Page 1

Model AD1024

MegaPower II

Matrix Switching Bays

Installation and Operating Instructions

This manual describes the installation and operating procedures for the American Dynamics model AD1024 Matrix Switching

System Bays. The AD1024 MegaPower II is designed as an integrated matrix switching and control system for CCTV

surveillance systems having multiple cameras, multiple monitors, and multiple control stations. The AD1024 Systems consist of

a matrix switching bay, its power supply module, a data receiver/buffer module, the required video input modules (VIM), video

output modules (VOM), and appropriate rear panels.

Page 2

This software/firmware is confidential to and is copyrighted by SENSORMATIC ELECTRONICS CORPORATION. It is not to

be copied or disclosed in any manner without the express written consent of SENSORMATIC. The software is furnished to the

purchaser under a license for use on a single system.

NOTE: Information furnished by SENSORMATIC is believed to be accurate and reliable. However, no responsibility is assumed

by SENSORMATIC for its use; nor for any infringements of other rights of third parties which may result from its use. No

license is granted by implications or otherwise under any patent or patent rights of SENSORMATIC.

Copyright 1999 by SENSORMATIC. All rights reserved.

Page 3

The installation of this product should be made by qualified

service personnel and should conform to all local codes.

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK,

!

AMERICAN

DYNAMICS

The lightning flash with arrowhead

symbol, within an equilateral

triangle, is intended to alert the

user to the presence of uninsulated

"dangerous voltage" within the

product's enclosure that may be of

sufficient magnitude to constitute a

risk of electric shock to persons.

DO NOT REMOVE COVERS (OR BACK) .

NO USER-SERVICEABLE PARTS INSIDE.

REFER SERVICING TO QUALIFIED SERVICE PERSONNEL

WWWWAAAARRRRNNNNIIIINNNNGG

To reduce the risk of fire or shock hazard, do

not expose this product to rain or moisture.

GG

This equipment has been tested and

found to comply with Part 15 of the

FCC Rules.

Operation is subject to the

following two conditions: 1. This

device may not cause harmful

interference, and 2. This device

must accept any interference

received, including interference

that may cause undesired operation.

The exclamation point within an

equilateral triangle is intended to

alert the user to the presence of

important operating and maintenance

!

UUUUNNNNPPPPAAAACCCCKKKKIIIINNNNGGGG AAAANNNNDDDD IIIINNNNSSSSPPPPEEEECCCCTTTTIIIIOOOONN

Unpack carefully. This is an electronic product and should

be handled as such. Compare the items received with the

packing list with your order.

Be sure to save:

1. The shipping cartons and insert pieces. They are the )

safest material in which to make future shipments of

the product.

2. The IMPORTANT SAFEGUARDS sheet.

3. These Installation and Operating Instructions.

MMMMAAAAIIIINNNNTTTTEEEENNNNAAAANNNNCCCCEE

User maintenance of this unit is limited to external cleaning

and inspection. For specific recommendations refer to the

IMPORTANT SAFEGUARDS sheet packaged with this product.

IIIINNNNSSSSTTTTAAAALLLLLLLLAAAATTTTIIIIOOOONNNN AAAANNNNDDDD SSSSEEEERRRRVVVVIIIICCCCEE

If you require information during installation of this

product or if service seems necessary, contact the

Sensormatic Repair and Service Department at (800)

442-2225. You must obtain a Return Authorization Number

and shipping instructions before returning any product for

service.

(servicing) instructions in the

literature accompanying the product.

NN

EE

EE

Do not attempt to service this product yourself. Opening or

removing covers may expose you to dangerous voltages or

other hazards. Refer all servicing to qualified personnel.

QA301D

Page 4

Page 5

CONTENTS

Page

General Description.........................................................................1

System Modules Description

Power Supply Module 2010PS..................................................2

Data Buffer Module 2010DB.....................................................4

Video Loss Detection Data Buffer 2010DBVL.........................6

Video Input Module 2016AVIM................................................8

Video Output Module 2024VOM..............................................9

Master Date Time Module 2024MDT.....................................10

Installation

Power Sources..........................................................................11

Mounting..................................................................................11

Connections..............................................................................11

Setup

Data Buffer Module.................................................................12

Video Loss Detector Data Buffer.............................................13

Video Input Module.................................................................14

Video Output Module ..............................................................16

Power Supply Module..............................................................18

Powering Up

Powering the Matrix Bay.........................................................19

Page 6

CONTENTS

Page

System Configurations

Level 1 Systems

Level 1 - 256 X 16, One Bay with No Titles.....................20

Level 1 - 192 X 16, One Bay System ................................21

Level 1 - 448 X 16, Two Bay System................................22

Level 1 - 704 X 16, Three Bay System..............................23

Level 1 - 960 X 16, Four Bay System ...............................24

Level 1 - 1024 X 16, Five Bay System..............................25

Level 2 Systems

Level 2 - 64 X 32, One Bay System ..................................27

Level 2 - 192 X 32, Two Bay System................................28

Level 2 - 320 X 32, Three Bay System..............................29

Level 2 - 448 X 32, Four Bay System ...............................30

Level 2 - 704 X 32, Six Bay System..................................31

Level 2 - 960 X 32, Eight Bay System ..............................32

Level 2 - 1024 X 32, Nine Bay System.............................34

Level 3 Systems

Level 3 - 192 X 48, Three Bay System..............................36

Level 3 - 256 X 48, Four Bay System ...............................37

Level 3 - 448 X 48, Six Bay System..................................38

Level 3 - 512 X 48, Seven Bay System.............................39

Level 3 - 704 X 48, Nine Bay System...............................40

Level 3 - 768 X 48, Ten Bay System.................................42

Level 3 - 960 X 48, Twelve Bay System ...........................44

Level 3 - 1024 X 48, Fourteen Bay System.......................46

ADULP Looping Panel............................................................48

Appendix

Level 1 Interconnect Drawings.......................................A1 - A5

Level 2 Interconnect Drawings.....................................A6 - A11

Level 3 Interconnect Drawings...................................A12 - A16

Level 8 Interconnect Drawings.............................................A17

Video Loss Detector Connections...............................A18 - A21

Video Buffer Interconnection................................................A22

Page 7

GENERAL DESCRIPTION

The MegaPower II AD1024 Switcher/Control System is an

integrated matrix switching and control system for CCTV

surveillance systems. It is capable of controlling up to 1024

video input sources such as cameras, and 128 video outputs

such as monitors and video tape recorders.

The AD1024 system consists of a matrix switching bay, its

power supply module, a data receiver/buffer module, the

required video input modules (VIM), video output modules

(VOM), and appropriate rear panels. All AD1024 systems are

controlled with a separate central processing unit (CPU) and

keyboard.

AD1024 Switcher/Control Systems are supplied as completely

configured switching bays. Only the bay interconnections, the

CPU connections, the video input and output connections, and

any optional accessory connections need be made prior to

operation. The AD1024 system, as delivered, is a complete

system with all inputs terminated in 75 ohms. Each bay is

packed in a separate shipping carton labeled with the AD1024

bay assembly number on the outside of the carton.

Matrix Switching Bay

The 2010R and 2020R switching bays include the physical

chassis, a back plane, a power supply module, and a data

receiver. Each bay has the capability of looping the DATA

LINE input and looping an external vertical synchronization

pulse to other bays. Each bay also accommodates a

combination of video input modules and video output modules,

up to a total of 16 modules.

Power: 50 watts (full system)

Size: 10-1/2” height. Full-width 19” rack mount

Weight: 60 lbs. (28 kg) (full system)

CPU (Central Processing Unit)

The CPU for the AD1024 system is a separate rack-mounted

unit that includes its own power supply, system software, ten

RS-232 ports, a system diagnostic monitor output, and two

DATA LINE outputs. These DATA LINE outputs distribute

high speed data control signals to the AD1024 matrix

switching bays and optional accessories.

AD1024 Central Processing Unit

Power: 4 watts

Size: 1.75” height. Full-width 19” rack mount

Weight: 10 lbs. (4.5 kg)

OPTIONAL EQUIPMENT

The following separate units may be connected to the AD1024

system for added capabilities. For specific information, refer

to the respective data sheets.

2091 Control Code Generator/Distributor

The 2091 provides 64 control-code outputs for control of 1640

and 1680 Series Receivers actuating pan/tilt; lens zoom, focus,

and iris; and auxiliaries at suitably-equipped camera sites.

2031 Switcher/Follower,

2032 Alarm Responder,

2033 Auxiliary Follower

The 2030 Series Followers switch external circuits when

designated cameras are called to designated monitors (2031),

when designated monitors are in alarm conditions (2032), or

when designated auxiliaries are called up or designated

cameras are alarmed (2033).

ADULP Looping Panel

The ADULP Looping Panel is used to facilitate the looping of

video signals for the AD1024 system from external inputs or to

external devices such as time-lapse video recorders, switchers,

monitors, etc.

Other Switcher/Control System Accessories

• 1640 and 1680 Series Receivers

• 1670 and 2078 Series Keyboards

• 1680MG Manchester Generator

• 1683 Control Code/PSK Modem

• 1981 Port Expander

• 2081 Port Expander

• 1983 Code Converter

• 2083 Code Translators

• 2096 Alarm Interface Unit

• 1985A Hot Switch

This installation should be made by qualified service personnel

and should conform to all local codes. Safeguards must be

taken to avoid unintentional operation by employees and

maintenance personnel working about the premises, by falling

objects, by customers, by building vibration, and by similar

causes.

1

GENERAL DESCRIPTION

IF YOU ENCOUNTER ANY PROBLEMS

OPERATING THIS UNIT, OR NEED ASSISTANCE,

CALL OUR TECHNICAL SUPPORT CENTER AT:

within the United States: 1-800-442-2225

outside the United States: (845) 624-7600

Page 8

SYSTEM MODULES

The following pages describe the plug-in modules available for

AD1024 switching bays. These include:

Power Supply Module, 2010PS

Data Buffer Module, 2010DB

Video Loss Detection Data Buffer Module, 2010DBVL

Video Input Module, 2016AVIM

Video Output Module, 2024VOM

Master Date Time Module, 2024MDT

Power Supply Module - 2010PS

The power supply module for the matrix switching bay

converts AC power to the necessary DC voltages which are

supplied to all the modules in the switching bay.

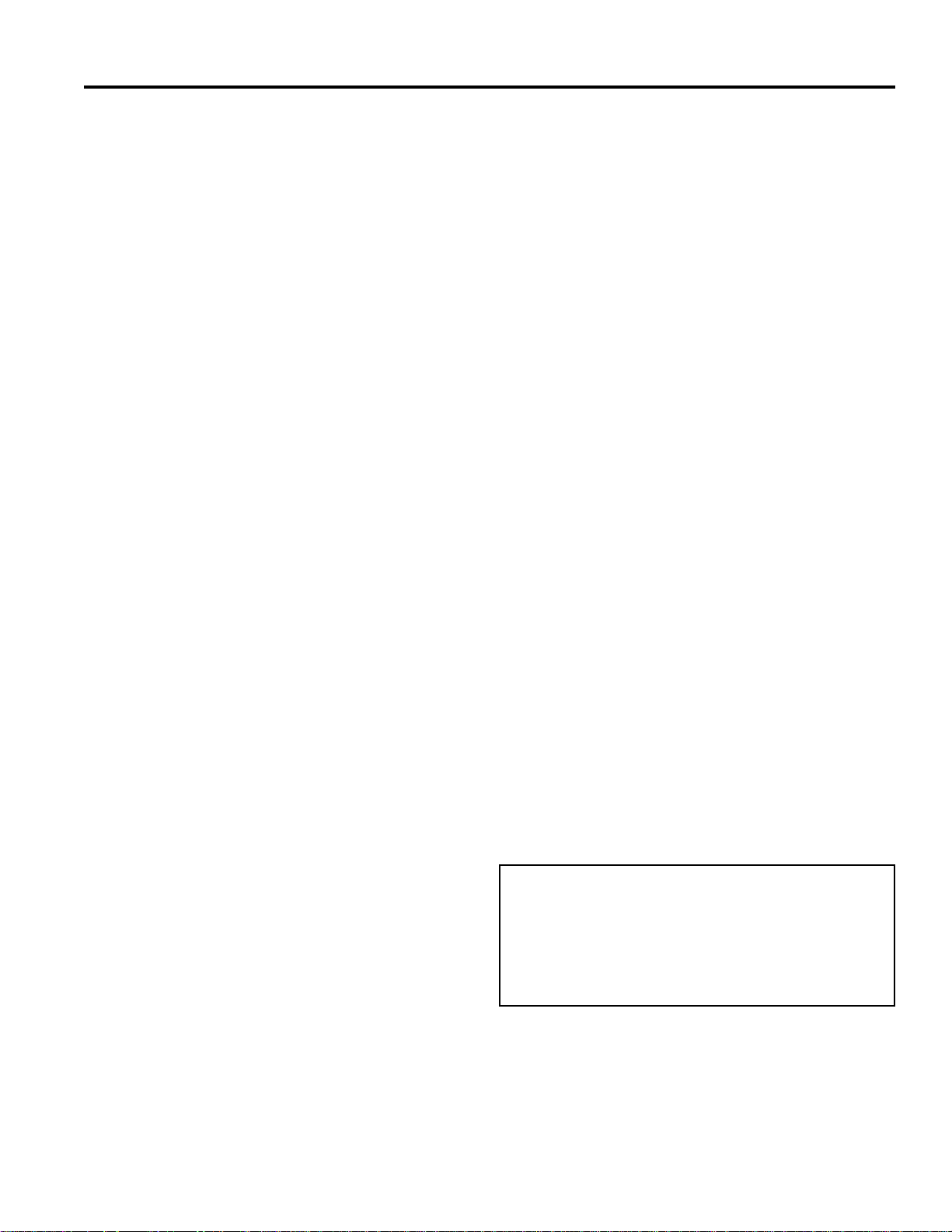

Front Panel

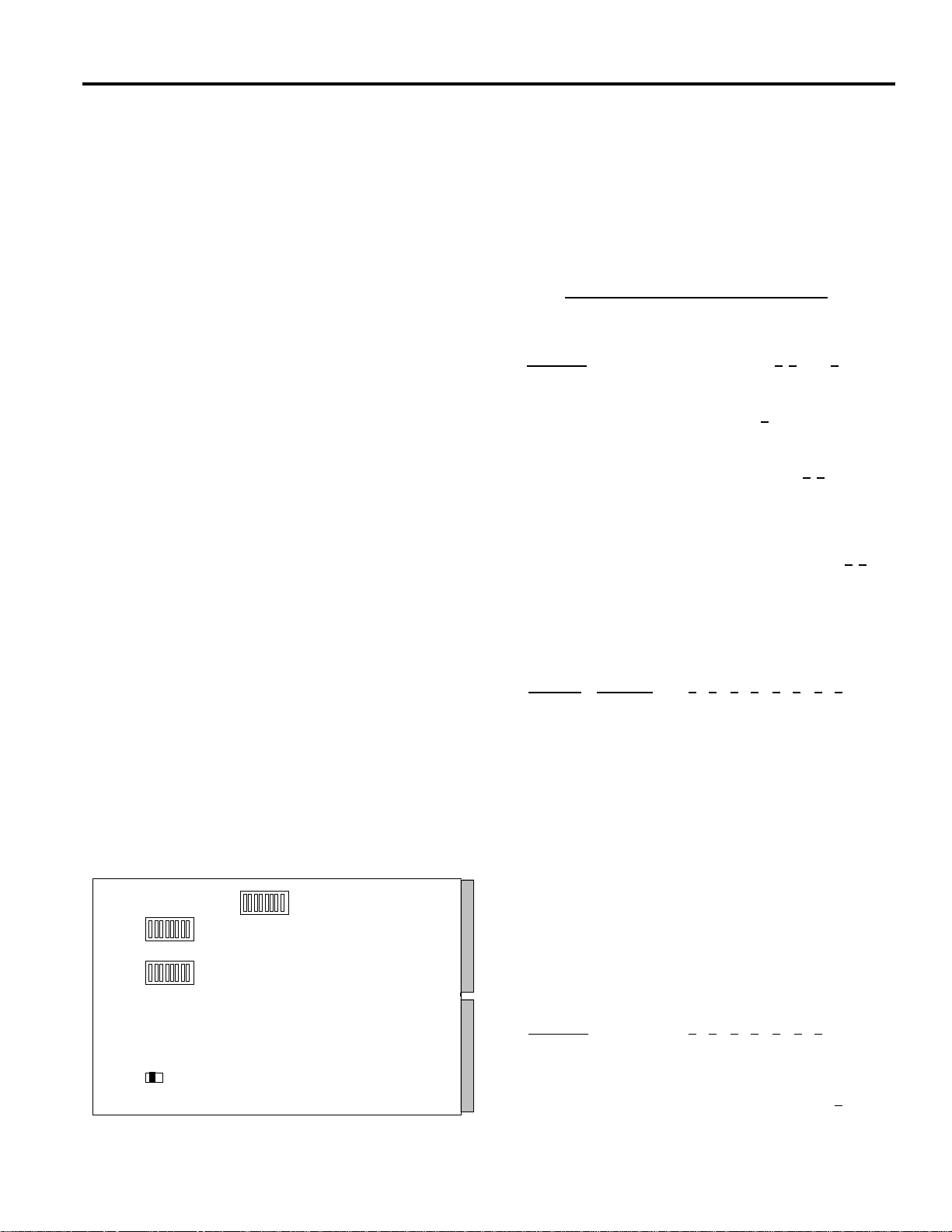

Figure 1 illustrates the features described below.

