Page 1

0MAYTAG

COMMERCIAL DRYER -

30 lb. STACKED MODELS

INSTALLATION AND

OPERATING INSTRUCTIONS

li^AVE THESE INSTRUCTIONS WITH THE OWNER

RETAIN THESE INSTRUCTIONS IN A SAFE PLACE FOR FUTURE REFERENCE.

846VD-0795

printed in U.S.A.

112127

Page 2

TABLE OF CONTENTS

Installation Instructions

Important Information................................................................................. 3

Specifications............................................................................................. 5

Installation Procedures............................................................................... 6

Operating Instructions.......................................................................................... 19

Maintenance............................................................................................. 21

Functional Check Of Components............................................................ 23

INSTALLATION INSTRUCTIONS

WARNING: For your safety the information in this manual must be followed to

minimize the risk of fire explosion or to prevent property damage, personal injury

or loss of life.

Do not store or use gasoline or other flammable vapors and liquids in the

vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your

building.

• Clear the room, building or area of all occupants.

• Immediately call your gas supplier from a neighbor's phone.

Follow the gas supplier's instructions.

• If you cannot reach your gas supplier; call the fire department.

Installation and service must be performed by a qualified installer; service

agency or the gas supplier.

Page 3

The following caution should be posted near the dryer in a prominent location.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors and liquids in the

vicinity of this or any other appliance.

You should caution users of this product: Not to permit children to play in,

on, with or around this equipment and that children should be supervised if

near at hand when the equipment is in use.

CAUTION

Label ALL wires prior to disconnection when servicing the computer board

and the ignition module. Wiring errors can cause improper and dangerous

operation.

Please post in a prominent location, instructions to be followed in the event

the user smelts gas. The information posted shall be obtained by consulting

with your local gas supplier.

The wiring diagram for the dryer is located in the front electrical control box.

Page 4

This product embodies advanced concepts in engineering, design and safety. If this

product is properly maintained, it will provide many years of safe, efficient, and trouble

-free operation.

ONLY qualified professional technicians should service this equipment.

Observe all safety precautions displayed on the equipment or specified in the

installation instructions included with the dryer.

Under NO circumstances should the dryer door switch or the heat circuit safety

devices ever be disabled.

We have tried to make these instructions as complete as possible and hope you will

find it useful. Manufacturer reserves the right to make changes from time to time,

without notice or obligation, in prices, specifications, colors, and materials and to

change or discontinue models.

For replacement parts, contact the distributor from which the dryer was purchased

or contact:

Maytag

One Dependability Square

Newton, Iowa 50208

(515) 792-7000

IMPORTANT

For your convenience, log the following information:

Date of Purchase

Distributor's Name

Serial Number(s)

NOTE: The model number(s) and serial number(s) can be found on the data label

located on the back side of the control (middle) door.

_______

Model No.

Page 5

IMPORTANT INFORMATION

RECEIVING AND HANDLING

Th e dr ye r is ship pe d in a pro te cti ve

st re tch wr ap cov er an d pr ot ec tiv e

ca rd boa rd co rne rs an d t op co ver as a

me an s of pr ev ent in g da mag e in tr an sit .

Up on de li ve ry, t he dr ye r an d wo od en sk id

sh ou ld be vi su all y i ns pe cte d for s hip pi ng

da ma ge. I f a ny da ma ge wh at soe ve r i s

no ti ced , in spe ct f urt he r.

Wh en dr ye rs ha ve be en da ma ged i n

sh ip men t, f oll ow t hes e pr oce du re s:

1. Al l dr ye rs s hou ld be in sp ec ted upo n

re ce ipt a nd be fo re th ey a re si gn ed fo r.

2. I f th er e i s su sp ec ted da ma ge o r a ct ual

da ma ge, th e t ruc ke r' s r ece ip t s hou ld

be s o n ot ed .

3. I f th e d ry er i s d ama ge d b eyo nd re pai r,

it s ho uld b e re fu se d. T ho se d ry ers

wh ic h w er e no t da mag ed i n a

da ma ged sh ip men t s ho uld be

ac ce pte d, bu t t he n um be r r ece iv ed

an d nu mbe r re fus ed m ust b e n ot ed on

th e rec ei pt .

4. If yo u d et erm in e t ha t t he dr yer ha s

be en d am ag ed af te r the tr uc ker ha s

le ft yo ur l oca ti on , yo u s ho ul d c al l y ou r

lo ca l f re ig ht te rm in al im me dia te ly a nd

re qu est a n i ns pe cti on a nd fr ei gh t

cl ai m f orm . T he fr ei ght co mp an y

co ns ide rs th is con ce al ed dam ag e.

Th is ty pe of fr ei ght cl ai m i s v ery

di ff icu lt w hen a d ay or t wo pa ss es

af te r t he f rei gh t was d el ive re d.

5. Fr ei ght c la ims a re th e re spo ns ib ili ty

of t he co nsi gn ee, an d al l c la ims mu st

be fi led at r ec ei vin g e nd. Ma nu fac tu re r

as su mes n o re sp on sib il it y fo r f re ig ht

cl ai ms or d ama ge s.

IMPORTANT:

TH E DR YE R S HO UL D BE

TR AN SPO RT ED A ND HA NDL ED IN A N

UP RI GHT P OS ITI ON A T A LL T IME S.

SAFETY PRECAUTIONS

1. D o no t s to re or us e g as ol in e o r o th er

fl am mab le v ap or s a nd l iq uid s i n t he

vi ci nit y of th is o r a ny o the r ap pli an ce .

2. Pu rc has er /u ser sho ul d co nsu lt the

lo ca l ga s su pp li er f or pro pe r

in st ruc ti on s to be fo llo we d i n th e e ve nt

th e u se r s mel ls ga s. Th e i ns tr uct io ns

sh ou ld be po st ed in a p ro mi nen t

lo ca tio n.

3. D ry er mu st be ex hau st ed to th e

ou td oor s.

4. Al th ou gh th is c om me rci al dr ye r is a

ve ry v ers at il e m ac hi ne, t he re ar e

so me ar ti cle s t ha t, du e t o f ab ri c

co mp osi ti on o r cle an ing me th od,

sh ou ld no t be dr ie d i n it .

WARNING: DRY ONLY WATER-

WASHED FABRICS. DO NOT DRY AR

TICLES SPOTTED OR WASHED IN DRY

CLEANING SOLVENTS, A COMBUSTI

BLE DETERGENT, OR “ALL

PURPOSE’’ CLEANERS. FIRE OR EX

PLOSION COULD RESULT.

WARNING: DO NOT DRY RAGS OR

ARTICLES COATED WITH GASOLINE,

KEROSENE, PAINT, WAX, OIL, OR

GREASE. FIRE OR EXPLOSION

COULD RESULT.

Page 6

WARNING: DO NOT DRY MOPHEADS.

CONTAMINATION BY WAX OR

FLAMMABLE SOLVENTS WILL CRE

ATE A FIRE HAZARD.

WARNING:

DRYING ARTICLES THAT CONTAIN

PLASTIC, FOAM, SPONGE RUBBER,

OR SIMILARLY TEXTURED RUBBER

LIKE MATERIALS. DRYING IN A

HEATED TUMBLER MAY DAMAGE

PLASTICS OR RUBBER AND ALSO

MAY BE A FIRE HAZARD.

DO

NOT USE HEAT FOR

NOTE:

Fa il

Lire

to d o so w il l vo id t he

wa rr ant y.

7.

Un de r n o c irc um st anc es sh ou ld t he

dr ye r do or s wi tch (e s) o r he at s afe ty

de vi ces e ve r b e di sab le d.

WARNING: PERSONAL INJURY OR

FIRE COULD RESULT.

8. Ar ti cl es be in g d ri ed sh oul d nev er be

le ft u na tt en ded fo r a n e xte nd ed p er iod

of t ime i n t he t umb le r af ter c omp le ti on

of t he dr yi ng an d coo li ng cy cl es .

5. A pr og ram s hou ld be es ta bl ish ed fo r

th e i ns pe cti on an d c le an ing of th e l in t

in t he b urn er a rea s an d ex ha ust d uct

wo rk . T he f req ue nc y of cl ea nin g ca n

be st b e d et erm in ed f ro m ex pe ri enc e

at e ach l oc ati on .

WARNING: THE COLLECTION OF LINT

IN THE BURNER AREA AND EXHAUST

DUCT WORK CAN CREATE A POTEN

TIAL FIRE HAZARD.

6. Fo r pe rs ona l sa fe ty , t he d rye r mu st b e

el ec tri ca ll y gr ou nd ed i n a cco rd an ce

wi th l oc al c od es an d/o r t he N at ion al

El ec tri c Co de AN SI / NFP A No. 7 0 (L at

es t Edi ti on ).

WARNING: ARTICLES LEFT IN THE

DRYER AFTER THE DRYING AND

COOLING CYCLES HAVE BEEN COM

PLETED CAN CREATE A FIRE HAZ

ARD.

9. Th is d ry er i s n ot t o be us ed i n th e

pr es enc e of d ry cl ea nin g so lv en ts o r

fu me s.

10 . Rea d a nd fo ll ow a ll c au ti on a nd

di re cti on l abe ls a tta ch ed to t he dr ye r.

