Page 1

Thermal Design Guide for

Socket F (1207) Processors

32800Publication # 3.00Revision:

August 2006Issue Date:

Advanced Micro Devices

Page 2

© 2005 Advanced Micro Devices, Inc. All rights reserved.

The contents of this document are provided in connection with Advanced Micro Devices,

Inc. (“AMD”) products. AMD makes no representations or warranties with respect to the

accuracy or completeness of the contents of this publication and reserves the right to make

changes to specifications and product descriptions at any time without notice. The information contained herein may be of a preliminary or advance nature and is subject to change

without notice. No license, whether express, implied, arising by estoppel or otherwise, to

any intellectual property rights is granted by this publication. Except as set forth in AMD’s

Standard Terms and Conditions of Sale, AMD assumes no liability whatsoever, and disclaims any express or implied warranty, relating to its products including, but not limited

to, the implied warranty of merchantability, fitness for a particular purpose, or infringement

of any intellectual property right.

AMD’s products are not designed, intended, authorized or warranted for use as components in systems intended for surgical implant into the body, or in other applications

intended to support or sustain life, or in any other application in which the failure of

AMD’s product could create a situation where personal injury, death, or severe property or

environmental damage may occur. AMD reserves the right to discontinue or make changes

to its products at any time without notice.

Trademarks

AMD, the AMD Arrow logo, and combinat ions ther eo f, are trad em arks of Adva nced Mic ro Devi ces , Inc .

Other product names used in this publication are for identification purposes only and may be trademarks of their respective companies.

Page 3

32800 Rev. 3.00 August 2006

Thermal Design Guide for Socket F (1207) Processors

Contents

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Chapter 1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

1.1 Summary of Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Chapter 2 Processor Thermal Solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

2.1 Processor Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

2.2 Socket Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Chapter 3 Thermal Design of Platforms Using the AMD Processor-In-a-Box (PIB)

Thermal Solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3.1 Motherboard Component Height Restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3.2 Thermal Solution Design Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

3.3 Sample Heat Sinks and Attachment Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

3.3.1 Backplate Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

3.3.2 Retention Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Chapter 4 Thermal Design of Custom 1U-2P Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

4.1 Motherboard Component Height Restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

4.2 Thermal Solution Design Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

4.3 Sample Heat Sinks and Attachment Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

4.3.1 Backplate Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

4.3.2 Spring Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

4.3.3 Heat Sink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

4.3.4 Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

4.3.5 Thermal Interface Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Chapter 5 Thermal Design of Custom 2U-4P Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

5.1 Motherboard Component Height Restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

5.2 Thermal Solution Design Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

5.3 Sample Heat Sinks and Attachment Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

5.3.1 Backplate Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

5.3.2 Spring Clip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

5.3.3 Retention Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Contents 3

Page 4

Thermal Design Guide for Socket F (1207) Processors

32800 Rev. 3.02 August 2006

5.3.4 Heat Sink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

5.3.5 Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

5.3.6 Thermal Interface Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Appendix A Keep-Out Drawings for Platforms Using the PIB Thermal Solution for

Socket F (1207) Processors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Appendix B Keep-Out Drawings for Custom 1U-2P Systems Based on the

Socket F (1207) Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Appendix C Keep-Out Drawings for Custom 2U-4P Systems Based on the

Socket F (1207) Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Appendix D Flow Simulation Results for Custom 2U-4P Systems Based on

Socket F (1207) Processors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

4 Contents

Page 5

32800 Rev. 3.00 August 2006

Thermal Design Guide for Socket F (1207) Processors

List of Figures

Figure 1. The 1207-Pin Socket. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Figure 2. Motherboard Component Height Restrictions for Platforms Using the

AMD PIB Thermal Solution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Figure 3. Exploded View of Thermal Solution AMD PIB Platforms based on

Socket F (1207) Processors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Figure 4. Motherboard Component Height Restrictions for Custom 1U-2P Systems. . . . . . . . . .21

Figure 5. Exploded View of Thermal Solution for Custom 1U-2P Systems. . . . . . . . . . . . . . . . .24

Figure 6. High Performance Heat Sink for Custom 1U-2P Systems . . . . . . . . . . . . . . . . . . . . . . .25

Figure 7. Thermal Performance Chart of Heat Sink When Used with a Dual-Core Processor

in 90 nm Process. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Figure 8. Motherboard Component-Height Restrictions for Custom 2U-4P Systems. . . . . . . . . .29

Figure 9. Exploded View of Thermal Solution for Custom 2U-4P System Based on Socket F

(1207) Processors32

Figure 10. High Performance Heat Sink for Custom 2U-4P Systems . . . . . . . . . . . . . . . . . . . . . . .34

Figure 11. Thermal Performance Chart of Heat Sink When Used with a Dual-Core Processor

in 90 nm Process. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Figure 12. Socket F (1207) PIB Board Component Height Restrictions. . . . . . . . . . . . . . . . . . . . .38

Figure 13. Socket F (1207) PIB Mounting Holes, Contact Pads, and No-Routing Zone . . . . . . . .39

Figure 14. Socket F (1207) PIB Socket Outline and Socket Window. . . . . . . . . . . . . . . . . . . . . . .40

Figure 15. Socket F (1207) PIB Heat Sink Height Restriction Zone. . . . . . . . . . . . . . . . . . . . . . . .41

Figure 16. Socket F (1207) PIB Board No-Through-Hole Keep-Out . . . . . . . . . . . . . . . . . . . . . . .42

Figure 17. Socket F (1207) PIB Board Bottom Side Keep-Out. . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Figure 18. Socket F (1207) 1U-2P Board Component Height Restrictions. . . . . . . . . . . . . . . . . . .46

Figure 19. Socket F (1207) 1U-2P Mounting Holes, Contact Pads, and No-Routing Zone . . . . . .47

Figure 20. Socket F (1207) 1U-2P Socket Outline and Socket Window. . . . . . . . . . . . . . . . . . . . .48

Figure 21. Socket F (1207) 1U-2P Heat Sink Height Restriction Zone. . . . . . . . . . . . . . . . . . . . . .49

Figure 22. Socket F (1207) 1U-2P Board No-Through-Hole Keep-Out . . . . . . . . . . . . . . . . . . . . .50

Figure 23. Socket F (1207) 1U-2P Backplate Contact Zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Figure 24. Socket F (1207) 2U-4P Board Component Height Restrictions. . . . . . . . . . . . . . . . . . .54

Figure 25. Socket F (1207) 2U-4P Mounting Holes, Contact Pads, and No-Routing Zone . . . . . .55

List of Figures 5

Page 6

Thermal Design Guide for Socket F (1207) Processors

32800 Rev. 3.02 August 2006

Figure 26. Socket F (1207) 2U-4P Socket Outline and Socket Window. . . . . . . . . . . . . . . . . . . . .56

Figure 27. Socket F (1207) 2U-4P Heat Sink Height Restriction Zone. . . . . . . . . . . . . . . . . . . . . .57

Figure 28. Socket F (1207) 2U-4P Board No-Through-Hole Keep-Out . . . . . . . . . . . . . . . . . . . . .58

Figure 29. Socket F (1207) 2U-4P Backplate Contact Zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Figure 30. Floor-Plan of AMD Reference Custom 2U-4P System . . . . . . . . . . . . . . . . . . . . . . . . .61

Figure 31. Streamline Plot of AMD Reference Custom 2U-4P System . . . . . . . . . . . . . . . . . . . . .62

6 List of Figures

Page 7

32800 Rev. 3.00 August 2006

Thermal Design Guide for Socket F (1207) Processors

List of Tables

Table 1. Mechanical and Thermal Specifications for Socket F (1207) Processors. . . . . . . . . . . .13

Table 2. Thermal Solution Design Requirements for Platforms Using Socket F (1207)

PIB processors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Table 3. Components for the Processor Thermal Reference Design for the AMD PIB

Thermal Solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Table 4. Thermal Solution Design Requirements for Custom 1U-2P Systems . . . . . . . . . . . . . .22

Table 5. Components for the Processor Thermal Reference Design for Custom

1U-2P Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Table 6. Fin Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Table 7. Thermal Solution Design Requirements for Custom 2U-4P Systems . . . . . . . . . . . . . .30

Table 8. Components for the Processor Thermal Reference Design for Custom

2U-4P Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Table 9. Chemical Element of SK7 Spring Steel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Table 10. Fin Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

List of Tables 7

Page 8

Thermal Design Guide for Socket F (1207) Processors

32800 Rev. 3.02 August 2006

8 List of Tables

Page 9

32800 Rev. 3.00 August 2006

Revision History

Thermal Design Guide for Socket F (1207) Processors

Date Revision

July 2006 3.00 Initial Public release.

Description

Revision History 9

Page 10

Thermal Design Guide for Socket F (1207) Processors

32800 Rev. 3.02 August 2006

10 Revision History

Page 11

32800 Rev. 3.00 August 2006

Thermal Design Guide for Socket F (1207) Processors

Chapter 1 Introduction

This document specifies performance requirements for the design of thermal and mechanical

solutions for socket F (1207) processors, utilizing AMD 64-bit technology. Detailed drawings,

descriptions, and design targets are provided to help manufacturers, vendors, and engineers meet the

requirements for the socket F (1207) processors.

