American Magnetics 12200PS User Manual

Note to Online Reader

gy

This manual has been altered f rom the original to

protect Xantrex's intellectual property.

The replacement parts lists and schematics have

been removed. If you wish to receive a com plete

printed copy of this manual, please call Xantrex

Sales and Support at 1-800-667-8422 (in North

America) or send e-mail to sales@xantrex.com.

Confidential Information

The information contained in this document is

confidential and is the exclusive property of

Xantrex Technology Inc. It m ay not be disclosed to

any person without the express writt en consent of

Xantrex Technolo

Inc.

View Manual

OPERATING

MANUAL

NOTE TO ONLINE READER

This manual has been altered from the original to

protect Xantrex's intellectual property.

The replacement parts lists and schematics have

been removed. If you wish to receive a c omplete

printed copy of this manual, please call Xantrex

Sales and Support at 1-800-667-8422 (in North

America) or send e-mail to sales@xantrex.com.

Confidential Information

The information contained in this document is

confidential and is the exclusive pr operty of X antr ex

Technology Inc. It may not be disclosed to any

person without the express written consent of

Xantrex Technology Inc.

Operating

Manual for

XFR SERIES

Power Supply

This manual covers

2800 Watt models:

7.5-300 100-28

12-220 150-18

20-130 300-9

40-70 600-4

60-46

TM-F2OP-01XN

WARRANTY

This unit is guaranteed for five (5) years from the date of delivery against defects in material and workmanship.

This does not apply to products damaged through accident, abuse, misuse, or unauthorized repair. The

manufacturer shall not be liable for any special or consequential damage of any nature. The manufacturer will

repair or replace the non-conforming product or issue credit, at its option, provided the manufacturer's

inspection establishes the existence of a defect. Packing, freight, insurance and other charges incurred in

returning the defective products to the manufacturer will be paid by the purchaser. T he manufacturer will pay

return freight if the repaired unit is deemed to be under warranty. If any questions arise concerning the warranty,

check with the manufacturer prior to taking any action.

When requesting information, assistance, or authorization, please state the serial number of the unit, available

from the label on the unit. Give a brief description of the problem with the unit. For information about

packaging for shipping, see Section 2.3.3.

GENERAL WARNINGS AND CAUTIONS

HIGH ENERGY AND HIGH VOLTAGE WARNINGS

Exercise caution when using and servicing a power supply. High energy

levels can be stored at the output voltage terminals on a power supply in

normal operation. In addition, potentially lethal voltages exist in the power

circuit and on the output and sense connectors of a power supply with a

rated output greater than 40V. Filter capacitors store potentially dangerous

energy for some time after power is removed.

OPERATING AND SERVICE PRECAUTIONS

Operate the power supply in an environment free of flammable gases or

fumes. To ensure that the power supply's safety features are not

compromised, use the power supply as specified in this manual and do not

substitute parts or make any unauthorized modifications. Contact the

service technician for service and repair help. Repairs must be made by

experienced service technicians only.

POWER SUPPLY SAFETY MARKINGS

Protective Conductor Terminal

Caution (Check manual for details.)

CONFIDENTIAL INFORMATION

The information contained in this document is confidential and is the exclusive prop erty of Xantrex Technolo gy

Inc. It may not be disclosed to any person without the express written consent of Xantrex Technology Inc.

PRINTED IN CANADA

OPERATING MANUAL ABOUT THIS MANUAL

ABOUT THIS MANUAL

This OPERATING MANUAL contains user information for the XFR Series of variable DC output power

supplies, which are available in several voltage models at 2800 Watts. It provides information about features

and specifications, installation procedures, and basic functions testing, as well as operating procedures for using

both front panel control and remote analog programming functions.

Who Should Use This Manual

This manual is designed for the user who is familiar with basic electrical laws especially as they apply to the

operation of power supplies. This implies a recognition of Constant Vo ltage and Constant Current operating

modes and the control of input and output power, as well as the observance of safe techniques while effecting

supply or pin connections and any changes in switch settings. The more technical user can refer to the

schematics in the service manual for troubleshooting and for configuring new applications.

Section 1. Features and Specifications

Describes the power supply and lists its features and

specifications.

Section 2. Installation

Goes through basic se tup procedures. Desc ribes inspection,

cleaning, shipping, and storage procedures. Includes AC

input connection, basic functions testing, and load and sense

lines connections.

Section 3. Local Operation

Provides procedures for local (front panel) operation.

Includes procedures for using over voltage protection,

shutdown function, multiple supplies, and over temperature

protection.

Section 4. Remote Operation

Covers remote analog programming operation and remote

monitoring of output voltage a nd current.

Section 5. Calibration

Includes calibration for programming and readback

accuracy.

Manual Revisions

The current release of this manual is listed below. Insert pages will update already-printed manuals. Reprinted

manuals may note any minor corrections and additions on the Manual Changes list (page ii). A new release of

the manual is identified by a new release number and printing date and will include all of the additional or

corrected information since the last release.

Release 1.0 (98/07/24)

Warnings, Cautions, and Notes

Warnings, cautions, and notes are defined and formatted in this manual as shown below.

WARNING

Describes a potential hazard which could result in injury or death, or, a

procedure which, if not performed correctly, could result in injury or death.

CAUTION

Describes a procedure which, if not performed correctly, could result in

damage to data, equipment, or systems.

Note: Describes additional operating information which may affect the performance of the equipment.

Release 1.0 (98/07) i

MANUAL CHANGES OPERATING MANUAL

MANUAL CHANGES

There are no changes at this time.

ii Release 1.0 (98/07)

OPERATING MANUAL CONTENTS

CONTENTS

About This Manual......................................................................................................................................i

Manual Changes...........................................................................................................................................ii

Contents.......................................................................................................................................................iii

List of Illustrations.......................................................................................................................................v

List of Tables................................................................................................................. ..............................v

1. FEATURES AND SPECIFICATIONS

1.1 Description.....................................................................................................................................1-1

1.2 Features and Options......................................................................................................................1-1

1.3 Specifications.................................................................................................................................1-2

1.3.1 Electrical Specifications.......................................................................................................1-2

1.3.2 Additional Specifications.....................................................................................................1-4

1.3.3 Input Conditions...................................................................................................................1-4

1.3.4 Additional Characteristics ....................................................................................................1-4

1.3.5 Remote Programming and Monitoring.................................................................................1-5

1.3.6 Environmental Specification................................................................................................1-5

1.3.7 Mechanical Specification.....................................................................................................1-5

2. INSTALLATION

2.1 Introduction ....................................................................................................................................2-1

2.2 Basic Setup Procedure....................................................................................................................2-1

2.3 Inspection, Cleaning, and Packaging..............................................................................................2-1

