American Magnetics 430 User Manual

Model 430 Power Supply Programmer

and

Integrated

Magnet Power

Supply Systems

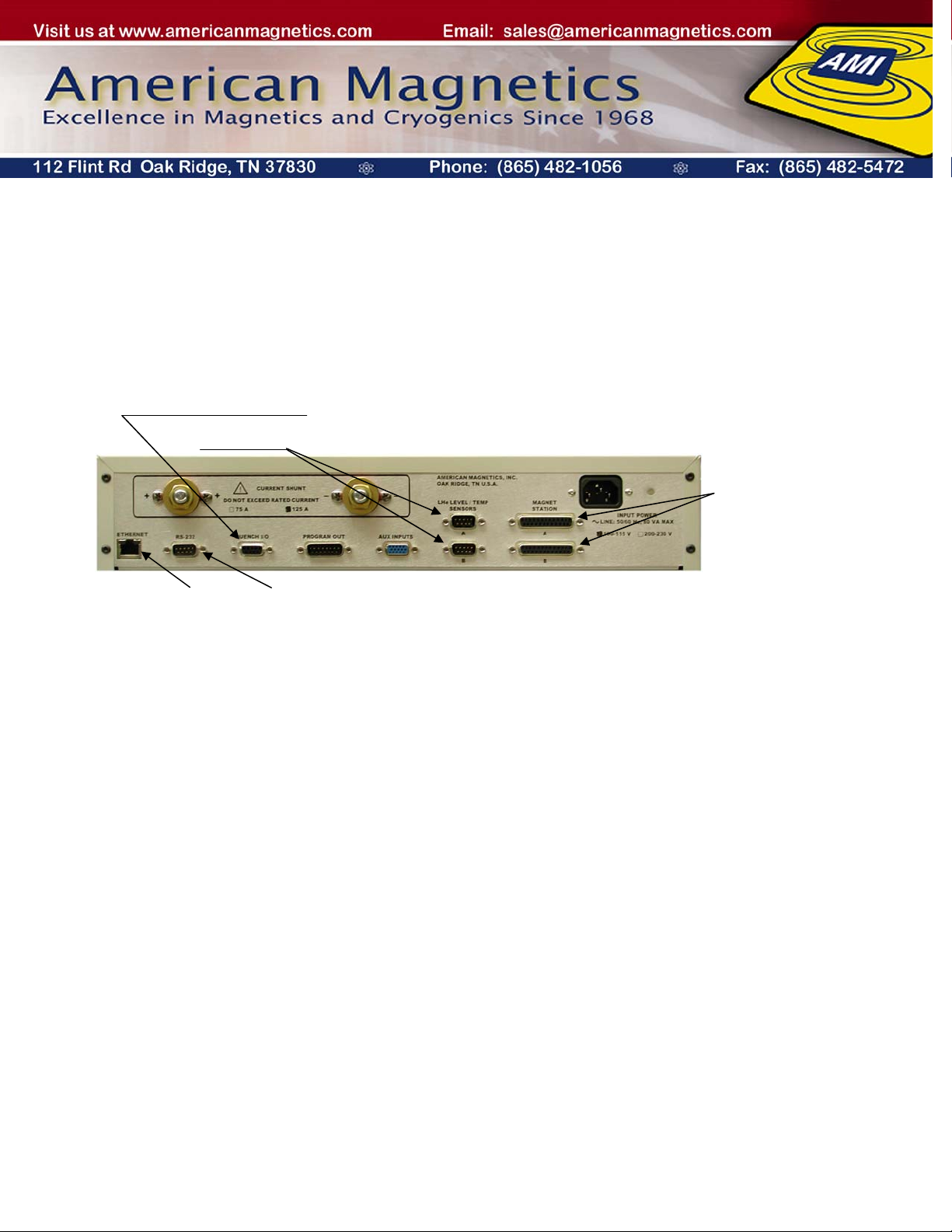

Shown here: AMI’s most popular Magnet Power

Supply System, the Model 4Q06125PS-430

Model 430 Programmer

The AMI Model 430 Power Supply Programmer is a

sophisticated digital power supply controller that allows an

operator to manage a superconducting magnet system

with unprecedented accuracy and ease. T he Model 430 is

designed to control a wide range of single, dual, an d fourquadrant linear and switching power supplies. The most

frequently used functions are accessible via single

keystroke or shift plus keystroke. For other functions, a

menu driven format guides the user to enter inputs using

the push button front panel interface.

Multi-axis Systems

Accuracya (A) with Standard Shunt System:

Stabilitya (A) with Standard Shunt System:

a

After 20 minutes; stability and accuracy of systems 250 A and lessb are improved more than a factor of 10 with the optional high-stability (flux-gate) system.

b

Systems larger than 250 A include the high stability (flux-gate) option as the standard configuration.

c

After 10 minutes;

Multiple Model 430 Power Supply Programmers can control a multi-axis magnet system for virtual rotation of

the magnetic field. An infinite combination of field vectors is possible when the coils of the multi-axis magnet

system are energized and controlled independently and simultaneously.

MMooddeell 443300 PPoowweerr SSuuppppllyy PPrrooggrraammmmeerr SSppeecciiffiiccaattiioonnss ffo

Standard Model 430 Configurations: Programmable Limits

Magnet Current Control Parameter

Accuracyc (A) - High Stability System:

Stabilityc (A) - High Stability System:

Minimum Ramp Rate (mA/min): 0.01 0.01 0.01 0.1 0.1 0.1 0.1 0.1

Maximum Ramp Rate (A/sec): 1 1 1 10 20 20 30 30

d

Drift is further reduced to half that shown after 60 minutes.