1.1 Summary of Requirements

To allow optimal reliability of a processor, the thermal and cooling solution dissipates heat from that

processor operating at the thermal design power. This document specifies the required values for the

thermal and mechanical parameters of systems based on socket F (1207) processors.

Chapter 1 Introduction 11

Page 12

Thermal Design Guide for Socket F (1207) Processors

32800 Rev. 3.02 August 2006

12 Introduction Chapter 1

Page 13

32800 Rev. 3.00 August 2006

Thermal Design Guide for Socket F (1207) Processors

Chapter 2 Processor Thermal Solutions

This chapter describes the thermal solutions for systems based on socket F (1207) processors.

2.1 Processor Specifications

The objective of thermal solutions is to maintain the processor temperature within specified limits.

Thermal performance, physical mounting, acoustic noise, mass, reliability, and cost must be

considered during the design of a thermal solution.

Table 1 lists the pertinent processor specifications for a thermal solution design for systems based on

socket F (1207) processors.

Table 1. Mechanical and Thermal Specifications for Socket F (1207) Processors

Symbol Description

T

Case

A

CPU

Form

Factor

Maximum case

temperature

Processor contact

area

Processor form

factor

Maximum

Value

67°C - 72°C Consult the processor data sheet for the

thermal requirements specific to the

processor.

32.5 mm x

32.5 mm

LGA LGA form factor for socket F (1207)

Interfaces with heat sink

processors

Notes

Chapter 2 Processor Thermal Solutions 13

Page 14

Thermal Design Guide for Socket F (1207) Processors

32800 Rev. 3.02 August 2006

2.2 Socket Description

Figure 1 shows a three-dimensional view of the 1207-pin socket used with socket F (1207)

processors. This socket is based on LGA (land-grid array) technology . The LGA socket has 35 pads x

35 pads on a 1.1 mm pitch, with a 3.52 mm wide de-populated BGA (ball grid array) zone in the

center, plus a 0.66 mm offset between the two BGA arrays. A small solder-ball makes the electrical

and mechanical connection to the motherboard at each socket contact.

Figure 1. The 1207-Pin Socket

14 Processor Thermal Solutions Chapter 2

Page 15

32800 Rev. 3.00 August 2006

Thermal Design Guide for Socket F (1207) Processors

Chapter 3 Thermal Design of Platforms Using

the AMD Processor-In-a-Box (PIB)

Thermal Solution

This chapter describes the motherboard component height restrictions, thermal-solution design

requirements, sample heat sinks, and attachment methods for platforms using the AMD Processor-Ina-Box (PIB) thermal solution for socket F (1207) processors.

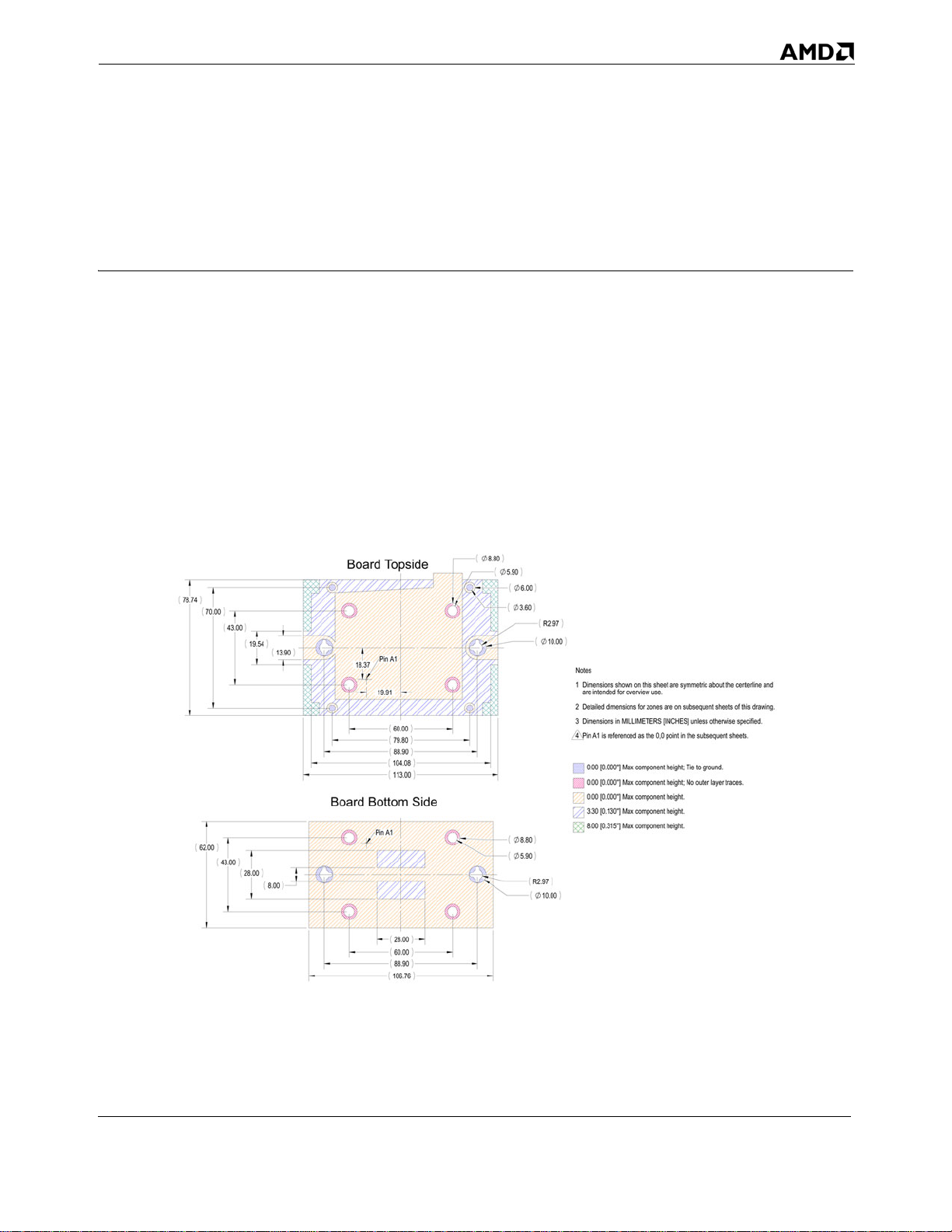

3.1 Motherboard Component Height Restrictions

The mounting solution for the heat sink calls for a standard motherboard keep-out region and

mounting holes for the processor. Figure 2 shows an overview of the motherboard component height

restrictions for platforms using the PIB thermal solution for socket F (1207) processors.

Figure 2. Motherboard Component Height Restrictions for Platforms Using the AMD PIB

Thermal Solution

Chapter 3 Thermal Design of Platforms Using the AMD Processor-In-a-

Box (PIB) Thermal Solution

15

Page 16

Thermal Design Guide for Socket F (1207) Processors

32800 Rev. 3.02 August 2006

Depending on the system features and layout, more space around the socket may be available for the

thermal solution than is shown in Figure 2 on page 15. This space permits heat sink designs with

better thermal performance.

Appendix A on page 37 shows a complete, detailed set of keep-out drawings for the AMD PIB

thermal solution for socket F (1207).

3.2 Thermal Solution Design Requirements

T able 2 provides the design-target specifications that must be met for the processor to operate reliably

in a typical platform using the AMD PIB thermal solution for socket F (1207) processors.

Table 2. Thermal Solution Design Requirements for Platforms Using Socket F (1207) PIB

processors

Symbol Description Maximum

L Length of heat sink 68 mm

W Width of heat sink 77 mm

H Height of heat sink 60 mm

θ

ca

M

HS

F

clip

T

A

Notes:

1. This is the thermal resistance required for dual-core, 90-nm socket F (1207) processors. The thermal resistance

requirement may vary depending on the product OPN. The user should consult the processor data sheet for the

thermal requirements specific to the part.

2. Heat sinks weighing up to 450 g can be attached to the motherboard. Heat sinks weighing over 450 g should be tied

directly to the chassis for reliable shock and vibration performance.

Case-to-ambient thermal

resistance

Mass of heat sink

Clip force 75 lbs ±15 lbs

Local ambient temperature near

processor

0.26°C/W

450 g to 700 g

38°C

1

2

3.3 Sample Heat Sinks and Attachment Methods

The heat sink, fan, mounting spring clip, and thermal interface material used for the AMD PIB

thermal solution for socket F (1207) processors are the same as the heat sink, fan, mounting spring

clip, and thermal interface material used for systems based on the socket 940 processor.

The backplate and retention frame are different from those used in the socket 940 processor. The

EMC shield implemented in the socket 940-based systems is not recommended for AMD PIB thermal

solutions for socket F (1207) processors.

