American Magnetics 135, 136 User Manual

EXCELLENCE IN MAGNETICS AND CRYOGENICS

MODEL 135/136 LIQUID HELIUM

AMI

LEVEL INSTRUMENT

INSTALLATION, OPERATION, AND

MAINTENANCE INSTRUCTIONS

American Magnetics, Inc.

PO Box 2509, 112 Flint Road, Oak Ridge, TN 37831-2509, Tel: 865 482-1056, Fax: 865 482-5472

Rev. 3, December 2000

Declaration of Conformity

Application of Council Directives: Low Voltage Directive 72/23/EEC

EMC Directive 89/336/EEC

Manufacturer’s Name: American Magnetics, Inc.

Manufacturer’s Address: 112 Flint Road,

P.O. Box 2509

Oak Ridge, TN 37831-2509

U.S.A.

Type of Equipment: Liquid Level Instruments

Model Numbers: Model 135 and 136

Standar ds to which Conformity is Declared:

Safety: EN 61010-1 (1993) w/A1, A2

EMC: EN55011 (1991) Group 1, Class A

EN50082-1 (1997) / EN61000-4-2 (1995) 8kV AD, 4kV CD

EN50082-1 (1997) / EN61000-4-3 (1996) 3V/m

EN50082-1 (1997) / EN61000-4-4 (1995) 1kV Power Supply

0.5kV I/O cables

EN50082-1 (1997) / EN61000-4-5 (1995) 2kV CM, 1kV DM

EN50082-1 (1997) / EN61000-4-6 (1996) 3V

EN58082-1 (1997) / EN61000-4-11 (1994) Voltage dips 30% - 10ms

Voltage dips 60% - 100ms

Short interruption >95% - 5s

I, the undersigned, hereby declare that the equipment specified above complies with the requirements of the aforementioned Directives and Standards and carries the "CE" mark accordingly.

Gregory J. Laughon September 12, 2002

Quality Assurance Manager

American Magnetics, Inc.

Oak Ridge, TN, U.S.A.

Model 135/136 Liquid Helium Level Instrument

Instrument Configuration

AMI Order Number:_____________________

Shipping Date:_________________________

Model/Serial #:_________________________

Firmware Revision:_____________________

Input Power Requirements:___________________________________________________________

Configuration Notes:

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

AMI Warranty

All products manufactured by AMI are warranted to be free of defects in materials and

workmanship and to perform as specified for a period of one year from date of shipment. In

the event of failure occurring during n ormal use, AMI, at its o ption, will r epair or replac e al l

products or components that fail under warranty, and such repair or replacement shall

constitute a fulfillment of all AMI liabilities with respect to its pro ducts. Since, however,

AMI does not have control over the installation conditions or the use to which its products

are put, no warranty can be made of fitness for a particular purpose, and AMI cannot be

liable for special or consequential damages. All warranty repairs are F.O.B. Oak Ridge,

Tennessee, USA.

Copyright © 2000 by American Magnetics, Inc., Oak Ridge, Tennessee, USA

Rev. 3

Table of Contents

1.1

Model 135/136 Features

................................................. ...........

1

1.2

Model 135 Front Panel Layout

...............................................

3

1.3

Model 135 Rear Panel Layout

................................................

4

1.4

Model 136 Front Panel Layout

................................................

5

1.5

Model 136 Rear Panel Layout

.................................................

6

1.6

Model 135/136 Specifications @ 25

°C......................................

7

2.1

Unpacking the Instrument

................................................... ....

9

2.2

Rack Mounting the Instrument

..............................................

10

2.3

Preparing th e Sensor fo r C o nn e ction

.....................................

10

2.4

Installing the Optional Solenoid-Operated Fill Valve

..........

12

2.5

Connecting any Communications Option

..............................

12

2.6

Connecting the Instrument to Power

.....................................

13

3.1

Sensor-Burnout Protection Mode

...........................................

15

3.2

Normal Operational Mode

.................................................. ....

15

3.2.1

Turn on the power

................................................... ....

15

3.2.2

Configure the active length setting

............................

16

3.2.3

Configure the HI SETPOINT and the

LO SETPOINT

.................................................. ...........

16

3.2.4

Configure the A SETPOINT and the B SETPOINT

..173.2.5

Select the operational mode of the controller

output receptacle

................................................... ......

18

3.2.6

Configure the sample time interval setting

...............

19

3.2.7

Select either continuous or sampled update

configuration

................................................... .............

19

3.2.8

Select the appropriate units display option

...............

19

3.2.9

Connect the optional analog output signal

................

19

3.3

Dirty Sensor Operational Mode

..............................................

20

4.1

Serial Communication/Data Logger Option

..........................

21

4.1.1

Serial port connector and cabling

...............................

21

4.1.2

Command/return termination characters

..................

21

4.1.3

Serial Communication DIP Switch Settings

..............

22

4.1.4

Serial Command Set Reference

..................................

24

1 Introduction.............................................................................. 1

2 Installation................................................................................ 9

3 Operation................................................................................ 15

4 Remote Interface Reference.................................................. 21

Rev. 3

iii

Table of Contents

4.2

IEEE-488 Communication Option

..........................................

28

4.2.1

Command/return termination characters

...................

