Page 1

Service

RST and RSS

Gas Ranges

Models and manufacturing numbers

in this manual see page 2A.

Service Manual for

Caloric

®

This manual is to be used by qualified appliance

technicians only. Amana does not assume any

responsibility for property damage or personal injury

for improper service procedures done by an

unqualified person.

RC231002

Revision 3

May 1998

Page 2

INDEX

General Information. ............................................................................................. 3 - 6

Installation Instructions.......................................................................................... 7 - 20

Safe Operating Procedures ................................................................................... 21 - 23

Operation And Service Procedure

Electronic Clock Timer (Slide in Models) ......................................................... 24 - 31

Electronic Range Control (Two Piece Control) ................................................ 32 - 45

Electronic Range Control (One Piece Control) ................................................ 46 - 55

Automatic Electronic Timer .............................................................................. 56 - 59

Cook And Off Clock Timer ............................................................................... 60 - 64

Clock Timer - Mechanical ................................................................................ 65 - 66

Automatic Electronic Timer (Solid State) ......................................................... 67 - 69

Bake And Broil Ignitors, Electric Gas Valve ..................................................... 70

Selector Switch, Oven Thermostat .................................................................. 71

Spark Module, Spark Switch ............................................................................ 72

Door Latch Mechanism, Latch Switch ............................................................. 73

Troubleshooting Guide .......................................................................................... 74 - 84

Disassembly Procedures....................................................................................... 85 - 99

Upper Oven Operation And Service Procedures .................................................. 100 - 106

Wiring Diagrams and Schematics ......................................................................... 107 - 123

REPLACE MANUAL 56397 AND 56074 WITH THIS MANUAL, RC231002.

REV. 1 - ADDED RSS MODELS TO MANUAL.

REV. 2 - ADDED RST382UK, P1141228N; RST388UWW, P1141246N; and RST399UL/W, P1132642N.

RC231002 Rev. 3 2

Page 3

MODEL AND MANUFACTURING NUMBERS

MODEL M/N

RSS307

RSS307-OF

RSS343

RSS352-OF

RSS353-OF

RSS354-OF

RSS355-OF

RSS356UL P1141233N, P1141234N, P1130975N

RSS356UW P1141233N, P1141234N, P1130975N

RSS358UL P1130875N, P1141226N, P1130974N

RSS358UL P1141231N

RSS358ULG P1141218N, P1141226NLG, P1141232N

RSS358ULGCO P1141219N

RSS358UW P1130875N

RSS358UW/L P1141231N

RSS358UWG P1141218N, P1141226NWG, P1141232N

RSS358UWGCO P1141219N

RSS359

RSS359-OF

RSS361

RSS361-OF

RSS363

RSS363-OF

RSS369

RSS369-OF

RSS380

RSS380-OF

RST307

RST308UK P1130723N, P1130725N, P1130727N

RST308UW P1130723N, P1130725N, P1130727N

RST308UL P1130723N, P1130725N, P1130727N

RST308UWW P1130724N, P1130725N

RST308UWW1 P1130726N, P1130728N

RST309

RST354

RST359

RST361

RST362

RST365

RST369

RST376

RST378UL P1141203N

RST378UW P1141203N

RST380

RST381

RST382UK P1141220N, P1141228N

RST387

RST388UWW P1141221N, P1141229N, P1141246N

RST3997UL/W P1132635N, P1132642N, P1132621N, P1132622N

2A RC231002 Rev. 3

Page 4

IMPORTANT INFORMATION

Great pride and workmanship go into every product to provide our Customers with the highest possible quality. We

realize, however, that during its lifetime the product may require service. The information contained in this manual is

intended for use by a qualified service technician who is familiar with the safety procedures required in the repair and

who is equipped with the proper tools and testing instruments.

REPAIRS COVERED IN THIS MANUAL THAT ARE MADE BY UNQUALIFIED PERSONS CAN RESULT IN

HAZARDS DUE TO IMPROPER ASSEMBLY OR ADJUSTMENTS SUBJECTING INEXPERIENCED PERSONS

MAKING SUCH REPAIRS TO THE RISK OF INJURY OR ELECTRICAL SHOCK WHICH CAN BE SERIOUS OR

EVEN FATAL.

IMPORTANT NOTE TO CONSUMER

IF YOU PERFORM SERVICE ON YOUR OWN PRODUCT, YOU MUST ASSUME RESPONSIBILITY FOR ANY

PERSONAL INJURY OR PROPERTY DAMAGE WHICH MAY RESULT. AMANA WILL NOT BE RESPONSIBLE

FOR ANY INJURY OR PROPERTY DAMAGE ARISING FROM IMPROPER SERVICE AND/OR SERVICE

PROCEDURES.

In order to locate an authorized service agency. please consult your telephone book or the dealer from whom you

purchased this product. If you require further assistance, please contact:

CUSTOMER RELATIONS DEPT. OR 1-319-622-5511

AMANA, IOWA 52204 CALL and ask for the

Customer Relations Department

Users of Caloric products outside of the United States and Canada should contact:

EXPORT CUSTOMER RELATIONS DEPARTMENT

AMANA REFRIGERATION, INC.

AMANA, IOWA 52204, USA

TELEX: 4330076 AMANA

CABLE: "AMANA", AMANA, IOWA, USA

RECOGNIZE SAFETY SYMBOLS, WORDS AND LABELS

DANGER - Immediate hazards which WILL result in

severe personal injury or death.

WARNING - Hazards or unsafe practices which COULD

result in severe personal injury or death.

CAUTION - Hazards or unsafe practices which COULD

result in minor personal injury or product or property

damage.

RC231002 Rev. 3 3

Page 5

GENERAL INFORMATION

F

r

e

e

o

V

V

V

GENERAL INFORMATION

This manual provides you with complete instructions and

suggestions for handling, installing, and servicing Caloric

Self-Cleaning Gas Ranges.

This manual is based on information gained through

experience and careful testing. This information, if followed carefully, will assure the customer of proper unit

operation with a minimum of servicing requirements, thus

insuring the maximum benefits of clean, modern cooking.

