American Energy Systems MagnuM 7500 User Manual

MAGNUM 6500® / 7500®

CORN/WOOD PELLET FURNACE

THIS APPLIANCE HAS BEEN TESTED AND APPROVED TO CSA B 366.1-M91-CAN/USA & UL 391-99

OWNER’S MANUAL

Installation – Operation – Maintenance Instructions

WARNING: THIS INSTRUCTION MANUAL MUST BE SAVED FOR FUTURE REFERENCE

PLEASE READ THIS ENTIRE MANUAL BEFORE INSTALLATION AND USE OF THIS CORN/WOOD PELLET BURNING FURNACE. FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN PROPERTY DAMAGE, BODILY INJURY OR EVEN DEATH.

REFER TO ADDITIONAL MARKINGS ON APPLIANCE FOR ADDITIONAL INSTRUCTIONS

IMPORTANT: Always contact your local dealer/installer with questions before contacting the factory. When you call have your serial number, purchase date, who installed the unit and a list of questions.

This appliance must be installed by a HVAC licensed/trained factory approved installer

When installing your Magnum 6500/7500 Corn/Wood Pellet Furnace, particular attention needs to be made in regards to fire protection. If the unit is not properly installed, a house fire may result. For your safety, follow the installation and operation instructions provided, and if a question arises contact local building or fire officials about restrictions and installation requirements in your area.

Read the operations and fuel section of this manual before plugging in your unit.

Always unplug the unit before attempting any service work.

Do not connect the unit to a chimney flue already serving another appliance.

When installing the chimney pipe to the unit, it is important to remember that the unit operates on a negative pressure and the chimney on a positive pressure. All chimney connections, elbows and fittings must be airtight. (proper venting practices must be followed. Consult with a venting professional)

Ashes must be disposed of in a metal container with a tight fitting lid. Do not let ashes build up in ashpan.

All minimum clearances to combustibles must be followed. Ductwork clearances must be maintained.

The Magnum 6500/7500 Corn/Wood Pellet Furnace is tested for operation with 14% or less moisture corn or with wood pellets with an ash content of no more than 3%. It is recommended that Corn with

11-12% moisture or wood pellets with an ash content of 1% or less be used for efficient operation of this unit. Corn over 12% moisture has a lower BTU value and will be hard to burn on the lower settings. Fuel over 12% moisture will dramatically reduce the heating ability of this appliance.

It is important to use fuel that is clean, dry and consistent. Make sure that your supplier is giving you the same fuel each time that you purchase. It is recommended that you purchase your entire heating season supply of fuel at one time so that the fuel will be the same.

A voltage surge protector or ground fault outlet is required for this unit. The warranty on the circuit board will be voided if proper surge protection is not installed before operating this unit

Proper voltage, polarity and grounding must be assured for appliance to operate correctly. Consult with your electrician before operating this appliance to assure electrical is proper.

AMERICAN ENERGY SYSTEMS, INC. GRANTS NO WARRANTY, IMPLIED OR STATED, FOR THE INSTALLATION OR MAINTENANCE OF THE STOVE AND ASSUMES NO RESPONSIBILITY FOR ANY CONSEQUENTIAL DAMAGE(S).

Disclaimer Notice: No guarantee is made regarding the heating capacity of this unit. The actual area that this unit will heat depends on factors such as fuel quality, fuel moisture, installation configuration, venting and fresh air configuration, operational practices, conditions of the building, heat loss, type of construction, amount and type of insulation, type of air movement, and the location of the Furnace.

AMERICAN ENERGY SYSTEMS, INC. -150 Michigan Street SE - HUTCHINSON, MINNESOTA 55350

