American Energy Systems Harvester User Manual

AMERICAN ENERGY SYSTEMS INC.

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

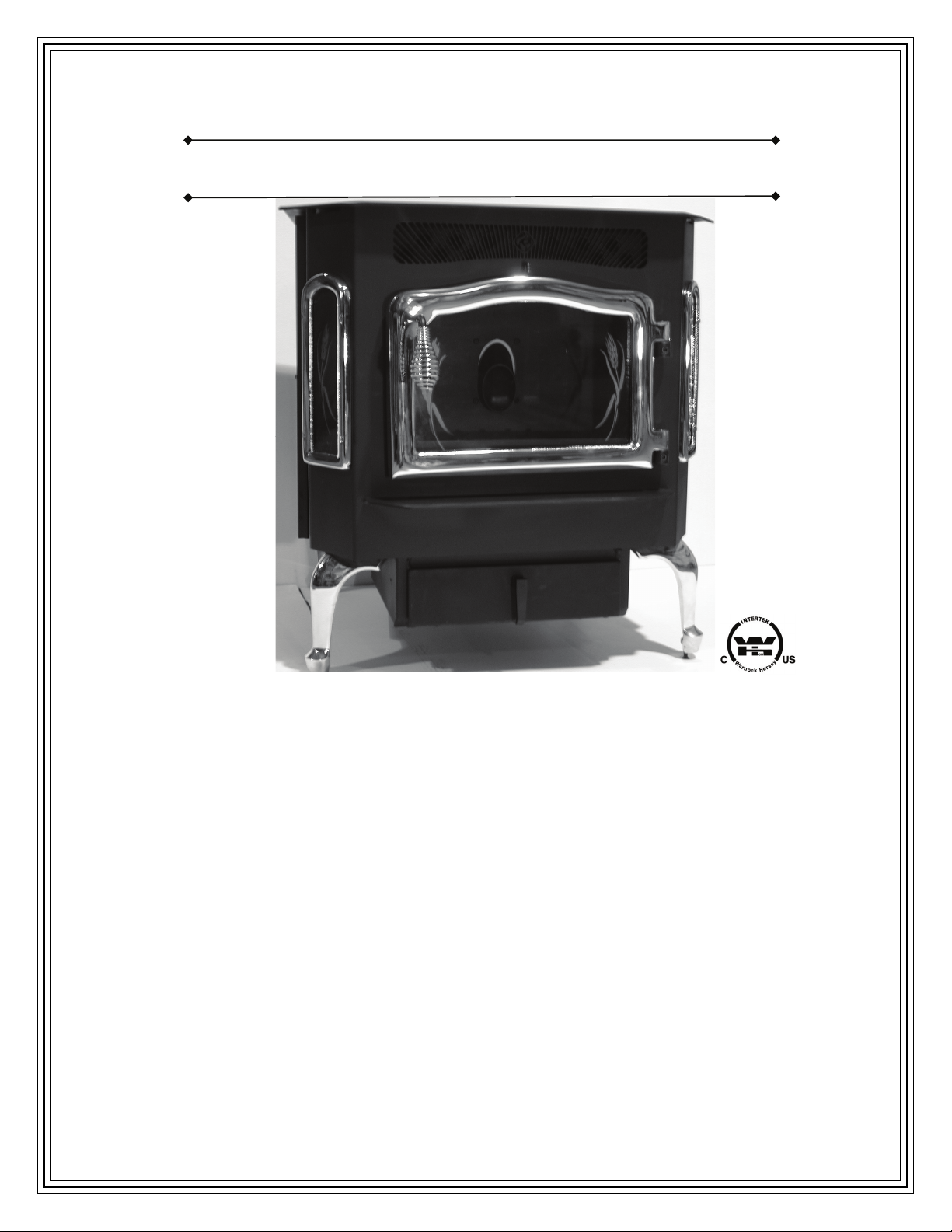

HARVESTER BIOMASS SOLID FUEL STOVE

MODEL HR-01 – HR-01-B

Rev. Update 01/2012

USA & CANADA TEST: TESTED BY:

ASTM E1509-04, UL 1482, WARNOCK HERSEY

ULC S627, ULC/ORD C1482 (and ULC S628

if listed for fireplace insert installation in Canada)

Oregon Administrative Rules 814-23-909

WARNING: If the directions in this manual are not followed exactly, a fire

may result causing property damage, personal injury or loss of life.

FOR YOUR SAFETY

Do not store or use gasoline or other flammables (vapor or liquids) in or

around the vicinity of this appliance.

Installation and repair must be performed by a qualified service agency.

Always check with local jurisdiction or code agency before installing this

product. Local jurisdiction may require a permit prior to installation.

