Page 1

Service Procedures

for the

Model 20/31 Dryers

Electric and Hot Surface Ignitor Gas

American Dryer Corporation

88 Currant Road

Fall River MA 02720-4781 USA

Telephone: (508) 678-9000 / Fax: (508) 678-9447

e-mail: techsupport@amdry.com

www.amdry.com

ADC Part No. 450262

Page 2

Table of Contents

Part Locations and Removal ........................................ 3

Lower Front Panel Removal............................................................. 3

Upper Front Panel Removal............................................................. 3

T op Cover Removal ......................................................................... 3

Lint Box/Blower Assembly Removal................................................. 4

Gas V alve/Ignition System Removal................................................. 5

Oven Chamber Removal.................................................................. 5

Gas V alve/Ignition System Components........................................... 6

Oven Housing Components ............................................................. 6

Tumbler Support Wheel Assembly Replacement .............................. 6

Tumbler Alignment ........................................................................... 7

Belt Replacement ............................................................................ 6

Placing the Belt Back on the Motor Sheave...................................... 9

Electrical Component Locations ............................... 10

Electrical Panel.............................................................................. 10

Fire Suppression System Items, T erminal Block,

and Axial T emperature Probe......................................................... 11

Sail Switch Assembly..................................................................... 11

Exhaust Probe, Exhaust Hi-Limit, and Lint Drawer Switch .............. 11

Oven Contactor.............................................................................. 11

We have tried to make this manual as complete as possible and hope you will find it useful. ADC reserves the right to

make changes from time to time, without notice or obligation, in prices, specifications, colors, and material, and to

change or discontinue models. The illustrations included in this manual may not depict your particular dryer exactly.

Page 3

Part Locations and Removal

LOWER FRONT PANEL REMOVAL:

Remove the lint drawer. Remove the four screws

located just below the loading door. Tilt the top of

the panel out and lift the panel up and away from the

dryer.

TOP COVER REMOVAL:

First remove the back guard, then pull top cover

toward the rear of the dryer and lift up.

UPPER FRONT PANEL REMOVAL:

Remove the four screws located just above the

loading door. Tilt the bottom of the p anel out and lift

the panel up and away from the dryer .