Web Site: www.magnumheat.com

Rev. date 11/01/11

TABLE OF CONTENTS |

PAGE |

INTRODUCTION & SPECIFICATIONS………….……………………………………….... |

3 |

UNPACKING YOUR MAGNUM 7500 CORN/PELLET FURNACE / SAFETY STEPS…. |

4-6 |

BURNING SOLID FUELS (SHELLED CORN AND WOOD PELLETS)……………..…... |

7-8 |

CLEARANCE TO COMBUSTIBLES………………………………………………………. |

9 |

FLOOR PROTECTION………………..………..................................................................... |

10 |

GUILDELINES FOR EXHAUST VENTING SYSTEMS DESIGNS……………………… |

11-13 |

DESIGN GUIDELINES FOR OUTSIDE COMBUSTION AIR CONNECTION…………... |

14 |

INSTALLATION CONFIGURATIONS…………………………………………………….. |

15-17 |

DUCTING……………………………………………………………………………………. 18-20 |

|

GLASS MAINTENANCE, ADJUSTMENT, REMOVAL AND REPLACEMENT………… |

21 |

STOVE CONTROLS…………………………………………………………………………. |

22 |

LIGHTING INSTRUCTIONS 7500………………………………………………………….. |

23 |

CIRCUIT BOARD FUNCTIONS……………………………………………………………. |

24 |

SETTING THE DRAFT……………………………………………………………………… |

25 |

6500 LIGHTING INSTRUCTIONS /CIRCUIT BOARD FUNCTIONS/SETTING DRAFT |

26-28 |

MAINTENANCE INSTRUCTIONS………………………………………………………… |

29-32 |

AUTOMATIC SAFETY FEATURES……………………………………………………….. |

32 |

THERMOSTAT INSTALLATION…………………………………………………………... |

33 |

MAGNUM 7500 WIRING DIAGRAM………………………………………………………. |

34 |

MAGNUM 6500 WIRING DIAGRAM……………………………………………………… |

35 |

TROUBLE SHOOTING GUIDE…………………………………………………………….. |

37 |

SETTING THE CIRCUIT BOARD………………………………………………………….. |

41 |

DRAFT SLIDE GATE CORRECTOR INSTALL AND ADJUSTMENT………………….. |

42 |

REPACEMENT PARTS LIST…………………………………………………………….. |

43 |

WARRANTY INFORMATION…………………………………………………………….. |

44 |

SERVICE RECORD………………………………………………………………………….. |

45 |

WARRANTY REGISTRATION CARD……(IN HARDWARE PACKET) |

|

2

DEAR VALUED MAGNUM 7500 OWNER,

We appreciate your decision to help preserve our precious environment by purchasing the Magnum 6500 or the 7500 Corn/Wood Pellet Furnace. With everyone working together, we can have clean air and renewable heat for our homes. Making a decision today to conserve energy will result in lower energy costs tomorrow along with conserving our precious natural resources.

Please read this Owners Manual carefully before using this appliance and if you have any questions contact your local Magnum reseller. We appreciate your business and wish you many warm days and nights with your new Magnum 6500/7500 Corn/Wood Pellet Furnace.

Sincerely,

Mike

Mike Haefner, President

American Energy Systems, Inc.

P.S. You are very important to the success of our business and your referral of our products is very much appreciated. Many of our Resellers have referral rewards available and I encourage you to ask your local dealer how to get involved in helping make our country energy self-sufficient. GOOD LUCK !

SPECIFICATIONS

American Energy Systems, Inc., manufacturer of the Magnum 6500/7500 Corn/Wood Pellet Appliances, reserves the right to alter its products, their specifications and/or price without notice.

Safety tested by Warnock Hersey to UL 391-99, CAN/CSA-B366.1-M91,

Heat Input* |

7500 = up to 78,000 BTU/hr with corn |

|

6500 = up to 78,000 BTU/hr with corn |

||

|

||

Fuel Storage Capacity |

180-210 Lbs. |

|

|

|

|

Width |

26” |

|

|

|

|

Height with Pedestal |

47 ½” |

|

|

|

|

Depth (includes ash lip) |

36” |

|

|

|

|

Shipping Weight |

480 pounds (7500), 560 pounds (6500) |

|

|

|

|

Electrical Requirements |

115 volts – 60 cycle – 10 amp Circuit |

|

|

|

|

Flue Size (rear exit) |

4” Type L Corn/Pellet Vent |

|

|

|

|

Warm Air Outlet |

12” Round or 14” x 14” rectangular |

|

|

|

|

Room Air Blower |

1240 CFM furnace blower |

|

|

|

|

Cold Air Return |

14” x 24” |

|

|

|

|

Filter Size |

16 x 25” |

|

|

|

|

Overall unit efficiency |

As high as 78% |

|

|

|

|

Total Amp. Draw |

Full load = 9 amp. |

|

|

|

*BTU input can vary from 10-60 percent, depending on the brand of fuel, size of fuel, quality of fuel and moisture content. Improper installation, venting configuration, combustion air configuration and maintenance practices will seriously decrease the heating ability of this appliance. Consult your authorized Magnum reseller for information to get the best results out of your Magnum appliance.

3

UNPACKING YOUR MAGNUM CORN/PELLET/ BIOMASS FUEL FURNACE

When you receive your Magnum Corn/Pellet Furnace, be careful to inspect all parts and components to make sure that nothing was damaged or lost in shipment. If there was shipping damage, be sure to report it to your Magnum reseller, and the shipping company that delivered your unit. Freight damage claims must be made to the Freight Company (not the AES factory) immediately. If parts are missing contact your local Magnum reseller or contact the factory right away. Your satisfaction is our top priority. If damage is not reported to the freight company before signing for it, you will not receive reimbursement for freight damage.

To uncrate your Magnum Corn/Pellet Furnace:

1)Cut the banding straps and open the carton lid. The carton is stapled to the wood pallet so it will be necessary to pull the cardboard loose from the pallet. Remove the crating box carefully lifting up over the top of the unit. Be careful not to scratch the unit with the staples. Remove the wood blocks and plastic. We strongly urge you to recycle the packaging materials to help protect the environment.

SAFETY STEPS

IMPORTANT: Proper installation of this furnace is crucial for proper and safe operation. Installing this product improperly may result in a house fire and personal injury. All applicable building codes for your location must be followed. In areas where building codes require additional steps to the installation of this product not included in this manual, the building codes will take precedent and must be followed. Contact your local building inspector to obtain any necessary permits or inspection guidelines before installing the product. (This appliance must be installed and serviced by a trained licensed heating contractor to assure proper installation and warranty of this product) The label located on the back of the appliance must be filled out by a Licensed HVAC contractor. Warranty Labor, parts, shipping or any other costs will not be covered if a trained installer does not install the unit.