28

4.2.2

Communicating with the Model 135/136

....................

28

4.2.3

IEEE-488 Communication DIP Switch Settings

........

30

4.2.4

IEEE-488 Command Set Reference

............................

32

4.2.5

Serial Poll Status Byte

.................................................

36

4.3

Error Codes

.................................................. .............. ............. ..

37

5.1

RS-232 Virtual Instrument

.....................................................

39

5.1.1

Launching and initializing the RS-232 VI

..................

40

5.1.2

Interacting with the running VI

..................................

42

5.2

IEEE-488 Virtual Instrument

.................................................

43

5.2.1

Launching and initializing the GPIB VI

.....................

44

5.2.2

Interacting with the running VI

..................................

45

5.2.3

Running multiple GPIB devices

..................................

46

6.1

Troubleshooting Procedures

....................................................

47

6.1.1

No level reading

............................................................

48

6.1.2

Erratic or erroneous level reading

...............................

49

6.1.3

Controller output does not energize

............................

50

6.1.4

Unit not responding to communications

.....................

51

6.2

Custom Instrument Configurations

........................................

52

6.2.1

Modifying the line voltage requirements

....................

52

6.2.2

Enabling dirty sensor operational mode

.....................

52

6.2.3

Changing time adjustments from minutes to hours

..536.3

Additional Technical Support

..................................................

53

6.4

Return Authorization

...............................................................

53

A.1

4-20 ma Current Loop Option

.................................................

55

A.2

Sensor Connector J1 Wiring

....................................................

56

A.3

Auxiliary Connector J2 Pinout

................................................

57

A.4

RS-232 Cable DB-25 to DB-9 Translation

..............................

58

A.5

RS-422 Cable Wiring

................................................................

58

5 Virtual Instrument Operation.................................................39

6 Service Guide..........................................................................47

Appendix..................................................................................55

Index.........................................................................................59

iv

Rev. 3

Foreword

This manual contains the operation and maintenance instructions for the

American Magnetics, Inc. Model 135/136 Liquid Level Instrument. The

manual outlines the instructions for instrument use in various system

designs. Since it is impossible to cover all possible system/sensor designs,

the most common configuration is discussed a nd the user is encouraged to

contact an authorized AMI Technical Support Representative fo r

information regarding specific configurations not explicitly covered in this

manual.

Introduction

introduces the reader to the functions and characteris tics of

the instrument. It provides the primary illustrations of the front and rear

panel layouts as well as documenting the performance specifications.

Installation

describes how the instrument is unpacked and installed in

conjunction with ancillary equipment in a typical cryogenic system.

Operation

describes how the instrument is used to measure and control

liquid level.

All

instrument controls are documented.

Remote Interface Reference

documents all remote commands and

queries available through the serial and IEEE-488 interfaces. A quick-

reference summary of commands is provided as well as a detailed

description o f ea c h .

Service

provides guidelines to assist Qualified Service Personnel in

troubleshooting possible system and instrument malfunctions.

Information for contacting AMI Technical Support personnel is also

provided.

The

Appendix

documents the rear panel connectors.

Purpose and Scope

Contents of This Manual

Rev. 3

v

Foreword

The Model 135/136 has been designed to operate with an AMI Liquid

Helium Level Sensor. Operation with other equipment is not

recommended and may void the warranty.

Personnel handling cryogenic liquids should be thoroughly instructed and

trained as to the nature of the liquids. Training is essential to minimize

accidental spilling. Due to the coldness of these materials, a cryogen

spilled on many objects or surfaces may damage the surface or cause the

object to shatter, often in an explosive manner.

Inert gases released into a confined or inadequately ventilated space can

displace sufficient oxygen to make the local atmosphere incapable of

sustaining life. Cryogenic liquefied gases are potentially extreme

suffocation hazards since a small amount of liquid will vaporize and yield

a very large volume of oxygen-displacing gas. Always ensure the location

where the cryogen is used is well ventilated. Breathing air with

insufficient oxygen content may cause unconsciousness without warning.

If a space is suspect, purge the space completely with air and test before

entry. If this is not possible, wear a forced-air respirator and enter only

with a co-worker standing by wearing a forced-air respirator.

Cryogenic liquids, due to their extremely low temperatures, will burn the

skin in a similar manner as would hot liquids. Never permit cryogenic

liquids to come into contact with the skin or allow liquid nitrogen to soak

clothing. Serious burns may result from careless handling. Never touch

uninsulated pipes or vessels containing cryogenic liquids. Flesh will stick

to extremely cold materials. Even nonmetallic materials are dangerous to

touch at low temperatures. The vapors expelled dur ing the venting process

are sufficiently cold to burn flesh or freeze optic tissues. Insulated gloves

should be used to prevent frost-bite when operating valves on cryogenic

tanks. Be suspicious of valves on cryogenic systems; the extremes of

temperature they undergo causes seals to fail frequently.

In the event a person is burned by a cryogen or material cooled to

cryogenic temperatures, the following first aid treatment should be given

pending the arrival and treatment of a physician or other medical care

worker:

1.

If any cryogenic liquid contacts the skin or eyes, immediately flush

the affected area gently with tepid water (102°F

105°F, 38.9°C

40.5°C) and then apply cold compresses.