2.3.1 Initial Inspection ..................................................................................................................2-1

2.3.2 Periodic Cleaning.................................................................................................................2-4

2.3.3 Packaging for Shipping or Storage.......................................................................................2-4

2.4 Location, Mounting, and Ventilation .............................................................................................2-5

2.4.1 Rack Mounting.....................................................................................................................2-5

2.4.2 Ventilation............................................................................................................................2-5

2.5 AC Input Power..............................................................................................................................2-6

2.5.1 AC Input Connector and Voltage Selection.........................................................................2-6

2.5.2 AC Input Cord......................................................................................................................2-6

2.5.3 AC Input Wire Connection..................................................................................................2-7

2.6 Functional Tests.............................................................................................................................2-8

2.6.1 Equipment Required.............................................................................................................2-8

2.6.2 Power-on Check................................................................................................................... 2-8

2.6.3 Voltage Mode Operation Check...........................................................................................2-8

2.6.4 Current Mode Operation Check...........................................................................................2-9

2.6.5 Front Panel Function Checks...............................................................................................2-9

2.7 Load Connection............................................................................................................................2-10

2.7.1 Load Wiring.........................................................................................................................2-10

2.7.2 Making Load Connections...................................................................................................2-11

2.7.3 Inductive Loads....................................................................................................................2-14

2.7.4 Connecting Single Loads .....................................................................................................2-15

2.7.5 Connecting Multiple Loads..................................................................................................2-15

2.8 Local and Remote Sensing.............................................................................................................2-17

2.8.1 Sense Wiring........................................................................................................................2-17

2.8.2 Local Sensing.......................................................................................................................2-17

2.8.3 Using Remote Sensing.........................................................................................................2-18

Release 1.0 (98/07) iii

CONTENTS OPERATING MANUAL

3. LOCAL OPERATION

3.1 Introduction................................................................................................................................... 3-1

3.2 Standard Operation........................................................................................................................ 3-1

3.2.1 Operating Modes and Automatic Crossover........................................................................ 3-1

3.2.2 Shipped Configuration (Local Control Mode) .................................................................... 3-2

3.2.3 Setting Output Voltage and Current Limit.......................................................................... 3-3

3.3 Using Over Voltage Protection (OVP).......................................................................................... 3-4

3.3.1 Front Panel OVP Operation................................................................................................ 3-4

3.3.2 Resetting the OVP Circuit................................................................................................... 3-4

3.4 Using the Shutdown Function........................................................................................................ 3-5

3.4.1 STANDBY Switch.............................................................................................................. 3-5

3.4.2 Controlling the Shutdown Function via the J2 Connector................................................... 3-5

3.5 Using Multiple Supplies................................................................................................................ 3-6

3.5.1 Configuring Multiple Supplies for Series Operation........................................................... 3-6

3.5.2 Configuring Multiple Supplies for Parallel Operation ........................................................ 3-7

3.5.3 Configuring Multiple Supplies for Split Supply Operation ................................................. 3-8

3.6 Over Temperature Protection (OTP)............................................................................................. 3-9

3.7 User Diagnostics............................................................................................................................ 3-10

3.7.1 Emergency Shutdown.......................................................................................................... 3-10

3.7.2 Unusual or Erratic Operation..............................................................................................3-10

3.7.3 Troubleshooting for Operators............................................................................................ 3-11

4. REMOTE OPERATION

4.1 Introduction................................................................................................................................... 4-1

4.2 Switches and Connector Used for Remote Programming and Monitoring.................................... 4-1

4.2.1 Rear Panel SW1 Switch...................................................................................................... 4-1

4.2.2 Rear Panel J2 Connector..................................................................................................... 4-2

4.3 Remote Analog Programming of Output Voltage and Current Limit............................................ 4-4

4.3.1 Remote Programming Options............................................................................................ 4-4

4.3.2 Remote Analog Programming Procedure............................................................................ 4-4

4.4 Remote Monitoring of Output Voltage and Current...................................................................... 4-6

4.4.1 Readback Signals................................................................................................................4-6

4.5 Using the Isolated (ISOL) Programming Interface Option............................................................ 4-7

4.5.1 ISOL Specifications............................................................................................................4-7

4.5.2 ISOL Setup and Operating Instructions............................................................................... 4-7

4.5.3 ISOL Calibration ................................................................................................................. 4-7

5. CALIBRATION

5.1 Introduction................................................................................................................................... 5-1

5.2 Calibration Setup........................................................................................................................... 5-1

5.2.1 Service Environment and Precautions ................................................................................. 5-1

5.2.2 Equipment Required............................................................................................................ 5-1

5.2.3 Accessing Calibration Potentiometers................................................................................. 5-2

5.3 Calibrating for Programming Accuracy......................................................................................... 5-3

5.3.1 Voltage Programming Circuit Calibration........................................................................... 5-3

5.3.2 Current Limit Programming Circuit Calibration................................................................. 5-3

5.4 Calibrating for Readback Accuracy............................................................................................... 5-4

5.4.1 Output Voltage Monitor Circuit Calibration....................................................................... 5-4

5.4.2 Output Current Monitor Circuit Calibration........................................................................ 5-4

iv Release 1.0 (98/07)

OPERATING MANUAL ILLUSTRATIONS AND TABLES

LIST OF ILLUSTRATIONS

Figure 1.3-1 Typical Input Current Characteristics......................................................................................1-4

Figure 1.3-2 Dimensional Drawings............................................................................................................1-6

Figure 2.3-1 Power Supply Front Panel.......................................................................................................2-2

Figure 2.3-2 Power Supply Rear Panel........................................................................................................2-3

Figure 2.3-3 Shipping or Storage Carton Label...........................................................................................2-4

Figure 2.5-1 AC Input Label and Strain Relief............................................................................................2-7

Figure 2.7-1 Maximum Load Wire Length for 1V Line Drop.....................................................................2-11

Figure 2.7-2 Output Strain Relief and Bus Bar Cover.................................................................................2-12

Figure 2.7-3 Typical Load Connection Hardware........................................................................................2-13

Figure 2.7-4 Output Voltage Connector.......................................................................................................2-14

Figure 2.7-5 Single Load with Local Sensing (Default)...............................................................................2-15

Figure 2.7-6 Single Load with Remote Sensing...........................................................................................2-15

Figure 2.7-7 Multiple Loads with Local Sensing.........................................................................................2-16

Figure 2.7-8 Multiple Loads with Remote Sensing......................................................................................2-16

Figure 2.8-1 J10 Sense Connector...............................................................................................................2-17

Figure 2.8-2 Connecting Remote Sense Lines .............................................................................................2-19

Figure 3.2-1 Operating Modes .....................................................................................................................3-1