Consult your local heating contractor for proper heating requirements, placement of your Magnum Corn/Wood Pellet Furnace and duct sizing.

OUTSIDE AIR HOOKUP TO THE FURNACE IS REQUIRED (4” required)

This furnace has to be exhausted with 4” class L vent. Furnace cannot be vented with another appliance. 4” venting is recommended on the model 7500 and required on the model 6500 furnace.

DISCONNECT THE POWER CORD BEFORE SERVICING THIS FURNACE. A power surge protector is required. The unit must be plugged in to a grounded 120 -volt power source.

Always route the power cord away from the unit. Do not route cord in foot traffic areas. Do not pinch cord under furniture. Do not add any additional length to the power cord.

This product requires simple periodic maintenance for proper operation and long life of the furnace. Read and follow the maintenance schedule closely.

The Magnum Biomass furnace is designed, approved and tested to burn shelled corn, wheat, or Premium quality wood pellets. The burning of other solid fuels such as cord wood in this furnace is not permitted. If you are burning fuels not approved for this appliance it will void the warranty and no service/warranty will be allowed. When burning fuels other than corn, consult your dealer for proper heat setting adjustments. You will have to run your unit on lower settings when burning smaller size fuel.

4

The Magnum 6500/7500 will burn high ash content fuels but will require additional maintenance/cleaning.

A working smoke detector must be installed in the same room as this product.

Flammable or explosive liquids such as gasoline, naphtha or engine oil must NEVER be used in or around this stove. These liquids must be stored well away from this furnace as the open flame in the burner chamber could ignite the fumes of such liquids. Do not burn garbage in this unit.

According to HUD requirements, when installed in a mobile home, this stove must be grounded directly to the steel chassis of the mobile home and bolted to the floor.

The moving parts of this stove are propelled by high torque electric motors. The auger and Fuel Stirrer can cause severe injury to body parts that may get near them. Keep all body parts away from the auger and Fuel Stirrer while the furnace is plugged into an electrical outlet. These moving parts may begin moving at any time while the furnace is plugged in.

This unit may be installed on a non-combustible surface. Make sure that the unit is level. This unit must have floor protection of at least 6 inches (150mm) in front and 6 inches (150 mm) on either side of the fuel loading and ash-removal doors.

Do not attempt internal service to the unit when it is burning and or plugged into power.

It is important to plan your installation so that service work can be performed on the appliance. Leave ample space around the furnace to open cabinet doors. Minimum clearances to combustibles must be maintained.

Your Magnum reseller is required to go over in detail with the owner/operator as to the correct operation of the furnace and its components.

Never block or obstruct any air intake ports including the vents on the furnace panels. Overheating can occur without proper air movement.

Make sure your circuit is not overloaded as to cause the furnace to lose power.

Furnace must be installed with adequate return and supply duct systems. Failure to have adequate return air to the furnace will void your warranty.

A minimum rise of 5’ is required on all side vent applications.

Proper cleaning and maintenance is necessary. You will need to follow the directions for cleaning that are in this manual. A furnace that is properly maintained and cleaned will give you years of trouble free performance.

The warm-air supply-duct system must be constructed out of materials that will withstand a minimum temperature rating of 250 degrees Fahrenheit. Plenums installed to the furnace must be constructed out of metal. It is the responsibility of the homeowner to assure proper ducting installation.

The warm-air supply outlet of the supplementary furnace cannot be connected to the cold-air return inlet of the central furnace (series) because a possibility exists of components of the central furnace overheating and causing the central furnace to operate other than intended.

5

DO NOT USE DUCT ELBOWS HAVING AN INSIDE RADIUS OF LESS THAN 6 INCHES (150MM) ON THE (oil, electric, gas) furnaces.

DO NOT CONNECT DUCTWORK SO THAT A REVERSE FLOW IS POSSIBLE. IT IS REQUIRED TO HAVE PROPER BACK DRAFT DAMPERS BETWEEN THE 6500/7500 FURNACE AND THE DUCTWORK THAT YOU ARE INSTALLING INTO AND ALSO IN THE PLENUM OF THE PRIMARY FURNACE.

OPERATE THE (gas, oil, electric) FURNACE PERIODICALLY TO ENSURE THAT IT WILL OPERATE SATISFACTORILY WHEN NEEDED.

THIS APPLIANCE IS CERTIFIED FOR INSTALLATION ONLY AS SHOWN IN THIS INSTALLATION MANUAL. SEE DIAGRAMS ON PAGES 15-17

DO NOT RELOCATE OR BYPASS ANY OF THE SAFETY CONTROLS IN THE ORIGINAL (gas, oil, electric) FURNACE INSTALLATION.