Applicable Hardware

Applicable Hardware

General Precautions

Cryogen Safety

vi

−

−

Rev. 3

Foreword

2.

Do not apply heat. Loosen any clothing that may restrict

circulation. Apply a sterile protective dressing to the affected area.

3.

If the skin is blistered or there is any chance that the eyes have

been affected, get the patient immediately to a physician for

treatment.

Containers of cryogenic liquids are self pressurizing (as t he liquid boils of f,

vapor pressure increases). Hoses or lines used to transfer these liquids

should never be sealed at both ends (i.e. by closing valves at both ends).

When pouring cryogenic liquids from one container to another, the

receiving container should be cooled gradually to prevent damage by

thermal shock. The liquid should be poured slowly to avoid spattering due

to rapid boil off. The receiving vessel should be vented during the transfer.

Introduction of a substance at or near room temperature into a cryogenic

liquid should be done with great caution. There may be a violent gas boil

off and a considerable amount of splashing as a resul t of this rapid boil ing.

There is also a chance that the material may crack or catastrophically fail

due to forces caused by larg e difference s in thermal contraction o f different

regions of the material. Personnel engaged in this type of activity should

be instructed concerning this hazard and should always wear a full face

shield and protective clothing. If severe spraying or splashing could occur,

safety glasses or chemical goggles along with body length protective

aprons will provide additional protection.

The properties of many materials at extremely low temperatures may be

quite different from the properties that these same materials exhibit at

room temperatures. Exercise extreme care when handlin g materials cooled

to cryogenic temperatures until the properties of these materials under

these conditions are known.

Metals to be used for use in cryogenic equipment application must posses

sufficient physical properties at these low temperatures. Since ordinary

carbon steels, and to somewhat a lesser extent, alloy steels, lose much of

their ductility at low temperat ures, they are considered unsatisf actory and

sometimes unsafe for these applications. The austinetic Ni-Cr alloys

exhibit good ductility at these low temperatures and the most widely used

is 18-8 stainless steel. Copper, Monel

®

, brass and aluminum are also

considered satisfactory materials for cryogenic service.

Cryogenic storage systems are complex systems with the potential to

seriously injure personnel or equipment if not operated according to

procedures. Proper use of safety mechanisms (pressure relief valves,

Safety Summary

Safety Summary

Rev. 3

vii

Foreword

rupture disks, etc.) included in the cryostat and top plate assembly are

necessary.

First

Aid kit

Fire extinguisher rated for class C fires

Leather gloves

Face shield

Signs to indicate that there are potentially dangerous cr yo ge ns in

use in the area.

Instruction manual symbol: the product is marked with this

symbol when it is necessary for you to refer to the instruction

manual in order to protect against damage to the product or

personal injury.

Hazardous voltage symbol.

Alternating Current (Refer to IEC 417, No. 5032).

Off (Supply) (Refer to IEC 417, No. 5008).

On (Supply) (Refer to IEC 417, No. 5007).

The Warning sign denotes a hazard. It calls attention to a procedure or

practice, which if not correctly adhered to, could result in personal injury.

Do not proceed beyond a Warning sign until the indicated conditions are

fully understood and met.

The Caution sign denotes a hazard. It calls attention to an operating

procedure or practice, which if not adhered to, could cause damage or

destruction of a part or all of the product. Do not proceed beyond a Caution

sign until the indicated conditions are fully understood and met.

This marking in the left margin of the manual designates a feature,

procedure, or specification that is unique to the Model 136.

Safety/Manual Legend

Recommended Safety Equipment

Safety/Manual Legend

Warning

Caution

0RGHO

viii

Rev. 3

1 Introduction

The American Magnetics, Inc. (AMI) Model 135/136 Liquid Helium Level

Instrument is an advanced, microprocessor-based instrument utilizing

AMI’s patented sample-and-hold principle with automatic helium sensor

vacuum burnout protection. The instruments are designed for unattended

operation in systems where it is important to monitor and/or control the

liquid helium levels and minimize the liquid helium losses.

The Model 135/136 is designed to be used in conjunction with an AMI

liquid helium level sensor. The liquid helium level sensor consists of a

small diameter NbTi filament in a hollow tube. A constant current is

passed through this filament causing the portion of the filament in helium

gas to become resistive, while the portion in the liquid helium remains

superconducting. The resulting voltage across the resistive portion of the

filament is read by the instrument, converted to a liquid level, and

displayed on the front panel LED display.

In order to minimize liquid helium loss, the Model 135/136 automatically

energizes the liquid helium level sensor at predetermined time intervals

and monitors the normal (resistive) zone as it progresses from the top of

the sensor toward the surface of the liquid helium. As soon as the normal

zone reaches the liquid surface the level reading is saved and the sensor

current is turned off until the next sample interval occurs. The SENS OR

CURRENT LED is illuminated during each sample. Sample intervals are

user programmable from the front panel and can be set between 0.0 (no

delay between samples) to 600.0 minutes or hours. A sampling mode toggle

switch provided on the front panel can be toggled for continuous readings

during a helium transfer period or for just a quick level reading update.

The Model 136 provides automatic level control capabilities. Two

independent setpoints, A and B, are provided for determining a control

band to activate/deactivate a power recept acle on the rear panel. The

Model 136 is designed for unattended operation in systems where

automated refills are required.