Unless the unit is properly installed and carefully explained, the customer will not receive the utmost advantages that gas cooking provides.

Feel free at all times, to call Caloric to discuss any

problems which may not be fully understood.

Refer to the Parts Catalog when replacement parts are

needed.

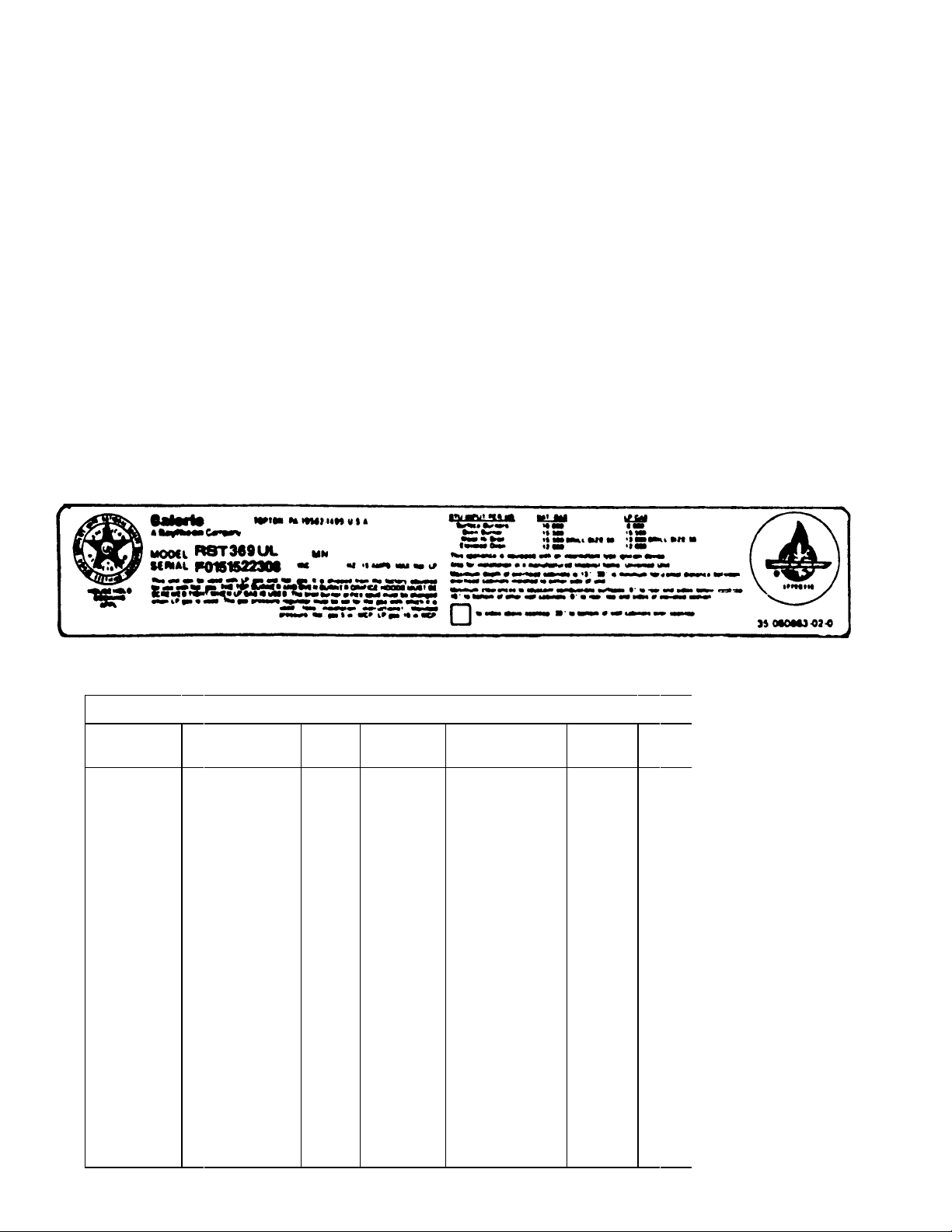

MODEL IDENTIFICATION

The correct model number, manufacturing number (MN or

P), and serial number should be known prior to ordering

parts so that incorrect shipments and delays can be

avoided. (See Rating Label example.)

The rating label is located in the burner box of the unit and

can be observed by raising the main top. The rating label

on sealed burner units is located on the front frame behind

the storage drawer.

The wiring diagram is located on the bottom of the storage

drawer assembly.

E

Electric

R

Gas

T

Trash

Compactor

H

Vent Hood

Microwave

M

CALORIC MODEL DESCRIPTION BREAKDOWN

R S T 3 8 O

PRODUCT

LINE

PRODUCT TYPE SERIES

C

Convertible

H

High Boil

J

Hi-Broil w/ Cont.

Cleaning Panels

Upper Oven

Microwave

K

Lower-Self

Cleaning

Low boil

Low Boil w/

L

Cont. Cleaning

M

Panels

Portable

Self-Clean

P

Cook Top

S

Under-Counter

T

Wall Oven

U

Wall Oven w/

W

Cont. Cleaning

X

Panels

Self-Cleaning

Wall Oven

Y

MicroCombination

R

D

S

T01

2

3

4

6

WIDTH

ON TOP

No Width

Required

15" - 18"

20" - 18"

30" - 35"

40" - 42"

36"

BACKGUARD FEATURE

0

No Backguard

1

Plain Rail/

Laminated Top

Plain Rail/

2

Cutting Board

4" Backguard

3

w/Auto-Timer

Special

4

Designation

Standard

5

Deluxe

6

Backguard

Special

7

Designation

Deluxe

8

Backguard

Double Decker

9

Varible N

Natu

L

Bottl

U

Univ

X

Exp

1

115

2

230

8

208

RC231002 Rev. 3 4

Page 6

GENERAL INFORMATION

RECEIVING

Inspect unit thoroughly at time of delivery. Report any

visible damage to the carrier immediately. If the damage

is "concealed" and not discovered until after delivery has

been accepted, make a "concealed damage report" to the

carrier. "Concealed damage report" forms may be obtained from the carrier's agent.