Figure 3.5-1 Series Operation of Multiple Supplies.....................................................................................3-6

Figure 3.5-2 Parallel Operation of Multiple Supplies..................................................................................3-7

Figure 3.5-3 Split Supply Operation of Multiple Supplies (Two Positive Voltages) ...................................3-8

Figure 3.5-4 Split Supply Operation of Multiple Supplies (Positive-negative Supply) ...............................3-9

Figure 4.2-1 Programming and Monitoring SW1 Switch ............................................................................4-1

Figure 4.2-2 Programming and Monitoring J2 Connector...........................................................................4-2

Figure 4.3-1 Connecting Programming Sources to J2 Connector................................................................4-6

Figure 5.2-1 Programming and Monitoring Calibration Locations..............................................................5-2

LIST OF TABLES

Table 1.1-1 Available Voltage and Current Ranges.....................................................................................1-1

Table 1.3-1 Specifications for 7.5V to 60V Models....................................................................................1-2

Table 1.3-2 Specifications for 100V to 600V Models.................................................................................1-3

Table 2.2-1 Basic Setup Procedure..............................................................................................................2-1

Table 2.5-1 AC Input Voltage Range and Frequency..................................................................................2-6

Table 2.5-2 AC Wire Specification..............................................................................................................2-6

Table 2.5-3 AC Input Connector Terminals and Connections.....................................................................2-7

Table 2.7-1 Current Carrying Capacity for Load Wiring.............................................................................2-10

Table 2.8-1 Rear Panel J10 Sense Connector Terminals and Functions......................................................2-17

Table 3.2-1 Shipped Configuration (Local Control Mode)..........................................................................3-2

Table 3.4-1 Switch Settings for TTL Shutdown Circuit Logic....................................................................3-5

Table 3.6-1 Switch Settings for Over Temperature Recovery Options........................................................3-9

Table 3.7-1 User Diagnostics.......................................................................................................................3-11

Table 4.2-1 Rear Panel SW1 Switch Assignments (Factory Defaults Underlined)...................................... 4-2

Table 4.2-2 Rear Panel J2 Connector Terminals and Functions..................................................................4-3

Table 4.3-1 Remote Programming Options .................................................................................................4-4

Table 4.3-2 Power Supply Settings for Different Programming Sources.....................................................4-5

Table 4.4-1 Power Supply Settings for Remote Monitoring of Readback Signals.......................................4-6

Table 4.5-1 Isolated (ISOL) Programming Interface Specifications............................................................4-7

Table 5.2-1 Current Carrying Capacity for Wiring...................................................................................... 5-1

Release 1.0 (98/07) v

OPERATING MANUAL FEATURES AND SPECIFICATIONS

1. FEATURES AND SPECIFICATIONS

1.1 Description

This series of power supplies provides low noise, precisely regulated, variable DC output at 2800 Watts of

output power. Over voltage protection and thermal shutdown are standard. Front panel controls and indicators

are extensive. Select from several remote control choices: standard analog programming, standard remote

monitoring of output voltage and current; optional isolated programming or readback, and optional GPIB

programming or RS-232 control. Use this power supply either on yo ur bench or in a standard 19" rack: the unit

occupies only 3.5" (2U) of vertical rack space. Designed for continuous use in standalone or systems

applications, this power supply is typically used to power DC equipment, control magnets, or burn in

components. See Table 1.1-1 for the list of available models.

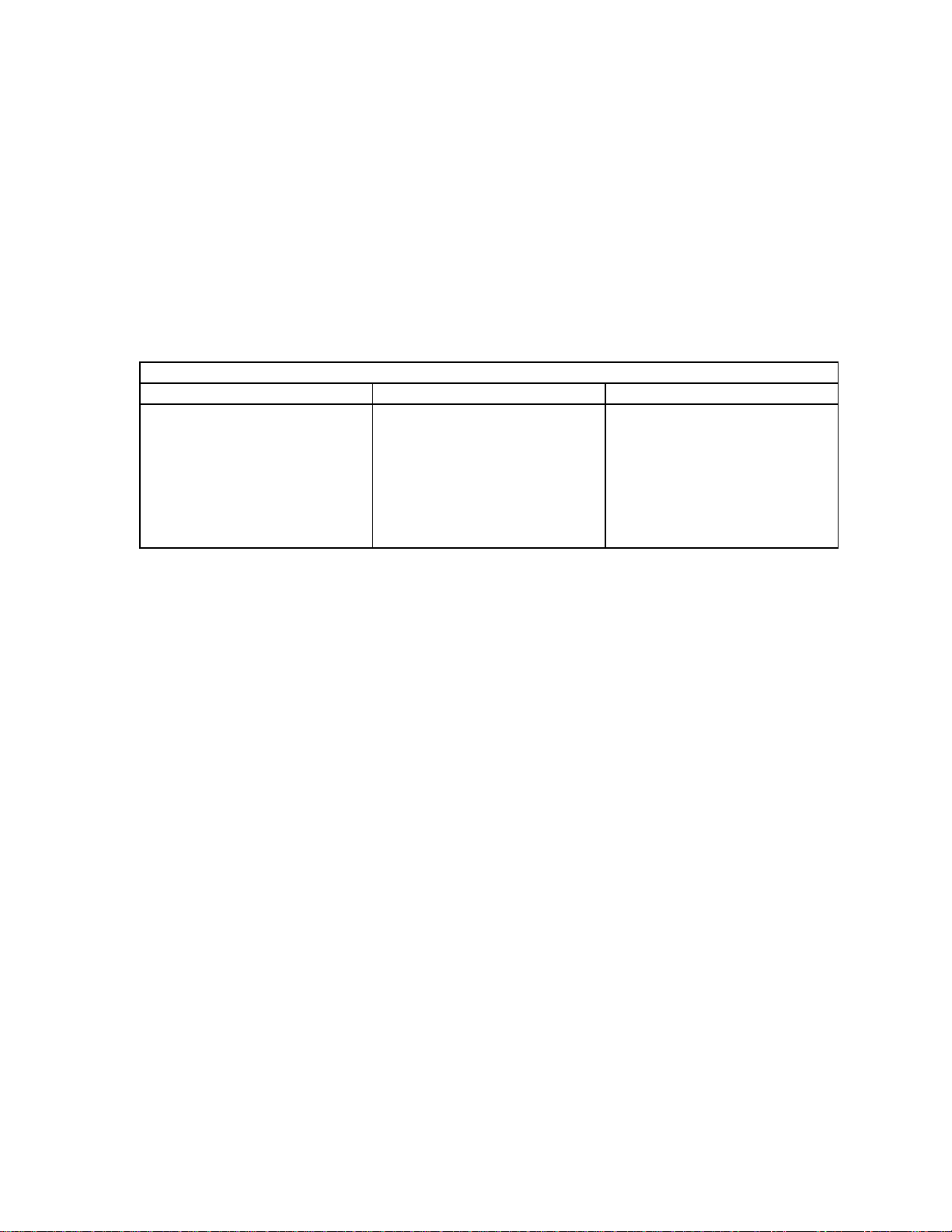

Table 1.1-1 Available Voltage and Current Ranges

Model Voltage Range Current Range

7.5-300 0-7.5V 0-300A

12-220 0-12V 0-220A

20-130 0-20V 0-130A

40-70 0-40V 0-70A

60-46 0-60V 0-46A

100-28 0-100V 0-28A

150-18 0-150V 0-18A

300-9 0-300V 0-9A

600-4 0-600V 0-4A

1.2 Features and Options

• Simultaneous digital display of both voltage and current.