MOBILE HOME APPROVED

Table of Contents

SAFETY NOTES:………………………………………………………………………………………………3-5

EPA STANDARDS:…………………………………………………………………………………........5

LISTING / TESTING AGENCY (AUTHORITY)………………………………………………………..5

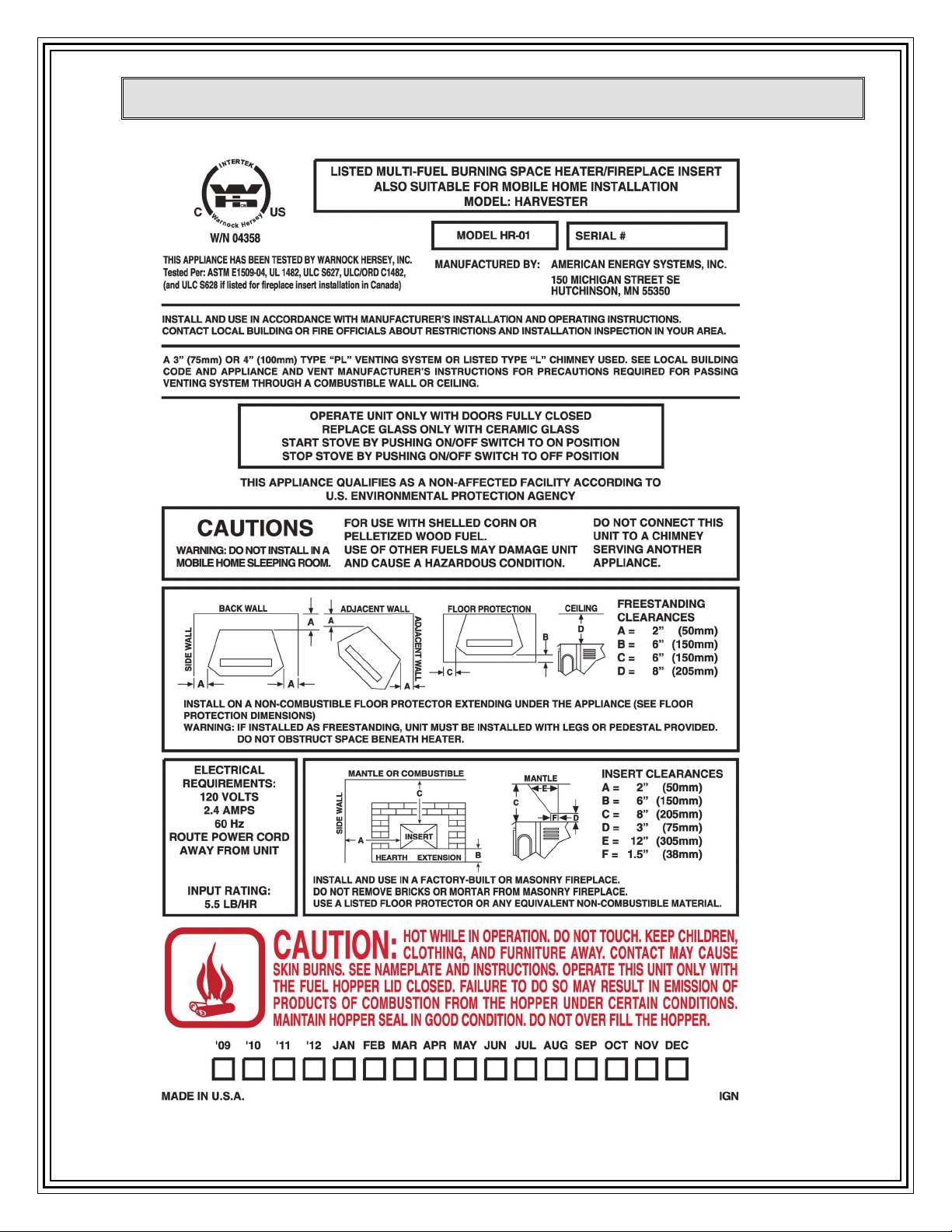

CERTIFICATION SAFETY LABEL (sample)…………………………………………………………………6

FORWARD………………………………………………………………………………………………………..7

HARVESTER LIMITED WARRANTY………………………………………………………………….......8-9

THE HARVESTER OPERATION…...……………………………………………………………………...... 10

FEATURES……………………………………………………………………………………………. . 10

SAFETY FEATURES………………………………………………………………………………….. 11

BATTERY BACKUP SYSTEMS…………………………………………………………………...… .11

HARVESTER COMPONENTS……………………………………………………………………….. . 12

FUEL REQUIREMENTS, STARTUP, PRIMING, FIRST FIRE…………………………...………..... 13

ASH REMOVAL………………………………………………………………………………………. . 14

CONTROL BOARD………………………………………………………………………………… 14-16

CONTROL BOARD OPERATIONS, FEATURES………………………………………………… 17-19

ELECTRICAL DIAGRAM…………………………………………………………………………….. 20

SPECIFICATIONS, ELECTRICAL REQUIREMENTS, ……………………………………………... 21

PLATED (gold or nickel) DOOR CARE………………………………………………………………. .21

OPTIONAL FEATURES, THERMOSTAT OPERATION, …………………………………………… 21

CHANGE HEAT LEVEL (thermostat active)…………………………………………………………...21

CHANGE HEAT LEVEL (thermostat in-active), COMBUSTION FRESH AIR CONTROL………….22

INSTALLATION:……………………………………………………………………………………………….23

INSTALLATION PREPARATION, STOVE CLEARANCES, MIN. CLEARANCES………………. 23

VENT SYSTEMS, FACTORY BUILT CHIMNEY, MASONRY BUILT CHIMNEY……………….. 24

ALCOVE INSTALLATION……………………………………………………………………………. 25

FLOOR PROTECTION REQUIREMENTS…………………………………………………………… 26

PELLET VENT SYSTEMS…………………………………………………………………………. 27-29

OUTSIDE AIR COMBUSTION REQUIREMENTS…………………………………………………... 30

MOBILE HOME INSTALLATION…………………………………………………………………………...31

MOBILE HOME RULES, CLEARANCES……………………………………………………………..31

MOBILE HOME STOVE ATTACHMENT, FLOOR PROTECTION………………………………… 32

MOBILE HOME CHIMNEY AND DUCT…………………………………………………………..33-34

MAINTENANCE REQUIREMENTS.................................................................................................................35

GENERAL REQUIREMENTS, STOVE DOOR INSTALLATION…………………………………… 35

STOVE DOOR ADJUSTMENT, CLEANING…………………………………………………………. 36

GLASS REPLACEMENT………………………………………………………………………………. 36

GASKET REPLACEMENT…………………………………………………………………………….. 37

APPENDIX A: TROUBLESHOOTING GUIDE………………………………………………………….38-39

APPENDIX B: MAINTENANCE GUIDE…………………………………………………………………40-42

APPENDIX C: TECHNICAL SPECIFICATIONS…………………………………………………………...43

APPENDIX D: REPLACEMENT PARTS…………………………………………………………………….44

2

SAFETY NOTES

The Harvester Model HR-01 corn / wood pellet/ biomass fuel stove is significantly different from a

conventional wood-burning stove. One major difference is that the HR-01 requires a reliable source of

electrical energy to properly operate. The owner, installer, and operator must understand this manual and

