American Magnetics 175 User Manual

MODEL 175

Two-Wire

Continuous Level

Transmitter

INSTALLATION,

OPERATION &

MAINTENANCE MANUAL

[mn-175, Rev 2]

Feb 2007

American Magnetics, Inc.

112 Flint Road

Oak Ridge, TN 37830

Phone#: (865) 482-1056

Fax#: (865) 482-5472

www.americanmagnetics.com

TABLE OF CONTENTS

SECTION A

Foreword .......................................................................................................................... 3

Safety Precautions........................................................................................................... 3

Warranty .......................................................................................................................... 4

Return Authorization ........................................................................................................ 4

Introduction ......................................................................................................................... 4

System Description .......................................................................................................... 5

Instrument Model Configuration....................................................................................... 5

Model 175 Transmitter Dimensional Drawings ................................................................ 6

Probe (Capacitance Sensor) Model Configuration........................................................... 7

Instrument Specifications ................................................................................................ 8

Probe Specifications ....................................................................................................... 8

Operating Principle .......................................................................................................... 8

Installation .......................................................................................................................... 8

Integral-mounted Transmitters......................................................................................... 9

Remote-mounted Transmitters ........................................................................................ 10

SECTION B

Set-up ................................................................................................................................ 13

ProxCal Calculation ......................................................................................................... 13

Menu Item Descriptions ................................................................................................... 14

Menu Structure ................................................................................................................ 15

Troubleshooting .................................................................................................................. 16

General .......................................................................................................................... 16

Error Display .................................................................................................................... 16

Drift Test .......................................................................................................................... 17

System Loop Test ............................................................................................................ 17

Check Probe .................................................................................................................... 17

2 of 18

SECTION A

Foreword

This section contains the Installation instructions for the American Magnetics (AMI) Model 175

Two-Wire Continuous Level Transmitter. Since it is impossible to cover all possible

sensor/systems configurations, only the most common are discussed in this document. The

user is encouraged to contact an authorized American Magnetics Customer Support

Representative for specific situations.

Foreword discusses safety precautions and safety notations as well as other generic information

used throughout this manual.

Introduction explains the functions and characteristics of the instrument, describes the model

number configurations for the instrument and the probe, and documents the performance

specifications, as well as, an explanation of the operating principle.

Installation describes the procedure for properly unpacking and installing the transmitter into

your vessel.

Safety Precautions

Conventions

The conventions used in this manual follow ANSI Z535.4-2002 for “Product Safety Signs and

Labels”. The safety markings in this manual are as follows:

WARNING

!

CAUTION

!

Cryogen Safety

Cryogenic liquefied gases are potentially extreme suffocation hazards since a small amount of

liquid will vaporize and yield a very large volume of oxygen-displacing gas. Always ensure the

location where the cryogen used is well ventilated.

Cryogenic liquids, due to their extremely low temperatures, will burn the skin in a similar manner

as hot liquids. Never permit cryogenic liquids to come into contact with the skin or allow them to

soak clothing. Serious burns may result from careless handling. Never touch uninsulated pipes

or vessels containing cryogenic liquids. Flesh will stick to extremely cold materials. Even

nonmetallic materials are dangerous to touch at low temperatures. The vapors expelled during

the venting process are sufficiently cold to burn flesh or freeze optic tissues.

Containers of cryogenic liquids are self-pressurizing (as the liquid boils off, vapor pressure

increases). Hoses or lines used to transfer these liquids should never be sealed at both ends

(i.e. by closing valves at both ends).

The properties of many materials at extremely low temperatures may be quite different from the

properties that these same materials exhibit at room temperatures. Exercise extreme care when

handling materials cooled to cryogenic temperatures until the properties of these materials

under these conditions are known.

WARNING indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury. This category also

includes potential equipment damage.

3 of 18

Cryogenic storage systems are complex systems with the potential to seriously injure personnel

or equipment if not operated according to procedures. Proper use of safety mechanisms

(pressure relief valves, rupture disks, etc.) included in the cryostat and top plate assembly are

necessary.

Warranty

American Magnetics warranties its products to conform to the specifications described in its

quotation for a period of fifteen months from the date of shipment. AMI makes no other

warranty of any kind, expressed or implied. In the event of failure occurring during normal use,

AMI, at its option, will repair or replace all products or components that fail under warranty and

such repair or replacement shall constitute a fulfillment of all AMI liabilities with respect to its

products. Since, however, AMI does not have control over the installation conditions or the use

to which its products are put, no warranty can be made of fitness for a particular purpose, and

AMI cannot be liable for special or consequential damages. All repairs are F.O.B. Oak Ridge,

Tennessee, USA. If the repairs are covered under this warranty then standard shipping for

return to the customer is paid for by AMI within the USA.

