EXCELLENCE IN MAGNETICS AND CRYOGENICS

MODEL 4Q12125PS-430

INTEGRATED POWER

SUPPLY SYSTEM

INSTALLATION, OPERATION, AND

MAINTENANCE INSTRUCTIONS

American Magnetics, Inc.

P.O. Box 2509, 112 Flint Road, Oak Ridge, TN 378 31 -25 09, Tel: 865-482-1056, Fax: 865-482-5472

Rev. 5; Issue: November 28, 2011

1 Table of Contents

Table of Contents

Table of Contents............................................................................... iii

List of Figures.................................................................................... ix

List of Tables...................................................................................... xi

Foreword........................................................................................... xiii

Introduction......................................................................................... 1

1.1 Model 4Q12125PS-430 Integrated Power Supply System Features.. 1

Purpose and Scope .............................................................................xiii

Contents of this Manual .................................................................... xiii

General Precautions........................................................................... xiv

Safety Summary................................................................................. xvi

1.1.1 Digitally-Controlled................................................................... 1

1.1.2 Superior Resolution and Stability ............................................ 1

1.1.3 Intuitive Human-Interface Design........................................... 1

1.1.4 Flexibility................................................................................... 2

1.1.5 Standard Remote Interfaces..................................................... 2

1.1.6 Programmable Safety Features................................................ 2

1.1.7 Condition-Based Magnet Auto-Rampdown.............................. 2

1.1.8 Model 4Q12125PS-430 General Description............................ 3

