Page 1

EXCELLENCE IN MAGNETICS AND CRYOGENICS

MODEL 05100PS-430-601

INTEGRATED POWER

SUPPLY SYSTEM

INSTALLATION, OPERATION, AND

MAINTENANCE INSTRUCTIONS

American Magnetics, Inc.

P.O. Box 2509, 112 Flint Road, Oak Ridge, TN 378 31 -25 09, Tel: 865-482-1056, Fax: 865-482-5472

Rev. 5; Issue: November 28, 2011

Page 2

Page 3

1 Table of Contents

Table of Contents

Table of Contents............................................................................... iii

List of Figures.................................................................................... ix

List of Tables...................................................................................... xi

Foreword........................................................................................... xiii

Introduction......................................................................................... 1

1.1 Model 05100PS-430-601 Integrated Power Supply System Features 1

Purpose and Scope .............................................................................xiii

Contents of this Manual .................................................................... xiii

General Precautions........................................................................... xiv

Safety Summary................................................................................. xvi

1.1.1 Digitally-Controlled................................................................... 1

1.1.2 Superior Resolution and Stability ............................................ 1

1.1.3 Intuitive Human-Interface Design........................................... 1

1.1.4 Flexibility................................................................................... 2

1.1.5 Standard Remote Interfaces..................................................... 2

1.1.6 Programmable Safety Features................................................ 2

1.1.7 Condition-Based Magnet Auto-Rampdown.............................. 2

1.1.8 Model 05100PS-430-601 General Description ......................... 3

1.1.9 Power Supply System Rack Front Panel Layout .............. 4

1.2 Model 430 Front Panel Layout............................................................. 5

1.3 Model 430 Rear Panel Layout ............................................................. 6

1.4 Power Supply Unit Front Panel Layout .............................................. 7

1.5 Model 601 Energy Absorber Front Panel Layout ............................... 8

1.6 System Specifications @ 25°C ...................................................... 9

1.7 Operating Characteristics ................................................................. 10

1.7.1 Dual-Quadrant Operation ...................................................... 10

Installation......................................................................................... 11

2.1 Inspecting and Unpacking.................................................................. 11

2.2 Power Supply System Mounting ........................................................ 11

2.3 Power Requirements........................................................................... 12

2.3.1 Changing the Model 430 Programmer Operating Voltage ... 12

2.4 Collecting Necessary Information...................................................... 12

2.5 System Interconnects.......................................................................... 13

2.5.1 Model 05100PS-430-601 Bipolar Supply................................ 13

Rev. 5 iii

Page 4

Table of Contents

2.6 Special Configurations.........................................................................17

2.7 Superconducting Magnets with No Persistent Switch ......................17

2.8 Short-Circuit or Resistive Load...........................................................17

2.9 Power-Up and Test Procedure ............................................................18

Operation............................................................................................23

3.1 System Power On/Off Sequence .........................................................23

3.1.1 Model 430 Programmer Power On/Off....................................23

3.1.2 Energizing Power Supply and Components ...........................24

3.2 Model 430 Programmer Default Display............................................25

3.2.1 Field / Current Display ............................................................25

3.2.2 Voltage Display ........................................................................26

3.2.3 Status Indicator .......................................................................26

3.2.4 Main Display ............................................................................27

3.3 Entering Numeric Values....................................................................27

3.4 Using Fine Adjust Knob to Adjust Numeric Values ..........................28

3.5 Entering Picklist Values......................................................................29

3.6 Single-key Commands / Menu.............................................................30

3.6.1 Persistent Switch Control Key ................................................31

3.6.2 Target Field Setpoint Key ......................................................33

3.6.3 Ramp / Pause Key ....................................................................33

3.6.4 Ramp To Zero Key....................................................................33

3.7 SHIFT-key Commands / Menus..........................................................34

3.7.1 Ramp Rate SHIFT-key ............................................................35

3.7.2 Voltage Limit SHIFT-key ........................................................38

3.7.3 Reset Quench SHIFT-key ........................................................39

3.7.4 Increment Field SHIFT-key ....................................................39

3.7.5 Field <> Current SHIFT-key...................................................39

3.7.6 Decrement Field SHIFT-key ...................................................40

3.7.7 Field Units SHIFT-key ............................................................40

3.7.8 Persistent Switch Heater Current SHIFT-key.......................40

3.7.9 Stability SHIFT-key.................................................................41

3.7.10 Vs <> Vm SHIFT-key...............................................................41

3.7.11 Volt Meter SHIFT-key .............................................................41

3.7.12 Fine Adjust SHIFT-key............................................................41

3.7.13 Persist. Switch Control SHIFT-key ........................................41

3.8 LED Indicators.....................................................................................41

3.8.1 Power-on Indicator...................................................................41

3.8.2 Magnet Status Indicators ........................................................42

3.8.3 SHIFT Indicator.......................................................................43

iv Rev. 5

Page 5

Table of Contents

3.9 Setup Menu ......................................................................................... 43

3.9.1 Entering / Exiting Setup Menu .............................................. 43

3.9.2 Menu Navigation..................................................................... 43

3.10 Setup Submenu Descriptions ............................................................. 44

3.10.1 Supply Submenu ..................................................................... 45

3.10.2 Load Submenu......................................................................... 50

3.10.3 Misc Submenu ......................................................................... 61

3.10.4 Net Settings Submenu ............................................................ 70

3.10.5 Net Setup Submenu ................................................................ 72

3.11 Example Setup .................................................................................... 74

3.12 Ramping Functions ............................................................................ 77

3.12.1 Ramping States and Controls ................................................ 77

3.12.2 Manual Ramping..................................................................... 78

3.12.3 Automatic Ramping ................................................................ 78

3.12.4 Ramping to Zero ...................................................................... 79

3.12.5 Fine Adjust of Field / Current in Holding Mode.................... 79

3.13 Persistent Switch Control................................................................... 79

3.13.1 Procedure for Initial Heating of the Switch .......................... 80

3.13.2 Procedure for Entering Persistent Mode .............................. 80

3.13.3 Procedure for Exiting Persistent Mode ................................. 83

3.13.4 Toggling the State of the Persistent Switch Heater.............. 86

3.14 Ramping Functions Example ............................................................ 87

3.15 Quench Detection ............................................................................... 88

3.15.1 External Quench Detection..................................................... 89

3.15.2 Disabling Internal Quench Detection .................................... 89

3.16 External Rampdown .......................................................................... 90

3.16.1 External Rampdown while in Persistent Mode .................... 90

3.16.2 External Rampdown while not in Persistent Mode .............. 92

3.17 Summary of Operational Limits and Default Settings..................... 92

Remote Interface Reference ............................................................ 95

4.1 SCPI Command Summary ................................................................. 95

4.2 Programming Overview.................................................................... 102

4.2.1 SCPI Language Introduction................................................ 102

4.2.2 SCPI Status System.............................................................. 102

4.2.3 Standard Event Register ...................................................... 105

4.2.4 Command Handshaking ....................................................... 106

4.3 RS-232 Configuration ....................................................................... 108

4.3.1 Serial Connector.................................................................... 108

4.3.2 Termination Characters........................................................ 108

Rev. 5 v

Page 6

Table of Contents

4.4 Ethernet Configuration .....................................................................108

4.4.1 Ethernet Connector................................................................109

4.4.2 Termination Characters ........................................................109

4.5 Command Reference ..........................................................................110

4.5.1 System-Related Commands...................................................110

4.5.2 Status System Commands.....................................................111

4.5.3 SETUP Configuration Commands and Queries...................112

4.5.4 Protection Commands and Queries.......................................117

4.5.5 Ramp Configuration Commands and Queries......................122

4.5.6 Ramping State Commands and Queries...............................126

4.5.7 Switch Heater Command and Query ....................................127

4.5.8 Quench State Commands and Queries .................................128

4.5.9 Rampdown State Queries ......................................................128

4.5.10 Trigger Functions...................................................................130

4.6 Error Messages ..................................................................................132

4.6.1 Command Errors....................................................................132

4.6.2 Query Errors ..........................................................................133

4.6.3 Execution Errors ....................................................................134

4.6.4 Device Errors..........................................................................134

Service..............................................................................................137

5.1 System Component Maintenance .....................................................137

5.1.1 Model 430 Programmer Routine Maintenance.....................137

5.1.2 Model 08150PS Power Supply Routine Maintenance ..........137

5.1.3 Model 601 Energy Absorber Routine Maintenance..............137

5.2 Troubleshooting Hints .......................................................................137

5.2.1 Electrostatic Discharge Precautions .....................................138

5.2.2 The Model 430 does not appear to be energized...................138

5.2.3 FAILURE TO LOAD message displayed after power-up ....140

5.2.4 Power supply unstable - magnet voltage oscillates..............140

5.2.5 The power supply system will not charge the magnet.........141

5.2.6 Cannot charge the magnet at the selected ramp rate..........141

5.2.7 Cannot discharge the magnet at the selected ramp rate.....142

5.2.8 Cannot charge the magnet to desired field...........................142

5.2.9 Cannot place the magnet in persistent mode. ......................142

5.2.10 Cannot bring the magnet out of persistent mode.................143

5.2.11 The magnet quenches for no apparent reason......................143

5.2.12 Cannot lower the magnet field ..............................................143

5.2.14 The Model 601 FAULT LED energized with audible alarm144

5.2.15 There is excessive LHe boil-off during operation. ................144

5.2.16 Cannot display the magnetic field strength, only current...145

5.2.17 Cannot use remote communications commands. .................145

5.2.18 Magnet current drifts unacceptably while PSwitch cooling 146

5.2.19 Model 430 appears to lock up when connecting to network 146

vi Rev. 5

Page 7

Table of Contents

5.3 Additional Technical Support........................................................... 146

5.4 Return Authorization........................................................................ 147

Appendix.......................................................................................... 149