1- SYNC TEST ON/OFF LED: This red LED is illuminated

when the SET UP/NORMAL switch (below) is in the SET

UP position.

2- SET UP/NORMAL SWITCH: When set to the SET UP

position, this switch implements sync test and adjustment.

(See Power Supply Setup, page 18.)

3- SYNC LOSS LED: This red LED is off if video sync is

locked. When illuminated, it indicates that sync is not

locked due either to a poor sync signal, no sync signal, or

the wrong sync signal (as determined by the setting of the

sync selection switch below).

4- SYNC REFERENCE SELECTION SWITCH: This

switch selects one of three video sync references:

EXT V-DRIVE (Up position): Selects the external vertical

drive pulse input on the rear panel (EXT SYNC IN).

EXT CAM (Center position): Selects composite video.

AC LINE (Down position): Selects the AC line (as

supplied).

5- SYNC PHASE ADJUSTMENT: This potentiometer,

accessed thru the hole in the front panel of the Power

Supply, adjusts the phase of the sync pulse with respect to

the selected reference. When the sync test switch is set to

SET UP, a horizontal trace line is displayed on Monitor 1,

showing the location of the sync pulse with respect to the

picture. (See Power Supply Setup, page 18.)

6- +9 VDC AND -9 VDC LED's: These green LED's, when

illuminated, indicate the presence of DC voltages (Note: For

the 230 VAC systems, the output voltages are +/-8 VDC).

7- POWER ON/OFF SWITCH: This switch is used to apply

power to the bay. When the switch is in the ON position, a

green light is illuminated behind the Power On/Off Switch.

Fusing: Four replaceable fuses are located on the power

supply circuit board. Replacement fuses must meet national

and local use code requirements.

Fuse Ratings:

For 120VAC Systems:

F1: 125V, 5 AMP, 5 x 20 mm

F2: 125V, 5 AMP, 5 x 20 mm

F3: 250V, SB, 0.5 AMP, 5 x 20 mm, UL listed

F4: 250V, SB, 0.5 AMP, 5 x 20 mm, UL listed

For 230VAC CE Compliant Systems:

F1: 250V, T, 3.15 AMP, 5 x 20 mm

F2: 250V, T, 3.15 AMP, 5 x 20 mm

For 230VAC Non-CE Compliant Systems:

F1: 125V, 5 AMP, 5 x 20 mm

F2: 125V, 5 AMP, 5 x 20 mm

F3: 250V, T, 0.25 AMP, 5 x20 mm

F4: 250V, T, 0.25 AMP, 5 x 20 mm

SYSTEM MODULES DESCRIPTION

Figure 1 - Front Panel of Power Supply Module

SET UP

NORMAL

EXT V-DRIVE

EXT CAM

AC LINE

PHASE

+9VDC

-9VDC

SYNC

LOSS

1

2

3

4

5

6

7

2

Page 9

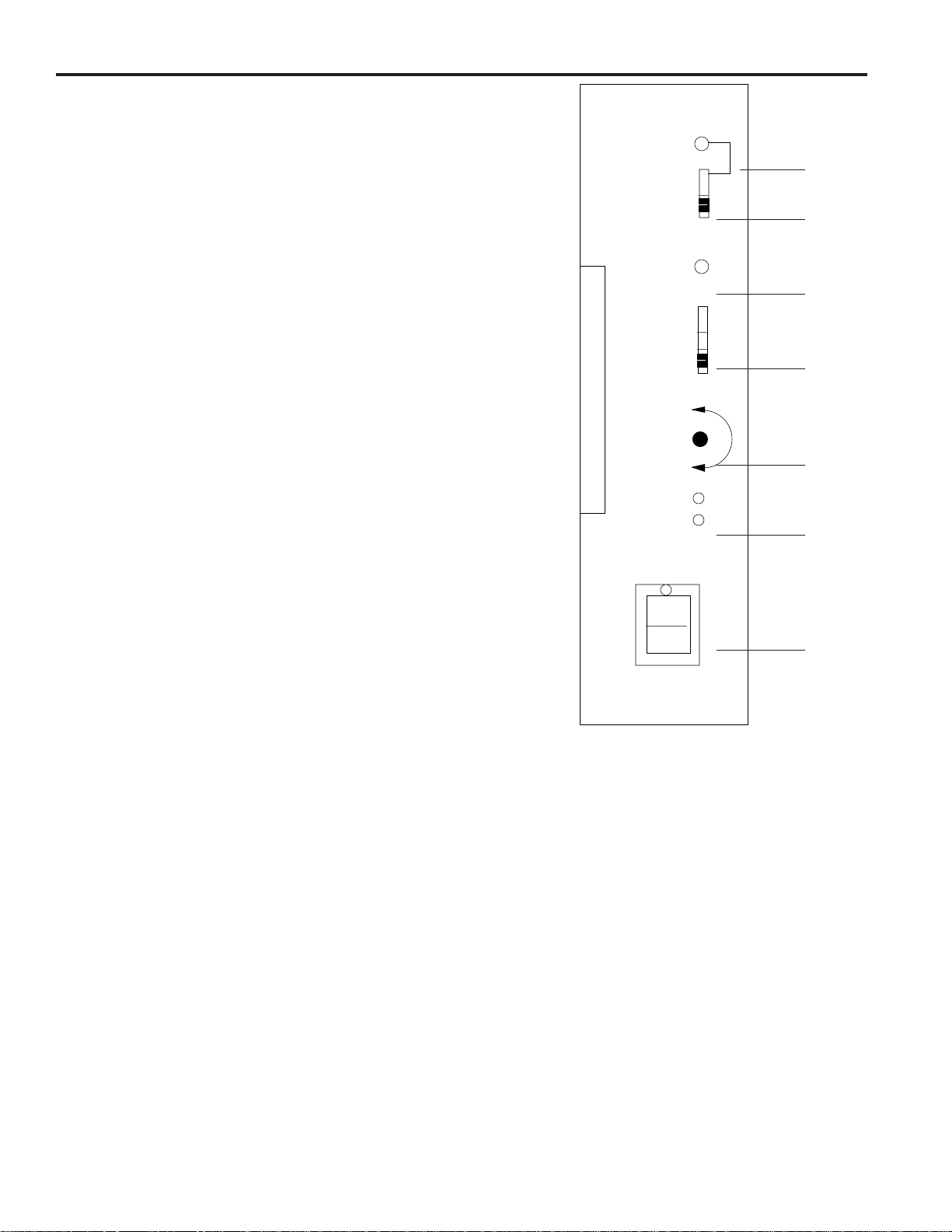

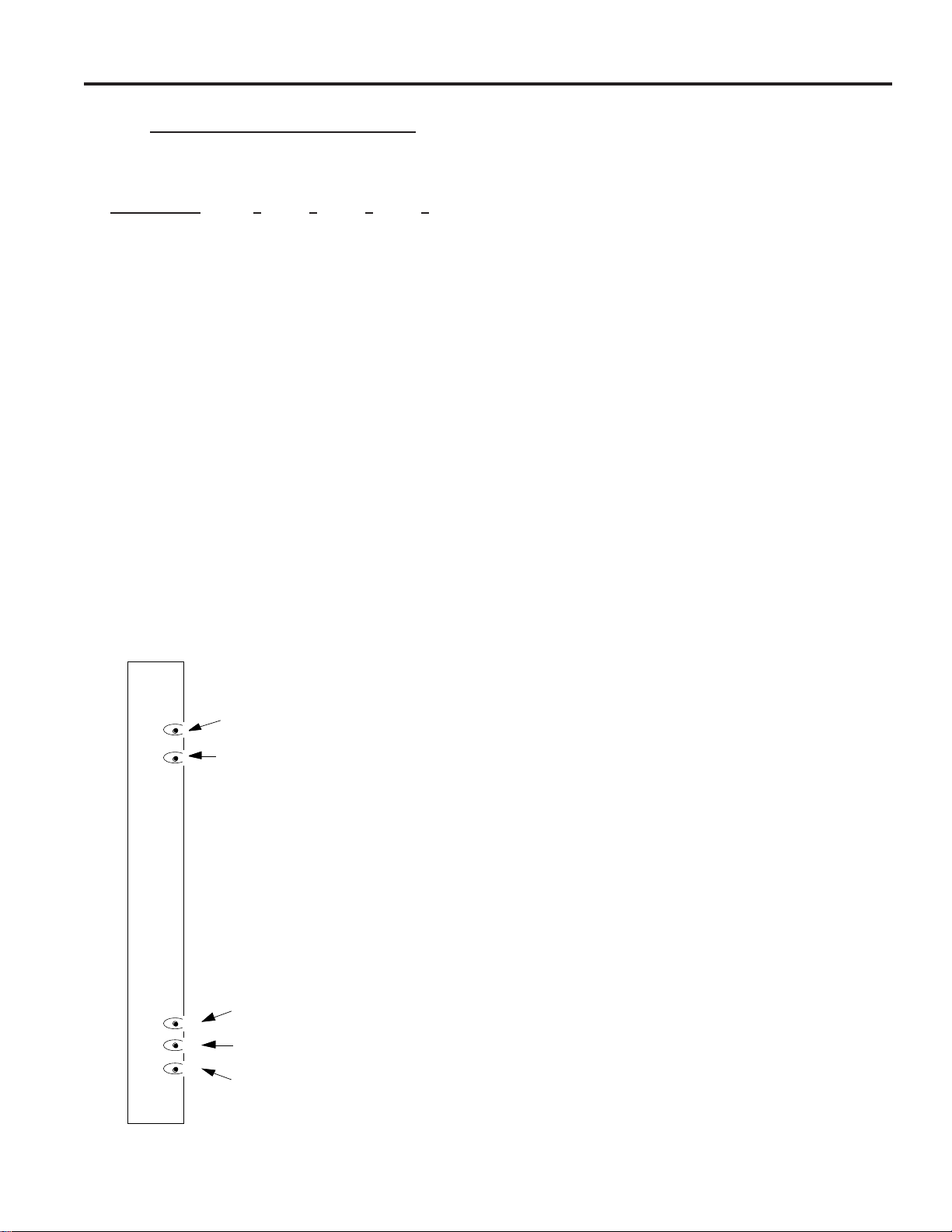

Power Supply Module - Rear Panel

Figure 2 is the illustration associated with the features

described below.

8- SERIAL # TAG: Serial number assigned to this AD1024

switching bay.

9- DATA LINE IN: Input for DATA LINE.

10- DATA LINE OUT: Looping output for DATA LINE.

This line must be terminated with a 75-ohm terminator.

11- EXTERNAL SYNC IN: Input for external vertical

synchronous pulse, either camera sync or an externally

created sync pulse.

12- EXTERNAL SYNC OUT: Looping output for EXT

SYNC. This line must be terminated with a 75-ohm

terminator.

3

SYSTEM MODULES DESCRIPTION

Model: AD2010

S/N: XXXXX

IN

DATA LINE

OUT

120 V

60 Hz

IN

EXT

SYNC

OUT

Figure 2 - Rear Panel of Power Supply Module

8

9

10

11

12

Page 10

Data Buffer Module - 2010DB

The Data Buffer Module serves a dual purpose. First, it

distributes switched video, from the bay's Video Input

Modules, to other bays in multiple bay systems. The video

observed from these outputs contain no character information,

only standard video.

The second purpose of the Data Buffer is to filter incoming

system information from the DATA LINE. Filtering is

performed to allow for the passage of localized information.

The 2010DB rear panel has 16 video output BNC's for

connection to Video Output Modules in other switching bays.

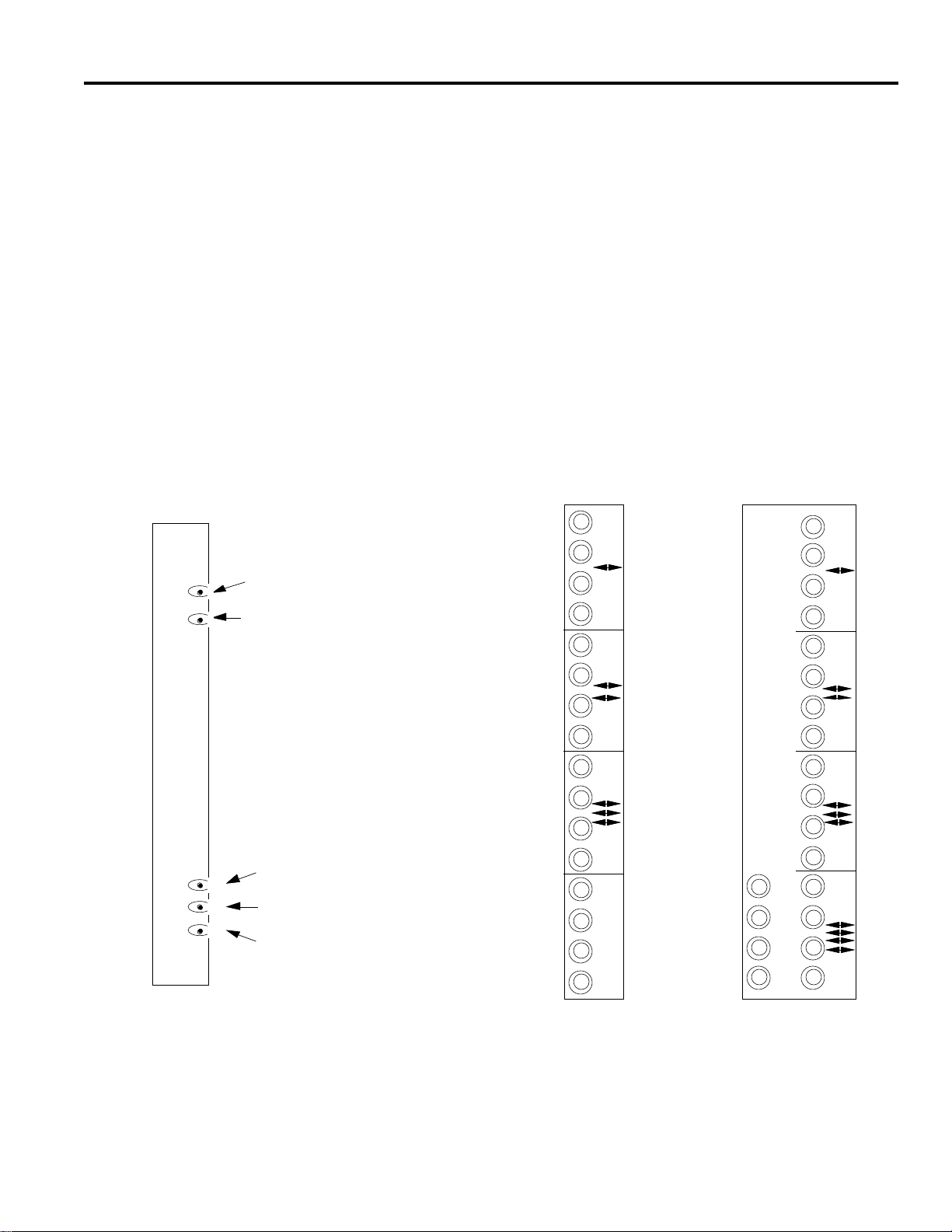

The illustrations in Figures 3 through 8 show the various types

of rear panels of the Data Buffer module.

