Amazone Amalog+ User Manual

Operating Manual

AZ

On-board computer

AMALOG+

MG3828 BAH0017.5 06.15

en

Read and follow this operating manual before putting the machine into operation.

Keep it in a safe place for future use!

Reading the instruction

manual and to adhere to it should not appear to be inconvenient and superfluous as it is not enough to hear from others and to realise that a machine is good, to buy it and to believe that now everything would work by itself. The person concerned would not only harm himself but also make the mistake of blaming the machine for the reason of a possible failure instead of himself. In order to ensure a good success one should go into the mind of a thing or make himself familiar with every part of the machine and to get acquainted with its handling. Only this way, you would be satisfied both with the machine as also with yourself. To achieve this is the purpose of this instruction manual.

Leipzig-Plagwitz 1872.

2 |

AMALOG BAH0017.5 06.15 |

Identification data

Identification data

AMALOG On-board Computer

Manufacturer's address

AMAZONEN-WERKE

H. DREYER GmbH & Co. KG

Postfach 51

D-49202 |

Hasbergen, Germany |

|

Tel.: |

+ 49 (0) |

5405 50 1-0 |

Fax: |

+ 49 (0) |

5405 501-234 |

E-mail: |

amazone@amazone.de |

|

Spare part orders

Spare parts lists are freely accessible in the spare parts portal at

www.amazone.de.

Please send orders to your AMAZONE dealer.

Formalities of the operating manual

Document number: |

MG3828 |

Compilation date: |

06.15 |

Copyright AMAZONEN-WERKE H. DREYER GmbH & Co. KG, 2015 All rights reserved.

Reprinting, even of sections, permitted only with the approval of AMAZONEN-WERKE H. DREYER GmbH & Co. KG.

AMALOG BAH0017.5 06.15 |

3 |

Foreword

Foreword

Dear Customer,

You have chosen one of the quality products from the wide product range of AMAZONEN-WERKE, H. DREYER GmbH & Co. KG. We thank you for your confidence in our products.

Before commissioning for the first time, read and understand this operating manual, particularly the safety information.

User evaluation

Dear Reader,

We update our operating manuals regularly. Your suggestions for improvement help us to create ever more user-friendly manuals. Send us your suggestions by fax.

AMAZONEN-WERKE

H. DREYER GmbH & Co. KG

Postfach 51

D-49202 Hasbergen, Germany

Tel.: |

+ 49 (0) |

5405 50 1-0 |

Fax: |

+ 49 (0) |

5405 501-234 |

E-mail: |

amazone@amazone.de |

|

4 |

AMALOG BAH0017.5 06.15 |

|

|

Table of Contents |

1 |

User Information .......................................................................................... |

7 |

1.1 |

Purpose of the document......................................................................................................... |

7 |

1.2 |

Locations in the operating manual........................................................................................... |

7 |

1.1 |

Diagrams used......................................................................................................................... |

7 |

2 |

General Safety Instructions ........................................................................ |

8 |

2.1 |

Obligations and liability ............................................................................................................ |

8 |

2.2 |

Informal safety measures......................................................................................................... |

8 |

2.3 |

User workstation ...................................................................................................................... |

8 |

2.4 |

Safety-conscious working ........................................................................................................ |

9 |

2.5 |

Handling the product................................................................................................................ |

9 |

2.6 |

Representation of safety symbols.......................................................................................... |

10 |

3 |

Product description................................................................................... |

11 |

3.1 |

Intended use .......................................................................................................................... |

12 |

3.2 |

CE marking ............................................................................................................................ |

12 |

4 |

Layout and function................................................................................... |

13 |

4.1 |

Operation with DMC Primera direct seed drills...................................................................... |

13 |

4.2 |

Operation with rotary cultivator .............................................................................................. |

13 |

4.3 |

Operation with seed drills....................................................................................................... |

14 |

4.3.1 |

Operation with cam wheel seed drill ...................................................................................... |

14 |

4.3.2 |

Operation with pneumatic seed drills..................................................................................... |

15 |

4.4 |

Work display........................................................................................................................... |

16 |

4.5 |

Key assignment ..................................................................................................................... |

18 |

4.6 |

Creation of tramlines.............................................................................................................. |

19 |

5 |

Commissioning.......................................................................................... |

22 |

5.1 |

Installing the terminal ............................................................................................................. |

22 |

5.2 |

Connecting the terminal ......................................................................................................... |

22 |

5.3 |

Switching the terminal on/off.................................................................................................. |

23 |

6 |

Settings....................................................................................................... |

24 |

6.1 |

Entering machine data ........................................................................................................... |

24 |

6.2 |

Displaying / altering the working width................................................................................... |