read it in its entirety. This understanding should be completed and followed before installation or

operation of the HR-01 is attempted. Failure to follow installation and operation instructions may result in

property damage, bodily injury, or even death. The Factory strongly recommends that a certified

professional install the Harvester Model HR-01 to assure proper performance and validation of warranty.

W

ARNING: THE AUTHORITY HAVING JURISDICTION (such as a municipal building

department, fire department, or fire prevention bureau, etc

BEFORE BEGINNING INSTALLATION. A PERMIT MAY BE REQUIRED IN

ORDER TO PERFORM INSTALLATION.

W

ARNING: It is recommended that a smoke detector be installed in the vicinity of the HR-01.

W

ARNING: American Energy Systems Inc. has no control over installation maintenance procedures;

therefore, American Energy Systems Inc. grants no warranty, implied or written, for the

installation or maintenance of the HR-01. Further, the factory assumes no responsibility

for any consequential damage resulting from said installation or maintenance of this

product.

W

ARNING: After operation, always allow the Harvester stove to completely cool before performing

any maintenance operations.

W

ARNING: The HR-01 stove requires reliable electric energy to properly operate. If electrical power

is not available, DO NOT operate a Harvester stove with only natural draft.

W

ARNING: Only a certified professional should install the HR-01 stove and only a qualified service

technician should perform maintenance on this stove. Any parts removed for installation

or servicing must be replaced prior to operational use of this stove.

W

ARNING: Modification of this product is not authorized and any modification voids the Country

Flame warranty.

W

ARNING: The Harvester must be connected to a code compliant grounded 120-volt, 15 ampere, and

60 hertz electrical outlet. Use of a dedicated circuit is recommended. NEVER use an

adapter, extension cord or cut or remove any prong from the power cord. It is required to

use a proper voltage surge protector to validate any electrical warranty for this product.

W

ARNING: NEVER place or store any combustible or flammable products on or near the Harvester.

W

ARNING: The Harvester is designed to immediately shutdown in the event the front door is opened.

Keep the viewing and ash removal door tightly closed during operation. Always clean the

HR-01 after the stove has been allowed to return to normal room temperature.

W

ARNING: Do not connect the Harvester to a chimney flue serving another stove of any type.

W

ARNING: FOLLOW all operating instructions in this manual. Short cuts in operating procedures,

of any kind, can be dangerous.

) SHOULD BE CONSULTED

3

W

ARNING: Maintain all minimum safety clearances of the Harvester stove and chimney system.

Never install the Harvester in a sleeping room.

