American Magnetics 286 User Manual

EXCELLENCE IN MAGNETICS AND CRYOGENICS

AMI

MODEL 286 LIQUID LEVEL CONTROLLER

INSTALLATION, OPERATION, AND

MAINTENANCE INSTRUCTIONS

American Magnetics, Inc.

PO Box 2509, 112 Flint Road, Oak Ridge, TN 37831-2509, Tel: 865 482-1056, Fax: 865 482-5472

May 2005

Declaration of Conformity

Application of Council Directives: Low Voltage Directive 72/23/EEC

EMC Directive 89/336/EEC

Manufacturer’s Name: American Magnetics, Inc.

Manufacturer’s Address: 112 Flint Road,

P.O. Box 2509

Oak Ridge, TN 37831-2509

U.S.A.

Type of Equipment: Liquid Level Instruments

Model Numbers: Model 286

Standar ds to which Conformity is Declared:

Safety: EN 61010-1 (1993) w/A1, A2

EMC: EN55022 (1998) Class A

EN61326 (1997) / EN61000-4-2 (1995) 8kV AD, 4kV CD

EN61326 (1997) / EN61000-4-3 (1996) 1V/m

EN61326 (1997) / EN61000-4-4 (1995) 1kV Power Supply

0.5kV I/O cables

EN61326 (1997) / EN61000-4-5 (1995) 1kV CM, 0.5kV DM

EN61326 (1997) / EN61000-4-6 (1996) 1V

EN61326 (1997) / EN61000-4-11 (1994) 100% interruption - 10ms

I, the undersigned, hereby declare that the equipment specified above complies with the requirements of the aforementioned Directives and Standards and carries the "CE" mark accordingly.

Gregory J. Laughon September 12, 2002

Quality Assurance Manager

American Magnetics, Inc.

Oak Ridge, TN, U.S.A.

Model 286 Liquid Level Controller

Model 286 Configuration

AMI Order Number:_____________________ Shipping Date:_________________________

Model 286 Serial #:______________________ Firmware Revision:_____________________

Input Power Requirements:___________________________________________________________

Calibration Passcode:____________________

Configuration Notes:

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

AMI Warranty

All products manufactured by AMI are warranted to be free of defects in materials and

workmanship and to perform as specified for a period of one year from dat e of shipme nt. In

the event of failure occur ring during n ormal use, AMI, at its o ption, will r epai r or r eplace al l

products or components that fail under warranty, and such repair or replacement shall

constitute a fulfillment of all AMI liabilities with respect to its products. Since, however,

AMI does not have control over the installation conditions or th e use to which its products

are put, no warranty can be made of fitness for a particular purpose, and AMI cannot be

liable for special or consequential damages. All warranty repairs are F.O.B. Oak Ridge,

Tennessee, USA.