DO NOT CONNECT TO ANY GAS FURNACE THAT HAS NOT BEEN CERTIFIED INITALLY AS COMPLYING WITH CAN/CGA-2.3

A GAS FITTER WHO IS RECOGNIZED BY THE REGULATORY AUTHORITY MUST VERIFY THE OPERATION OF THE GAS FURNACE FOR ACCEPTABLE OPERATION BEFORE AND AFTER INSTALLATION OF THE ADD-ON APPLIANCE.

DO NOT CONNECT TO ANY GAS FURNACE THAT IS NOT EQUIPPED WITH AN AIRCIRCULATION BLOWER, OR TO A CHIMNEY OR VENT SERVING A GAS FURNACE OR GAS APPLIANCE.

THE MAGNUM 6500/7500 CORN/WOOD PELLET FURNACE IS COMPATIBLE WITH THE FOLLOWING (gas, oil, electric) INPUT SIZES: 50,000 to 200,000 BTU.

The Magnum 6500/7500 Corn/Wood Pellet furnace should only be installed on a furnace duct system and venting that is in good operating condition. It is recommended and sometimes necessary to install separate ductwork because the existing ductwork might not support the proper air flow or temperature.

The installation of the Magnum 6500/7500 Corn/Wood Pellet furnace must comply with requirements of CAN/CSA-B365, and changes to the installation should comply with CSA B139 (for oil-fired), C22.1 (for electric), or CAN/CGA-B149.1 or CAN/CGA-B149.2 (for gas-fired)

Prior to installation you will need to determine the compatibility of the existing furnace to the Magnum 6500/7500 Corn Furnace. Following are the guidelines for determining compatibility.

CFM compatibility would be rated at app. 1250 CFM. If the cfm in the central furnace is less than this a back draft damper will need to be installed in the plenum of the central furnace. The static pressure in the ductwork cannot exceed the name plate rating on the central furnace and must be compatible with the static pressure rating on the name plate of the Magnum Corn Furnace.

Adjust the static pressure in the ductwork to maintain a temperature rating of 130-150 deg. F.

Note: If the installation requirements are not followed your Magnum furnace will not operate or heat properly. This is not the fault of the appliance and the warranty may be voided if any damage to the heat exchangers is a result of improper installation.

6

BURNING SOLID FUELS (Shelled Corn and Wood Pellets)

Unlike petroleum and natural gas products, solid fuels such as corn and wood pellets create ash as the fuel is burned. Even with the highly efficient flame your Magnum will produce, the solid fuels used will produce ash. This ash will have to be cleaned out of the furnace from time to time. The cleaning procedure will be discussed later in this manual. You can minimize the amount of cleaning required and maximize the efficiency of your furnace by maintaining the correct draft settings.

The draft setting on your furnace may have to be changed from time to time to accommodate your specific burning conditions. Proper draft setting will be discussed later in this manual. The point we wish to make here is that your Magnum furnace, due to the nature of solid fuels, will require brief periodic attention. Please do not expect to light your furnace and walk away from it until you want to shut it off in the spring. A few moments of adjustment and cleaning from time to time are an important part of burning solid fuels.

The Magnum 6500/7500 furnace has been designed to burn shelled corn and other agricultural rated fuels or wood pellets that meet the Association of Pellet Fuel Industries standards. Since both of these fuels vary greatly in quality and consistency, AES cannot be responsible for damage done to your furnace due to fuel problems. The following are guidelines to using and selecting proper fuels for your furnace.

SHELLED CORN (11-12 percent moisture recommended)

Store your corn supply in a dry place and keep the bags or container sealed to prevent your corn from absorbing excess moisture. Test the moisture content periodically to maintain the proper dryness.

Check your Corn for foreign objects. Your furnace warranty will not cover damage done to your furnace and/or auger system due to foreign objects in the fuel supply.

Do not carry your corn supply over into the next heating season if possible unless properly stored. If you carry over your corn supply make sure to check the corn for proper moisture content.

DO NOT BURN “TREATED” SEED CORN IN YOUR FURNACE. Seed corn is treated with chemical pesticides that are harmful or fatal if swallowed; therefore, seed corn is dangerous to have in the house, especially where children can reach it. Burning treated seed corn in your furnace will void the warranty and will destroy the exhaust system on the unit.

Corn must be 14% or less moisture content. Wet corn will cause rapid plugging and deterioration of the stove and exhaust system, lower the heat output and could void the product warranty due to rusting and improper operation of the appliance.

Corn must be cleaned and free from debris. Corn right from the field will often have stalks, sticks, bolts and cob debris, which can plug the auger and/or cause damage to the auger and motor. Damage caused by dirty corn and other foreign objects is not covered by the product warranty. Ask for clean corn when you purchase it from your local corn supplier. Clean corn can be purchased in bulk or bagged from most elevators, feed stores or even your local farmer.

ALWAYS ASK FOR CORN WITH 11-12% MOISTURE CONTENT

7

There are many varieties of corn grown around the world. Each variety has unique characteristics including the shape and size of the kernel. Your furnace will burn more consistently with a small to mid-size kernel corn.