25 |

6.3 |

Displaying / altering the target blower fan speed (during standstill) ...................................... |

25 |

6.4 |

Displaying / altering the target blower fan speed (during operation) ..................................... |

26 |

6.4.1 |

Displaying / altering the tramline rhythm................................................................................ |

26 |

6.5 |

Calibration value (impulses per 100 m) ................................................................................. |

27 |

6.5.1 |

Determining / storing the calibration value (impulses per 100 m).......................................... |

27 |

6.5.2 |

Display / change the stored calibration value (pulses per 100 m)......................................... |

28 |

6.5.3 |

Calculating the number of crank turns for the calibration test ............................................... |

29 |

7 |

Starting work.............................................................................................. |

30 |

7.1 |

Tramline counter .................................................................................................................... |

31 |

7.1.1 |

Setting the tramline counter ................................................................................................... |

31 |

7.1.2 |

Block the tramline counter ..................................................................................................... |

31 |

7.2 |

Worked area........................................................................................................................... |

32 |

7.2.1 |

Displaying the worked part area ............................................................................................ |

32 |

7.2.2 |

Erasing the part area memory ............................................................................................... |

32 |

7.2.3 |

Display the total area ............................................................................................................. |

32 |

7.3 |

Display during work................................................................................................................ |

33 |

7.4 |

Function keys ......................................................................................................................... |

33 |

7.4.1 |

Display of the current blower fan speed ................................................................................ |

33 |

8 |

Faults .......................................................................................................... |

34 |

8.1 |

Fault display A3 ..................................................................................................................... |

34 |

AMALOG BAH0017.5 06.15 |

5 |

|

Table of Contents

8.2 |

Fault display A4..................................................................................................................... |

34 |

8.3 |

Fault display A5..................................................................................................................... |

35 |

8.4 |

Fault display A6 (DMC Primera, Condor and Citan 01 only) ................................................ |

36 |

9 |

Tables......................................................................................................... |

37 |

9.1 |

Machine data table ................................................................................................................ |

37 |

9.2 |

Table for adjustable tramline rhythms................................................................................... |

39 |

9.3 |

Tables: calibration values / crank turns (guide values) ......................................................... |

40 |

9.4 |

Table for calibration values / crank turns for the calibration test........................................... |

43 |

6 |

AMALOG BAH0017.5 06.15 |

User Information

1 User Information

The User Information section supplies information on use of the operating manual.

1.1Purpose of the document

This operating manual

•describes the operation of the on-board computer

•provides important information on safe and efficient handling

•is a component of the on-board computer and should always be kept with the machine or the traction vehicle

•keep it in a safe place for future use.

1.2Locations in the operating manual

All the directions specified in the operating manual are always seen from the direction of travel.

1.1Diagrams used

Handling instructions and reactions

Activities to be carried out by the user are given as numbered instructions. Always keep to the order of the handling instructions. The reaction to the handling instructions is given by an arrow.

Example:

1. Handling instruction 1

Reaction of the machine to handling instruction 1 2. Handling instruction 2

Lists

Lists without an essential order are shown as a list with bullets.

Example:

•Point 1

•Point 2

Number items in diagrams

Numbers in round brackets refer to the item numbers in the diagrams.

The first number refers to the diagram and the second number to the item in the figure.

Example (Fig. 3/6)

•Figure 3

•Item 6

AMALOG BAH0017.5 06.15 |

7 |

General Safety Instructions

2 General Safety Instructions

This section contains important information on safe operation of the on-board computer.

2.1Obligations and liability

Comply with the instructions in the operating manual

Knowledge of the fundamental safety information and safety regulations is a basic requirement for safe handling and fault-free operation of the on-board computer.

Guarantee and liability

Our "General conditions of sales and delivery" are always applicable.

These shall be available to the operator, at the latest on the completion of the contract.

Guarantee and liability claims for damage to people or goods will be excluded if they can be traced back to one or more of the following causes:

•Improper use of the on-board computer

•Improper installation, commissioning and operation of the onboard computer

•Non-compliance with the instructions in the operating manual regarding commissioning, operation and maintenance

•Independently executed constructive changes to the on-board computer.

2.2Informal safety measures

As well as all the safety information in this operating manual, comply with the general, national regulations pertaining to accident prevention and environmental protection.

2.3User workstation

The on-board computer may be operated by only one person sitting in the driver's seat of the tractor.

8 |

AMALOG BAH0017.5 06.15 |

General Safety Instructions

2.4Safety-conscious working

Besides the safety information in this operating manual, the national general workplace safety and accident prevention regulations are binding.

2.5Handling the product

•Do not subject the on-board computer to any mechanical vibrations or jolts.

•Do not drop the on-board computer.