The Model 135/136 provides automatic helium sensor vacuum burnout

protection. A sensor which is energized in a vacuum environment without

contact with liquid helium will self-heat to the point of burnout. AMI’s

1.1 Model 135/136 Features

0RGHO

1.1.1 Minimal liquid helium losses

1.1.2 Automatic Level Control

1.1.3 Burnout protection

Rev. 3

1

Introduction

innovative microprocessor-based circuitry det ects incipient sensor burnout

and de-energizes the sensor before damage can occur. A 5% increase in

sensor resistance will trigger this protec tion, causing the current to be

switched off for 6 seconds before attempting to resume normal operation.

Due to safety concerns, the high voltage power supply used for the sensor

is a floating supply. This minimizes the possibility o f personal injury in the

inadvertent event of someone who is grounded coming in contact with the

energized sensor electrical wires.

The Model 135/136 is equipped with a 4-digit LED digital display which

provides liquid helium level indication in inches, ce ntimeters or perc ent as

selected by a front panel switch. A front panel switch allows the user to

adjust the instrument quickly and easily for any length sensor up to 80

inches (203 cm). The sensor active length can be entered in either inches or

centimeters.

Microprocessor-based electronics provide 0.1% readout accuracy.

Nonvolatile memory maintains instrument calibration without battery

backup. Watchdog timer circuitr y and low line voltage ( brownout) detector

prevent microprocessor lockup and provide fail-safe operation.

The Model 135/136 is provided with a 0- 10 volt reco rder output . A 4-20 mA

current loop option is available in lieu of the recorder output. Available

computer interface options include RS-232/422 Serial Port/Data Logger or

IEEE-488.

The Model 135/136 may be optionally configured for a maximum of one

analog output option and one computer interface opt ion.