Copyright © 2005 by American Magnetics, Inc., Oak Ridge, Tennessee, USA

Rev. 1

Table of Contents

1 Introduction.............................................................................. 1

1.1 Model 286 Fea tu res........ .. ............... ................ ............... ........... 1

1.2 Front Panel Layout ................................................................... 3

1.3 Rear Panel La yo u t.......... .. .. ................ ............... ................ .. ...... 4

1.4 Model 286 Spe ci f i ca t i on s @ 25 °C .............. ............... ............. 6

1.5 Controller Modes Description................................................... 7

1.5.1 Normal Mode ................................................................. 7

1.5.2 Auto-Changeover Mode................................................. 8

1.5.3 Pre-Cool Mode..... ............... .. ................ ............... ........... 9

2 Installation.............................................................................. 11

2.1 Unpacking the Instrument..................................................... 11

2.2 Rack Mounting the Instrument ............................................. 12

2.3 Installing th e Se n sors in the Vess el s ............................... ...... 12

2.4 Connecting the Oscillator Cables to the AMI Sensors..........13

2.5 Connecting C and D Sensor Inputs to the Oscillator............ 13

2.6 Installing the Optional Solenoid-operated Fill Valves..........14

2.7 Connecting to Optional Analog Outputs................................ 15

2.8 Connecting to Communication Options ................................. 15

2.9 Connecting th e In st r u me n t to P ower.... ................ .. ............... 15

3 Calibration .............................................................................. 17

3.1 Calibration C on c e pt s............... ............... .. ................ ............... 17

3.2 Calibration Me th o d s........................... .. ............... ................ .... 19

3.2.1 Open Dewar Ca l i b ra t i on ............ .. ................ ............... 21

3.2.2 Closed Dewar Cal i b ra tion........ ............... ................ .... 22

3.2.3 Approximate Calibratio n ............. ............................. .. 26

3.3 Calibration Me n u Reference........... ... .. ............... ................ .. .. 29

3.3.1 CAL Menu and Passcode Entry..................................30

3.3.2 Sensor Input Se l ec t io n ........ ... ............... ...................... 3 0

3.3.3 Action for Sele ct ed Input..... ................ ............... ......... 3 0

3.3.4 Select Calib ration Sub-M e n u..................... ................. 31

3.3.5 Perform Calibration Sub-Menu .................................. 33

4 Operation................................................................................ 37

4.1 Operational Guidelines........................................................... 37

4.1.1 Energize the In strument..... ................ .. ................ ...... 37

4.1.2 Assign Sensor In p ut s to the Channels ... ................ .. .. 38

i

Table of Contents

4.1.3 Select the Appropriate Uni t s.......... ................ .............3 8

4.1.4 Configure the HI an d L O Ala r ms................... .. ...........38

4.1.5 Configure the A SETPOINT and the B SETPOINT...39

4.1.6 Select the Con t ro l l e r Mo de ..... ............................ .........40

4.2 Sensor Contamination .............................................................42

4.3 Menu Reference........................................................................43

4.3.1 Accessing Menus ..........................................................43

4.3.2 HI Menu...... .. ................ .. ............... ................ .. .............4 4

4.3.3 LO Menu. .. ............... ................ .. ............... ................ ....45

4.3.4 A Menu..........................................................................45

4.3.5 B Menu..........................................................................46

4.3.6 RATE Menu..................................................................46

4.3.7 FILL Menu in Norm a l M od e........... ... .. ............... ... ......46

4.3.8 FILL Menu in Auto-Changeover Mode. .. ... ............... .. 4 8

4.3.9 FILL Menu in Pre- C ool M o de... .. .. ................ .. .............50

4.3.10 ASN Menu .................... ............... ................ ............... .. 5 3

4.3.11 MODE Menu ...............................................................53

4.3.12 MISC Menu... ................ .. ............... ................ ............... 5 4

4.3.13 CAL Menu.....................................................................55

4.4 Feature Matrix.........................................................................56

5 Remote Interface Reference..................................................57

5.1 SCPI Command Summary ......................................................57

5.2 Programming Overview...........................................................61

5.2.1 SCPI Language Introduction.......................................61

5.2.2 SCPI Status System.....................................................61

5.2.3 Standard Event Registers............................................64

5.2.4 Alarm Registers............................................................65

5.2.5 Measurement Re gi st e rs ............ .. ................ .. ...............67

5.2.6 Command Handshaking ..............................................68

5.2.7 Remote Units.................. ............... ................ ............... 6 9

5.3 RS-232/422 Configuratio n.................................. .....................69

5.3.1 Serial Port Connector...................................................70

5.3.2 Termination Characters...............................................70

5.3.3 Device Clear.................... ............... ............................. ..71

5.4 Command Reference ................................................................71

5.4.1 System-Related Commands.........................................71

5.4.2 Status System Commands...........................................72

5.4.3 Alarm Configuration Commands and Queries...........74

5.4.4 Level and Usag e Que r i es .............. ................ ............... 7 5

5.4.5 Fill Modes Control and Query Commands .................75

5.4.6 Assignment C o mmands and Queri e s ...... ... .. ............... 7 8

5.4.7 Calibration C ommands and Qu er i es... .. ......................79

5.4.8 Remote Units Commands and Qu er i e s................. .. ....80

ii

Table of Contents

5.5 Error Messages........................................................................ 82

5.5.1 Command Errors......................................................... 82

5.5.2 Query Errors................................................................ 84

5.5.3 Execution Errors.......................................................... 84

5.5.4 Device Error s .... .. ............... ............................. ............. 85

6 Service .................................................................................... 87

6.1 Model 286 Maintenance. ......................................................... 87

6.2 Model 286 Trou b l e sh ooting Hints .. ................ ............... ... ...... 87

6.3 Modifying the Line Voltage Input Range............................... 92

6.4 Additional Technical Support................................................. 93

6.5 Return Authorization.............................................................. 93

Appendix................................................................................. 95

A.1 4-20 mA Current Loop Option................................................ 95

A.2 J5A and J5B Connector Pinout .............................................. 96

A.3 RS-232 Connector (optional) .................. .. ........................... 98

A.4 RS-422 Connector (optional)................................................ ... 99

Index...................................................................................... 101

iii

Table of Contents

iv

Foreword

Purpose and Scope

This manual contains the operation and maintenance instructions for the

American Magnetics, Inc. Model 286 Liquid Level Controller. The manual

outlines the instructions for instrument use in typical s ystem designs.

Since it is impossible to cover all possible system/sensor designs, the most

common configurations are discussed and the user is encouraged to

contact an authorized AMI Technical Support Represent ative for

information regarding specific configurations not explicitly covered in this

manual.

Contents of This Manual

Introduction introduces the reader to the functions and characteristic s of

the instrument. It provides the primary illustrations of the front and rear

panel layouts as well as documenting the performance specifications.

Installation describes how the instrument is unpacked and installe d in

conjunction with ancillary equipment in a typical liquid delivery system.

Calibration details the available calibration methods and discusses all

related display menu items.

Operation describes how the instrument is used to measure and control

the liqui d level. All instrument displays and controls are documented.

Remote Interface Reference documents all remote commands and

queries available through the serial interface. A quick-reference summary

of commands is provided as well as a detailed description of each.

Service provides guidelines to assist the user in troubleshooting possible

system and instrument malfunctions. Information for contacting AMI

Technical Support personnel is also provided.

The Appendix documents the rear panel connectors.

i

Foreword

Applicable Hardware

Applicable Hardware

The Model 286 has been designed to operate with AMI Capacitance-Based

Liquid Level Sensors. Operation with other sensors is not recommended

and may void the warranty.

General Precautions

Cryogen Safety

Personnel handling cryogenic liquids should be thoroughly instructed and

trained as to the nature of the liquids. Training is essential to minimize

accidental spilling. Due to the low temperature of these materials, a

cryogen spilled on many objects or surfaces may damage the surface or

cause the object to shatter, often in an explosive manner.

Inert gases released into a confined or inadequately ventilated space can

displace sufficient oxygen to make the local atmosphere incapable of

sustaining life. Cryogenic liquefied gases are potentially extreme

suffocation hazards since a small amount of liquid will vaporize an d yi eld

a very large volume of oxygen-displacing gas. Always ensure the location

where the cryogen is used is well ventilated. Breathing air with

insufficient oxygen content may cause unconsciousness without warning.

If a space is suspect, purge the space completely with air and tes t before

entry. If this is not possible, wear a forced-air respirator and enter only

with a co-worker standing by wearing a forced-air respirator.

Cryogenic liquids, due to their extremely low temperatures, will burn the

skin in a similar manner as would hot liquids. Never permit cryogenic

liquids to come into contact with the skin or allow liquid nitrogen to soak

clothing. Serious burns may result from careless handling. Never touch

uninsulated pipes or vessels containing cryogenic liquids. Flesh will stick

to extremely cold materials. Even nonmetallic materials are dangerous to

touch at low temperatures. The vapors expe lled during the venting p rocess

are sufficiently cold to burn flesh or freeze optic tissues. Insulated gloves

should be used to prevent frost-bite when operating valves on cryogenic

tanks. Be suspicious of valves on cryogenic systems; the extremes of

temperature they undergo cause seals to fail frequent ly.

In the event a person is burned by a cryogen or material cooled to

cryogenic temperatures, the following first aid treatment should be given

pending the arrival and treatment of a physician or other medical care

worker:

1. If any cryogenic liquid contacts the skin or eyes, immediately flush

the affected area gently with tepid water (102°F − 105°F, 38.9°C −

40.5°C) and then apply cold compresses.

ii

Foreword

Safety Summary

2. Do not apply heat. Loosen any clothing that may restrict

circulation. Apply a sterile protective dressing to the affected area.

3. If the skin is blistered or there is any chance that the eyes have

been affected, get the patient immediately to a physician for

treatment.

Containers of cryogenic liquids are self pressuri zing (as the li quid boils off,

vapor pressure i n cr e a se s) . Ho se s or li n e s us e d t o tr a ns f e r th e se liq u i d s

should never be sealed at both ends (i.e. by closing valves at both ends).

When pouring cryogenic liquids from one container to another, the

receiving container should be cooled gradually to prevent damage by

thermal shock. The liquid should be poured slowly to avoid spattering due

to rapid boil off. The receiving vessel should be vented during the transfer.

Introduction of a substance at or near room temperature into a cryogenic

liquid should be done with great caution. There may be a violent gas boil

off and a considerable amount of splas hing as a result of this rapid boil ing.

There is also a chance that the material may crack or catastrophically fail

due to forces caused by large differences i n thermal cont raction of diff erent

regions of the material. Personnel engaged in this type of activity should

be instructed concerning this hazard and should always wear a full face

shield and protective clothing. If sever e sp raying or splashing could occur,

safety glasses or chemical goggles along with body length protective

aprons will provide additional protect ion.

The properties of many materials at extremely low temperatures may be

quite different from the properties that these same materials exhibit at

room temperatures. Exercise extreme care when handlin g materials co oled

to cryogenic temperatures until the properties of these materials under

these conditions are known.

Metals for use in cryogenic equipment application must posses s ufficient

physical properties at these low temperatures. Since ordinary carbon

steels, and to somewhat a lesser extent, alloy steels, lose much of their

ductility at low temperatures, they are considered unsatisfactory and

sometimes unsafe for these applications. The austinetic Ni-Cr alloys

exhibit good ductility at these low temperatures and the most widely used

is 18-8 stainless steel. Copper, Monel

considered satisfactory materials for cryogenic service.

®

, brass and aluminum are also

Safety Summary

Cryogenic storage systems are complex systems with the potential to

seriously injure personnel or equipment if not operated according to

procedures. Proper use of safety mechanisms (pressure relief valves,

iii

Foreword

Safety Summary

rupture disks, etc.) included in the cryostat and top plate assembly are

necessary.