11 . A mi ni mum of si x ( 6) in che s ( 24 in che s

re co mme nd ed ) mu st be l ef t b ehi nd th e

dr ye r t o a ll ow ad equ at e c le ara nc e f or

ai r ope ni ng s i nt o the c om bus ti on

ch am ber .

Page 7

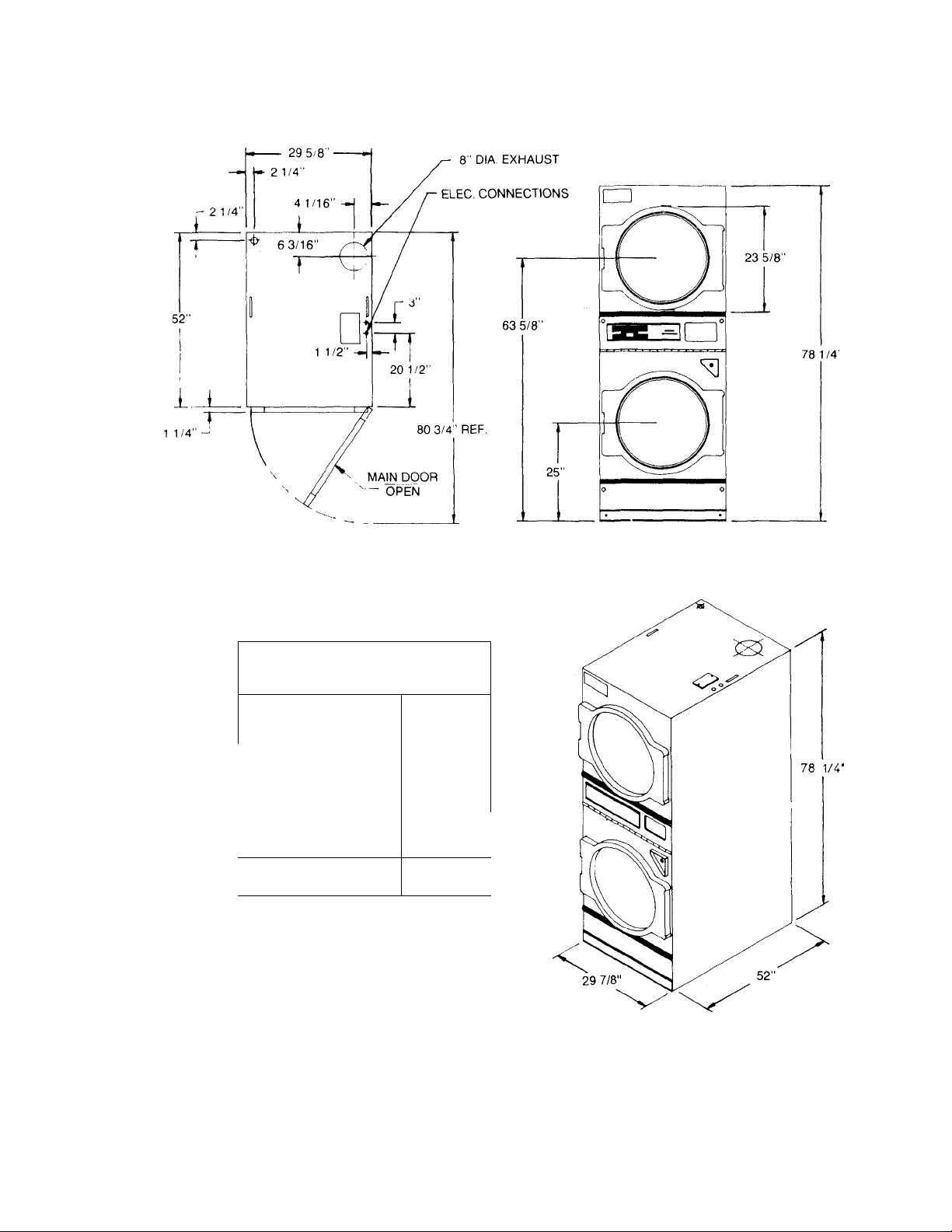

SPECIFICATIONS

PLAN VIEW FRONT VIEW

SPECIFICATIONS

TUM BL ER CAPAC ITY (Dry weigh t)

TUM BL ER (Basket) DIAMETE R 27 1.4'

TUM BL ER (Basket) DEPT H

DOOR OPENING

APP RO X, WEIGHT lUncra ted)

APP RO X S HIP PIN G W EIGHT

MOTOR (H orsepower)

EXH AU ST DUCT OUT LET

AIR FLOW (Total for tx»lh tum blers)

GAS IN LET CO NN ECTION

GAS IN PUT (Total for both Tumblers)

ELE CTRIC REQUIREMEN TS

|Per tum ble r)

tt5 VOL TS, 1 P HASE

NOTE:

Ma nu fac tu re r re se rve s t he r ig ht t o ma ke c ha ng es i n s pec if ic ati on s at a ny t im e,

wi th out n ot ice o r obl ig at ion .

30 lbs.

30'

21 1 2 ■ Dia .

850 lbs

880 lbs.

1 2 HP

8 " Oia

800 CFM

3 4 NPT

U4.000 BTUH

8 AMPS

NOTE:

To p ro vi de pr ope r c le ara nc e f or l in t a nd s er vi ce a cc es s pa ne ls , at le as t 1 /4"

cl ea ran ce s hou ld b e a ll ow ed be tw een d ry ers .

Page 8

INSTALLATION PROCEDURES

In st all at io n sh ou ld b e pe rf orm ed b y q ual if ied pr ofe ss io nal s in ac cor da nce wi th l oca l an d

st at e co de s. I n t he a bs en ce o f t he se c od es , i nst al lat io n m us t co nf or m to ap pl ica bl e

Am er ica n Na tio na l sta nd ar ds:

AN SI Z2 23 .1 - La te st Ed it ion ( Na ti ona l Fu el Ga s C od e)

an d/ or

AN SI /NF PA N o. 70 - La te st Ed it io n (Na ti ona l El ec tri c Cod e)

UNPACKING/SETTING UP

Re mo ve s tr etc h w rap pr ot ect iv e co ve r,

sh ip pin g cor ne rs an d top c ove r fr om

dr ye r.

NOTE:

Th e ac ce ss k eys t o th e se rv ic e

do or s are inc lud ed in th e i nf or mat io n

pa ck et s hi ppe d in th e to p tu mbl er . Th es e

ke ys s hou ld b e re mo ved a nd p ut i n a sa fe

pl ac e. Yet , mad e a cc ess ib le be ca use

so me wi ll b e n ee de d t hr ou gho ut va ri ou s

ph as es in t he in st all at io n o f th e d ry er .

Th e dr ye r c an b e mo ved t o it s fi na l

lo ca tio n wh il e s ti ll at ta ch ed to t he sk id o r

wi th t he s ki d r em ove d. T o u ns ki d th e

dr ye r, l oca te a nd re mo ve th e fo ur ( 4) b olt s

se cu rin g t he ba se of th e d rye r t o t he

wo od en sk id . Two ( 2) ar e lo cat ed at t he

re ar o f the b as e, a nd tw o (2 ) are l oc ate d in

th e f ro nt . O nc e t he bo lt s a re re mo ve d,

sl id e t he d rye r of f t he s kid .

Wi th th e s kid re mo ve d, to ma ke it e as ie r

to sl ide th e d rye r i nto it s f ina l p os iti on ,

sl ig htl y lo we r a ll le ve lin g le gs so th at th e

dr ye r wi ll s li de o n th e l eg s in st ead of t he

ba se f ra me. T he d ry er i s eq uip pe d wi th

fo ur (4 ) l ev el ing l egs , o ne at ea ch co rn er

of t he dr yi ng ba se .

Th e sl ot ted ad jus tm en t bo lt s fo r th e tw o

fr on t le ve li ng le gs a re lo ca ted di re ct ly

be hi nd th e lo we r a cce ss d oor , a nd th e

re ar two ad jus tm en ts a re dir ec tl y be hi nd

th e low er r ear b ac k ( gu ar d) pa ne l.

FRONT LEVELING LEGS

LOCATION OF THE DRYER

Be fo re in st al lin g t he dr yer , b e s ur e t he

lo ca tio n con fo rm s t o l oc al co de s a nd

or di nan ce s.

Th e d ry er m us t b e i nst al le d on a s ou nd ,

le ve l f loo r c ap ab le of su ppo rt in g i ts

we ig ht. It i s re com me nd ed t hat car pe ti ng

be r em ove d f rom t he f lo or a re a on w hic h

th e dry er i s t o re st.

Ev en th oug h a si x- inc h c le ara nc e i s

ac ce pta bl e, it is r ec omm en ded t hat t he

re ar of th e d rye r b e p os it ion ed

ap pr oxi ma te ly tw o ( 2) fe et aw ay fr om th e

ne ar est ob st ruc ti on (i .e. , w al l) fo r ea se of

in st all at io n, ma in ten an ce an d se rvi ce .