If the kernel size of the corn varies greatly or if you switch sources frequently, you will get a less consistent burn, which will require more attention to the draft setting on your furnace. Therefore, purchasing corn from the same source will help achieve a more consistent burn.

There can be dramatic changes in heating ability depending on fuel quality, test weight and moisture content. BTUh value can drop 25-60 percent using high moisture fuel, improper venting, improper installation, improper fresh air and poor maintenance practices.

DO NOT USE CORN WITH A HIGH WAX CONTENT!

OTHER AGRICULTURAL RATED FUELS:

Your Magnum furnace will burn a variety of agra fuels such as switch grass, oats, wheat, barley and rye. It is important to work with your local dealer on how to burn these fuels as you will have to burn on lower heat settings due to the smaller kernel size and burning nature of the fuels. If you are having trouble burning other fuels consult your dealer.

WOOD PELLETS

As with corn, be consistent in your pellet supplier. Pellets will vary in content and burn characteristics from supplier to supplier. A consistent supply of pellets will require fewer adjustments to the draft of the furnace.

Mixing Corn with the Wood Pellets can be done and will provide a little less heat in the spring and fall. Also, if the Corn is a little wet, mixing pellets in will help the fire maintain especially on the lower settings.

Check your pellets for foreign objects. Your furnace warranty will not cover damage done to your furnace due to foreign objects in the fuel supply.

Store your pellets in a dry place to prevent them from absorbing excess moisture.

Vacuum the hopper out after every 6-7 bags to eliminate buildup of sawdust. More often if the pellets are poor quality. If sawdust is a problem you will have to screen each bag of fuel for a consistent feed.

Wood pellets vary from supplier to supplier in ash content from less than 1% to 3% or more. Low ash content pellets will allow you to burn the furnace longer between cleanings. Only wood pellets manufactured to the Association of Pellet Fuel Industries (A.P.F.I.) standard for residential pellets fuels are recommended. Look for A.P.F.I. registration number on the back of pellets. Consult your local Magnum reseller for more information on approved wood pellet fuel.

It is recommended not to store fuel over the summer months. Plan your fuel supply so that you use up the fuel by the end of the heating season. Pellets left over the summer can draw moisture and cause excessive ash in the system or plug the auger.

8

CLEARANCE TO COMBUSTIBLES

CLEARANCE TO COMBUSTIBLES

Back |

1” |

Supply Plenum |

2” |

|

|

|

|

Side |

1” |

Class L Vent |

3” |

|

|

|

|

Corner |

1” |

|

|

|

|

|

|

Front |

48” |

|

|

|

|

|

|

|

|

|

|

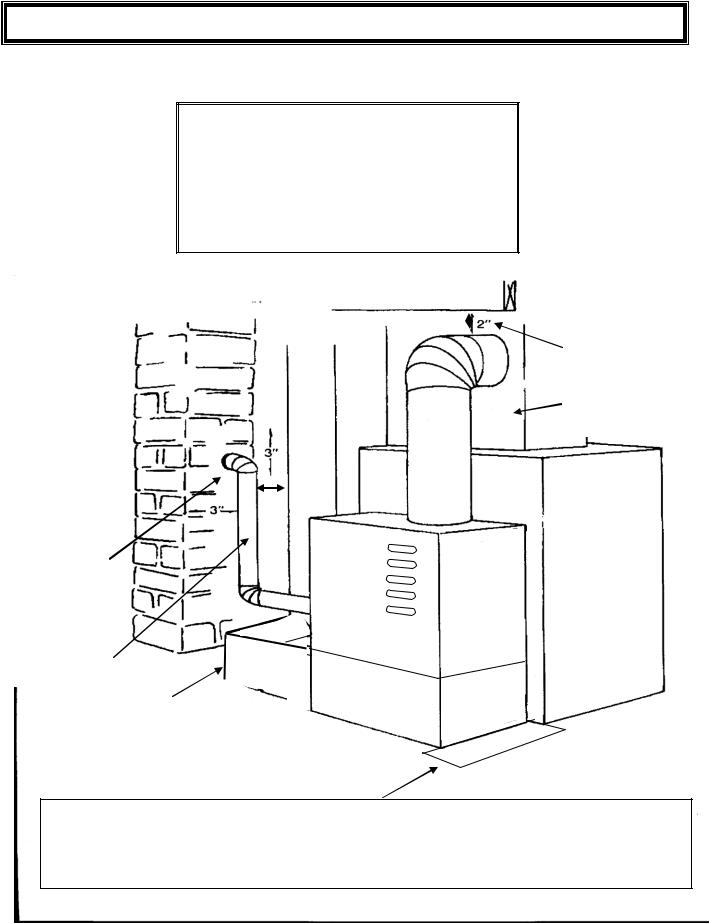

Do not hook into a chimney servicing another appliance.

You must make sure that when using an old chimney as a chase way access, that the chimney is in proper condition.

Combustible Ceiling

Have a certified chimney sweep inspect the chimney before using.

This installation is acceptable only if there are no other appliances hooked in and the venting goes all the way out the top of the existing chimney.