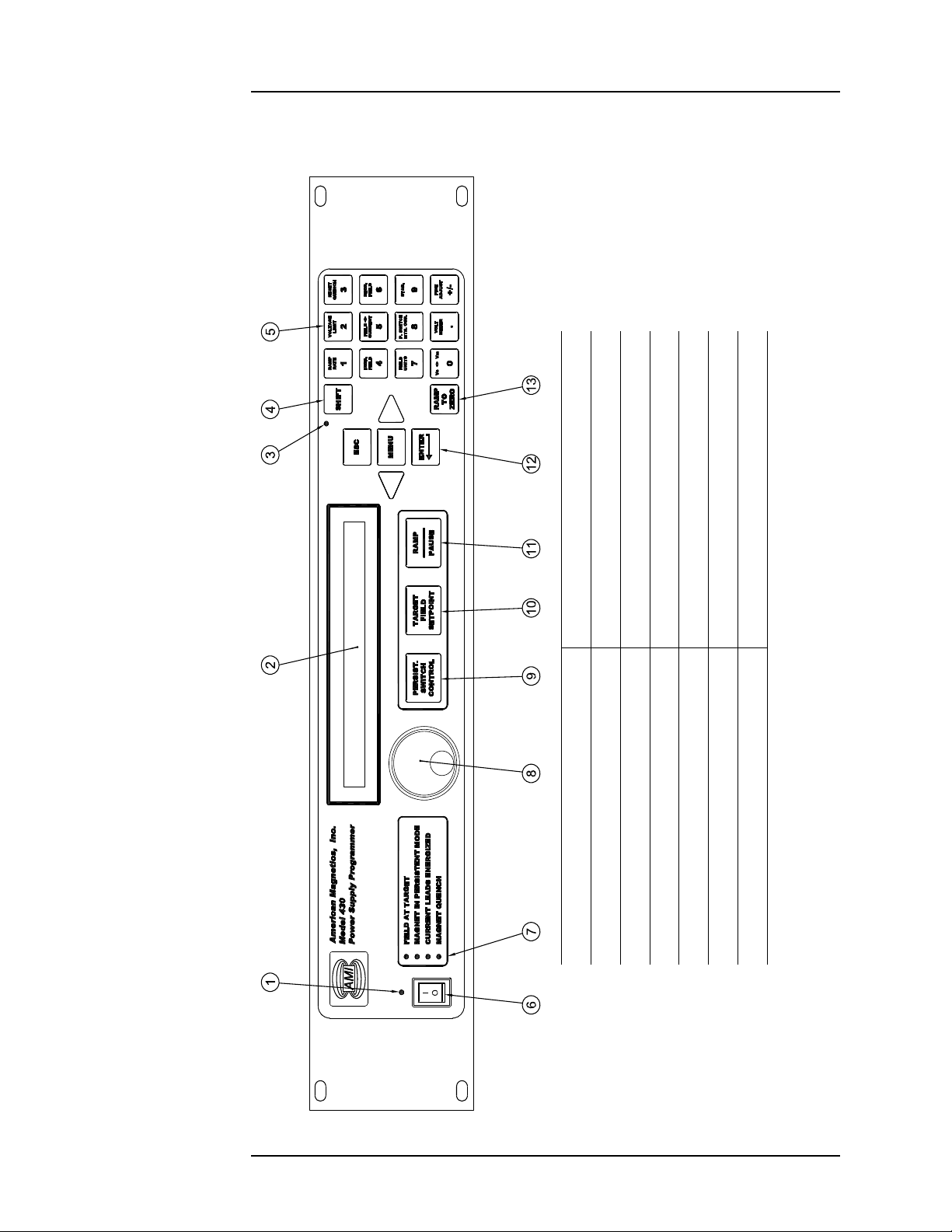

1.1.9 Power Supply System Rack Front Panel Layout ............... 4

1.2 Model 430 Front Panel Layout............................................................. 5

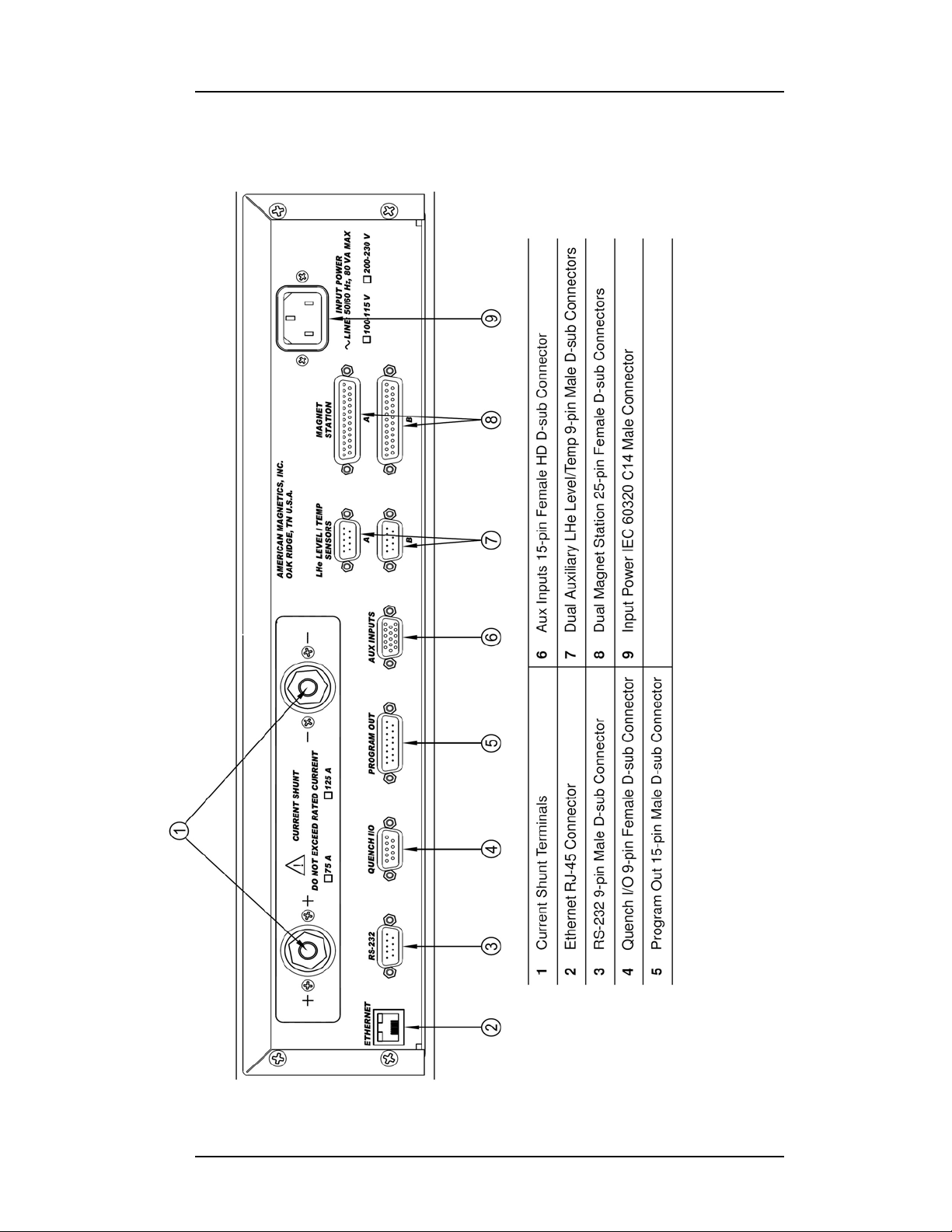

1.3 Model 430 Rear Panel Layout ............................................................. 6

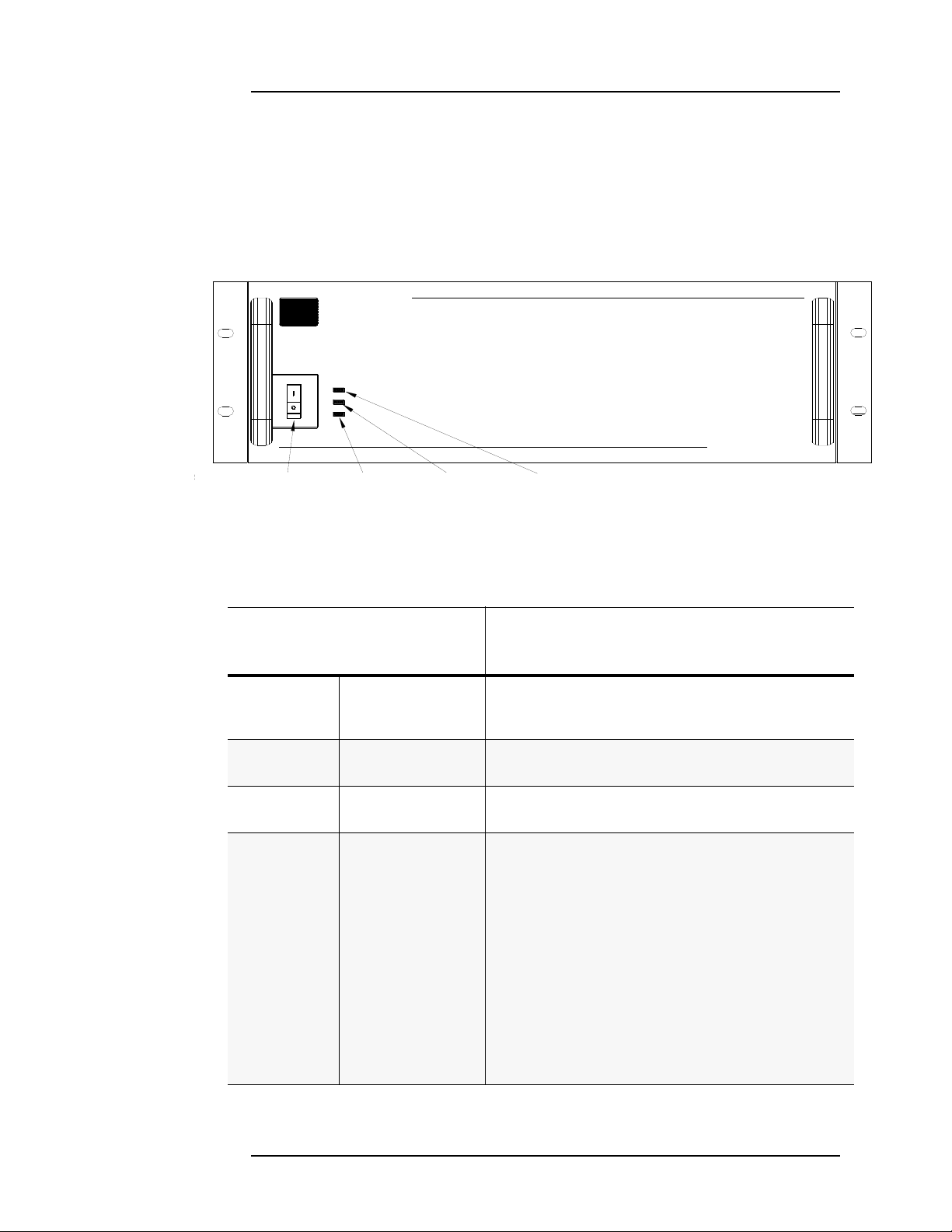

1.4 Power Supply Unit Front Panel Layout .............................................. 7

1.5 System Specifications @ 25°C ...................................................... 8

1.6 Operating Characteristics ................................................................... 9

1.6.1 Four-Quadrant Operation......................................................... 9

Installation......................................................................................... 11

2.1 Inspecting and Unpacking.................................................................. 11

2.2 Power Supply System Mounting ........................................................ 11

2.3 Power Requirements........................................................................... 12

2.3.1 Changing the Model 430 Programmer Operating Voltage ... 12

2.4 Collecting Necessary Information...................................................... 12

2.5 System Interconnects.......................................................................... 13

2.5.1 High-Current 4-Quadrant Supply.......................................... 13

Rev. 5 iii

Table of Contents

2.6 Special Configurations.........................................................................17

2.7 Superconducting Magnets with No Persistent Switch ......................17

2.8 Short-Circuit or Resistive Load...........................................................17

2.9 Power-Up and Test Procedure ............................................................18

Operation............................................................................................21