Page 9

DRYER ENCLOSURE REQUIREMENTS

Bu lk hea ds a nd par ti ti ons sho ul d be mad e

of no nco mb us ti ble ma te ri als an d m us t b e

lo ca ted a mi nim um o f si x (6 ) in ch es a bov e

th e d rye r o ut er t op , e xce pt a lo ng t he f ro nt

of t he dr yer w hi ch ma y be cl os ed in , i f

de si red .

CLEARANCES SHOWN ARE MINIMUM DIMENSIONS TO NEAREST COMBUSTIBLE MATERIALS.

NOTE:

Ev en th ou gh a mi ni mum o f s ix (6 )

in ch es abo ve th e d ry er ou ter to p i s

ac ce pta bl e, a c le ara nc e o f 1 8 i nc he s ( or

mo re ) i s s ugg es te d f or e as e o f i nst al la tio n

an d ser vi ce (e le ct ric al c onn ec ti ons ).

Wh en f ire s pr in kle r sy st em s a re l oc ate d

ab ov e t he dr yer s, a mi ni mum o f 1 2 i nc he s

ab ov e t he d rye r ou ter t op is r eq uir ed .

NOTES:

A. Minimum of 6" clearance is acceptable for ease of installation and service

(Power connections), at least 18" is recommended.

B. Minimum of 6" clearance is acceptable for ease of installation, maintenance

and service, at least 24" is recommended.

FRESH AIR SUPPLY

Ai r su pp ly ( mak e- up a ir) m us t be g ive n

ca re ful con si de rat io n to a ss ur e pr ope r

an d s af e p er for ma nc e o f e ac h d rye r. An

un re str ic te d so urc e o f ai r of 800 cfm is

ne ce ssa ry fo r ea ch dr yer . A n un re str ic te d

ai r en tr anc e fr om t he o ut doo rs

(a tm osp he re ) of a m in im um o f 1- 1/ 2 sq . ft .

is re qu ire d fo r e ac h d rye r. Th is ar ea m us t

be enl ar ge d if l ou ve rs o r re gi ste rs c ov er

th e o pen in g. I t i s n ot n ec es sar y t o ha ve a

se pa rat e m ak e- u p a ir o pe ni ng f or ea ch

dr ye r. Co mm on m ak e-u p ai r op eni ng s ar e

ac ce pta bl e. How ev er , th ey mus t b e se t- up

in su ch a m an ner th at th e m ak e-u p a ir is

di st rib ut ed e qu all y t o t he d ry ers . F or

ex am ple , f or a b an k of e ig ht ( 8) d rye rs , a

to ta l m ak e- up ai r op en in g of 1 2 sq . f t. i s

re qu ire d. Tw o ( 2) op en ing s m ea su rin g 2 f t.

X 3 ft. ( 6 sq . f t. ) are a cc ept ab le .

Al lo wan ce s m ust be m ad e fo r r em ote or

co ns tri ct in g p as sa ge way s o r w he re d rye rs

ar e lo ca te d at e xc es siv e a lti tu de s or

pr ed omi na nt ly lo w pre ss ur e a re as .

Page 10

3 FT

1

2 FT

T

2 FT

- 3FT H

r

MAKE UP AIR OPENINGS

TY PI CAL I NS TAL LA TI ON SH OW ING M AK E-U P AI R O PE NI NGS

IMPORTANT:

MA KE -UP A IR MU ST BE

PR OV IDE D FR OM A SO URC E FR EE OF

DR Y CLE AN IN G SO LV ENT F UME S.

MA KE -UP AI R C ONT AM IN ATE D B Y DR Y

CL EA NIN G SOL VEN T FU ME S W ILL

RE SU LT I N IR RE PAR AB LE D AMA GE T O

MO TO RS AN D OT HE R DRY ER

CO MP ONE NT S.

NOTE:

Co mp one nt f ail ur e du e to d ry

cl ea nin g so lve nt f um es vo id s t he

wa rr ant y.

EXHAUST REQUIREMENTS

Ex ha ust d uc t wo rk s hou ld b e de si gne d

an d in st al led by a qu ali fi ed p ro fe ssi on al .

Im pr ope rl y s iz ed du ct w ork w il l c re ate

ex ce ssi ve ba ck pr ess ur e w hi ch re sul ts in

sl ow d ry in g, in cr eas ed us e o f e ne rgy ,

ov er hea ti ng of th e d ry er, an d s hu tdo wn of

th e bu rn er b y th e ai rfl ow ( sa il) swi tc he s,

bu rn er hi -li mi ts , o r t um ble r h i- he at

pr ot ect or t her mo st ats .

CAUTION: Improperly sized or installed

exhaust duct work can create a potential

fire hazard.

1. Single Dryer Venting

Wh er e po ss ibl e, i t i s su gg est ed t o

pr ov ide a s epa ra te ex ha us t d uc t fo r

ea ch d rye r. T he e xh au st d uc t wo rk

sh ou ld b e l ai d o ut i n s uc h a w ay t ha t

th e du ct wo rk t ra vel s as d ir ect ly a s

po ss ibl e t o t he ou tdo or s w ith as fe w

tu rn s a s po ss ib le. I t i s su gg es ted t ha t

th e us e o f 90 de gr ee t ur ns i n du ct in g

be a vo ide d; u se 3 0 de gr ee o r 45

de gr ee a ng les in st ead . T he s ha pe o f

th e e xh aus t d uc t w ork is no t c ri tic al so

lo ng as t he mi ni mu m cr os s s ec ti on

ar ea is p ro vid ed .

IMPORTANT:

Ex ha ust ba ck p re ss ure

me as ure d b y a ma no met er at t he

dr ye r e xh au st du ct a re a s ho uld n ot

ex ce ed 0 .3 i nc he s wa te r co lum n wh en

bo th tu mb le rs ar e ope ra ti ng.

It is s ug ge ste d t hat th e du ct wor k f rom

ea ch dr yer no t e xc ee d 2 0 f eet wi th no

mo re th an t wo (2 ) elb ow s.

Page 11

If th e du ct wor k e xc eed s 2 0 f eet or has

nu me rou s e lb ow s, th e c ro ss s ec tio n

ar ea o f t he d uc t w ork mu st b e

in cr eas ed i n pr op ort io n to i ts le ng th o r

nu mb er o f el bo ws i n it . In c alc ul at ing

du ct s ize , th e cr os s se cti on a re a of a

sq ua re o r r ec ta ngu la r d uct mu st be

in cr eas ed 20 per ce nt for ea ch

ad di tio na l 2 0 fee t. Th e d ia me ter o f a

ro un d e xh aus t sh oul d be in cre as ed 10

pe rc ent fo r ea ch ad dit io na l 20 fe et.

Ea ch 9 0 d eg re e e lbo w i s e qui va le nt t o

an ad di ti ona l 15 fe et an d e ac h 4 5

de gr ee el bo w, an a ddi ti on al 10 f ee t.

IMPORTANT:

Fo r e xt end ed du ct wo rk

ru ns , t he cr os s s ec ti on ar ea of t he du ct

wo rk ca n on ly be i nc rea se d to a n

ex te nt. Ma xi mum pr opo rt io na l du ct

wo rk r un ca nno t e xc eed 20 fe et m or e

th an th e o rig in al li mit at io ns of 20 fe et

wi th tw o ( 2) el bo ws . W he n th e d uc t

wo rk a ppr oa ch es t he m ax imu m l imi ts

as n ote d in th is ma nu al , a p rof es si ona l

He at ing , Ve nti ng & Ai r C on di tio ni ng

(H VA C) f ir m s hou ld be con su lt ed f or

pr op er ve nt ing i nf orm at io n.

Th e du ct wo rk s hou ld b e sm oot h

in si de w it h no pro je ct ion s fr om she et

me ta l sc re ws o r o th er o bs tr uc tio ns

wh ic h w il l co ll ec t l in t. W he n a dd ing

du ct s, th e du ct to b e a dd ed sh ou ld

ov er lap th e du ct to wh ich i t i s t o b e

co nn ect ed . Al l d uc t wo rk jo in ts mu st

be ta pe d t o p re ve nt mo ist ur e a nd li nt

fr om e sc api ng in to t he b ui ldi ng . Al so ,

in sp ect io n d oo rs sh ou ld be i ns tal le d

at s tra te gic p oi nts i n th e e xh au st du ct

wo rk f or p er iod ic i ns pe cti on a nd

cl ea nin g.

NOTE:

Wh er e t he ex ha ust d uct p ass es

th ro ugh a w al l, c ei lin g, or r oo f ma de

of co mbu st ib le m at er ial s, th e op en ing

mu st be t wo ( 2) in ch es la rg er (a ll t he

wa y a ro un d) th an th e d uc t. Th e d uc t

mu st be c en ter ed w ith in t his o pe nin g.

To pr ot ect th e o ut sid e e nd of

ho ri zon ta l duc t wo rk fr om th e we ath er ,

a 90 d egr ee el bo w b en t d ow nw ard

sh ou ld b e in sta ll ed w he re t he e xh aus t

ex it s t he b ui ld ing (s ee ill us tr at ion on

pa ge 1 1) . If t he e xh aus t du ct w or k

tr av els v er tic al ly up t hro ug h t he r oof ,

it s hou ld b e p ro te cte d fr om th e

we at her by u si ng a 1 80 d eg re e tu rn t o

po in t th e op en ing dow nw ar d (s ee

il lu str at io n on p ag e 11 ). I n ei th er c ase ,

al lo w a t le as t tw ice t he di am et er of t he

du ct be tw een t he du ct op en in g a nd

ne ar est o bs tru ct io n.

