American Magnetics 188CPS User Manual

EXCELLENCE IN MAGNETICS AND CRYOGENICS

MODEL 188CPS

AMI

POINT-SENSING INSTRUMENT

INSTALLATION, OPERATION, AND

MAINTENANCE INSTRUCTIONS

American Magnetics, Inc.

PO Box 2509, 112 Flint Road, Oak Ridge, TN 37831-2509, Tel: 865 482-1056, Fax: 865 482-5472

Rev. 1, Feb 1998

Introduction

The American Magnetics, Inc. (AMI) Model 188CPS Point Sensing Instrument

system is a microprocessor-based solution designed to provide sensing for up to five

(5) points for virtually any non-conducting liquid.

Capacitance-based point sensing

The system consists of a Model 188CPS Point Sensing Instrument, plate sensors, and

connecting cables. The instrument sensing elements are typically parallel plate

capacitors which are mounted on a stainless steel support tube. The plate capacitors

allow a non-c ondu cting liqui d (or ot her mat erial ) to become t he di elect ric between th e

plates. The instrument measures the plate capacitance which is directly related to the

percentage of the plate immersed in the non-conducting liquid.

The plate sensors are normal ly constructed i n diameters of 3.5" to 5" , howe v er , custom

designs which require smaller diameter tank penetrations can be provided for specific

needs. Up to five plate sensors can be monitored by a single Model 188CPS

instrument. The support tube may also function as a cylindrical capacitor which may

be used for continuous level measurement using a separate AMI level instrument.

Simple operation

The instrument is equipped with five tri-color LED’s which provide positive

indication of immersed or exposed state for each point, as well as providing fault

indications. No user input is required for normal operation of the instrument.

Remote monitoring

The Model 188CPS provides five relay contact pairs available through a terminal

block located on the rear panel. When a plate sensor is immersed in the nonconducting liquid, the respective relay contact pair closes.