W

ARNING: The Harvester is designed and approved for burning of number 2 yellow shelled corn with

a maximum moisture content of 14% or biomass / wood pellet fuel. Any fuel used in this

stove must meet or exceed APFI standards. Do not burn untested fuels, seed corn, or

foreign materials in this product. Failure to comply with this restriction voids Country

Flame’s warranty and the safety listing of the unit. Poor quality fuel will directly (and

adversely) affect efficiency and cleanliness of operation. Country Flame’s local authorized

dealer can help in recommending a quality fuel

W

ARNING: NEVER use gasoline, lantern fuel, kerosene, charcoal lighter fluid or other combustible

liquids to start or “freshen up” the fire in this product. Do not store or use gasoline or

other flammable liquids or allow combustible vapors in the vicinity of product.

W

ARNING: NEVER put foreign objects in the hopper and NEVER burn trash or unapproved material

in the Harvester. Using improper fuel voids the Country Flame warranty and damage to

the stove resulting from foreign objects is not covered by warranty.

W

ARNING: Ensure free and adequate airflow to and around the Harvester. This stove is a combustion

system that requires continuous flow of fresh air for proper operation. Failure to provide

an adequate fresh air supply can lead to operational problems such as: negative pressure

in the home, poor operation of this or other home combustion appliances, or a host of

other issues. Remember that other combustion appliances compete for fresh air in the

home. Consult with a professional to ensure positive air flow is provided to the stove

during operation.

W

ARNING: The Harvester’s exhaust system works with a negative combustion chamber pressure and a

low positive chimney pressure. It is very important that the stove’s exhaust and chimney

system be airtight and properly installed. The chimney joints should be sealed with 500

degrees Fahrenheit (500

O

F or 260 OC) silicone sealant (RTV) and secured with at least (3)

sheet metal screws. An improperly installed stove or chimney system is the major cause

of a home fire.

W

ARNING: When installed in a mobile home, the Harvester must be grounded to the steel chassis of

the mobile home. In addition, the stove must be bolted to the floor. A mobile home

installation of the Harvester should be in accordance with the Manufactured Home and

Safety Standard (HUD), CFR 3280, Part 24. Consult the local code authority.

W

ARNING: SOOT AND FLY ASH: The products of combustion will contain small particles of fly

ash. The fly ash will collect in the exhaust venting system and restrict the flow of the flue

gases. Incomplete combustion, such as occurs during start-up, shut down, or incorrect

operation of the Harvester will lead to soot formation in the exhaust venting system. The

exhaust venting system should be inspected at least twice every year to determine if

cleaning is necessary.

W

ARNING: ASH REMOVAL: The ash pan is designed to be emptied every day. If the ash pan is not

emptied regularly, ash will build up and restrict the flow of fresh air to the combustion

chamber. The ash pan door should not be opened for prolonged periods of time (greater

than 3 minutes.) If the ash pan door is opened for long periods of time an unrestricted

supply of air can flow into the combustion chamber. This unrestricted air flow can cause

4

an over fire condition. The airtight seal of the ash pan door ensures a combustion process

per the stove design.

CAUTION: Operate the Harvester with the fuel hopper lid closed at all times. Failure to keep the

hopper lid closed during operation may result in the release of combustion gasses into the

home from the hopper under certain conditions. Maintain any hopper seal in good

condition and do not overfill the hopper.

CAUTION:

THE HARVESTER IS HOT WHILE IN OPERATION. DO NOT TOUCH. KEEP CHILDREN,

CLOTHING, AND FURNITURE AWAY. CONTACT WITH HOT SURFACES MAY CAUSE

SEVERE SKIN BURNS

. REFER TO THE SAFETY LABEL FOR INSTRUCTIONS.

NOTE: RETAIN this MANUAL for future reference as needed and ensure that the model and

serial number of the Harvester is written down for use in the future should maintenance be

required.

EPA STANDARDS

The Country Flame Harvester meets rigorous emission standards. All Country Flame Harvester Model

HR-01 stoves conform to United States Environmental Protection Agency standards.

LISTING/TESTING AGENCY

The Harvester Model HR-01 has been independently tested and listed in accordance with ASTM E150904, UL 1482, ULC S627, ULC/ORD C1482 (and ULC S628 if listed for fireplace insert installation in

Canada) and Oregon Administrative Rules 814-23-909. This listing is for installation into residential

dwellings, including standard construction units, mobile home units, or modular home units. The

Harvester Model HR-01 was tested to standards by Intertek Testing Services, NA, Inc., 8431 Murphy

Drive, Middleton, WI 53562.

5

CERTIFICATION SAFETY LABEL (sample)

6

FORWARD

INTERNATIONAL ISSUES

Global concerns about climate change, along with rising world oil prices, are creating unprecedented

interest in the development of economical and convenient renewable energy fuel burning products. For

decades there has been a “grass roots” effort to utilize biomass feedstock as a viable heating fuel. Use of

agricultural products such as corn, switch grass, and other annual crops can abate greenhouse gas

emissions by increasing carbon storage in the surrounding landscape while displacing fossil fuel use in

combustion heating products. Agricultural based pellet fuel is capable of sustained high volume

throughput rates that use less energy to produce when compared to the present wood industry. Long term,

biomass pellet fuel will become a key part of the global community’s effort to reduce if not reverse the

greenhouse effect. This is especially true when emerging third world countries, their growth rates, and

their demand for energy is factored into the greenhouse equation.