See Appendix Figure A22 for illustration of interconnection

from these modules to the Video Output Modules.

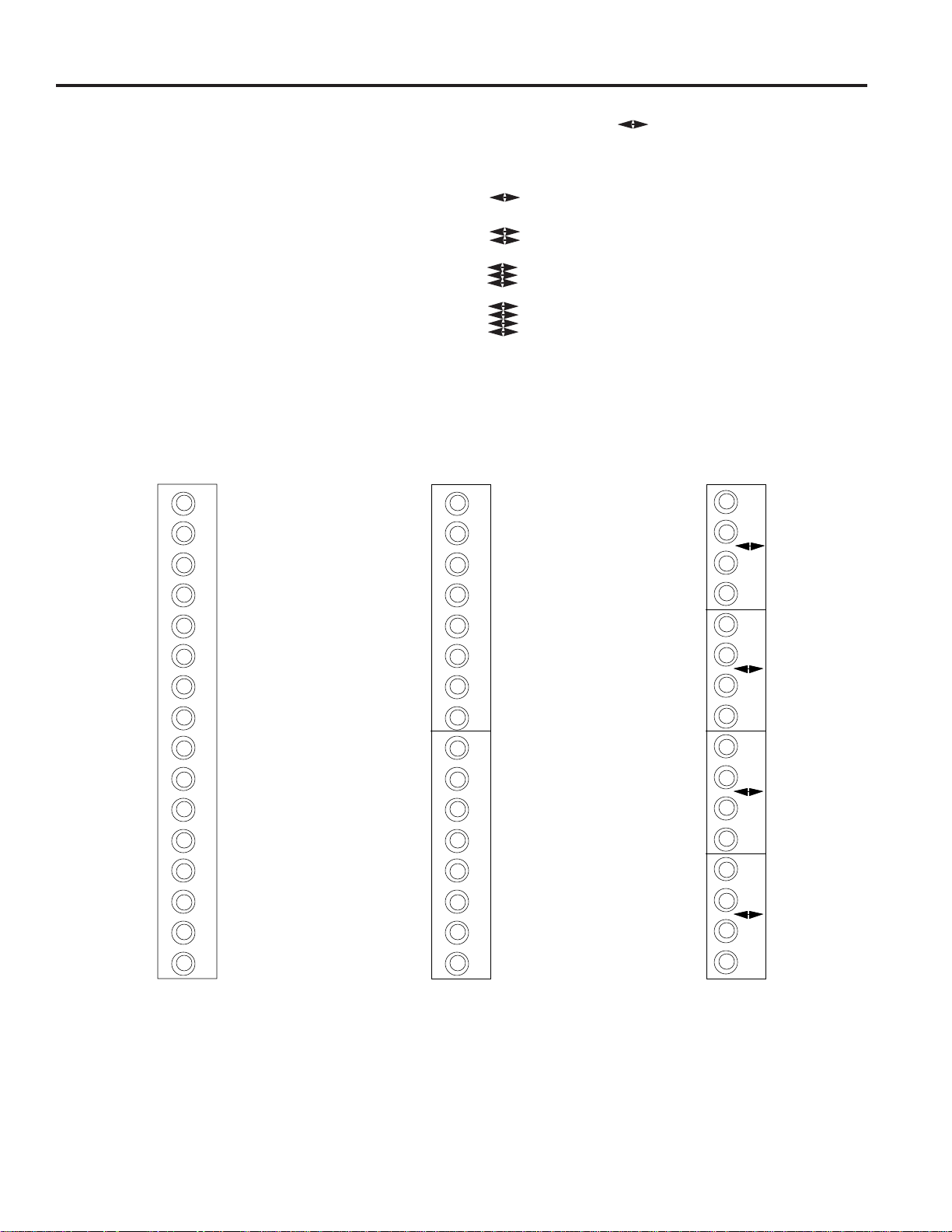

Icon Definition: The is the video/interconnect symbol

for connecting switched video among the matrix switching

bays.

Switched video inputs from cameras 1 to 256.

Switched video inputs from cameras 257 to 512.

Switched video inputs from cameras 513 to 768.

Switched video inputs from cameras 769 to 1024.

Figure 3

2010DB-00

Rear Panel

Figure 4

2010DB-01

Rear Panel w/ 16 BNCs

Camera Card Bay

(No Monitor Modules)

Figure 5

2010DB-11 to 2010DB- 18

Rear Panel w/ 16 BNCs

Multiple-Bay System

for cameras 1-256

1

6

Output 16

81Output 1

9

4

1

2

1

3

5

Output 8

4

SYSTEM MODULES DESCRIPTION

T

E

S

T

/

E

X

P

A

N

S

I

O

N

O

N

L

Y

16

Output 16

Output 8

81Output 1

O

U

T

9

O

U

T

Page 11

5

SYSTEM MODULES DESCRIPTION

1

6

Output 16

Output 8

81Output 1

9

4

1

2

1

3

5

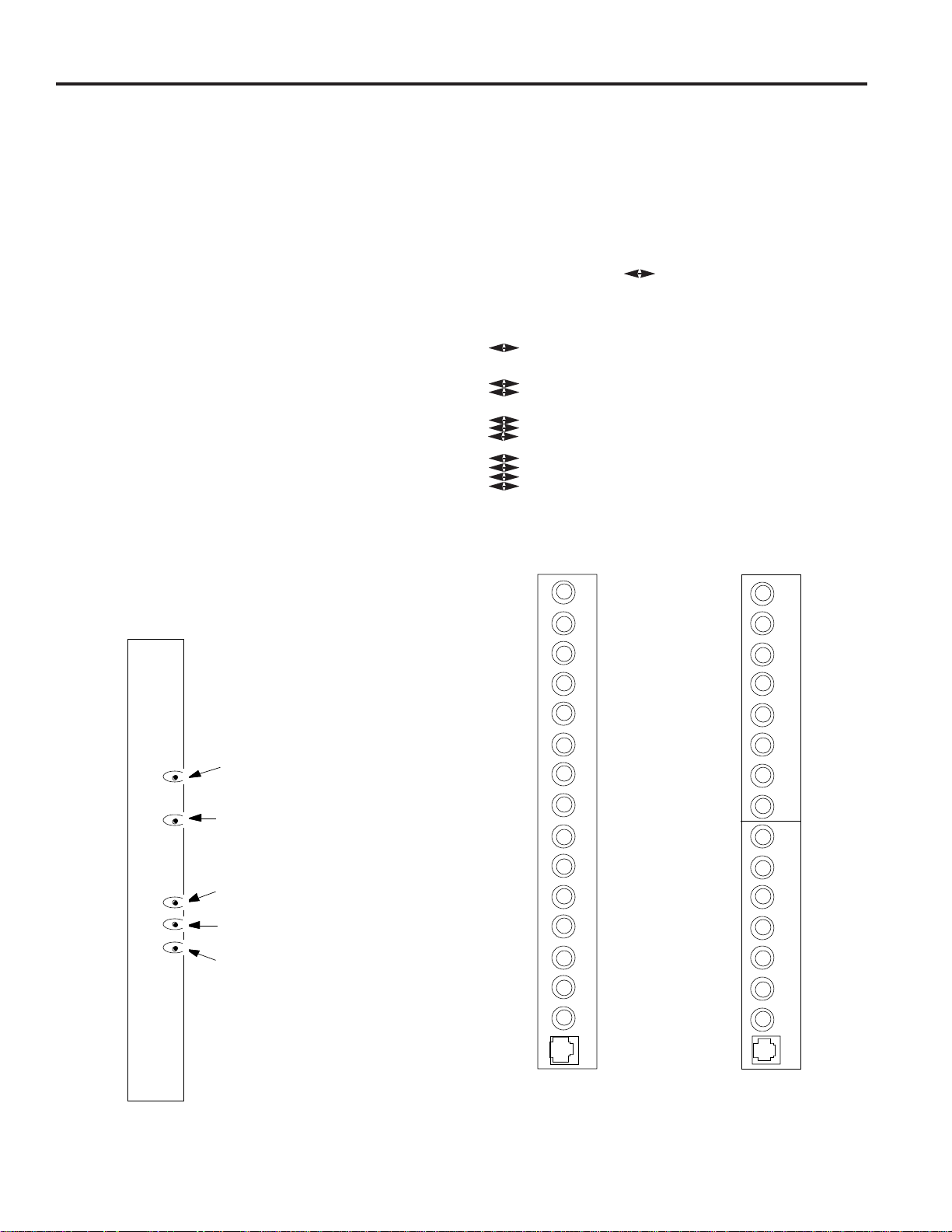

Data Buffer Module - 2010DB (continued)

1

6

Output 16

Output 8

81Output 1

9

4

1

2

1

3

5

1

6

Output 16

Output 8

81Output 1

9

4

1

2

1

3

5

Figure 6

2010DB-21 to 2010DB-28

Rear Panel w/ 16 BNCs

Multiple-Bay System

for cameras 257-512

Figure 7

2010DB-31 to 2010DB-38

Rear Panel w/ 16 BNCs

Multiple-Bay System

for cameras 513-768

Figure 8

2010DB-41 to 2010DB-48

Rear Panel w/ 16 BNCs

Multiple-Bay System

for cameras 769-1024

Page 12

Video Loss Detection Data Buffer Module - 2010DBVL

The Video Loss Detector Data Buffer Module provides the

same capabilities as the 2010DB Data Buffer Module, with one

significant addition. First, it distributes switched input video,

with no character information, to multiple bay systems. It also

filters incoming information from the DATA LINE to allow for

the passage of localized information.

The additional function of this module is to detect the presence

of a video signal for each camera input. Each module can

detect video loss for a maximum of 256 cameras. For a full

matrix switching system of 1024 cameras, four 2010DBVL

modules are required, one for each block of 256 cameras.

The 2010DBVL module must be placed in the matrix

switching bay that is connected to the highest numbered

monitor output, and this bay must contain Video Input

Modules. The 2010DBVL cannot be used in a switching bay

that does not include Video Input Modules.

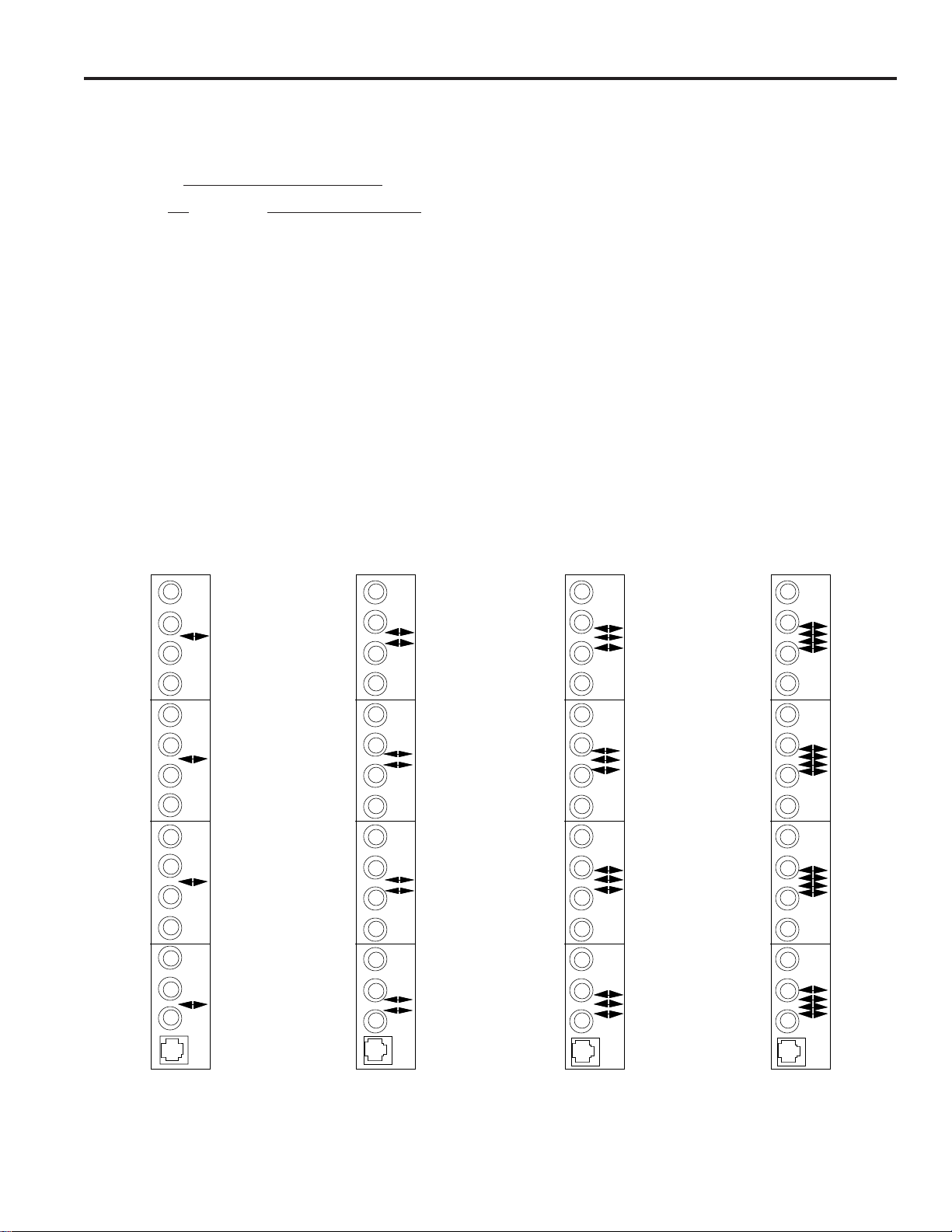

Front Panel

The front panel of the 2010DBVL provides indicator LED's

that illuminate if a video or sync loss is detected, and indicate

the SYNC and VIDEO content of the video input signal being

monitored. See Figure 9 for location of these LED's.