Recommended Safety Equipment

•

First Aid kit

•

Fire extinguisher rated for class C fires

•

Leather gloves

•

Face shield

•

Signs to indicate that there are potentially dangero us cr yo ge ns in

use in the area.

Safety Legend

Instruction manual symbol: the product is marked with this

symbol when it is necessary for you to refer to the instruction

manual in order to protect against damage to the product or

personal injury.

Ch 1 & 2

Hazardous voltage symbol.

Alternating Current (Refer to IEC 417, No. 5032).

Off (Supply) (Refer to IEC 417, No. 5008).

On (Supply) (Refer to IEC 417, No. 5007).

Warning

The Warning sign denotes a hazard. It calls attention to a procedure or

practice, which if not corre ctly adhered to, could result in personal inju ry.

Do not proceed beyond a Warning sign until the indicated conditi ons are

fully understood and met.

Caution

The Caution sign denotes a hazard. It calls attention to an operating

procedure or practice, which if not adhered to, could cause damage or

destruction of a part or all of the product. Do not proce ed beyond a Caution

sign until the indicated conditions are fully understood and met.

This notation in the margin indicates a feature that is only available for

Channels 1 and 2 of the Model 286.

iv

1 Introduction

1.1 Model 286 Features

The American Magnetics, Inc. (AMI) Model 286 Liquid Level Controller is

a microprocessor-based instrume n t designed to provide multiple sensor

capacitance-based monitoring and control of liquid levels. In addition to

the brief feature descriptions provided below, a detailed feature matrix is

provided on page 54.

1.1.1 Capacitance-Based Level Sensing

A typical control system consists of a Model 286 Liquid Level Controller ,

up to four AMI liquid level sensor(s), and connecting coaxial cable(s). The

primary instrument sensing element is typically a 3/8 inch (9.5 mm) OD

concentric-tube cylindrical capacitor constructed of stainless steel which

allows the fluid to become the dielectric between the concentric cylinders.

The instrument measures the sensor c apacitanc e, which is di rectly re lated

to the perce n ta g e of the sensor immerse d i n the liquid.

1.1.2 Multiple Sensor Monitoring and Control

The Model 286 is capable of monitoring four independent, capacitance

level sensors and controlling liquid level in up to two vessels by directly

controlling the actuation of two solenoid-operat ed flow control valves.

1.1.2.1 Factory calibrated

The Model 286 is typically calibrated by AMI for matched sensors

in liquid nitrogen, and is ready for immediate use upon delivery. If

the working fluid is something other than nitrogen, an approximate

calibration can be performed or the customer must perform an open

or closed dewar calibration after installation when the sensor can

be immersed in the target fluid.

1.1.2.2 Multiple calibrations per sensor

Each of the four sensor inputs to the Model 286 can ha ve up to four

independent calibrations, which are user-selectable. The user

simply selects the desired calibration using the menu-type

interface. All calibration data is passcode protected and stored in

nonvolatile memory.

1.1.3 Convenient Display and Direct Keypad Entry

The instrument is equipped with a 16-character x 2-line backlit charact ermode LCD display which provides liquid level and setpoint indication in

inches, centimeters, or percent as sele cted by the user. The default dis play

1

Introduction

Model 286 Features

indicates liquid level and fill/loss rate. The current liquid level is updated

and visible in many of the display modes used in configuring various

settings of the instrument.

The 4 x 4 keypad is provided for d irec t entry of values f or setpo ints, sen sor

length, and other functions. The keypad also provides a convenient me nutype interf a ce fo r co n figuring vari o u s i nstrument se tt i n g s th a t require

selection from a list of options.

1.1.4 HI/LO Alarms

Two user-defined setpoints, HI and LO, are provided for all four channels

with front panel LED indications for Channels 1 and 2. The HI and LO

setpoints may also operate two pairs of low-current, rear panel relay

contacts and a built-in audible alarm. The HI/LO relay contact pairs may

be assigned to Channels 1 and 2, or to Channels 3 and 4.

1.1.5 Controller Modes

The Model 286 provides three controller modes: normal, auto-changeover,

and pre-cool. The preferred mo de can be selected via the front panel

keypad or remote interface. The le vel co ntrol s equence varie s based on the

selected mode. See the discussion beginning on page 7 for more

information regarding the function of the controlle r modes .

1.1.6 Remote Operation

The Model 286 is capable of providing up to two analog 0−10 VDC signals,

which corresponds to 0−100% liquid level, accessible from the rear panel of

the instrument for use with a voltage recorder. This is a fac tory-installed

option and should be specified at the time the instrument is purchased.

Up to two self-powered (i.e. does n ot require an external power supply) 420 mA current loop outputs can also be ordered as an option.

Additional digital interface options, including RS-232 or RS-422, are

available as options. The serial remote int erface provid es a comprehensive

command set for remote monitoring and configuration of all functions of

the instr u m e nt.