16 Thermal Design of Platforms Using the AMD Processor-In-a-

Chapter 3

Box (PIB) Thermal Solution

Page 17

32800 Rev. 3.00 August 2006

Thermal Design Guide for Socket F (1207) Processors

Table 3 lists the parts used in the thermal reference design for the AMD PIB thermal solution for

socket F (1207) processors.

Table 3. Components for the Processor Thermal Reference Design for the AMD PIB

Thermal Solution

Part Description Material Quantity

Heat sink Copper with aluminum fins 1

Heatpipe Sintered-powder copper 2

Fan Plastic 1

Spring clip SK7 heat treated spring steel 1

Retention frame Lexan, 20% glass-filled 2

Backplate Low-carbon steel, anti-corrosive

finish

Insulator Formex GK-17 1

1

Figure 3 on page 18 shows an exploded view of the thermal solution for platforms using an AMD PIB

based on socket F (1207) processors.

Chapter 3 Thermal Design of Platforms Using the AMD Processor-In-a-

Box (PIB) Thermal Solution

17

Page 18

Thermal Design Guide for Socket F (1207) Processors

32800 Rev. 3.02 August 2006

Figure 3. Exploded View of Thermal Solution AMD PIB Platforms based on Socket F (1207)

Processors

3.3.1 Backplate Assembly

The backplate is mounted on the backside of the motherboard and enhances local stiffness to support

shock and vibration loads acting on the heat sink. The backplate assembly prevents excessive

motherboard warpage in the area near the processor. Without a backplate, excessive warpage could

cause serious damage to electrical connections of the processor socket and integrated circuit packages

surrounding the processor. The backplate also serves as a stiffener plate for the LGA socket.

The reference backplate is made from a 1/16-inch, hard-milled steel, has an overall thickness of 0.138

inch (3.5 mm), including stiffening ribs, and has a mounting-hole pitch of 3.5 inches. To

accommodate the capacitors on the backside of the board, there is a square hole in the center of the

backplate.

18 Thermal Design of Platforms Using the AMD Processor-In-a-

Box (PIB) Thermal Solution

Chapter 3

Page 19

32800 Rev. 3.00 August 2006

Thermal Design Guide for Socket F (1207) Processors

Note: Do not cut entirely through the center rib. Doing so will compromise the stiffness of the

backplate.

The plate uses two PennEngineering (PEM) standoffs that serve multiple purposes. The PEM

standoffs serve as attachment points for the retention frame screws. They also align the backplate

properly to the motherboard. Features in the retention frame slide over the standoffs and allow the

installation of the screws with a minimum chance of cross threading. Additionally, four M3.5 PEM

standoffs in the backplate serve as attachment points for the socket.

The insulator prevents the backplate from electrically shorting to the motherboard. A pressuresensitive adhesive in the insulator keeps the backplate in place against the motherboard during

assembly. The insulator also is thick enough to prevent any significant capacitive coupling between

the motherboard and backplate.

3.3.2 Retention Frame

The plastic retention frame, made of 20% glass-filled Lexan, is a two-piece implementation rather

than the single-piece frame used for socket 940. This change accommodates the larger foot-print of

socket F (1207) processors.

The retention frame serves multiple purposes. The retention frame aligns the heat sink and provides a

stop for the heat sink in large shock-force events. The retention frame and backplate are attached to

the motherboard by the motherboard vendor. Two screws securely hold the backplate and retention

frame together. The two mounting tabs on the retention frame serve as attachment points for the heat

sink spring clip.

Chapter 3 Thermal Design of Platforms Using the AMD Processor-In-a-

Box (PIB) Thermal Solution

19

Page 20

Thermal Design Guide for Socket F (1207) Processors

32800 Rev. 3.02 August 2006

20 Thermal Design of Platforms Using the AMD Processor-In-a-

Box (PIB) Thermal Solution

Chapter 3

Page 21

32800 Rev. 3.02 3.0 0 August 2006

Thermal Design Guide for Socket F (1207) Processors

Chapter 4 Thermal Design of Custom 1U-2P

Systems

This chapter describes the motherboard component-height restrictions, thermal-solution design

requirements, sample heat sinks, and attachment methods for custom 1U-2P systems based on socket

F (1207) processors.

Note: These keep-outs are defined for custom rack mount equipment to optimize thermal and

acoustic performance in these systems. These keep-outs are not compliant with AMD

Processor-In-a-Box (PIB) thermal solutions.

4.1 Motherboard Component Height Restrictions

The mounting solution for the heat sink calls for a standard motherboard keep-out region and

mounting holes for the processor. Figure 4 shows an overview of the motherboard component height

restrictions for custom 1U-2P systems based on the thermal solution for socket F (1207) processors.

Figure 4. Motherboard Component Height Restrictions for Custom 1U-2P Systems

Chapter 4 Thermal Design of Custom 1U-2P Systems 21

Page 22

Thermal Design Guide for Socket F (1207) Processors

32800 Rev. 3.02 August 2006

Depending on the system features and layout, more space around the socket may be available for the

thermal solution than is shown in Figure 4 on page 21. This space permits heat sink designs with

better thermal performance.

Appendix B on page 45 shows a complete, detailed set of keep-out drawings for custom 1U-2P

systems based on socket F (1207) processors.

4.2 Thermal Solution Design Requirements

T o maintain the case temperature of the processor below the maximum specification, certain heat sink

design parameters must be considered. Table 4 provides the design-target specifications that must be

met for socket F (1207) processors to operate reliably.

Table 4. Thermal Solution Design Requirements for Custom 1U-2P Systems

Symbol Description Maximum

L Length of heat sink 87 mm

W Width of heat sink 74 mm

H Height of heat sink 28 mm

θ

ca

M

HS

F

clip

T

A

Notes:

1. This is the thermal resistance required for dual core, 90-nm socket F (1207) processors. The thermal resistance

requirement may vary depending on the product OPN. The user should consult the processor data sheet for the

thermal requirements specific to the part.

2. Heat sinks weighing up to 450 g can be attached to the motherboard. Heat sinks weighing over 450 g should be tied

directly to the chassis for more reliable shock and vibration performance.

3. This chapter describes a heat sink weighing less than or equal to 450 g.

Case-to-ambient thermal

resistance

Mass of heat sink 450 g to 700 g

Clip force 75 lbs ±15 lbs

Local air temperature entering

processor heat sink

0.26°C/W

1, 2, 3

38°C

4.3 Sample Heat Sinks and Attachment Methods

The following sections provide one possible thermal design solution and the specifics on attaching

that solution to the motherboard.

Table 5 on page 23 lists the parts used in the thermal reference design solution for 1U-2P systems

based on socket F (1207) processors.

22 Thermal Design of Custom 1U-2P Systems Chapter 4

Page 23

32800 Rev. 3.02 3.0 0 August 2006

Thermal Design Guide for Socket F (1207) Processors

Table 5. Components for the Processor Thermal Reference Design for Custom 1U-2P

Systems

Part Description Material Quantity

Heat sink Copper base, aluminum fins 1

Fan Plastic 1

Spring screw SK7 heat treated spring steel 2

Backplate Low carbon steel, anti-corrosive

finish

Insulator Formex GK-17 1

1

Figure 5 on page 24 shows an exploded view of the components used in the thermal reference design

solution for custom 1U-2P systems based on socket F (1207) processors.

Chapter 4 Thermal Design of Custom 1U-2P Systems 23

Page 24

Thermal Design Guide for Socket F (1207) Processors

32800 Rev. 3.02 August 2006

Figure 5. Exploded View of Thermal Solution for Custom 1U-2P Systems

The following sections describe the mechanical requirements of the components shown in Figure 5.

4.3.1 Backplate Assembly

For details on the backplate assembly, see section 3.3.1 on page 18.

Note: The backplate for this custom design has a mounting-hole pitch of 4.1 inches.

4.3.2 Spring Screws

The spring screws are designed to apply 75 lbs of force to the heat sink. This force is necessary to

help prevent the heat sink from lifting off the package during shock- or vibration-induced events.

24 Thermal Design of Custom 1U-2P Systems Chapter 4

Page 25

32800 Rev. 3.02 3.0 0 August 2006

Thermal Design Guide for Socket F (1207) Processors

Lifting the heat sink away from the processor can result in damage to the processor contact pads, the

socket contacts, or the socket solder-ball joints. Maintaining the spring force is important for the life

of the processor and the socket and for repeated installations and upgrades of the processor.

4.3.3 Heat Sink

Figure 6 shows a picture of the reference design heat sink for 1U-2P systems. The footprint of the

heat sink is 87 mm x 74 mm. The heat sink weighs 420 g and has aluminum fins soldered to a copper

base. The copper base tapers from a thickness of 6 mm at the center to 1.5 mm at the edges. This

tapering provides optimum heat-spreading performance from the processor to the heat sink while

keeping the heat sink weight within specification. The fin geometry is designed to provide optimized

thermal performance in combination with the fans, as described in Section 4.3.4, on page 26, in a

typical 1U-2P system.