3.1 System Power On/Off Sequence .........................................................21

3.1.1 Model 430 Programmer Power On/Off....................................21

3.1.2 Energizing Power Supply ........................................................22

3.2 Model 430 Programmer Default Display............................................22

3.2.1 Field / Current Display ............................................................23

3.2.2 Voltage Display ........................................................................24

3.2.3 Status Indicator .......................................................................24

3.2.4 Main Display ............................................................................25

3.3 Entering Numeric Values....................................................................25

3.4 Using Fine Adjust Knob to Adjust Numeric Values ..........................26

3.5 Entering Picklist Values......................................................................27

3.6 Single-key Commands / Menu.............................................................28

3.6.1 Persistent Switch Control Key ................................................29

3.6.2 Target Field Setpoint Key ......................................................31

3.6.3 Ramp / Pause Key ....................................................................31

3.6.4 Ramp To Zero Key....................................................................31

3.7 SHIFT-key Commands / Menus..........................................................32

3.7.1 Ramp Rate SHIFT-key ............................................................33

3.7.2 Voltage Limit SHIFT-key ........................................................36

3.7.3 Reset Quench SHIFT-key ........................................................37

3.7.4 Increment Field SHIFT-key ....................................................37

3.7.5 Field <> Current SHIFT-key...................................................38

3.7.6 Decrement Field SHIFT-key ...................................................38

3.7.7 Field Units SHIFT-key ............................................................38

3.7.8 Persistent Switch Heater Current SHIFT-key.......................39

3.7.9 Stability SHIFT-key.................................................................39

3.7.10 Vs <> Vm SHIFT-key...............................................................39

3.7.11 Volt Meter SHIFT-key .............................................................39

3.7.12 Fine Adjust SHIFT-key............................................................39

3.7.13 Persist. Switch Control SHIFT-key ........................................39

3.8 LED Indicators.....................................................................................40

3.8.1 Power-on Indicator...................................................................40

3.8.2 Magnet Status Indicators ........................................................40

3.8.3 SHIFT Indicator.......................................................................41

iv Rev. 5

Table of Contents

3.9 Setup Menu ......................................................................................... 41

3.9.1 Entering / Exiting Setup Menu .............................................. 41

3.9.2 Menu Navigation..................................................................... 42

3.10 Setup Submenu Descriptions ............................................................. 42

3.10.1 Supply Submenu ..................................................................... 43

3.10.2 Load Submenu......................................................................... 48

3.10.3 Misc Submenu ......................................................................... 59

3.10.4 Net Settings Submenu ............................................................ 68

3.10.5 Net Setup Submenu ................................................................ 70

3.11 Example Setup .................................................................................... 72

3.12 Ramping Functions ............................................................................ 74

3.12.1 Ramping States and Controls ................................................ 75

3.12.2 Manual Ramping..................................................................... 76

3.12.3 Automatic Ramping ................................................................ 76

3.12.4 Ramping to Zero ...................................................................... 77

3.12.5 Fine Adjust of Field / Current in Holding Mode.................... 77

3.13 Persistent Switch Control................................................................... 77

3.13.1 Procedure for Initial Heating of the Switch .......................... 78

3.13.2 Procedure for Entering Persistent Mode .............................. 78

3.13.3 Procedure for Exiting Persistent Mode ................................. 81

3.13.4 Toggling the State of the Persistent Switch Heater.............. 84

3.14 Ramping Functions Example ............................................................ 85

3.15 Quench Detection ............................................................................... 86

3.15.1 External Quench Detection..................................................... 87

3.15.2 Disabling Internal Quench Detection .................................... 88

3.16 External Rampdown .......................................................................... 88

3.16.1 External Rampdown while in Persistent Mode .................... 89

3.16.2 External Rampdown while not in Persistent Mode .............. 90

3.17 Summary of Operational Limits and Default Settings..................... 90

Remote Interface Reference ............................................................ 93

4.1 SCPI Command Summary ................................................................. 93

4.2 Programming Overview.................................................................... 100

4.2.1 SCPI Language Introduction................................................ 100

4.2.2 SCPI Status System.............................................................. 100

4.2.3 Standard Event Register ...................................................... 103

4.2.4 Command Handshaking ....................................................... 104

4.3 RS-232 Configuration ....................................................................... 106

4.3.1 Serial Connector.................................................................... 106

4.3.2 Termination Characters........................................................ 106

Rev. 5 v

Table of Contents

4.4 Ethernet Configuration .....................................................................106

4.4.1 Ethernet Connector................................................................107

4.4.2 Termination Characters ........................................................107

4.5 Command Reference ..........................................................................108

4.5.1 System-Related Commands...................................................108

4.5.2 Status System Commands.....................................................109

4.5.3 SETUP Configuration Commands and Queries...................110

4.5.4 Protection Commands and Queries.......................................115

4.5.5 Ramp Configuration Commands and Queries......................120

4.5.6 Ramping State Commands and Queries...............................124

4.5.7 Switch Heater Command and Query ....................................125

4.5.8 Quench State Commands and Queries .................................126

4.5.9 Rampdown State Queries ......................................................126

4.5.10 Trigger Functions...................................................................128

4.6 Error Messages ..................................................................................130

4.6.1 Command Errors....................................................................130

4.6.2 Query Errors ..........................................................................131

4.6.3 Execution Errors ....................................................................132

4.6.4 Device Errors..........................................................................132

Service..............................................................................................135

5.1 System Component Maintenance .....................................................135

5.1.1 Model 430 Programmer Routine Maintenance.....................135

5.1.2 Model 4Q12125PS Power Supply Routine Maintenance .....135

5.2 Troubleshooting Hints .......................................................................135

5.2.1 Electrostatic Discharge Precautions .....................................135

5.2.2 The Model 430 does not appear to be energized...................136

5.2.3 FAILURE TO LOAD message displayed after power-up ....137

5.2.4 Power supply unstable - magnet voltage oscillates..............138

5.2.5 The power supply system will not charge the magnet.........138

5.2.6 Cannot charge the magnet at the selected ramp rate..........139

5.2.7 Cannot discharge the magnet at the selected ramp rate.....139

5.2.8 Cannot charge the magnet to desired field...........................139

5.2.9 Current in only one direction from 4-quadrant supply........139

5.2.10 Cannot place the magnet in persistent mode.......................139

5.2.11 Cannot bring the magnet out of persistent mode.................140

5.2.12 The magnet quenches for no apparent reason......................140

5.2.13 Cannot lower the magnet field ..............................................140

5.2.14 There is excessive LHe boil-off during operation. ................141

5.2.15 Cannot display the magnetic field strength, only current...141

5.2.16 Cannot use remote communications commands. .................142

5.2.17 Magnet current drifts unacceptably while PSwitch cooling 142

5.2.18 Model 430 appears to lock up when connecting to network 142

vi Rev. 5

Table of Contents

5.3 Additional Technical Support........................................................... 143

5.4 Return Authorization........................................................................ 143

Appendix.......................................................................................... 145

A.1 Magnet Station Connectors ......................................................... 145

A.2 LHe Level / Temp Connectors ...................................................... 146

A.3 Programmer Shunt Terminals ......................................................... 147

A.4 Program Out Connector ................................................................... 148

A.5 Quench I/O Connector....................................................................... 149

A.5.1 External Quench Detection Input ........................................ 149

A.5.2 External Rampdown Input ................................................... 150

A.5.3 External Quench Detection Output ..................................... 151

A.6 Aux Inputs Connector....................................................................... 152

A.7 Ethernet Connector ...................................................................... 153

A.8 RS-232 Connector.............................................................................. 153

A.9 Abbreviations and Acronyms used in this Manual ......................... 154

A.10 Model 430 Programmer Specifications ......................................... 158

A.11 Power Supply Details........................................................................ 161

A.11.1 Model 4Q06125PS Single Unit Electrical Specifications .... 162

A.11.2 Model 4Q06125PS Single Unit Dimensional Specifications 165

A.11.3 Four-Quadrant Characteristics ............................................ 166