•Do not touch the on-board computer display with any sharp objects, as this may damage the display.

•Protect the on-board computer from wetness and moisture.

•Do not place the on-board computer near heat sources such as radiators or ovens.

•Never open the housing of the on-board computer.

If repairs are necessary, contact a specialist workshop.

AMALOG BAH0017.5 06.15 |

9 |

General Safety Instructions

2.6Representation of safety symbols

Safety instructions are indicated by the triangular safety symbol and the highlighted signal word. The signal word (DANGER, WARNING, CAUTION) describes the gravity of the risk and has the following significance:

DANGER

Indicates an immediate high risk, which will result in death or serious physical injury (loss of body parts or long-term damage) if not avoided.

If the instructions are not followed, then this will result in immediate death or serious physical injury.

WARNING

Indicates a medium risk, which could result in death or (serious) physical injury if not avoided.

If the instructions are not followed, then this may result in death or serious physical injury.

CAUTION

Indicates a low risk, which could incur minor or medium-level physical injury or damage to property if not avoided.

IMPORTANT

Indicates an obligation to special behaviour or an activity required for proper machine handling.

Non-compliance with these instructions can cause faults on the machine or in the environment.

NOTE

Indicates handling tips and particularly useful information.

These instructions will help you to use all the functions of your machine to the optimum.

10 |

AMALOG BAH0017.5 06.15 |

Product description

3 Product description

Fig. 1

Standard equipment Fig. 1/...

(1)On-board computer with fixing console

(2)Socket connection, 12V

(3)Cable harness with 20-pin connector

Special optional equipment Fig. 1/...

(4)Console with battery cable choice of

one or two sockets

AMALOG BAH0017.5 06.15 |

11 |

Product description

3.1Intended use

The on-board computer is intended exclusively for conventional use as a display and monitoring unit in agricultural applications.

Intended use also includes observing all instructions in this instruction manual.

Other uses to those specified above are forbidden and shall be considered as improper. For any damage resulting from improper use:

•the operator bears the sole responsibility,

•AMAZONEN-WERKE assumes no liability whatsoever.

3.2CE marking

The CE marking (Fig. 2) signalises compliance with the stipulations of the valid EU directives.

Fig. 2

Electrical system

Battery voltage: |

12 V (volts) |

12 |

AMALOG BAH0017.5 06.15 |

Layout and function

4 Layout and function

The following section provides information on the structure of the on-board computer and the functions of the individual components.

The on-board computer features a 6-digit display

(Fig. 3/1).

The on-board computer is equipped with an EEPROM (memory chip) for storing data.

The data are again available for the next use, even after a long period of deactivation of the onboard power supply.

Fig. 3

4.1Operation with DMC Primera direct seed drills

The on-board computer initiates an alarm when the set minimum fertiliser quantity is reached in the fertiliser hopper.

4.2Operation with rotary cultivator

The on-board computer monitors the function of the overload clutch.

Acoustic alarm in event of tool carrier standstill.

AMALOG BAH0017.5 06.15 |

13 |

Layout and function

4.3Operation with seed drills

AMALOG+

•determines the cultivated part area [ha]

•stores the cultivated total area [ha]

•indicates the travel speed [km/h] an

•controls the tramline control and the tramline marker

•indicates the position of the hydraulically operated track markers

•initiates an alarm when the set minimum quantity is reached in the tank (level sensor required).

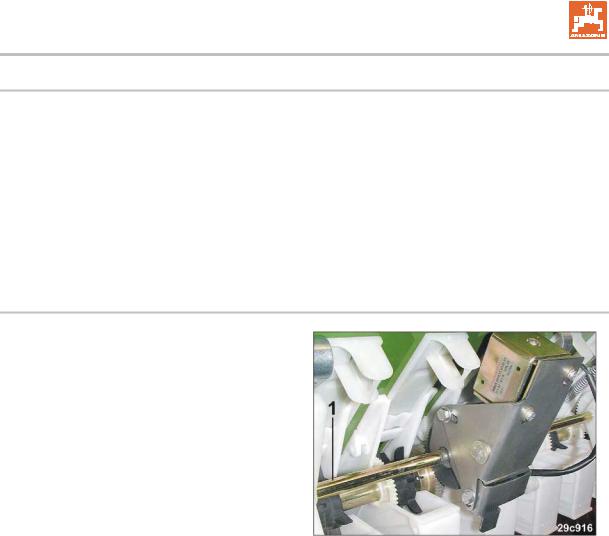

4.3.1Operation with cam wheel seed drill

The on-board computer monitors the lay shaft drive (Fig. 4/1) for seed drills equipped with tramline control (optional).

Fig. 4

14 |

AMALOG BAH0017.5 06.15 |

Loading...

Loading...