Figure 6. High Performance Heat Sink for Custom 1U-2P Systems

Table 6 shows the parameters of the aluminum fins for the high-performance heat sink shown in

Figure 6.

Table 6. Fin Parameters

Length

87 mm 22 mm 26.5 mm 0.4 mm 1.48

Height (at

Center)

Height (at Edges) Thickness Pitch No. of Fins

50

mm

Chapter 4 Thermal Design of Custom 1U-2P Systems 25

Page 26

Thermal Design Guide for Socket F (1207) Processors

32800 Rev. 3.02 August 2006

Other fan and heat sink combinations may yield adequate thermal performance. The system designer

must ensure that the thermal solution provides required cooling for the processor for the given system

layout and flow characteristics.

Because the processor-mounting surface extends above the surface of the cam box on the socket, the

heat sink bottom can be flat. The heat sink must have a flat surface of at least 40 mm x 40 mm,

centered over the processor.

Figure 7 shows the measured thermal performance vs. flow rate for a slightly shorter version of this

heat sink (3.5" hole pitch vs. 4.1" hole pitch). This data represents the expected performance of this

heat sink on a dual-core socket F (1207) processor. Based on flow tests on the AMD reference 1U-2P

system, the flow through the heat sink is estimated to be approximately 20 cubic feet per minute

(CFM). Figure 7 shows that this corresponds to case-to-ambient thermal resistance of 0.24°C/W. This

case-to-ambient thermal resistance has been confirmed through system thermal tests. The

requirement (see Table 4 on page 22) is 0.26°C/W.

Figure 7. Thermal Performance Chart of Heat Sink When Used with a Dual-Core Processor

in 90 nm Process

4.3.4 Fans

AMD has tested the heat sink described in Section 4.3 on page 22 with a row of five 40 mm x 50 mm

x 56 mm fans (Delta Part number GFB0412EHS) in a typical 1U-2P system. The fan has a 27.3-CFM

maximum flow rate and a 1.63-inches water maximum pressure head. The heat sinks are ducted so

the flow from two fans enters each of the processor heat sinks.

26 Thermal Design of Custom 1U-2P Systems Chapter 4

Page 27

32800 Rev. 3.02 3.0 0 August 2006

Thermal Design Guide for Socket F (1207) Processors

4.3.5 Thermal Interface Material

The heat sink contacts the top surface of the processor package and utilizes the thermal interface

material between the processor lid and the heat sink. AMD recommends using a high performance

grease such as Shin-Etsu 7783D or Dow Corning TC-5022. AMD does not recommend using phase

change materials between the heat sink and the processor. Phase-change materials develop high

adhesion forces between the heat sink and processor when the material is in the solid phase. This

strong adhesive force can cause the processor to stick to the heat sink, making heat sink removal

difficult and damaging the socket solder balls.

Chapter 4 Thermal Design of Custom 1U-2P Systems 27

Page 28

Thermal Design Guide for Socket F (1207) Processors

32800 Rev. 3.02 August 2006

28 Thermal Design of Custom 1U-2P Systems Chapter 4

Page 29

32800 Rev. 3.02 August 2006

Thermal Design Guide for Socket F (1207) Processors

Chapter 5 Thermal Design of Custom 2U-4P

Systems

This chapter describes the motherboard component-height restrictions, thermal-solution design

requirements, sample heat sinks, and attachment methods for custom 2U-4P systems based on socket

F (1207) processors.

Note: These keep-outs are defined for custom rack mount equipment to optimize thermal and

acoustic performance in these systems. These keep-outs are not compliant with AMD

Processor-In-a-Box (PIB) thermal solutions.

5.1 Motherboard Component Height Restrictions

The mounting solution for the heat sink calls for a standard motherboard keep-out region and

mounting holes for the processor. Figure 8 shows an overview of the motherboard component height

restrictions for custom 2U-4P systems based on the thermal solution for socket F (1207) processors.

Figure 8. Motherboard Component-Height Restrictions for Custom 2U-4P Systems

Chapter 5 Thermal Design of Custom 2U-4P Systems 29

Page 30

Thermal Design Guide for Socket F (1207) Processors

32800 Rev. 3.00 August 2006

Depending on the system features and layout, more space around the socket may be available for the

thermal solution than is shown in Figure 8 on page 29. This space permits heat sink designs with

better thermal performance.

Appendix C on page 53 shows a complete, detailed set of keep-out drawings for custom 2U-4P

systems based on socket F (1207) processors.

5.2 Thermal Solution Design Requirements

Table 7 provides the design-target specifications that must be met for socket F (1207) processors to

operate reliably in a typical 2U-4P system based on socket F (1207) processors.

Table 7. Thermal Solution Design Requirements for Custom 2U-4P Systems

Symbol Description Maximum

L Length of heat sink 92 mm

W Width of heat sink 58 mm

H Height of heat sink 40 mm

θ

ca

Case-to-ambient thermal

0.26°C/W

1, 2, 3

resistance

M

F

T

HS

clip

A

Local ambient temperature near

Mass of heat sink 450 g to 700 g

Clip force 75 lbs ±15 lbs

38°C

processor

Notes:

1. This is the thermal resistance required for dual-core, 90-nm socket F (1207) processors. The thermal resistance

requirement may vary depending on the product OPN. The user should consult the processor data sheet for the

thermal requirements specific to the part.

2. Heat sinks weighing up to 450 g can be attached to the motherboard. Heat sinks weighing over 450 g should be tied

directly to the chassis for more reliable shock and vibration performance.

3. This chapter describes a heat sink weighing less than or equal to 450 g. Design examples of solutions up to 700 g are

in development.

5.3 Sample Heat Sinks and Attachment Methods

The following sections provide one possible thermal design solution and the specifics on attaching

that solution to the motherboard.

Table 8 on page 31 lists the parts used in the thermal reference design for Custom 2U-4P systems

based on socket F (1207) processors.

30 Thermal Design of Custom 2U-4P Systems Chapter 5

Page 31

32800 Rev. 3.02 August 2006

Thermal Design Guide for Socket F (1207) Processors

Table 8. Components for the Processor Thermal Reference Design for Custom 2U-4P

Systems

Part Description Material Quantity

Heat sink Aluminum 1

Fan Plastic 1

Spring clip SK7 heat treated spring steel 1

Retention frame Lexan , 20% glass-fi lled 2

Backplate Low carbon steel, anti-corrosive

finish

Insulator Formex GK-17 1

1

Figure 9 on page 32 shows an exploded view of the components used in the thermal reference design

solution for custom 2U-4P systems based on socket F (1207) processors.

Chapter 5 Thermal Design of Custom 2U-4P Systems 31

Page 32

Thermal Design Guide for Socket F (1207) Processors

32800 Rev. 3.00 August 2006

Figure 9. Exploded View of Thermal Solution for Custom 2U-4P System Based on Socket F

(1207) Processors

The following sections describe the mechanical requirements of the components shown in Figure 9.

5.3.1 Backplate Assembly

For details on the backplate assembly, see section 3.3.1 on page 18.

Note: The backplate for this custom design has a mounting-hole pitch of 4.1 inches.

32 Thermal Design of Custom 2U-4P Systems Chapter 5

Page 33

32800 Rev. 3.02 August 2006

Thermal Design Guide for Socket F (1207) Processors

5.3.2 Spring Clip

The spring clip is designed to apply 75 lbs of force to the center of the heat sink. This force is

necessary to help prevent the heat sink from lifting off of the package during shock or vibrationinduced events. Lifting the heat sink away from the processor can result in damage to the processor

contact pads, the socket contacts, or the socket solder-ball joints. Maintaining the spring force is

important for the life of the processor and for repeated installations and upgrades of the processor.

The spring clip material is heat-treatable spring steel, SK7. AMD strongly recommends using SK7 or

an equivalent material for the spring clip. The clip should be plated after heat treatment for cosmetic

and anti-corrosive reasons. Table 9 gives the chemical composition of SK7. The heat treatment used

should bring the ultimate strength of the material to a minimum of 1,300 megapascals (MPa) or 189

kilopounds per square inch (kpsi), and it should bring the yield strength to 940 MPa (or 136 kpsi).

Other materials commonly used for heat sink spring clips have been shown to yield under the high

load of the initial spring-clip deflection and become deformed so that the spring clip can no longer

apply the same load.

Table 9. Chemical Element of SK7 Spring Steel

Element Percentage of the Element

C 0.60-0.70

Si Maximum 0.35

Mn 0.80-0.90

P Maximum 0.030

S Maximum 0.030

Fe Remaining balance

5.3.3 Retention Frame

The plastic retention frame, made of 20% glass-filled Lexan, is a two-piece implementation rather

than the single-piece frame used for socket 940. This change accommodates the larger foot-print of

socket F (1207) processors.

The retention frame serves multiple purposes. The retention frame aligns the heat sink and provides a

stop for the heat sink in large shock-force events. The retention frame and backplate are attached to

the motherboard by the motherboard vendor. Two screws securely hold the backplate and retention

frame together. The two mounting tabs on the retention frame serve as attachment points for the heat

sink spring clip.