4” diameter venting recommended

|

|

|

|

|

Back draft |

|

|

damper |

3” |

|

required |

|

|

|

6500 or 7500 furnace

14” x 24” cold air return or 12” round

return or 12” round

with adapter.

Minimum clearance above the ductwork on the Corn Furnace to the floor joists is

2”.

Back draft damper and high limit cut out required

Existing primary furnace must be properly hooked into for proper operation. Sometimes you may have to run separate ductwork to comply with codes

Floor protection must be provided because of possible spillage of ashes and burning fuel. There must be noncombustible materials placed 6” in front of and 6” to the side of the fuel loading and ash removal doors. If the unit is setting on a cement floor no protection is needed. Consult your local dealer for possible sources for non-combustible materials acceptable to be used.

9

FLOOR PROTECTION

The Magnum 6500/7500 Corn/Wood Pellet Furnace may be installed on a combustible floor, with proper floor protection, or on a masonry hearth. The hearth or non-combustible floor protector must extend a minimum of (6) six inches in front of and (6) six inches from each side of the ash removal door.

It is recommended that the unit be placed on a non-combustible surface.

It is a good idea, but not required, that you place the unit up on a (4) inch high raised surface to keep it out of water, etc that may collect on the floor.

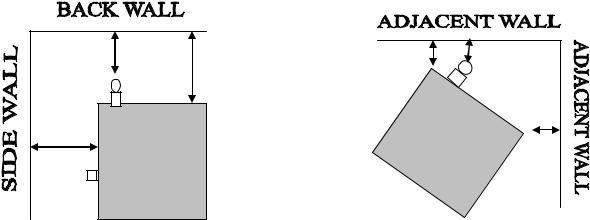

CLEARANCES TO COMBUSTIBLES

The furnace must be installed with the following minimum clearances to side and back wall combustible materials. NOTE: These are minimum clearances to combustible walls established by the testing lab. The amount of room needed on the left side of the unit to access the electrical panel is (6) six inches.

When venting straight out the back of the unit, the B clearance is 1”. C clearance is for a vertical vent install.

C |

B |

|

E |

D |

|

|

|

|

|

|

|

A=1” B=7” or 1” |

|

|

|

|

if straight out the |

|

|

|

|

wall install |

|

|

A |

|

C=3” if tee is |

E |

|

|

|

installed |

D=3” |

|

|

|

|

||

|

|

E=1” |

|

|

Residential/ Mobile Home |

|

|

Residential/Mobile Home |

|

|

|

Horizontal + Vertical |

||

Vertical Installation |

|

|

|

|

|

|

|

Corner Installation |

|

|

|

|

|

|

It is highly recommended that you have 2 feet clearance around the unit for servicing and maintenance. Both the left and right sides of the unit have panels that are hinged and will need to be opened periodically to clean, inspect or replace motors and parts.

If there is not room to have this much clearance you must leave 2-3 feet of clearance on the back of the unit. If the back panel is taken off, the motors can be accessed and removed.

IMPORTANT: Make sure that there is ample room to remove the unit if extensive service work needs to be done. Also there must be adequate room on the side of the furnace to load the fuel into the hopper.

If the room that the furnace is going to be in is small and also closed off, you will need to plan adequate ventilation to get the radiant heat out of the room. Having a 8 x 12 register in the lower and upper area of the wall or door will be adequate ventilation.

10

GUIDELINES FOR EXHAUST VENTING SYSTEMS DESIGN

It is required that only authorized licensed installers install your Magnum furnace. The following installation guidelines must be followed to ensure conformity with both the safety listing of this furnace and to local building codes.

NOTE: We recommend that you use listed Type PL “CORN Rated” venting to assure long life and tight seal.

A listed 4” (4” required on 6500, recommended on 7500) type “PL” Corn vent exhaust system must be used for installation and attached to the pipe connector provided on the back of the stove. Use a 3” to 4” adapter for the initial pipe. A cap must be used at the termination of type “L” vent chimneys.

Do not terminate vent in any enclosed or semi-enclosed area, such as; carports, garage, attic, crawl space, under a sundeck or porch, narrow walkway or closed in area, or any location that can build up a concentration of fumes such as a stairwell, covered breezeway etc.

Vent surfaces can get hot enough to cause burns if touched by children. Non-combustible shielding or guards may be required. Do not install a flue damper in the exhaust vent of this unit.

Termination must exhaust above air inlet elevation. It is highly recommended that at least 5 ft. of vertical pipe be installed when the appliance is vented directly through a wall or in a basement. This will create some natural draft to prevent the possibility of smoke or odor during appliance shutdown and to keep exhaust from causing a nuisance or hazard from exposing people or shrubs to high temperatures. In any case, the safest and preferred venting method is to extend the vent through the roof. Do not connect this unit to a chimney flue serving another appliance.

Distance from doors and windows, gravity or ventilation air inlet into building:

Not less that 4 ft. / 1.2 m below, 4 ft. / 1.2 m horizontally from, 1 ft. / 305 mm above (This does not apply if the Windows are non-opening or have been fixed so they cannot open.)