Features

1.1.4 Floating supply

1.1.5 Convenient display

1.1.6 Microprocessor-based electronics

1.1.7 Remote computer monitoring or controlled operation

2

Rev. 3

Introduction

0RGHO

0RGHO

/LTXLG +HOLXP

/LTXLG +HOLXP

/HYHO 0RQLWRU

/HYHO 0RQLWRU

$0,

$0,

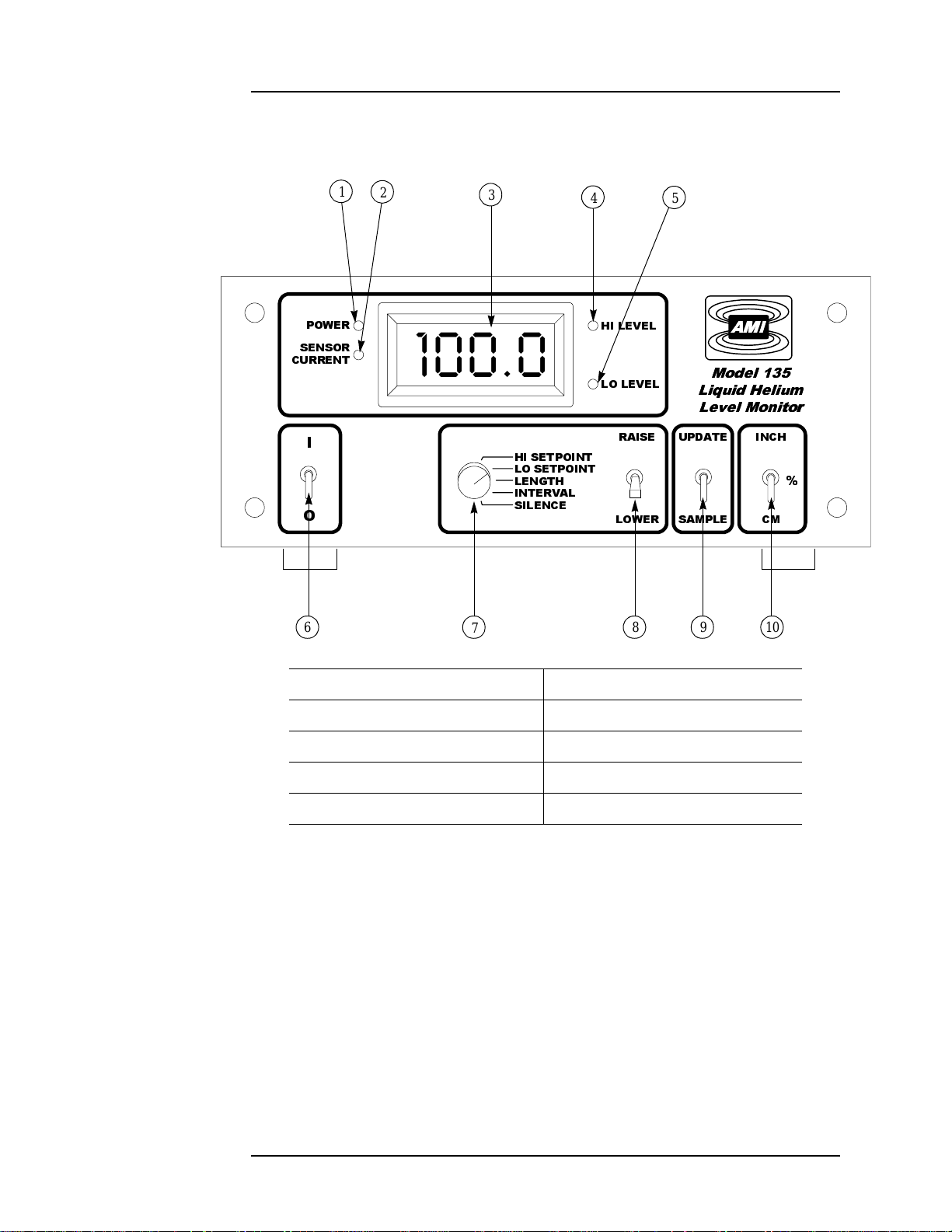

Model 135 Front Panel Layout

1.2 Model 135 Front Panel Layout

1

2

3

4

5

32:(5

6(1625

&855(17

O

2

6

1

Power O N LED

2

Sensor current LED

3

LED level display

100.0

+, 6(732,17

/2 6(732,17

/(1*7+

,17(59$/

6,/(1&(

7

+, /(9(/

/2 /(9(/

5$,6(

/2:(5

6

Power toggle switch

7

Control mode rotary switch

8

Raise/lower toggle switch

83'$7(

6$03/(

8 9 10

,1&+

&0

Rev. 3

4

Hi level LED

5

Lo level LED

9

Sampling mode toggle switch

10

Units mode toggle switch

3

Introduction

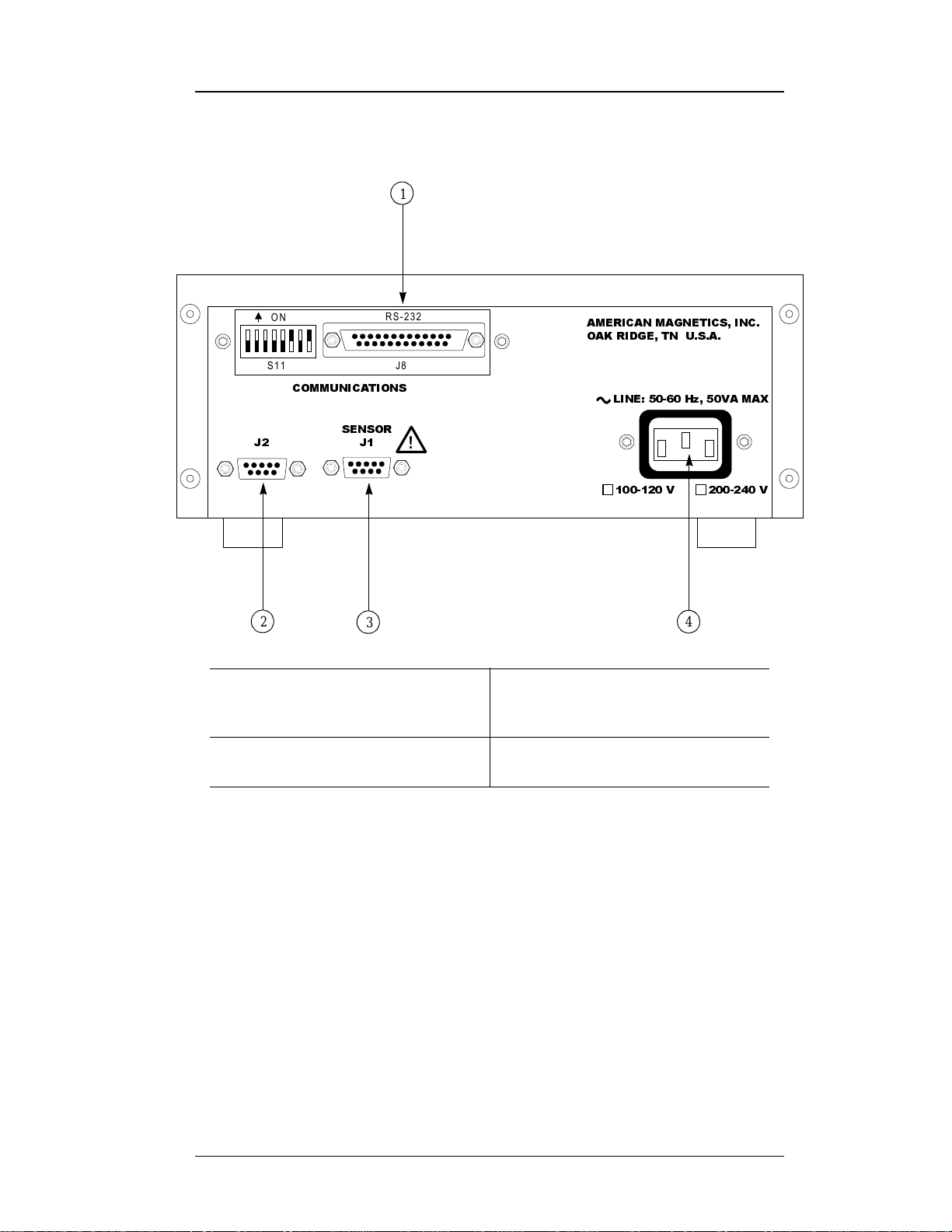

Model 135 Rear Panel Layout

1.3 Model 135 Rear Panel Layout

1

ON

S11

&20081,&$7,216

-

2

Optional RS-232 or GPIB

1

RS-232

6(1625

-

3

communications port

(RS-232 shown)