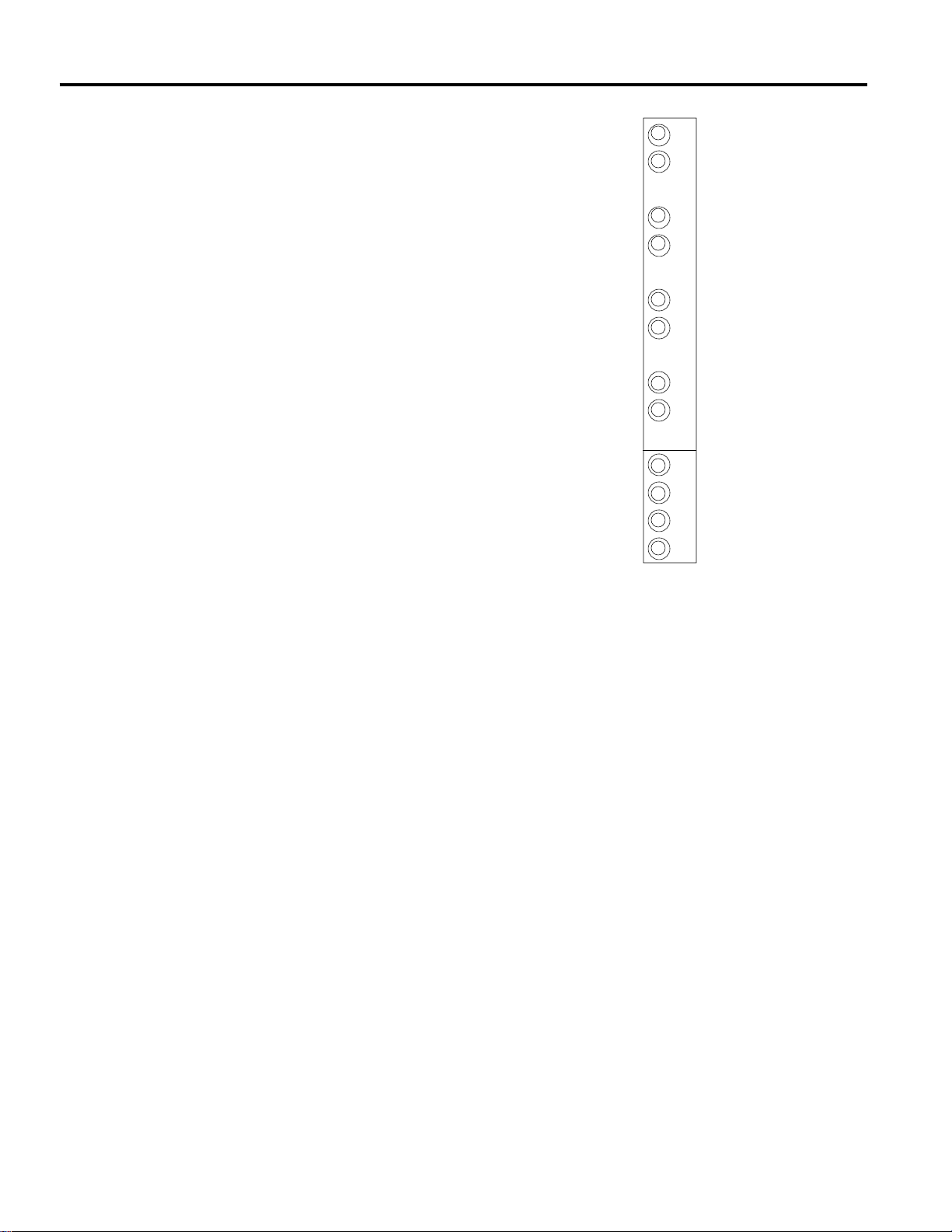

Rear Panels

The 2010DBVL rear panel has 15 video output BNC's for

connection to Video Output Modules, and one 8-pin, RJ45 RS232 connector for Video Loss Detection data output and Alarm

Contact output to an Alarm Interface Unit. Figures 9 through

15 show the various types of rear panels of the Video Loss

Detector Data Buffer module.

Icon Definition: The icons on the rear panels are the

video/interconnect symbol for connecting switched video

among the matrix switching bays.

Switched video inputs from cameras 1 to 256.

Switched video inputs from cameras 257 to 512.

Switched video inputs from cameras 513 to 768.

Switched video inputs from cameras 769 to 1024.

See Appendix Figure A22 for illustration of interconnection

from these modules to the Video Output Modules.

Figure 10

2010DBVL-00

Rear Panel

Figure 11

2010DBVL-01 Rear Panel

Camera Card Bay

(No Monitor Modules)

T

E

S

T

/

E

X

P

A

N

S

I

O

N

O

N

L

Y

SYSTEM MODULES DESCRIPTION

6

1

5

8

1

O

U

T

9

O

U

T

H

M

L

indicates Video or Sync Loss

indicates Sync present

indicates High video content

indicated Medium video content

indicates Low video content

VIDEO

LEVEL

ALARM

SYNC

Figure 9

2010DBVL Front Panel LED Indicators

Page 13

When a video loss is detected, a video loss message is

transmitted from the 2010DBVL via the RJ45 connector RS232 pins. An alarm contact is also provided by pins 1 and 2 of

this connector. The connector pin definitions are as follows.

RJ45 Connector Pin Definitions

Pin Function (RS-232 Code)

1 Alarm Contact Output

2 Alarm Ground

4 Receive Data (RCD)

5 Transmit Data (XMIT)

7 Ground (GND)

The RS-232 pins are connected to an RS-232 port, on the

AD1024 CPU, which is set for VIDEO LOSS use. The RS232 port can be connected using the supplied modularcable. if

the distance between the 2010DBVL and the CPU is less than

7 feet.

If the distance exceeds 7 feet, or if the Alarm Contact output is

used, an 8-pin Terminal Box is provided for

connections. The Terminal Box is connected to the

2010DBVL RS-232 port with the supplied modular cable. The

maximum cable length between an RS-232 device and the

Terminal Box is 1000 feet, using 18-AWG shielded, computer

grade cable.

All American Dynamics equipment is configured as RS-232

DTE (Data Terminal Equipment) devices. For DTE-to-DTE

connection to the 2010DBVL Terminal Box:

- the XMIT pin of the 1996 port is connected to RCD (pin

4) of the 2010DBVL Terminal Box.

- the RCD pin of the 1996 port is connected to XMIT (pin

5) of the 2010DBVL Terminal Box.

- the Ground of the 1996 port is connected to GND (pin 7)

of the 2010DBVL Terminal Box.

Pins 1 and 2 provide a logic-level alarm closure, in accordance

with the Alarm Contact mode set for the module (see page 13).

These pins are connected to the alarm contact inputs of a 2096

Alarm Interface Unit, pin 1 to “A” input and pin 2 to ground.

Where multiple 2010DBVL modules are used, 1981 or 2081

port expanders are used to connect these modules to the

AD1024 CPU. The 2010DBVL-1x module must be connected

to port A of the 1981, 2010DBVL-2x to port B, 2010DBVL-3x

to port C, and 2010DBVL-4x to port D. Video loss detection

will not operate unless all modules are connected to the

AD1024 CPU.

Typical connections of the 2010DBVL module are illustrated

in the Appendix, Figures A18 to A21.

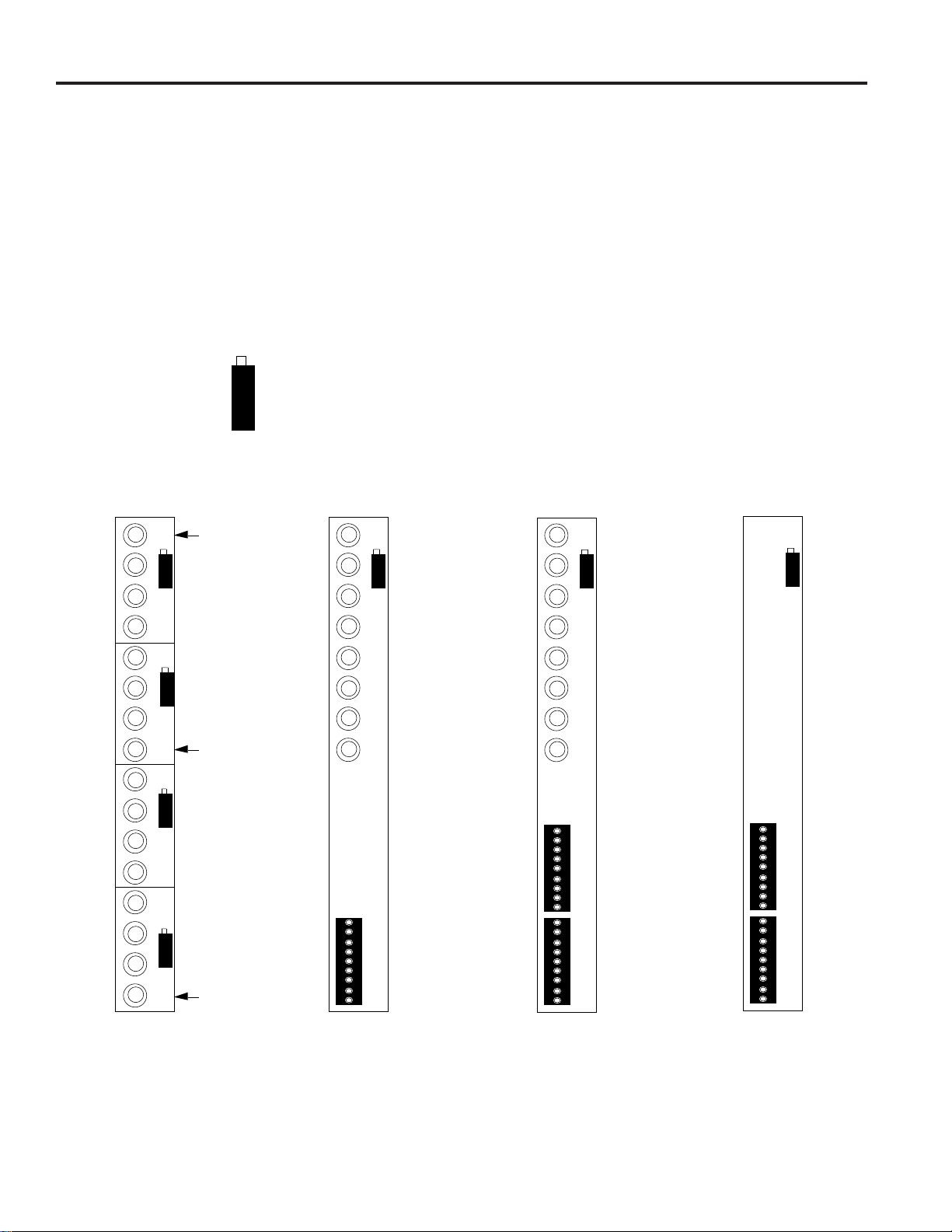

Figure 12

2010DBVL-11 to -18

Multiple-Bay System

for cameras 1-256

Figure 13

2010DBVL-21 to -28

Multiple-Bay System

for cameras 257-512

Figure 14

2010DBVL-31 to -38

Multiple-Bay System

for cameras 513-768

Figure 15

2010DBVL-41 to -48

Multiple-Bay System

for cameras 769-1024

SYSTEM MODULES DESCRIPTION

7

1

581941213

5

1

58194

121

3

515

8

1

9

41213

515

8

1

9

41213

5

Page 14

Video Input Modules - 2016AVIM

The 2016AVIM performs the actual video switching in the

AD1024 switching bay. Each module can switch any one of

16 video inputs to any video output, or multiple combinations

of video outputs, up to 16. The 16 video inputs to the module

are connected at the rear panel associated with the video input

module. The switched video outputs are provided to the Video

Output Modules and the Data Buffer Module in the bay.

There are four different types of rear panels, shown below.

Icon Definition: The following icon denotes video inputs.

The 2016AVIM-1, as seen in Figure 16, has 16 BNC

connectors for video inputs. The number next to each BNC

reflects the actual input numbers.

The 2016AVIM-2, as seen in Figure 17, has eight BNC

connectors for the upper group of eight video inputs and one

34-pin connector. The number next to the BNC reflects the

actual input numbers.

The third rear panel, 2016AVIM-3, as seen in Figure 18, has

eight BNC connectors for the lower group of eight cameras to

complete the larger group of 16 video inputs and two 34-pin

connectors. The number next to the BNC reflect the actual

input numbers.

The fourth type of rear panel, 2016AVIM-4, as seen in Figure

19, has only two 34-pin connectors. They are used for

expansion in multiple switching bay configurations.

Figure 16

2016AVIM-1

Figure 17

2016AVIM-2

1

6

Input 16

Input 8

81Input 1

9

4

1

2

1

3

581

O

U

T

SYSTEM MODULES DESCRIPTION

8

16

9

O

UTI

N

Figure 18

2016AVIM-3

Figure 19

2016AVIM-4

16

1

O

UTI

N

Page 15

Video Output Module - 2024VOM

The 2024VOM (Video Output Module) creates the titles that

are added to the video output. Each module has four video

outputs on its rear panel.