2

Introduction

Front Panel Layout

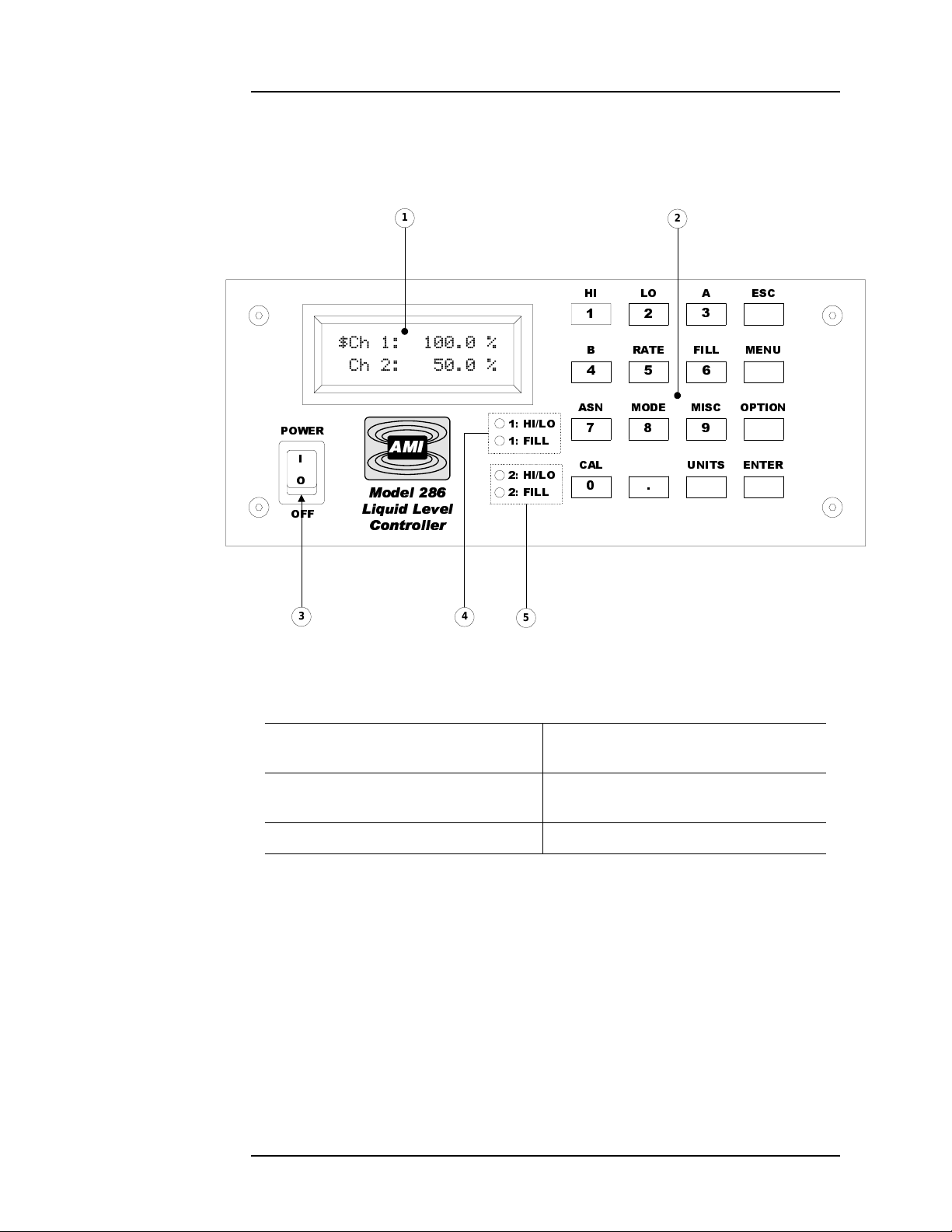

1.2 Front Panel Layout

POWER

I

O

OFF

3

1

$Ch 1: 100.0 %

Ch 2: 50.0 %

AMI

Model 286

Liquid Level

Controller

4

1: HI/LO

1: FILL

2: HI/LO

2: FILL

5

2

HI LO

12

B RATE FILL

456

ASN MODE MISC

789

CAL

0

.

A

3

UNITS ENTER

ESC

MENU

OPTION

1 16 Character x 2 Line LCD Display

with LED Backlighting

4 HI/LO Alarm and Fill LED

Indicators for Channel 1

2 4 x 4 Keypad 5 HI/LO Alarm and Fill LED

Indicators for Channel 2

3 Powe r Switc h

3

Introduction

Rear Panel Layout

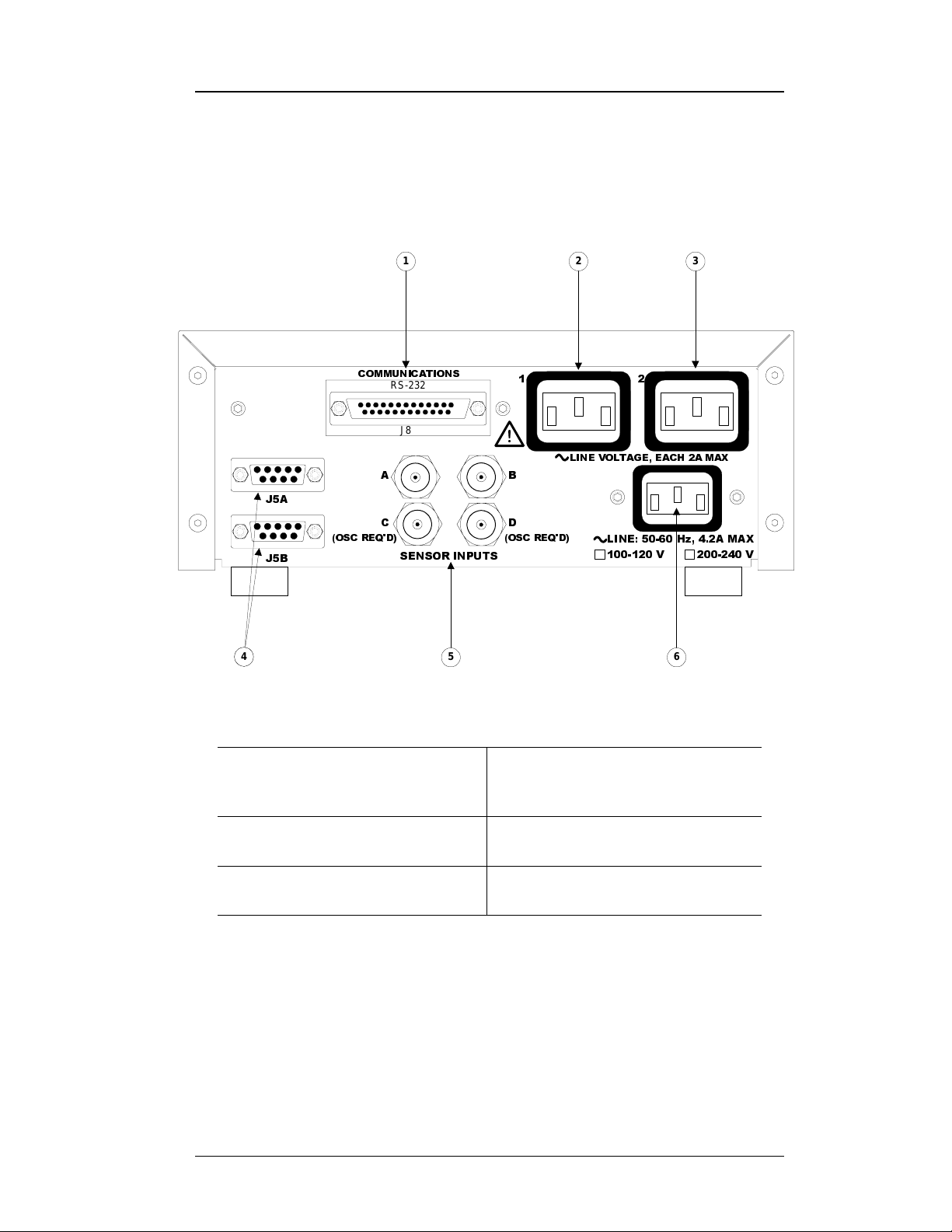

1.3 Rear Panel Layout

1 2 3

COMMUNICATIONS

RS-232

J8

J5A

CD

J5B

74

SENSOR INPUTS

5 6

1 Optional Digital Communications

Port (RS-232 option illustrated;

RS-422 also available)

12

!

LINE VOLTAGE, EACH 2A MAX

BA

(OSC REQ'D)(OSC REQ'D)

4 Auxiliary DB-9 Connectors

(see

Appendix

LINE: 50-60 Hz, 4.2A MAX

100-120 V 200-240 V

for pinout)

2 Switched AC Output 1

(IEC-320 female connector)

3 Switched AC Output 2

(IEC-320 female connector)

4

5 Four BNC Coaxial Sensor Inputs

[denoted as A - D]

6 Power cord connector

(IEC-320 male)