IMPORTANT:

Do n ot us e sc re en s or

ca ps o n th e o ut sid e o f op en ing o f

ex ha ust d uc t w or k.

2.

Multiple Dryer (common) Venting

If i t i s no t fe as ib le t o pr ov ide s ep ar ate

ex ha ust d uct s fo r ea ch dr ye r, du ct s

fr om in di vid ua l dr ye rs m ay be

ch an nel ed in to a “c om mo n m ai n

du ct ” (s ee i ll ust ra ti on o n pa ge 1 1) . Th e

in di vid ua l d uc ts sho ul d e nt er the

bo tt om o r s id e of th e ma in d uct a t an

an gl e no t m ore th an 4 5 d eg ree s i n t he

di re cti on of a irf lo w. Th e m ai n d uc t

sh ou ld b e t ap er ed, w it h th e d ia me ter

in cr eas in g be fo re e ach i nd iv idu al d uc t

is ad de d. Th e c ros s s ec ti on ar ea

sh ou ld be 6 0 s qu are i nc hes f or ea ch

ei gh t ( 8) i nch d uc t a dd ed .

IMPORTANT:

No mo re th an fo ur (4 )

dr ye rs to ta l s ho ul d b e c on nec te d t o

on e mai n co mmo n du ct.

Th e ma in du ct m ay b e any s ha pe o r

cr os s se ct ion ar ea , so lo ng a s th e

mi ni mum cr os s s ect io n a re a i s

pr ov ide d. T he il lu st rat io n on pa ge 1 1

sh ow s t he m ini mu m cro ss s ect io n

ar ea fo r m ult ip le dr yer ve nt in g. Th ese

fi gu res m us t be i nc re ase d in

pr op ort io n i f t he ma in du ct r un s f ro m

th e la st d ry er t o wh er e it e xh au sts t o

th e o utd oo rs i s u nus ua ll y lo ng ( ov er

20 fe et) or ha s n ume ro us e lb ow s

(m or e t ha n two { 2} ) in it .

Page 12

In c al cul at in g d uc t si ze , t he c ros s

se ct ion ar ea of a squ ar e o r

re ct ang ul ar d uc t mu st b e in cr ea sed 20

pe rc ent f or e ach a dd iti on al 2 0 f ee t.

Th e d ia me ter of a ro und ex ha us t m ust

be in cre as ed 1 0 p er cen t f or e ac h

ad di tio na l 1 5 f ee t. Ea ch 9 0 d egr ee

el bo w i s e qu iv ale nt to an a ddi ti on al 15

fe et an d e ac h 4 5 d eg re e e lbo w, an

ad di tio na l 10 fe et .

IMPORTANT:

Fo r ex te nd ed d uc t wo rk

ru ns , t he cr os s s ect io n a re a of th e d uc t

wo rk ca n o nly be in cr ea sed to an

ex te nt. Ma xi mu m p rop or ti on al du ct

wo rk r un c an not e xc ee d 20 f ee t mo re

th an t he o ri gin al l im it ati on s of 2 0 fe et

wi th th e t wo (2 ) e lbo ws . W he n t he du ct

wo rk ap pr oa che s th e ma xi mum l imi ts

as no te d i n t his ma nu al , a pr ofe ss io nal

HV AC f irm s ho ul d b e co ns ul ted f or

pr op er ve nt ing i nf orm at io n.

Th e du ct w or k sh ou ld b e sm oo th

in si de wit h n o pro je ct ion s f ro m s he et

me ta l sc re ws or o th er o bs tru ct io ns

wh ic h wi ll c oll ec t li nt . Wh en a dd ing

du ct s, t he d uct t o be a dd ed s ho uld

ov er lap th e du ct t o wh ich it i s to b e

co nn ect ed . A ll d uc t wo rk joi nt s mu st

be t ap ed t o p rev en t mo is tur e a nd l int

fr om es ca pin g i nt o t he bu il din g. Al so ,

in sp ect io n do or s hou ld b e in st all ed a t

st ra teg ic p oin ts i n th e ex hau st d uct

wo rk f or p er io dic in sp ect io n a nd

cl ea nin g.

NOTE:

Wh er e t he ex hau st pa ss es

th ro ugh a wa ll, ce il in g o r r oo f m ade of

co mb ust ib le m ate ri al s, th e op eni ng

mu st b e t wo ( 2) in che s l ar ger (a ll t he

wa y a rou nd ) t han th e du ct . T he d uc t

mu st be c en ter ed w ith in t his o pe nin g.

To pr ot ec t t he ou ts id e e nd of th e

ho ri zon ta l d uc t w or k f rom t he we ath er ,

a 90 de gr ee el bow b en t d own wa rd

sh ou ld b e i nst al le d wh er e th e e xha us t

ex it s t he b uil di ng (s ee il lu st rat io n o n

pa ge 1 1) . If t he e xh aus t d uct wo rk

tr av els v er ti cal ly u p th ro ugh t he r oo f,

it s ho ul d be p ro tec te d fr om t he

we at her by u sin g a 1 80 de gr ee tu rn to

po in t th e o pe ni ng d own wa rd ( see

il lu str at io n on pa ge 11 ). I n e it her ca se ,

al lo w at le ast twi ce th e di am ete r o f th e

du ct be tw een t he du ct op en in g a nd

ne ar est o bs tru ct io n.

10

IMPORTANT:

Do n ot u se sc ree ns o r

ca ps o n t he o ut si de of o pe ni ng o f

ex ha ust d uc t w or k.

Page 13

SI NG LE DR YE R VEN TI NG

INSPECTION

DOOR

HORIZONTAL

MULTIPLE DRYER VENTING

WIDTH 8" DIAMETER EXHAUST

HORIZONTAL

T"

------------------ / I UMbLtR EXHAUST MUST ENTER MAIN ^ 29.f

T WALL EXHAUST DUCT AT A 45» ANGLE.

2 X D CLEARANCE

CROSS SECTIONAL AREA OF ROUND DUCT = .785 x WHERE D = DIAMETER OF THE DUCT.

CROSS SECTIONAL AREA OF RECTANGULAR DUCT = W x H WHERE W = WIDTH AND H = HEIGHT.

NOTEA

NO. OF DRYERS 4

Minimum cross

section area (sq. in.)

Minimum round

duct diameter (in.)

TO INDIVIDUAL DRYERS

NOTE: FOR THE INTRODUCTION OF EACH 8" DUCT FROM

FORMULAS TO CALCULATE DUCTING CROSS SECTIONAL AREA

240

16

'''HE DRYERS, ADD 60 so. IN. TO THE CROSS

SECTIONS OF THE MAIN DUCT.

3

180

14

2 1

120 60

12

8

NOTEA

INSPECTION

DOORS

1.625" MIN.

VERTICAL

ROOF

1

H

-H w 1^

NOTE A: OPENING MUST BE TWO (2) INCHES LARGER THAN DUCT (ALL THE WAY AROUND). THE DUCT

MUST BE CENTERED WITHIN THIS OPENING.

11

Page 14

ELECTRICAL INFORMATION

1 Electrical Requirements

It i s yo ur re sp on si bil it y to ha ve a ll e lec tr ic al co nn ec tio ns m ad e b y a pr op er ly li ce ns ed

an d c om pe ten t el ec tr ici an to a ssu re th at th e e le ct ric al in st al lat io n i s a de qu ate a nd

co nf orm s wi th l oca l an d sta te r eg ula ti ons o r co des . In t he ab se nc e o f su ch co de s, al l

el ec tri ca l c onn ec ti ons , m at eri al a nd w or kma ns hi p mu st c on fo rm t o t he a ppl ic ab le

re qu ire me nt s o f th e N at io nal E le ctr ic C ode A NS I/N FP A No. 7 0 (L ate st E dit io n) .

IMPORTANT:

Fa il ure to co mp ly wi th th ese co de s o r o rd ina nc es, an d/ or t he re qu ire me nt

st ip ula te d in th is ma nu al ca n re sul t in pe rs on al in ju ry or c omp on en t f ai lu re.

NOTE:

Co mp one nt f ail ur e due t o imp ro pe r i ns ta lla ti on vo id s the w ar ran ty .

It is re co mme nd ed th at a s ep ara te ci rc ui t se rv in g e ach tu mb le r be pr ov id ed. Th e d ry er

mu st b e co nne ct ed w ith c op pe r wi re o nl y. D o n ot u se al um in um w ire w hi ch co ul d ca us e

a fi re ha za rd.

NOTE:

2.

Electrical Service

Th e use o f alu mi nu m w ir e voi ds t he wa rr ant y.

El ec tri ca l ser vi ce re co mm end ed s pec s (p er tu mb ler ):

Voltage Phase

11 5

IMPORTANT:

No. of Amp. Draw Per Wire Wires Tumbler Size

1 8

#12

Th e dr ye r mu st b e c on ne ct ed t o t he e lec tr ic al su pp ly sh ow n on t he da ta

Breaker Size Per Tumbler

15 A mp.

la be l l oc at ed on t he in si de of t he mi dd le ac ce ss (c on tro l) d oor .