Return Authorization

Before shipping any item to AMI for repair, you must first obtain an RMA number from an

authorized AMI representative. Do not attempt to repair or replace any items without first

speaking to an authorized AMI representative. Doing so may expose the customer to hazards

and will void this warranty. Customers requiring a more comprehensive warranty program may

purchase additional coverage, the price of which may vary by product type.

Introduction

The instructions in this manual pertain to the American Magnetics, Inc. Model 175 Two-Wire

Continuous Level Transmitter. The Model 175 is designed to measure the level of various

liquids, slurries, granular materials, liquid-liquid interfaces, and cryogenic fluids.

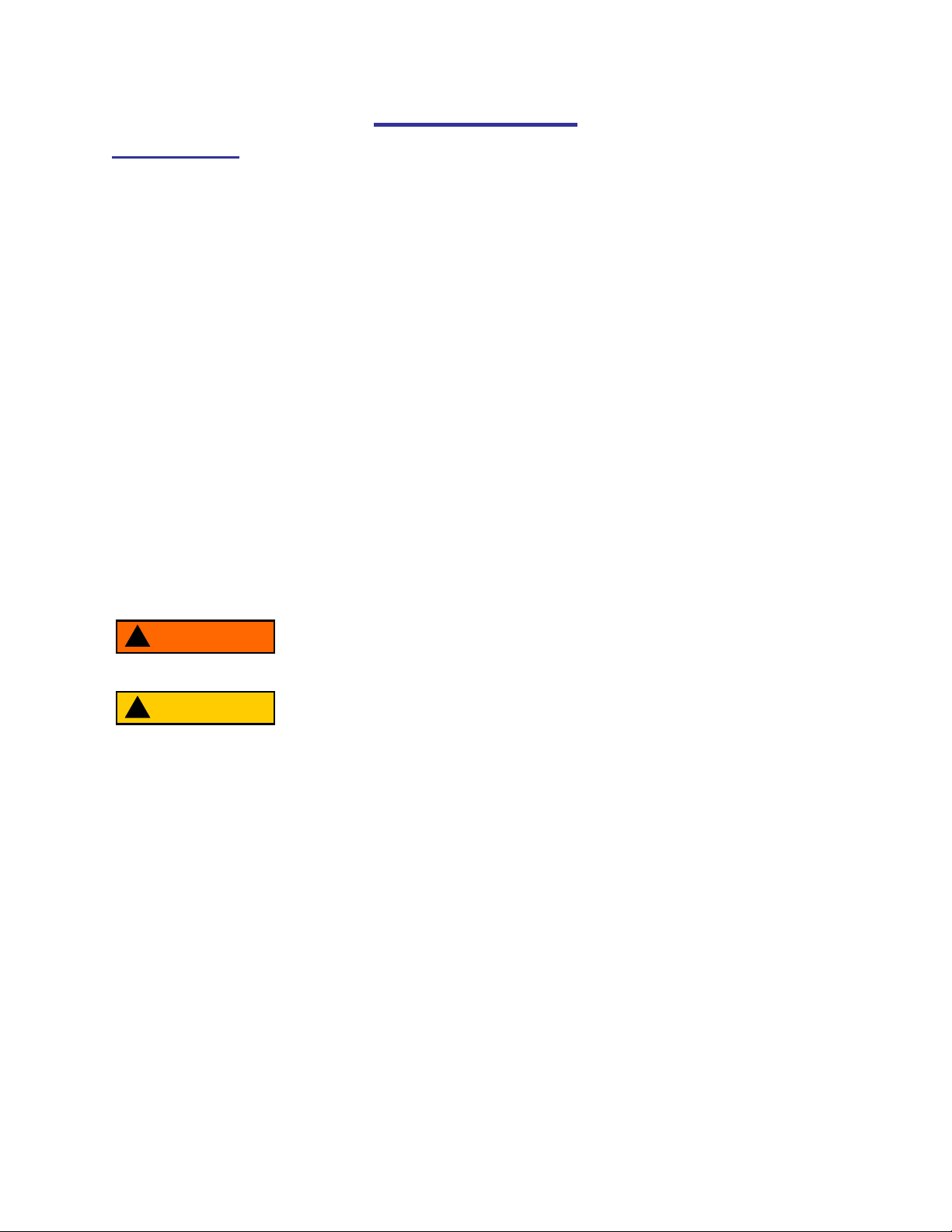

The Model 175 is available in two different mounting configurations: integral-mounting with the

probe (see Photo #1), or remote-mounting a maximum of 10 feet from the probe (Photo #2).