450262-1 www.amdry.com 3

Page 4

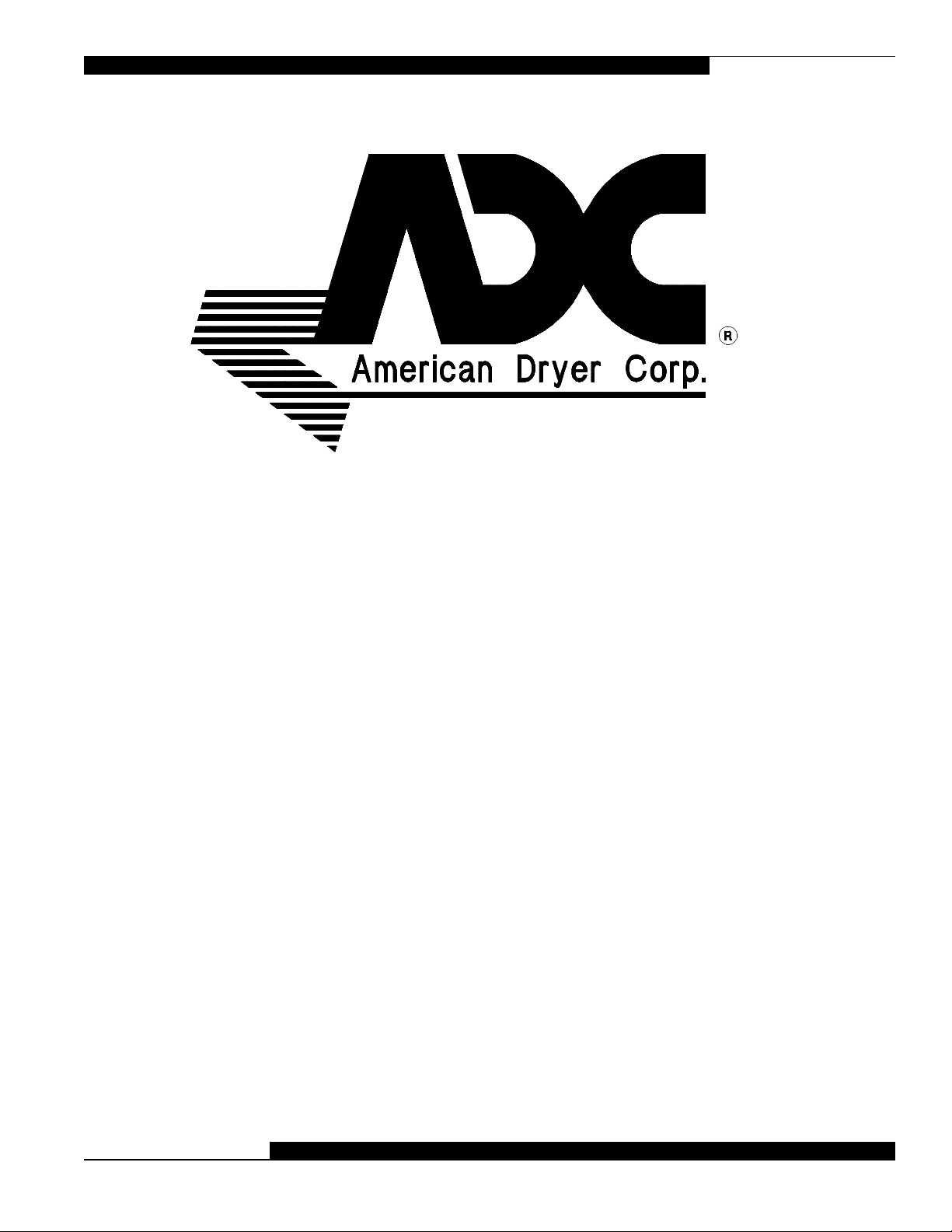

LINT BOX/BLOWER ASSEMBLY REMOVAL:

Remove screws and nuts at the rear of the lint box.

Unplug wires from the capacitor.

Remove two screws just above the lint drawer and

pull the lint box down from the front and out slightly .

T o remove motorized impellor assembly , remove the

five screws and four nuts, shown with arrows.

Remove cover and pull the motorized impellor

assembly out through the opening.

Unplug three connections at the left of the lint box.

The lint box may now be pulled out through the front

of the dryer.