WARNING: ANY DAMAGE DONE TO DRYER COMPONENTS DUE TO IMPROPER

VOLTAGE APPLICATION OR CONNECTIONS WILL AUTOMATICALLY VOID THE

WARRANTY.

3.

Electrical Connections

A wi ri ng d ia gra m is inc lu de d wi th e ac h dr yer s ho wi ng t he w iri ng c onn ec ti on s equ en ce .

Th e e le ctr ic al co nne ct io ns ar e m ade in a b ox lo ca ted at th e t op of th e d ry er. Th e d ry er

is s hip pe d wi th t hre e ( 3) c on nec ti on le ad s (L I, L 2/N eu tr al, a nd Gr ou nd ) f or ea ch

tu mb ler .

Electrical Connection Leads

Gr ee n

Gr ou nd

(G ND )

12

Bl ac k Wh ite

+

-

Po si tiv e Ne ut ral

(L I)

(L 2)

Page 15

MAKE

ELECTRICAL \ >,

CONNECTIOH$

If l oc al c ode s p er mit , p ow er t o th e

dr ye r ca n be m ade b y us e of a f le xi ble

U. L. li st ed po we r c or d/ pig ta il (w ir e

si ze mu st co nf orm to ra ti ng of dr yer )

or the dry er can be h ard wir ed dir ec tl y

to th e s erv ic e b rea ke r p ane l. In b ot h

ca se s, a st rai n re lie f mu st be in sta ll ed

wh er e t he w iri ng e nte rs t he dr ye r.

NOTE:

It is re co mme nd ed t ha t a ci rc uit

se rv ing ea ch t um ble r (b as ke t/d ru m)

be p rov id ed .

MAKE CONNECTIONS

AS MARKED

.

--------

-----

be t o a p rov en ea rt h g ro un d a t th e

lo ca tio n se rvi ce p ane l.

Fo r a dd ed p er so na l sa fe ty , w he n po ss ib le,

it I S s ugg es te d th at a s ep ar at e gr ou nd

wi re (s iz ed pe r l oc al co de s) be co nn ect ed

fr om t he gr ou nd co nn ec tio n of t he d rye r to

a gr ou nde d co ld w at er pi pe . D o no t gr ou nd

to a ga s o r h ot wa ter pi pe . T he gr oun de d

co ld wa te r p ipe mu st be me ta l t o m et al

co nn ect io ns al l th e wa y to th e el ect ri ca l

gr ou nd. I f t he re ar e a ny no n- met al li c

in te rru pt io ns, s uc h a s, a me te r, p um p,

pl as tic , r ub ber , o r o th er in su lat in g

co nn ect or s, t he y m ust be j um pe d o ut w it h

No . 4 w ir e an d s ecu re ly c la mpe d t o ba re

me ta l a t bo th en ds .

IMPORTANT:

Fo r p er so nal s afe ty an d

pr op er o pe ra tio n, th e dr ye r m ust be

gr ou nde d.

GAS INFORMATION

It i s y ou r r es po ns ibi li ty to h av e a ll

pl um bin g co nn ect io ns m ade b y a qu al ifi ed

pr of ess io na l to ass ur e th at t he gas

pl um bin g in st al lat io n is a de qu ate and

co nf orm s w ith loc al a nd sta te r eg ul ati on s

or co de s. In th e ab sen ce of s uch co de s,

al l pl um bin g co nn ec tio ns , ma te ria l, an d

wo rk man sh ip mu st co nf or m t o the

ap pl ica bl e re qui re me nt s o f th e .N at ion al

Fu el G as C od e A NSI Z2 23. 1 ( Lat es t

Ed it ion ).

PUNCH-OUT

PLUGS

CANADA ONLY

4. Grounding

Gr ou ndi ng ( ea rt h) co nn ec tio n mu st b e

pr ov ide d an d i ns tal le d i n ac cor da nc e

wi th s ta te a nd lo cal co de s. I n t he

ab se nce o f th ese c od es , g ro un din g

mu st co nf orm t o a pp lic ab le

re qu ire me nt s o f th e N at io nal El ec tr ic

Co de AN SI /N FPA N o. 7 0 ( La te st

Ed it ion ). T he g ro un d co nn ec tio n m ay

IMPORTANT:

Fa il ure t o co mpl y wi th th es e

co de s or ord in an ces , a nd/ or the

re qu ire me nt s s tip ul at ed in th is m an ua l

ca n r es ul t i n p er so nal in ju ry an d i mp rop er

op er ati on o f t he d rye r.

13

Page 16

Th e el ry er a nd i ts i ndi vi du al s hut -o ff va lv e

mu st b e di sc on nec te d fr om t he g as s upp ly

pi pi ng s yst em d uri ng a ny pr es su re t est in g

of th at s ys tem at te st p re ss ure s i n e xce ss

of 1 /2 ps ig ( 3.5 k Pa ).

Th e dr ye r m ust be i so lat ed f ro m th e g as

su pp ly pip in g s yst em by cl osi ng it s

in di vid ua l ma nua l sh ut -of f va lv es du ri ng

an y p re ssu re te st ing o f th e ga s s upp ly

pi pi ng sy st em at t est p re ssu re s eq ual t o

or l ess t ha n 1 /2 p si g ( 3. 5 kPa ).

NOTE:

un de rsi ze d ga s pi pi ng w ill r es ul t in

ig ni tio n pr ob le ms, s lo w dr yi ng, a nd

in cr eas ed us e o f e ne rgy an d c an cr ea te a

sa fe ty ha za rd.

Th e dr yer m us t b e co nn ect ed t o t he t ype

of he at /ga s in di ca ted on t he dr ye r d at a

la be l loc at ed o n t he i ns ide o f th e mi ddl e

ac ce ss ( co nt rol ) d oor . I f t his in for ma ti on

do es n ot ag re e w it h t he ty pe of ga s

av ai lab le , co nt act t he di st ri but or w ho so ld

th e dry er o r t he f act or y.

IMPORTANT:

Fa il ure t o is ol ate o r

di sc onn ec t dr ye r fr om s upp ly a s no te d c an

ca us e i rre pa rab le da ma ge t o t he g as

va lv es .. . vo idi ng t he wa rra nt y.

WARNING: FIRE OR EXPLOSION COULD

RESULT.

Gas Supply

Th e gas d rye r in st all at ion m us t m ee t t he

Am er ica n Na tio na l Sta nd ar d, Na ti on al

Fu el G as C od e AN SI Z 223 .1 ( La te st

Ed it ion ), as w el l a s l oc al c od es an d

or di nan ce s a nd mu st be do ne b y a

qu al ifi ed p rof es si ona l.

Technical Gas Data

Gas Specifications

IMPORTANT:

An y bu rn er c ha nge s or

co nv ers io ns mu st be m ade b y a qu al if ied

pr of ess io na l.

Th e i npu t r at ing s s ho wn on t he dr yer da ta

la be l ar e fo r el ev ati on s of u p to 2 ,0 00 f eet

un le ss el ev ati on re qu ir eme nt s o f o ve r

2, 00 0 fe et we re s pe ci fie d a t th e t ime th e

dr ye r o rd er was pl ac ed wi th th e f ac tor y.

Th e ad ju st men t f or d ry er s in t he f ie ld f or

el ev ati on s o ve r 2, 000 f ee t a re ma de by

ch an gin g ea ch bu rn er or if ice . If th is

ad ju stm en t is ne ces sa ry , co nt act th e

di st rib ut or w ho s old t he d rye r or c on tac t

th e fac to ry .

Type of Gas

Natural Liquid Propane (L.P.)

Ma ni fol d Pr ess ur e*

In -L ine P re ssu re ( W.C .)

Or if ice S iz e ( D. M. S.)

... ... ... ... ... ... ... ... ... ... ... ... ... ....

... ... ... .... ... ... .... ... ... .... ...

... ... ... ... ... ... ... ... ... ... ... ... ... ..

4. 0 Inc he s W. C. 10 .5 In ch es W. C.

6. 0 In. t o 12 .0 In . 1 0. 5 I nc he s W .C .

#2 0 #3 8

Ga s Inl et S ize .. ... .. ... .. ... ... .. ... .. ... .. ... .. ... ... .. ... .. ... .. ... ... ..3 /4 " N.P .T .

BT UH In pu t (ea ch t umb le r)

BT UH In pu t (pe r dr yer )

... ... ... ... ... ... ... ... ... ... ... ... ... .

... ... ... .... ... ... .... ... ... .... ... .... ... ..

72 ,0 00

14 4, 000

* Me as ur ed a t g as v alv e pr es su re ta p wh en t he g as v alv e is o n. M eas ur ed in i nc hes o f wa te r

co lu mn.

(D .M .S. ) Dri ll M anu fa ct ure r' s S ta nd ard - e qui va le nt to st an dar d tw ist d ril l or st ee l w ir e

ga ug e n um be rs.

(W .C .) Wa te r c ol um n i n in che s.