Introduction

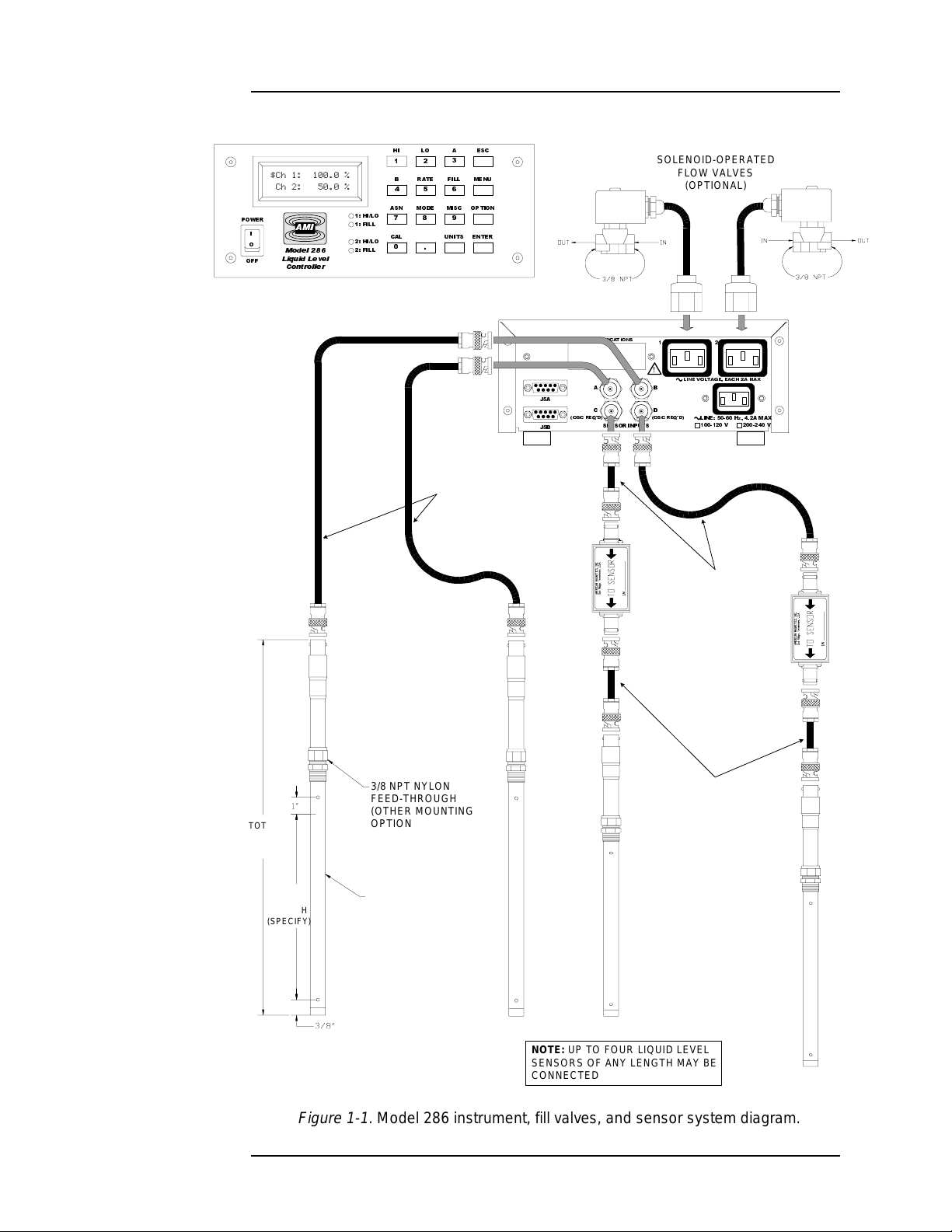

System Diagram

FRONT PANEL

$Ch 1: 100.0 %

Ch 2: 50.0 %

POWER

O

OFF

MODEL 286

LIQUID LEVEL

CONTROLLER

I

AMI

Model 286

Liquid Level

Controller

1: HI/LO

1: FILL

2: HI/LO

2: FILL

ASN MODE MISC

CAL

.

A

3

UNITS ENTER

HI LO

12

B RATE FILL

456

789

0

OSCILLATOR CABLES

RG-59/U COAXI A L

CABLE, 6 FT. LENGTH

(FIXED)

ESC

MENU

OPTION

REAR PANEL

J5A

J5B

SOLENOID-OPERATED

FLOW VALVES

COMMUNICATIONS

CD

SENSOR INPUTS

12

!

BA

(OSC REQ'D)(OSC REQ'D)

(OPTIONAL)

LINE VOLTAGE, EACH 2A MAX

LINE: 50-60 Hz, 4.2A MAX

100-120 V 200-240 V

TOTAL

SENSOR

LENGTH

(SPECIFY)

ACTIVE

SENSOR

LENGTH

3/8 NPT NYLON

FEED-THROUGH

(OTHER MOUNTI NG

OPTIONS AVAILABLE )

SENSOR

EXTENSION CABLES

RG-59/U COAXI A L

CABLE, 6 FT. LENGTH

STANDARD (VARIABLE

UP TO 500 FT.)

OSCILLATOR CABLES

RG-59/U COAXI A L

CABLE, 6 FT. LENGTH

(FIXED)

A PROPERLY CONNECTED W ARM

SENSOR CAN READ ~ +2% UNTIL COOL

Figure 1-1.

Model 286 instrument, fill valves, and sensor system diagram.

NOTE: UP TO FOUR LIQUID LEVEL

SENSORS OF ANY LENGTH M AY BE

CONNECTED

5

Introduction

Specifications

1.4 Model 286 Specifications @ 25 °C

Level Measurements

Resolution: 0.1 %, 0.1 cm, or 0.1 in

Linearity: ± 0.1 % or 1 mm (whichever is greater)

Operating Parameters

HI, A, B, and LO Setpoints: 0 % to 100 % adjustable

HI/LO Alarm Relay Contact Ratings: 30 VAC or 60 VDC, 10 VA (up to 0.5A

maximum) — 20 V at 0.5 A to 60 V at 0.167 A

(normally open, closed on alarm)

Controller Outputs: AC line voltage at 2 A maximum each output

Analog Outputs

Integral Non-linearity: ± 0.012 %

Resolution: 16 bits

Total Error: ± 0.75 % for 4-20 mA output

± 1 % for 0-10 V output

Current Drift (4-20 mA): ± 75 ppm / °C maximum

Voltage Drift (0-10 V): ± 100 ppm / °C maximum

Power Requirements

Primary: 100-120 or 200-240 VAC ±10%, 50 - 60 Hz

4.2 A maximum (25 VA plus sum of controller

output currents)

Physical

Dimensions (Standard): 97 mm H x 213 mm W x 290 mm D

(3.8" H x 8.4" W x 11.4" D)

Weight (Standard): 1.9 kg (4.2 lbs.)

Dimensions (Rack Mount): 89 mm H x 483 mm W x 290 mm D

(3.5" H x 19" W x 11.4" D)

Weight (Rack Mount): 2.2 kg (4.9 lbs.)

RG-59U Extension Cable Length: 500 ft. maximum

Environmental

Ambient Temperature: Operating: 0 °C to 40 °C (32 °F to 104 °F)

Nonoperating: −20 °C to 60 °C (−4 °F to 140 °F)

Relative Humidity: 0% to 95%; non-condensing

6

Introduction

Controller Modes Description: Normal Mode

1.5 Controller Modes Description

The Model 286 provides a unique feat ure in th e availability o f three modes

for level control. The function of each mode is summarized below and a

diagram is provided to help illustrate the function. The controller modes

provide flexibility for solving a wide range of level control problems with a

minimum of external hardware or logic.