This procedure must be followed: All shipments, i.e.,

complete range or parts, are shipped at the buyer's risk.

Manufacturer's responsibility ends when the consignment

is accepted by the carrier in "good order". Manufacturer

will give every assistance on damage claims by supplying

any necessary supporting papers, such as invoices or bills

of lading. It must be understood that this assistance does

not imply acceptance of responsibility for settlement of

such claims. Claims for loss or damage cannot be deducted from the invoice or payment of the invoice cannot

be withheld pending adjustment of claims. Do not return

any unit or parts for credit without written consent.

CARE AND HANDLING OF PORCELAIN ENAMEL

1. Porcelain enamel is glass that has been fused onto a

metal surface. Because it is glass, however, it cannot

be guaranteed.

It is impossible to make perfect color match in commercial enamel, and occasional variations must be

expected. Minor imperfections are not just causes for

complaint or rejection.

Porcelain will not stand heavy, sharp blows from

cooking utensils or any other object.

soon as cool enough using dry cloth. If not cleaned,

there may be noticeable smoke, odor, or visible dirt

the next time the unit is used.

3. Crazing - Craze is the name given to the small hair

line marks which are sometimes found in enameled

surfaces after use. They look like little cracks, but

they are not. The enamel around them will never chip

or peel off due to these marks. As we cannot

guarantee enamel against crazing or discoloration,

the customer should be informed as to the proper care

of enamel.

To the customer, any mark is a defect, as they do not

understand enamel. They are afraid the enamel will

peel or crack off leaving a rusty spot. This is not true

as craze marks will never peel or crack. A craze mark

is simply a place where the outer coat of enamel has

separated. The dark color that appears in the crack

is dust that catches in the opening.

To service a craze complaint, it is best to use the

following: Explain crazing to the customer using as

an illustration the effect of hot water in a cold glass it cracks. Compare it to the hairlines in dishes and

cups due to continued heating and cooling. If the

customer can be made to understand that the enamel

will never come off, the customer will be satisfied.

One point to remember with service calls on crazing

is to take care of it immediately. The longer the

customer has to wait, the worse it appears to her.

While this is true of all service work, it is especially

true of crazing complaints. Make it a point to go out

the same day the complaint is received.

In cleaning enamel, soap and water will usually

suffice. Remove any discoloration promptly, but do

not apply cold water to a hot surface.

Fruit juices, vegetable acids, sour milk, or strong

mineral acids may discolor or etch enamel.

2. Cleaning Broiler Pan

For simplest method of cleaning, it is recommended

that broiler pan be submerged in warm water immediately after use. Use a stiff brush, if necessary.

Reheating broiler pan after it has been used without

cleaning will result in fats and greases burning on and

becoming much more difficult to remove.

NOTE: After the food has been removed from the

oven or broiler, and the unit has been turned off, leave

the oven and broiler door open for a few minutes to dry

out the interior. If food has cooked over or grease has

spattered the interior, clean the parts thoroughly as

CARE AND HANDLING OF CHROME, GLASS, OR

METAL FINISH

To keep the stainless, chrome, or glass finishes "looking

new" wash with soap and water, rinse, then dry with a clean

cloth. If a polish is necessary, only the highest quality

chrome cleaning compounds are recommended.

Finger marks and smears may easily be removed with a

mild cleaner such as glass wax and simonize cleaner.

Such agents should be used sparingly. Never use ordinary

steel wool as it may leave a film of iron which will rust and

discolor creating the illusion that the finish is rusting.

Never use harsh, gritty cleaners which can "age" or damage the porcelain and/or polished metal trim.

Never use strong chemical oven cleaners in a self-clean

oven. They are unnecessary and their residues can

produce noxious odors during self-clean, with oven temperatures of 900°F. or more.

5 RC231002 Rev. 3

Page 7

GENERAL INFORMATION

SPECIFICATIONS - Burner Ratings - RST

Non Sealed Nat 10,000 BTU/HR

Top Burner LP 7,000 BTU/HR

Sealed Top Nat 9,000 BTU/HR

Burner LP 7,000 BTU/HR

Cast Sealed RST/RSS

Top Burner

Large (3) Nat 9,000 BTU/HR

LP 8,000 BTU/HR

Small (1) Nat 7,000 BTU/HR

LP 6,000 BTU/HR

Oven Burner Nat 15,500 BTU/HR

Lower LP 15,000 BTU/HR

Broil Nat 15,500 BTU/HR

Burner LP 13,000 BTU/HR

Oven Burner Nat 12,000 BTU/HR

Upper LP 12,000 BTU/HR

BURNER ORIFICE SIZES - Universal Models

SPECIFICATIONS - Burner Ratings - RSS

NON SEALED

Top Burner Nat 10,000 BTU/HR

Top Burner LP 8,000 BTU/HR

Oven Burner Nat 15,5000 BTU/HR

Lower LP 15,500 BTU/HR

Broil Nat 15,500 BTU/HR

Burner LP 13,000 BTU/HR

Non Sealed Top Burners are equipped with #54 double

coaxial orifices and universal pin.

Sealed Top Burners are equipped with a 4-#54 orifice

spud for natural gas and separately packed 4-#68 orifice

spud to convert to LP gas.

or

beginning October 22, 1990 at serial number F0430127550

the venturi type top burners are equipped with #54 double

coaxial orifices and universal pin.

Cast Sealed Top Burners are equipped with 3-#54 double

coaxial orifices with universal pins and 1-#56 double

coaxial orifice with universal pin.

Lower Oven Burner is equipped with a #50 double coaxial

orifice and universal pin.

Broil Burner is equipped with a #54 orifice spud and

separately packed orifice spud to convert to LP gas.

Upper Oven Burner is equipped with a #52 double coaxial

orifice and universal pin.