14

Page 17

Natural Gas

Re gu lat io n is co nt rol le d b y ea ch g as

va lv e's in ter na l r egu la to r. I nc om ing

su pp ly pr ess ur e m us t b e co ns is ten tl y

be tw een a mi ni mu m of 6 .0 in che s an d a

ma xi mum o f 1 2. 0 i nc he s w at er co lu mn

pr es sur e.

Liquid Propane (L.P.) Gas

Dr ye rs m ade f or u se w it h L. P. ga s ha ve

th e ga s v al ve' s p res su re r egu la to rs

bl oc ked o pe n s o th at t he g as p res su re

mu st be r eg ul ate d up st rea m of t he dr ye r.

Th e pre ss ure m ea su red a t e ac h gas v al ve

bo dy p res su re t ap m us t b e a c on si st ent

10 .5 in che s w at er co lu mn. Th er e i s n o

re gu lat or pr ov ide d in an L.P . dry er . T he

wa te r co lu mn p re ssu re mus t b e re gul at ed

at t he s ou rc e (L .P . ta nk ), o r an e xt er nal

re gu lat or m ust b e add ed t o e ac h dry er .

Piping/Connections

su pp ly li ne t ra ve ls f ro m t he ga s me te r ( or

in t he ca se o f L. P. ga s, t he su pp ly t ank ),

th e n um be r o f te es , o th er ga s o pe ra ted

ap pl ian ce s o n th e s up pl y li ne , e tc. Sp eci fi c

in fo rma ti on r eg ar din g s up ply lin e s iz e

sh ou ld be d ete rm in ed by t he ga s sup pl ie r.

NOTE:

Un de rsi ze d g as su pp ly pi pi ng ca n

cr ea te a lo w or i nco ns is ten t ga s pre ss ur e

wh ic h wi ll res ul t i n er ra tic op era ti on of t he

bu rn er ig ni tio n sy ste m.

Co ns ist en t ga s pr es su re i s es se nti al a t al l

ga s co nne ct io ns. I t i s re co mme nd ed th at

a 3 /4 " p ip e l oo p b e i nst al le d i n t he su ppl y

li ne se rv in g t he ba nk o f d ry ers . An i n-l in e

pr es sur e re gu la tor m us t be i ns tal le d in t he

ga s su pp ly li ne ( hea de r) i f ( na tu ral ) ga s

li ne p res su re e xc eed s 1 2. 0 in ch es w at er

co lu mn pr ess ur e. (R ef er to il lu st rat io n on

pa ge 16 f or de ta il s. )

IMPORTANT:

Wa te r co lum n pr es su re o f

4. 0 i nc hes fo r n at ur al ga s dr ye rs an d 1 0.5

in ch es fo r L .P . g as is re qu ire d at th e g as

va lv e p re ssu re ta p of ea ch dr ye r f or

pr op er an d saf e op era ti on .

Al l co mp one nt s/ mat er ia ls m ust co nfo rm t o

Na ti ona l Fu el Ga s Cod e sp eci fi ca tio ns .

It i s i mp ort an t t ha t gas pr es su re

re gu lat or s me et ap pl ic abl e pr es sur e

re qu ire me nt s a nd th at ga s met er s b e

ra te d f or t he t ota l am ou nt of a ll th e

ap pl ian ce B TU' s be ing s up pli ed .

Th e d ry er is pr ov id ed wi th on e c om mo n

3/ 4" N. P. T. i nl et pi pe co nn ect io n. It is

re co mme nd ed t ha t a ga s s hu t- off va lv e

se rv ing e ach d ry er be p rov id ed fo r ea se

in s erv ic in g.

Th e siz e of t he g as su pp ly l ine ( he ad er)

wi ll va ry, de pe nd ing on th e d is ta nce th is

A 1/ 8" N .P. T. p lu gge d ta pp ing , ac ces si bl e

fo r a te st ga ug e c onn ec ti on, m ust be

in st all ed i n th e ma in g as s up ply l ine

im me dia te ly up st re am of e ach d ry er.

IMPORTANT:

Pi pe j oin t co mp ou nds t ha t

re si st t he a cti on o f na tu ra l an d L .P . ga se s

mu st be u se d.

WARNING: TEST ALL CONNECTIONS FOR

LEAKS BY BRUSHING ON A SOAPY

WATER SOLUTION (LIQUID DETERGENT

ALSO WORKS WELL). NEVER TEST FOR

GAS LEAKS WITH AN OPEN FLAME.

15

Page 18

TY PI CAL N AT URA L GA S I NS TA LLA TI ON

16

TY PI CAL L .P . G AS I NST AL LA TIO N

Page 19

PREPARATION FOR OPERATION

Th e fol lo wi ng it em s s ho ul d b e ch eck ed

be fo re at te mpt in g to op er ate t he dr ye r.

1. R ea d an d fo llo w al l ca ut io n, w arn in g

an d di re ct ion l ab el s at ta che d to t he

dr ye r.

2. C he ck in co min g sup pl y v ol ta ge to be

su re tha t i t i s t he s am e a s in di ca ted on

th e d rye r d at a la be l l oca te d o n th e

re ar s ide of t he m idd le a cc es s

(c on tro l) d oor .

3. Ch ec k t o as su re th at th e dr ye r i s

co nn ect ed t o th e ty pe o f ga s in di cat ed

on t he dr ye r d at a lab el .

WHITES I PERMT iOELICATE

COLORS 1 PRESS I FABRICS

WHITES ■ PERMT I DELICATE

COLORS

HI ■ MED ■ LO

FABRIC-TEMPSETTINGS

I

PRESS

HI ■ ■ LO

I

LOWER

DRYER

QUARTI

FABRICS

2. C om put er S yst em O per at io nal T es t.

O.

0

COIN

RETURN

4. Th e sa il s wi tc h d amp er a ss em bli es

ar e i ns tal le d a nd p re adj us te d a t th e

fa ct ory p ri or to d ry er sh ip me nt.

Ho we ver , e ac h sa il sw it ch ad ju stm en t

sh ou ld b e ch ec ke d to a ss ure th at t his

im po rta nt s afe ty c ont ro l is fu nc tio ni ng .

5. C he ck bo lt s, nu ts , sc re ws, t er min al s

an d fit ti ng s f or s ecu ri ty .

6. Be su re a ll ga s s hu t-o ff va lve s a re in

th e ope n po sit io n.

7. B e s ur e a ll ba ck p an el s (g ua rd s) a nd

el ec tri c bo x c ov ers h av e b ee n

re pl ace d.

8. C hec k a ll s er vi ce d oo rs t o as su re t ha t

th ey ar e cl ose d an d s ec ur ed in p lac e.

9. Ro ta te th e t um bl ers ( dru ms ) by ha nd

to b e s ur e the y mo ve fr ee ly.

a. Di sp la y( s) w ill f la sh b ack a nd f ort h

be tw een “F ILL ” an d th e a mou nt

ne ed ed t o st art t he dr ye r (i .e ., “ 25” ),

me an ing th e d rye r i s av ai la ble an d 2 5

ce nt s i s re qui re d to st ar t i t.

b. I nse rt t he pr op er nu mb er of c oin s

in to c oi n a cce pt or . On ce t he c or re ct

am ou nt n ee ded to s ta rt t he d rye r h as

be en in ser te d, di spl ay (s ) wi ll re ad

“P US H” .. . “t EnP ”.

c. S ta rt t he d ry er b y p re ssi ng t he

de si red s ett in g f or ei th er th e u pp er or

lo we r dr yer tum bl er ( i. e. ,“L O”

se le cti on f or u ppe r dr ye r) . D is pl ay wi ll

no w re ad s el ect io n (s et tin g) m ade a nd

am ou nt of t ime v en ded ( i. e., “ LO 10 ”) .

NOTE:

Dr ye r c an be st opp ed at an y

ti me by op en ing ma in do or . T o r es tar t

dr ye r, s hu t ma in d oo r an d p res s

de si red s et tin g.

PREOPERATIONAL TEST

Al l d ry ers ar e t ho ro ugh ly te st ed an d

in sp ect ed bef or e le av ing th e fa cto ry .

Ho we ver , a pre op er ati on al tes t s hou ld be

ta ke n be fo re t he d rye r i s pu bli cl y us ed . It

is p os si ble t ha t ad ju st men ts h av e ch an ged

in t ran si t.

1. Tu rn o n el ec tri c po we r to d ry er. O pe n

al l gas s hu t-o ff v alv es .

d. O pen m ain d oo r t o st op dr ye r a nd

ch an ge se le cti on to “ MED ” (m ed ium )

se tt ing . R epe at t hi s pr oc edu re , bu t

ch an ge s ele ct io n (s et tin g) t o “H I”

(h ig h). Th is wi ll co nfi rm th at se tti ng

ke y ci rc uit s an d do or s wi tch c ir cu its

ar e fun ct io nin g pr ope rl y.

NOTE:

Se le cti on ( set ti ng ) c ha nge s can

be m ad e at an y ti me d ur ing t he d ry in g

cy cl e b y o pen in g a nd cl os ing ma in

do or an d th en ma ki ng ne w sel ec ti on.

17

Page 20

e. R epe at abo ve pro ce du re f or o th er

tu mb ler .