5.3.4 Heat Sink

Figure 10 on page 34 shows a picture of the reference design heat sink for 2U-4P systems. The

footprint of the reference design heat sink is 92 mm x 58 mm. The heat sink weighs 378 g and has an

aluminum fin stack soldered to the copper base. The copper base tapers from a thickness of 7 mm at

Chapter 5 Thermal Design of Custom 2U-4P Systems 33

Page 34

Thermal Design Guide for Socket F (1207) Processors

32800 Rev. 3.00 August 2006

the center to 2.5 mm at the edges. The heat sink also has three heat pipes soldered to the base and

connected to the top of the fin stack to improve fin efficiency. This design provides optimum heat

spreading performance from the processor to the heat sink. The fin geometry has been designed to

provide optimized thermal performance in combination with the fans, as described in Section 5.3.5,

on page 35, in a typical 2U-4P system.

Figure 10. High Performance Heat Sink for Custom 2U-4P Systems

Table 10 shows the parameters of the aluminum fins for the high-performance heat sink shown in

Figure 10.

Table 10. Fin Parameters

Length Height (at Center) Height (at Edges) Thickness Pitch No of Fins

92 mm 32.5 mm 37 mm 0.2 mm 1.5 mm 39

Other fan and heat sink combinations may yield adequate thermal performance. The system designer

must ensure that the thermal solution provides required cooling for the processor for the given system

layout and flow characteristics.

Because the processor-mounting surface extends above the surface of the cam box on the socket, the

heat sink bottom can be flat. The heat sink must have a flat surface of at least 40 mm x 40 mm,

centered over the processor.

Figure 11 shows the measured thermal performance vs. flow rate for this heat sink. This data

represents the expected performance of this heat sink on a dual-core socket F (1207) processor. Based

34 Thermal Design of Custom 2U-4P Systems Chapter 5

Page 35

32800 Rev. 3.02 August 2006

Thermal Design Guide for Socket F (1207) Processors

on flow simulations of an AMD reference 2U system, the flow-through of the heat sink is

approximately 18 CFM. Figure 1 1 shows that this flow rate corresponds to a case-to-ambient thermal

resistance of 0.22°C/W. This case-to-ambient thermal resistance exceeds requirements (see Table 7

on page 30).

Figure 11. Thermal Performance Chart of Heat Sink When Used with a Dual-Core Processor

in 90 nm Process

5.3.5 Fans

AMD has conducted simulations of the heat sink described in Section 5.3.4 on page 33 with two 60

mm x 60 mm x 38 mm fans (Delta Part number FFB0812EHE-HS2) in series, that is, back to back.

The fans have a maximum flow rate of 80.2 CFM and a maximum pressure drop of 0.8 inches of

water. The heat sinks are ducted so the flow from the two fans enters the processor heat sinks with

some bypass. The bypass is designed to cool the core VRM.

5.3.6 Thermal Interface Material

The heat sink makes contact with the top surface of the processor package utilizing the thermal

interface material between the processor lid and the heat sink. AMD recommends using a high

performance grease such as Shin-Etsu 7783D or Dow Corning TC-5022. AMD does not recommend

using phase change materials between the heat sink and the processor. Phase-change materials

develop high adhesion forces between the heat sink and processor when the material is in the solid

phase. This strong adhesive force may cause the processor to stick to the heat sink, making heat sink

removal difficult and damaging the socket solder balls.

Chapter 5 Thermal Design of Custom 2U-4P Systems 35

Page 36

Thermal Design Guide for Socket F (1207) Processors

32800 Rev. 3.00 August 2006

36 Thermal Design of Custom 2U-4P Systems Chapter 5

Page 37

32800 Rev. 3.00 August 2006

Thermal Design Guide for Socket F (1207) Processors

Appendix A Keep-Out Drawings for Platforms

Using the PIB Thermal Solution for

Socket F (1207) Processors

Appendix A contains detailed recommended keep-out drawings for processor heat sink and mounting

hardware for platforms using socket F (1207) Processor-In-a-Box (PIB) processors. Depending on the

system features and layout, more space around the processor may be available for the thermal

solution than is shown in these drawings. This space permits the design of heat sinks with better

thermal performance.