Distance from bottom of termination and grade – 1 ft. / 305 mm minimum. This is conditional upon the plants and nature of grade surface. The exhaust gases are not hot enough to ignite grass, plants or shrubs located in the vicinity of the termination. The grade surface must not be a lawn. Distance from bottom of termination and public walkway is 7ft. /2.1m minimum.

Distance to combustible materials – 2 ft. / 610 mm. This includes adjacent building, fences, protruding parts of the structure, roof overhang, plants and shrubs, etc.

It is recommended that a single or double clean-out “tee”, for cleaning the vent in both directions, be installed at every 900 junction to enable collection of fly ash and to permit periodic cleaning of the exhaust system. 900 elbows accumulate fly ash and soot thereby reducing exhaust flow and performance of the furnace.

Total length of horizontal vent must not exceed (10 ft.) / 3,000 mm. All joints in the vent system must be fastened by at least 3 screws, and all joints must be sealed with RTV silicone sealer to be airtight.

When venting into an existing masonry or factory built chimney, the chimney must be cleaned, with all creosote removed. The chimney must be a type suited for solid fuel. WARNING: The chimney and the chimney connections must be kept clean and in good condition. Venting must extend to the outside of the existing chimney.

The “PL” vent or single wall stainless exhaust system must be installed so as to be GAS TIGHT! The vent manufacturer’s installation procedures must be followed. In addition, pipe connections, joints and all pipe seams within the home should be sealed with high temperature RTV silicone sealer.

If the furnace is to be installed into an unlined masonry chimney, it is necessary that a 4” stainless steel pipe be extended to the top of the existing chimney. The top of the existing chimney should be sealed with a steel plate (see diagram on page 17).

11

GUIDELINES FOR EXHAUST VENTING SYSTEMS DESIGN, CONT……

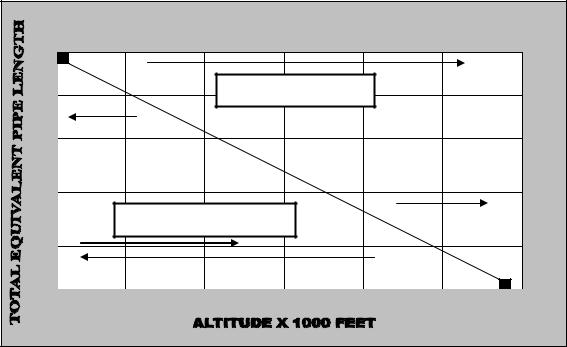

1)Determine the “equivalent pipe length” for each component used according to the comparison chart below. Add the “equivalent pipe length” of all components to get the “total equivalent pipe length”.

2)Determine the altitude at which you are installing the stove.

3)Cross-reference the “total equivalent pipe length” and the altitude using the graph below.

NOTE: The “total equivalent pipe length” should not exceed 30-35 feet.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Component |

|

|

Equivalent Length |

|

|

|

|

Equivalent Pipe Length |

|

|

||

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Horizontal Straight Pipe |

|

Actual Length in ft. x 1.0 |

|

|

Horizontal Pipe |

= |

|

1 x (2+1) = |

3 ft. |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

Vertical Straight Pipe |

|

Actual Length in ft. x 0.5 |

|

|

Vertical Pipe |

= |

|

0.5 x 8 = |

4 ft. |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

900 Elbow or Tee |

|

5.0 feet |

|

|

90 Degree Tee |

= |

|

2 x 5 = |

10 ft. |

|

||

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

450 Elbow |

|

3.0 feet |

|

|

45 Degree Tee |

= |

|

1 x 3 = |

3 ft. |

|

||

|

|

|

|

|

|

|

|

|

TOTAL |

= |

|

|

20 ft. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NOTE: These are guidelines only. Proper venting is accomplished by design and common sense. In most installations 4 inch diameter venting is required. It is the responsibility of the installer to determine proper venting operation of the furnace. If the proper venting and combustion air balancing is not achieved, the furnace will burn dirty, have a tendency to have the fire go out inconsistently and will cause the unit to plug up the heat exchangers and back areas of the appliance. If the heat exchangers and back heat exchangers are plugged and it causes the tubes to burn through or the heat exchanger to break, this is not covered under warranty.

|

|

CRITERIA FOR SELECTING PIPE DIAMETER |

|

|

|||

|

|

|

MAXIMUM |

|

|

|

|

25 |

|

|

|

|

|

|

|

20 |

|

|

4” DIAMETER ONLY |

|

|

|

|

15 |

|

|

|

|

|

|

|

10 |

|

|

|

|

|

|

|

5 |

|

3” OR 4” DIAMETER |

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

0 |

2 |

4 |

6 |

|

8 |

10 |

12 |

0 |

2 |

4 |

6 |

8 |

10 |

12 |

|

|

|

|

ALTITUDE X 1,000 FEET |

|

|

||

|

|

|

12 |

|

|

|

|

GUIDELINES FOR EXHAUST VENTING SYSTEMS DESIGN, CONT……

CHIMNEY AND VENTING (4” diameter is required)

Chimney required for the Magnum Corn Furnace is 4" (4” required on 6500) Class "L" (also known as PL vent). A starting collar must be used to attach the venting system to the furnace. When connecting into a Class "A" or masonry chimney an approved 4" liner MUST be used to prevent back drafting of the chimney.