AMERICA

United States and Canadian stove manufacturers are approaching three decades of providing wood pellet

fuel and wood pellet burning products to the hearth industry market. The maturity of this market has

ensured a continuous supply of both pellet fuels and pellet appliances while world fossil fuel issues have

ensured an ever increasing market demand for more of these products.

These same American and Canadian manufacturers continue to innovate and improve wood pellet

products with each passing year. At the same time, an ever increasing demand for the wood fuel puts

pressure on both sustaining the volume and the quality of fuel raw materials needed to meet the needs of

the fuel market. Transportation costs associated with moving the raw materials to the pellet mill

significantly impact the local and regional availability of pellet fuel. Research has proved that there are

many agricultural based crops and crop byproducts that can be utilized to fuel biomass heating stove

products to meet this ever growing market demand. Demand for biomass burning fuel stoves will grow in

the coming years.

COUNTRY FLAME by American Energy Systems Inc.

Country Flame has worked for over two decades in researching and developing pellet fuel burning stove

products. Today, Country Flame offers both freestanding and fireplace-insert model pellet fuel stoves.

Country Flame has a dedicated research effort underway to produce advanced pellet stove products

capable of burning a wide variety of biomass fuel. In 2002, Country Flame was selected for national

recognition for the design and development of its Harvester HR-01 biomass burning fuel stove by the

Hearth Industry Association.

The Harvester HR-01 was designed to burn shelled corn and biomass pellet fuel (Wood Pellets.) At the

same time, Country Flame customers claim to have test burnt a wide variety of agricultural products that

are available in different locales around the United States.

THE PURCHASE OF A COUNTRY FLAME HARVESTER BIOMASS FUEL STOVE IS A VOTE TO

REDUCE AMERICA’S DEPENDENCE ON FOREIGN OIL. THE USE OF A COUNTRY FLAME

HARVESTER BIOMASS FUEL STOVE WILL AID IN CURBING THE GREENHOUSE GAS

PROBLEM OUR WORLD IS FACING. Country Flame is very proud of this American born, American

tested, and American made product. With pride and dedication, American Energy Systems Inc.

employees wish you and your family a lifetime of happiness and warmth through the use of this product.

7

AMERICAN ENERGY SYSTEMS INC. LIMITED PRODUCT

WARRANTY

This warranty is in effect on all products sold after 01/01/2009 and supersedes any and all warranties

currently in existence.

Please keep a copy of this warranty for your personal records or in the event of a claim

American Energy Systems Inc., hereinafter referred to as (AES), warrants to you, the original consumer

purchaser, that this product is free from defects in material and workmanship for a period of five (5) years

from the original purchase date minus any time past one (1) year from manufacturing date, and that the

product’s electrical parts and steel firepot, are free from defects in material and workmanship for a period of

one (1) year from the original consumer purchase date minus any time past one (1) year from manufacturing

date, and that the cast iron firepot models carry a lifetime warranty against defect in material or workmanship

(excluding war page or deterioration), and that door glass carries a lifetime replacement warranty against heat

breakage (does not cover accidental breakage) . There is expressly no warranty on installation of product,

any venting, grates, gaskets, door latches, insulation, ceramic or brick boards/logs/backing, paint, plated

surfaces/doors/trims, baffles, bushings, bearings, auger flightings, war page or discoloration of steel or plated

parts or any other normal wearing part. In the event the product fails to conform to this warranty, AES,

through the place where you purchased the product or if purchased on the AES E-Com store directly through

AES, will provide the parts and components necessary to remedy such nonconformity. AES will not be

responsible for any labor, mileage or freight cost to the factory under this warranty. This warranty is not

transferable.

In order to obtain performance under this warranty, you must (1) have registered this warranty within 30 days

of purchase by completing and returning the warranty registration card or filling in the on-line warranty

registration form at www.magnumheat.com, and (2) promptly report the claimed nonconformity to your

place of purchase, also providing your name, address, phone number, proof of purchase, date of purchase, the

model and serial number of the stove, digital pictures of installation and venting inside and outside of the

home, pictures of the claimed nonconformity part and the claimed nonconformity. All claims must be

submitted in writing to your place of purchase.

AES shall have no warranty obligations if this product; (1) was not purchased from an authorized AES dealer;

(2) was not installed by a AES dealer or other qualified installer; does not have outside combustion air

hooked directly to the unit; (3) was not operated and maintained in strict accordance with the manufacturer’s

instructions, local or national codes or (4) was subject to abuse, misuse, negligence or accident. AES shall

have no warranty obligation for damage caused by improper handling, freight damage (must be reported to

freight provider), over-firing, unapproved fuel, variance in feed rates, variances in BTU output or the

unauthorized disassembly or modification of the product. AES shall have no warranty obligation if this

warranty is not timely registered, for claims which are not submitted through the selling AES dealer, or for

claims submitted verbally or without the required information and documentation.