1

Introduction

2

Introduction

1

2 3

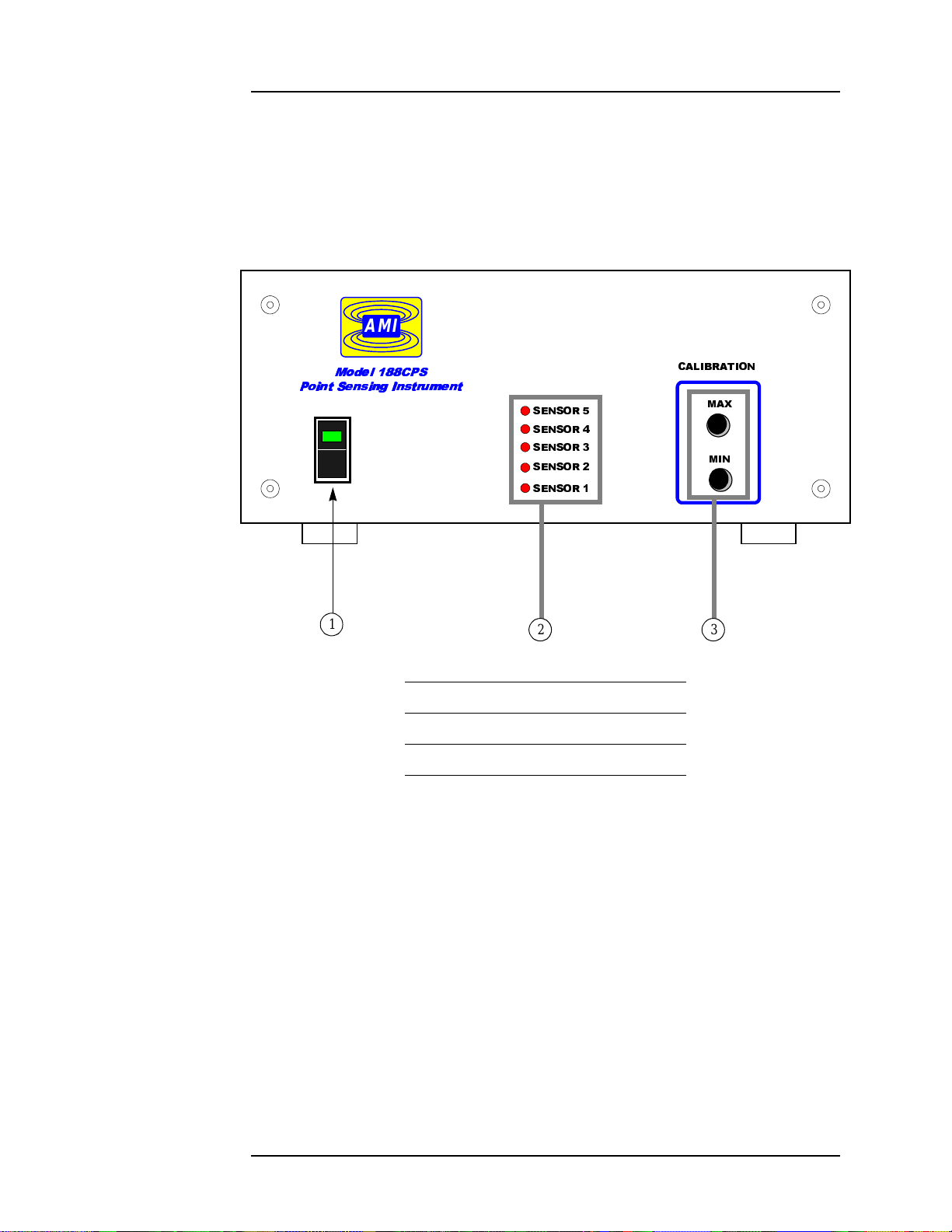

Front Panel Layout

AMI

0RGHO &36

0RGHO &36

3RLQW 6HQVLQJ ,QVWUXPHQW

3RLQW 6HQVLQJ ,QVWUXPHQW

1

Power switch and indicator LED

2

LED indicators

3

Recessed calibration push-buttons

6(1625

6(1625

6(1625

6(1625

6(1625

&$/,%5$7,21

0$;