ELECTRICAL REQUIREMENTS

These ranges should be connected to a separate 115 volt,

60 cycle AC three-wire "U" ground receptacle, parallel

slots.

RC231002 Rev. 3 6

Page 8

INSTALLATION INSTRUCTIONS

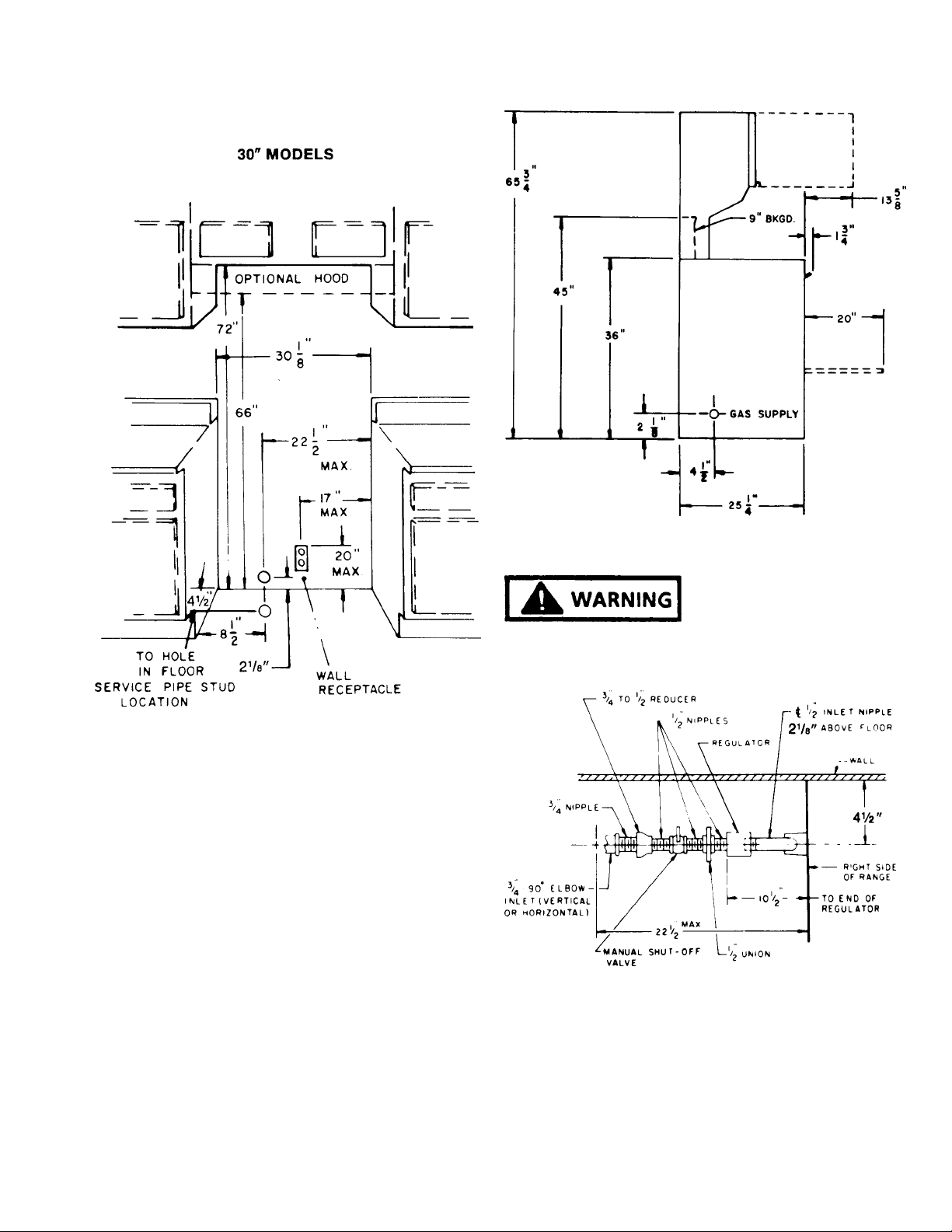

SUGGESTED LOCATION OF SERVICE PIPE - REAR

WALL OR FLOOR

FIGURE 1

UNIVERSAL MODELS (Nat or LP Gas)

The regulator is factory adjusted for natural gas with a

supply line pressure of not less than 6-inches water column

pressure (W.C.P.). With the regulator adjusted for liquefied petroleum (LP) gas, the minimum supply pressure is

11 inches W.C.P. For conversion procedure to LP gas see

the section on regulators and LP conversion procedures.

Cabinet Installation opening for gas slide-in range. See

Page 10.

FIGURE 2

FIRE OR EXPLOSION

HAZARD

THE MAXIMUM GAS SUPPLY PRESSURE FOR THESE

MODELS MUST NOT EXCEED 14-INCHES W.C.P.