Before exercising this warranty, an AES representative (the place where the product was purchased or AES

approved person) must inspect the part/unit to determine if the part/unit is defective. If a local AES

representative is not available the original purchaser of the product must submit digital pictures of the

part/unit, installation of the unit to AES at technical@magnumheat.com

failure is due to defective material or workmanship and the part is covered by the conditions of this warranty,

AES will, at its option, repair the defective part/unit. The sole duty of AES and liability under this warranty

is limited to the repair of the covered defective part/unit. The purchaser shall assume all costs related to

shipping the replacement parts or return of the unit to the factory for repairs. If it is determined that the defect

was caused by AES, AES will cover the costs of shipping the repaired part/unit to an AES approved shipping

point. AES will not cover additional freight or delivery services such as residence delivery charges, special

handling, etc.

INSTALLATION, VENTING, REMOVAL OR REINSTALLATION COSTS ARE NOT COVERED

BY THIS WARRANTY.

If the inspection reveals that the

8

THE WARRANTY PRINTED ABOVE IS THE ONLY WARRANTY APPLICABLE TO THE

PRODUCT. ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING,

WITHOUT LIMITATION, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE, ARE DISCLAIMED. IT IS UNDERSTOOD AND

AGREED THAT AES’S LIABILITY UNDER THIS WARRANTY SHALL BE LIMITED TO

THE PROVISION OF REPLACEMENT PARTS AND SHALL NOT INCLUDE LIABILITY

FOR SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES. ANY ACTION

BROUGHT UNDER THIS WARRANTY MUST BE BROUGHT WITHIN ONE YEAR OF THE

ACCRUAL OF THE CAUSE OF ACTION AND MAY ONLY BE BROUGHT IN THE CIRCUIT

COURT OF MCCLOUD COUNTY, MINNESOTA.

Some states do not allow limitations on how long an implied warranty lasts or the exclusion or limitation of incidental or

consequential damage, so the above limitations may not apply to you. This warranty gives you specific legal rights, and

you may also have other rights which vary from state to state.

ALL WARRANTY CLAIMS MUST BE SUBMITTED IN WRITING THROUGH THE PLACE WHERE

THE PRODUCT WAS PURCHASED. In the event where the place of purchase has ceased business or if

you feel that there is a legitimate reason that you cannot submit your claim to the place where the product was

purchased you may make a written request to the factory by emailing your request along with all of the

required information to technical@magnumheat.com

it is determined that warranty could have been performed by the place of purchase, the factory will

deny the claim.

Included with the claim must be the following information: (if this information is not complete, the claim will

be denied)

Name, address, telephone number, email address, of place of business where product was purchased

& also purchaser contact info.

Date of purchase, model and serial number of product, digital pictures of product (front, sides, back,

venting inside and outside)

(If there is ductwork, there must be digital pictures of entire ductwork installation, static pressures,

air flow measurements, and contact information of licensed/factory certified contractor that installed

unit)

Nature of defect, what has been serviced (service record), who installed product along with contact

information.

. NOTE: Verbal requests will not be recognized. If

9

THE HARVESTER OPERATION

FEATURES

Country Flame designed and built the Harvester stove to burn 100% shelled corn or wood pellets. Unlike

conventional pellet stoves, the Harvester is capable of handling larger amounts of ash. This means the

Harvester can burn corn, wood pellets, and other biomass fuel while not being choked out by ash. Country

Flame customers who own the Harvester claim they have successfully burnt a wide variety of different

biomass fuels. Although Country Flame is pleased that customers are finding wide success in burning locally

available fuels, Country Flame cannot support or warranty the burning of untested fuel or seed corn in the

Harvester.

Before beginning to install or operate the Model HR-01 Harvester, please consult with the local building

authority to obtain a permit. A certified professional should install this product. Before a homeowner

operates this stove, a thorough operational understanding should be obtained from reading and understanding

this manual. Failure to adhere to all safety notes and instructions contained herein can impact homeowner

insurance, void warranty, and create hazardous situations leading to smoke damage, fire, or even death.

The Model HR-01 was designed as a freestanding leg model stove. The legs come in a variety of finishes.

Contact American Energy Systems Inc. or one of its local authorized dealers to discuss and select product

options. Once installed, the Harvester is remarkably simple and safe to operate. FIGURE 1, shown with

optional gold legs, defines some of the Harvester components. From a relatively small firebox the Harvester

generates a very beautiful flame with lots of heat being produced into the room where the unit is installed.

Clean certified or AFPI approved fuel is to be loaded into the hopper. A motor turns an auger that delivers

fuel to the combustion chamber on a timed basis. Corn, pellets, or a combination of any solid fuels can be fed

into the Harvester burn pot.