4 American Dryer Corp. 450262-1

Page 5

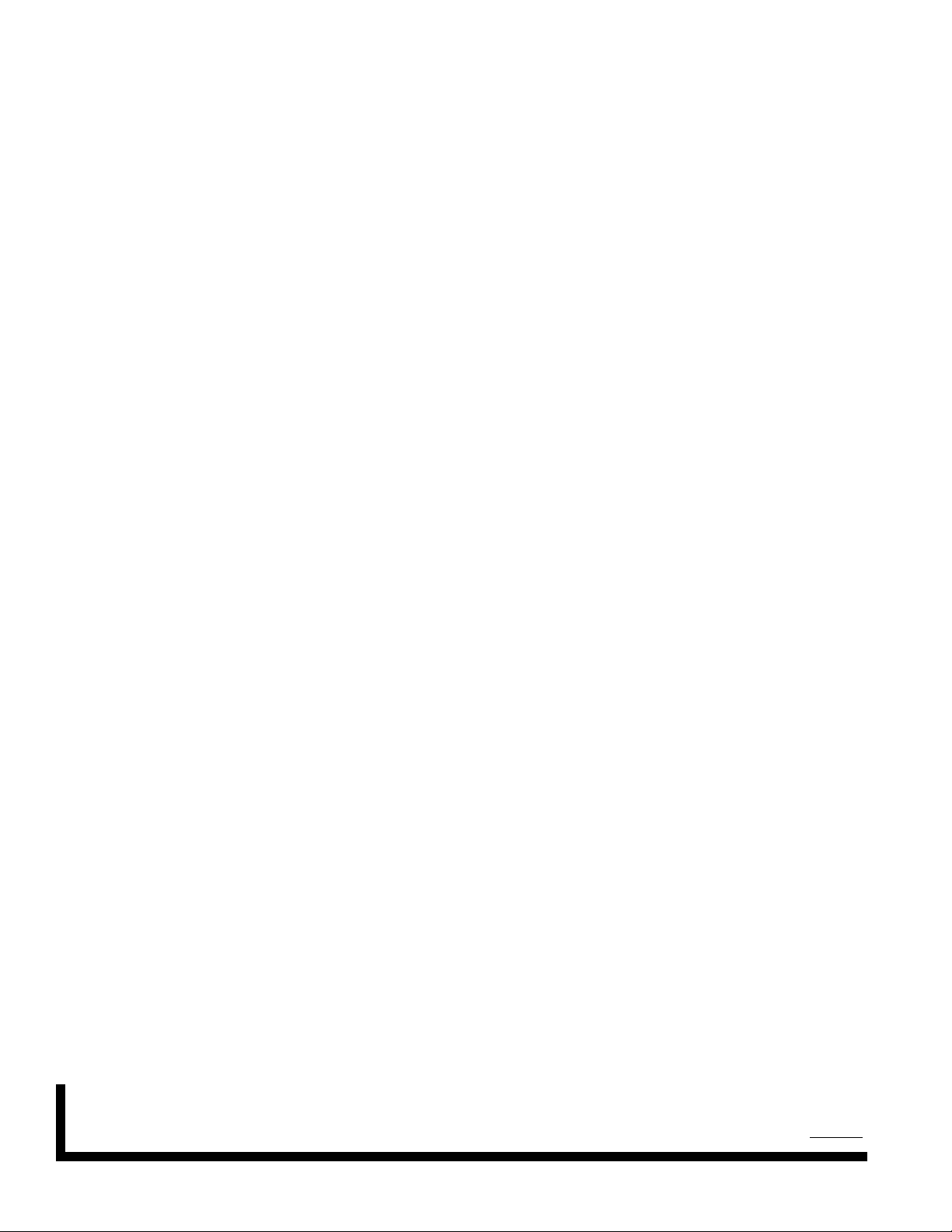

GAS VALVE/IGNITION SYSTEM REMOVAL:

OVEN CHAMBER REMOVAL:

Be sure to shut off the gas main and then proceed

to remove electrical connections and screws

indicated. Remove lower front panel. Disconnect

union and screws noted with arrows.

The gas valve and burner orifice can now be carefully

pulled toward the front of the dryer.

Be sure to pull the assembly straight back so as not

to strike the very fragile carbon ignitor. With the

assembly partly out of the oven, the ignitor and the

two gas valve electrical connections can be

disconnected. At this point the assembly can be

removed from the dryer.

Replace assembly in the reverse order but make

sure the tab at the rear of the assembly engages

into the oven base slot.

Inspect all wires to be sure all lead directly toward

the front of the dryer. Be sure no wires are caught

on the burner tube or ignitor.

The oven chamber can be removed after the gas

valve/ignition system has been removed.

Remove the two screws indicated by the arrows.

Pull the oven housing part way out through the front

and disconnect all wire connections. The oven

housing can now be removed.

Replace assembly by leading the housing cone into

the hole in the rear wall. Replace screws and wire

connections.

450262-1 www.amdry.com 5

Page 6

GAS VALVE/IGNITION SYSTEM COMPONENTS

IGNITOR

BURNER TUBE

GAS VAL VE

OVEN HOUSING COMPONENTS

TUMBLER SUPPORT

WHEEL ASSEMBLY REPLACEMENT:

The front wheel assemblies can be replaced with

the lower front panel removed. Remove the three

bolts by reaching upward with a socket or box

wrench. The illustration below is provided to show

the location of these wheels as the wheels cannot

easily be seen while standing in front of the dryer .

HEA T SENSOR

OVEN CHAMBER

The left rear wheel assembly can be removed with

just the back guard removed. The rear right wheel

requires removing the back guard, heat duct, and

oven. Be sure to mark the position of rear wheel

brackets prior to removal (refer to page 7).

All wheel assemblies are mounted on slots to allow

for alignment of the tumbler. After one or more wheel

assemblies are replaced, the tumbler must be

realigned.