Top View

Figure 3

7 RC231002 Rev. 3

Page 9

INSTALLATION INSTRUCTIONS

INSTALLATION

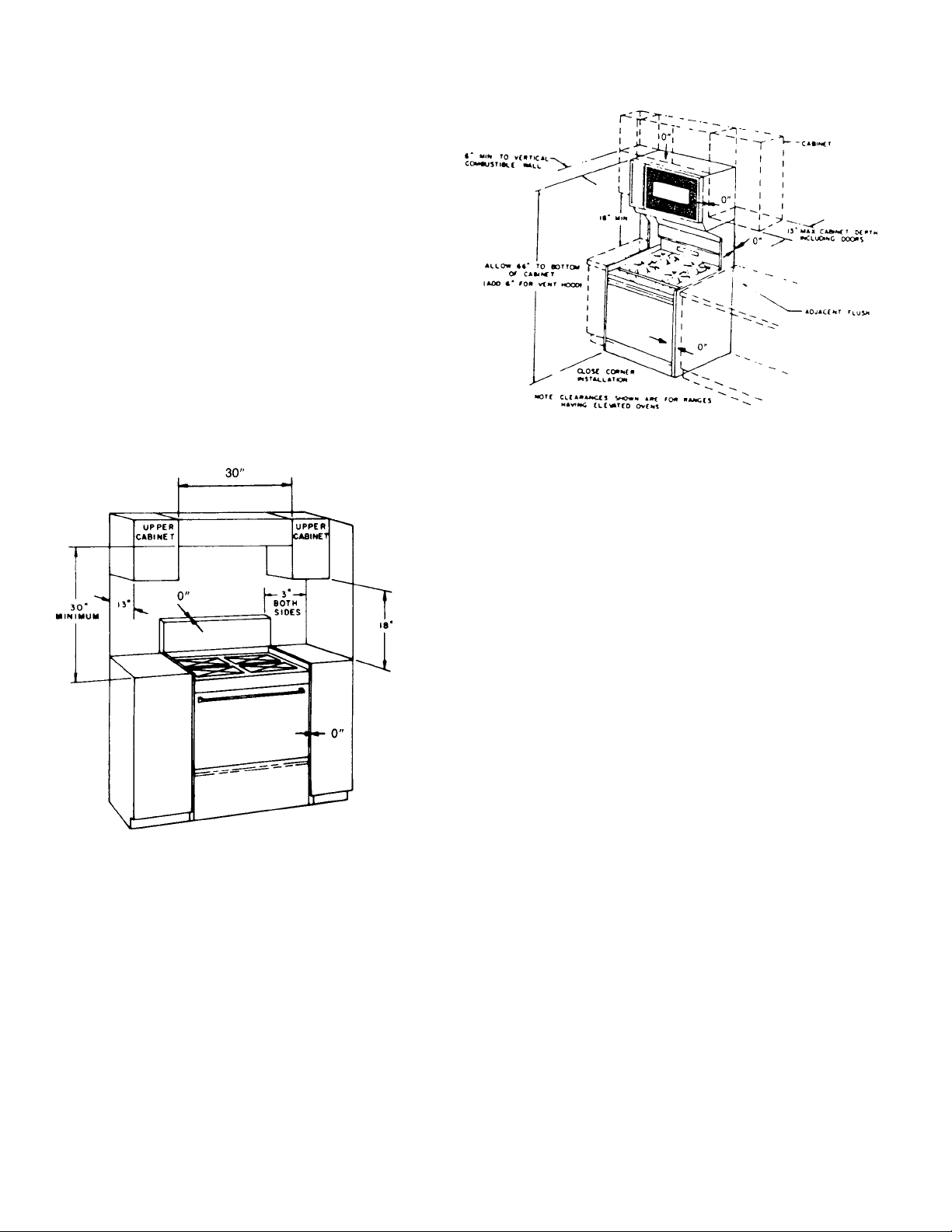

Location

The location of the range should be selected so proper

illumination, freedom from drafts, and convenience to

other appliances in the kitchen are obtained. Carefully

level the range, using the leveling legs provided. The

range must be level in order to assure uniform cooking and

baking. A level or a large pan of water placed on an oven

rack or on top of range can be used to level the unit. The

range is to be installed flush to rear wall, and may be

installed flush to side base cabinets. Spacing to vertical

side wall above cooking surface 3" (as shown in Figure 2),

6" (as shown in Figure 3), for ranges with elevated ovens.

Minimum distance to horizontal combustible surface above

cooking surface is 30" and must be the width of the range.

Maximum depth of cabinets installed above the range is

13".

Ranges With Elevated Ovens

Figure 5

It is the responsibility of the installer to comply with the

installation clearances specified on the rating plate

attached to the appliance.

Single Ovens

Figure 4

NOTE: Clearance specified to combustible construction

(walls and materials) are based on a temperature rise of

wood structures resulting from appliance operation. These

clearances are suitable for walls of studding, lath and

plaster, or other types of combustible materials which have

a density of 20 pounds per cubic foot or more. No

evaluation of the clearances required has been made for

installations adjacent to low density cellulose, fiber board,

and similar materials which have a density of less than 20

pounds per cubic foot; nor to plastic tiles, or sheeting.