A.12 Remote Computer Communication with the Model 430................ 167

A.12.1 Communication via RS-232 .................................................. 167

A.12.2 Communication via Ethernet ............................................... 170

A.13 Upgrading the Model 430 Firmware via FTP ................................. 173

A.13.1 Hardware and Software Requirements................................ 173

A.13.2 Preparation............................................................................ 174

A.13.3 Procedure ............................................................................... 175

A.14 Upgrading the Model 430 Firmware via Flash Card Reader ......... 180

A.14.1 Hardware and Software Requirements................................ 180

A.14.2 Preparation............................................................................ 180

A.14.3 Procedure ............................................................................... 181

A.15 Model 430 Remote Control Application ........................................... 184

A.16 Model 430IP Power Supply Programmer ........................................ 187

A.17 Persistent Switch Operation Flowchart .......................................... 190

Index ............................................................................................... 193

Rev. 5 vii

Table of Contents

viii Rev. 5

1 List of Figures

List of Figures

Figure 1-1 Typical Model 4Q12125PS-430 System Rack Layout ............................ 4

Figure 1-2 Model 4Q06125PS Front Panel............................................................... 7

Figure 1-3 The Four Regions, or Quadrants, of System Operation. ....................... 9

Figure 1-4 Four-Quadrant System with Resistive Shunt........................................ 9

Figure 2-1 Typical Model 4Q12125PS-430 System Rack Interconnections.......... 14

Figure 2-2 Model 4Q12125PS-430 System Interconnections ................................ 15

Figure 3-1 Default Display. ..................................................................................... 23

Figure 3-2 Numeric Keypad and Associated Keys ................................................. 25

Figure 3-3 Menu Navigation Keys .......................................................................... 28

Figure 3-4 Single Input Keys .................................................................................. 29

Figure 3-5 SHIFT-Key Functions ........................................................................... 32

Figure 3-6 Magnet Status LED Indicators. ............................................................ 40

Figure 3-7 Setup Menu Structure ........................................................................... 43

Figure 3-8 Example Power Supply Outputs........................................................... 46

Figure 3-9 Stability Setting vs. Magnet (with PSwitch) Inductance .................... 49

Figure 3-10 Typical Power Supply Self-Limits ........................................................ 51

Figure 3-11 Magnet Current Rating Set Within Supply Range.............................. 52

Figure 3-12 Example Current Limit Setup .............................................................. 53

Figure 3-13 Example Magnet Specification Sheet. .................................................. 73

Figure 3-14 Ramping to Two Different Target Field/Current Settings. ................. 85

Figure 4-1 The Model 430 Programmer Status System. ..................................... 101

Figure 4-2 Asterisk Indicating Model 430 in Remote Mode ................................ 109

Figure A-1 4Q06125PS Outline Drawing, Front and Rear Views ....................... 165

Figure A-2 4Q06125PS Outline Drawing Top and Side Views............................ 166

Figure A-3 Four-Quadrant Supply Output Characteristics................................. 167

Figure A-4 http:// - IP Address or System Name Entry ....................................... 185

Figure A-5 Initial Screen for Browser Access of the Model 430........................... 186

Figure A-6 Model 430IP Front Panel .................................................................... 187

Figure A-7 Browser Depiction of the Model 430................................................... 187

Figure A-8 http:// - System Name Entry ............................................................... 188

Figure A-9 Initial Screen for Browser Access of the Model 430IP....................... 188

Figure A-10 Browser Control of the Model 430IP .................................................. 189

Figure A-11 Persistent Switch Operation Flowchart, Page 1 ................................ 190

Figure A-12 Persistent Switch Operation Flowchart, Page 2 ................................ 191

Figure A-13 Persistent Switch Operation Flowchart, Page 3 ................................ 192

Rev. 5 ix

List of Figures

x Rev. 5

1 List of Tables

List of Tables

Table 1-1 Model 430 Front Panel Description ........................................................ 5

Table 1-2 Model 430 Resistive Shunt Version Rear Panel Description ................ 6

Table 1-3 Power Supply Front Panel Controls and Indicators ..............................7

Table 3-1 Description of Status Indicators ........................................................... 24

Table 3-2 Select Supply picklist values and associated parameters. .................. 45

Table 3-3 V-V Mode Input Range Picklist Values ................................................48

Table 3-4 Maximum Recommended Stability Setting Changes ......................... 50

Table 3-5 Example Setup Configuration...............................................................74

Table 3-6 Ramp modes and descriptions............................................................... 76

Table 3-7 Summary of Model 430 Programmer Limits and Defaults ................. 91

Table 4-1 Bit Definitions for the Status Byte Register ......................................102

Table 4-2 Bit Definitions for the Standard Event Register ............................... 104

Table 4-3 Return Values and Meanings for SUPPly:TYPE? Query.................. 111

Table 4-4 Return Values and Meanings for SUPPly:MODE? Query.................. 112

Table 4-5 Return Values and Meanings for STATE? Query............................... 125

Table 4-6 Model 430 Programmer Trigger Function Bit Definitions ................128

Table 5-1 V-V Mode Input Range Picklist Values ..............................................137

Table A-1 Magnet Station Connectors Pin Definitions.......................................145

Table A-2 LHe Level / Temp Connectors Pin Definitions...................................146

Table A-3 Program Out Connector Pin Definitions ............................................ 148

Table A-4 Quench I/O Connector Pin Definitions ...............................................149

Table A-5 Aux Inputs Connector Pin Definitions ...............................................152

Table A-6 Ethernet RJ-45 Connector Pin Definitions ........................................153

Table A-7 RS-232 Connector Pin Definitions ...................................................... 153

Table A-8 PC (DB9)-to-Model 430 RS-232 Cable Connections........................... 154

Table A-9 Abbreviations and Acronyms ..............................................................154

Table A-10 Model 430 Programmer Specifications @ 25°C ................................. 158

Table A-11 Model 4Q06125PS Electrical Specifications....................................... 162

Rev. 5 xi

List of Tables

xii Rev. 5

Foreword

Purpose and Scope

This manual contains the operation and maintenance instructions for the

American Magnetics, Inc. Model 4Q12125PS-430 Power Supply System.

The user is encouraged to contact an authorized AMI Technical Support

Representative for information regarding specific configurations not

explicitly covered in this manual.

Contents of this Manual

Introduction introduces the reader to the functions and characteristics of

the Model 430 Power Supply Programmer and the Power Supply System.

It provides illustrations of the front and rear panel layouts as well as

documenting the performance specifications. Additional information is

provided in the form of system circuit diagrams.

Installation describes how the Model 430 Power Supply Programmer is

unpacked and installed in conjunction with ancillary equipment in typical

superconducting magnet systems. Block-level diagrams document the

interconnects for various system configurations.

Operation describes how the Model 430 Programmer is used to control a

superconducting magnet. All Model 430 Programmer displays and controls

are documented. The ramping functions, persistent switch heater controls,

and the quench detect features are also presented.

Remote Interface Reference documents all remote commands and

queries available through the Model 430 Programmer RS-232 and

Ethernet interfaces. A quick-reference summary of commands is provided

as well as a detailed description of each.

Service provides guidelines to assist the user in troubleshooting possible

system and Model 430 Programmer malfunctions. Information for

contacting AMI Technical Support personnel is also provided.