EXISTING CLASS "A" CHIMNEY:

Run 4” Class "L" venting from the furnace connection to a positive connection with the class "A" chimney. AN APPROVED 4" LINER MUST

BE USED IN CLASS "A" CHIMNEYS. Make sure each joint is firmly locked in place. Make sure the attachment of Class "L" to the Class "A"

chimney is secure with sheet metal screws. Seal all joints with hightemperature silicone Class "L" venting should maintain a pitch on rise from the furnace to the chimney

of at least 1/4" per foot. .

A): "L" Vent venting 4" B): "L" Vent elbow 90°, adj. 4" Tee

EXISTING MASONRY CHIMNEY: Run 4" Class "L" venting from the furnace connection to a positive connection with the masonry

chimney. Make sure each joint is firmly locked in place. Make sure the penetration of the Class "L" venting into the masonry chimney

is sound and secured with hightemperature cement. Seal all joints with hightemperature silicone. Class "L" venting should maintain a pitch on rise

from the furnace to the chimney of at least 1/4" per foot.

AN APPROVED 4" LINER MUST BE USED IN MASONRY CHIMNEYS. Your new furnace is so efficient; an unlined chimney could remain cold and cause a downward pressure creating poor burning, incomplete combustion or back draft. A.)"L" Vent venting 4" B.)"L" Vent elbow, 90° adj. 4" Tee

NEW VERTICAL INSTALLATIONS: Install 4" Class "L" venting and

accessories according to manufacturers instructions and local codes

(3" clearance to combustibles). Run Class "L" venting all the way from the furnace connection to point of termination. Make sure each joint is

firmly locked in place. Seal all joints with high temperature silicone. Class "L" venting should maintain a pitch on rise from the furnace to the chimney of at least 1/4" per foot.

A.) Vertical top 4" |

D.) Adj. flashing 4" |

|

B.) "L" Vent pipe or 4" |

E.) Fire stop spacer or 4" |

|

|

C.) Storm Collar or 4" |

F.) "L" Vent 90° adj. 4" clean out tee |

HORIZONTAL/VERTICAL VENTING: If venting the Magnum

Horizontally through an exterior wall, a vertical section needs to be installed to provide natural draft in the event of power failure.

Use only 4" Class "L" venting all the way from the furnace connection to point of termination. Make sure each joint is firmly locked in place.

Seal all joints with high temp silicone. Max. horizontal run length - 10ft.;

Min. vertical length - 5 ft.

A.) "L" Vent pipe 4" |

B.) Wall thimble 4" C.) "L" vent 4" cleanout "T" |

D.) "L" Vent pipe 5ft |

E.) Wall Bracket F.) "L" vent 90° elbow ." |

G.) "L" vent Termination collar 4”

If installing the venting on the exterior of the home or shop, the venting must be enclosed in an insulated chase to prevent condensation and creosoting.

DIRECT VENT HORIZONTAL TERMINATION IS NOT RECOMMENDED

13

DESIGN GUIDELINES FOR OUTSIDE COMBUSTION AIR CONNECTION

OUTSIDE MAKE-UP AIR FOR COMBUSTION IS REQUIRED ON ALL INSTALLATIONS

1)For all Furnace installations, it is REQUIRED that the furnace combustion air intake be connected to a fresh air intake outside. If the home is newer or has been tightly insulated it is imperative to the operation of the unit to install outside combustion air and also have makeup air provided for the home. It is the responsibility of the installer and homeowner to determine and achieve proper balancing of fresh air for the home and for the appliance. If proper balancing of the fresh air is not achieved the

furnace will not be able to operate correctly and serious damage to the heat exchangers will happen.

`

2) Connection to outside the house is REQUIRED for mobile home installations.

3)Fresh-Air pipe 4 inches in diameter is approved to use for outside air connections (straight or flexible). PVC pipe is allowed. You might need to use 6” diameter fresh air piper if the run is over

10 feet long.

4)When air inlet is connected to the outside, it MUST be terminated with a vertical 90-degree bend (down) or with a wind hood. Failure to do so could result in a burn back during high winds blowing directly up the air inlet during a simultaneous power failure (see diagram above).

5)It is important not to terminate the inlet of the fresh air intake too close to the venting outlet for the smoke. It is recommended that the inlet for the fresh air is a minimum of 3 feet away from the venting outlet and at least 1-2 feet below.

6)Blockage, excessive length, or bends in the air intake pipe will starve the furnace of combustion air. A 90-degree bend is equivalent in restriction to approximately 30 inches of straight inlet pipe. Use 4” diameter fresh air intake to alleviate these issues.

7)Furnace must have fresh air (oxygen) to perform properly. Incomplete combustion is caused by negative pressure in the home when the furnace is starved for fresh air. This causes carbon monoxide (CO) and can be dangerous. Provisions for outside air must be made and kept clean and free from blockage outside the home.

14

Loading...

Loading...