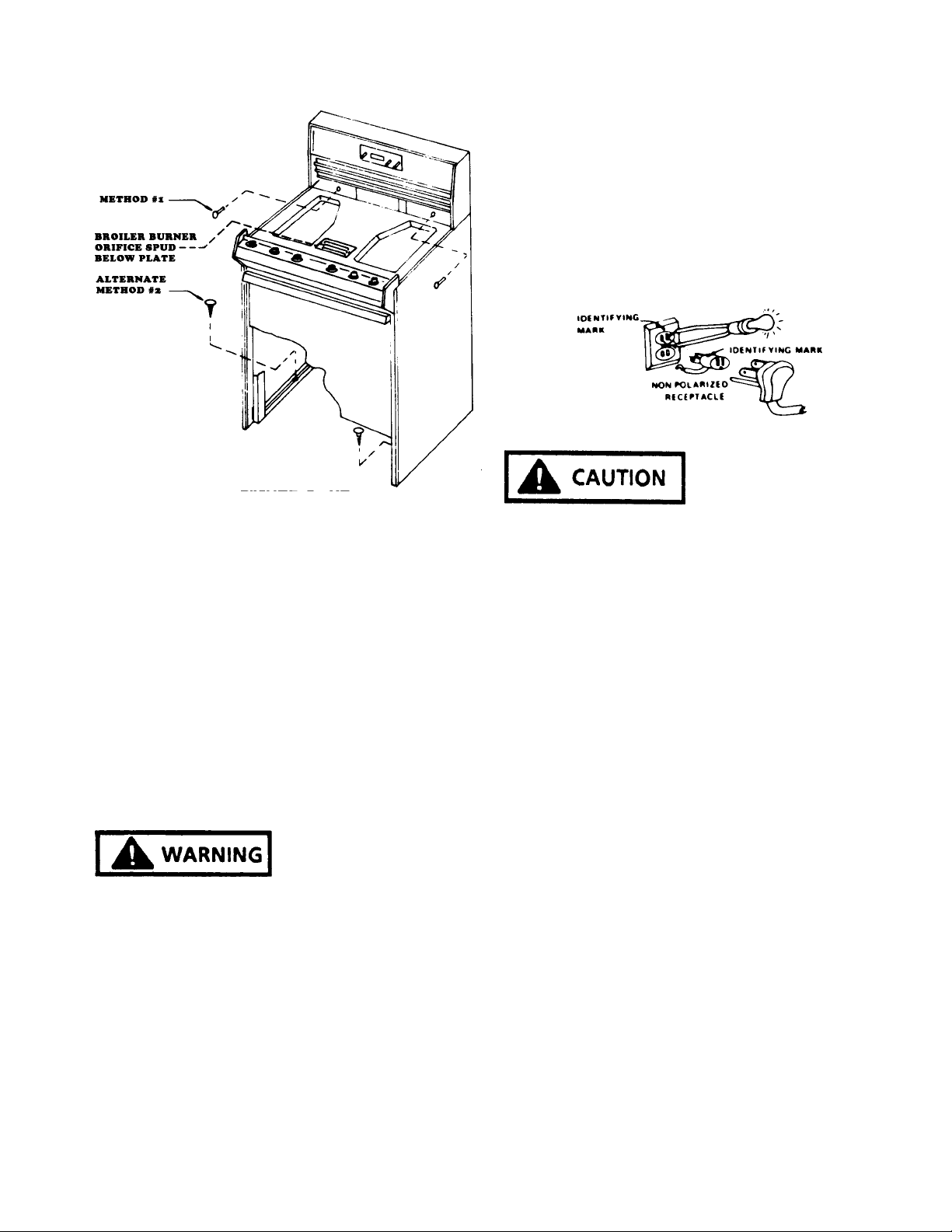

SECURE RANGE TO HOUSE STRUCTURE

For safety consideration means have been provided for

this range, except one having an elevated oven, to be

secured to th house wall behind the range, METHOD 1#

(see Figure 5A). If the wall behind the range is solid wood

or a vertical stud is available, a wood screw or lag bolt of

sufficient length may be employed to secure the range. If

the wall behind the range is not solid such as paneling or

dry wall (sheet rock) construction use of a Molly Bolt is

required. The anchor portion of the Molly Bolt should be of

sufficient lenght to hold it securely to the building material.

The thicker the material, the longer the anchor portion

must be.

RC231002 Rev. 3 8

Page 10

INSTALLATION INSTRUCTIONS

Figure 5A

IN MOBILE HOMES:

Any installtion in a mobile home must conform with the

Manufactured Home Consutruction and Safety Standards.

Title 24CFR, Part 32-80 (in Canada, CSA standard Z240,4-

1) or when such standard is not applicable, with the local

codes.

For mobile home installation it is necessary to use alternate METHOD #2 (see Figure 5A) to secure range to floor.

See rating label to determine if range can be used in this

application.

ANY OPENINGS IN THE WALL BEHIND THE RANGE

OR THE FLOOR UNDER THE RANGE MUST BE SEALED.

Where local codes permit, a TEMPORARY CONNEC-

TION may be made to properly ground a two-prong wall

receptacle by the use of an adaptor which is available at

most local hardware stores.

An adaptor plug can temporarily be used (see Figure 4)

preferably with polarized male blades. If an unpolarized

adaptor plug must be used, determine which is the "hot"

side and ground. Place an identifying mark on the adaptor

to assure proper polarization in the future.

Figure 6

ATTACHING THE ADAPTOR GROUND WIRE TO THE

WALL RECEPTACLE COVER SCREW DOES NOT

GROUND THE APPLIANCE UNLESS THE COVER

SCREW IS GROUNDED THROUGH THE HOUSE

WIRING.

If there is any doubt as to whether the wall receptacle is

properly grounded, the customer should have it checked

by a qualified electrician.

DO NOT, UNDER ANY CIRCUMSTANCES, CUT OR

REMOVE THE THIRD (GROUND) PRONG FROM THE

POWER PLUG.

ELECTRICAL CONNECTIONS

FIRE OR EXPLOSION

HAZARD

FOR GROUNDING - THIS APPLIANCE MUST BE

ELECTRICALLY GROUNDED IN ACCORDANCE WITH

LOCAL CODES, OR, IN THE ABSENCE OF LOCAL

CODES, WITH THE NATIONAL ELECTRIC CODE, ANSI/

NFPA NO. 70-1990. FAILURE TO FOLLOW THESE

INSTRUCTIONS MAY RESULT IN ELECTRIC SHOCK,

PERSONAL INJURY OR DEATH.

The power cord on this appliance is equipped with a threeprong (grounding) plug which mates with standard threeprong (grounding) receptacles.

Where a standard two-prong wall receptacle is encountered, it is the personal responsibility and obligation

of the customer to have it replaced with a properly grounded

three-prong wall receptacle.

9 RC231002 Rev. 3

Page 11

INSTALLATION INSTRUCTIONS

CONNECTING TO GAS SUPPLY LINE

Access to connection is behind bottom storage drawer.

The pressure regulator has a 1/2" female pipe thread. It is

recommended that a 1/2" close nipple, a union and shutoff valve, be assembled into the regulator. This places the

assembly for each connection to the gas supply and access

to the shut-off valve as illustrated in Figure 1.

The gas supply pipe to the range should be 3/4" rigid pipe

then reduced to 1/2" pipe at the pressure regulator. If a long

run of fuel is required, a larger size pipe may be required.

With the liquified petroleum (LP) gases, the size of the

piping or tubing can be 1/2" minimum. LP gas suppliers

usually determine the size and material used on the

system. We do not recommend that flexible connectors be

used in connecting our appliance to the gas supply, unless

American Gas Association approved. Poorly designed

connectors can be a source of gas leak. Even when AGA

approved flexible connectors are used the customer should

be cautioned against kinking or damaging the connector

when moving the range for cleaning or any reason. This

could cause a gas leak.

A shut-off valve should be installed in the line supplying

gas to the range. Check local building codes and utility

requirements. (See Figure 1 for details.)