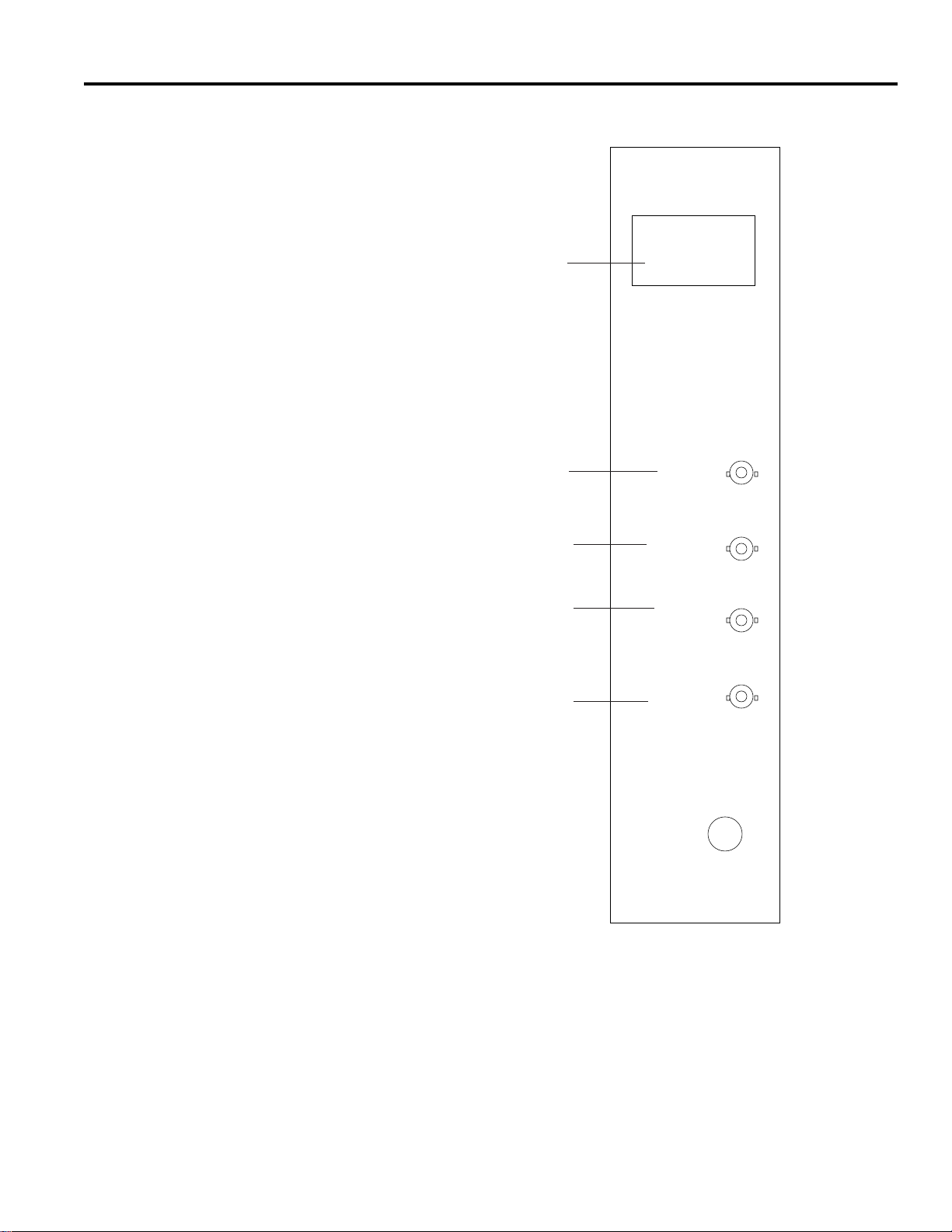

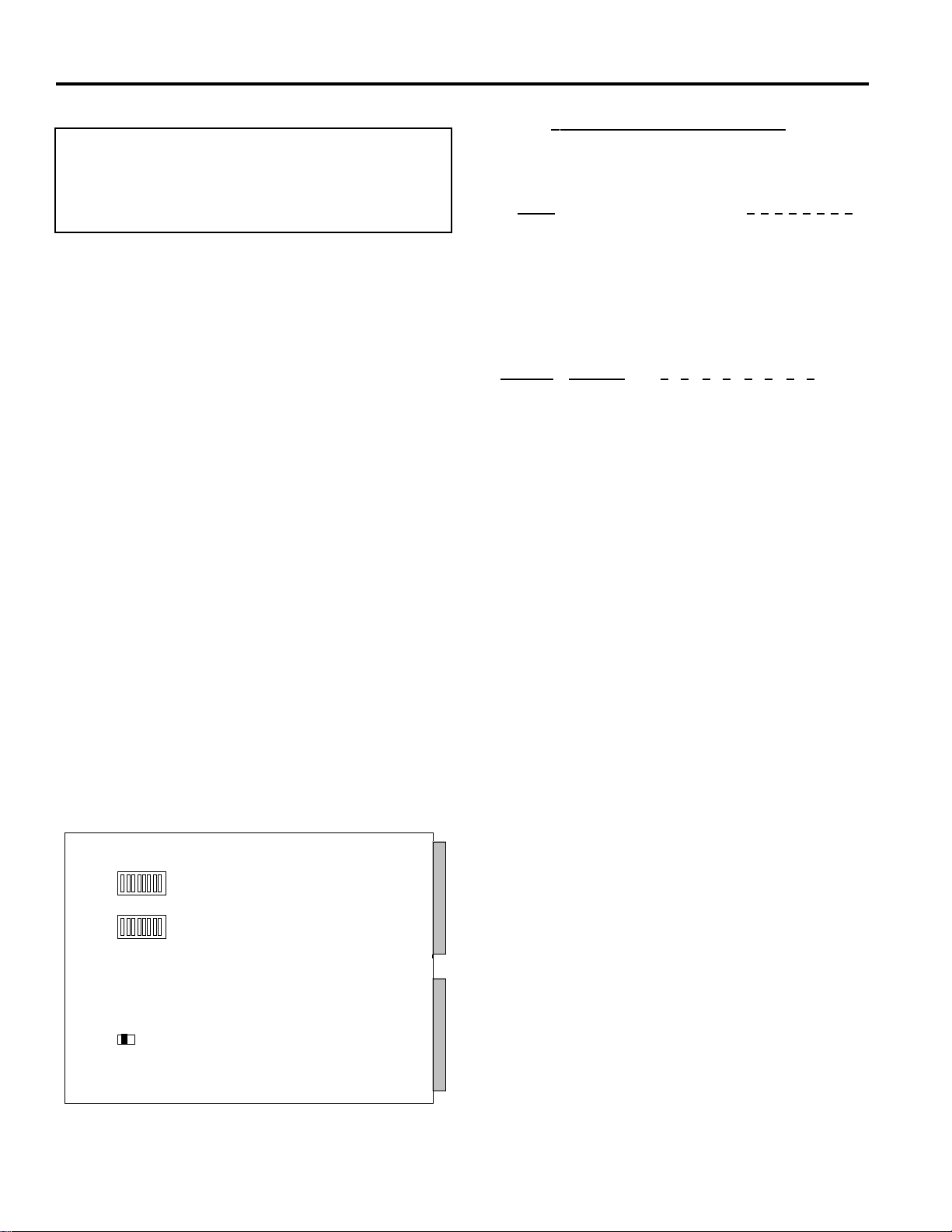

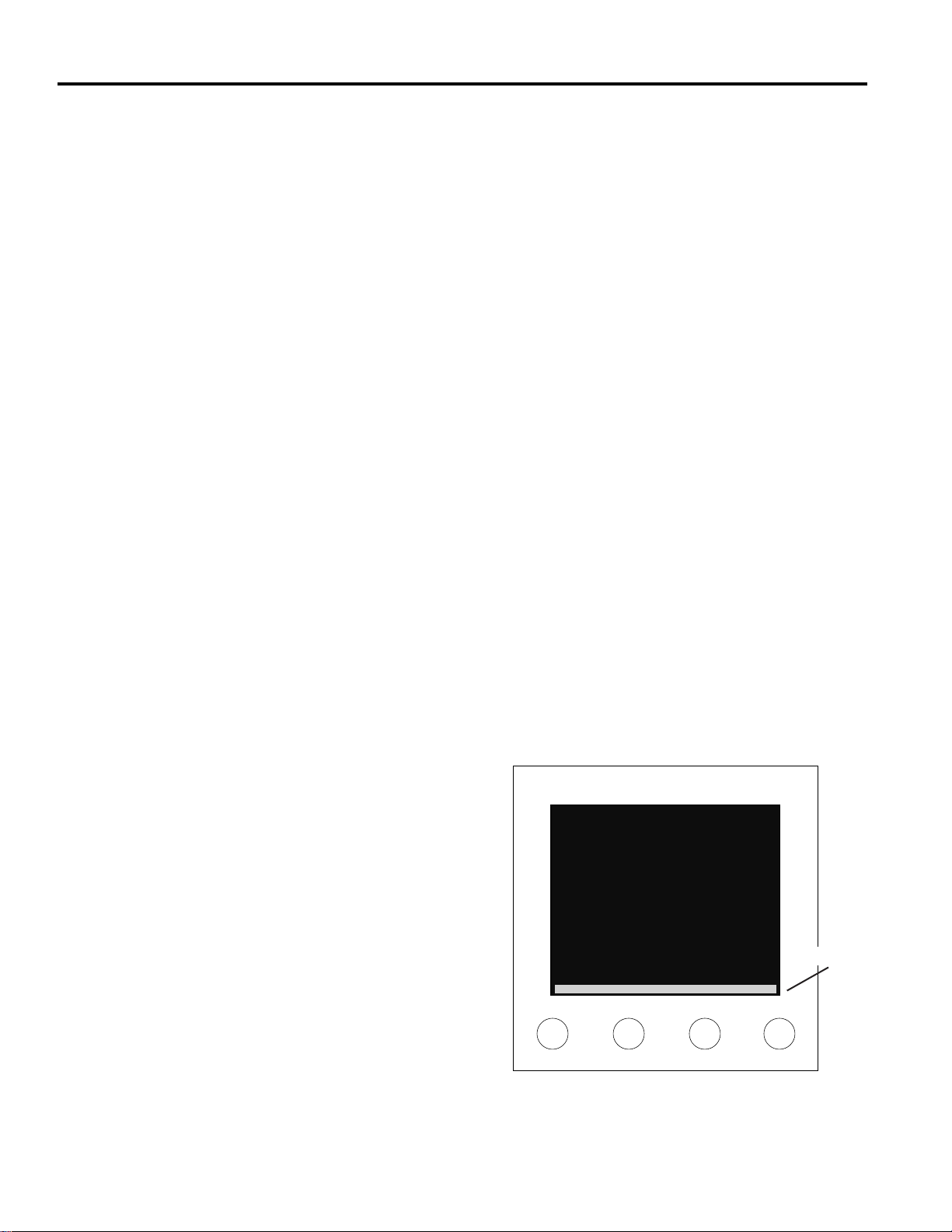

Front Panel

Front panel controls on the Video Output Module adjust the

brightness, vertical, and horizontal position for each title

displayed on each of the four video outputs. The 4-position

rotary switch on the front panel governs which output you

control. The front panel LED blinks to verify proper operation

of the 2024VOM. See Figure 20 below. Further details on

operation of these controls is provided in the Video Output

Module SETUP description, page 17.

Rear Panels

The 2024VOM-1 rear panel, as seen in Figure 21, has 16 BNC

connectors. The bottom four BNCs are video outputs while

the remaining upper three groups, each containing four BNCs,

are for video inputs from other matrix switching bays in the

system.

The 2024VOM-2 rear panel, as seen in Figure 22, has four

sections of four BNCs for video inputs from other matrix

switching bays. A fifth section of four BNCs, in the lower left

corner, is used for video outputs.

9

SYSTEM MODULES DESCRIPTION

Figure 20

Video Output Module

Front Panel Indicators and Controls

HVBAD..

Blinking LED for proper operation

4-position rotary switch

Horizontal control push button

Vertical control push button

Brightness control push button

Figure 21

Video Output Module

2024VOM-1

Rear Panel

Figure 22

Video Output Module

2024VOM-2

Rear Panel

1441141

4

O

U

T

O

U

T

141441141

4

Page 16

Master Date Time Module - 2024MDT

The 2024MDT Master Date Time Module provides looping

connection of the video input signals and insertion of system

time and date information on the video output connections.

These modules are used with dedicated inputs for dedicated

outputs, and do not perform any inter-bay switching.

The 2024MDT has four looping video inputs and four separate

video outputs with system time and date information.

Front Panel

The 2024MDT front panel controls the brightness, vertical, and

horizontal position for each title displayed on each of the four

video outputs. The 4-position rotary switch governs which

output is selected for control. The LED blinks to verify proper

operation of the 2024MDT. The front panel controls operate

identical to those on the 2024VOM module, see Figure 20 on

page 9. Further details on operation of these controls is

provided in the Video Output Module SETUP description,

page 17.

Rear Panels

The 2024MDT rear panel, shown in Figure 23, has 12 BNC

connectors and handles four separate video input channels: A,

B, C, and D. The bottom four BNC's are video outputs which

contain time and date information from the system Data Line

interface. The upper four groups of BNC's are for video inputs

from matrix switching bays and looping outputs to other video

equipment, such as VCR's. Each BNC pair in the upper groups

is an unterminated looping connection.

Video inputs to the 20204MDT module may be connected to

either of the input pair of BNC's for each input channel. If the

video is terminated in the 2024 module, and not looped to

additional equipment via the paired BNC, a 75-ohm

terminating cap must be connected to the paired input BNC.

75-ohm terminating caps are supplied for the looping BNC

connectors.

If any video input is looped to another video device, ensure

that the line is terminated properly in 75 ohms.

The video output connections from the bottom four BNC's on

each 2024 module must be terminated in 75 ohms.

Setup Switches

The 2024MDT module PCB card contains jumpers that are set

to identify the monitors that the video output is being directed

to. These are factory set for monitors one, two, three, and four.

10

SYSTEM MODULES DESCRIPTION

AABBCCDDABC

D

Figure 23

2024MDT Rear Panel

4 channels, looping inputs

4 channels, outputs

Page 17

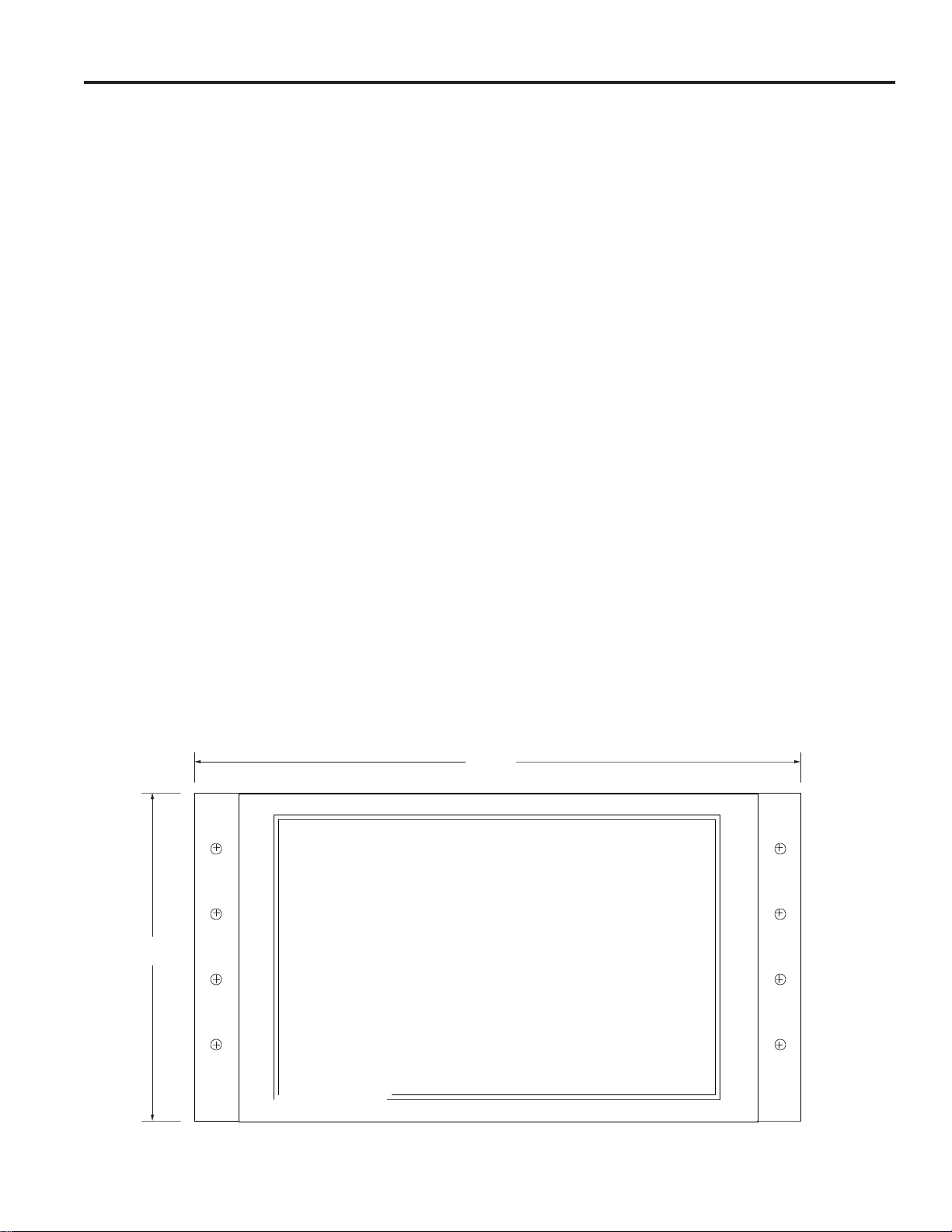

INSTALLATION

Mounting

Bays are manufactured for standard 19-inch rack mounting and

have a rack height of 10 1/2-inches, or one rack wide by 6

racks high. Bays must be installed with a minimum of 1 3/4inch clearance between each bay (one rack unit). It is the

responsibility of the installer to insure proper airflow around

the bays to provide adequate ventilation.

In multiple bay configurations, identify the various bays

carefully before mounting. In all multiple bay systems, place

the video inputs near the top of the racks.

Power Sources

System model AD1024R is configured for use with a 120VAC,

50/60 Hz primary power source. Model ADS1024RX is

configured for a 230VAC, 50/60 Hz primary power source.

All 120 V units are supplied with a pendant, 3-wire cord and

plug for mating to the primary source outlet. All 230 V units

are supplied with a Euro style IEC type inlet. A suitable

detachable cord should be connected between the IEC 320

inlet and the power source. The cord should conform to all

national and local use code requirements.

DO NOT PHYSICALLY CONNECT

EQUIPMENT TO THE POWER SOURCE UNTIL

"POWER UP"

PROCEDURES HAVE BEEN COMPLETED.

Read the section on POWERING UP (page 19) before

connecting the system to the power source, and check the

various System Configurations shown in the Appendix.

Connections

All system connections are made on the rear panels of the

system bays. Connections for several typical System

Configurations are described in pages 20 through 47. See the

Appendix for illustrations of various system connections.

Note: Make all internal jumper switch settings on the

modules before system connections are started (see SETUP,

pages 12 - 18). Be certain that all connections are properly

completed before applying power.