A.1 Magnet Station Connectors ......................................................... 149

A.2 LHe Level / Temp Connectors ...................................................... 150

A.3 Programmer Shunt Terminals ......................................................... 151

A.4 Program Out Connector ................................................................... 152

A.5 Quench I/O Connector....................................................................... 153

A.5.1 External Quench Detection Input ........................................ 153

A.5.2 External Rampdown Input ................................................... 154

A.5.3 External Quench Detection Output ..................................... 155

A.6 Aux Inputs Connector....................................................................... 156

A.7 Ethernet Connector ...................................................................... 157

A.8 RS-232 Connector.............................................................................. 157

A.9 Abbreviations and Acronyms used in this Manual ......................... 158

A.10 Model 430 Programmer Specifications ......................................... 162

A.11 Power Supply Details........................................................................ 165

A.11.1 Model 08150PS Electrical Specifications ............................. 166

A.11.2 Model 08150PS Dimensional Specifications........................ 169

A.12 Model 601 and Energy Absorption .................................................. 171

A.12.1 Model 601 Specifications....................................................... 171

A.12.2 Model 601 Energy Absorber Functional Description ......... 172

A.13 Remote Computer Communication with the Model 430................. 175

A.13.1 Communication via RS-232 .................................................. 175

A.13.2 Communication via Ethernet ............................................... 178

A.14 Upgrading the Model 430 Firmware via FTP ................................. 181

A.14.1 Hardware and Software Requirements................................ 181

A.14.2 Preparation............................................................................ 182

A.14.3 Procedure ............................................................................... 183

A.15 Upgrading the Model 430 Firmware via Flash Card Reader ......... 188

A.15.1 Hardware and Software Requirements................................ 188

A.15.2 Preparation............................................................................ 188

A.15.3 Procedure ............................................................................... 189

Rev. 5 vii

Page 8

Table of Contents

A.16 Model 430 Remote Control Application ............................................192

A.17 Model 430IP Power Supply Programmer .........................................195

A.18 Persistent Switch Operation Flowchart ...........................................198

Index ................................................................................................201

viii Rev. 5

Page 9

1 List of Figures

List of Figures

Figure 1-1 Typical Model 05100PS-430-601 System Rack Layout ......................... 4

Figure 1-2 Model 08150PS Front Panel ................................................................... 7

Figure 1-3 Model 601 Front Panel Layout ............................................................... 8

Figure 1-4 The Four Regions, or Quadrants, of System Operation. ..................... 10

Figure 1-5 Dual-Quadrant System with Resistive Shunt...................................... 10

Figure 2-1 Typical Model 05100PS-430-601 System Rack Interconnections ....... 14

Figure 2-2 Model 05100PS-430-601 Bipolar System Interconnections................. 15

Figure 3-1 Default Display. ..................................................................................... 25

Figure 3-2 Numeric Keypad and Associated Keys ................................................. 27

Figure 3-3 Menu Navigation Keys .......................................................................... 30

Figure 3-4 Single Input Keys .................................................................................. 31

Figure 3-5 SHIFT-Key Functions ........................................................................... 34

Figure 3-6 Magnet Status LED Indicators. ............................................................ 42

Figure 3-7 Setup Menu Structure ........................................................................... 45

Figure 3-8 Example Power Supply Outputs........................................................... 48

Figure 3-9 Stability Setting vs. Magnet (with PSwitch) Inductance .................... 51

Figure 3-10 Typical Power Supply Self-Limits ........................................................ 53

Figure 3-11 Magnet Current Rating Set Within Supply Range.............................. 54

Figure 3-12 Example Current Limit Setup .............................................................. 55

Figure 3-13 Example Magnet Specification Sheet. .................................................. 75

Figure 3-14 Ramping to two different target field/current settings........................ 87

Figure 4-1 The Model 430 Programmer Status System. ..................................... 103

Figure 4-2 Asterisk Indicating Model 430 in Remote Mode ................................ 111

Figure A-1 Model 08150PS Terminal Block Connections .................................... 168

Figure A-2 Model 08150PS Dimensions - Front and Rear Views ........................ 169

Figure A-3 Model 08150PS Dimensions - Top and Side Views............................ 170

Figure A-4 Loop Voltages - Actively Discharging (with Model 601).................... 172

Figure A-5 Loop Voltages - Magnet Charging ...................................................... 173

Figure A-6 Loop Voltages - Magnet Charged (Steady State) ............................... 173

Figure A-7 Loop Voltages - Magnet Passively Discharging ................................. 174

Figure A-8 http:// - IP Address or System Name Entry ....................................... 193

Figure A-9 Initial Screen for Browser Access of the Model 430........................... 194

Figure A-10 Model 430IP Front Panel .................................................................... 195

Figure A-11 Browser Depiction of the Model 430 ................................................... 195

Figure A-12 http:// - System Name Entry ............................................................... 196

Figure A-13 Initial Screen for Browser Access of the Model 430IP....................... 196

Figure A-14 Browser Control of the Model 430IP .................................................. 197

Figure A-15 Persistent Switch Operation Flowchart, Page 1 ................................ 198

Figure A-16 Persistent Switch Operation Flowchart, Page 2 ................................ 199

Figure A-17 Persistent Switch Operation Flowchart, Page 3 ................................ 200

Rev. 5 ix

Page 10

List of Figures

x Rev. 5

Page 11

1 List of Tables

List of Tables

Table 1-1 Model 430 Front Panel Description ........................................................ 5

Table 1-2 Model 430 Resistive Shunt Version Rear Panel Description ................ 6

Table 1-3 Power Supply Front Panel Controls and Indicators ..............................7

Table 3-1 Description of Status Indicators ........................................................... 26

Table 3-2 Select Supply picklist values and associated parameters. .................. 47

Table 3-3 V-V Mode Input Range Picklist Values ................................................50

Table 3-4 Maximum Recommended Stability Setting Changes ......................... 52

Table 3-5 Example Setup Configuration...............................................................76

Table 3-6 Ramp modes and descriptions............................................................... 78

Table 3-7 Summary of Model 430 Programmer Limits and Defaults ................. 93

Table 4-1 Bit Definitions for the Status Byte Register ......................................104

Table 4-2 Bit Definitions for the Standard Event Register ............................... 106

Table 4-3 Return Values and Meanings for SUPPly:TYPE? Query.................. 113

Table 4-4 Return Values and Meanings for SUPPly:MODE? Query.................. 114

Table 4-5 Return Values and Meanings for STATE? Query............................... 127

Table 4-6 Model 430 Programmer Trigger Function Bit Definitions ................130

Table 5-1 V-V Mode Input Range Picklist Values ..............................................139

Table A-1 Magnet Station Connectors Pin Definitions.......................................149

Table A-2 LHe Level / Temp Connectors Pin Definitions...................................150

Table A-3 Program Out Connector Pin Definitions ............................................ 152

Table A-4 Quench I/O Connector Pin Definitions ...............................................153

Table A-5 Aux Inputs Connector Pin Definitions ...............................................156

Table A-6 Ethernet RJ-45 Connector Pin Definitions ........................................157

Table A-7 RS-232 Connector Pin Definitions ...................................................... 157

Table A-8 PC (DB9)-to-Model 430 RS-232 Cable Connections........................... 158

Table A-9 Abbreviations and Acronyms ..............................................................158

Table A-10 Model 430 Programmer Specifications @ 25°C ................................. 162

Table A-11 Model 08150PS Power Supply Specifications ....................................166

Table A-12 Model 601 Energy Absorber Specifications ........................................ 171

Rev. 5 xi

Page 12

List of Tables

xii Rev. 5

Page 13

Foreword

Purpose and Scope

This manual contains the operation and maintenance instructions for the

American Magnetics, Inc. Model 05100PS-430-601 Power Supply System.

The user is encouraged to contact an authorized AMI Technical Support

Representative for information regarding specific configurations not

explicitly covered in this manual.

Contents of this Manual

Introduction introduces the reader to the functions and characteristics of

the Model 430 Power Supply Programmer and the Power Supply System.

It provides illustrations of the front and rear panel layouts as well as

documenting the performance specifications. Additional information is

provided in the form of system circuit diagrams.

Installation describes how the Model 430 Power Supply Programmer is

unpacked and installed in conjunction with ancillary equipment in typical

superconducting magnet systems. Block-level diagrams document the

interconnects for various system configurations.

Operation describes how the Model 430 Programmer is used to control a

superconducting magnet. All Model 430 Programmer displays and controls

are documented. The ramping functions, persistent switch heater controls,

and the quench detect features are also presented.

Remote Interface Reference documents all remote commands and

queries available through the Model 430 Programmer RS-232 and

Ethernet interfaces. A quick-reference summary of commands is provided

as well as a detailed description of each.

Service provides guidelines to assist the user in troubleshooting possible

system and Model 430 Programmer malfunctions. Information for

contacting AMI Technical Support personnel is also provided.

Appendix provides additional details and/or procedures in the following

areas:

1. Model 430 Programmer rear panel connectors.

2. Individual power supply unit specifications

3. Model 601 specifications

Rev. 5 xiii

Page 14

Foreword

General Precautions

4. Establishing RS-232 or Ethernet communications with the Model

430.

5. Model 430 firmware upgrade.

6. Abbreviations and acronyms used in this manual.

7. Persistent switch operation (flow diagram).

General Precautions

Cryogen Safety

The two most common cryogenic liquids used in superconducting magnet

systems are nitrogen and helium. Both of these cryogens are extremely

cold at atmospheric pressure (−321°F and −452°F, respectively). The

following paragraphs outline safe handling precautions for these liquids.