A suitable pipe thread sealing material should be used,

which is approved for use with LP gases.

Caloric ranges are designed for easy connection between

the supply line and the inlet fitting. However, all strains

must be removed from the supply and fuel lines so the

range will be level and in line.

Use two (2) wrenches when connecting to the regulator.

burner valves should be closed and the gas supply turned

on. All connections in the gas supply line and in the range

should be tested with soap suds for any leaks. If a leak is

present, bubbles will appear. The leak should be corrected

by tightening the joint, or unscrewing it completely and

applying additional dope. Any connections which may

have been disturbed should be tested for leaks.

FIRE OR EXPLOSION

HAZARD

A LIGHTED MATCH OR FLAME SHOULD NEVER BE

USED WHEN TESTING FOR LEAKS. ALL FITTINGS

AND CONNECTIONS HAVE BEEN TIGHTENED AND

TESTED AT THE FACTORY. IF A LEAK IS DETECTED,

TIGHTEN THE FITTING, DO NOT USE PIPE DOPE ON

FACTORY FITTINGS.

The gas supply pipe to the range should be 3/4" rigid pipe

then reduced to 1/2" pipe at the pressure regulator. If a long

run of fuel line is required, a larger size pipe may be

required. With liquefied petroleum (LP) gases, the size of

the piping or tubing can be 1/2" minimum. LP gas suppliers

usually determine the size and material used on the

system. We do not recommend that flexible connectors be

used in connecting our appliance to the gas supply, unless

American Gas Association approved. Poorly designed

connectors can be a source of gas leak. Even when AGA

approved flexible connectors are used the customer should

be cautioned against kinking or damaging the connector

when moving the range for cleaning or any reason. This

could cause a gas leak.

A shut-off valve should be installed in the line supplying

gas to the range. Check local building codes and utility

requirements.

A suitable pipe thread sealing material should be used,

which is approved for use with LP gases.

FIRE OR EXPLOSION HAZARD - LEAK TEST

COMPONENTS AFTER CONNECTION.

THE REGULATOR IS DIE CAST AND WILL CRACK,

RESULTING IN A GAS LEAKAGE AND POSSIBLE FIRE

OR EXPLOSION, IF YOU MAKE THE CONNECTION

TOO TIGHT.

The stack on the regulator must be in vertical position. BE

SURE to use pipe dope to seal connections.

Be sure the shut-off valve is open between the inlet nipple

and gas valve.

TEST FOR GAS LEAKS

After the final gas connection has been made, all the top

RC231002 Rev. 3 10

Caloric ranges are designed for easy connection between

the supply line and the inlet fitting. However, all strains

must be removed from the supply and fuel lines so the

range will be level and in line.

Page 12

INSTALLATION INSTRUCTIONS

3. From the right rear edge of the prepared cutout,

measure the distance "A" and mark a point. Repeat

this procedure for the left hand side, then draw a

straight line between these points. (See Figure A.)

Figure 8

4. Place the bracket with the inside edge against the

straight line and the end against the cabinet side.

(See Figure C.) If you do not have cabinets on both

sides of the range, it will be necessary to measure the

width of the range (W) and place the bracket at the

appropriate location. (See Figure D.) Mark two (2)

hole locations.