All video connections should be made using a good grade, 75ohm, RG-59U video cable (i.e., Belden 8241 or equivalent)

with BNC connectors.

All video outputs must be terminated in 75 ohms at the last

unit in the run. Set the intermediate units to HiZ. If the video

run is not terminated, or if it is double terminated, the resulting

picture will be of poor quality. If the run is not terminated a

brighter picture than desired will be displayed. Conversely, if

the run is double terminated, a darker picture than desired will

be displayed.

Each installation should be made in a planned and orderly

manner. The operation of each piece of equipment should be

confirmed as early as possible during the installation

procedure. It is much easier to remove a few temporary

terminations, or connections, after a confirmation check than it

is to disconnect and re-wire a large number of "permanent"

connections.

To facilitate maintenance and assist in service, all connecting

cables should be identified with source/destination numbers.

INSTALLATION

11

Figure 24 - Bay Mounting Dimensions

A D

2050 video

switcher

19"

10.5"

Page 18

SETUP

SETUP - Internal Jumper Switches

Data Buffer Module Switches

The 2010DB Data Buffer Module serves a dual purpose. First,

it sends video to the monitors and second, it filters incoming

information from the high speed LAN line.

Filtering is accomplished with two 8-position DIP switches, S2

and S3. Switch position 1 of switch S2 turns the filter "ON" or

"OFF." If S2 is set to"ON", all information passes and S3 does

not have to be set. If S2 is set to "OFF", only specified

information passes and S3 must be set. The S3 switch allows

only the necessary information to pass for that particular bay.

In the Condensed Bay configuration, or when a bay

contains 2024VOM monitor modules, the filter is set such

that all information passes. Therefore, position 1 of switch

S2 is set to ON.

For all other configurations the filter is set such that

information is filtered, thus position 1 of switch S2 is set to

OFF and S3 must be set accordingly. This applies to bays

which contain only 2016 VIM camera modules.

The Data Buffer Module also has a 2-position slide switch, S1.

S1 switches the card into either a normal mode or test mode.

S1 should be kept at the normal position.

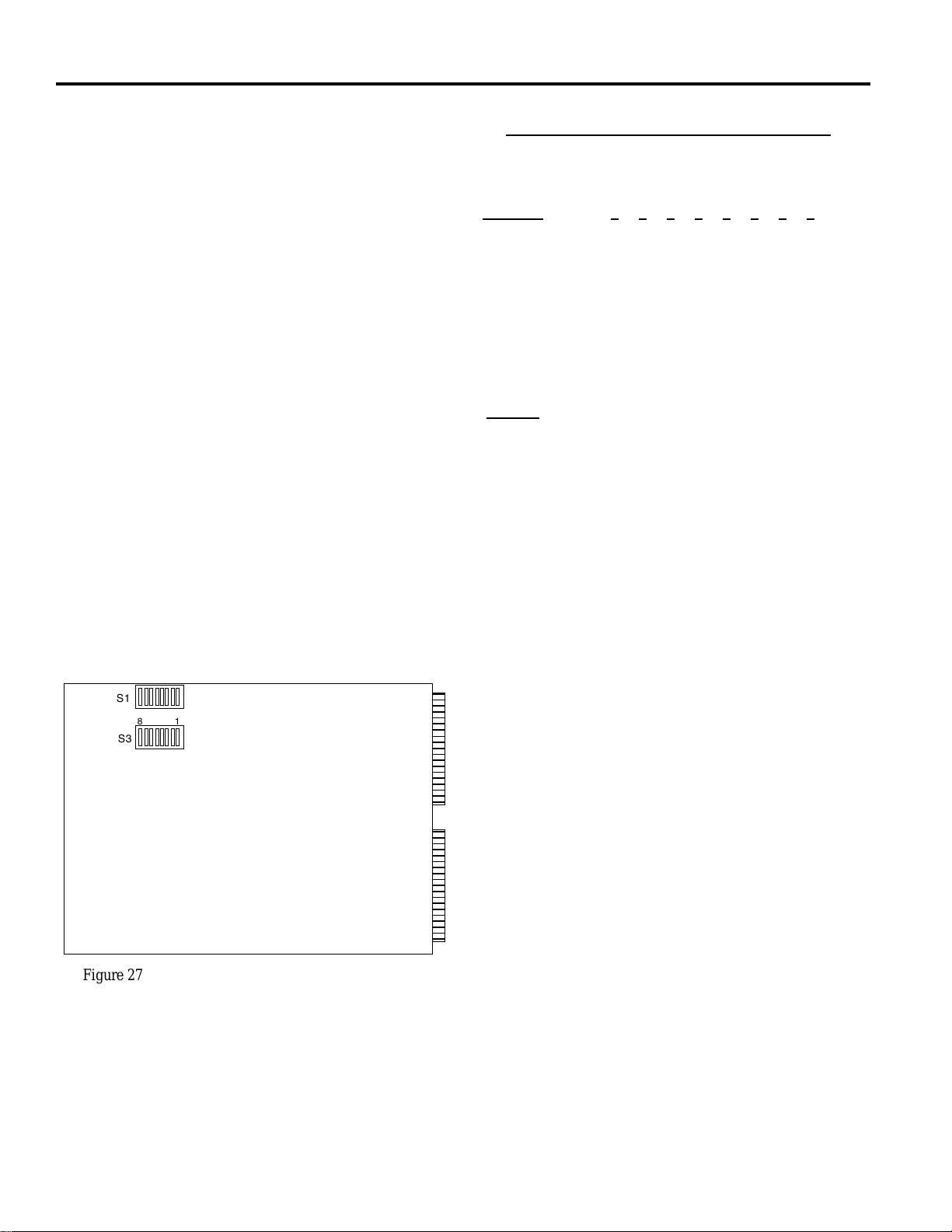

Figure 25 shows the location of these switches on the 2010DB

PCB card.

Table 1 - S2 and S3 switch settings

1=On; 0=Off; X=Don't care

Switch S2

Filter 1 2 3 4 5 6 7 8

Pass all information (S2 ON) 1 0XXXXXX

Pass only specified information (S2 OFF) 0 0XXXXXX

Note: S2 must be set to pass all information (ON) in

bays which contain 2024VOM monitor modules.

Switch S3

Camera Monitor 1 2 3 4 5 6 7 8

1-256 1-16 X X 0 0 X 0 0 X

257-512 1-16 X X 1 0 X 0 0 X

513-768 1-16 X X 0 1 X 0 0 X

769-1024 1-16 X X 1 1 X 0 0 X

1-256 17-32 X X 0 0 X 1 0 X

257-512 17-32 X X 1 0 X 1 0 X

513-768 17-32 X X 0 1 X 1 0 X

769-1024 17-32 X X 1 1 X 1 0 X

1-256 33-48 X X 0 0 X 0 1 X

257-512 33-48 X X 1 0 X 0 1 X

513-768 33-48 X X 0 1 X 0 1 X

769-1024 33-48 X X 1 1 X 0 1 X

1-256 49-64 X X 0 0 X 1 1 X

257-512 49-64 X X 1 0 X 1 1 X

513-768 49-64 X X 0 1 X 1 1 X

769-1024 49-64 X X 1 1 X 1 1 X

12

CAUTION - Due to the presence of non-insulated

components with hazardous voltages, the

following internal adjustments should be

performed by qualified service personnel only.

1

8

1

8

S3S2S1

Figure 25 - Data Buffer Card Switches

Page 19

SETUP

Video Loss Detector Data Buffer Module Switches

The 2010DBVL (Video Loss Detector Data Buffer Module) is

similar to the 2010DB, with the added capability of video loss

detection for each camera of the bay. A video loss detection

message is transmitted via the RJ45 port on the 2010DBVL

rear panel. An Alarm Contact is also provided from this port

(see connector pinouts, page 7).

The 2010DBVL is configured with a 2-position slide switch,

S1, and three 8-position DIP switches: S2, S3, and S4. S1 is

set for normal/test mode, as described for the 2010DB module.

DIP switch S2 sets the filtering mode, as described for the

2010DB, the Alarm Contact mode, and the RJ45 port baud

rate. Switch position 2 of S2 must be set to ON for the module

to function as a Video Loss Detection module.

The Alarm Contact modes are:

Alarm during Video or Sync Loss - The Alarm Contact is

closed and the ALARM LED on the 2010DBVL front

panel is illuminated when a sync or video loss is first

detected; both remain on until the loss is cleared.

Alarm during loss, plus 10 seconds - The Alarm Contact is

closed and the ALARM LED is illuminated as above, but

both remain on for 10 seconds after the loss is cleared.

Alarm at loss for 10 seconds - The Alarm Contact is closed

and the ALARM LED is illuminated as above, but both

remain on for only 10 seconds.

Alarm at loss for 20 seconds - The Alarm Contact is closed

and the ALARM LED is illuminated as above, but both

remain on for only 20 seconds.

The baud rate setting of DIP switch S2 configures the RJ45

port on the 2010DBVL for the desired communications rate.

DIP switch S3 must be set to the camera and monitor group

numbers assigned to the switching bay modules.

DIP switch S4 sets the type of communication used via the

RJ45 port and enables or disables the 2010DBVL front panel

LED's. This port may be configured for RS-232, RS-422, or

RS-485 communications.

The following tables show the switch position settings for DIP

switches S2, S3, and S4. Figure 26 shows the location of these

DIP switches on the 2010DBVL PCB card.

Table 2 - S2, S3, and S4 switch settings

1=On; 0=Off; X=Don't care

DIP Switch S2

Function 2 3 6

Video Loss Enabled 1 X X

Video Loss Disabled 0 X X

1

Pass all information 1

Pass only specified information 0

4 5

Alarm during Video or Sync loss 0 0

Alarm during loss, plus 10 seconds 1 0

Alarm at loss for 10 seconds 0 1

Alarm at loss for 20 seconds 1 1

7 8

1200 Baud Rate 0 0

2400 Baud Rate 1 0

4800 Baud Rate 0 1

9600 Baud Rate 1 1

DIP Switch S3

Camera Monitor 1 2 3 4 5 6 7 8

1-256 1-16 X X 0 0 X 0 0 X

257-512 1-16 X X 1 0 X 0 0 X

513-768 1-16 X X 0 1 X 0 0 X

769-1024 1-16 X X 1 1 X 0 0 X

1-256 17-32 X X 0 0 X 1 0 X

257-512 17-32 X X 1 0 X 1 0 X

513-768 17-32 X X 0 1 X 1 0 X

769-1024 17-32 X X 1 1 X 1 0 X

1-256 33-48 X X 0 0 X 0 1 X

257-512 33-48 X X 1 0 X 0 1 X

513-768 33-48 X X 0 1 X 0 1 X

769-1024 33-48 X X 1 1 X 0 1 X

1-256 49-64 X X 0 0 X 1 1 X

257-512 49-64 X X 1 0 X 1 1 X

513-768 49-64 X X 0 1 X 1 1 X

769-1024 49-64 X X 1 1 X 1 1 X

DIP Switch S4

Function 1 2 3 4 5 6 7

RS-232 1 1 0 0 0 0 0

RS-422 0 0 1 1 0 0 0

RS-485 0 0 1 1 1 1 0

8

Front Panel LED's ON 1

Front Panel LED's OFF 0

13

181

8

S3

S2

1

8

S4

S1

Figure 26 - DBVL Data Buffer Card Switches

Page 20

SETUP

Video Input Module Switches

The 2016AVIM (Video Input Module) performs the actual

video switch. Each module can switch any one of 16 video

inputs to any video output, or multiple combinations of video

outputs, up to 16.

The 2016A Video Input Module must be set to the cameras and

monitors it is to respond to. There are two 8-position dip

switches. DIP switch S1 is used to set all field configurations.

The eight position dip switch S1, located on the circuit board,

must be set to identify the camera and monitor group. The first

two switches select one of four groups of 16 monitors and the

last six select one of 64 groups of 16 cameras. Switch settings

are shown in Table 3.

The monitor group selection is independent of the camera

group selection. Yet both monitor and camera group must be

selected correctly depending on the particular slot the card is

being placed in. Note: The silkscreen on the board clearly

shows the correct dip switch to use. The word "CAM GRP" is

screened adjacent to the correct dip switch.

The DIP switch S3 is not used in this module.

Table 3 - S1 Camera and Monitor Identification

1=On; 0=Off; X=Don't care

Switch Positions

Monitors 1 2 3 4 5 6 7 8

1- 16 0 0 XXXXXX

17- 32 0 1 XXXXXX

33- 48 1 0 XXXXXX

49 - 64 1 1 XXXXXX

65- 80 0 0 XXXXXX

81- 96 0 1 XXXXXX

97 - 112 1 0 XXXXXX

113 - 128 1 1 XXXXXX

Camera

1-16 X X 000000

17-32 X X 000001

33-48 X X 000010

49-64 X X 000011

65-80 X X 000100

81-96 X X 000101

97-112 X X 000110

113-128 X X 000111

129-144 X X 001000

145-160 X X 001001

161-176 X X 001010

177-192 X X 001011

14

81

S3

S1

Figure 27 - Video Input Module Card Jumper Switches

Page 21

Table 3 - S1 Camera and Monitor Identification

(continued)