Personnel handling cryogenic liquids should be thoroughly instructed and

trained as to the nature of the liquids. Training is essential to minimize

accidental spilling. Due to the low temperature of these materials, a

cryogen spilled on many objects or surfaces may damage the surface or

cause the object to shatter, often in an explosive manner.

Inert gases released into a confined or inadequately ventilated space can

displace sufficient oxygen to make the local atmosphere incapable of

sustaining life. Liquefied gases are potentially extreme suffocation

hazards since a small amount of liquid will vaporize and yield a very large

volume of oxygen-displacing gas. Always ensure the location where the

cryogen is used is well ventilated. Breathing air with insufficient oxygen

content may cause unconsciousness without warning. If a space is suspect,

purge the space completely with air and test before entry. If this is not

possible, wear a forced-air respirator and enter only with a co-worker

standing by wearing a forced-air respirator.

Cryogenic liquids, due to their extremely low temperatures, will also burn

the skin in a similar manner as would hot liquids. Never permit cryogenic

liquids to come into contact with the skin or allow liquid nitrogen to soak

clothing. Serious burns may result from careless handling. Never touch

uninsulated pipes or vessels containing cryogenic liquids. Flesh will stick

to extremely cold materials. Even nonmetallic materials are dangerous to

touch at low temperatures. The vapors expelled during the venting process

are sufficiently cold to burn flesh or freeze optic tissues. Insulated gloves

should be used to prevent frost-bite when operating valves on cryogenic

tanks. Be cautious with valves on cryogenic systems; the temperature

extremes they are typically subjected to cause seals to fail frequently.

xiv Rev. 5

Page 15

Foreword

General Precautions

In the event a person is burned by a cryogen or material cooled to

cryogenic temperatures, the following first aid treatment should be given

pending the arrival and treatment of a physician or other medical care

worker:

1. If any cryogenic liquid contacts the skin or eyes, immediately flush

the affected area gently with tepid water (102°F − 105°F, 38.9°C −

40.5°C) and then apply cold compresses.

2. Do not apply heat. Loosen any clothing that may restrict

circulation. Apply a sterile protective dressing to the affected area.

3. If the skin is blistered or there is any chance that the eyes have

been affected, get the patient immediately to a physician for

treatment.

Containers of cryogenic liquids are self pressurizing (as the liquid boils off,

vapor pressure increases). Hoses or lines used to transfer these liquids

should never be sealed at both ends (i.e. by closing valves at both ends).

When pouring cryogenic liquids from one container to another, the

receiving container should be cooled gradually to prevent damage by

thermal shock. The liquid should be poured slowly to avoid spattering due

to rapid boil off. The receiving vessel should be vented during the transfer.

Introduction of a substance at or near room temperature into a cryogenic

liquid should be done with great caution. There may be a violent gas boiloff and a considerable amount of splashing as a result of this rapid boiling.

There is also a chance that the material may crack or catastrophically fail

due to forces caused by large differences in thermal contraction of different

regions of the material. Personnel engaged in this type of activity should

be instructed concerning this hazard and should always wear a full face

shield and protective clothing. If severe spraying or splashing could occur,

safety glasses or chemical goggles along with body length protective

aprons will provide additional protection.

The properties of many materials at extremely low temperatures may be

quite different from the properties that these same materials exhibit at

room temperatures. Exercise extreme care when handling materials cooled

to cryogenic temperatures until the properties of these materials under

these conditions are known.

Metals to be used for use in cryogenic equipment application must posses

sufficient physical properties at these low temperatures. Since ordinary

carbon steels, and to somewhat a lesser extent, alloy steels, lose much of

their ductility at low temperatures, they are considered unsatisfactory and

sometimes unsafe for these applications. The austenitic Ni-Cr alloys

exhibit good ductility at these low temperatures and the most widely used

Rev. 5 xv

Page 16

Foreword

Safety Summary

is 18-8 stainless steel. Copper, Monel®, brass and aluminum are also

considered satisfactory materials for cryogenic service.

Magnet Quenches

When an energized superconducting magnet transitions from

superconducting state to normal state, the magnet converts magnetic

energy to thermal energy thereby rapidly converting the liquid helium to a

vapor. When this phase transformation occurs, pressures can build rapidly

in the cryostat due to the fact that one part of liquid helium will generate

782 parts of gaseous helium at STP (standard temperature and pressure).

The cryostat must be designed to allow the generated vapor to rapidly and

safely vent to an area of lower pressure. Cryostats are designed with

pressure relief valves of sufficient capacity so as to limit the pressure

transients within the container in order to prevent damage to the vessel.

Operating a superconducting magnet in a cryostat without properly sized

relief mechanisms or disabled relief mechanism is unsafe for the operator

as well as for the equipment. If there is any doubt as to the sufficiency of

the pressure relief system, contact the manufacturer of the magnet and

cryostat for assistance.

Safety Summary

Superconducting magnet systems are complex systems with the potential

to seriously injure personnel or equipment if not operated according to

procedures. The use of cryogenic liquids in these systems is only one factor

to consider in safe and proper magnet system operation. Proper use of

safety mechanisms (pressure relief valves, rupture disks, etc.) included in

the cryostat and top plate assembly are necessary. Furthermore, an

understanding of the physics of the magnet system is needed to allow the

operator to properly control the large amounts of energy stored in the

magnetic field of the superconducting coil. The Model 430 Programmer has

been designed with safety interlocks to assist the operator in safe

operation, but these designed-in features cannot replace an operator’s

understanding of the system to ensure the system is operated in a safe and

deliberate manner.

Recommended Safety Equipment

• First Aid kit

• Fire extinguisher rated for class C fires

• Cryogenic gloves

• Face shield

• Signs to indicate that there are potentially damaging magnetic fields

in the area and that cryogens are in use in the area.

xvi Rev. 5

Page 17

Foreword

O

I

Safety Summary

Safety Legend

Instruction manual symbol: the product is marked with this

symbol when it is necessary for you to refer to the instruction

manual in order to protect against damage to the product or

personal injury.

Hazardous voltage symbol.

Alternating Current (Refer to IEC 417, No. 5032).

Off (Supply) (Refer to IEC 417, No. 5008).

On (Supply) (Refer to IEC 417, No. 5007).

Warning

The Warning sign denotes a hazard. It calls attention to a procedure or

practice, which if not correctly adhered to, could result in personal injury.

Do not proceed beyond a Warning sign until the indicated conditions are

fully understood and met.

Caution

The Caution sign denotes a hazard. It calls attention to an operating

procedure or practice, which if not adhered to, could cause damage or

destruction of a part or all of the product. Do not proceed beyond a Caution

sign until the indicated conditions are fully understood and met.

Rev. 5 xvii

Page 18

Foreword

Safety Summary

xviii Rev. 5

Page 19

1 Introduction

1.1 Model 05100PS-430-601 Integrated Power Supply System Features

The AMI Model 05100PS-430-601 Power Supply System is a sophisticated

digitally-controlled power supply which allows an operator to manage a

superconducting magnet system with unprecedented accuracy and ease of

use. Integral components of the system include a Model 430 Programmer,

Model 601 Energy Absorber, and Model 08150PS Power Supply. The AMI

Model 05100PS-430-601 Power Supply System provides for a degree of

flexibility and accuracy previously unavailable in an economical

commercial product.

1.1.1 Digitally-Controlled

The Power Supply System is controlled by a microcomputer-based controller which controls all analog data conversion, display/keypad functions,

communications I/O, generation of analog programming signals for the

external power supply, and control law computations. The Power Supply

System incorporates digital signal processing (DSP) functions that provide

for accurate control, low drift, and flexibility of use.

1.1.2 Superior Resolution and Stability

The Model 430 Power Supply Programmer incorporates high-resolution

converters to translate signals between the analog and digital domains.

Precision instrumentation techniques and potentiometer-free designs are

employed throughout the Model 430 Programmer to ensure accurate signal translation for a wide range of conditions. The magnet current is sampled at 24-bit resolution in hardware and is software-programmable to 15digits resolution. All pause and hold functions are performed in the digital

domain which provides for excellent stability and drift of the programmed

magnetic field.

1.1.3 Intuitive Human-Interface Design

The Power Supply System was designed to simplify the interface where

possible. All functions were analyzed and subsequently programmed so

that the most commonly used functions are addressed with the least

number of keystrokes. The menus are also presented in a logical fashion so

that the operation of the Power Supply System is intuitive to the user.

The provision of a velocity-sensitive rotary encoder on the front panel also

allows the operator to fine-adjust many of the operating parameters of the

magnet system.

Rev. 5 1

Page 20

Introduction

Features

1.1.4 Flexibility

The Model 05100PS-430-601 system is configured as a two-quadrant

power supply system which is able to both supply and remove electrical

energy from the superconducting magnet system. The Power Supply

System was engineered to be compatible with most magnet systems.

1.1.5 Standard Remote Interfaces

The Power Supply System provides an RS-232 serial port as well as an

Ethernet port as standard features. All settings can be controlled via the

remote interfaces and the front panel can be remotely locked to prevent

accidental operation. The Power Supply System also provides trigger

functions for data collection and/or logging during operation.

1.1.6 Programmable Safety Features

The Power Supply System is designed to be operated from the front panel

of the Programmer or remotely with operational parameters which must

not be exceeded for the given conditions of the system. Once set, should an

operator inadvertently attempt to take the magnet system to an excessive

magnetic field strength or charge at an excessive voltage, the Programmer

will not accept the parameter and will alert the operator that a value was

rejected because it was outside the user-defined limits.

In addition, each setup parameter can be individually selected for locking.

A user-defined password is required to lock or unlock settings. This allows

an administrator to set and password protect any critical parameters that

should not be changed by the operator. Then the administrator can be

confident that an operator will not subsequently change any of these

critical parameters, and yet will be free to change any non-critical

(unlocked) parameters.