• Ten-turn front pane l voltage and current co ntrols for high resolutio n setting of the o utput voltage and

current from zero to the rated output.

• Automatic mode crossover into current or voltage mode.

• Front panel push button control of output standby mode and preview of voltage, current, or over

voltage protection (OVP) setpoints. Front p anel light emitting diode (LED) indicators for voltage and

current mode operation, OVP, remote programming mode, and shutdown. Front panel control

of OVP.

• Multiple units can be connected in parallel or series to provide increased current or voltage.

• Thermal shutdown, latching or auto reset.

• Remote analog voltage and current limit programming with selectable programming ranges.

• External monitor signals for output voltage and current.

• Isolated analog remote programming control of the output voltage or current and isolated readback of

output voltage and current with the optional ISOL Interface.

• Optional internal GPIB or RS-232 computer control for remote digital programming and readback

capability.

• Rack mount brackets at the front panel are standard.

Release 1.0 (98/07) 1-1

FEATURES AND SPECIFICATIONS OPERATING MANUAL

1.3 Specifications

1.3.1 Electrical Specifications

These specifications are warranted over a temperature range of 0°C to 50°C. Nominal ambient temperature

assumed is 25°C. Nominal line voltage is 208Vac, 60Hz. Table 1.3-1 and Table 1.3-2 post maximum values for

model-dependent specifications. Specifications are subject to change without notice.

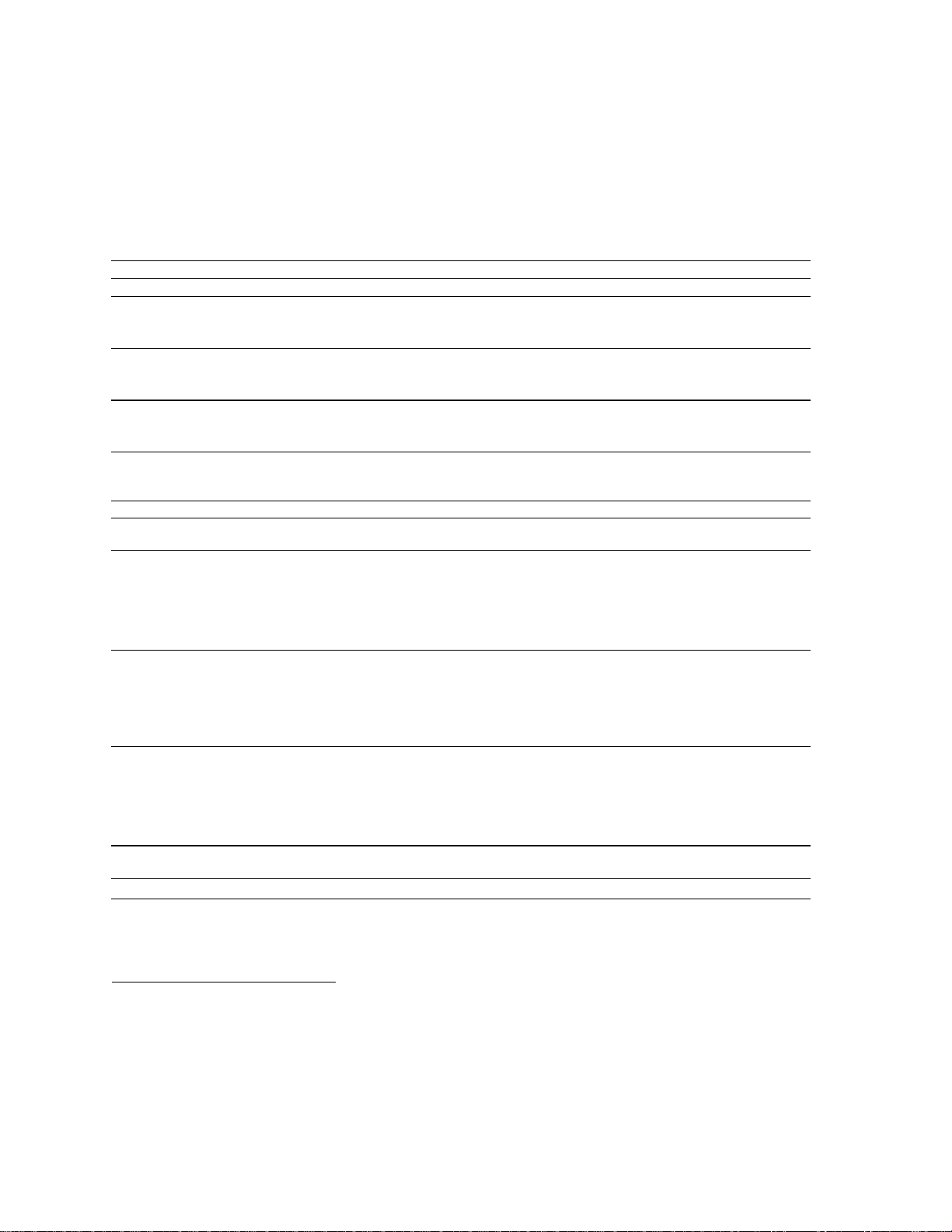

Table 1.3-1 Specifications for 7.5V to 60V Models

Models 7.5-300 12-220 20-130 40-70 60-46

Output Ratings: Output Voltage

Output Current

Output Power

Line Regulation:

2

Voltage (0.01% of Vmax + 2mV)

Current (0.01% of Imax + 2mA)

Load Regulation:

3

Voltage (0.02% of Vmax + 5mV)

Current (0.02% of Imax + 5mA)

Meter Accuracy:

Voltage (1% of Vmax + 1 count)

Current (1% of Imax + 1 count)

Output Noise (0-20MHz): Voltage (p-p) 100mV 100mV 100mV 150mV 150mV

Output Ripple (rms): Voltage

Current

Drift (30 minutes):