1.5.1 Normal Mode

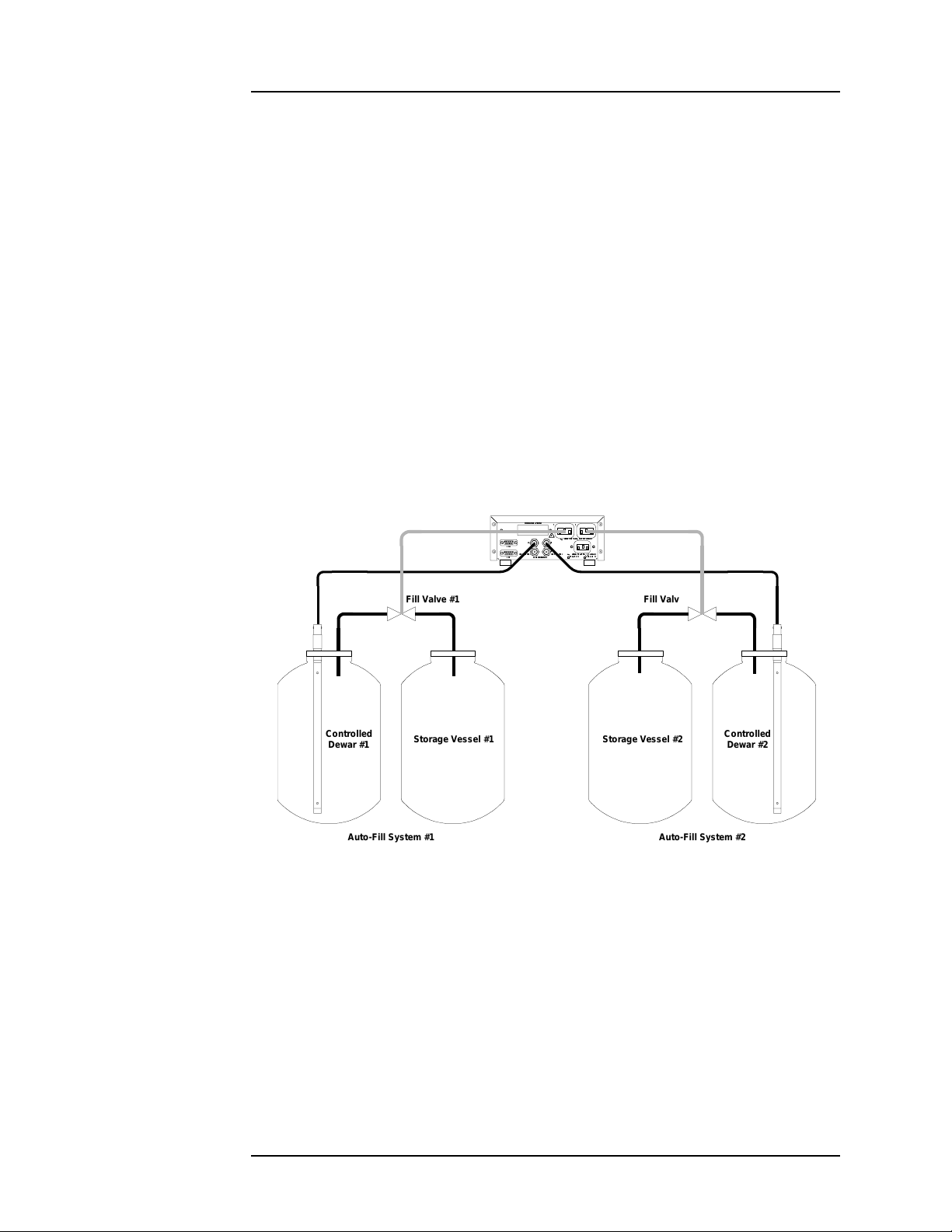

In the normal mode, as shown in Figure 1-2, Channels 1 and 2 of the

Model 286 act as independent auto-fill systems. As each level falls below

the “B” setpoint, an independent fill cycle is initiated and fills the

controlled dewar to the “A” setpoint via two separate solid-state-relaycontrolled AC outputs which can drive solenoi d-actuated valves. The A and

B setpoints for Channels 1 and 2 operate as independent liquid level

control bands.

Model 286

COMMUNICATIONS

12

!

LINE VOLTAGE, EACH 2A MAX

BA

J5A

CD

(OSC REQ'D)(OSC REQ'D)

LINE: 50-60 Hz, 4.2A MAX

100-120 V 200-240 V

SENSOR INPUTS

J5B

Controlled

Dewar #1

Auto-Fill System #1

Figure 1-2.

Fill Valve #1 Fill Valve #2

Storage Vessel #1

Storage Vessel #2

Auto-Fill System #2

Normal mode diagram illustrating two

independent

auto-fill systems.

Controlled

Dewar #2

7

Introduction

Controller Modes Description: Auto-Changeover Mode

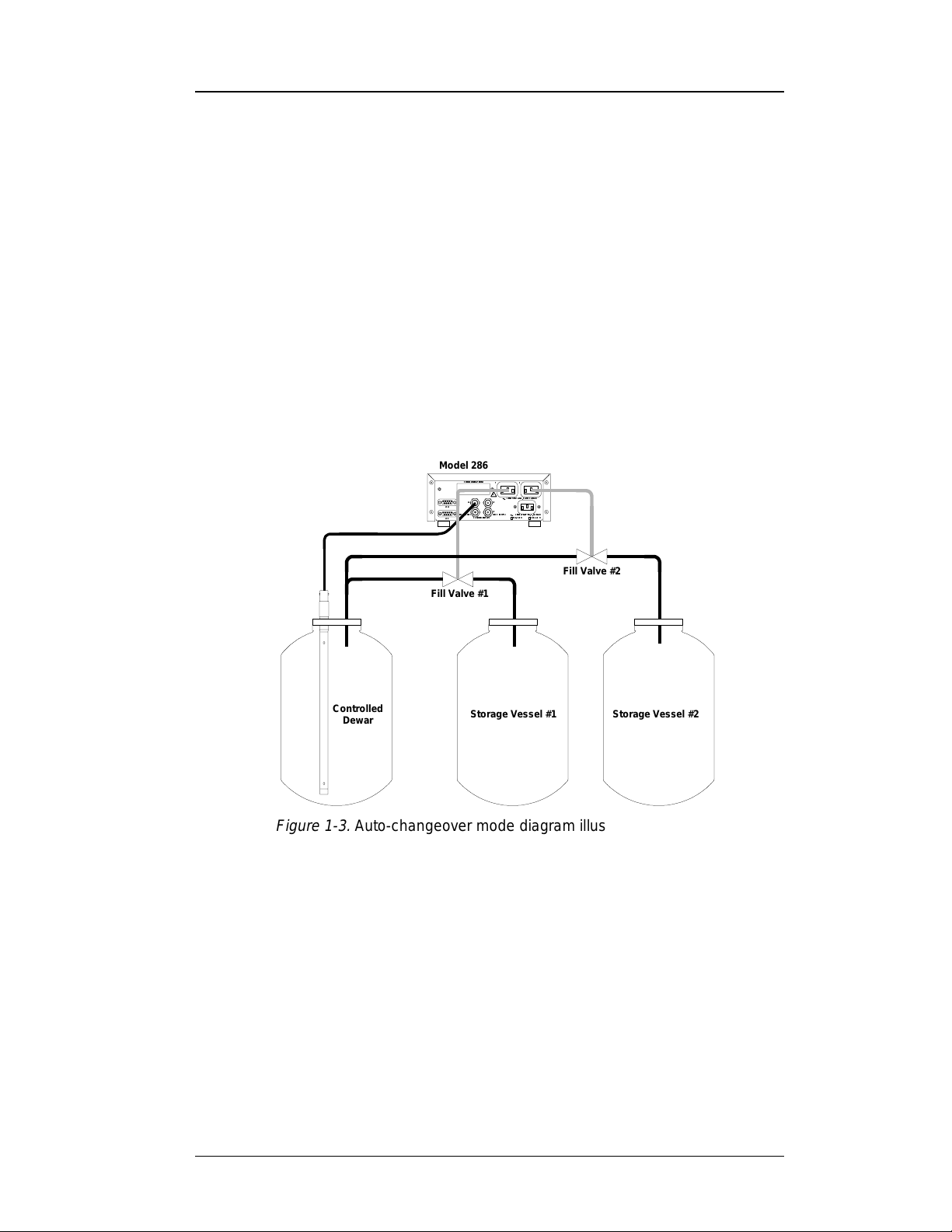

1.5.2 Auto-Changeover Mode

In auto-changeover mode, as illustrated in Figure 1-3, the Model 286

monitors and controls liquid l evel measured via Channel 1, and us es liquid

supplied from two storage vessels. The A and B setpoints for Channel 1

function as the liquid level cont rol band for the cont rolled d ewar. The d ual

AC outputs control a fill valve for each of the two storage vessels. Channel

2 is unavailable in the auto-changeover mode.