Appendix provides additional details and/or procedures in the following

areas:

1. Model 430 Programmer rear panel connectors.

2. Individual power supply unit specifications

Rev. 5 xiii

Foreword

General Precautions

3. Establishing RS-232 or Ethernet communications with the Model

430.

4. Model 430 firmware upgrade.

5. Abbreviations and acronyms used in this manual.

6. Persistent switch operation (flow diagram).

General Precautions

Cryogen Safety

The two most common cryogenic liquids used in superconducting magnet

systems are nitrogen and helium. Both of these cryogens are extremely

cold at atmospheric pressure (−321°F and −452°F, respectively). The

following paragraphs outline safe handling precautions for these liquids.

Personnel handling cryogenic liquids should be thoroughly instructed and

trained as to the nature of the liquids. Training is essential to minimize

accidental spilling. Due to the low temperature of these materials, a

cryogen spilled on many objects or surfaces may damage the surface or

cause the object to shatter, often in an explosive manner.

Inert gases released into a confined or inadequately ventilated space can

displace sufficient oxygen to make the local atmosphere incapable of

sustaining life. Liquefied gases are potentially extreme suffocation

hazards since a small amount of liquid will vaporize and yield a very large

volume of oxygen-displacing gas. Always ensure the location where the

cryogen is used is well ventilated. Breathing air with insufficient oxygen

content may cause unconsciousness without warning. If a space is suspect,

purge the space completely with air and test before entry. If this is not

possible, wear a forced-air respirator and enter only with a co-worker

standing by wearing a forced-air respirator.

Cryogenic liquids, due to their extremely low temperatures, will also burn

the skin in a similar manner as would hot liquids. Never permit cryogenic

liquids to come into contact with the skin or allow liquid nitrogen to soak

clothing. Serious burns may result from careless handling. Never touch

uninsulated pipes or vessels containing cryogenic liquids. Flesh will stick

to extremely cold materials. Even nonmetallic materials are dangerous to

touch at low temperatures. The vapors expelled during the venting process

are sufficiently cold to burn flesh or freeze optic tissues. Insulated gloves

should be used to prevent frost-bite when operating valves on cryogenic

tanks. Be cautious with valves on cryogenic systems; the temperature

extremes they are typically subjected to cause seals to fail frequently.

xiv Rev. 5

Foreword

General Precautions

In the event a person is burned by a cryogen or material cooled to

cryogenic temperatures, the following first aid treatment should be given

pending the arrival and treatment of a physician or other medical care

worker:

1. If any cryogenic liquid contacts the skin or eyes, immediately flush

the affected area gently with tepid water (102°F − 105°F, 38.9°C −

40.5°C) and then apply cold compresses.

2. Do not apply heat. Loosen any clothing that may restrict

circulation. Apply a sterile protective dressing to the affected area.

3. If the skin is blistered or there is any chance that the eyes have

been affected, get the patient immediately to a physician for

treatment.

Containers of cryogenic liquids are self pressurizing (as the liquid boils off,

vapor pressure increases). Hoses or lines used to transfer these liquids

should never be sealed at both ends (i.e. by closing valves at both ends).

When pouring cryogenic liquids from one container to another, the

receiving container should be cooled gradually to prevent damage by

thermal shock. The liquid should be poured slowly to avoid spattering due

to rapid boil off. The receiving vessel should be vented during the transfer.

Introduction of a substance at or near room temperature into a cryogenic

liquid should be done with great caution. There may be a violent gas boiloff and a considerable amount of splashing as a result of this rapid boiling.

There is also a chance that the material may crack or catastrophically fail

due to forces caused by large differences in thermal contraction of different

regions of the material. Personnel engaged in this type of activity should

be instructed concerning this hazard and should always wear a full face

shield and protective clothing. If severe spraying or splashing could occur,

safety glasses or chemical goggles along with body length protective

aprons will provide additional protection.

The properties of many materials at extremely low temperatures may be

quite different from the properties that these same materials exhibit at

room temperatures. Exercise extreme care when handling materials cooled

to cryogenic temperatures until the properties of these materials under

these conditions are known.

Metals to be used for use in cryogenic equipment application must posses

sufficient physical properties at these low temperatures. Since ordinary

carbon steels, and to somewhat a lesser extent, alloy steels, lose much of

their ductility at low temperatures, they are considered unsatisfactory and

sometimes unsafe for these applications. The austenitic Ni-Cr alloys

exhibit good ductility at these low temperatures and the most widely used

Rev. 5 xv

Foreword

Safety Summary

is 18-8 stainless steel. Copper, Monel®, brass and aluminum are also

considered satisfactory materials for cryogenic service.

Magnet Quenches

When an energized superconducting magnet transitions from

superconducting state to normal state, the magnet converts magnetic

energy to thermal energy thereby rapidly converting the liquid helium to a

vapor. When this phase transformation occurs, pressures can build rapidly

in the cryostat due to the fact that one part of liquid helium will generate

782 parts of gaseous helium at STP (standard temperature and pressure).

The cryostat must be designed to allow the generated vapor to rapidly and

safely vent to an area of lower pressure. Cryostats are designed with

pressure relief valves of sufficient capacity so as to limit the pressure

transients within the container in order to prevent damage to the vessel.

Operating a superconducting magnet in a cryostat without properly sized

relief mechanisms or disabled relief mechanism is unsafe for the operator

as well as for the equipment. If there is any doubt as to the sufficiency of

the pressure relief system, contact the manufacturer of the magnet and

cryostat for assistance.

Safety Summary

Superconducting magnet systems are complex systems with the potential

to seriously injure personnel or equipment if not operated according to

procedures. The use of cryogenic liquids in these systems is only one factor

to consider in safe and proper magnet system operation. Proper use of

safety mechanisms (pressure relief valves, rupture disks, etc.) included in

the cryostat and top plate assembly are necessary. Furthermore, an

understanding of the physics of the magnet system is needed to allow the

operator to properly control the large amounts of energy stored in the

magnetic field of the superconducting coil. The Model 430 Programmer has

been designed with safety interlocks to assist the operator in safe

operation, but these designed-in features cannot replace an operator’s

understanding of the system to ensure the system is operated in a safe and

deliberate manner.

Recommended Safety Equipment

• First Aid kit

• Fire extinguisher rated for class C fires

• Cryogenic gloves

• Face shield

• Signs to indicate that there are potentially damaging magnetic fields

in the area and that cryogens are in use in the area.

xvi Rev. 5

Foreword

O

I

Safety Summary

Safety Legend

Instruction manual symbol: the product is marked with this

symbol when it is necessary for you to refer to the instruction

manual in order to protect against damage to the product or

personal injury.

Hazardous voltage symbol.

Alternating Current (Refer to IEC 417, No. 5032).

Off (Supply) (Refer to IEC 417, No. 5008).

On (Supply) (Refer to IEC 417, No. 5007).

Warning

The Warning sign denotes a hazard. It calls attention to a procedure or

practice, which if not correctly adhered to, could result in personal injury.

Do not proceed beyond a Warning sign until the indicated conditions are

fully understood and met.

Caution

The Caution sign denotes a hazard. It calls attention to an operating

procedure or practice, which if not adhered to, could cause damage or

destruction of a part or all of the product. Do not proceed beyond a Caution

sign until the indicated conditions are fully understood and met.