BURNER HIGH-LIMIT

6 American Dryer Corp. 450262-1

Page 7

TUMBLER ALIGNMENT:

EXAMPLES:

Proper alignment is achieved by making the gap

between the tumbler and openings in the front and

rear bulkheads equal on all sides.

The front to bulkhead may be checked for accuracy

by using a thickness gauge. The rear gap is not

accessible. Marking the position of the rear wheel

brackets before removing the brackets will help in

replacing the tumbler back into it’s original position

when the wheel brackets are reinstalled.

Below, both wheel assemblies must be moved to

the right in order to move the tumbler right. The left

wheel assembly must move a little more than the

right in order to lift the tumbler.

Adjust the tumbler position by loosening the three

bolts and forcing the wheel assembly toward the

center of the dryer to raise the tumbler and to move

it away from the side. A large screwdriver can

provide the necessary leverage. Adjustment of the

front of the tumbler is made by equalizing the gap

on the top, bottom, left and right by moving the wheel

assemblies.

Below, both wheel assemblies must be moved

inward in order to move the tumbler straight upward.

450262-1 www.amdry.com 7

Page 8

BELT REPLACEMENT

Shut off electrical power. Disconnect wiring leading to the tumbler support panel. Remove the back guard,

top, and the exhaust support bracket. Unbolt and remove the thrust washers from the rear of the tumbler

shaft. While someone holds the tumbler through the loading door remove all six screws from left and right

side of the rear tumbler support panel. Spread the right and left side panels at the top and pull the tumbler

support panel off of the dryer . Slip the new belt around the tumbler. Replace the rear tumbler support panel.

To maneuver the rear tumbler support panel back into position the rear wheels must be slipped under the

tumbler and the oven housing guided into the circular opening on the inner side of the tumbler support panel.

Replace the six tumbler support panel screws. Apply a few drop s of Loctite 290 to the thrust bearing bolt and

bolt the thrust washers back onto the tumbler shaft in the order shown. Place the belt back on the motor

sheave before replacing the exhaust support bracket, back guard, and top.

Note

A woodworker furniture clamp can be used

!

through the loading door to hold the

tumbler in place (refer to photo below). This will

allow the above procedure to be completed by one

person.

8 American Dryer Corp. 450262-1

Page 9

PLACING THE BELT BACK ON THE MOTOR SHEAVE:

REQUIRED ITEMS:

3 foot Section of 1-1/2” Electrical Tubing

Replacement Belt

To stretch the belt back onto the sheave involves using a two foot length of 1-1/2” electrical tubing (Fig. 1).

Preparing the end of the tubing as shown makes it easier to use. Position the belt around the tumbler and

directly above the motor sheave . Insert the tubing through the belt and onto the motor sheave (Fig. 2).

FIG . 1

FIG. 2

FIG . 3

While pushing the electrical tubing toward the motor, pull the end toward the bottom right corner (Fig. 3).

From this position, rotate the tubing clockwise. The belt will move to a position over the motor sheave. Hold

the belt against the motor (Fig. 3). Rotate the tubing one more revolution while pulling the tubing out. The belt

should drop onto the motor sheave. Rotate the tumbler a few turns while manually preventing the belt from

falling off the sheave. This should center the belt on the tumbler and prevent the belt from being thrown off

later. Replace all dryer panels.

450262-1 www.amdry.com 9

Page 10

Electrical Component Locations

ELECTRICAL PANEL:

The electrical panel is located behind the front upper panel.

DOOR SWITCH

MICROPROCESSOR

ROT ATION SENSOR

10 American Dryer Corp. 450262-1

Page 11

FIRE SUPPRESSION SYSTEM ITEMS,

TERMINAL BLOCK, AND AXIAL

TEMPERATURE PROBE

Located behind back guard.