Switch Positions

Camera 1 2 3 4 5 6 7 8

193-208 X X 001100

209-224 X X 001101

225-240 X X 001110

241-256 X X 001111

257-272 X X 010000

273-288 X X 010001

289-304 X X 010010

305-320 X X 010011

321-336 X X 010100

337-352 X X 010101

353-368 X X 010110

369-384 X X 010111

385-400 X X 011000

401-416 X X 011001

417-432 X X 011010

433-448 X X 011011

449-464 X X 011100

465-480 X X 011101

481-496 X X 011110

497-512 X X 011111

513-528 X X 100000

529-544 X X 100001

545-560 X X 100010

561-576 X X 100011

577-592 X X 100100

593-608 X X 100101

609-624 X X 100110

625-640 X X 100111

641-656 X X 101000

657-672 X X 101001

673-688 X X 101010

689-704 X X 101011

705-720 X X 101100

721-736 X X 101101

737-752 X X 101110

753-768 X X 101111

769-784 X X 110000

785-800 X X 110001

801-816 X X 110010

817-832 X X 110011

833-848 X X 110100

849-864 X X 110101

865-880 X X 110110

881-896 X X 110111

897-912 X X 111000

913-928 X X 111001

929-944 X X 111010

945-960 X X 111011

961-976 X X 111100

977-992 X X 111101

993-1008 X X 111110

1009-1024 X X 111111

15

SETUP

Page 22

SETUP

Video Output Module Switches

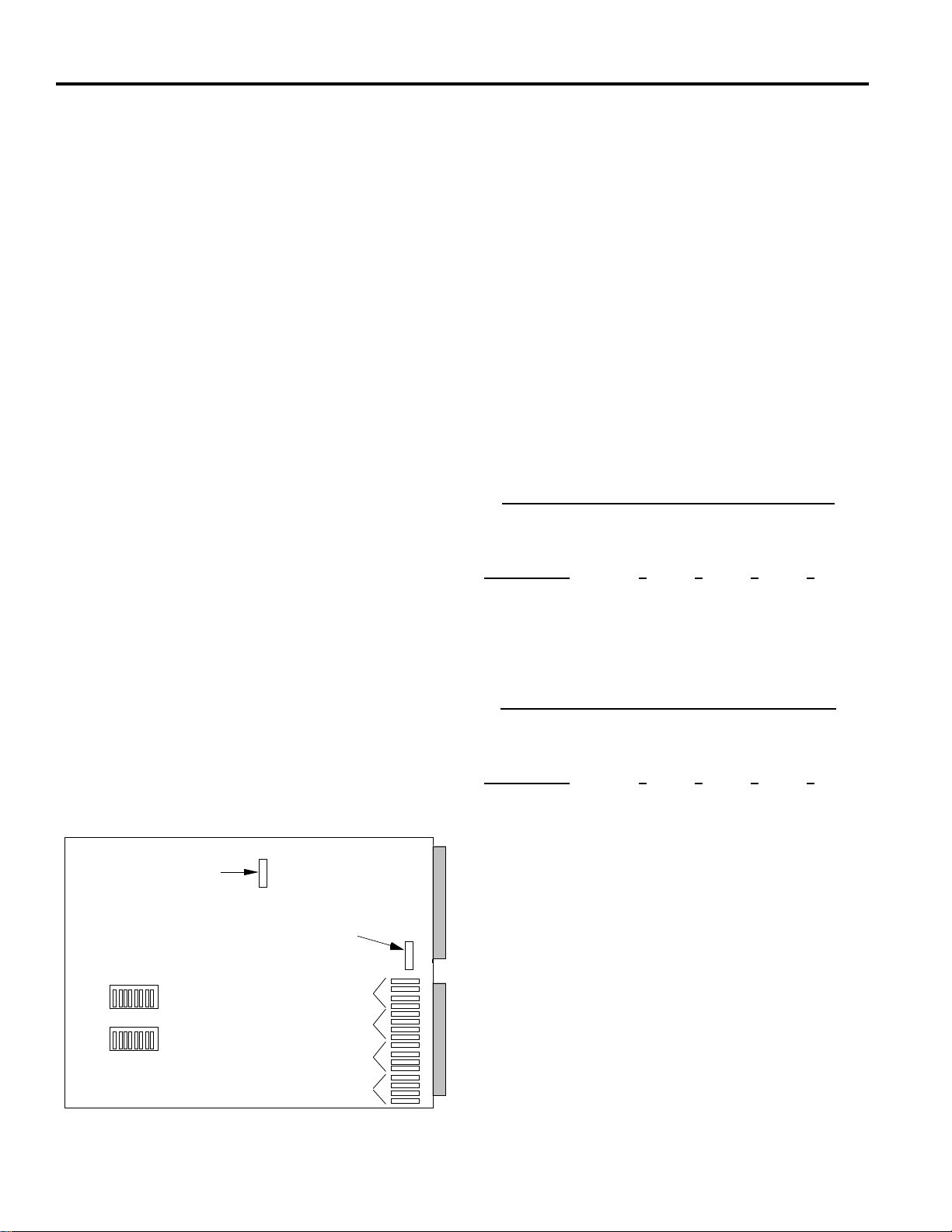

The 2024VOM (Video Output Module) adds character

information in the form of titles and time and date to switched

video from 2016AVIM modules. Each 2024VOM card

contains 2-pin jumpers and one 8-position DIP switch (see

Figure 28). These are set with the module removed from the

bay.

Four 2-pin jumpers for setting monitor identification are set at

the back of the card (end with gold-plated connections). Each

card can be set for monitors:

one, two, three, and four; or

five, six, seven, and eight; or

nine, ten, eleven, and twelve; or

thirteen, fourteen, fifteen, and sixteen.

There is no other variations, only the four types described

above.

Note: The silkscreen labeling on the VOM board shows which

jumper is for which monitor; these are labeled M1 through

M16. When setting monitors over sixteen, subtract multiples

of sixteen from the monitor number you want to set. For

example, to set monitors 33-36, subtract 32 to obtain monitors

one through four (33-32=1; 35-32=3, etc).

For selection of video type (Phase Adjusted Line, PAL or

National Television Systems Committee, NTSC), locate the

2-position jumper terminal near the center edge of the card.

Position the plastic 2-pin jumper to the appropriate location.

For selection of bay configuration (Standard or Condensed),

locate the 2-position jumper terminal near the center of the two

gold connectors. All bays are configured with the jumper

position set to "standard bay". In Condensed Bays, the jumper

is set to "standard bay" for cards corresponding to monitors 17

to 32, while the jumper is set to "condensed (or split) bay" for

cards corresponding to monitors 1 to 16.

Note: The bay configuration switch was implemented on Rev

"B" boards. Before Rev "B" boards, resistors were placed on

the solder side of the board (Condensed Bays only).

The 8-position DIP switch S2, located on the circuit board,

must be set to identify the video inputs and outputs the module

must respond to. Switch settings are dependent on the slot

location in the matrix bay as well as which matrix bay the card

is located. Switch settings are shown in Tables 4a, 4b, and 5.

Table 4 represents the first four switches of S2, which

identifies video input. If the video output is located in a matrix

switching bay that includes video input cards its video input

would be considered internal. If the video output card is

located in a matrix switching bay which contained only output

cards its video inputs would be considered external.

Table 5, on page 17, identifies which video outputs the card

will be controlling.

Table 4a - S2 Internal Video Input Identification

1=On 0=Off

Switch Positions

Video Inputs 1 2 3 4

1 to 256 0000

257 to 512 1000

513 to 768 0100

769 to 1024 0010

Table 4b - S2 External Video Input Identification

1=On 0=Off

Switch Positions

Video Inputs 1 2 3 4

1 to 256 1000

257 to 512 0100

513 to 768 0010

769 to 1024 0001

Note: Table 4a is used when the 2024VOM is located in a

matrix switching bay which includes 2016AVIM. Table 4b is

used when the 2024VOM is located in a matrix switching bay

which does not include 2016AVIM modules. In both

instances, the Filter DIP switch S2 on the 2010DB/2010DBVL

Data Buffer Module must be set to pass all data (see page 12).

DIP Switch S1 and slide Switch S3 are not used on the

2024VOM card.

NTSC/PAL

jumper

Condensed or

Standard Bay

Monitors 1 - 4

Monitors 5 - 8

Monitors 9 -12

Monitors 13-16

181

8

S2

S1

16

Figure 28 - VOM Card Jumper Switches

Page 23

Table 5 - S2 Video Output Identification

1=On 0=Off

Switch Positions

Video Output 5 6 7 8

1 to 4 0000

5 to 8 1000

9 to 12 0100

13 to 16 1100

17 to 20 0010

21 to 24 1010

25 to 28 0110

29 to 32 1110

33 to 36 0001

37 to 40 1001

41 to 44 0101

45 to 48 1101

49 to 52 0011

53 to 56 1011

57 to 60 0111

61 to 64 1111

Video Output Module - Horizontal, Vertical, and

Brightness Adjustment

The 2024VOM has four video outputs each with title

information displayed on the video picture. The title

information on the screen is adjustable for horizontal and

vertical position. The brightness of the characters is also

adjustable. The rotary switch located on the front panel of

each output module selects which output will be adjusted. The

''H", ''V" and ''B" pushbuttons are used to adjust the desired

setting. See Figure 29 for location of these controls.

The video output title to be controlled is selected from the

rotary switch labeled ''A . . D". To select the first video output,

turn the rotary switch to position ''A". To select the second

video output for title adjustment, move the rotary switch

clockwise one position. Proceed in this manner for the final

two video outputs.

After selecting one of the four outputs, press the ''H"

pushbutton. The title shifts to the right until the pushbutton is

released.

Note: If the pushbutton is not released, the title will reach an

end point and return to the left-most position and begin to shift

to the right again.

After the proper horizontal position has been selected, depress

the ''V" pushbutton. The title will shift downward until the

pushbutton is released. Note: If the pushbutton is not

released, the title will reach the bottom of the screen, as

defined by the vertical sync, move to the top of the screen, and

begin to shift down again.

After the proper horizontal and vertical positions have been

selected, proceed to the brightness control. The characters of

the title are white with a black border. This enhances visibility

under varying light conditions. The brightness control

provides eight steps of white levels to change the characters

from white to black. To change the brightness of the titles,

depress the ''B" pushbutton. The title steps through each level

until the pushbutton is released.

The video output rotary switch may be placed to any position

when title adjustment is completed.

17

SETUP

HVBAD..

Blinking LED for proper operation

4-position rotary switch

Horizontal control push button

Vertical control push button

Brightness control push button

Figure 29 - Video Output Module Front Panel

Page 24

Power Supply Set Up - Vertical Phase Adjustment

The matrix switching bays are designed as vertical interval

switches, thus giving the matrix switching bay the ability to

switch between properly phased video inputs without

producing a vertical roll, or a black bar, between each video

switch. Use of this feature allows vertical interval switching to

be controlled by the AC Line (Line Locked ), External Vertical

Drive (Generator Locked), or Composite video input.

1. AC LINE: The most common form of synchronization is

AC line lock of the vertical switching point. To use this

feature, switch the Sync Reference Selection switch to AC

LINE (see Figure 1 on page 2). This will use the AC (either 60

or 50 Hz) line to determine the vertical timing. If all video

inputs use the same phase of AC power to determine the

vertical timing, no roll will appear.

As an aid to the installer, a switch on the Power Supply

Module is available to check the vertical switch location for

each video input. This function is initiated when the SET

UP/NORMAL switch is selected to the SET UP position.

A. Connect a monitor to the top most BNC of the 2010DB-00

labeled Test/Expansion Only, or the first monitor output of

any level VOM. If the monitor card is present, connect to

the video output module monitor 1. If not, use the Data

Buffer output #1.

B. From an external keyboard call input 1 to output 1.

C. Place the SET UP/NORMAL switch to the SET UP

position. This implements the phase adjustment procedure.

Note: The Sync Test On/Off LED will be blinking when

the sync test switch is in the SETUP position.

Notice that the alignment bar, displayed on output 1, shows the

location of the vertical switch with respect to the picture.

D. The phase adjustment potentiometer, accessed thru the hole

in the front panel of the Power Supply, adjusts the phase of

the vertical interval synchronization pulse for the switcher

with respect to the selected reference.

E. Adjust the position of the bar with a TV alignment tool, or

equivalent, by turning the phase potentiometer, until the

line is located as seen in Figure 30. The line should be

visible on the screen.

Once the alignment bar is set, no further adjustment to the

potentiometer is necessary.

F. Select the second video input in the system. If the

horizontal bar is not in the same location as seen in Figure

30, adjust the sync location on the "video device" (i.e.,

video camera) until the horizontal bar is located towards

the bottom of the screen. If this is not possible, and the

alignment bar is located in a different position than it was

in the previous camera, you will experience camera roll

during switching operations to that camera.

G. Repeat this for all video inputs to the system.

Note: Before adjusting all of the video inputs, quickly scan

all inputs to see if only a few are out of phase and adjust

accordingly (input one may be the only oddball!).

H. Once all cameras have been synchronized, place the SET

UP/NORMAL switch to the NORMAL position.

If multiple matrix switching bays are used, repeat steps A - H

for each bay. The sync/test output for these bays is the top

most output BNC located on each 2010DB-XX rear panel at

the first monitor of the bay, i.e., monitor 17-32, etc.

2. EXT V-DRIVE: If an external generator is used to control

the vertical switching point, switch the Sync Reference

Selection switch to EXT V-DRIVE (external vertical drive).

For proper operation, the output voltage of the generator

should not exceed 5V peak-to-peak (p-p). Connect the drive

output from the generator to the EXT SYNC IN BNC located

on the 2010PS rear panel. Connect a 75-ohm terminator to the

EXT SYNC OUT BNC. If other bays are used, loop the EXT

SYNC from input to output for all bays and terminate the last

bay EXT SYNC OUT BNC in 75-ohms.

3. EXT CAM: If composite video is used to control the

vertical switching point, switch the Sync Reference Selection

switch to EXT CAM (external camera). For proper operation,

the composite sync signal is specified at 1.1V p-p. Connect

the composite sync to the EXT SYNC IN BNC located on the

2010PS rear panel. Connect a 75-ohm terminator to the EXT

SYNC OUT BNC. If other bays are used, loop the EXT

SYNC from input to output for all bays and terminate the last

bay EXT SYNC OUT BNC in 75-ohms.

18

Figure 30 - Placement of Setup Alignment Bar

Alignment bar should be visible on the monitor and not in the

vertical sync.

alignment bar

Monitor 1

SETUP

Page 25

POWERING UP

The system may be brought on line after:

- The CPU has been installed and connected.

- A video input has been connected.

- A monitor has been connected for viewing the output.

- All lines have been properly terminated.

- One keyboard (or external computer) has been connected for

control.

- Power has been connected to the equipment, one bay at a

time, ending with the CPU.

Powering the Matrix Bay

1. Unscrew the two thumbscrews located at the top corners of

front panel of each matrix switching bay.

2. Remove the front panel by first slowly pulling the top of the

panel towards the front, then lifting the panel up.

Note: DO NOT remove the foam material attached to the

front panel.

3. Verify that the unit is turned off. The unit is turned off by

pressing the bottom of the front panel power On/Off switch.

4. Power is supplied via a pendant cord and plug. Connect the

pendant cord to the required voltage input:

AD1024R 120VAC, 50/60 Hz

ADS1024RX 230VAC, 50/60 Hz

5. To turn the unit on, press the top of the front panel power

On/Off switch.

Replace the front panel only after all setup adjustments have

been made related to powering up instructions (Power Supply

Module and Video Output Module, prior pages).

6. To replace the front panel, slip the bottom of the panel into

the slot at the bottom of the bay. Push the top of the panel

towards the bay and tighten the two corner thumb screws.

POWER UP

19

Page 26

SYSTEM CONFIGURATIONS

SYSTEM CONFIGURATIONS

The following sections of this manual are organized specific to

the system level to be installed. A level is defined as 16 video

outputs, and may consist of one to several bays. Level 1 is for

a maximum of 16 outputs, Level 2 is for 32 outputs, and so on

up to Level 8 which is for a maximum of 128 outputs.

System bays are supplied in the following two configurations:

Standard (Model 2010R) and Condensed (Model 2020R).

References to "Right" or "Left" in the following

instructions apply to the Bays as viewed from the REAR.

LEVEL 1 SYSTEMS

Level 1 systems can have a maximum of five 2010R Standard

matrix switching bays that each contain the 2010PS Power

Supply Module and a 2010DB or 2010DBVL Data Buffer

Module. Level 1 Systems can consist of a maximum of

AD1024 video inputs and a maximum of 16 video outputs (15

outputs if the 2010DBVL module is used).

For a Level 1 system with Video Loss Detection capability, the

video output for monitor 16 is replaced by the Video Loss

Detection function in the 2010DBVL Module. Since each

2010DBVL can detect video losses for a maximum of 256

cameras, an additional 2010DBVL Module is required in each

camera bay, for each block of 256 cameras. The first camera

bay would use a 2010DBVL-11, the second bay a 2010DBVL21, the third bay a 2010DBVL-31 and the fourth bay a

2010DBVL-41. In a multi-bay system where the last bay

contains both camera modules and monitor modules, that bay

would use a 2010DBVL-00 module. In a five-bay system, the

fifth bay is exclusively a monitor bay and would require the

2010DB-00 Module, not the 2010DBVL-00.

LEVEL 1 - 256 X 16, One Bay System with no Titles

A one bay, Level 1 system, without VOM modules for video

titles, allows a maximum of 256 video inputs switched to a

maximum of 16 video outputs.

This system does not contain 2024VOM modules.

From the rear of the bay, the modules are installed at the

factory in the following manner; the far right module is the

2010PS; the next module is the 2010DB-01 with 16 BNCs for

untitled video outputs, followed by one to sixteen 2016AVIM1 modules. Smaller matrices, such as those ordered with future

expansion in mind, may have fewer modules installed.

IDENTIFY THESE MODULES CAREFULLY

BEFORE PROCEEDING.

Data Interconnect: Connect a 75-ohm coaxial cable from the

DATA LINE-1 output on the AD1024 CPU, to the Data IN

BNC on the 2010PS rear panel. Connect a 75-ohm BNC

terminator (supplied with the CPU) to the Data Out BNC on

Power Supply rear panel.

Video Input Connections: The 2016AVIM is identified with

the camera input icon .