Rev. 5 xvii

Foreword

Safety Summary

xviii Rev. 5

1 Introduction

1.1 Model 4Q12125PS-430 Integrated Power Supply System Features

The AMI Model 4Q12125PS-430 Power Supply System is a sophisticated

digitally-controlled power supply which allows an operator to manage a

superconducting magnet system with unprecedented accuracy and ease of

use. Integral components of the system include a Model 430 Programmer

and two Model 4Q06125PS Power Supplies. The AMI Model 4Q12125PS430 Power Supply System provides for a degree of flexibility and accuracy

previously unavailable in an economical commercial product.

1.1.1 Digitally-Controlled

The Power Supply System is controlled by a microcomputer-based controller which controls all analog data conversion, display/keypad functions,

communications I/O, generation of analog programming signals for the

external power supply, and control law computations. The Power Supply

System incorporates digital signal processing (DSP) functions that provide

for accurate control, low drift, and flexibility of use.

1.1.2 Superior Resolution and Stability

The Model 430 Power Supply Programmer incorporates high-resolution

converters to translate signals between the analog and digital domains.

Precision instrumentation techniques and potentiometer-free designs are

employed throughout the Model 430 Programmer to ensure accurate signal translation for a wide range of conditions. The magnet current is sampled at 24-bit resolution in hardware and is software-programmable to 15digits resolution. All pause and hold functions are performed in the digital

domain which provides for excellent stability and drift of the programmed

magnetic field.

1.1.3 Intuitive Human-Interface Design

The Power Supply System was designed to simplify the interface where

possible. All functions were analyzed and subsequently programmed so

that the most commonly used functions are addressed with the least

number of keystrokes. The menus are also presented in a logical fashion so

that the operation of the Power Supply System is intuitive to the user.

The provision of a velocity-sensitive rotary encoder on the front panel also

allows the operator to fine-adjust many of the operating parameters of the

magnet system.

Rev. 5 1

Introduction

Features

1.1.4 Flexibility

The Model 4Q12125PS-430 system is configured as a four-quadrant power

supply system which is able to both supply and remove electrical energy

from the superconducting magnet system. The Power Supply System was

engineered to be compatible with most magnet systems.

1.1.5 Standard Remote Interfaces

The Power Supply System provides an RS-232 serial port as well as an

Ethernet port as standard features. All settings can be controlled via the

remote interfaces and the front panel can be remotely locked to prevent

accidental operation. The Power Supply System also provides trigger

functions for data collection and/or logging during operation.

1.1.6 Programmable Safety Features

The Power Supply System is designed to be operated from the front panel

of the Programmer or remotely with operational parameters which must

not be exceeded for the given conditions of the system. Once set, should an

operator inadvertently attempt to take the magnet system to an excessive

magnetic field strength or charge at an excessive voltage, the Programmer

will not accept the parameter and will alert the operator that a value was

rejected because it was outside the user-defined limits.

In addition, each setup parameter can be individually selected for locking.

A user-defined password is required to lock or unlock settings. This allows

an administrator to set and password protect any critical parameters that

should not be changed by the operator. Then the administrator can be

confident that an operator will not subsequently change any of these

critical parameters, and yet will be free to change any non-critical

(unlocked) parameters.

1.1.7 Condition-Based Magnet Auto-Rampdown

The Power Supply System can be connected to an AMI Model 13x Liquid

Helium Level Instrument to allow automatic rampdown of the magnet

(even in persistent mode) should the liquid helium (LHe) level drop to a

preset level. This feature ensures the magnet will be protected and not

experience a quench should the LHe level reach an unsafe level for magnet

operation. A single cable is required to use this feature and is covered in

more detail in section A.5.2 on page 150 of the Appendix. Contact AMI for

more information.

In addition to low LHe level, this input to the Power Supply System can be

used with other instrumentation as well. Other uses for this input include

faults from a cryocooler, temperature instrumentation, etc.

2 Rev. 5

Introduction

General Description

1.1.8 Model 4Q12125PS-430 General Description

A Model 430 Power Supply Programmer and two Model 4Q06125PS Power

Supplies are configured to make up the system designated as 4Q12125PS-

430. The Model 4Q06125PS is a 750 Watt, ±6 Volt, ±125 ampere, 4-

quadrant, voltage and current stabilized DC supply. Two Model

4Q06125PS Power Supplies are connected in a Master/Slave series

configuration to provide the rated voltage. The power supplies are

remotely controlled by the Model 430 Power Supply Programmer.

The Model 4Q12125PS-430 is a true 4-quadrant voltage and current power

1

supply capable of both sourcing and sinking

power smoothly through zero

to provide true ±voltage and ±current. It is ideal for controlling inductive

loads such as large magnets or motors.

The power supplies are controlled by a ±10 Vdc remote analog signal

supplied by the Model 430 Programmer and applied to the power supply

analog inputs. Programming and control of the current loop (composed of

the magnet, power supplies, and Model 430 Programmer shunt), is

provided by a Model 430 ramp-generated current reference with

parameters as set by the user in the Model 430. The Model 430 compares

the measured current (via the shunt) with the current reference to provide

precise closed-loop control of the actual current.

2

The power supply units are operated in voltage-voltage

programming

mode, with the Model 430 Programmer output scaled to operate the power

supply units over their available voltage output range. The Programmer

signal will continually adjust the power supply output voltage to

automatically regulate the power supply current; precise linear power

supply current control will result as long as the system voltage and

current demand do not exceed the total power supply rating or load

limiting parameters.

1. The power supply is operating as a source if the current direction and voltage polarity are the same (i.e., the situation that would exist when supplying a resistive load).

If the voltage polarity and current direction are opposite, the supply is operating as

a sink and energy is being absorbed or returned to the “ac-line”.

2. Voltage reference controlling voltage output.

Rev. 5 3

Introduction

Figure 1-1. T ypical Model 4Q12125PS-430 System Rack Layout

System Rack

1.1.9 Power Supply System Rack Front Panel Layout

4 Rev. 5

Introduction

1 Power Indicator LED 8 Fine Adjust Knob

2 280 x 16 Dot Graphic VF Display 9 Persistent Switch Heater Control Key

3 Shift Indicator LED 10 Target Field Setpoint Key

4 Shift Key 11 Ramp/Pause Switch

5 4 Row x 3 Column Keypad 12 Menu Navigation and Data Entry Keys

6 Power Switch 13 Ramp to Zero Key

7 Magnet Status Indicator LEDs

Table 1-1. Model 430 Front Panel Description

Model 430 Front Panel

1.2 Model 430 Front Panel Layout

Rev. 5 5

Introduction

Table 1-2. Model 430 Resistive Shunt Version Rear Panel Description

Model 430 Rear Panel Layout

1.3 Model 430 Rear Panel Layout

6 Rev. 5

Introduction

SLAVE

MASTER / STANDALONE

FAULT

American Magnetics, Inc.

AMI

Model 4Q06125PS

Four-Quadrant Power Supply

AMI

123 4

Power Supply Front Panel Layout

1.4 Power Supply Unit Front Panel Layout

The power supply individual front panels contain the input ON/OFF

circuit breakers and the FAULT, MASTER / STANDALONE and SLAVE

indicators. Refer to Figure 1-2 and Table 1-3. for a description of front

panel controls and indicators.