Appendix A Keep-Out Drawings for Platforms Using the PIB Thermal

Solution for Socket F (1207) Processors

37

Page 38

Thermal Design Guide for Socket F (1207) Processors

8

7

56 4

3

2

1

D

DE

VORPPAETADNOITPIRCSED.VER

WN5002/80/11esaeleRlaitinI0.2

WN6002/81/1

SNOISIVER

C

.gniwardsi

dnaenilretnecehttuobacirtemmyserateehssihtnonwohssnoisnemiD1

.deificepsesiwrehtosselnu]SEHCNI[SRETEMILLIMnisno

.steehstneuqesbusehtnitniop0,0ehtsadecnerefersi1AniP4

htfosteehstneuqesbusnoerasenozrofsnoisnemiddeliateD2

32800 Rev. 3.02 August 2006

B

.secartreyalretuooN;thgiehtnenopmocxaM]''000.0[00.0

.dnuorgoteiT;thgiehtnenopmocxaM]''000.0[00.0

A

6FO1TEEHS

VER

SECIVEDORCIMDECNAVDA

tnenopmoCrossecorP)7021(FtekcoS

SAXET,NITSUA

:ELTIT

1.2

tnailpmoCsnoitcirtseRthgieHdna

1

BIPDMAhtiw

4210000Z97

.ON.GWD

tuopeeK

23

.eltitgniwarddegnahC

1.2

00.6

09.5

08.8

00.01

79.2R

06.3

.esuweivrevorofdednetniera

isnemiD3

setoN

09.88

00.06

1AniP

19.91

73.81

08.97

.thgie

.thgiehtnenopmocxaM]''513.0[00.8

.thgiehtnenopmocxaM]''031.0[03.3

htnenopmocxaM]''000.0[00.0

00.01

79.2R

08.8

09.5

00.311

8

0

.4

01

1AniP

00.06

00.82

4

5

67.601

09.88

6

Board Topside

Board Bottom Side

09.31

45.91

00.34

00.07

47.87

D

Figure 12. Socket F (1207) PIB Board Component Height Restrictions

C

00.26

B

00.8

00.82

00.34

A

38 Keep-Out Drawings for Platforms Using the PIB Thermal

Solution for Socket F (1207) Processors

78

Appendix A

Page 39

32800 Rev. 3.00 August 2006

8

7

56 4

3

2

1

Thermal Design Guide for Socket F (1207) Processors

D

elohgnitnuomdetalp-noN

x352.1940.0

711.079.2R

R

x2ALIATED

1:2ELACS

831.0 x305.3

x2101.2

73.35

B

C

reppocdetaocredloS

241.006.3

632.000.6

x4BLIATED

1:2ELACS

x2054.0

x223.52

x2075.178.93

x273.81327.0

799.0

24.11

A

x2556.0

x231.3

000.0

321.0

36.61

00.0

B

elohgnitnuomdetalp-noN

232.009.5

643.008.8

x4CLIATED

1:2ELACS

3.00876.41

2.53464.36

2.35 5 2x

59.81

49.91

1.96 5 2x

A

6FO2TEEHS

VER

SECIVEDORCIMDECNAVDA

tnenopmoCrossecorP)7021(FtekcoS

SAXET,NITSUA

:ELTIT

1.2

tnailpmoCsnoitcirtseRthgieHdna

1

BIPDMAhtiw

4210000Z97

.ON.GWD

tuopeeK

23

4

5

1AniP

C

o -Ndna,sdaPtcatnoC,seloHgnitnuoM

weiVenoZgnituoR

x259.6R472.0

D

C

0.0000.00

0.39 7 2x10.09

0.787

2x19.99

0.96624.54

1.44136.59

B

6

.secartreyalretuooN;thgiehtnenopmocxaM]''000.0[00.0

.dnuorgoteiT;thgiehtnenopmocxaM]''000.0[00.0

.thgie

78

htnenopmocxaM]''000.0[00.0

A

Figure 13. Socket F (1207) PIB Mounting Holes, Contact Pads, and No-Routing Zone

Appendix A Keep-Out Drawings for Platforms Using the PIB Thermal

Solution for Socket F (1207) Processors

39

Page 40

Thermal Design Guide for Socket F (1207) Processors

8

7

56 4

3

2

1

32800 Rev. 3.02 August 2006

D

634.278.16

189.133.05

001.233.35

C

327.073.81

854.036.11

000.000.0

B

A

6FO3TEEHS

VER

SECIVEDORCIMDECNAVDA

SAXET,NITSUA

tnenopmoCrossecorP)7021(FtekcoS

:ELTIT

1.2

tnailpmoCsnoitcirtseRthgieHdna

1

BIPDMAhtiw

4210000Z97

.ON.GWD

tuopeeK

23

4

1AniP

2.18955.61

38.6 1 1.520

5

19.9 1 0.784

0.0000.00

6

0.72418.39

.dnuorgoteiT;thgiehtnenopmocxaM]''000.0[00.0

wodniWtekcoSdnaeniltuOtekcoS

.thgiehtnenopmocxaM]''000.0[00.0

78

D

C

B

A

Figure 14. Socket F (1207) PIB Socket Outline and Socket Window

40 Keep-Out Drawings for Platforms Using the PIB Thermal

Solution for Socket F (1207) Processors

Appendix A

Page 41

32800 Rev. 3.00 August 2006

8

7

56 4

3

2

1

Thermal Design Guide for Socket F (1207) Processors

D

x247.75372.2

x241.05 479.1

C

801.1 x241.82

x2933.006.8

x2825.004.31

000.000.0

B

A

6FO4TEEHS

VER

SECIVEDORCIMDECNAVDA

tnenopmoCrossecorP)7021(FtekcoS

SAXET,NITSUA

:ELTIT

1.2

tnailpmoCsnoitcirtseRthgieHdna

1

BIPDMAhtiw

4210000Z97

.ON.GWD

tuopeeK

23

x2728.000.12

4

3.00 8 2x76.41

2x71.95

2.833

2.65 4 2x67.41

5

1AniP

0.0000.00

enoZnoitcirtseRthgieHkniStaeH

1.08 6 2x27.59

1.26 5 2x32.13

6

1.44 1 2x36.59

.thgiehtnenopmocxaM]''513.0[00.8

.thgiehtnenopmocxaM]''031.0[03.3

D

C

B

A

78

Figure 15. Socket F (1207) PIB Heat Sink Height Restriction Zone

Appendix A Keep-Out Drawings for Platforms Using the PIB Thermal

Solution for Socket F (1207) Processors

41

Page 42

Thermal Design Guide for Socket F (1207) Processors

8

7

56 4

3

2

1

32800 Rev. 3.02 August 2006

D

C

B

A

6FO5TEEHS

VER

SECIVEDORCIMDECNAVDA

tnenopmoCrossecorP)7021(FtekcoS

SAXET,NITSUA

:ELTIT

1.2

tnailpmoCsnoitcirtseRthgieHdna

1

BIPDMAhtiw

4210000Z97

.ON.GWD

tuopeeK

23

4

449.173.94

794.036.21

000.000.0

5

2.88573.29

6

0.0000.00

1.31833.47

78

stnenopmocelohhguorhtoN

1AniP

No-Through-H ole Com ponents Zone

D

C

B

A

Figure 16. Socket F (1207) PIB Board No-Through-Hole Keep-Out

42 Keep-Out Drawings for Platforms Using the PIB Thermal

Solution for Socket F (1207) Processors

Appendix A

Page 43

32800 Rev. 3.00 August 2006

8

7

56 4

3

2

1

Thermal Design Guide for Socket F (1207) Processors

D

x2321.0

794.036.21

31.3

C

x2075.1

x2327.0

665.073.41

472.173.23

000.000.0

188.0

271.073.4

73.81

73.22

449.173.94

78.93

B

A

6FO6TEEHS

VER

SECIVEDORCIMDECNAVDA

tnenopmoCrossecorP)7021(FtekcoS

SAXET,NITSUA

:ELTIT

1.2

tnailpmoCsnoitcirtseRthgieHdna

1

BIPDMAhtiw

4210000Z97

.ON.GWD

tuopeeK

23

4

2.88573.29

5

2.53464.36

)draoBfoedisrednUmorfweiV(ediSmottoBdraoB

elohurhtdetalp-noN

x408.8643.0

1.96 5 2x

1.33 5 2x33.91

49.91

6

.secartreyalretuooN;thgiehtnenopmocxaM]''000.0[00.0

0.233

5.91

2x

0.00

0.000

0.39 7 2x

10.09

0.96624.54

.dnuorgoteiT;thgiehtnenopmocxaM]''000.0[00.0

.thgie

78

htnenopmocxaM]''000.0[00.0

1.31833.47

elohurhtdetalp-noN

x200.01493.0

D

C

B

A

Figure 17. Socket F (1207) PIB Board Bottom Side Keep-Out

Appendix A Keep-Out Drawings for Platforms Using the PIB Thermal

Solution for Socket F (1207) Processors

43

Page 44

Thermal Design Guide for Socket F (1207) Processors

32800 Rev. 3.02 August 2006

44 Keep-Out Drawings for Platforms Using the PIB Thermal

Solution for Socket F (1207) Processors

Appendix A

Page 45

32800 Rev. 3.00 August 2006

Thermal Design Guide for Socket F (1207) Processors

Appendix B Keep-Out Drawings for Custom 1U-

2P Systems Based on the Socket F

(1207) Processor

Appendix B contains detailed recommended keep-out drawings for processor heat sink and mounting

hardware for a custom 1U-2P system based on the socket F (1207) processors. Depending on the

system features and layout, more space around the processor may be available for the thermal

solution than is shown in these drawings. This space permits the design of heat sinks with better

thermal performance.

Note: These keep-outs are defined for custom rack mount equipment to optimize thermal and

acoustic performance in these systems. These keep-outs are not compliant with AMD

Processor-In-a-Box (PIB) thermal solutions.

Appendix B Keep-Out Drawings for Custom 1U-2P Systems Based on the

Socket F (1207) Processor

45

Page 46

Thermal Design Guide for Socket F (1207) Processors

8

7

56 4

3

2

1

32800 Rev. 3.02 August 2006

SNOISIVER

D

DEVORPPAETADNOITPIRCSED.VER

WN5002/60/21

WN6002/13/10

5002/10

5002/30

xnimm68.0-f

.daCotuAfodaetsniskroWdiloSnituopeekdetaerC

gniwardtuo-peekS2U1)7021(FtekcoSfoesaeleR

otfihsnoigirooteudsegnahcnoisnemiD

P2/U1otnoitatonS2U1degnahC

.

segnahcgnittamroF

ynimm86.0-dna

0.1

1.3

0.2

0.3

.sdap

dezilatemevahdnarenalpocebdluohssenoztcatnocerawrdaH

setoN

1

26.7

C

.deificepsesiwrehtosselnu]SEHCNI[SRETEMILLIMnisnoi

.steehstneuqesbusehtnitniop0,0ehtsadecnerefersi1AniP

.detalptoneraselohgnitnuomerawdrahknistaeH

snemiD

2

3

4

.secartreyalretuooN;thgiehtnenopmocxaM]''000.0[00.0

.dnuorgoteiT;thgiehtnenopmocxaM]''000.0[00.0

.thgie

htnenopmocxaM]''000.0[00.0

B

.thgiehtnenopmocxaM]''787.0[00.02

.thgiehtnenopmocxaM]''031.0[03.3

A

6FO1TEEHS

VER

SECIVEDORCIMDECNAVDA

tnenopmoCrossecorP)7021(FtekcoS

SAXET,NITSUA

:ELTIT

1.3

,snoitcirtseRthgieHdnatuopeeK

rotcaFmroFP2/U1m

otsuCrof

1

8210000Z97

.ON.GWD

23

4

08.8

09.5

5

42.521

09.88

00.06

1AniP

1AniP

00.121

00.82

6

Board To pside

00.31

BoardBottomSide

78

09.31

00.34

00.65

47.87

D

C

00.8

B

00.8

00.82

00.66

A

Figure 18. Socket F (1207) 1U-2P Board Component Height Restrictions

46 Keep-Out Drawings for Custom 1U-2P Systems Based on the

Socket F (1207) Processor

Appendix B

Page 47

32800 Rev. 3.00 August 2006

8

7

56 4

3

2

1

Thermal Design Guide for Socket F (1207) Processors

D

elohgnitnuomdetalp-noN

493.000.01

432.049.5

seloHgnitnuoM

x2ALIATED

1:2ELACS

x305.3

831.0

x305.2890.0

C

241.006.3

003.026.7

sdaPtcatnoCerawdraH

x4BLIATED

1:2ELACS

reppoc

detaocredloS

A

B

C

B

elohgnitnuomdetalp-noN

643.008.8

232.0

09.5

seloHgnitnuoMtekcoS

1:2ELACS

CLIATED

2.83471.98

2.53 4 2x

1.96 5 2x

A

6FO2TEEHS

VER

SECIVEDORCIMDECNAVDA

tnenopmoCrossecorP)7021(FtekcoS

SAXET,NITSUA

:ELTIT

64.36

49.91

1.3

,snoitcirtseRthgieHdnatuopeeK

rotcaFmroFP2/U1m

otsuCrof

1

8210000Z97

.ON.GWD

23

4

5

1AniP

472.059.6R

0.0000.00

0.39 7 2x10.09

o -Ndna,sdaPtcatnoC,seloHgnitnuoM

0.96 6 2x24.54

1.26632.16

.dnuorgoteiT;thgiehtnenopmocxaM]''000.0[00.0

weiVenoZgnituoR

x224.11054.0

x223.52 799.0

x2628.1

x2075.178.93

x2327.073.81

73.64

D

C

x2973.036.9

x231.3

000.0

321.0

00.0

B

A

6

.secartreyalretuooN;thgiehtnenopmocxaM]''000.0[00.0

78

.thgie

htnenopmocxaM]''000.0[00.0

Figure 19. Socket F (1207) 1U-2P Mounting Holes, Contact Pads, and No-Routing Zone