The starting camera

number, for the particular

VIM, is located at the top

BNC. Each 2016AVIM-1 includes 16 terminated BNCs for

video input connections. The first 2016AVIM-1, located

immediately to the left of the 2010DB-01, is for video inputs 1

- 16, the second 2016AVIM-1 module is for inputs 17 - 32, etc.

In succession, connect the video inputs to each 2016AVIM-1

module, top to bottom. Each VIM will accept 16 video inputs.

Continue until all inputs are connected to the system. Unused

video inputs, on the VIM, do not require any external

connection or termination, and may be left open. See Figure

16, Video Input Module, page 8.

Video Output Connections with No Titles: Each 2010DB-01

in the system has 16 BNCs. The top most BNC corresponds to

video output 1 and the bottom video output corresponds to

number 16. Connect the video outputs to any device that

accepts standard video such as monitors or video recorders.

See Figure 4, 2010DB-01 Rear Panel with 16 BNCs, page 4.

In the Appendix, see Figure A1, 256 X 16, One Bay System

with No Titles.

20

Page 27

LEVEL 1 - 256 X 15, One Bay System with Video Loss

Detection

A one bay, Level 1 system, with video loss detection and

without video titles, allows a maximum of 256 video inputs

switched to a maximum of 15 video outputs.

This system is the same configuration of modules as the

LEVEL 1 - 256 X 16 system except that the 2010DBVL-01

Video Loss Detection Data Buffer module is installed in place

of the 2010DB-01 module. The connections are as described

for that system configuration, except that only 15 BNCs are

provided for video outputs.

See Appendix Figure A18, 256 X 15, One Bay System with

Video Loss Detection Module.

LEVEL 1 - 192 X 16, One Bay System

A one bay, Level 1 system, with 2024VOM modules for video

titles, allows a maximum of 192 video inputs switched to a

maximum of 16 video outputs.

From the rear of the bay, the modules are installed at the

factory in the following manner; the far right module is the

2010PS; the next module is the 2010DB-00, followed by

twelve 2016AVIM-1 modules, and four 2024VOM-1 modules.

Smaller matrices, such as those ordered with future expansion

in mind, may have fewer modules installed.

IDENTIFY THESE MODULES CAREFULLY

BEFORE PROCEEDING.

Data Interconnect: Connect a 75-ohm coaxial cable from the

DATALINE-1 output on the AD1024 CPU to the DATA IN

BNC on the 2010PS rear panel. Connect a 75-ohm BNC

terminator (supplied with the CPU) to the Data Out BNC on

the Power Supply rear panel.

Video Input Connections: The 2016AVIM is identified with

the video input icon.

The starting video input number, for the particular VIM, is

located at the top BNC. Each 2016AVIM-1 includes 16

terminated BNCs for video input connections. The first

2016AVIM-1, located immediately to the left of the 2010DB00, is for video inputs 1-16, the second 2016AVIM-1 module is

for inputs 17- 32, etc.

In succession, connect the video inputs to each 2016AVIM-1

module, top to bottom. Each VIM will accept 16 video inputs.

Continue until all inputs are connected to the system. Unused

video inputs, on the VIM, do not require any external

connection or termination, and may be left open. See Figure

16, Video Input Module, page 8.

Video Output Connections: Each 2024VOM-1 has a rear

panel with 16 BNCs. For single bay systems, only the bottom

four BNCs are used for video output connections. The left

most module is assigned to outputs 1 - 4. Moving left to right,

the next VOM module is assigned to outputs 5 - 8, etc. (The

modules are numbered 1 - 4, 5 - 8, etc.) Connect the video

outputs to any device that accepts standard video such as

monitors or video recorders. See Figure 21, Video Output

Module, page 9.

In the Appendix, see Figure A2, 192 X 16, One Bay System.

SYSTEM CONFIGURATIONS

21

Page 28

LEVEL 1 - 448 X 16, Two Bay System

A two bay, Level 1 system allows a maximum of 448 video

inputs switched to a maximum 16 video outputs. Bay one

consists of the first 256 video inputs. Bay two consists of the

remaining 192 video inputs and four video output modules.

From the rear of bay one, the modules are installed at the

factory in the following manner; the far right module is the

2010PS, the next module is the 2010DB-11 with 16 BNCs for

connection to the 2024VOM-1 modules in bay two, followed

by sixteen 2016AVIM-1 modules for inputs 1 - 256.

From the rear of bay two, the modules are installed at the

factory in the following manner; the far right module is the

2010PS, the next module is the 2010DB-00, followed by

twelve 2016AVIM-1 modules for inputs 257 - 448, and four

2024VOM-1 modules for outputs 1 - 16.

Smaller matrices, such as those ordered with future expansion

in mind, may have fewer modules installed.

IDENTIFY THESE MODULES CAREFULLY

BEFORE PROCEEDING.

Data Interconnect: Connect a 75-ohm coaxial cable from the

DATALINE-1 output on the AD1024 CPU to the DATA IN

BNC of Bay 1. Connect a 75-ohm coaxial cable from the

DATA OUT BNC of bay 1 to the DATA IN BNC 2010PS rear

panel of bay 2. Connect a 75 ohm BNC terminator (supplied

with the CPU) to the Data Out BNC of Bay 2.

Video Interconnections: The 16 video outputs from bay 1,

located on the rear panel of the 2010DB-11, are grouped by

fours and identified by the icon . Each 2024VOM-1 is

similarly grouped with three sections of four BNCs, with

identifying icons. See Figure 5, Data Buffer, page 4.

Using high grade RG-59U video cables, connect the topmost

BNC from bay 1 on the 2010DB-11 panel, numbered 1, to the

topmost input BNC, labeled 1 on the 2024VOM-1 in bay 2, for

output 1, matching icon to icon . See Appendix Figure

A18, Video Interconnections, for illustration of these

connections.

Continue in this manner until 1-4 of the 2010DB-11 panel are

connected to inputs 1-4 of the first 2024VOM-1. Proceed to

the next group of four BNCs on the 2010DB-11 panel.

Connect these four to the second 2024VOM-1 for outputs 5-8.

Continue in this manner until all 16 connections of the

2010DB-11 panel are connected to all of the 2024VOM-1

modules. If there are less than four 2024VOM modules in the

system, leave the remaining BNCs on 2010DB-11 of bay 1

open.

Video Input Connections: The 2016AVIM is identified with

the camera input icon.

The starting camera number for the particular VIM is located

at the top BNC. Each 2016AVIM-1 includes 16 terminated

BNCs for video input connections. The first 2016AVIM

module is for video inputs 1 - 16, the second VIM module is

for inputs 17 - 32, etc.

In succession, connect the video inputs to each 2016AVIM-1

module, top to bottom. Each VIM will accept 16 video inputs.

Continue until all inputs are connected to the system. Unused

video inputs, on the VIM, do not require any external

connection or termination, and may be left open. See Figure

16, Video Input Modules, page 8.

Video Output Connections: Each 2024VOM-1 has a rear

panel with 16 BNCs, only the bottom four BNCs are used for

video output connections. The left most module is assigned to

outputs 1 - 4. Moving left to right, the next VOM module is

assigned to outputs 5 - 8, etc. (The modules are numbered 1 4, 5 - 8, etc.) Connect the video outputs to any device that

accepts standard video such as monitors or video recorders.

See Figure 21, Video Output Module, page 9.

In the Appendix, see Figure A3, 448 X 16, Two Bay System.

LEVEL 1 - 448 X 16, Two Bay System with Video Loss

Detection

A two bay, Level 1 system, with video loss detection, allows a

maximum of 448 video inputs switched to a maximum of 15

video outputs.

This system is the same configuration of modules as the

LEVEL 1 - 448 X 16 system above, except that the

2010DBVL-11 module is installed in place of the 2010DB-11

module in bay one and the 2010DBVL-00 module is installed

in place of the 2010DB-00 module in bay two. The

connections are as described for the above system

configuration, except that only 15 BNCs are provided for video

outputs.

Since two 2010DBVL modules are used, this configuration

requires the use of the 1981 Port Expander for connection to

the ADAD1024 CPU.

See Appendix Figure A21, 256 X 15, Two Bay System with

Video Loss Detection Module.

SYSTEM CONFIGURATIONS

22

Page 29

LEVEL 1 - 704 X 16, Three Bay System

A three bay, Level 1 system allows a maximum of 704 video

inputs switched to a maximum 16 video outputs. Bays one and

two consist of 256 video inputs and bay three consists of 192

video inputs and 16 video outputs.

From the rear of bay one, the modules are installed at the

factory in the following manner; the far right module is the

2010PS, the next module is the 2010DB-11 with 16 BNCs for

connection to the 2024VOM-1 modules in bay three, followed

by sixteen 2016AVIM-1 modules for inputs 1 - 256.

From the rear of bay two, the modules are installed at the

factory in the following manner; the far right module is the

2010PS, the next module is the 2010DB-21 with 16 BNCs for

connection to the 2024VOM-1 modules in bay three, followed

by sixteen 2016AVIM-1 modules for inputs 257 - 512.

From the rear of bay three, the modules are installed at the

factory in the following manner; the far right module is the

2010PS, the next module is the 2010DB-00, followed by

twelve 2016AVIM-1 modules for inputs 513 - 704 and four

2024VOM-1 modules for outputs 1-16.

Smaller matrices, such as those ordered with future expansion

in mind, may have fewer modules installed.

IDENTIFY THESE MODULES CAREFULLY

BEFORE PROCEEDING.

Data Interconnect: See Level 1 - 448 X 16, Two Bay System

and connect all bays in a similar manner.

Video Interconnections: The 16 video outputs from bay 1

and bay 2, located on the rear panel of the 2010DB-11 ,

and 2010DB-21 , are grouped by fours.

Each 2024VOM-1 is similarly grouped with three sections of

four BNCs, with identifying icons. A fourth section of four

BNCs is used for video output connections. See Figure 21,

Video Output Module, page 9.

Using high grade RG-59U video cables, connect the topmost

BNC from bay 1 on the 2010DB-11 panel, numbered 1, to the

top-most input BNC, labeled 1 on the 2024VOM-1 in bay 3,

for output 1, matching icon to icon. Continue in this

manner until BNCs 1-4 of the 2010DB-11 panel are connected

to inputs 1-4 of the first 2024VOM-1. Proceed to the next

group of four BNCs on the 2010DB-11 of the first bay.

Connect these four to the second 2024VOM -1 for outputs 5 -

8. Continue in this manner until all 16 connections of the

2010DB-11 panel are connected to all of the 2024VOM-1

modules.

Connect bay 2 in a similar manner to the 2024VOM-1 modules

of bay 3 for video outputs 1-16, matching icon to icon.

See Appendix Figure A18, Video Interconnections, for

illustration of these connections.

If there are less than four 2024VOM-1s in the system, the

remaining BNCs on the 2010DB-XX do not require any

connection.

Video Input Connections: See Level 1 - 448 X 16, Two Bay

System and connect in a similar manner.

Video Output Connections: See Level 1 - 448 X 16, Two

Bay System and connect in a similar manner.

In the Appendix, see Figure A4, 704 X 16, Three Bay System.

SYSTEM CONFIGURATIONS

23

Page 30

SYSTEM CONFIGURATIONS

LEVEL 1 - 960 X 16, Four Bay System

A four bay, Level 1 system allows a maximum of 960 video

inputs switched to a maximum 16 video outputs. Bays one,

two, and three each consist of 256 video inputs. Bay four

consists of 192 video inputs and 16 video outputs.

From the rear of bay one, the modules are installed at the

factory in the following manner; the far right module is the

2010PS, the next module is the 2010DB-11 with 16 BNCs for

connection to the 2024VOM-1 modules in bay four, followed

by sixteen 2016AVIM-1 modules, inputs 1 - 256.

From the rear of bay two, the modules are installed at the

factory in the following manner; the far right module is the

2010PS, the next module is the 2010DB-21 with 16 BNCs for

connection to the 2024VOM-1 modules in bay four, followed

by sixteen 2016AVIM-1 modules, inputs 257 - 512.

From the rear of bay three, the modules are installed at the

factory in the following manner; the far right module is the

2010PS, the next module is the 2010DB-31,with 16 BNCs for

connection to the 2024VOM-1 modules in bay four, followed

by sixteen 2016AVIM-1 modules, inputs 513 - 768.

From the rear of bay four, the modules are installed at the

factory in the following manner; the far right module is the

2010PS, the next module is the 2010DB-00, followed by

twelve 2016AVIM-1 modules for inputs 769 - 960, and four

2024VOM-1 modules for outputs 1 - 16.

Smaller matrices, such as those ordered with future expansion

in mind, may have fewer modules installed.

IDENTIFY THESE MODULES CAREFULLY

BEFORE PROCEEDING.

Data Interconnect: See Level 1 - 448 X 16, Two Bay System

and connect all bays in a similar manner.

Video Interconnections: The 16 video outputs from bays 1,

2, and 3, located on the rear panel of the 2010DB-11 ,

2010DB-21 , and 2010DB-31 , are grouped by

fours and identified by the icons.

Each 2024VOM-1 is similarly grouped with three sections of

four BNCs, with identifying icons. A fourth section of four

BNCs is used for video output connections. See Figure 21,

Video Output Module, page 9.

Using high grade RG-59U video cables, connect the topmost

BNC from bay 1 on the 2010DB-11 panel, numbered 1, to the

topmost input BNC, labeled 1 on the 2024VOM-1 of bay 4, for

output 1, matching icon to icon.

Continue in this manner until 1-4 of the 2010DB-11 panel are

connected to inputs 1-4 of the first 2024VOM-1. Proceed to

the next group of four BNCs on the 2010DB-11 of the first

bay. Connect these four to the second 2024VOM-1 for outputs

5 - 8. Continue in this manner until all 16 connections of the

2010DB-11 panel are connected to all of the 2024VOM-1

modules.

Connect bay 2 in a similar manner to the 2024VOM-1 modules

of bay 4 for video outputs 1-16, matching icon to icon.

Connect bay 3 in a similar manner to the 2024VOM-1 modules

of bay 4 for video outputs 1-16, matching icon to icon.

See Appendix Figure A18, Video Interconnections, for

illustration of these connections.

If there are less than four 2024VOM-1s in the system, the

remaining BNCs on the 2010DB-XX do not require any

connection.

Video Input Connections: See Level 1 - 448 X 16, Two Bay

System and connect in a similar manner.

Video Output Connections: See Level 1 - 448 X 16, Two

Bay System and connect in a similar manner.

In the Appendix, see Figure A5, Level 1 - 960 X 16, Four Bay

System.

24

Page 31

LEVEL 1 - 1024 X 16, Five Bay System

A five bay, Level 1 system allows a maximum of 1024 video

inputs switched to a maximum 16 video outputs. Bays one

through four each consists of 256 video inputs, and bay five

consists of the 16 video outputs.

From the rear of bay one, the modules are installed at the

factory in the following manner; the far right module is the

2010PS, the next module is the 2010DB-11 with 16 BNCs for

connection to the 2024VOM-2 modules, followed by sixteen

2016AVIM-1 modules, inputs 1 - 256.

From the rear of bay two, the modules are installed at the

factory in the following manner; the far right module is the

2010PS, the next module is the 2010DB-21 with 16 BNCs for

connection to the 2024VOM-2 modules in bay five, followed

by sixteen 2016AVIM-1 modules, inputs 257 - 512.

From the rear of bay three, the modules are installed at the

factory in the following manner; the far right module is the

2010PS, the next module is the 2010DB-31 with 16 BNCs for

connection to the 2024VOM-2 modules in bay five, followed

by sixteen 2016AVIM-1 modules, inputs 513 - 768.

From the rear of bay four, the modules are installed at the

factory in the following manner; the far right module is the

2010PS, the next module is the 2010DB-41 with 16 BNCs for

connection to the 2024VOM-2 modules in bay five, followed

by sixteen 2016AVIM-1 modules, inputs 769 - 1024.

From the rear of bay five, the modules are installed at the

factory in the following manner; the far right module is the