The instrument either monitors dry contacts to determine availability of

liquid from each of the two storage vessels or determines availability by fill

timeouts. The Model 286 automa tically switches from one storage vessel t o

the next. This allows one of the two storage vessels to be replaced when

empty without interrupting the availability of liquid to the contro lled

dewar.

Model 286

COMMUNICATIONS

12

!

LINE VOLTAGE, EACH 2A MAX

J5A

J5B

BA

CD

(OSC REQ'D)(OSC REQ'D)

SENSOR INPUTS

LINE: 50-60 Hz, 4.2A MAX

100-120 V 200-240 V

Controlled

Dewar

Figure 1-3.

Fill Valve #2

Fill Valve #1

Storage Vessel #1

Storage Vessel #2

Auto-changeover mode diagram illustrating the two

storage vessels and one controlled dewar.

8

Introduction

Controller Modes Description: Pre-Cool Mode

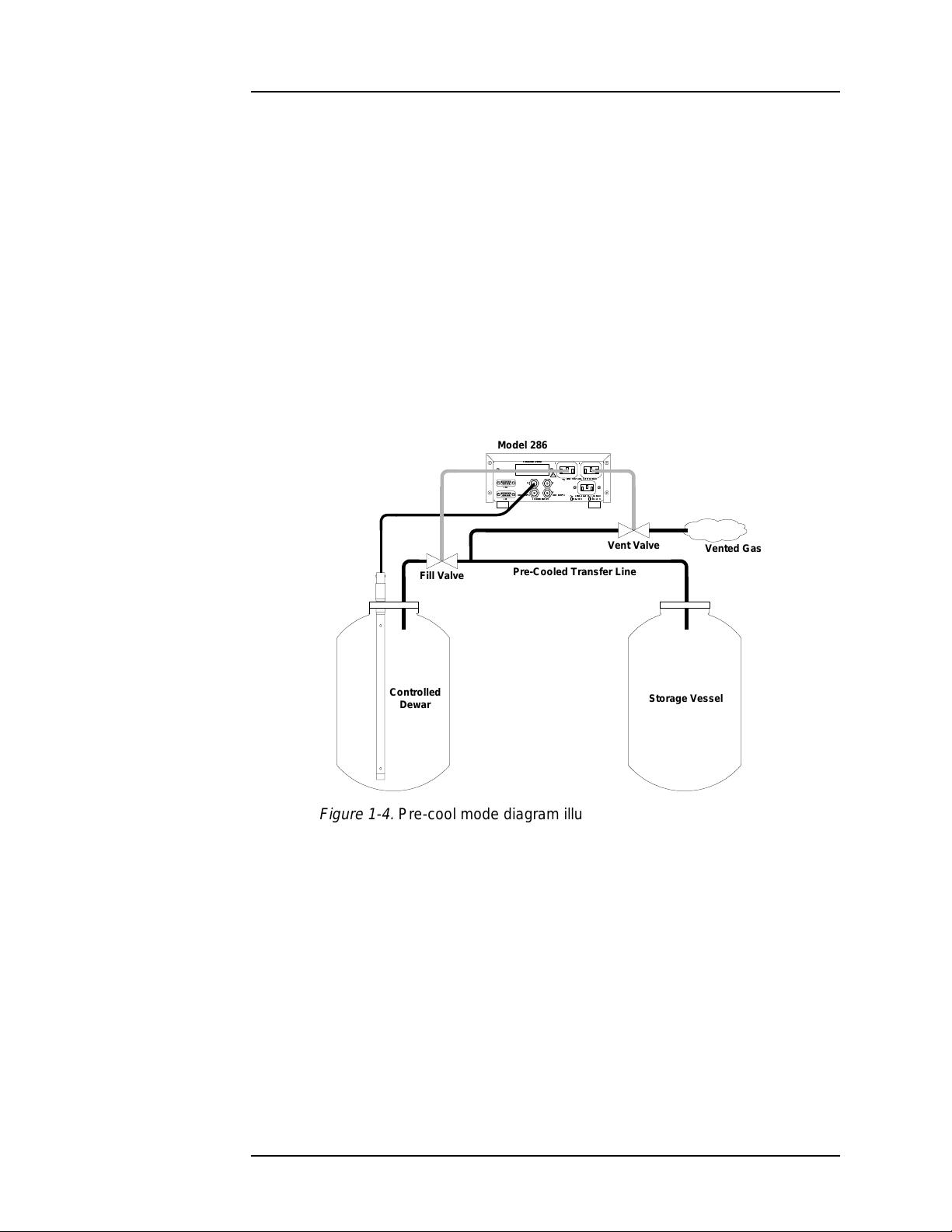

1.5.3 Pre-Cool Mode

The pre-cool mode, as illustrated in Figure 1-4, provides fo r cooling of a

cryogen transfer line before opening the transfer line to the controlled

dewar. The A and B setpoints for Channel 1 function as the liquid level

control band for the controlled dewar. AC Output 1 controls a fill valve for

the controlled dewar, while AC Output 2 controls a vent valve. Channel 2

is unavailable in the pre-cool mode.

When a fill cycle is initiated, the vent valve is initially opened for a userprogrammed time, after which the vent valve is closed and the fill valve to

the controlled dewar is opened. During the time the vent valve is open, the

cryogen cools the transfer line, so that there is a minimal amount of

cryogen gas entering the controlled dewar once the fill valve is opened.

Model 286

COMMUNICATIONS

12

!

LINE VOLTAGE, EACH 2A MAX

J5A

J5B

BA

CD

(OSC REQ'D)(OSC REQ'D)

SENSOR INPUTS

LINE: 50-60 Hz, 4.2A MAX

100-120 V 200-240 V

Figure 1-4.

Fill Valve

Controlled

Dewar

Vent Valve

Pre-Cooled Transfer Line

Storage Vessel

Vented Gas

Pre-cool mode diagram illustrating one storage vessel,

a vent valve, and one controlled dewar.

9

Introduction

Controller Modes Description: Pre-Cool Mode

10

2Installation

Warning

Before energizing the instrument, the earth ground of the power

receptacle must be verified to be at earth potential and able to carry

the rated current of the power ci rcuit. Using extension cords should

be avoided; however, if one must be used, ensure the ground

conductor is intact and capable of carrying the rated curr ent.