Appendix B Keep-Out Drawings for Custom 1U-2P Systems Based on the

Socket F (1207) Processor

47

Page 48

Thermal Design Guide for Socket F (1207) Processors

8

7

56 4

3

2

1

32800 Rev. 3.02 August 2006

D

C

B

A

6FO3TEEHS

VER

SECIVEDORCIMDECNAVDA

tnenopmoCrossecorP)7021(FtekcoS

SAXET,NITSUA

:ELTIT

1.3

,snoitcirtseRthgieHdnatuopeeK

rotcaFmroFP2/U1m

otsuCrof

1

8210000Z97

.ON.GWD

23

4

1AniP

wodniWtekcoSdnaeniltuOtekcoS

2.18955.61

5

19.9 1 0.784

0.0000.00

6

0.72418.39

.secartreyalretuoon,thgiehtnenopmocxaM]''000.0[00.0

enoZnoitcirtseRthgieH

78

.thgiehtnenopmocxaM]''000.0[00.0

000.000.0

189.133.05

634.278.16

001.233.35

D

C

327.073.81

854.036.11

B

A

Figure 20. Socket F (1207) 1U-2P Socket Outline and Socket Window

48 Keep-Out Drawings for Custom 1U-2P Systems Based on the

Socket F (1207) Processor

Appendix B

Page 49

32800 Rev. 3.00 August 2006

8

7

56 4

3

2

1

Thermal Design Guide for Socket F (1207) Processors

D

C

B

A

6FO4TEEHS

VER

SECIVEDORCIMDECNAVDA

tnenopmoCr

SAXET,NITSUA

ossecorP)7021(FtekcoS

:ELTIT

1.3

,snoitcirtseRthgieHdnatuopeeK

rotcaFmroFP2/U1motsuCrof

1

8210000Z97

.ON.GWD

23

knistaehhguorhtwolfriawollaotsienoZthgieH

4

3.24982.53

2.83 4 2x

71.98

5

1AniP

0.0000.00

6

weiVenoZnoitcirtseRthgieHkniStaeH

1.26 6 2x

32.16

728.000.12

372.247.75

D

C

000.000.0

B

1.68142.71

..thgiehtnenopmocxaM]''787.0[00.02

.thgiehtnenopmocxaM]''031.0[03.3

A

78

Figure 21. Socket F (1207) 1U-2P Heat Sink Height Restriction Zone

Appendix B Keep-Out Drawings for Custom 1U-2P Systems Based on the

Socket F (1207) Processor

49

Page 50

Thermal Design Guide for Socket F (1207) Processors

8

7

56 4

3

2

1

32800 Rev. 3.02 August 2006

D

C

B

A

6FO5TEEHS

VER

SECIVEDORCIMDECNAVDA

tnenopmoCrossecorP)7021(FtekcoS

SAXET,NITSUA

:ELTIT

1.3

,snoitcirtseRthgieHdnatuopeeK

rotcaFmroFP2/U1motsuCrof

1

8210000Z97

.ON.GWD

23

4

3.16680.41

5

1AniP

0.0000.00

675.036.41

220.273.15

000.000.0

1.59840.59

6

78

.stnenopmocelohhguorhtoN

No-Through-Hole Component Zone

D

C

B

A

Figure 22. Socket F (1207) 1U-2P Board No-Through-Hole Keep-Out

50 Keep-Out Drawings for Custom 1U-2P Systems Based on the

Socket F (1207) Processor

Appendix B

Page 51

32800 Rev. 3.00 August 2006

8

7

56 4

3

2

1

Thermal Design Guide for Socket F (1207) Processors

D

C

x2972.0

x2630.029.0

271.073.4

80.7

472.173.23

188.0

665.073.41

73.22

B

x2527.1

x2014.128.53

A

6FO6TEEHS

VER

SECIVEDORCIMDECNAVDA

tnenopmoCr

SAXET,NITSUA

ossecorP)7021(FtekcoS

:ELTIT

1.3

,snoitcirtseRthgieHdnatuopeeK

rotcaFmroFP2/U1motsuCrof

1

8210000Z97

.ON.GWD

23

28.34

elohgnitnuomdetalp-noN

4

08.8 643.0

3.16680.41

2.94 7 2x74.86

2.83471.98

2.43 5 2x61.86

2x49.91 1.965

5

33.9 1 2x1.335

1AniP

5.9 1 2x0.233

0.0000.00

0.39 7 2x10.09

6

0.86 8 2x22.04

1.26632.16

weiVenoZtcatnoCetalpkcaB

675.036.41

D

493.000.01

elohgnitnuomdetalp-noN

x2

000.000.0

321.0

31.3

C

x2075.1

x273.81

220.273.15

327.0

78.93

B

1.38 0 2x35.04

1.59840.59

.secartreyalretuooN;thgiehtnenopmocxaM]''000.0[00.0

.dnuorgoteiT;thgiehtnenopmocxaM]''000.0[00.0

78

.thgiehtnenopmocxaM]''031.0[03.3

.thgie

htnenopmocxaM]''000.0[00.0

A

Figure 23. Socket F (1207) 1U-2P Backplate Contact Zone

Appendix B Keep-Out Drawings for Custom 1U-2P Systems Based on the

Socket F (1207) Processor

51

Page 52

Thermal Design Guide for Socket F (1207) Processors

32800 Rev. 3.02 August 2006

52 Keep-Out Drawings for Custom 1U-2P Systems Based on the

Socket F (1207) Processor

Appendix B

Page 53

32800 Rev. 3.00 August 2006

Thermal Design Guide for Socket F (1207) Processors

Appendix C Keep-Out Drawings for Custom 2U-

4P Systems Based on the Socket F

(1207) Processor

Appendix C contains detailed recommended keep out drawings for processor heat sink and mounting

hardware for a 2U-4P system based on the socket F (1207) processor. Depending on the system

features and layout, more space around the processor may be available for the thermal solution than is

shown in these drawings. This space permits the design of heat sinks with better thermal

performance.

Note: These keep-outs are defined for custom rack mount equipment to optimize thermal and

acoustic performance in these systems. These keep-outs are not compliant with AMD

Processor-In-a-Box (PIB) thermal solutions.

