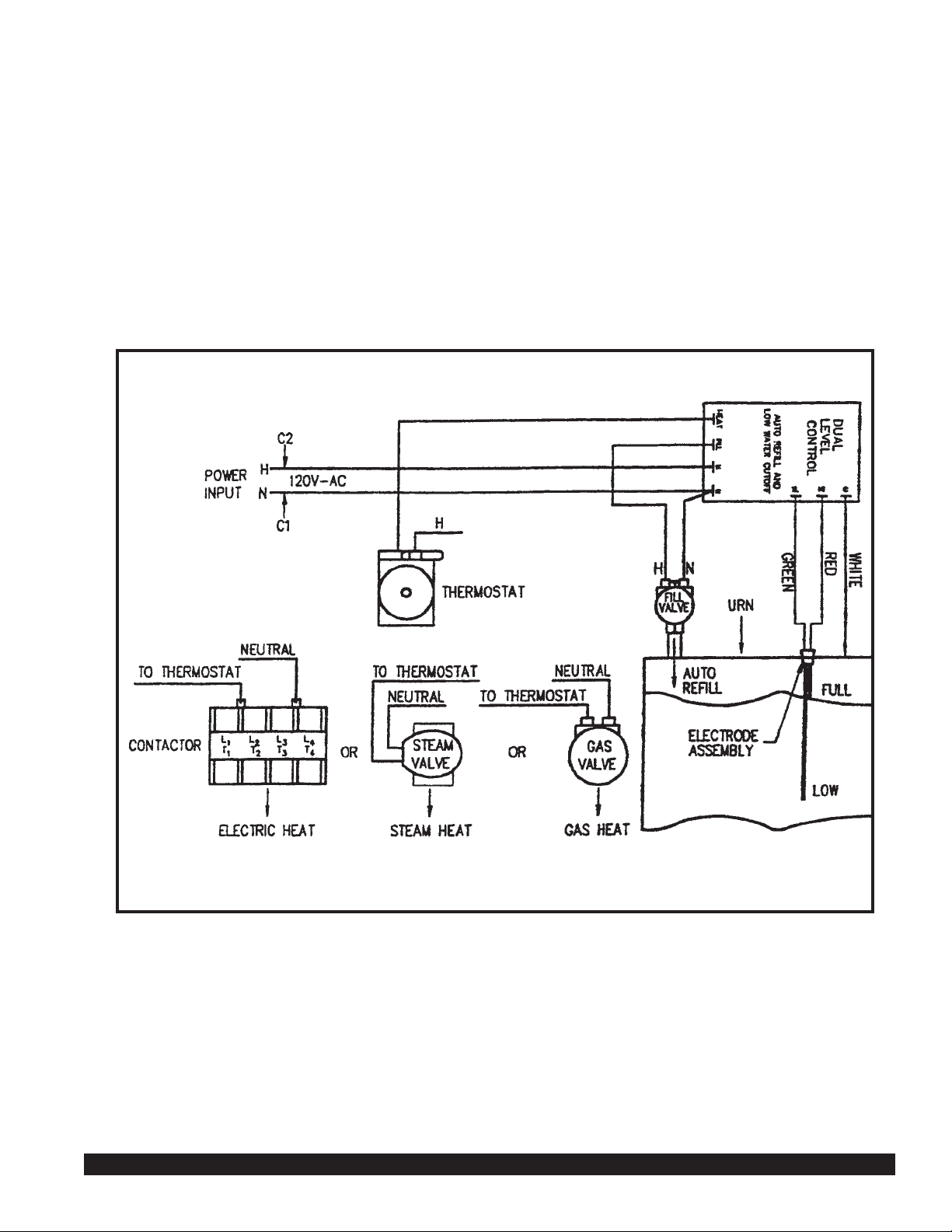

Dual Level Control: What it Does (Refer to Figure B):

A) AUTO REFILL of the water compartment to keep the tank filled with water. When the water is used, the

fill valve opens automatically to let in more water. The fill valve closes when the water level reaches full.

B) LOW WATER CUTOFF to prevent burnout of the electric immersion heater when there is not enough

water to cover it. When low water occurs, the heat automatically switches off. The heat stays off until

more water is added.

Quick Service Check of LIquid Level Control System:

1) All wires secure and properly connected.

2) Clean the electrodes. Lime (mineral scale) build-up can interfere with operation of any liquid control

system.

Drawing #090-813

Figure B

Page 9 American Metal Ware Midline & Space Saver Urns

Service

The rest of this manual contains information to aid the service technician who is maintaining this equipment.

This section has information on performing common service tasks.

Controls, options, and heater wiring diagrams are provided. To find the correct diagram you must know if the

urn has:

1) One thermostat (standard), or two (option 47: low temp/no brew).

2) Air agitation (standard on most models).

3) Which number of heaters and what electric ratings (see nameplate for electric ratings).

4) Fast jug fill hose or seven day timer.

Once you know the above, see the table of contents of this manual to find the drawing for the urn you are

working with.