PRESSURE SWITCH

AXIAL PROBE

SOLENOID VALVE

TERMINAL BLOCK

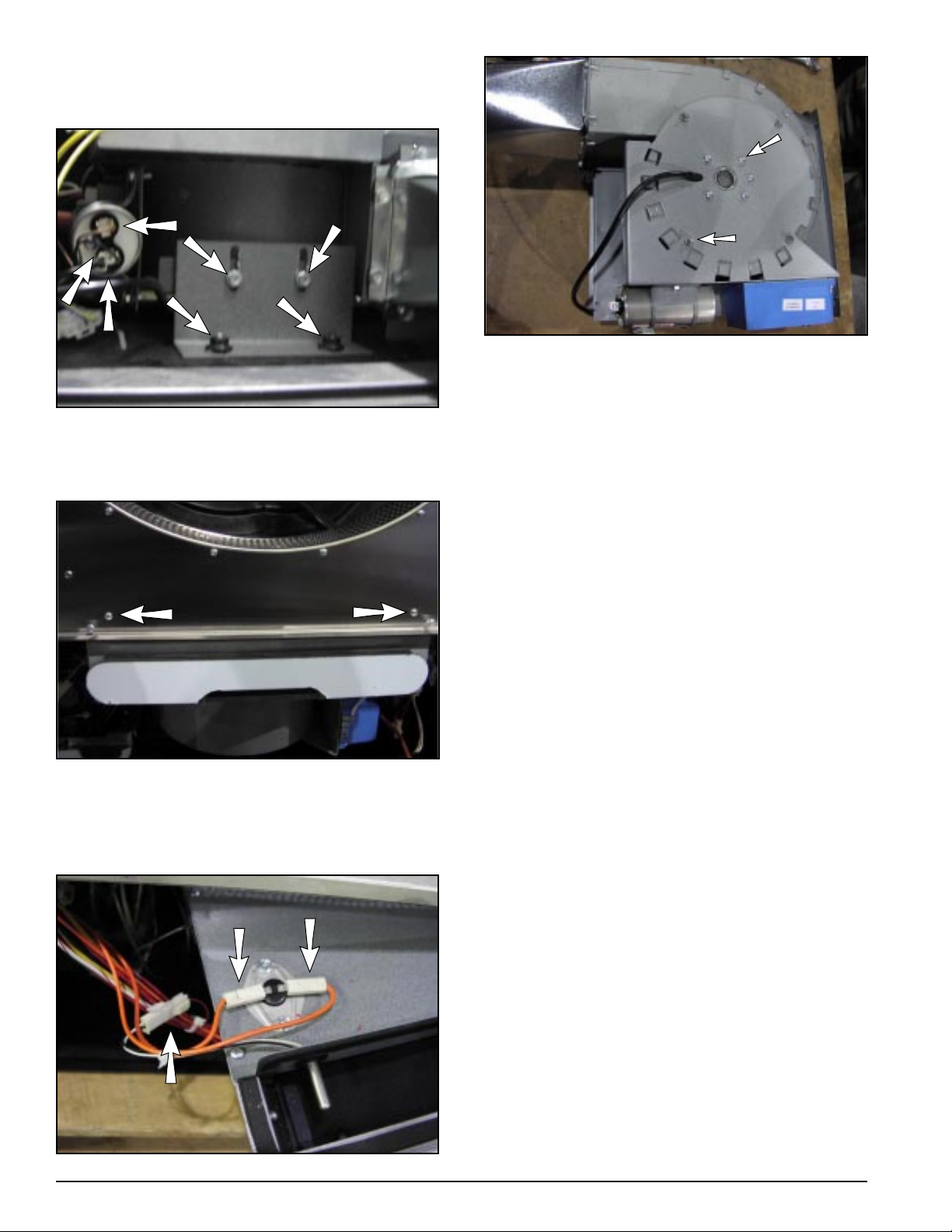

EXHAUST PROBE, EXHAUST HI-LIMIT,

AND LINT DRAWER SWITCH:

Temperature probe and exhaust hi-limit are

accessible once the lint box is removed. The lint

drawer switch can be removed after the cover has

been removed.

EXHAUST

HI-LIMIT SWITCH

EXHAUST TEMPERA TURE PROBE

LINT DRAWER SWITCH

SAIL SWITCH ASSEMBLY

Located behind back guard.

OVEN CONTACTOR:

Lower right front of the dryer (electric oven models).

ELECTRIC OVEN

OVEN CONT ACTOR

450262-1 www.amdry.com 11

Page 12

ADC Part No. 450262 1 - 02/25/05

Loading...

Loading...