1.1.7 Condition-Based Magnet Auto-Rampdown

The Power Supply System can be connected to an AMI Model 13x Liquid

Helium Level Instrument to allow automatic rampdown of the magnet

(even in persistent mode) should the liquid helium (LHe) level drop to a

preset level. This feature ensures the magnet will be protected and not

experience a quench should the LHe level reach an unsafe level for magnet

operation. A single cable is required to use this feature and is covered in

more detail in section A.5.2 on page 154 of the Appendix. Contact AMI for

more information.

In addition to low LHe level, this input to the Power Supply System can be

used with other instrumentation as well. Other uses for this input include

faults from a cryocooler, temperature instrumentation, etc.

2 Rev. 5

Page 21

Introduction

General Description

1.1.8 Model 05100PS-430-601 General Description

A Model 430 Power Supply Programmer and AMI Model 08150PS 1200

Watt unipolar voltage and current stabilized DC Power Supply are

configured with a Model 601 Energy Absorber to make up the +100 A, ±5

Vdc bipolar system designated as 05100PS-430-601. The power supply is

remotely controlled by the Model 430 Power Supply Programmer.

As a unipolar power supply, the Model 08150PS can only source

1

(not sink)

power. However, when the power supply is used in conjunction with the

AMI Model 601 Energy Absorber and controlled by an AMI Model 430

Power Supply Programmer, the result is the bipolar Model 05100PS-430601 integrated power supply system that is ideal for driving inductive

loads such as large magnets or motors.

The power supply is controlled by a ±10 Vdc remote analog signal supplied

by the Model 430 Programmer and applied to the power supply analog

input. Programming and control of the current loop (composed of the

magnet, power supply, Model 601 Energy Absorber, and Model 430

Programmer shunt), is provided by a Model 430 ramp-generated current

reference with parameters as set by the user in the Model 430. The Model

430 compares the measured current (via the shunt) with the current

reference to provide precise closed-loop control of the actual current.

2

The power supply is operated in voltage-voltage

programming mode, with

the Model 430 Programmer output scaled to operate the power supply over

its available voltage output range. The Programmer signal will continually

adjust the power supply output voltage to automatically regulate the

power supply current; precise linear power supply current control will

result as long as the system voltage and current demand do not exceed the

power supply rating or load limiting parameters.

1. The power supply is operating as a source if the current direction and voltage polarity are the same (i.e., the situation that would exist when supplying a resistive load).

If the voltage polarity and current direction are opposite, the supply is operating as

a sink.