Auxiliary DB-9 male connector

2

(see

Appendix

for pinout)

J8

$0(5,&$1 0$*1(7,&6 ,1&

2$. 5,'*( 71 86$

/,1( +] 9$ 0$;

9 9

4

Sensor input DB-9 female

3

connector (see the

the pinout diagram)

Power cord connector

4

Appendix

for

4

Rev. 3

Introduction

0RGHO

0RGHO

/LTXLG +HOLXP

/LTXLG +HOLXP

/HYHO &RQWUROOHU

/HYHO &RQWUROOHU

$0,

$0,

}

9

11 12

14

13

10

4

5 7

8

1 2 3 6

100.0

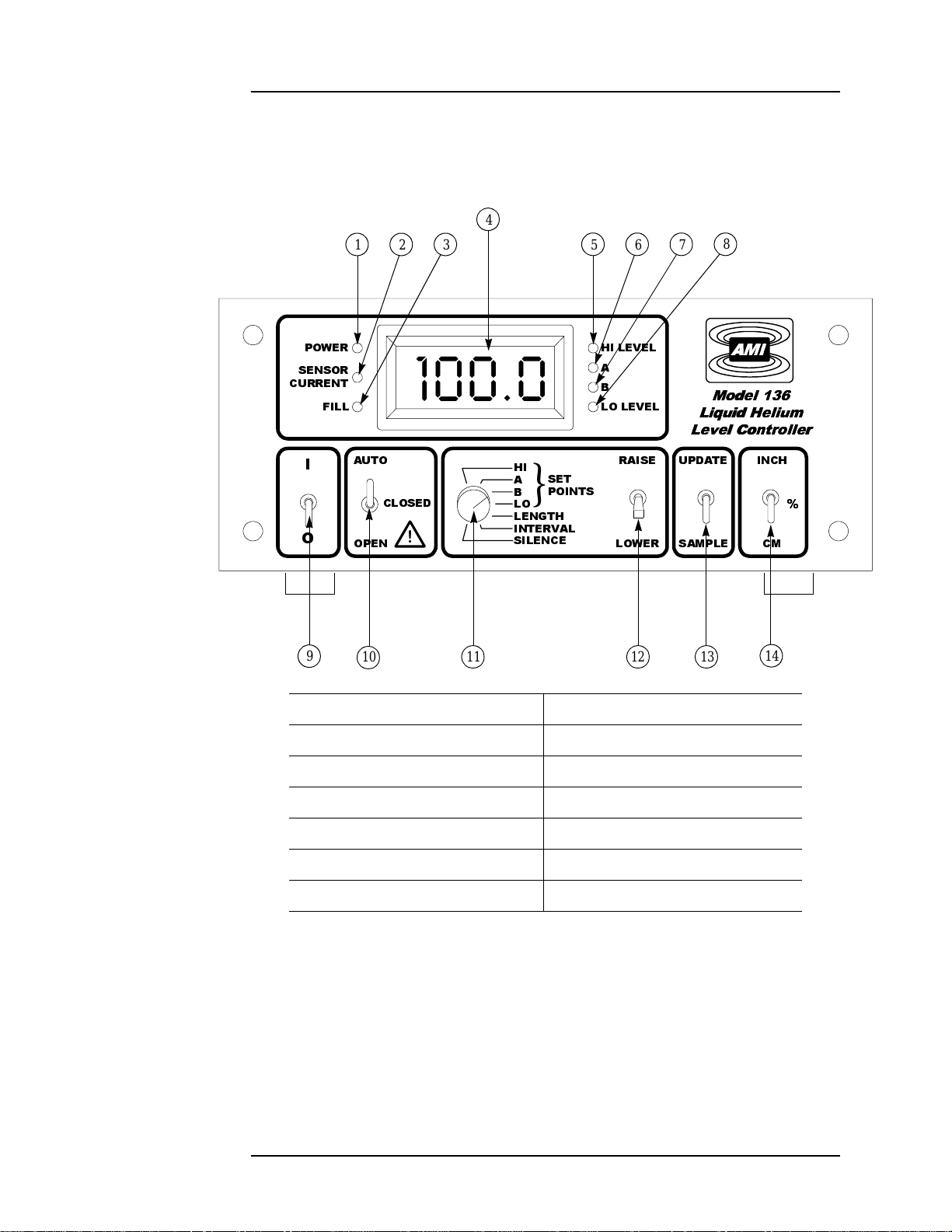

Model 136 Front Panel Layout

1.4 Model 136 Front Panel Layout

32:(5

6(1625

&855(17

),//

$872

O

&/26('