0,1

3

Introduction

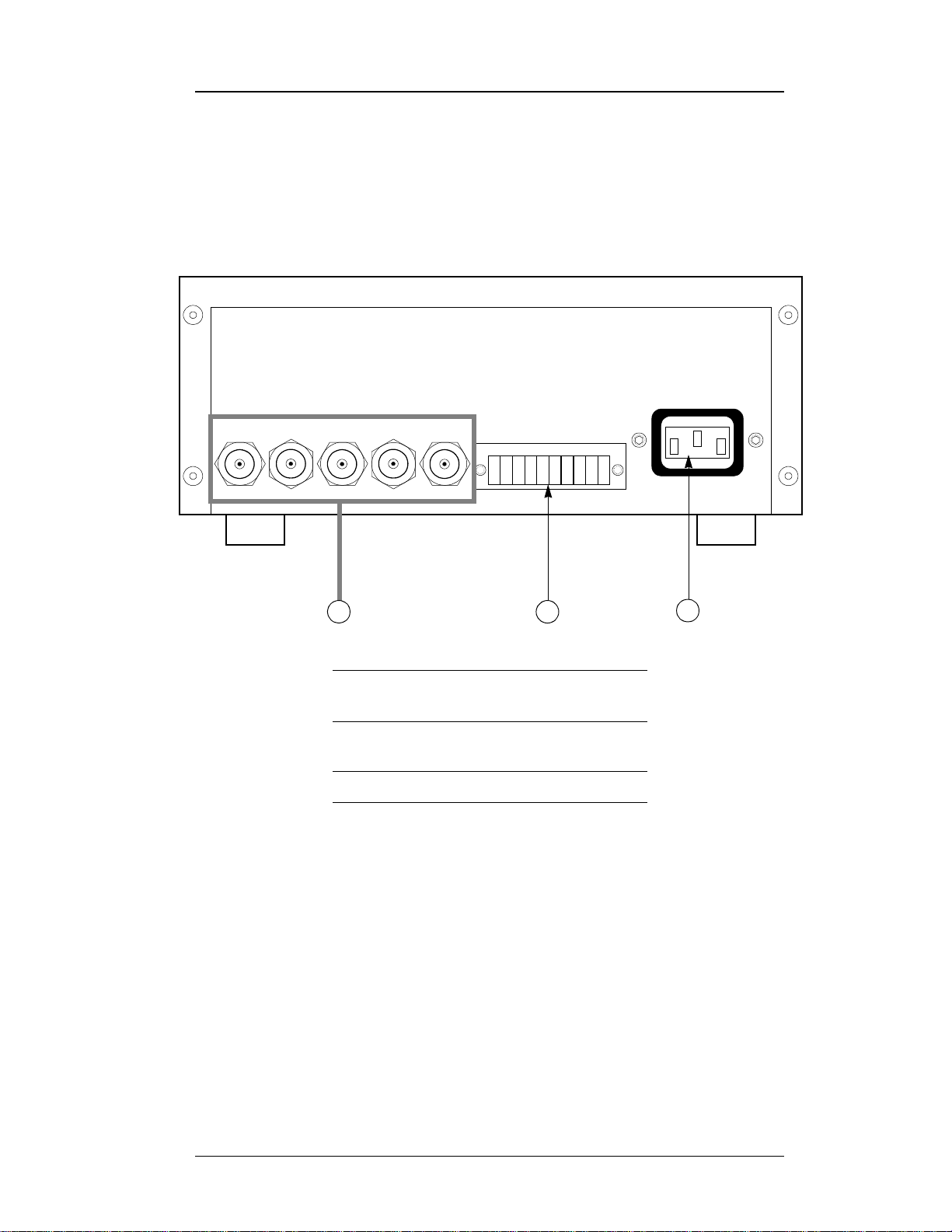

Rear Panel Layout

AMERICAN MAGNETICS, INC.

OAK RIDGE, TN U.S.A.

OSC1

OSC2 OSC4OSC3

OSC5

115/230 VAC 50/60 Hz

SELECTOR SW. INSIDE

RELAY CONTACTS

12345

1 2

1

coaxial connectors to

BNC

oscillator units via the extension cables

2

Relay contacts terminal block

(closed pair = immersed)