2. Voltage reference controlling voltage output.

Rev. 5 3

Page 22

Introduction

Figure 1-1. Typical Model 05100PS-430-601 System Rack Layout

System Rack

1.1.9 Power Supply System Rack Front Panel Layout

4 Rev. 5

Page 23

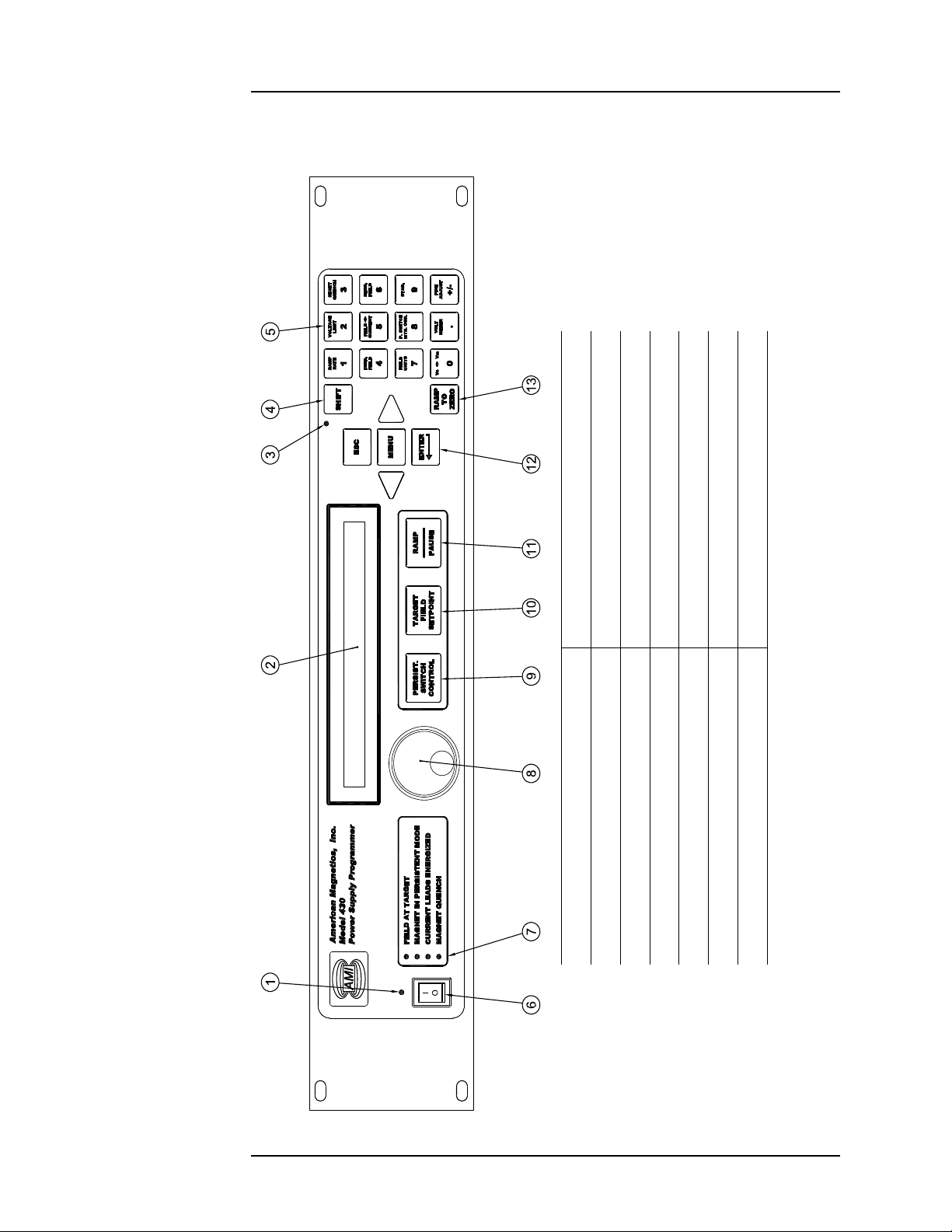

Introduction

1 Power Indicator LED 8 Fine Adjust Knob

2 280 x 16 Dot Graphic VF Display 9 Persistent Switch Heater Control Key

3 Shift Indicator LED 10 Target Field Setpoint Key

4 Shift Key 11 Ramp/Pause Switch

5 4 Row x 3 Column Keypad 12 Menu Navigation and Data Entry Keys

6 Power Switch 13 Ramp to Zero Key

7 Magnet Status Indicator LEDs

Table 1-1. Model 430 Front Panel Description

Model 430 Front Panel

1.2 Model 430 Front Panel Layout

Rev. 5 5

Page 24

Introduction

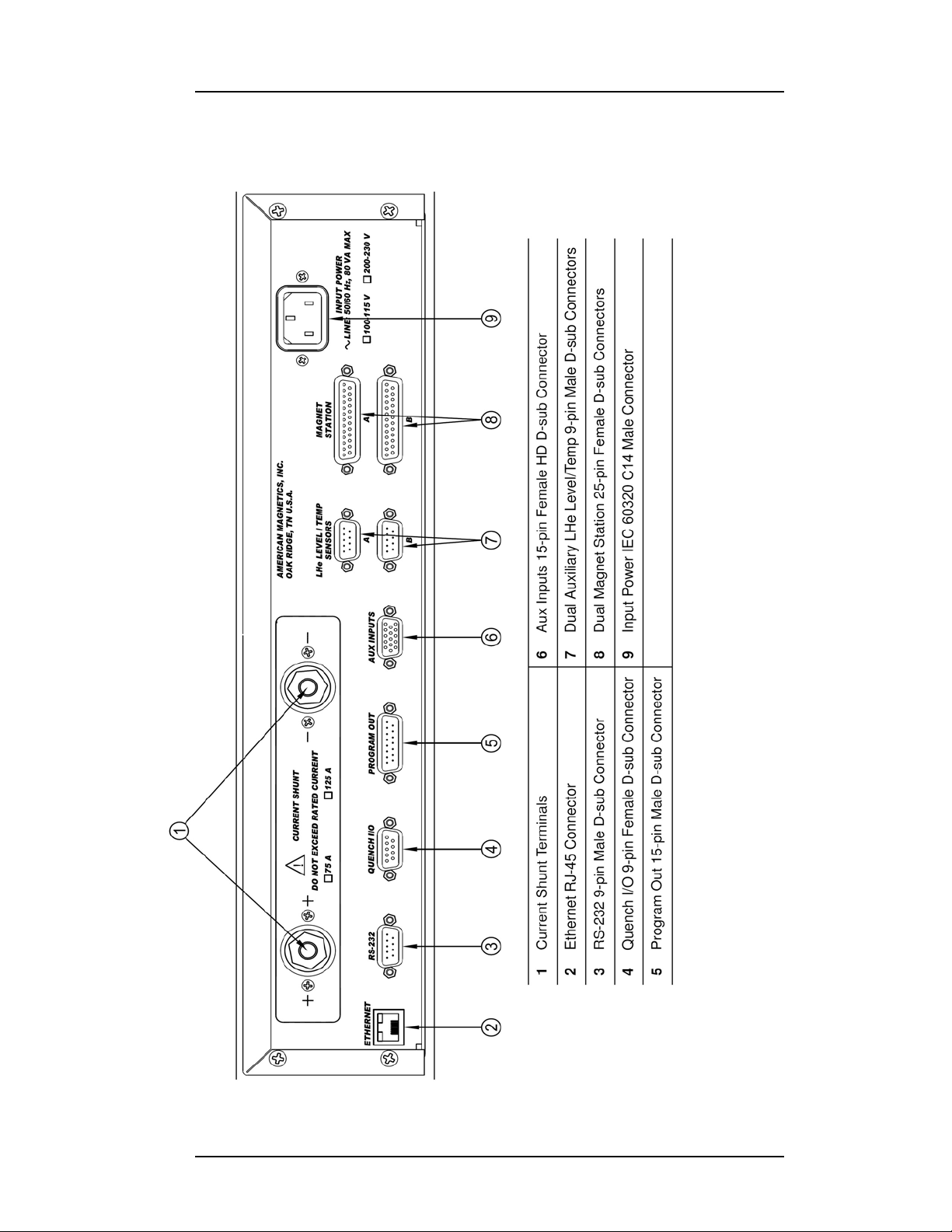

Table 1-2. Model 430 Resistive Shunt Version Rear Panel Description

Model 430 Rear Panel Layout

1.3 Model 430 Rear Panel Layout

6 Rev. 5

Page 25

Introduction

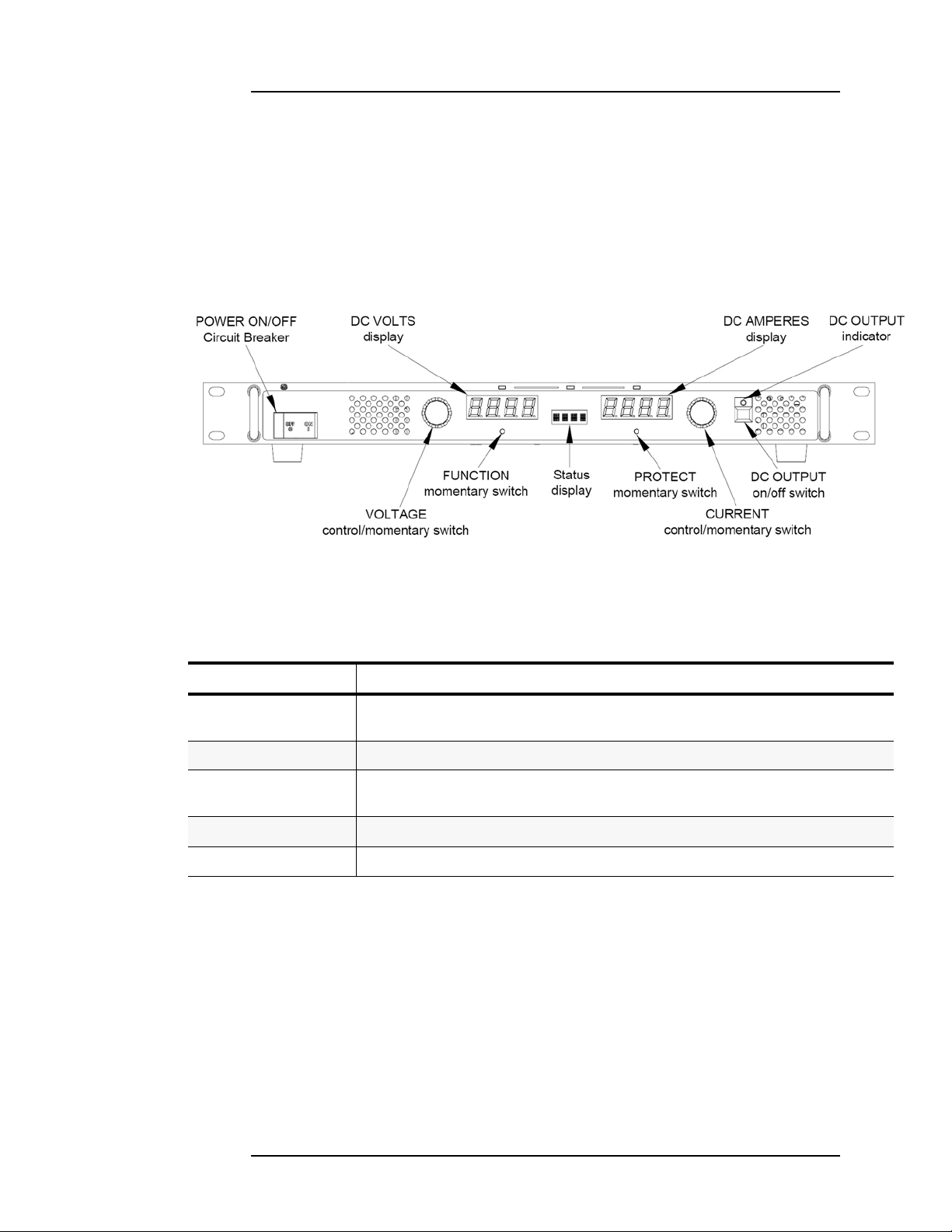

Power Supply Front Panel Layout

1.4 Power Supply Unit Front Panel Layout

The power supply front panel contains the input ON/OFF circuit breaker

and the OUTPUT indicators. The remaining front panel controls are not

used in the Model 05100PS-430-601 configuration because the output is

controlled by the Model 430 Programmer. Refer to Figure 1-2 and Table 1-

3. for a description of front panel controls and indicators.

Figure 1-2. Model 08150PS Front Panel

Table 1-3. Power Supply Front Panel Controls and Indicators

Control or Indicator Function

POWER ON/OFF

Circuit Breaker

DC VOLTS display Four-digit LED display that shows output voltage.

Status

4 character display

DC AMPERES display Four-dig it LED display that shows output current.

DC OUTPUT indicator Green LED lights when DC output is enabled. LED is off when output is disabled.

Turns the power supply on or off. Circuit breaker provides input overload protection.

Displays active function or blinks for error messages. N orm al l y bla nk.

Rev. 5 7

Page 26

Introduction

Figure 1-3. Model 601 Front Panel Layout

Model 601 Front Panel

1.5 Model 601 Energy Absorber Front Panel Layout

The Fault LED is the only device on the Model 601 front panel. If the Fault

LED is not energized, the Model 601 is operating correctly. If the Fault

LED is energized, then one or more of the internal energy absorbing

elements has malfunctioned or power has been lost to the rear-panel

power connector. An audible alarm will also sound when the Fault LED is

energized.

Caution

If the system is in operation when an energy absorber fault occurs, a

safe magnet system state (typically zero current or a cooled

persistent switch in a connected magnet) should immediately be

attained. Do not continue to operate the unit, and refer to the

“Troubleshooting Hints” on page 137 for further direction.

8 Rev. 5

Page 27

Introduction

Model 601 Front Panel

1.6 System Specifications @ 25°C

Magnet Current Control

Range: 0 to +100 A

Programming Accuracy: 40 mA

Stability: 20 mA after 20 min. at desired current

Minimum Ramp Rate: 100 μA/min

Maximum Ramp Rate: 10 A/sec

Output Voltage

Range: 0 to ±5 Vdc

Measurement Resolution: 10 mV

Load Inductance

Range: 0.5 to 100 H

Primary Power Requirements

Physical

Dimensionsa:

Approximate Weight: 70 lbm (30 kg)

Terminal Torque Limit: 48 lbf-in (5.4 N-m)

Environmental Limits

Ambient Temperature: 0 °C to 40 °C (32 °F to 104 °F)

Relative Humidity: 0 to 95%; non-condensing

a. H = height; W = width; D = depth

Range: 100 - 115 or 200 - 230 Vac ±10%

50 / 60 Hz, 1500 VA

12.5” H x 21” W x 24.5” D

(318 mm H x 533 mm W x 622 mm D)