Hopper Lid

Door (Cast, standard or

Gold, optional)

Ash Pan

FIGURE 1: HARVESTER MODEL HR-01 (corn, biomass, or pellet)

Ceramic Glass

Hearth Plate

10

SAFETY FEATURES

The Harvester comes standard with a number of advanced safety features; however, the first step in ensuring

maximum safety is to install the stove properly according to all national and local codes. The Harvester

requires a fresh air supply. This fresh air is used in the combustion process to achieve thorough burn of all

fuel. The Harvester needs a sealed and properly designed “all fuel” vent system. This vent system will be

used to remove combustion gasses from the combustion chamber to outside the home. REMEMBER: one

of the leading causes of house fires is due to improper installation or improper operation of a stove product.

Proper installation and operation of the Harvester is required to obtain homeowner insurance coverage. And,

the Harvester needs a reliable source of electrical power. Without reliable utility power or a means to ensure

reliability, the Harvester operation will be problematic.

The second step to safe operation is for the homeowner to thoroughly understand the operating characteristics

of the Harvester. More importantly, the operator needs to know how to control each one of the stove’s

operations. The Harvester has an electronic control system whose “brain” is constantly monitoring stove

operations in order to optimize the fuel efficiency and heat output of this product. The Harvester’s electronic

control provides a simple one stop location for the homeowner to control Harvester performance and heat

output. In order to ensure the safest operation, the Harvester’s electronic control is constantly monitoring

pressure and heat activated switches, and input power to ensure proper operation. Additional features include

an enclosed firebox, high temperature ceramic glass, optional thermostatic control, a high temperature wiring

harness, making the Harvester an extremely safe stove.

BATTERY BACKUP SYSTEMS

The Country Flame Harvester Model HR-01, like all pellet or biomass fuel stoves, relies on electrical energy

(wall power outlet) to properly operate. Without electrical energy or with interruptions to the source of

electrical energy, the Harvester stove’s operation will be erratic at best. Is power quality, power reliability, or

routine winter storm conditions a cause of power problems in a specific locale? If it is, the homeowner will

need to provide backup power to ensure stable operation of the Harvester. Fortunately, there are simple and

reliable power backup solutions readily available. Today, a homeowner can choose from a variety of cost

effective power conditioning systems from a number of reliable outlets today. For example, Home Depot,

Best Buy, WalMart, or many other stores carry standard power conditioning equipment. Two good quality

power conditioning equipment manufacturers are APC and TrippLite. Their uninterruptible power supplies

(UPS) include the capability to handle power failures, brown outs, power surges, and line noise. UPS system

cost is largely defined by the features included in the system. The amount of time (battery size) the system

must operate before recharging occurs directly relates to cost. UPS systems are usually sold by the number of

electrical outlets and the volt-amperes (watts, you need a minimum of 550) the system is rated to provide.

FIGURE 2 provides a description of the major electrical and operational components.

What does the Harvester stove require from a UPS system in order to sustain proper operation during a power

outage? To answer that question, the homeowner has to decide how long they want the Harvester to operate

in the absence of utility power. At the same time, an inexpensive solution that will handle a large percentage

of the issues would cost less than $100 or more depending on model and features. This UPS product will

operate a Harvester for close to an hour. This same UPS system should provide an audible, as well as visual

alarm, to alert the homeowner to local utility interruptions or power outages. The homeowner can then make

the decision to continue to operate the Harvester or shut it down until the local utility restores local power.

Further, this UPS system will ensure that minor utility glitches do not cause “nuisance” shutdowns or faults in

a Harvester stove. If a homeowner wants specific information concerning the size and quality of a specific

battery backup system for their Harvester stove, contact American Energy Systems Inc. or one of its local

authorized dealers who will assist in providing a specific solution.

11

FIGURE 2: HARVESTER COMPONENTS

(

t

t

T

g

Auger motor

3” Exhaust tube

250-degree over-temp

heat sensor

Hopper

79 CFM exhaust motor

Vacuum tube

orange)

Stir-rod

motor

110-degree exhaust

heat sensor

(Right - rear)

Hopper

110-degree room air

heat sensor

22-tooth sprocke

Stir rod chain

11-tooth sprocke

Wiring harness

160 CFM

room air

blower

(Left – rear)

Vacuum switch

Mounted on

inside of back

panel above

outside air tube

(Inside rear panel) (Outside rear panel)

1 ½”

outside air

120V receptacle

6-ampere fuse

hermostat plu

12

FUEL REQUIREMENTS

The Harvester Model HR-01 was designed to burn multiple types of fuel, including corn, wood pellets.

Country Flame recommends number 2 yellow shelled corn be used as fuel. This corn’s moisture content

should be limited to no more than 14% moisture content. Country Flame recommends corn fuel moisture

content be maintained somewhere in the range of 10% to 12%. USING SEED CORN AS FUEL IS

DANGEROUS TO OCCUPANTS AND BURNING SEED CORN VOIDS THE COUNTRY FLAME

WARRANTY.