3. H eat C ir cui t Op era ti on al Te st

Wh en a ga s d rye r is f ir st s ta rte d

(d ur ing i ni ti al s ta rt- up ), i t ha s a

te nd enc y n ot to ig ni te on th e f ir st

at te mpt . T hi s i s b eca us e t he gas

su pp ly pi pi ng is fi ll ed wi th ai r. So , it

ma y ta ke a fe w mi nu tes f or t hi s ai r to

be p urg ed f rom t he li ne s.

Th e dr ye r is e qui pp ed wi th a d ir ect

sp ar k i gn it ion ( DS I) sy st em wh ic h ha s

in te rna l d ia gno st ic s. I f i gn iti on is n ot

es ta bli sh ed a ft er f ir st a tt emp t, th e

sy st em w il l r etr y t wo ( 2) mor e t ime s. If

ig ni tio n is no t es tab li sh ed af te r t hr ee

(3 ) at te mpt s, th e he at ci rc ui t D SI

mo du le wil l l oc k o ut un ti l i t i s m anu al ly

re se t. T o re set th e DS I sy ste m, o pe n

an d c lo se ma in do or an d r es ta rt dr yer

(p re ss de si red t em per at ur e s el ec tio n) .

NOTE:

Du ri ng t he p urg in g pe ri od,

ch ec k t o b e s ure th at al l g as s hu t- off

va lv es ar e ope n.

On ce ig ni tio n is e sta bl ish ed , a ga s

pr es sur e t es t s ho ul d b e t ake n a t t he

ga s va lv e pr ess ur e ta p of eac h dr ye r

(t um ble r) t o a ss ur e t hat th e w at er

co lu mn p re ssu re is cor re ct a nd

co ns ist en t.

NOTE:

Wa te r c ol um n p re ss ure

re qu ire me nt s (m ea su red at th e g as

va lv e p re ss ure t ap ):

Natural Gas - 4.0 Inches VJ.C.

L. P. Gas - 10.5 Inches W.C.

IMPORTANT:

If d rye r ha s b ee n

co nv ert ed t o L .P. , t he w at er c ol um n

pr es sur e m us t b e r egu la te d at th e

so ur ce (L .P . t ank ) or an ex te rna l

re gu lat or mu st b e a dd ed to ea ch

dr ye r.

4. Ma ke a c omp le te o per at io nal c hec k of

al l sa fet y- re lat ed c irc ui ts (i .e ., li nt

ba sk et sw it che s an d s ai l swi tc he s).

NOTE:

Th e sa il s wit ch c an b e ch ec ked

fo r pr op er o per at io n b y o pen in g th e

mi dd le ac ces s ( co nt rol ) d oo r w hi le th e

dr ye r i s r un nin g a nd th e hea ti ng un it

(b ur ner ) a ct ive (o n) . Th e h eat in g

un it (s) sh oul d sh ut o ff w ith in a f ew

se co nds . If not , mak e n ec es sar y

ad ju stm en ts .

5. Ea ch tu mb ler sh ou ld be o pe rat ed

th ro ugh on e c om ple te cy cl e to as su re

th at n o fu rt her a dj us tme nt s ar e

ne ce ssa ry an d t ha t a ll co mp one nt s a re

fu nc tio ni ng pr op er ly.

NOTE:

Dr yi ng a nd co ol in g cy cle s ar e

co mp let e whe n d is pl ay rea ds . ..

“d on E”.

IMPORTANT:

Th e dry er t umb le rs

(b as ket s/ dr ums ) a re t re ate d w ith a

pr ot ect iv e c oat in g. T hi s c oat in g c an b e

re mo ved b y tu mb lin g ol d cl ot hes o r

ma te ria l i n t he ba ske ts /d rum s, us ing

a m il d de te rg ent t o r em ove th e

pr ot ect iv e coa ti ng .

6. Co mp ut er Pr ogr am s/ Se lec ti ons

Ea ch co mp ute r h as be en

pr ep rog ra mm ed b y t he f ac to ry w it h

th e m os t co mm onl y us ed pa ra me ter

se le cti on s. I f c om pu ter p ro gra m

ch an ges a re r equ ir ed , re fe r to t he

us er 's ma nua l w hi ch wa s sh ip pe d w ith

th e dry er .

18

Page 21

OPERATING INSTRUCTIONS

'I'I (-:

< fi l<

WHITES ■ PERMT I DELICATE

COLORS

I

PRESS

HI ■ MED ■ LO

I

FABRICS

FABRIC - TEMP SETTINGS

WHITES I PERMT «DELICATE

COLORS

I

PRESS

HI ■ MED ■ LO

I

FABRICS

! ■ jWI R

nt r/ RM

Th e dr ye r i s av ai lab le for us e wh en t he

L. E. D. d isp la y re ad s “F ILL ” an d/ or t he

am ou nt ne ed ed to st ar t t he dr ye r ( i. e. ,

“2 5” ). O nce t he l oa d h as b een p ut i nto t he

dr ye r a nd th e m ai n d oo r i s c lo se d, st art

th e dry er a s f ol lo ws:

1. In se rt t he pr op er nu mb er of c oin s in to

th e c oi n a cce pt or . O nce t he c or re ct

am ou nt t o s ta rt h as be en i nse rt ed ,

di sp lay s wi ll re ad “P US H” . .. “t En P".

2. De te rmi ne f abr ic se tt in g ( se le cti on ).

Se tt ing “W HI TE CO LOR S” is th e h igh

te mp era tu re r an ge, “P ER MT P RE SS ”

is t he me di um ra ng e s et ti ng an d

“D EL ICA TE FA BR ICS ” i s t he

lo w- ran ge t emp er at ure .

QU AR TER S

ON LY

COIN

RETURN

5. U po n co mp le tio n of t he d ryi ng a nd

co ol ing c yc les , th e dr ye r wi ll sh ut o ff,

th e to ne w ill s ou nd f or f iv e ( 5) s ec ond s

an d the d is pla y wi ll re ad “d on E” .

NOTE:

If th e a nti -w ri nkl e p ro gra m i s

ac ti ve, th e di sp la y wi ll r em ain re ad ing

“d on E”, a nd th e co mp ut er w ill

pr oc eed th ro ug h t he ant i- wr ink le

pr og ram u nti l th e m ax im um “g ua rd on

ti me ” ha s ex pi red or u nt il t he m ai n

do or is o pe ned , wh ich ev er co me s fir st .

If th e a nt i- wri nk le pr og ram i s n ot

ac ti ve or in us e, th e di spl ay wi ll re ad

"d on E” u nti l t he m ai n do or i s op en ed,

at w hi ch t im e, th e di sp la y wi ll r ead

“F IL L” an d t he a mo unt t o sta rt .

On ce th e f ab ric t emp er at ure s ett in g

(s el ect io n) h as b ee n de te rmi ne d, y ou

st ar t th e d ry er b y p re ssi ng th e fa br ic

se tt ing k ey f or t he t umb le r be in g us ed

(i .e ., “ DEL IC AT E FA BR ICS ” se tt ing for

th e upp er t umb le r) .

3. T he d rye r wi ll n ow st ar t an d th e

di sp lay fo r th e tu mb ler s el ec ted wi ll

re ad t he s et tin g a nd t he t im e ve nd ed

(i .e .. “L O 10” ).

4. Th e c yc le t im e w il l co un t d ow n un ti l

th e d ryi ng a nd c oo li ng c yc le s ar e

co mp let ed .

6. No te s

a. D ry er t um ble r can be sto pp ed a t any

ti me b y op eni ng th e m ai n d oo r. T o

re st art d ry er, s hu t ma in d oo r an d

pr es s d es ir ed se tt ing .

NOTE:

Wh en c yc le i s in te rr upt ed b y

op en ing m ai n d oo r, cy cl e ti me wi ll

co nt inu e t o co unt dow nw ar d,

re ga rdl es s i f do or i s o pe n or cl ose d

un ti l k ey bo ard s el ect io n is ma de .

19

Page 22

b. S el ec tio n (s ett in g) ch an ges ca n b e

ma de at an y ti me du ri ng th e d ry ing

cy cl e by op en ing an d c lo sin g m ain

do or an d th en ma ki ng a ne w s el ec tio n.

c. A dd it ion al ti me ca n b e p ur cha se d

at a ny tim e. I f t he d rye r is in ope ra tio n

(d ry ing mo de) an d ad di ti ona l c oin s a re

in se rte d, di sp lay s wi ll re ad “P US H” .. .

“i En P", a nd th e s el ec tio n (s et tin g) ke y

fo r t he ap pr opr ia te tum bl er mu st b e

pr es sed .

NOTE:

An y o re o f t he th re e ( 3)

se le cti on ke ys ca n be pr es sed fo r t he

ap pr opr ia te tu mbl er . N o m at te r w hic h

ke y i s p res se d, t he mi cro co mp ute r w il l

co nt inu e th e cy cl e se lec ti on t hat w as

in o pe rat io n at t he ti me of i ns ert in g

ad di tio na l coi ns .

Wh en b ot h tum bl er s a re i n op era ti on

an d a dd it ion al co in s a re in se rte d f or

on e tu mbl er a nd th e ap pr opr ia te

tu mb ler s el ect io n is m ad e, t he o the r

tu mb ler a ut om ati ca ll y r es um es c ycl e

st at us.