Table 1-3. Power Supply Front Panel Controls and Indicators

Reference

(Figure Fig-

Control or Indi-

ure 1-2.)

POWER ON/OFF

1

2 SLAVE indicator

3 MASTER indicator

4 FAULT indicator

circuit breaker

Figure 1-2. Model 4Q06125PS Front Panel

cator

Applies source power to unit

switch

Lights when set as SLAVE Model 4Q06125PS in the

4Q12125PS configuration.

Lights when configured as MASTER Model 4Q06125PS

in the 4Q12125PS configuration

Lights red when a fault is detected. The following failure

or fault conditions can cause the FAUL T indicator to light:

overtemperature, instant internal overcurrent, output

overvoltage/overcurrent, local 15V failure, input under/

overvoltage, input overcurrent, internal output under/

overvoltage, internal output overcurrent, overtemperature, fan failure.

When the FAULT indicator lights, an audible beep

sounds a warning for approximately two seconds and the

output is crowbarred by an internal contactor. The fault is

latched. After the cause of the fault is removed, the unit

can be restarted by cycling the POWER circuit breaker to

OFF, then ON, or by applying a START_EXT pulse at

Analog I/O Port pin 7

Function

Rev. 5 7

Introduction

Power Supply Front Panel Layout

1.5 System Specifications @ 25°C

Magnet Current Control

Range: −125 to +125 A

Programming Accuracy: 50 mA

Stability: 25 mA after 20 min. at desired current

Minimum Ramp Rate: 100 μA/min

Maximum Ramp Rate: 10 A/sec

Output Voltage

Range: −12 to +12 Vdc

Measurement Resolution: 10 mV

Load Inductance

Range: 0.5 to 100 H

Primary Power Requirements

Physical

Dimensionsa:

Approximate Weight: 190 lbm (85 kg)

Terminal Torque Limit: 48 lbf-in (5.4 N-m)

Environmental Limits

Ambient Temperature: 0 °C to 40 °C (32 °F to 104 °F)

Relative Humidity: 0 to 95%; non-condensing

a. H = height; W = width; D = depth

Range: 200 - 230 Vac ±10%

50 / 60 Hz, 3800 VA

19.5” H x 21”W x 24.5” D

(495 mm H x 533 mm W x 622 mm D)

8 Rev. 5

Introduction

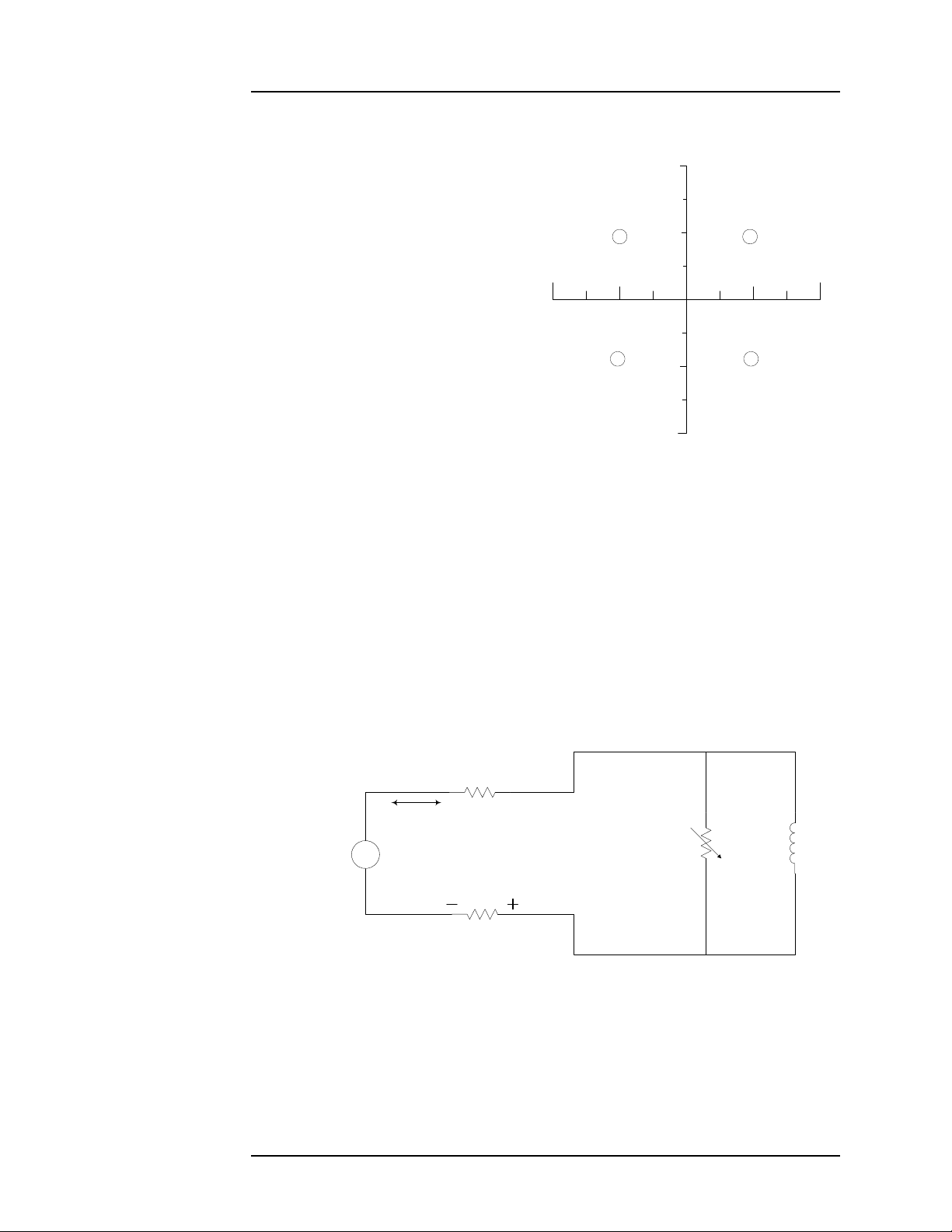

20

-20

200-200

V

I

Positive Current

Flow Direction

Positive Voltage

Polarity

Positive Current

Flow Direction

Negative Voltage

Polarity

Negative Current

Flow Direction

Positive Voltage

Polarity

Negative Current

Flow Direction

Negative Voltage

Polarity

12

43

Figure 1-3. The Four Regions, or Quadrants, of System Operation.