If pellet fuel (wood or other solid biomass pellet fuel) is used in the Harvester, Country Flame recommends

no more than 8% moisture content. If there are any questions about fuels to be used in the Harvester, please

contact a local authorized Country Flame Dealer for assistance.

HARVESTER STARTUP

The first step in preparing the Harvester corn-burning stove is to remove it from its shipping crate. Ensure

that all materials packed in the burn chamber have been removed and that the Gold (optional) door and its

glass have been cleaned per enclosed instructions included in this manual.

NOTE:

(1) Failure to properly pre-clean the Gold (or any plated) door and the glass before lighting the

first fire could permanently damage either or both of these items.

(2) DO NOT burn seed corn as it is dangerous and voids the Country Flame warranty.

PRIMING

If this is the first time that the Harvester has been burnt or the stove has run out of corn fuel from a previous

burn, priming must be completed in order to fill the auger tube with corn fuel. The Harvester prime mode

(with the new control system) can be entered by holding the on-off button (after the initial minute of startup)

and hold it until fuel is dropping out of the auger for about 2 minutes. Once corn fuel starts dropping into the

burn pot, the system should be shut off. Once priming is completed, the next step is to prepare the Harvester

for burning.

FIRST FIRE

Country Flame recommends using wood pellets to start the Harvester Corn Stove. Pellets should be added in

layers with igniter gel or igniter bricks sandwiched between the pellets inside the burn pot. It is important that

the firebox has a hot pellet fire going before corn fuel is fed into the burn pot. This hot pellet fire is required

due to the higher combustion temperatures required for corn fuel.

Wood pellets should be layered with igniter fluid at least level with the bottom of the stir pot arm inside the

burn pot. Once the wood pellets and igniter material are layered in the burn pot, light the fuel, wait about a

minute and then close the door. Then push the on button and the system is running. Monitor the wood pellet

fire until a good blaze has been established. (see section on control board operation later in this manual)

Based on the heat setting on the control board, the Harvester will automatically turn the stir rod at a

predetermined rate to ensure turbulence and proper mixing of the fuel during the burn process. The stir rod

will ensure that “clinkers” are minimized if not completely eliminated. In addition, the stir rod ensures that

the fuel and flame are constantly agitated within the burn pot so as to ensure proper mixing with combustion

air. The Harvester burn pot has been designed to ensure maximum efficiency of burn while minimizing the

amount of ash being produced while at the same time minimizing the clinkers that can choke out a fire.

Testing by Country Flame has shown that the unit can be operated for several days to up to two weeks

without requiring cleaning depending on the type of fuel being burnt. It should be recognized that

environmental variables as well as the type of fuel can have drastic effects on the amount of ash or clinkers

formed during the burn cycle. Burn pot cleaning will depend upon the quality, quantity, and moisture content

13

of the fuel. Ash removal will be required from time to time depending on the amount of usage and the heat

desired. The Harvester stove should be shut down and cooled before cleaning or removing the ash pan.

ASH REMOVAL

The Harvester stove has an ash pan located on the underside of the firebox. Access to the Harvester ash pan

is obtained below the ash lip at the bottom front of the stove. The door on the front of the ash box is a locking

handle with a gasket seal. The seal provides an airtight fit and the locking handle ensure the ash door doesn’t

vibrate open. Lift up on the handle and make a ¼ turn to unlock the handle. Once the ash pan cover is pulled

forward, lay the ash pan handle back against the face of the cover. This allows the ash pan cover to be

lowered to the floor allowing easing removal of the ash pan itself.

Always remove ashes after they have been allowed to cool properly. Hot ash is dangerous to both

surrounding areas and occupants and can cause fires or severe burns. Wait until the fire has been out for

several hours before removing the ash pan. After the ash has been allowed to cool, remove the ash pan for

cleaning. Protective gloves should be worn anytime the ash pan is removed. Dump the ash in a proper ash

container and remove to a safe outdoors area. Remember that although the ash may look and feel cool to the

touch, a smoldering ember can start a fire. CAUTION: Care should be used to store any ash in a proper

container with an approved airtight lid. If ash is taken outside, water should be poured over the ash to ensure

no fire flare up can occur.

CONTROL BOARD

In 2011 American Energy Systems Inc. introduced BRAND NEW control board technology. This control

board technology was introduced across all Country Flame wood pellets and corn stove product lines.

American Energy Systems Inc. developed its own control board in order to enhance its product offering and

provide better support to customers. American Energy Systems Inc. will seek to provide the most advanced

controls while maintaining the look and feel distributors, dealers, and customers have come to know and

expect. This also means a purchase of today’s American Energy Systems Inc. product will provide an

upgrade path for newer and more advanced technology if the customer chooses to obtain it. American Energy

Systems Inc. is committed to its customer base. That means bringing enhancements that provide more heat

and improved burn efficiency while lowering the cost of operation. American Energy Systems Inc. will strive

to make the service support process easier through systematic troubleshooting procedures and repair events

that should allow for evolving “plug n play” operations. FIGURE 3 depicts control board basic theory.

14

Loading...

Loading...