20

Page 23

MAINTENANCE

CLEANING

A p ro gr am or sc he dul e sh oul d b e es tab li sh ed fo r p eri od ic in sp ect io n, c le an ing a nd rem ov al

of li nt f ro m v ari ou s a rea s o f t he d ry er a s \ we ll a s t hr oug ho ut t he du ct w or k sy st em . Th e

fr eq uen cy * o f cl ea nin g ca n b es t b e de te rmi ne d f ro m e xp er ien ce at ea ch lo ca ti on. M axi mu m

op er ati ng ef fic ie nc y is de pen de nt u po n pr op er a ir ci rcu la tio n. Th e ac cu mul at io n of li nt c an

re st ric t t hi s a ir fl ow. I f t he gu id eli ne s i n t hi s s ec ti on ar e m et , y our ne w d ry er v^ ^il l p ro vi de

ma ny ye ar s of ef fi cie nt , tro ub le fre e an d . .. m ost i mp or tan tl y ... s af e ope ra ti on.

WARNING: LINT FROM MOST FABRICS IS HIGHLY COMBUSTIBLE, THE ACCUMULATION

OF LINT CAN CREATE A POTENTIAL FIRE HAZARD.

WARNING: KEEP DRYER AREA CLEAR AND FREE FROM COMBUSTIBLE MATERIALS,

GASOLINE, AND OTHER FLAMMABLE VAPORS AND LIQUIDS.

Suggested

Interval*

Function

Da il y

30 D ays

Cl ea n li nt f rom t he l in t b as ke t. I ns pec t li nt s cre en f or d ama ge a nd r epl ac e

if t orn .

Cl ea n l in t ac cu mul at ion f ro m ar oun d mi cr opr oc es sor t em pe rat ur e s en so r

pr ob es an d sen so r bra ck et as se mb lie s.

90 D ays

WARNING: TO AVOID THE HAZARD OF ELECTRICAL SHOCK,

DISCONNECT ELECTRICAL POWER SUPPLY TO THE DRYER.

Re mo ve li nt fr om t he mo to r a ir v ent s an d s ur ro und in g are a.

IMPORTANT:

Li nt a cc um ula ti on w il l r est ri ct t he ai rfl ow ov er t he mo tor ,

ca us ing o ve rh eat in g an d ir rep ar ab le m oto r da ma ge . Mot or f ai lur e du e to

li nt ac cu mu lat io n wil l vo id th e war ra nt y.

21

Page 24

Re mo ve l in t a ccu mu la tio n f rom ar ou nd t he o pe ni ngs in th e dr ye rs b ac k

pa ne ls.

Re mo ve l in t fr om g as v alv e bu rn er t ra in a rea w it h a d us tin g br us h or

va cu um cl ea ner a tt ach me nt .

Re mo ve an y l in t a cc um ula ti on fr om in sid e con tr ol bo x a nd at re ar ar ea

be hi nd co nt rol b ox .

Re mo ve an y li nt ac cu mu lat io n fr om co in a cce pt or a rea , in cl udi ng c oin

op ti c s wi tc h.

6 Mo nth s

ADJUSTMENTS

Suggested

Interval

In sp ect an d re mo ve l in t ac cu mul at io n in c us tom er f ur ni sh ed e xha us t du ct

wo rk sy st em an d fr om dr ye rs in te rna l ex hau st d uct in g.

WARNING: THE ACCUMULATION OF LINT IN THE EXHAUST DUCT WORK

CAN CREATE A POTENTIAL FIRE HAZARD.

WARNING: DO NOT OBSTRUCT THE FLOW OF COMBUSTION AND

VENTILATION AIR.

In sp ect a nd re mo ve li nt ac cu mu lat io n f ro m th e d ry er ex ha ust d uct w ork

ba ck dr af t dam pe rs .

NOTE:

A b ac k d raf t d am pe r th at i s s ti cki ng pa rti al ly c lo se d ca n r es ul t in

sl ow d ry ing a nd sh utd ow n o f t he h eat ci rc ui t sa fe ty s wi tch es or

th er mos ta ts .

In th e cl ean in g o f the c ab ine t, av oi d u si ng ha rs h a br as ive s. A pr odu ct

in te nde d fo r t he c lea ni ng of a pp lia nc es is r ec omm en de d.

Function

7 Da ys In sp ect b ol ts, n ut s s cr ew s ( be ar ing s et sc re ws ), no n- per ma ne nt ga s

Af te r co nn ect io ns (u ni on s, sh ut -of f va lve s, o rif ic es , e tc .) , e le ct ric al

In st all at io n t er mi nat io ns , a nd g rou nd in g c on ne cti on s. AN D. .. .

Ev er y 6 Mo to r a nd d riv e be lts s ho uld b e exa mi ne d. Cr ac ked o r ser io us ly fr ay ed

Mo nt hs be lt s s ho ul d b e re pla ce d. Ti gh te n l oo se V- Be lt s w he n nec es sa ry an d

ch ec k b el t ali gn me nt.

Co mp let e op era ti on al ch ec k o f co ntr ol s and v al ves .

Co mp let e o per at io nal ch eck of a ll s af et y de vi ces (do or sw itc he s, l in t

co mp art me nt sw it ch ed, s ai l s wi tc h, bu rn er an d hi- li mi t t he rm ost at s. )

LUBRICATION

Th e mot or b ear in gs , i dl er be ar in gs, a nd tu mb le r b ea ri ngs a re pe rm an ent ly l ubr ic at ed an d

no r elu br ic ati on i s n ec es sar y.

22

Page 25

PROCEDURE FOR FUNCTIONAL CHECK

OF REPLACEMENT COMPONENTS

MICROPROCESSOR (COMPUTER) BOARD

1. Upon completing installation of the replacement microprocessor (computer) board,

reestablish power to the dryer.

2. Start the drying cycle.

3. Verify that the motor(s) and the heat indicator dots, in the microprocessor

(computer) L.E.D. display are on. (Refer to the illustration below.)

^ FK'D»

-REV-

-HEAT

-ON

I

«OPL (NON-COIN! REVERSING MODELS ONLY

4. Verify that the motor(s), heat, and door indicator lights on the back side of the

microprocessor (computer) board are lit. (Refer to the illustration below.)

"dSFL" FUSE

1/8-Amp (Slo Bio)

DOOR" L.E.D. Indicator

HEAT" Output L.E.D. Indicator

MTR" Output L.E.D. Indicator

FWD" Output L.E.D. Indicator*

REV" Output L.E.D. Indicator*

* OPL (non-coin) REVERING MODELS ONLY.

5. Open main door. The dryer must stop and ALL indicator lights on the back side

of the microprocessor (computer) board must go out.

23

Page 26

6. Try to restart the dryer with the main door open.

7. The microprocessor (computer) board's L.E.D. display must read "DOOR".

8. Close the main door and restart the dryer.

9. Functional check of the microprocessor (computer) board is complete.

DIRECT SPARK IGNITION (DSI)

MODULE

1. Upon completing installation of

the replacement Direct Spark

Ignition (DSI) module,

reestablish power to the dryer.

2. Start the drying cycle.

3. The Ignition (DSI) module's

L.E.D. indicator will light "red" for

up to approximately 1.5 seconds

(prepurge time).

4. The module's indicator light will

then turn "green". The gas valve

will be energized and the ignitor probe

ж PJtlisM?*

- Pohit EB>obll*htd|

lyjiion sequtncel

- Floiite Conhrftie^

»4 • ignitor> Polled I

CaniQi locfctd QuH

STATUS

Disconnect Power Before Servicing

NOT FIELD REPAIRABLE. Explosion and

Serious Injury May Result

tf rtd fridcafor '• 'Or* солНпооиЫу.

dfcontnue power for 30 tecood«

*4 ond >hen reetioblieh power If red

indico>or etilt retnaiPt *0n'

conllnuoueiy. replace control

Direct 8park

Ignition Control

FOR USE VfiTH ALL GASES

ГЧмЛ: 24 VAC 50/60И2 .1 Ara

coniocte: 1 Aflp Conllmeue

Prepurge 15 Secondf Mo*.

Trial For Ignition: 5 Stconde Ho«

Lockout 6 Seconde Hpx

WARNINQ I

will spark for approximately 8

seconds. The burner flame should

now be established.

□ □ □ □

5. With the burner flame on, remove

the flame sensor wire from the

FS terminal of the DSI module.

6. The burner flame must shut off

and the ignition module must

lock out with the DSI module's

indicator light "red".

7. Stop the drying cycle, with the

flame sensor wire still removed,

restart the drying cycle.

8. The ignition module must proceed through the prepurge, with the indicator light

"red", the ignition trial time of approximately 8 seconds, with the indicator light

"green", and then proceed to lock out with the indicator light "red".

9. Functional check of the Direct Spark Ignition (DSI) Module is complete.

Indicator

о

Replace the flame sensor wire from the FS terminal to the DSI module.

CAUTION

LABEL ALL WIRES PRIOR TO DISCONNECT WHEN SERVICING THE

COMPUTER BOARD AND THE IGNITION MODULE. WIRING ERRORS CAN

CAUSE IMPROPER AND DANGEROUS OPERATION.

24

Loading...

Loading...