In the event that the ground path of the instrument becomes less

than sufficient to carry the rated current of the power circuit, the

instrument should be disconnected from power, la beled as unsafe,

and removed from place of operation.

Do not operate this instrument in the presence of flammable gases.

Doing so could result in a life-threatening explosion.

Do not modify this instrument in any way. If component

replacement is required, return the instrument to AMI facilities as

described in the Service section of this manual.

If the instrument is used in a manner not specified by AMI, the

protection provided by the equipment may be impaired.

2.1 Unpacking the Instrument

Carefully remove the instrument, sensor(s) , os cillator(s) and

interconnecting coaxial cables from the shipping carton and remove all

packaging material. A rack mounting kit is supplied if the instrument was

purchased with the rack mount option.

Note

If there is any shipping damage, save all packing material and

contact the shipping representative to file a damage claim. Do not

return the instrument to AMI unle ss prior authorization has been

received.

If the chassis is a table top model, place the instrument on a flat, secure

surface.

11

Installation

Installing the sensor

2.2 Rack Mounting the Instrument

If the instrument has a rack mount chassis, follow the following procedure :

a. Attach the rack mount a dapter piece s to the in strument by fi rst

removing the four screws on the side of the instrument that

attach the cover to the chassis. Atta ch the rack mount adapter

pieces to the sides of the instrument by reinstalling the screws.

b. Install the instrument in a 19" rack by securing the front panel

to the rail in each of the four corners with mounting hardware

supplied by the cabinet manufacturer.

Warning

Do not remove the rubber feet from the bottom of the intsrument and

then reinsert the origin al screws. Doing so could present a se vere

life-threatening electrical hazard. Screws longer than 1/4" will

contact and damage the printed circuit board inside the unit.

2.3 Installing the Sensors in the Vessels

Exercise care when installing the sensor since dents, crimps, bends or

other physical distort ions in the cylindric al capacito r will ch ange elect rical

characteristics, possibly caus ing calibration errors and/or disruption of

proper instrument operation. Before installing the sensor, the user may

want to review the Calibration and Operation sections to determine what,

if any, calibration procedures may be necessary.

Note

The coaxial interconnecting cables and the oscillator are

temperature sensitive and should be mounted in such a manner as

to avoid large t emper ature c hanges such a s th ose encount ere d in t he

path of dewar vents.

12

Installation

Sensor cabling

2.4 Connecting the Oscillator Cables to the AMI Sensors

For Model 286 inputs A and B, connect each sensor to the Model 286 using

a supplied 6 foot RG-59/U coaxial cable.

For Model 286 inputs C and D, an external AMI oscillator must be used

(note that inputs A and B do not require an external oscillator). For each

sensor to be connected to either inpu t C or input D of the i nstrument,

connect the sensor to the oscillator using a s upplied 6 foot RG-59/U coaxial

cable. Ensure the oscillator is connected in the correct orientation (see

page 5 for a system diagram).

The cable length between the in strument and sensor for inputs A and B (or

the oscillator and the sensor for inputs C and D) should not exceed 6 feet

unless longer lengths were discussed with an Authorized AMI Technical

Representative.

Caution

Moisture or contaminants in any of the BNC coaxial connectors can

short out the sensor and cause a

erroneous readings. A pack of non-conductive electrical connection

lubricant (ECL or “Dielectric Tune-up Grease”) has been included

with the liquid level sensor packaging to reduce the possibility of

this occurring. If desired, apply a small amount of ECL to any of the

BNC connectors that may be exposed to mo isture. Mate the ECLcoated connectors then remove any excess ECL from the outside of

the connector. Added protection can be achieved by covering the

ECL-coated connections with a short section of heat-shri nk tubing.

<No inp>

indication or other

Note

MSDS sheets for the ECL are available upon request.

2.5 Connecting C and D Sensor Inputs to the Oscillator

Caution

Operation of the AMI Model 286 Liquid Level Instrument with a

device other than an AMI Liquid Level Sensor may void the

instrument warranty.

Connect each oscillator to either the C or D input of the Model 286 using a

RG-59/U coaxial cable. The length of the extension cable can be varied to

suit the specific application. AMI has confirmed pro per operation for up to

500 feet of RG-59/U coaxial cabling between the instrument and oscilla tor.

13

Installation

Valve installation

2.6 Installing the Optional Solenoid-operated Fill Valves

Install each solenoid-operated fill valve by connecting the valve power

cable to the AC controller output receptacle on the rear panel of the

instrument (refer to the rear panel layout illustrated on page 4). The

standard AMI supplied valve has a 9/32 inch orifice and the input and

output are tapped for 3/8 NPT. Set ting the FILL function to AUTO should

be avoided until the channels have been assigned and the setpoints have

been specified. See t he Operation section for details on assigning channels,

specifying setpoints, and selecting the fill modes for the AC output

receptacles.

Note

When using the pre-cool mode, AC output 1 must be connected to the

fill valve and AC output 2 must be connected to the vent valve.

Caution

When using a solenoid-operated control val ve with the Model 286,

ensure the valve is configured for the operating voltage and line

frequency of the Model 286. Failure to do so will result in faulty

operation and may also result in valve damage.

Warning

Before touching any of the controller output receptacle terminals or

touching the wiring connected to these terminals, remove power to

the instrument by unplugging it or turning the powe r switch to the

off position.

The controller output re ceptacle supplies hazardo us AC line voltage

potentials. It is for use with equipment which has no live par ts

which are accessible. Conductors conn ected to its terminals must be

insulated from user contact by reinforced or double insulation

capable of withstanding 4250 V (impulse ) for a 240 VAC Category II

installation, or 2550 V (impulse) for a 120 VAC Category II

installation.

This instrument is desi gned for opera tion from a single- phase power

source for maximum safety. Th e controller output receptacle

circuitry only switches the “line” (“hot”) connection to the AC mains.

If two-phase power is applied, any equipment connected to the

controller output receptacle conducts hazardous AC voltage even

when the controller output receptacle is not energized.

14

Installation

Verifying power requirements

2.7 Connecting to Optional Analog Outputs

See paragraph A.1 on page 95 for connection details for the 4-20 mA

analog output option. See paragraph A.2 on page 96 for connection details

for the 0-10 VDC analog output option.

2.8 Connecting to Communication Options

See paragraph 5.3.1 on page 70 instructions concerning connection to the

serial communications options (RS-232 and RS-422). Paragraph A.3 on

page 98 shows RS-232 cable wiring. Paragraph A.4 on page 99 shows RS422 cable wiring.

2.9 Connecting the Instrument to Power

Warning

The Model 286 operates on 50-60 Hz power and may be configured

for 110-120 or 208-240 VAC ±10% (100 or 200 VAC ±10% for Japan

and South Korea). The power requirement for each ins tr ume nt is

marked on the ca l ib r ati o n st ic k e r on th e bo tto m o f th e in s t r u me n t .

Be sure your instrument is co nfigu red f or your powe r so urce pr ior to

plugging in the line cord. Do not fail to connect the input ground

terminal securely to an external eart h ground.

Ensure the front panel switch is in the OFF position. Verify that the

instrument is configured for the proper operat ing voltage by referring to

the calibration sticker affixed to the bottom of the instrument. If the

operating voltage is correct, plug the line cord into the appropriate power

receptacle.

Warning

Do not install the instrument in a manner that prevents removal of

the line cord from the rear panel of the instrument.

15

Installation

Verifying power requirements

16

Loading...

Loading...