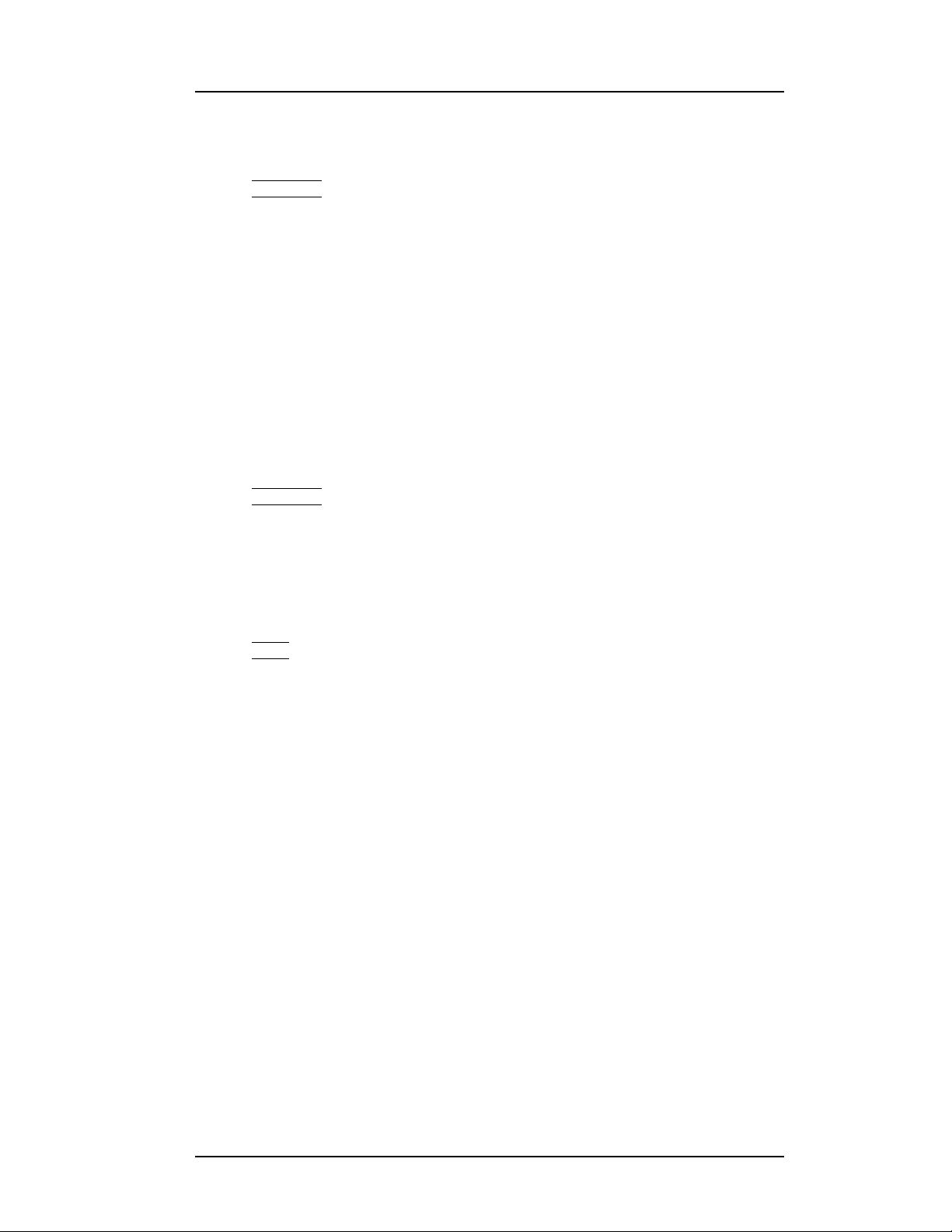

Magnet

Coil(s)

Persistent

Switch

(optional)

Misc. Line Losses

Model 420

Shunt

V

Four-Quadrant

Power Supply

Current

Figure 1-4. Four-Quadrant System with Resistive Shunt

430

Operating Characteristics

1.6 Operating Characteristics

The Model 430 Programmer has

been designed to perform with various power supplies to allow the

user the greatest degree of system

flexibility. The power supply and

Programmer combination are categorized by one of three forms: sin-

gle-quadrant, dual-quadrant, and

four-quadrant. For sake of clarity,

the term quadrant is defined as

one of four areas of a cartesian

coordinate system where the

abscissa is current and the ordinate is voltage. Refer to Figure 1-3.

1.6.1 Four-Quadrant Operation

The four-quadrant magnet power supply system illustrated in Figure 1-4

offers the most control of all the modes of operation. Efficiency is increased

and reversible magnetic field profiles are attainable without

discontinuities in the current. All of the voltage and current control is

performed electronically so that system reliability is improved.

Disadvantages of the four-quadrant system include somewhat increased

cost of the power supply over single or dual-quadrant power supplies, and

added complexity in protecting the power supply in the event of AC power

loss or magnet quenching. Nonetheless, modern four-quadrant power

supplies which include integral output protection against AC power loss

and magnet quenching are available at reasonable prices.

Rev. 5 9

Introduction

Operating Characteristics

10 Rev. 5

2 Installation

Warning

Before energizing the equipment, the earth ground of the power

receptacle must be verified to be at earth potential and able to carry

the rated current of the power circuit. Using extension cords should

be avoided; however, if one must be used, ensure the ground

conductor is intact and capable of carrying the rated current.

In the event that the ground path becomes less than sufficient to

carry the rated current of the power circuit, the equipment should be

disconnected from power, labeled as unsafe, and removed from place

of operation.

Do not operate this equipment in the presence of flammable gases.

Doing so could result in a life-threatening explosion.

Do not modify this equipment in any way. If component replacement

is required, return the equipment to AMI facilities as described in

the Troubleshooting section of this manual.

If used in a manner not specified in this manual, the protection

provided by the design, manufacture and documentation of the

system may be impaired.

2.1 Inspecting and Unpacking

Carefully remove the equipment, interconnecting cabling, and

documentation CD (and/or printed material) from the shipping carton, and

remove all packaging material.

Note

If there is any shipping damage, save all packing material and

contact the shipping representative to file a damage claim. Do not

return to AMI unless prior authorization has been received.

2.2 Power Supply System Mounting

If the system is to be used on a table top, place the equipment on a flat,

secure surface.

Rev. 5 11

Installation

Power Requirements

2.3 Power Requirements

Warning

The power requirement for each system component is marked on the

rear panel of the unit adjacent to the power entry connectors. Be sure

the power supply system is configured for the proper power source

prior to plugging in the line cords. Do not fail to connect the input

ground terminal securely to an external earth ground.

Ensure the front panel power switches are in the OFF (

that the power supply components are configured for the proper operating

voltage by referring to the equipment rear panels. If the operating voltage

is correct, plug the line cords into power entry connectors, and into the

appropriate power receptacles.

O) position. Verify

2.3.1 Changing the Model 430 Programmer Operating Voltage

Warning

The following procedure is to be performed only when the Model 430

Programmer is completely de-energized by removing the power-cord

from the power receptacle. Failure to do so could result in personnel

coming in contact with high voltages capable of producing lifethreatening electrical shock.

Note

The voltage selector switch is labeled “115” for nominal line voltages

from 100 to 115 VAC. The switch is labeled “230” for nominal line

voltages of 200 to 230 VAC.

If the Model 430 Programmer operating voltage must be changed, ensure

the instrument is de-energized by disconnecting the power cord from the

power source. Remove the Model 430 Programmer cover by removing the

four screws on both sides of the cover and the four screws from the corners

of the cover on the back panel; slide the voltage selector switch on the main

printed circuit board to the proper voltage. Replace the Model 430

Programmer cover.

2.4 Collecting Necessary Information

In order to properly configure the Model 430 Programmer, specific system

information is required. Such parameters as the magnet electrical

properties, type of power supply, persistent switch heating current

requirements, and voltage and current constraints of the magnet are

entered into the Model 430 Programmer once and nonvolatile memory will

retain the data even after power is removed from the instrument. An

12 Rev. 5

Loading...

Loading...