Appendix C Keep-Out Drawings for Custom 2U-4P Systems Based on the

Socket F (1207) Processor

53

Page 54

Thermal Design Guide for Socket F (1207) Processors

8

7

56 4

3

2

1

32800 Rev. 3.02 August 2006

SNOISIVER

D

DEVORPPAETADNOITPIRCSED.VER

WN5002/60/21

WN6002/13/10

5002/10

5002/30

tuo-peekesaercnI.noitallatsniroftuopeekpilcdednapxE

tuo-peekrossecorpS4U2)7021(FtekcoSfoesaeleR

.daCotuAfodaetsniskroWdilo

6teehSnoxnimm2yb

.segnahcgnittamroF

SnituopeekdetaerC

gniward

0.1

0.2

0.3

06.3

.sdapdezilatemevahdnarenalpocebdluohssenoztcatnocerawrdaH

P4/U2otnoitatonS4U2degnahC

setoN

1.3

1

26.7

C

.deificepsesiwreh

.steehstneuqesbuseht

tosselnu]SEHCNI[SRETEMILLIMnisnoisnemiD

.detalptoneraselohgnitnuomerawdrahknistaeH

nitniop0,0ehtsadecnerefersi1AniP

2

3

4

00.01

.secartreyalretuooN;thgiehtnenopmocxaM]''000.0[00.0

.dnuorgoteiT;thgiehtnenopmocxaM]''000.0[00.0

.thgie

htnenopmocxaM]''000.0[00.0

B

.thgiehtnenopmocxaM]''493.0[00.01

.thgiehtne

.thgiehtnenopmocxaM]''031.0[03.3

nopmocxaM]''787.0[00.02

A

6FO1TEEHS

VER

SECIVEDORCIMDECNAVDA

tnenopmoCrossecorP)7021(FtekcoS

SAXET,NITSUA

:ELTIT

1.3

,snoitcirtseRthgieHdnatuopeeK

rotcaFmroFP4/U2motsuCrof

1

9210000Z97

.ON.GWD

23

4

Board Topside

08.8

09.5

5

26.431

41.401

00.57

42.51

00.34

08.05

85.86

D

C

00.06

1AniP

00.31

Board Bottom Side

00.8

B

1AniP

00.82

00.26

A

42.521

09.88

00.121

00.82

6

78

Figure 24. Socket F (1207) 2U-4P Board Component Height Restrictions

54 Keep-Out Drawings for Custom 2U-4P Systems Based on the

Socket F (1207) Processor

Appendix C

Page 55

32800 Rev. 3.00 August 2006

8

7

56 4

3

2

1

Thermal Design Guide for Socket F (1207) Processors

D

elohgnitnuomdetalp-noN

432.049.5

493.000.01

x3890.005.2

seloHgnitnuoMemarF

x2ALIATED

1:2ELACS

x35.3

831.0

C

003.026.7

241.006.3

sdaPtcatnoCerawdraH

x4BLIATED

1:2ELACS

reppoc

detaocredloS

A

B

B

elohgnitnuomdetalp-noN

232.0

643.008.8

09.5

seloHgnitnuoMtekcoS

x4CLIATED

1:2ELACS

3.43487.22

2.97 1 2x75.47

71.9 8 2.834

2.53 4 2x64.36

A

6FO2TEEHS

VER

SECIVEDORCIMDECNAVDA

tnenopmoCr

SAXET,NITSUA

ossecorP)7021(FtekcoS

:ELTIT

1.3

,snoitcirtseRthgieHdnatuopeeK

rotcaFmroFP4/U2motsuCrof

1

9210000Z97

.ON.GWD

23

4

5

C

1AniP

472.059.6R

0.0000.00

o -Ndna,sdaPtcatnoC,seloHgnitnuoM

weiVenoZgnituoR

x2000.000.0

x2324.057.01

x2320.199.52

x2327.177.34

D

x2327.073.81

C

x230.7

772.0

B

1.86647.40

0.96 6 2x

32.1 6 1.266

1.40 4 2x35.65

24.54

.dnuorgoteiT;thgiehtnenopmocxaM]''000.0[00.0

A

6

.secartreyalretuooN;thgiehtnenopmocxaM]''000.0[00.0

78

.thgie

htnenopmocxaM]''000.0[00.0

Figure 25. Socket F (1207) 2U-4P Mounting Holes, Contact Pads, and No-Routing Zone

Appendix C Keep-Out Drawings for Custom 2U-4P Systems Based on the

Socket F (1207) Processor

55

Page 56

Thermal Design Guide for Socket F (1207) Processors

8

7

56 4

3

2

1

32800 Rev. 3.02 August 2006

D

C

B

A

6FO3TEEHS

VER

SECIVEDORCIMDECNAVDA

SAXET,NITSUA

tnenopmoCrossecorP)7021(FtekcoS

:ELTIT

1.3

,snoitcirtseRthgieHdnatuopeeK

rotcaFmroFP4/U2motsuCrof

1

9210000Z97

.ON.GWD

23

4

1

A

niP

2.18955.61

1.52038.61

0.0000.00

0.72418.39

5

19.9 1 0.784

6

.secartreyalretuooN;thgiehtnenopmocxaM]''000.0[00.0

wodniWtekcoSdnaeniltuOtekcoS

enoZnoitcirtseRthgieH

78

000.000.0

634.278.16

370.266.25

189.133.05

D

327.073.81

C

854.036.11

B

.thgiehtnenopmocxaM]''000.0[00.0

A

Figure 26. Socket F (1207) 2U-4P Socket Outline and Socket Window

56 Keep-Out Drawings for Custom 2U-4P Systems Based on the

Socket F (1207) Processor

Appendix C

Page 57

32800 Rev. 3.00 August 2006

8

7

56 4

3

2

1

Thermal Design Guide for Socket F (1207) Processors

D

C

B

A

6FO4TEEHS

VER

SECIVEDORCIMDECNAVDA

SAXET,NITSUA

tnenopmoCr

ossecorP)7021(FtekcoS

:ELTIT

1.3

,snoitcirtseRthgieHdnatuopeeK

rotcaFmroFP4/U2motsuCrof

1

9210000Z97

.ON.GWD

23

rofdengisedsituopeekwolfriasihttahtetoN

.erehtnoeblliwg

tsomehtsipotehT.tekcosehtfoedisrehtienoognacti

dna,deriuqeryltcirtstonsituopeekepiptaeH

.gniwardsihtotlanoziroheratahtsnif

nituorgnituorRDDesuacebeciohclacigol

4

2x3.249

82.53

2.83 4 2x

71.98

2.26057.41

5

1AniP

0.0000.00

6

0.69317.59

weiVenoZnoitcirtseRthgieHkniStaeH

1.266

32.1 6 2 x

x266.25370.2

475.273.56

D

C

000.000.0

726.029.51

B

1.681

2x42.71

.thgiehtnenopmocxaM]''493.0[00.01

.thgiehtnenopmocxaM]''787.0[00.02

.thgiehtnenopmocxaM]''031.0[03.3

A

78

Figure 27. Socket F (1207) 2U-4P Heat Sink Height Restriction Zone

Appendix C Keep-Out Drawings for Custom 2U-4P Systems Based on the

Socket F (1207) Processor

57

Page 58

Thermal Design Guide for Socket F (1207) Processors

8

7

56 4

3

2

1

32800 Rev. 3.02 August 2006

D

C

B

A

6FO5TEEHS

VER

SECIVEDORCIMDECNAVDA

tnenopmoCrossecorP)7021(FtekcoS

SAXET,NITSUA

:ELTIT

1.3

,snoitcirtseRthgieHdnatuopeeK

rotcaFmroFP4/U2motsuCrof

1

9210000Z97

.ON.GWD

23

4

3.16680.41

5

1AniP

0.0000.00

6

794.036.21

449.173.94

000.000.0

1.59840.59

78

iehtnenopmocxaM]''000.0[00.0 .stnenopmocelohhguorhtondnathg

No-Through-H ole Com ponent Zone Vie w

D

C

B

A

Figure 28. Socket F (1207) 2U-4P Board No-Through-Hole Keep-Out

58 Keep-Out Drawings for Custom 2U-4P Systems Based on the

Socket F (1207) Processor

Appendix C

Page 59

32800 Rev. 3.00 August 2006

8

56 4

3

2

Thermal Design Guide for Socket F (1207) Processors

3.16680.41

2.834

B

2.94 7 2x

2.43 5 2x

1.96 5 2x49.91

1.33 5 2x33.91

A

SECIVEDORCIMDECNAVDA

SAXET,NITSUA

tnenopmoCr

,snoitcirtseRthgieHdnatuopeeK

rotcaFmroFP4/U2motsuCrof

ossecorP)7021(FtekcoS

:ELTIT

74.86

71.98

61.86

6FO6TEEHS

VER

1.3

1

9210000Z97

.ON.GWD

23

4

5

D

1

x2972.080.7

x2630.029.0

643.008.8

elohurhtdetalp-noN

1AniP

C

x2014.128.53

665.073.41

271.073.4

188.073.22

x2527.1

472.173.23

28.34

0.23 3 2x5.91

0.0000.00

0.39 7 2x10.09

0.86 8 2x22.04

1.38 0 2x35.04

weiVenoZtcatnoCetalpkcaB

7

794.036.21

D

elohurhtdetalp-noN

x2

000.000.0

321.0

31.3

327.073.81

C

x2

493.000.01

449.173.94

075.1

78.93

1.59840.59

B

.secartreyalretuooN;thgiehtnenopmocxaM]''000.0[00.0

.dnuorgoteiT;thgiehtnenopmocxaM]''000.0[00.0

.thgie

htnenopmocxaM]''000.0[00.0

A

6

78

.thgiehtnenopmocxaM]''031.0[03.3

Figure 29. Socket F (1207) 2U-4P Backplate Contact Zone

Appendix C Keep-Out Drawings for Custom 2U-4P Systems Based on the

Socket F (1207) Processor

59

Page 60

Thermal Design Guide for Socket F (1207) Processors

32800 Rev. 3.02 August 2006

60 Keep-Out Drawings for Custom 2U-4P Systems Based on the

Socket F (1207) Processor

Appendix C

Page 61

32800 Rev. 3.02 August 2006

Thermal Design Guide for Socket F (1207) Processors

Appendix D Flow Simulation Results for Custom

2U-4P Systems Based on Socket F

(1207) Processors

Appendix D describes the flow simulation results for 2U-4P systems based on socket F (1207)

processors.

Figure 30 shows a floor plan of an AMD reference custom 2U-4P system.

Figure 30. Floor-Plan of AMD Reference Custom 2U-4P System

Figure 31 shows a streamline plot of an AMD reference 2U-4P system.

Appendix D Flow Simulation Results for Custom 2U-4P Systems Based on

Socket F (1207) Processors

61

Page 62

Thermal Design Guide for Socket F (1207) Processors

32800 Rev. 3.00 August 2006

Figure 31. Streamline Plot of AMD Reference Custom 2U-4P System

Thermal simulation of the 2U-4P system shown in Figure 30 on page 61 with the heat sink and fan

described in Chapter 5 on page 29 predicts a flow rate through the heat sink of approximately 18

CFM and an air inlet temperature at the processor heat sinks of 3°C above external ambient

temperature.

62 Flow Simulation Results for Custom 2U-4P Systems Based on

Appendix D

Socket F (1207) Processors

Loading...

Loading...