5

Voltage (0.05% of Vmax)

Current (0.6% of Vmax)

For Resistive Programming:

Voltage (0.6% of Vmax)

Current (0.6% of Imax)

Drift (8 hours):

6

Voltage (0.05% of Vmax)

Current (0.05% of Imax)

For Resistive Programming:

Voltage (0.3% of Vmax)

Current (0.3% of Imax)

Temperature Coefficient:

7

Voltage (0.02% of Vmax/°C)

Current (0.03% of Imax/°C)

For Resistive Programming:

Voltage (0.06% of Vmax/°C)

Current (0.06% of Imax/°C)

OVP Adjustment Range:

(5% to 110% of Vmax) 0.375-8.25V 0.6-13.2V 1-22V 2-44V 3-66V

Efficiency:

8

1

0-7.5V

0-300A

2250W

2.75mV

32mA

6.5mV

65mA

0.09V

4A

10mV

4

1600mA

3.75mV

1800mA

45mV

1800mA

3.75mV

150mA

22.5mV

900mA

1.5mV

90mA

4.5mV

180mA

0-12V

0-220A

2640W

3.2mV

24mA

7.4mV

49mA

0.13V

2.3A

10mV

1200mA

6mV

1320mA

72mV

1320mA

6mV

110mA

36mV

660mA

2.4mV

66mA

7.2mV

132mA

0-20V

0-130A

2600W

4mV

15mA

9mV

31mA

0.3V

1.4A

10mV

400mA

10mV

780mA

120mV

780mA

10mV

65mA

60mV

390mA

4mV

39mA

12mV

78mA

0-40V

0-70A

2800W

6mV

9mA

13mV

19mA

0.5V

0.8A

15mV

200mA

20mV

420mA

240mV

420mA

20mV

35mA

120mV

210mA

8mV

21mA

24mV

42mA

0-60V

0-46A

2760W

8mV

6.6mA

17mV

14.2mA

0.7V

0.56A

15mV

100mA

30mV

276mA

360mV

276mA

30mV

23mA

180mV

138mA

12mV

13.8mA

36mV

28mA

0.80 0.82 0.85 0.87 0.90

1 Minimum output voltage is <0. 15% of rated voltage at zero output setting.

2 For input voltage variation over the AC input vol tage range, with constant rated load.

3 For 0-100% load variation, with constant nominal line voltage.

4 Current mode noise is m easured from 10% to 100% of rat ed output voltage, full current .

5 Maximum drift over 30 minut es with constant line, load, and t emperature, after power on.

6 Maximum drift over 8 hours with constant line, load, and tem perat ure, after 30-minute warm-up.

7 Change in output per °C change in ambient temperature, with constant l i ne and l oad.

8 Typical efficiency at nominal input voltage and full output power.

1-2 Release 1.0 (98/07)

OPERATING MANUAL FEATURES AND SPECIFICATIONS

1.3.1 Electrical Specifications (continued)

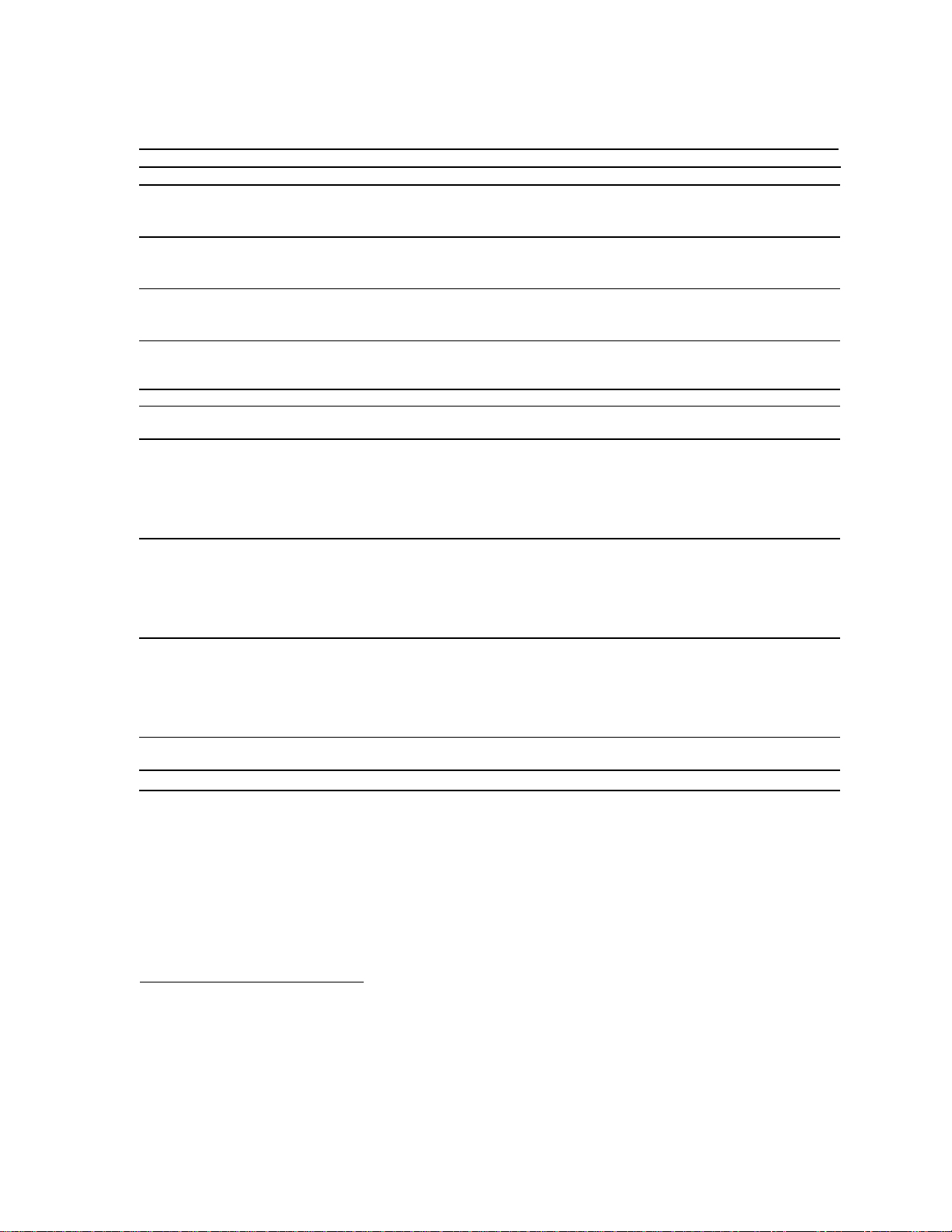

Table 1.3-2 Specifications for 100V to 600V Models

Models 100-28 150-18 300-9 600-4

Output Ratings: Output Voltage

Output Current

Output Power

Line Regulation:

2

Voltage (0.01% of Vmax + 2mV)

Current (0.01% of Imax + 2mA)

Load Regulation:

3

Voltage (0.02% of Vmax + 5mV)

Current (0.02% of Imax + 5mA)

Meter Accuracy:

Voltage (1% of Vmax + 1 count)

Current (1% of Imax + 1 count)

Output Noise (0-20MHz): Voltage (p-p) 175mV 200mV 400mV 500mV

Output Ripple (rms): Voltage

Current

Drift (30 minutes):

5

Voltage (0.05% of Vmax)

Current (0.6% of Vmax)

For Resistive Programming:

Voltage (0.6% of Vmax)

Current (0.6% of Imax)

Drift (8 hours):

6

Voltage (0.05% of Vmax)

Current (0.05% of Imax)

For Resistive Programming:

Voltage (0.3% of Vmax)

Current (0.3% of Imax)

Temperature Coefficient:

7

Voltage (0.02% of Vmax/°C)

Current (0.03% of Imax/°C)

For Resistive Programming:

Voltage (0.06% of Vmax/°C)

Current (0.06% of Imax/°C)

OVP Adjustment Range:

(5% to 110% of Vmax) 5-110V 7.5-165V 15-330V 30-660V

Efficiency:

8

1

0-100V

0-28A

2800W

12mV

4.8mA

27mV

10.6mA

1.1V

0.38A

25mV

4

80mA

50mV

168mA

600mV

168mA

50mV

14mA

300mV

84mA

20mV

8.4mA

60mV

16.8mA

0-150V

0-18A

2700W

17mV

3.8mA

35mV

8.6mA

1.6V

0.19A

25mV

40mA

75mV

108mA

900mV

108mA

75mV

9mA

450mV

54mA

30mV

5.4mA

90mV

10.8mA

0-300V

0-9A

2700W

32mV

2.9mA

65mV

6.8mA

4V

0.1A

40mV

20mA

150mV

54mA

1800mV

54mA

150mV

4.5mA

900mV

27mA

60mV

2.7mA

180mV

5.4mA

0-600V

0-4A

2400W

62mV

2.4mA

125mV

5.8mA

7V

0.05A

100mV

10mA

300mV

24mA

3600mV

24mA

300mV

2mA

1800mV

12mA

120mV

1.2mA

360mV

2.4mA

0.90 0.90 0.91 0.91

1 Minimum output voltage is <0. 15% of rated voltage at zero output setting.

2 For input voltage variation over the AC input vol tage range, with constant rated load.

3 For 0-100% load variation, with constant nominal line voltage.

4 Current mode noise is m easured from 10% to 100% of rat ed output voltage, full current .

5 Maximum drift over 30 minut es with constant line, load, and t emperature, after power on.

6 Maximum drift over 8 hours with constant line, load, and tem perat ure, after 30-minute warm-up.

7 Change in output per °C change in ambient temperature, with constant l i ne and l oad.

8 Typical efficiency at nominal input voltage and ful l output power.

Release 1.0 (98/07) 1-3

FEATURES AND SPECIFICATIONS OPERATING MANUAL

1.3.2 Additional Specifications

Rise Time (No Load, Full Load):

Fall Time (No Load):

Fall Time (Full Load):

2 4 s

3 7.5V to 60V models: 100 m s; 100V to 600V m odels : 170 m s

Voltage Mode Transient Response:

1 7.5V to 60V models: 100 m s; 100V to 600V m odels : 170 ms

4 <3 ms

Time Delay from power on until output stable 7 seconds maximum

1.3.3 Input Conditions

AC Input Voltage Ranges 190-264Vac, 1

φ

(24.3A maximum at 208Vac; 22.4A

maximum at 230Vac)

Source Frequency 47-63Hz

Power Factor 0.65 typical

I

N

P

U

T

C

U

R

R

E

N

T

(A)

30

25

20

15

10

5

100% at 190Vac

100% at 264Vac

50% at 190Vac

50% at 264Vac

O

U

T

P

U

T

C

U

R

R

E

N

T

0

OUTPUT VOLTAGE

50% 100%

Figure 1.3-1 Typical Input Current Characteristics

(Based on 100V, 28A model.)

1.3.4 Additional Characteristics

Switching Frequency Nominal 31kHz (62kHz output ripple)

Output Hold-up Time Greater than 10 ms with interruption of AC line, for

nominal AC input and full load

Maximum Voltage Differential

from either output to safety ground 600Vdc

1 Measured with stepped 0-10V analog programmi ng source and a resistive load.

2 Measured with stepped 0-10V analog programmi ng source and a resistive load.

3 Measured with stepped 0-10V analog programmi ng source and a resistive load.

4 Time for the output volt age t o recover within 0.5% of its previous l evel after a step c hange in load current of 10% to 90% of

rated output. Load slew rate <6A/µs.

1-4 Release 1.0 (98/07)

OPERATING MANUAL FEATURES AND SPECIFICATIONS

1.3.5 Remote Programming and Monitoring

Remote Analog Programming (Full Scale Input) Voltage and current programming:

0-5k, 0-10k resistances; 0-5V, 0-10V voltage sources

Remote Monitoring Output voltage and current: 0-5V, 0-10V

0 to full scale output 1% accuracy.

Maximum Remote Sense Line Drop Compensation 5V/line (Line drop is subtracted from total voltage

available at supply output.)

Remote Start/Stop and Interlock 2.5-15V signal or TTL-compatible input, selectable logic

Optional Isolated Program and Readback (V&I) 0-5V (ISOL Interface)

Optional Digital Control RS-232, GPIB Interfaces

1.3.6 Environmental Specification

Operating Temperature Range 0°C to 50°C

Storage Temperature Range -20°C to +70°C

Humidity Range 30% to 90% RH Non-condensing

Operating Altitude Derate maximum operating temperature by 1°C per 1,000

feet (300 m) for operation between 5,000 feet (1500 m)

and 15,000 feet (4500 m).

Storage Altitude Up to 50,000 feet (15 000 m).

Installation Category Intended for use in installation category (overvoltage

category) II (IEC 1010-1 standard).