Rev. 5 9

Page 28

Introduction

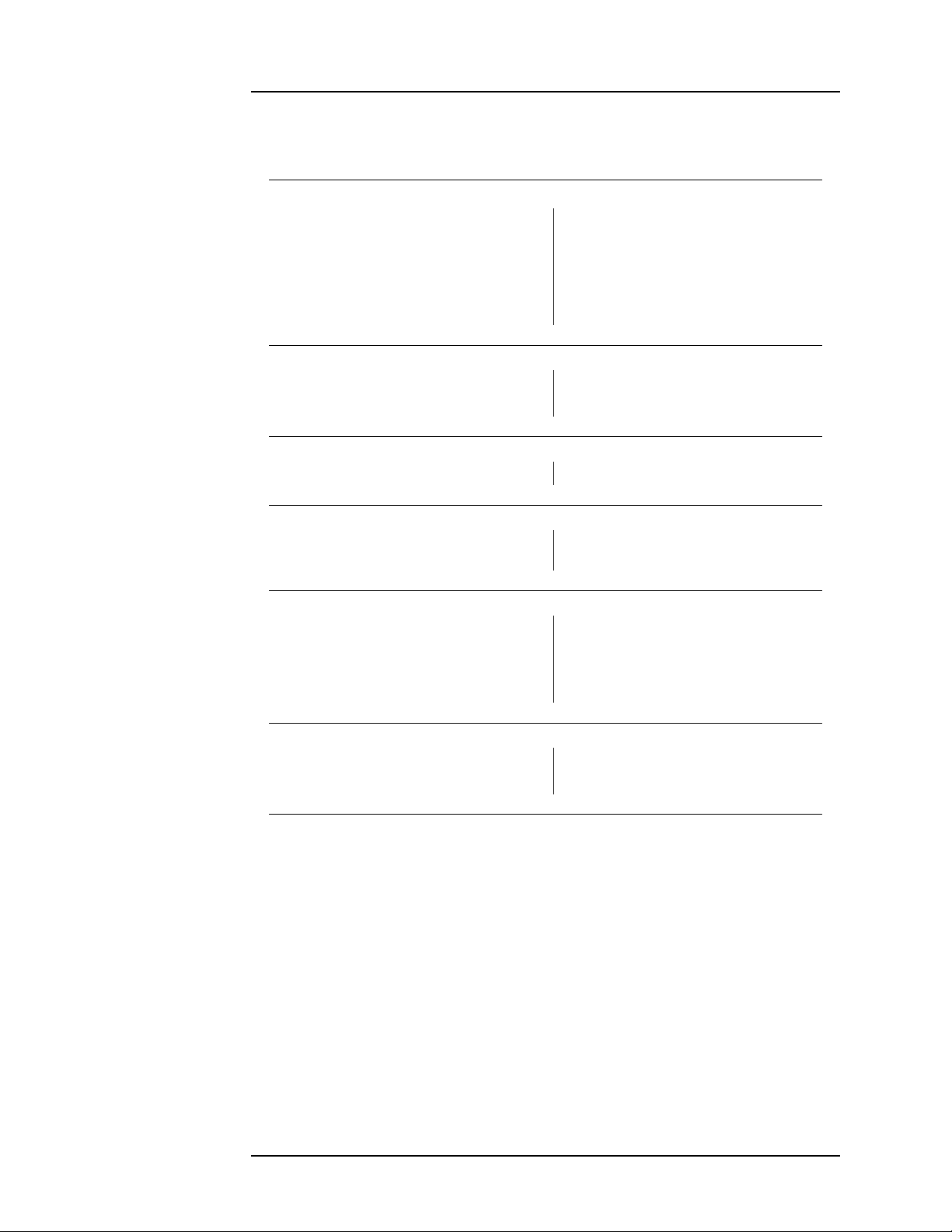

20

-20

200-200

V

I

Positive Current

Flow Direction

Positive Voltage

Polarity

Positive Current

Flow Direction

Negative Voltage

Polarity

Negative Current

Flow Direction

Positive Voltage

Polarity

Negative Current

Flow Direction

Negative Voltage

Polarity

12

43

Figure 1-4. The Four Regions, or Quadrants, of System Operation.

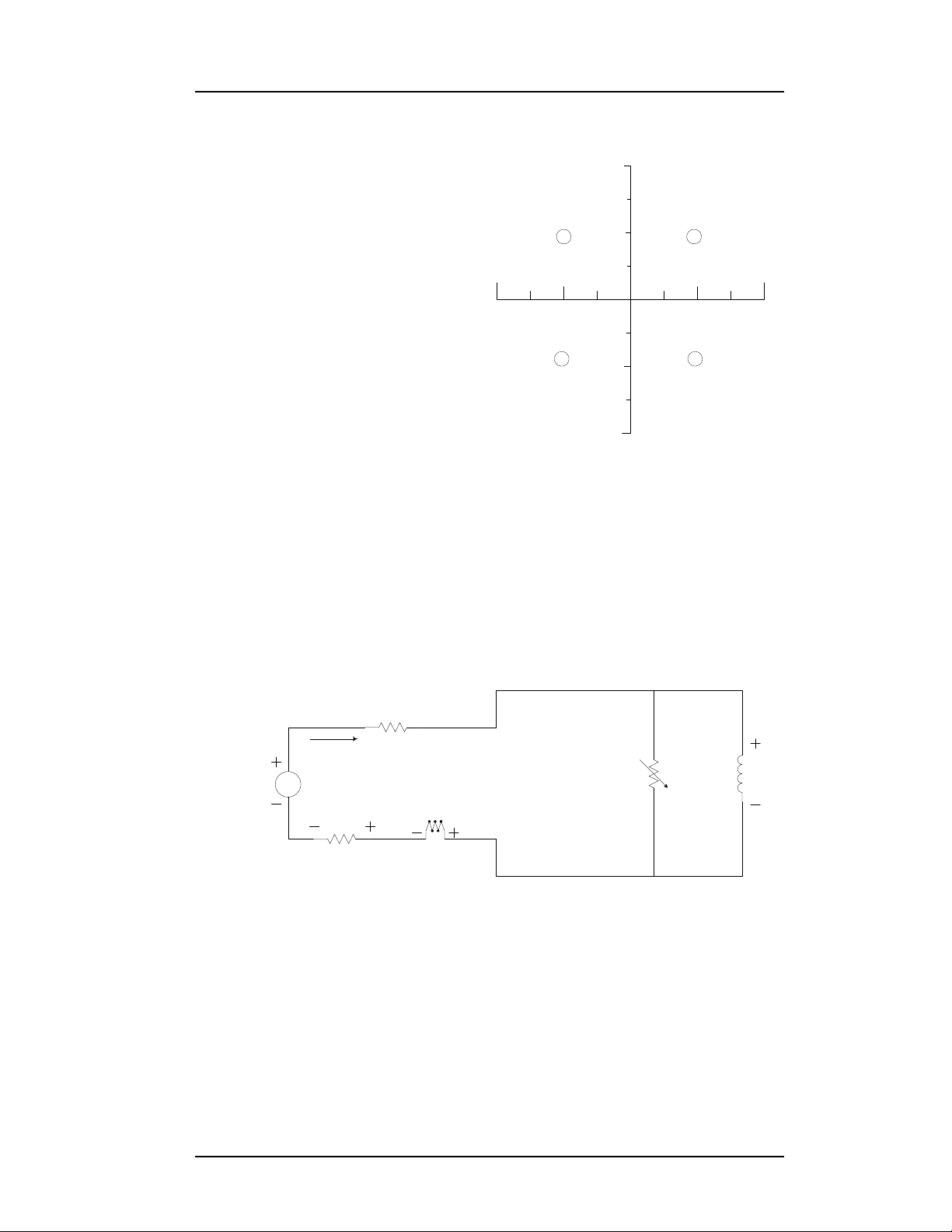

Magnet

Coil(s)

Persistent

Switch

(optional)

Misc. Line Losses

Model 420

Shunt

Energy

Absorber

V

Unipolar

Power Supply

Current

Figure 1-5. Dual-Quadrant System with Resistive Shunt

430

Operating Characteristics

1.7 Operating Characteristics

The Model 430 Programmer has

been designed to perform with various power supplies to allow the

user the greatest degree of system

flexibility. The power supply and

Programmer combination are categorized by one of three forms: sin-

gle-quadrant, dual-quadrant, and

four-quadrant. For sake of clarity,

the term quadrant is defined as

one of four areas of a cartesian

coordinate system where the

abscissa is current and the ordinate is voltage. Refer to Figure 1-4.

1.7.1 Dual-Quadrant Operation

In the Model 05100PS-430-601 dual-quadrant Power Supply system, an

energy absorber is added in series with the unipolar supply; this allows

stored magnetic energy to be converted to thermal energy, thereby

allowing much faster magnetic field reduction. This corresponds to

operation in quadrants 1 and 4 of Figure 1-4. The disadvantage to this

type of system is that energy is being dissipated in the energy absorbing

element whenever current is flowing. This loss is sometimes a significant

portion of the power required to operate the system.

10 Rev. 5

Page 29

2 Installation

Warning

Before energizing the equipment, the earth ground of the power

receptacle must be verified to be at earth potential and able to carry

the rated current of the power circuit. Using extension cords should

be avoided; however, if one must be used, ensure the ground

conductor is intact and capable of carrying the rated current.

In the event that the ground path becomes less than sufficient to

carry the rated current of the power circuit, the equipment should be

disconnected from power, labeled as unsafe, and removed from place

of operation.

Do not operate this equipment in the presence of flammable gases.

Doing so could result in a life-threatening explosion.

Do not modify this equipment in any way. If component replacement

is required, return the equipment to AMI facilities as described in

the Troubleshooting section of this manual.

If used in a manner not specified in this manual, the protection

provided by the design, manufacture and documentation of the

system may be impaired.

2.1 Inspecting and Unpacking

Carefully remove the equipment, interconnecting cabling, and

documentation CD (and/or printed material) from the shipping carton, and

remove all packaging material.

Note

If there is any shipping damage, save all packing material and

contact the shipping representative to file a damage claim. Do not

return to AMI unless prior authorization has been received.

2.2 Power Supply System Mounting

If the system is to be used on a table top, place the equipment on a flat,

secure surface.

Rev. 5 11

Page 30

Installation

Power Requirements

2.3 Power Requirements

Warning

The power requirement for each system component is marked on the

rear panel of the unit adjacent to the power entry connectors. Be sure

the power supply system is configured for the proper power source

prior to plugging in the line cords. Do not fail to connect the input

ground terminal securely to an external earth ground.

Ensure the front panel power switches are in the OFF (

that the power supply components are configured for the proper operating

voltage by referring to the equipment rear panels. If the operating voltage

is correct, plug the line cords into power entry connectors, and into the

appropriate power receptacles.

O) position. Verify

2.3.1 Changing the Model 430 Programmer Operating Voltage

Warning

The following procedure is to be performed only when the Model 430

Programmer is completely de-energized by removing the power-cord

from the power receptacle. Failure to do so could result in personnel

coming in contact with high voltages capable of producing lifethreatening electrical shock.

Note

The voltage selector switch is labeled “115” for nominal line voltages

from 100 to 115 VAC. The switch is labeled “230” for nominal line

voltages of 200 to 230 VAC.

If the Model 430 Programmer operating voltage must be changed, ensure

the instrument is de-energized by disconnecting the power cord from the

power source. Remove the Model 430 Programmer cover by removing the

four screws on both sides of the cover and the four screws from the corners

of the cover on the back panel; slide the voltage selector switch on the main

printed circuit board to the proper voltage. Replace the Model 430

Programmer cover.