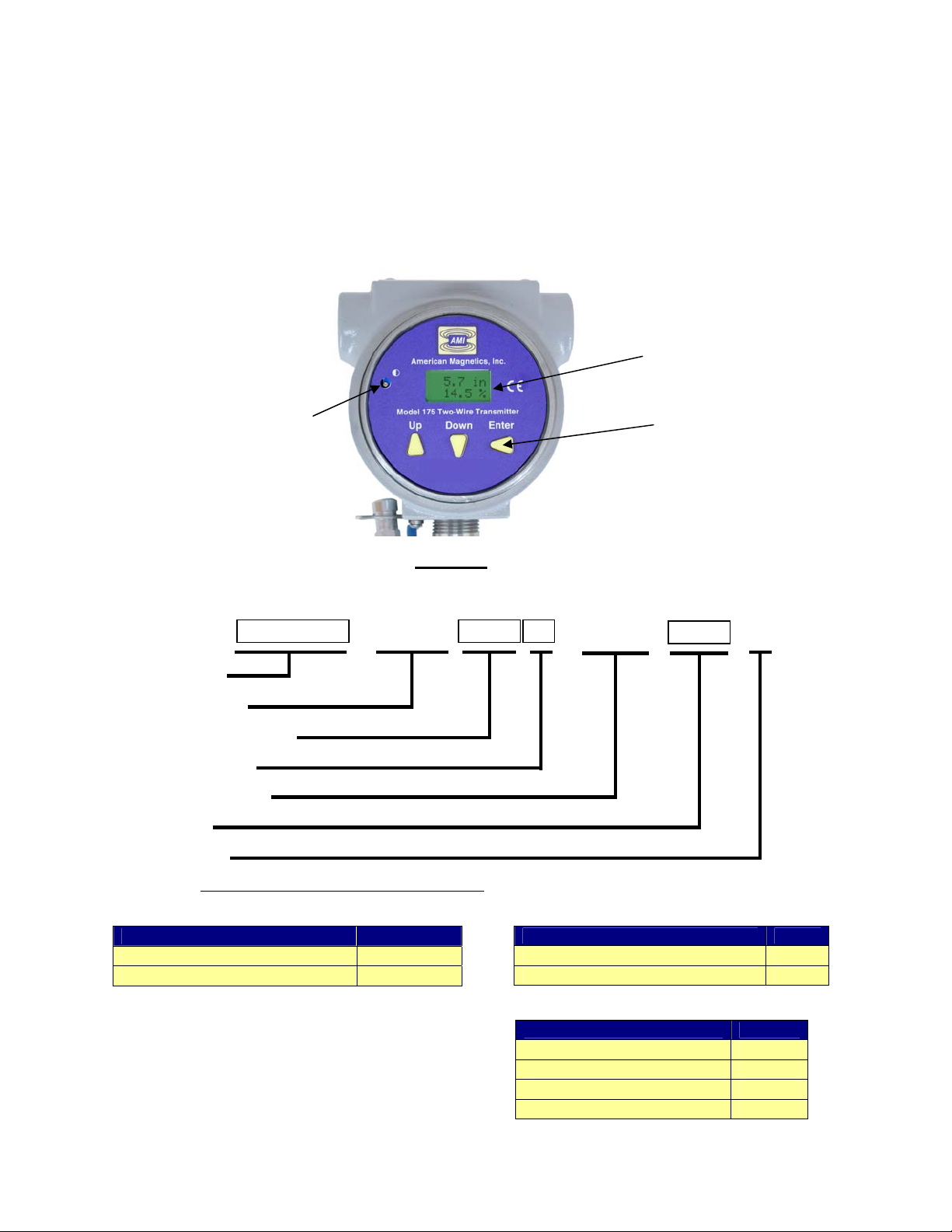

Magnet

Tool

Instrument

Housing

Electronic

Assembly

(“Puck”)

Wiring

Nipple

Interconnection

Housing

Probe

Photo #1

Probe

Remote Mounting

Bracket

Photo #2

4 of 18

System Description

The Model 175 liquid level system consists of the Model 175 Instrument and a CAPSEN

Capacitance Probe. The instrument consists of the electronic assembly (“puck”), a NEMA 4X /

7 explosion-proof enclosure, and an interconnection nipple. The enclosure provides two ¾″

NPT conduit openings for wiring. The windowed cover allows for viewing of process variables.

A magnet tool provides a way to set-up and calibrate the instrument without removing the cover.

The probe is a concentric-tube assembly designed to electrically and physically mate to the

Model 175, either directly or remotely (up to 10-feet). The operating or measurement length is

referred to as the “Active Length” while the “Overall Length” is the tip-to-tip length.

(Shown here with

Cover Removed)

2 Line by 8

character LCD

Contrast

Adjustment

3 Button Keypad

(Can be magnetically

actuated through the

windowed cover with

the Magnet Tool)

Photo #3

Instrument Model Configuration

175 - - 24Vdc - - 4/20mA - S

Mounting

Input Power

Calibration Length

Length Units

Analog Output

Liquid

Standard*

*Custom versions of the Model 175 are not available.