2

1

2

3

4

23(1

Power O N LED

Sensor current LED

Fill indication LED

LED level display

+,

$

%

/2

/(1*7+

,17(59$/

6,/(1&(

+, /(9(/

$

%

/2 /(9(/

5$,6(

6(7

32,176

/2:(5

8

Lo level LED

9

Power toggle switch

10

Fill toggle switch

11

Control mode rotary switch

83'$7(

6$03/(

,1&+

&0

5

6

7

Rev. 3

Hi level LED

A level LED

B level LED

12

Raise/lower toggle switch

13

Sampling mode toggle switch

14

Units mode toggle switch

5

Introduction

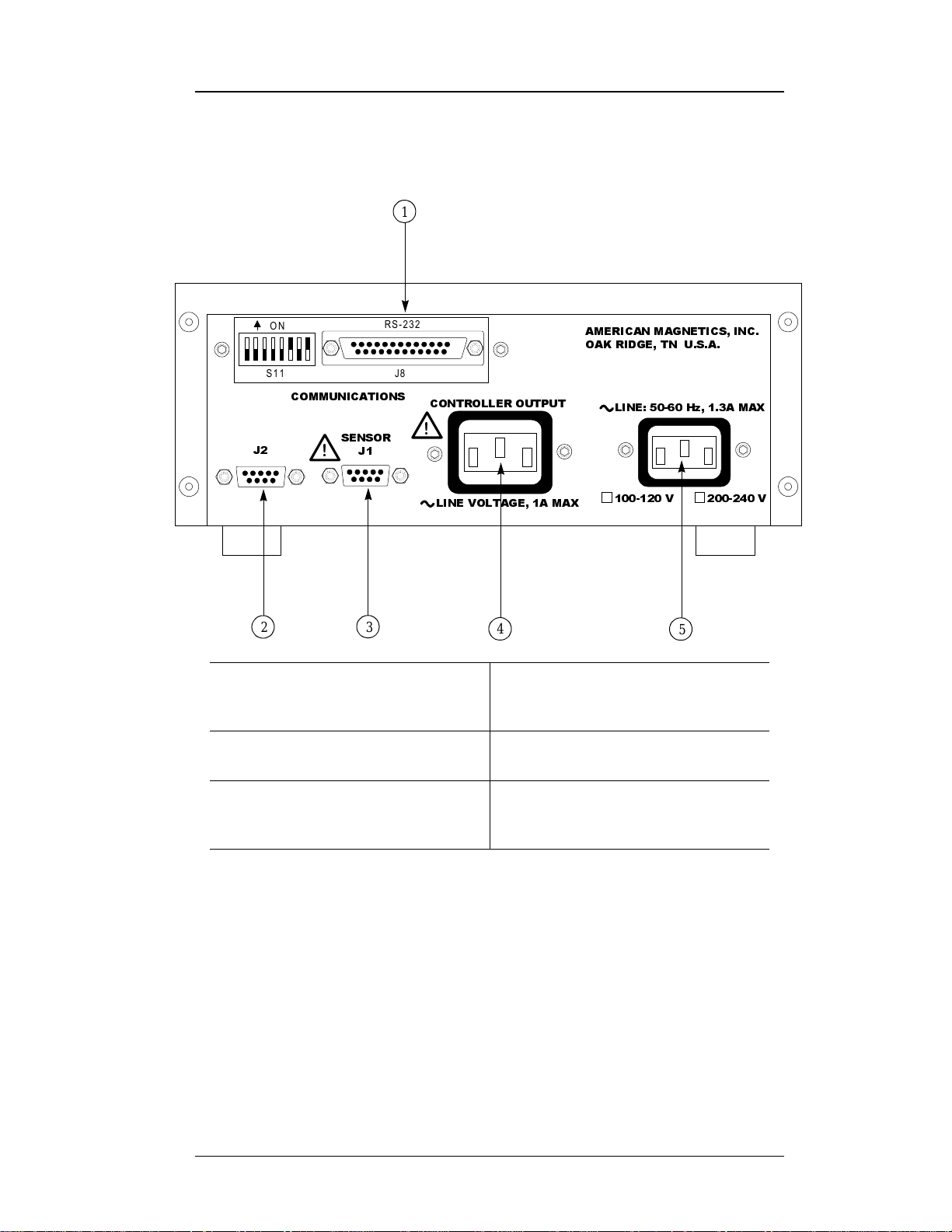

Model 136 Rear Panel Layout

1.5 Model 136 Rear Panel Layout

1

ON

S11

&20081,&$7,216

-

2

Optional RS-232 or GPIB

1

RS-232

6(1625

-

3

communications port

(RS-232 shown)

Auxiliary DB-9 male connector

2

(see

Appendix

for pinout)

J8

&21752//(5 287387

/,1( 92/7$*( $ 0$;

$0(5,&$1 0$*1(7,&6 ,1&

2$. 5,'*( 71 86$

/,1( +] $ 0$;

9 9

4

Controller output receptacle

4

Power cord connector

5

5

Sensor input DB-9 female

3

connector (see the

Appendix

for

the pinout diagram)

6

Rev. 3

0RGHO

0RGHO

0RGHO

Introduction

Specifications

1.6 Model 135/136 Specifications @ 25 °C

Level Measurements

Resolution: 0.1%, 0.1 cm, or 0.1 in

Accuracy

Sensor Current: 75 mA nominal

Sensor Voltage: approx. 70 VDC for 80" active sensor length

Operating Parameters

HI and LO Alarms: 0% to 100% adjustable

HI/LO Alarm Relay Contact Ratings: 10 VA, 30 VAC or 60 VDC, 0.5 A

Sample-and-Hold Period: 0.1 to 600.0 minutes or hours

A and B Control Setpoints:

Controller Output:

Fill Timer:

a

: ± 0.5% of active sensor length

Linearity: ± 0.1%

(normally open, closed on alarm)

0% to 100% adjustable

AC line voltage @ 1A max current

0.1 to 600.0 minutes or hours

0-10 Volt Analog Output

Integral Non-linearity: ± 0.012%

Resolution: 16 bits

Total Error: ± 1.1% for 0-10 V output

Voltage Drift (0-10 V): 100 ppm / °C

4-20 mA Analog Output @ 24 V

V

Supply Range: 13-32 VDC (see

ext

Integral Non-linearity: ± 0.012%

Resolution: 16 bits

Total Error: ± 0.25% for 4-20 mA output

Current Drift (4-20 mA): 75 ppm / °C

PSRR: 10 µA / V

Power Requirements

Primaryb:

Maximum Current: 50 VA for Model 135

Appendix

100-120 or 200-240 VAC ±10%

50 - 60 Hz

1.3 A for Model 136

for diagram)

Rev. 3

7

Introduction

Specifications

Physical

Dimensions (Standard): 97 mm H x 213 mm W x 273 mm D

(3.8" H x 8.4" W x 10.75" D)

Weight (Standard): 1.8 kg (4.0 lbs.) for Model 135

2.0 kg (4.3 lbs.) for Model 136

Dimensions (Rack Mount): 89 mm H x 483 mm W x 273 mm D

(3.5" H x 19" W x 10.75" D)

Weight (Rack Mount): 2.3 kg (5.0 lbs.)

Environmental

Ambient Temperature: Operating: 0 °C to 50 °C (32 °F to 122 °F)

Nonoperating: −20 °C to 60 °C (−4 °F to 140 °F)

Relative Humidity: 0 to 95%; non-condensing

a. Under extreme radiated electromagnetic field conditions (3V/m at 150 MHz to 170

MHz), the accuracy may be degraded to an absolute error of ±0.3 cm.

b. Maximum active sensor length is limited to 64 inches for input line voltages below

105 VAC or 210 VAC.

8

Rev. 3

2 Installation

Before energizing the instrument, the earth ground of the power

receptacle must be verified to be at earth potential and able to carry

the rated current of the power circuit. Using extension cords should

be avoided; however, if one must be used, ensure the ground

conductor is intact and capable of carrying the rated current.

In the event that the ground path of the instrument becomes less

than sufficient to carry the rated current of the power circuit, the

instrument should be disconnected from power, labeled as unsafe,

and removed fro m pl ac e o f operation.

Do not operate this instrument in the presence of flammable gases.

Doing so could result in a life-threatening explosion.

Do not modify this instrument in any way. If component

replacement is required, return the instrument to AMI facilities as

described in the Service section of this manual.

If the instrument is used in a manner not specified by AMI, the

protection provided by the equipment may be impaired.

Carefully remove the instrument, sensor, and interconnecting coaxial

cables from the shipping carton and r emove all packaging mate rial. A rac k

mounting kit is supplied if the instrument was purchased with the rack

mount option.

If there is any shipping damage, save all packing material and

contact the shipping representative to file a damage claim. Do not

return the instrument to AMI unless prior authorization has been

received.

If the chassis is a table top model, place the instrument on a flat, secure

surface.

Warning

2.1 Unpacking the Instrument

Note

Rev. 3

9

Installation

If the instrument has a rack mount chassis, follow the following procedure:

a.

Attach the rack mount adapter piece s to the instrum ent by first

removing the four screws on the side of the instrument that

attach the cover to the chassis. Attach the rack mount adapter

pieces to the sides of the instrument by reinstalling the screws.

b.

Install the instrument in a 19" rack by securing the front panel

to the rail in each of the four corners with mounting hardware

supplied by the cabinet manufacturer.

Do not remove the cabinet f eet and t hen r ein sert t he or igin al s cre ws.

Doing so could present a severe life-threatening el ectrical hazard. If

removal of the cabinet feet is desired, replace the original screws

with screws not to exceed 1/4" in length . Screws longer than 1/4"

will contact and damage the printed circuit board inside the unit.

Prepare the sensor to be connected to the instrument by soldering the

sensor leads to a male 9-pin D-Sub connector which will connect to J1 on

the rear panel of the instrument. Refer to the

Appendix

of this manual and

the AMI sensor manual for the proper pinout and wire color connections.

Connect the sensor to connector J1 on the rear panel.

Although the sensor connector terminals are isolated from earth

ground and therefore touching one terminal is not hazardous, the

voltage between terminals is at a hazardous potential. The sensor

connector is for use with an AMI LHe sensor and th e wi ring for the

sensor is to have no live parts which are accessible. Conductors

connected to it s terminals must be in su l ated from user co n ta ct by

basic insulation rated for 150 VAC (Category I).

The lead wire for the sensor may be sized by the following equations. For

input line voltages greater than or equal to 105 VAC or 210 VAC:

For input line voltages less than 105 VAC or 210 VAC:

Sensor Preparation

2.2 Rack Mounting the Instrument

Warning

2.3 Preparing the Sensor for Connection

Warning

R 420 5.21L–=

R 337 5.21L–=

10

Rev. 3

Loading...

Loading...