1.3.7 Mechanical Specification

Front Panel Control 10-turn voltage and current potentiometers

Front Panel Voltage Control Resolution 0.02% of V max

Meter Accuracy See Table 1.3-1 and Table 1.3-2

AC Input Connector Type 3-terminal, 34A, 250V, right angle, PC mount,

wire clamp connector with strain relief cover

Output 7.5V to 100V models: nickel-plated copper bus bars with

bus bar cover and strain relief; bus bar holes: 0.343"

(8.7 mm) D (1), 0.197" (5.0 mm) D (2);

150V to 600V models: 4-terminal, right angle, PC mount,

wire clamp connector

Sense Connector 5-terminal wire clamp connector (2 piece)

Analog Programming Connector 15-terminal wire clamp connector (2 piece)

Chassis Ground One chassis ground screw located on rear panel for

bonding connec tions

Cooling Fan cooled. Air exhausts to rear. Over temperature

shutdown: automatic restart or latch off.

Mounting Removable rack mount brackets. Mount at front panel or

mid-chassis location.

Weight Approximately 33 lbs. (15 kg)

Approvals CE-marked units meet IEC 1010-1 safety standard and

EN50081-2 and EN50082-1 EMC standards. Additional

standards: CSA C22.2 No. 1010.1, UL 3101, and FCC,

part 15, class A EMI standard.

.

Release 1.0 (98/07) 1-5

FEATURES AND SPECIFICATIONS OPERATING MANUAL

1.3.7 Mechanical Specification (continued)

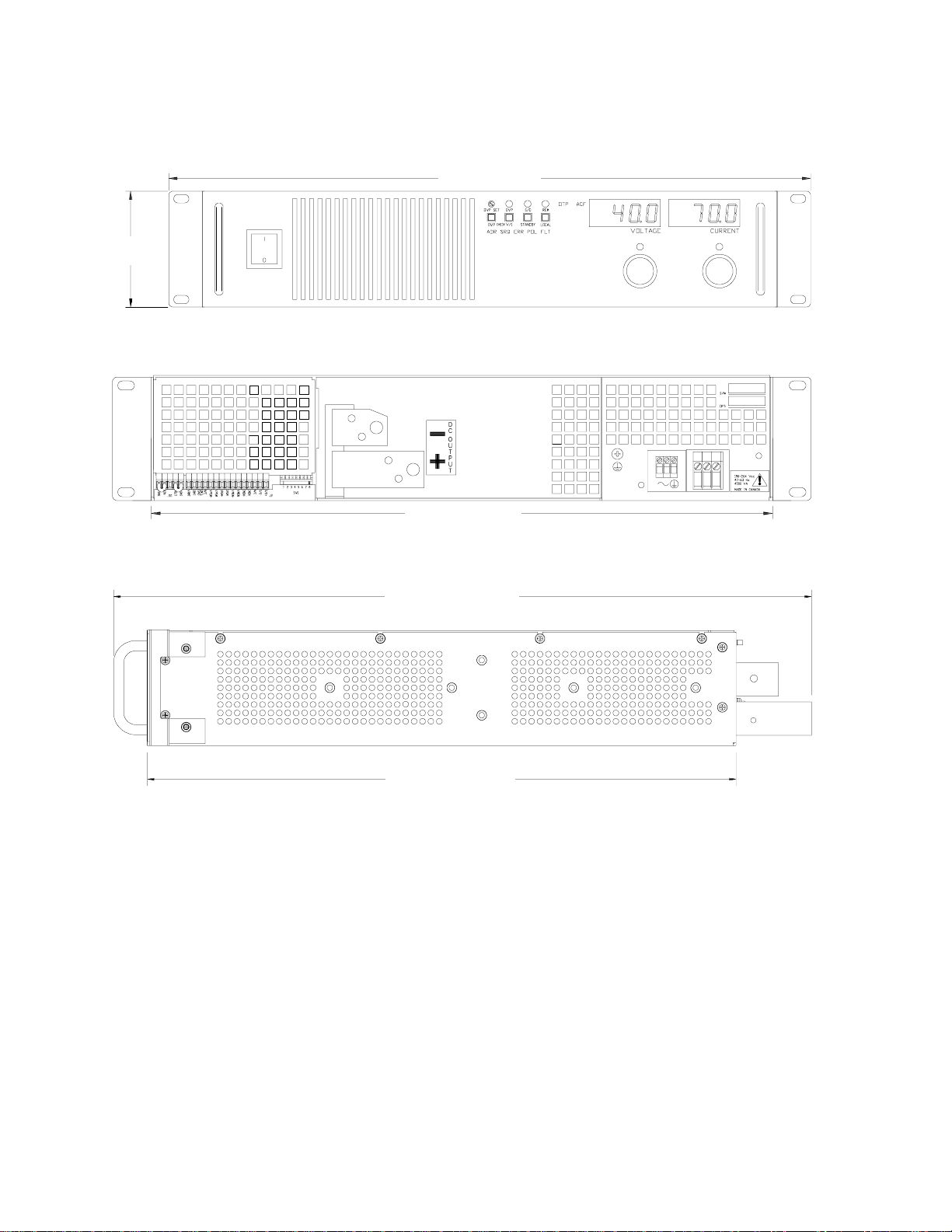

19" (483 mm)

3.45"

(87.63 mm)

16.9" (429 mm)

20.975" (533 mm)

17.475" (444 mm)

Figure 1.3-2 Dimensional Drawings

(Dimensions given are nominal.)

1-6 Release 1.0 (98/07)

OPERATING MANUAL INSTALLATION

2. INSTALLATION

2.1 Introduction

This section provides recommendations and procedures for insp ecting, installing, and testing the power supply.

Refer to the front and rear panel diagrams, Figure 2.3-1 and Figure 2.3-2, as necessary.

2.2 Basic Setup Procedure

Table 2.2-1 provides both a summary of the basic setup procedure and an overall view of the subsections in

Section 2. Use the procedure as a quick reference if you are familiar with the installation requirements for the

power supply. If you want more information, each step in the procedure refers to subsequent sections which

contain more details. Execute each step in the sequence given.

Table 2.2-1 Basic Setup Procedure

Step # Description Action Reference

1 Inspection Perform an initial physical inspection of

the supply.

2 Installation Install the supply (bench or rack mount),

ensuring adequate ventilation.

3 Input Power Connect AC input power. Section 2.5 AC Input Power Connection

4 Test Perform functional tests for voltage mode

operation, current mode operation, and

front panel controls.

5 Load Connect the load. Section 2.7 Load Connection

6 Sensing Connect sensing lines. Section 2.8 Local and Remote Sensing

Section 2.3 Inspection, Cleaning, and

Packaging

Section 2.4 Location, Mounting, and

Ventilation

Section 2.6 Functional Tests

See Section 3. Local Operation for instructions for front panel operation, over voltage and over temperature

protection, shutdown, and using multiple supplies. You will find remote programming and monitoring described

in Section 4. Remote Operation.

2.3 Inspection, Cleaning, and Packaging

2.3.1 Initial Inspection

When you first receive your unit, perform a quick physical check.