2.4 Collecting Necessary Information

In order to properly configure the Model 430 Programmer, specific system

information is required. Such parameters as the magnet electrical

properties, type of power supply, persistent switch heating current

requirements, and voltage and current constraints of the magnet are

entered into the Model 430 Programmer once and nonvolatile memory will

retain the data even after power is removed from the instrument. An

12 Rev. 5

Page 31

Installation

Power Requirements

example of the data to be entered and how it is entered is described in

section 3.11 on page 74.

If the Model 430 Programmer was purchased as part of a magnet system,

essential data will have already been entered at the AMI factory and a

configuration sheet will have been provided detailing the settings.

2.5 System Interconnects

If the Model 430 Programmer was purchased as part of a magnet system,

all applicable system components and wiring harnesses will have been

shipped with the system.

The diagrams that follow will assist in system equipment setup.

Caution

The wiring between the power supply and the magnet current leads

must be of sufficient size to carry the full rated current of the power

supply. Typically, for short runs (less than 25 ft, or 7.6 m), 2 AWG

wire is sufficient for 125 A current, and 2/0 AWG wire is best for

250 A current.

Note that an AMI Model 13x Liquid Helium Level Instrument is shown as

a possible component of each integrated system. The main

instrumentation cable connecting the magnet support stand to one of the

Model 430 Programmer

instrumentation and control connections needed to control and monitor

the magnet. The signals in this cable which are required to monitor LHe

level and temperatures are also presented at the LHe Level / Temp

Connectors. Refer to the Appendix for pin-outs of these and other

connectors.

MAGNET STATION connectors contains all the

2.5.1 Model 05100PS-430-601 Bipolar Supply

For the bipolar (dual-quadrant) mode with shunt method of current

sensing, the magnet power supply system consists of the Model 430

Programmer, a unipolar 08150PS Power Supply, a Model 601 Energy

Absorber, and associated interconnection cabling and buswork. Figure 2-1

Rev. 5 13

Page 32

Installation

Figure 2-1. Typical Model 05100PS-430-601 System Rack Interconnections

Power Requirements

and Figure 2-2 on page 15 depict the 05100PS-430-601 integrated power

supply system interconnects.

Refer to Figure 2-2 on page 15. Ensure the cabling is connected in the

following manner:

Note

The use of locking hardware is recommended for all high-current

connections.

Caution

Do not overtighten the hardware on the interconnection terminals

(refer to specifications table on page 9 for torque limits).

Overtightening can result in damage to the terminals.

Warning

Ensure the protective diode is installed across the output terminals

of the power supply with the anode at the negative (–) terminal and

the cathode at the positive (+) terminal. Removal or omission of this

protective diode may cause serious injury to personnel and damage

to the power supply under loss of AC power conditions.

14 Rev. 5

Page 33

Installation

!

Superconducting

Magnet

Model 430 Rear Panel

1

2

3

4

5

6

8

9

LINE VOLT AGE , 1A M A X

CONTROLLER OUTPUT

COMMUNICATIONS

50-60 Hz (SEL. SW. INSIDE)

J2

AMERICAN MAGNETICS, INC.

OAK RIDGE, TN U.S.A.

INPUT POWER

RS-232

J8

S11

ON

90-132 VAC 180-264 VA C

SENSOR

J1

!

!

AMI Model 13x Rear Panel

Model 08150PS Unipolar

Supply Rear Panel

7

10

1112

15

13

14

16

Model 601 Energy

Absorber Rear Panel

17

17

Figure 2-2. Model 05100PS-430-601 Bipolar System Interconnections

Power Requirements

Rev. 5 15

Page 34

Installation

Power Requirements

a. Connect the protective diode between the output terminals of the

power supply: anode to the negative (–) terminal and the cathode to

the positive (+) terminal.

b. Connect the positive (+) output terminal (1) of the power supply to

the Model 601 Energy Absorber positive (+) terminal (2).

c. Connect the negative (−) terminal (3) of the Model 601 Energy

Absorber to the positive (+) magnet current lead (4).

d. Connect the negative (−) magnet current lead (5) to the positive (+)

resistive shunt terminal (6) on the back of the Model 430

Programmer.

e. Connect the negative (−) resistive shunt terminal (7) of the Model

430 Programmer to the negative (–) output terminal of the power

supply (8).

f. Connect two jumpers (17) from terminal block position S- to M- and

from S+ to M+ on the power supply unit.

g. Connect the DB15 analog I/O cable from the

PROGRAM OUT

connector (14) on the back of the Model 430 Programmer to the

DB15

ANALOG I/O connector (9) on the rear of the power supply

unit.

h. Install an instrumentation cable between the magnet support

stand top plate connector (10) and one of the

MAGNET STATION

connectors (16) on the rear of the Model 430 Programmer.

i. Optional: Install an instrumentation cable between one of the

LEVEL / TEMP

connectors (15) on the rear of the Model 430

LHe

Programmer and the Model 13x Liquid Helium Level Instrument

and/or temperature instrument (11). Refer to section A.2 on page

150.

j. Optional: Install an instrumentation cable between the

I/O

connector (13) on the rear of the Model 430 Programmer and

Aux connector

J2 (12) on the rear panel of the Model 13x Liquid

QUENCH

Helium Level Instrument. Refer to section A.5.2 on page 154.

k. Connect Model 601 power adapter (17) and device line cords, and

plug them into appropriate power receptacles.

l. Remote communications via Ethernet and/or RS-232 can be

accomplished by connecting suitable cabling to the Model 430

Programmer rear panel

16 Rev. 5

ETHERNET and/or RS-232 connectors.

Page 35

Installation

Magnets w/o Persistent Switch

2.6 Special Configurations

The Model 430 Programmer has been designed for optimal operation with

a superconducting magnet (i.e. a very low resistance, high inductance

load) with a persistent switch. The Model 430 Programmer is capable of

controlling current to other loads; however, some modification to the

Model 430 Programmer settings and/or connections must usually be made.

Two commonly encountered configurations are: 1) superconducting

magnets without a persistent switch, and 2) operation on a short-circuit or

low resistance load.

2.7 Superconducting Magnets with No Persistent Switch

An external stabilizing resistor for superconducting magnets without a

1

persistent switch is no longer required

. However, these systems do

require a specific Model 430 Programmer stability setting based on the

magnet inductance as follows:

For magnet inductance

<= 100 Henries (H):

Stability Setting = (100 - H)

For magnet inductance

> 100 Henries:

Stability Setting = 0

2.8 Short-Circuit or Resistive Load

If operating with a short-circuit as a load without the presence of a

superconducting magnet, the Model 430 Programmer must be manually

configured for stability. Normally, when the persistent switch heater is

deactivated, the Model 430 Programmer sees essentially a short-circuit

load since the persistent switch shunts all current flow away from any

connected magnet. Therefore, one method of operating a short-circuit is to

indicate that a persistent switch is present, with the persistent switch

heater deactivated.

The preferred method

is to indicate that a persistent switch is not present

(see section 3.10.2.6 on page 56) and adjust the stability setting (see

section 3.10.2.1 on page 50) to control the load. A stability setting of 100%

will always allow control of a short-circuit as the load, regardless of the

state of the persistent switch heater.

If the resistance of the load is increased, the stability setting must be

decreased to improve the transient response of the system. If the current

1. Effective with Model 430 firmware version 1.62.

Rev. 5 17

Page 36

Installation

Power-Up Procedure

appears to lag, then decrease the stability setting until the system is

responsive. If the current appears to oscillate, increase the stability setting

until the oscillations are damped.

Note

If you have purchased a superconducting magnet with the Model

430 Programmer, AMI will normally provide a recommended

stability setting for optimal operation of the magnet system. If you

operate the Model 430 Programmer with a different load, be sure to

restore the stability setting to the recommended value when the

superconducting magnet is reconnected.

The stability setting is essentially manual control of the gain of an

integrator present in the control logic of the Model 430 Programmer.

Increasing the stability setting decreases the gain of the integrator.

A special case is with the energy absorber designs available from AMI. The

Model 601 Energy Absorber is a nearly infinite-resistance device until 5

Vdc is achieved across its terminals. Once the 5 Vdc “bias” is present, the

Model 601 allows current flow with a nominal 2 mΩ series resistance.

Therefore, the Model 430 Programmer will require an “integration time” to

overcome the 5 Vdc bias. Once the bias is achieved, the series resistance is

minimal and the Model 601 appears as a short-circuit. It is not possible to

decrease the stability setting to remove the integration time, since once

the 5 Vdc bias is achieved, the load is a short-circuit and the system will

become unstable.

However, when operating with a superconducting magnet in the circuit,

the integration gain of the Model 430 Programmer will be adequate to

quickly “bias” the Model 601 and achieve a proper current ramping profile.

The only time the “integration time” is long is when an energy absorber is

used, and the load is a short circuit.

2.9 Power-Up and T est Procedure

It is important to verify that the magnet system has been properly

connected before the superconducting magnet is energized. This is

especially recommended if the system is to be controlled via a computer

since this setup will allow software debugging without the potential for

damage to the magnet. The following procedures will assist the user in the

verifying key system components.

1. Using the appropriate diagram from section 2.5 as a guide, verify

all system components are connected as shown. If there is any

doubt as to the correct connection of a component, contact an AMI

Technical Support Representative. The user may be required to

18 Rev. 5

Page 37

Installation

Power-Up Procedure

properly make a few connections between the various system

components which were disconnected to facilitate packing and

shipping.

2. Temporarily place a short across the magnet current terminals.

Often this is most easily accomplished by unfastening the heavy

cables from the magnet current leads and fastening them together.

This will allow rudimentary power supply checks without

energizing the superconducting magnet.