Mounting

Description Code

Integral Integral

Remote Remote

Calibration Length

Calibration length will normally be set at Active Length

of the probe as defined in the probe configuration,

specified in inches (nearest 1/10″) or Centimeters

(integer, no decimal).

5 of 18

Length Units

Description Code

Inches (nearest 1/10″) in

Centimeters (integer, no decimal) cm

Liquid*

Description Code

Liquid Nitrogen N2

Liquid Oxygen O2

Liquid Hydrogen H2

Liquid Carbon Dioxide CO2

*For others, the commonly recognized chemical formula

(or abbreviation) will be used. Contact factory.

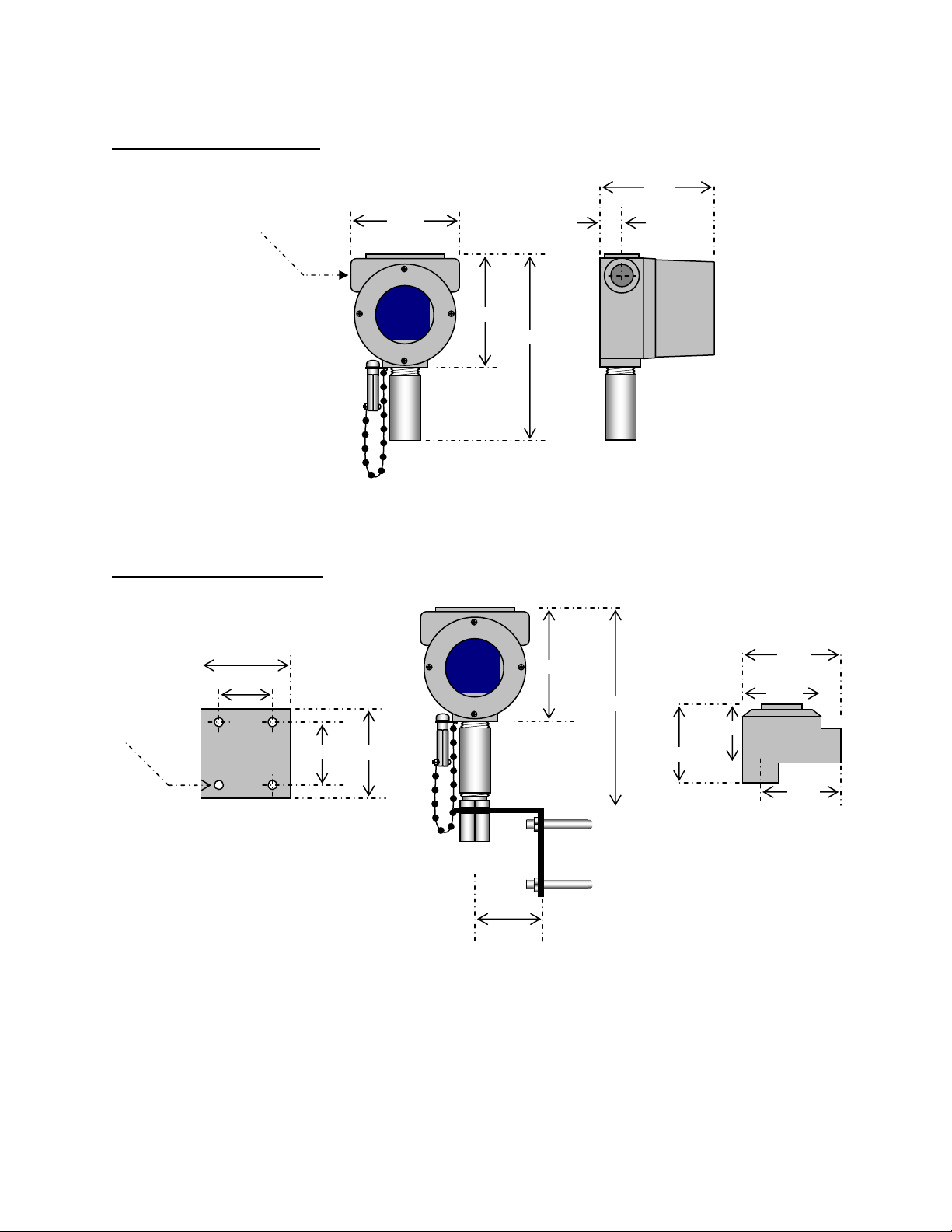

Model 175 Transmitter Dimensions – Inches

Integral-mounted Transmitters

4.54″

¾″ NPT

Remote-mounted Transmitters

4.0″

2.81″

0.332″

2.81″

5.0″

5.1″

8.4″

0.8″

4.5″

3.65″

4.0″

5.1″

7.5″

2.7″

3.55″

3.7″

Mounting Plate

(Back View)

2.88″

Interconnection

Housing

6 of 18

Loading...

Loading...