To Access Controls:

All controls are located on drawer(s) under the urn, or mounted in control box on the side of the urn (Midline

Urns). To access these controls:

1) Shut off power to the urn.

2) Remove screws on front of the control drawer of Space Saver Urns, or on side panel for Midline Urns.

3) Drop panel by lowering front and pulling forward. If diagnosis must be made with power

on and the drawer dropped, be sure no live parts contact the body of the urn.

WARNING! ELECTRIC SHOCK AND BURN HAZARD!

ALL TASKS DESCRIBED IN THIS SECTION ARE TO BE PERFORMED BY A

TRAINED AND QUALIFIED SERVICE TECHNICIAN.

American Metal Ware Midline & Space Saver Urns Page 10

Service (CON’T.)

WARNING! BURN HAZARD!

THIS URN IS FILLED WITH SCALDING HOT WATER. ALWAYS COMPLETELY

DRAIN THE URN AND ALLOW TO COOL BEFORE ATTEMPTING TO MOVE

AND/OR TRANSPORT THIS URN. FAILURE TO DRAIN AND COOL THE URN

COULD RESULT IN SEVERE BURNS.

To drain the tank:

Note: Read all instructions before draining.

1) Disconnect electric power to the urn.

2) The urn body contains one water tank. It will contain one, two, or three coffee liners, depending on

model, that may contain hot liquids.

3A) On urns with boiler drain valve with hose connection: Connect a drain hose with garden hose

fitting to valve. Make sure other end of drain hose is placed in proper drain receptacle such as a sink.

Open drain valve. Be careful, hot water will pour from urn.

3B) On urns provided with petcock type drain valve: Place a pan under the drain. Using pliers or hands

with heavy rubber gloves open the valve. Be careful, hot water will pour from the urn. With heavy

rubber gloves, push a 3/4" flexible rubber tube over the drain cock. The other end of the tube should be

in a proper drain receptacle.

4) To drain coffee liner(s): Drain each liner by opening the faucet in front of the urn for each liner.

5) Close the drain valve after the urn is drained. Note: To perform the tasks listed below, the urn must be

totally drained and cool.

NOTE: To perform the tasks listed below, the urn must be totally drained and cool.

To remove a liner:

1) Unscrew the liner nut at the bottom of the liner. A tool to do this may be purchased from Grindmaster

Corporation.

2) Remove any screws on the outside perimeter of the liner ring on the top of the urn.

3) With a rubber mallet, tap the side of the liner near the bottom until the liner is loose. Find and remove

the rubber washer which seals the bottom of the liner.

To replace a liner:

1) Place a liner washer over the inlet to the coffee tube. You must use a new washer whenever the liner

is removed.

2) Place the liner in the urn, lining the hole in the bottom of the liner to the coffee tube.

3) With a rubber mallet, tap the top of the liner ring to seat the liner on the coffee tube.

4) Tighten the liner nut at the bottom of the liner.

Page 11 American Metal Ware Midline & Space Saver Urns

Service (cont.)

To replace a heater (drain the urn first):

1) Remove the control drawer as described above. (Refer to page 9)

2) Locate the heater terminals under the urn, or on the side for Midline equipment.

3) Remove the heater liner which is closest to the terminals.

4) Loosen the heater connection and remove heater.

5) Place the copper sealing washer on the new heater with the split toward the element.

6) Position the new heater in the urn and tighten the nut.

7) Be sure the electrical connections are tight. Close the gap terminal with pliers if it is too loose.

Replace the wires if they are damaged.

To replace the thermostat (drain the urn first):

1) Remove the control drawer as described above. (Refer to page 9)

2) Locate the fitting on the bottom surface of the urn which the thermostat capillary passes through.

3) Remove the coffee liner closest to this fitting.

4) Locate the thermostat bulb and remember its location. Some urns have two thermostats. Be sure to

find the right one.

5) Unwrap the wire holding the bulb.

6) Unscrew the thermostat from the fitting on the bottom of the urn.

7) Disconnect the wires and remove the thermostat.

8) Attach the new thermostat and tighten the capillary tube fitting.

9) Use the wire to attach the bulb to the same location in the urn as the old thermostat.

10) Reattach the liner, as described above, close up the urn, allow the urn to heat to check the temperature

setting.

11) On Midline or Chinese Tea Urns, the thermostat is mounted on the control box on the side of the urn.

To convert between single and three phase (on urns with three heaters only, 208-240V only):

Refer to the heater wiring diagram #091-227 at the end of the manual.

Use extra caution in ensuring that all wires are correctly and securely connected.

To replace a sprayover pump on pump urns:

1) Disconnect power from urn.

2) Remove the cover over the controls.

3) Locate the hose clamp in the control panel.

4) Clamp off intake hose to pump from water jacket.

5) Disconnect wires from pump to timer (label wires).

6) Disconnect ground wires.

7) Slip hoses off of pump.

8) Loosen screws which hold pump in place and remove pump.

9) Retain fitting and bracket for use with replacement.

10) Replace pump, connect wiring and tubing, and pump should be level.

11) Restore power to the urn.

Loading...

Loading...