3

Input power connector

3

4

Introduction

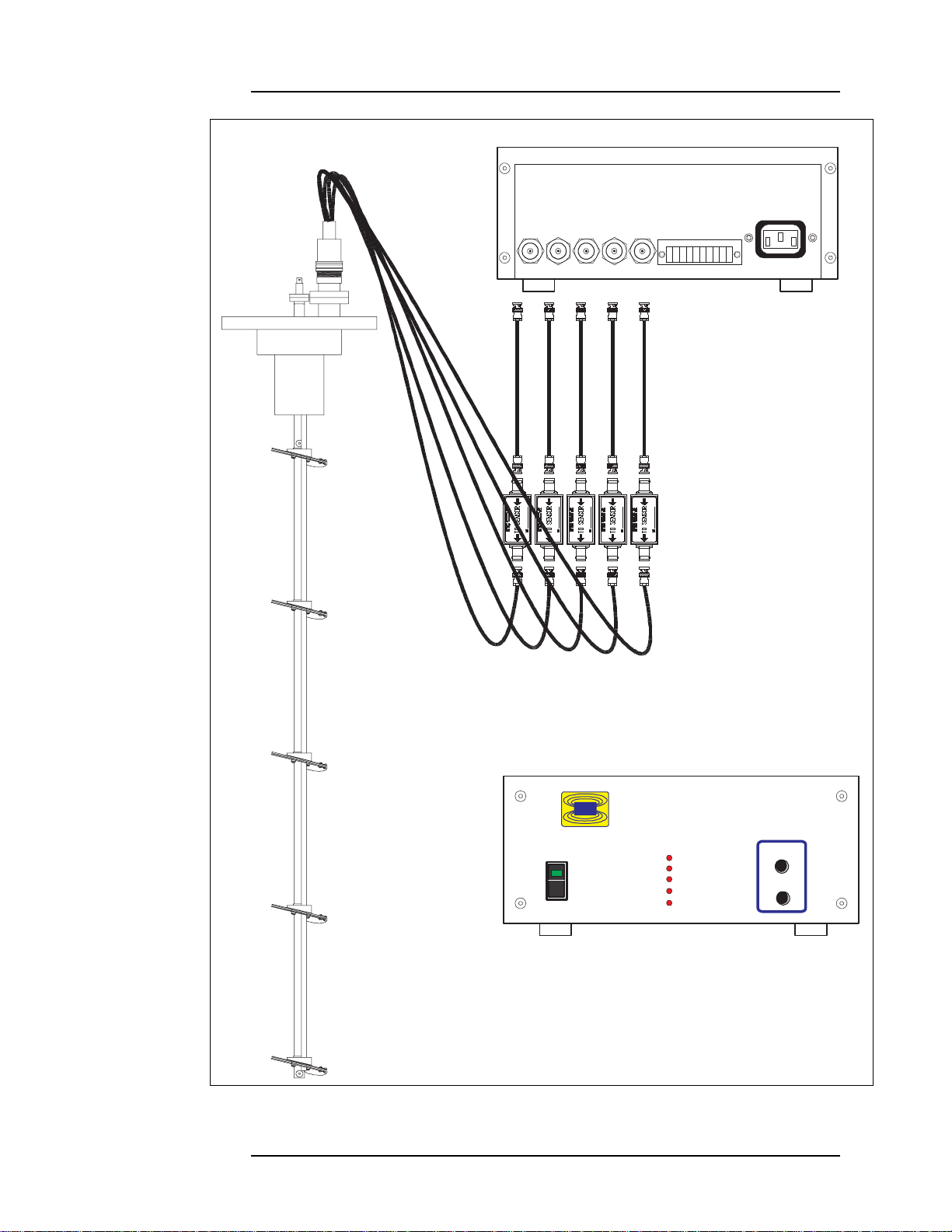

System Diagram

REAR PANEL

AMERICAN MAGNETICS, INC.

OAK RIDGE, TN U.S.A.

OSC1

OSC2 OSC4OSC3

RELAY CONTACTS

OSC5

12345

EXTENSION CABLES

RG-59/U COAXIAL

CABLE, 6 FT. LENGTH

STANDARD (VARIABLE)

115/230 VAC 50/60 Hz

SELECTOR SW. INSIDE

OSCILLATOR CABLES

RG-59/U COAXIAL

CABLE, 6 FT. LENGTH

SUGGESTED

FRONT PANEL

AMI

Model 188CPS

Point Sensing Instrument

MODEL 188CPS

POINT SENSING

INSTRUMENT

OSCILLATORS

SENSOR 5

SENSOR 4

SENSOR 3

SENSOR 2

SENSOR 1

CALIBRATION

MAX

MIN

Model 188CPS Point-Sensing System Diagram (not drawn to scale).