±5 A ±10 A +100 A ±125 A +200 A ±250 A +300 A +500 A

0.002 0.004 0.04 0.05 0.08 0.1

0.00025 0.0005 0.005 0.0063 0.01 0.0125 0.015 0.025

d

0.002d 0.02d 0.025d 0.04d 0.05d n/ab n/ab

0.001

0.00005 0.0001 0.001 0.00125 0.002 0.0025 0.003 0.005

Integrated Power Supply Systems

AMI Integrated Magnet Power Supply Systems incorporate

the digitally based Model 430 Po wer Supply Programmer

which provides simplified, flexible operation with precise

low drift magnet current control. Standard systems are

mounted in rugged 19” rack-style cabinets. Standard 4quadrant systems range from 5 A to 250 A, while the

standard bipolar current ratings range from 100 A to 500 A.

Bipolar systems incorporate the AMI Model 601 Energy

Absorber to achieve bipolar operation and a llow fast ramp

down with a unipolar power supply.

o

b

n/a

n/ab

o

CC

orr AAMMII’’ss SSttaannddaarrdd SSyysstteemmss @@ 2255

Model 430 Features

• Parameter for setting persistent switch cool time1

• Ultrahigh resolution and accuracy

2

• Intuitive user operation and comprehensive manual

• Upper current limit and voltage limit settings

• Easy to read digital V

(magnet and supply voltage) display meter

m/Vs

• Can automatically determine inductance of load

• Drivers for LabView

• User-adjustable threshold quench detection with detection I/O

• Automatic ramp down and quench inputs

• Output signals to helium level and temperature instruments via internal wiring from the magnet station co nnector

• Galvanically isolated Program Output signal to prevent ground loops

• Multifunction vacuum fluorescent display (VFD)

• Menu driven user interface and keypad – logical and intuitive

• One touch Ramp/Pause button

• Digital readout in Field (kilogauss or Tesla) or Current (Amperes)

• Control multiple parallel or series configured supplies

• Front panel indication that current is flowing in magnet leads

• Velocity sensitive encoder dial for fine adjustments

• Programmable piecewise-continuous ramping with 10 curr ent-

dependent rates

• Integrated DB-25 magnet

station connector with wired

DB-25 output signals available

for other system devices

• Built-in Ethernet and RS-232

• Ethernet port allows access to the Programmer across a local network or via the Internet

3

communication interfaces

• Operating software is stored in flash memory and can easily be updated via the Ethernet or RS-232 ports

1

Important for conduction-cooled magnets (dry switch) when a relatively long time is required to cool as compared with wet switches.

2

Manual is conveniently available in the Model 430 firmware (pdf format) - just access the instrument’s IP address via a web browser.

3

An optional external conversion unit is available for interfacing the RS-232 serial port to a GPIB bus.

Simplified Operation

Most frequently used functions are accessible via single ke ystroke or shift plus keystroke. The front panel velocity-accelerated rotary encoder

dial also allows the operator to make fine adjustments to operating param eters of the magnet system. Magnet system signal wiring, such as

magnet voltage/current, helium levels, and temperatures, connect to the rear panel through a s ingle DB-25 connector. Multiple connectors on

the rear panel allow the user to route the signals to the appropriate instruments at the control station; the need for complicated wiring

between the cryostat and magnet control station is thus eliminated.

Digital Control

The digitally-based Model 430 incorporates very high resolution analog <> digital converters and digita l signal processing (DSP) to achieve

excellent stability, precise control, and superior current resolution of the programmed magnetic field. An internal microc omputer manages all

computations, analog data conversion, display/keypad functions, communications I/O, and analog power supply programming signals.

High Resolution and Stability

Precision instrumentation techniques and potentiometer-free designs are employed throughout the instrument to ensure accurate signal

translation for a wide range of conditions. The magnet current is sampled at a resolution of 15.6 µA (for a 125 A supply) and is front-panel

programmable in 0.1 mA increments. A further order of magnitude in accuracy and stability can be achieved by choosing the optional

fluxgate based current measurement system in place of the standard resistive shunt.

Magnet Control and Protection

The Model 430 protects the magnet from runaway sup ply voltage/current or operator error. T he quench detect function, with user-adjustable

quench sensitivity, is designed to detect a magnet quench and quick ly stop power from being deliver ed to the resistive magnet. T he system

can optionally incorporate an AMI Liquid Heli um (LHe) Level Inst rument to prevent magnet quenching due to low LHe level; a utomatic ramp

down of the magnet (even in persistent mode) is initiated if the LHe level drops to a preset level.

A system administrator can program the instrument (from the front panel or remotely) with pass word protected operational limits or any other

parameter(s) which can thereafter not be exceeded or changed without the password. During operation of the system, if the operator

inadvertently attempts to take the magnet system to an excessive magnetic field strength or excessive voltage, the Programmer will not

accept the parameter and will alert the operator that the value exceed the limits.

The Model 430 automatically determines and sets the proper persistent switch heater current (range: 0 to 100 mA; compliance 13.5 V). The

persistent switch heater circuit is continually monitored and the user is notified of circuit problems. The Model 430 Programmer automatically

controls the power supply and persistent switch heater to aid the user in safe and quick transitions in and out of persistent mode.

Loading...

Loading...