3. Energize the Model 430 Programmer by placing the power switch

in the I (ON) position.

Note

Ensure the Model 601 energy absorber power adapter is properly

connected to the energy absorber and the AC power receptacle.

4. When prompted by the Model 430 Programmer, energize the power

supply and press ENTER on the Model 430 Programmer.

1

Note

Remember to adjust the programmer Voltage Limit settings as

necessary to account for the additional voltage (5 V) required to

operate the system with a Model 601 installed.

Warning

All power supply parameters, both hardware and software, have

been set at the AMI factory. Power supply control, with the exception

of powering

Power Supply Programmer. No field adjustments or reconfiguration

of the power supply should be attempted in the field unless

specifically described in this document or recommended in writing

by an AMI Technical Support Representative.

5. Enter a stability setting of 100%. Refer to sections 3.3 on page 27

and 3.7.9 on page 41.

6. Verify the various setup menu values for the system (with the

exception of the stability setting, which is to be temporarily left at

100%). If the power supply system was purchased with an AMI

magnet, AMI has preset the setup menu values for proper

operation. See sections 3.3, 3.5, 3.9 and 3.10 for more discussion of

ON and OFF, is done by way of the AMI Model 430

1. If the system shipped with CamLoc quick-disconnect connectors, they may be

quickly disconnected from the magnet leads and connected together.

Rev. 5 19

Page 38

Installation

Power-Up Procedure

the setup menu values and their entry into the Model 430

Programmer.

7. Set the Model 430 Programmer to display current (rather than

field). Refer to sections 3.2.1 and 3.7.5.

8. Set the ramp rate to 1 A/sec. Refer to sections 3.3 on page 27 and

3.7.1 on page 35.

9. Set the target current to 10 A. Refer to sections 3.3 on page 27 and

3.6.2 on page 33.

10. If a Persistent Switch is installed, set the PSw P/S Ramp Rate to 10

A/sec. Refer to paragraph 3.10.2.11 on page 58

11. Initiate ramping to the target current by pressing the

PAUSE

key (status indicator changes from P to ).

RAMP /

12. The system should ramp to 10 A in approximately 10 seconds.

Verify this is the case (if a PSwitch is installed and in the cooled

state, ramp time to 10 A should be slightly less than 2 seconds).

Note

With an energy absorber unit is connected, the Model 430

Programmer may take significantly longer to ramp the current to 10

A. The Model 430 must first develop a supply output voltage to

overcome the forward voltage drop of a connected energy absorber.

During actual magnet operation, the presence of an energy absorber

will not significantly delay the ramping operation since the Model

430 control gain is increased by orders of magnitude when an

inductive load is connected (unless stability setting is 100%).

13. When the target current is achieved, the

will be illuminated. The display should show “

indicating that the Model 430 Programmer is in the holding mode

at the target current value (+10.00 A).

FIELD AT TARGET LED

+10.00 A -”

Note

There may be a discrepancy between the current shown on the power

supply display

Programmer. The current measurement system incorporated in the

Model 430 is more accurate than the power supply shunt.

1. Not all power supplies have a local current readout.

20 Rev. 5

1

and the current displayed on the Model 430

Page 39

Installation

Power-Up Procedure

14. Verify that the power supply output current display indicates that

a total of approximately 10 A is being supplied to the load (which is

only the cabling in this case).

15. Set the target current to the Current Limit value. Refer to section

3.10.2.4 on page 54 to determine the Current Limit value. After the

new target current value is entered, the Model 430 Programmer

should ramp automatically to the new setting.

16. When the new target current value is reached, the power supply

current display (if provided) should also indicate the new value.

17. Press the

RAMP TO ZERO key to ramp the system to zero current.

18. Perform remote control software checkout as required.

19. Turn off the power supply.

20. Reset the stability setting and ramp rate of the Model 430

Programmer to an appropriate value for the magnet to be operated.

Then turn off the Model 430.

21. Remove the short from the power supply leads and connect the

leads to the magnet current leads of the magnet.

After successful completion of this test, the system is ready for operation

with a superconducting magnet. Refer to the ramping function example

presented in section 3.14 on page 87 for a discussion of the various

available ramping methods.

Rev. 5 21

Page 40

Installation

Power-Up Procedure

22 Rev. 5

Page 41

3 Operation

+0.00 A - Turn on power supply

+0.00 Vs Press ENTER to continue

This section describes the operation of the Model 430 Programmer. Every

menu and submenu item is illustrated and described in detail. An example

setup of the Model 430 Programmer is presented in section 3.11 on

page 74. An example ramping operation is presented in section 3.14 on

page 87.

Note

In some of the examples and figures that follow, the ± sign is used to

described various controlled parameter values such as current,

voltage, ramp rate, etc. Where used to describe voltages, currents,

and fields as relate to the Model 05100PS-430-601 Power Supply,

the ± should be ignored (considered illustrative only) since the power

supply provides only positive (unipolar) current.

3.1 System Power On/Off Sequence

The Model 430 Programmer should always be energized before the power

supply that it is controlling. The Model 430 Programmer is designed to

prompt the user in order to ensure the power supply is energized at the

proper time. The Model 430 Programmer should always be de-energized

after the power supply is shut down.

3.1.1 Model 430 Programmer Power On/Off

Place the Model 430 Programmer power switch in the ON position. After

the Model 430 Programmer is powered on and fully initialized (about 20

seconds), the following display will appear:

After this screen is displayed, the power supply can be powered up (See

“Energizing Power Supply and Components” on page 24.) followed by

pressing the

the default display

ENTER key on the Model 430 Programmer. This brings up

1

.

1. Refer to section 3.2 on page 25.

Rev. 5 23

Page 42

Operation

AMI Model 430 Programmer

FAILURE TO LOAD.

Energizing Power Supply System Components

Note

If turned off, the Model 430 Programmer must remain unpowered

for at least 5 seconds

be an initialization error, in which case the following screen will be

displayed.

If this occurs, turn the Model 430 Programmer off, wait 15 seconds

or more, and power the Model 430 Programmer back on.

When powering the system off, first turn off the power supply controlled by

the Model 430 Programmer followed by the Model 430 Programmer. The

controller will then ensure the load sees no abnormal power transients as

the power supply is turning off.

before it is powered back on. If not, there may

3.1.2 Energizing Power Supply and Components

Warning

Do not change power supply jumpers, dip-switches, or other factory

settings. If not rack-mounted, always position power supply and

Model 601 Energy Absorber for convenience in disconnecting the

power cords.

3.1.2.1 Power Supply

Place the power supply switch in the ON position. No local (front

panel) adjustments or connections are required since the power

supply control mode and other parameters have been factoryconfigured for control by the AMI Model 430 Power Supply

Programmer.

When powering the system off, turn OFF the power supply before

powering off the Model 430 Programmer.

3.1.2.2 Energy Absorber

The Model 601 Energy Absorbers is operational immediately upon

connection to a power receptacle. Power is supplied to the Model

601 by connecting the supplied external DC power converter to the

matching connector at the rear of the Model 601, and then

connecting the AC power cord to the appropriate power receptacle.

24 Rev. 5

Page 43

Operation

+50.00 A — Status: Holding

+0.50 Vs PSwitch Heater: ON

+50.00 A — -10 0Vm +10

+1.50 Vs |''''|''''|''''|'''''|

Field / Current Display.

Default display showing ramp mode and persistent switch heater status:

Default display showing voltmeter:

Figure 3-1. Default Display.

Voltage Display.

Status Indicator.

Main Display.

Default Display

3.2 Model 430 Programmer Default Display

The default display is illustrated in the figure below. It is displayed

whenever no menus are being accessed and no errors are being indicated.

The default display can be thought of as being logically divided into four

display areas — the Field / Current Display area, the Voltage Display

area, the Status Indicator area and the Main Display area.

3.2.1 Field / Current Display

The field / current display indicates either the field strength or current1.

This is always displayed in the upper left corner of the display (see Figure

3-1), regardless of what else is being displayed on the Model 430

Programmer display. The parameter displayed (field or current) is toggled

by pressing

is being displayed, pressing

SHIFT followed by FIELD <> CURRENT. Thus, if field strength

SHIFT followed by FIELD <> CURRENT will

cause the current to be displayed; conversely, if current is being displayed,

pressing

strength to be displayed. Operating current is always displayed in

amperes (A). Operating field strength may be displayed in kilogauss (kG)

or tesla (T) if a coil constant has been specified in the setup

strength is being displayed, the units (kG or T) in which it is displayed can

be toggled by pressing

SHIFT followed by FIELD <> CURRENT will cause the field

SHIFT followed by FIELD UNITS.

1. The value is always displayed in current (A) when an installed persistent switch is in

the cooled state since the value represents power supply current only, independent

of magnet current/field.

2. Refer to section 3.10.2.2 on page 52.

2

. If field

Rev. 5 25

Page 44

Operation

Table 3-1. Description of

Status Indicators

P

Paused

Ramping Up

Ramping Down

– Holding

Heating Persistent Switch

Cooling Persistent Switch

V

Voltage Limit

Default Display : Voltage

Note

Note that the displayed field strength is not directly measured, but

rather is calculated by multiplying the coil constant entered in the

setup menu by the measured current flow of the Model 430 power

supply system.

3.2.2 Voltage Display

The voltage display indicates either the voltage across the magnet (Vm) or

the power supply output voltage (Vs). This is always displayed in the lower

left corner of the display (see Figure 3-1), regardless of what else is being

displayed on the Model 430 Programmer display. The parameter displayed

(magnet voltage or power supply voltage) is toggled by pressing

followed by

Vs <> Vm. Vm indicates the voltage measured across the

terminals of the connected superconducting magnet. In order for the Model

430 Programmer to measure the magnet voltage, the magnet voltage taps