5

Introduction

System Diagram

6

Introduction

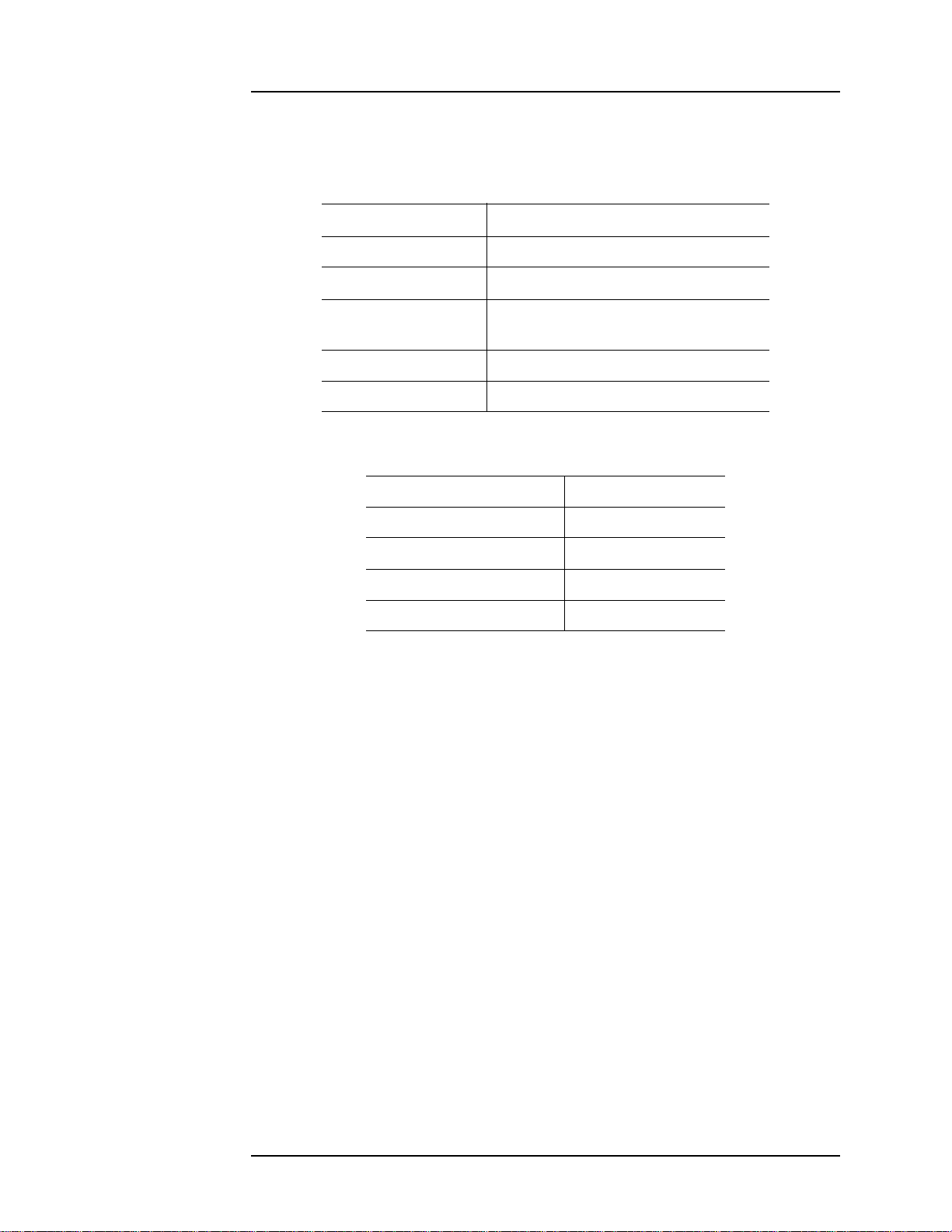

Specifications

Instrument Specifications

Input line voltage

Input line frequency 50-60 Hertz, 1 phase

Measurement accuracy

Dimensions 3.8" H x 8.4" W x 11.1" D, Standard

Weight 4.0 lbs. Standard; 4.9 lbs. Rack Mount

Operating environment 15 - 50°C non-condensing

115/230 or 100/200 VAC

±

0.25 inches

3.475" H x 19" W x 11.1" D, Rack Mount

±

10%

Relay Contact Specifications

Max switching VA 10

Max switching voltage 200 VDC

Max switching current 0.5 A

Max continuous current 1.5 A

Dielectric between contacts 200 VDC minimum

7

Introduction

Manual Legend

Instruction manual symbol: the product is marked with this symbol

when it is necessary for you to refer to the instruction manual in

order to protect against damage to the product or personal injury.

Hazardous voltage symbol.

Warning

The Warning sign denotes a hazard. It calls attention to a procedure

or practice, which if not correctly adhered to, could result in

personal injury. Do not proceed beyond a Warning sign until the

indicated conditions are fully understood and met.

Caution

The Caution sign denotes a hazard. It calls attention to an operating

procedure or practice, which if not adhered to, could cause damage

or destruction of a pa rt or all o f the pr oduct. Do not pr oceed bey ond

a Caution sign until the indicated conditions are fully understood

and met.

8

Loading...

Loading...