1. Inspect the unit for scratches and cracks, and for broken switches, connectors, and displays. See Figure

2.3-1 and Figure 2.3-2.

2. Have the service technician check the printed circuit board and its components if you suspect internal

damage.

If the unit is damaged, save all packing materials and notify the carrier immediately. See packing instructions in

Section 2.3.3.

Release 1.0 (98/07) 2-1

INSTALLATION OPERATING MANUAL

2.3.1 Initial Inspection (continued)

Shutdown LED (S/D)

OVP Shutdown LED (OVP)

Local Voltage & Current Limit Setting

Preview Switch (V/I CHE CK)

OVP Adjust Potentiometer (OVP SET)

OVP Setting Preview Switch

(OVP CHECK)

AC Power

Switch

Remote Programming LEDs

(For units with digital

programming interfac e i nstalled.)

Standby Switch (STANDBY)

Remote Programming LED (REM)

Return to Local Programming

(LOCAL)

for units with digital program ming

Over Temperature Shutdown LED

AC Fail LED (ACF)

Voltage Mode LED

Output Voltage Control Knob

Current Mode LED

Output Current Control Knob

Figure 2.3-1 Power Supply Front Panel

2-2 Release 1.0 (98/07)

OPERATING MANUAL INSTALLATION

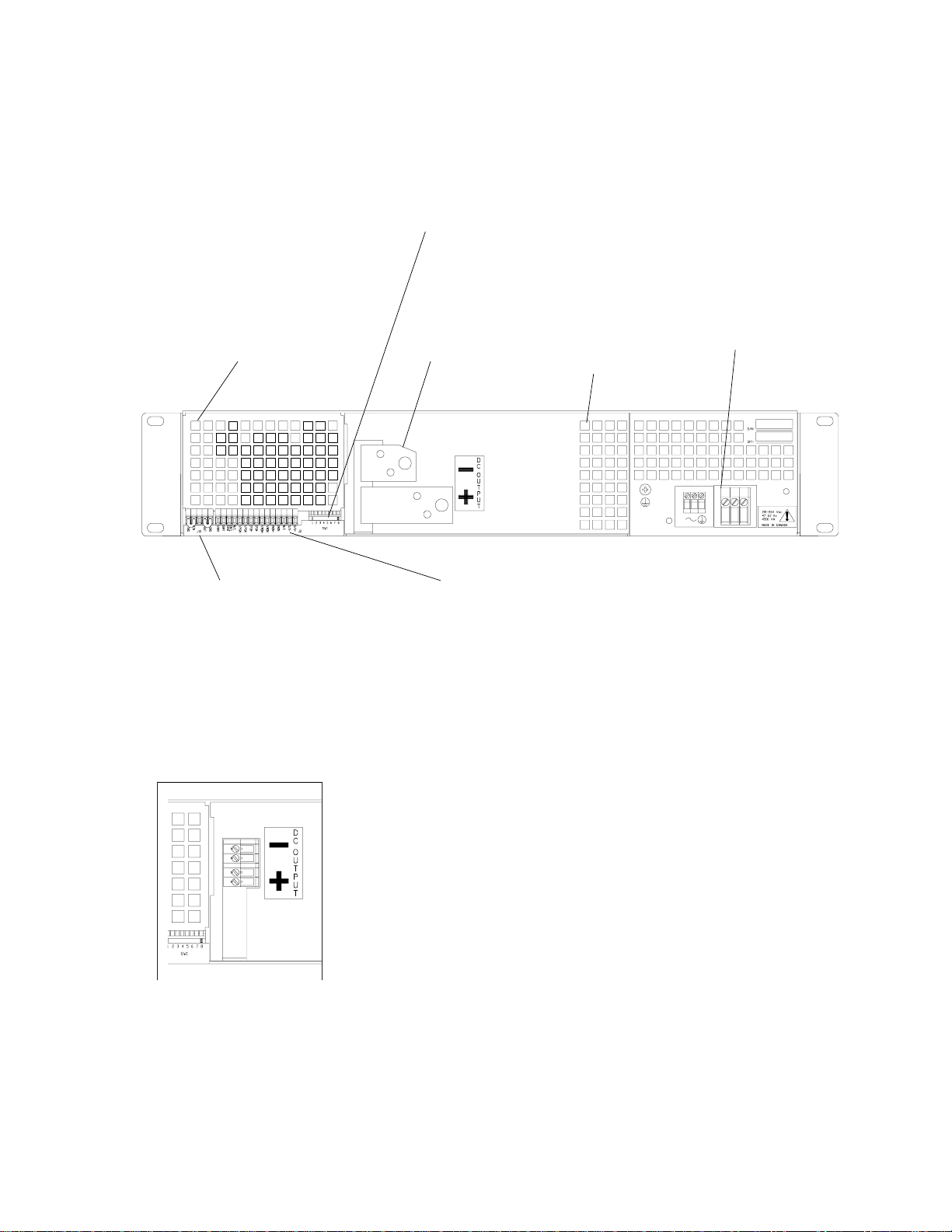

2.3.1 Initial Inspection (continued)

SW1 Switch (See Section 4.2 for more inf ormation.)

1 Resistive Programming of Output Voltage

2 Resistive Programming of Output Current Limi t

3 Output Voltage Programming Source Range

4 Output Current Limit P rogramming Source Range

5 Output Voltage Monitor Range

6 Output Current Monitor Range

7 Remote Shutdown Logic

8 Over Temperature Reset Mode

AC Input

Blank Subplate

(Replaced if digital

programming

interface

DC Output

(See inset and

Section 2.7 for

more information. )

Fan Exhaust Vents

(Do not obstruct.)

Connector

(See Section 2.5

for more

information.)

J10 Sense Connector

(See Section 2.8 for m ore

information.)

1 Return Sense

2 Negative Output (Return)

3 No connection (N/C)

4 Positive Output

5 Positive Sense

Output Voltage Connector

For high voltage (150V to 600V)

models.

J2 Programming and Monitori ng Connec tor

(See Section 4.2 for m ore i nformation.)

1 Remote Output Voltage P rogramming Select

2 Remote Output Current Limit Programming S el ect

3 Control Ground

4 N/C

5 Voltage Program Signal Ret urn

6 Output Voltage Program I nput

7 Current Program Signal Return

8 Output Current Limit P rogramming Input

9 Voltage Monitor Signal Return

10 Output Voltage Monitor

11 Current Monitor Signal Return

12 Output Current Monitor

13 N/C

14 Shutdown (S/D) Signal Return (-)

15 S/D Input (+)

Figure 2.3-2 Power Supply Rear Panel

(Bus bar output model (7.5V to 100V) shown.)

Release 1.0 (98/07) 2-3

Loading...

Loading...