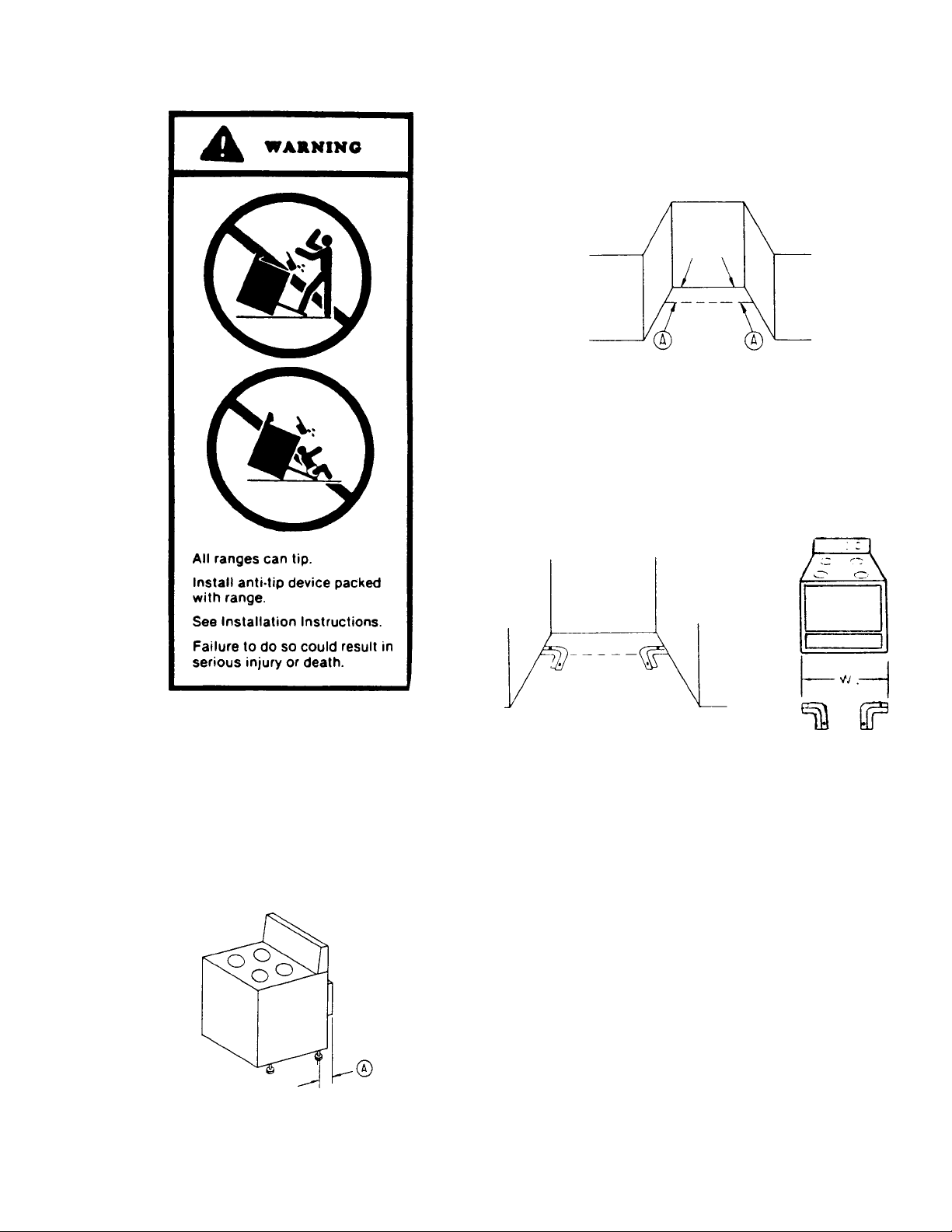

INSTALLATION INSTRUCTIONS FOR ANTI-TIP

BRACKET

To Install Anti-Tip Bracket, Carefully Follow these

Instructions:

1. Prepare counter cutout per range Installation Instructions.

2. Measure the distance from the range leveling leg

shaft to the rear most projection of the range. (See

Figure A). This will be referred to as distance "A".

Figure 7

Figure 9

5. If mounting into wood flooring, drill two (2) 3/32" holes

as marked. If mounting into concrete, using a masonry drill bit, drill two (2) 3/16" holes and insert plastic

anchors. Position bracket and mount using supplied

screws.

6. Turn the leveling legs out approximately 1/4". The

range may now be pushed into position. Remove the

storage drawer and check that the leg has engaged

the mounting bracket. If it has not, the bracket must

be relocated to ensure engagement of the leveling leg

into the bracket. If the range is moved from its original

mounting location, the bracket must be removed and

used for the new mounting location.

Figure 10

11 RC231002 Rev. 3

Page 13

INSTALLATION INSTRUCTIONS

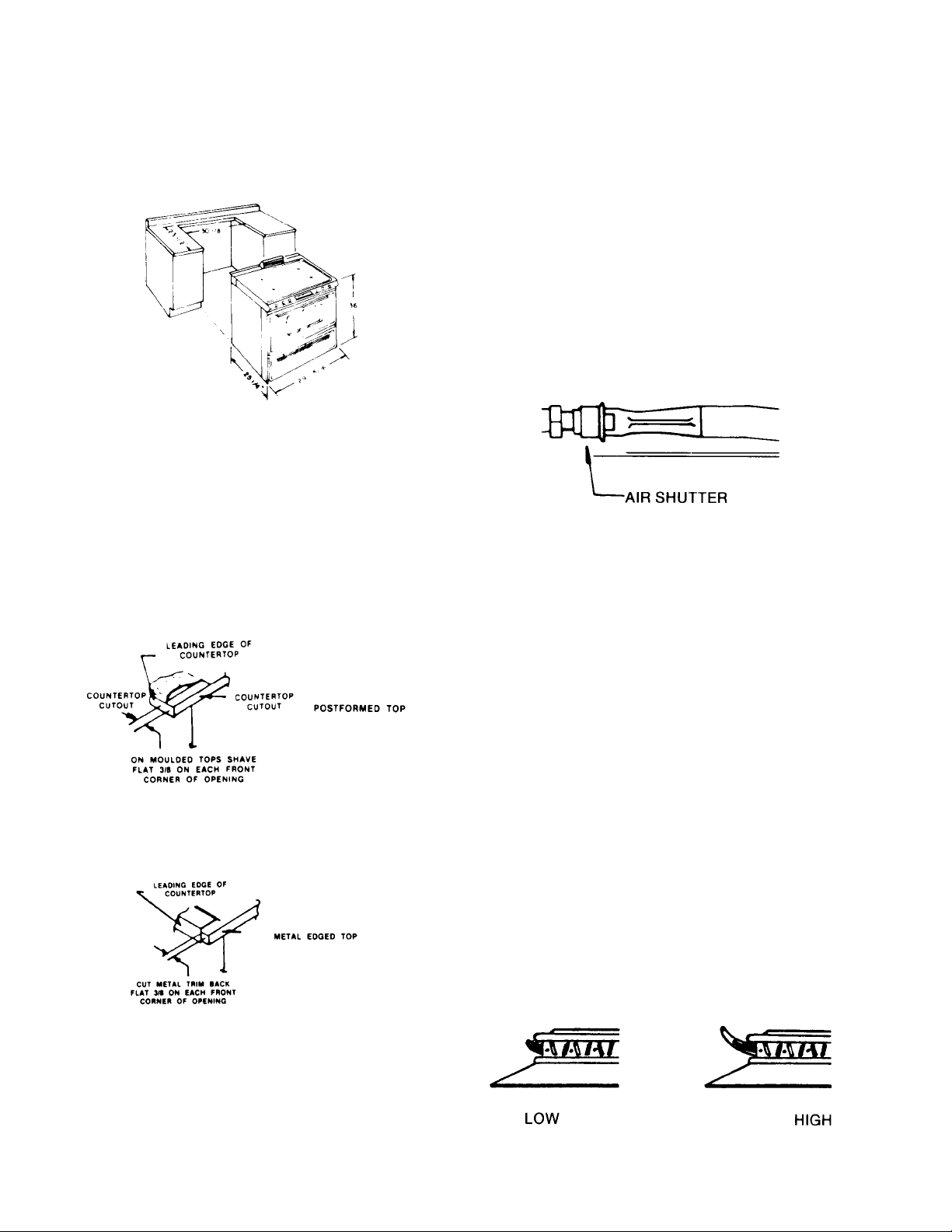

CABINET INSTALLATION OPENING FOR GAS

SLIDE-IN RANGE

A. Cabinet cutout must be prepared as shown in Figure

11. Never install a range over kitchen carpeting.

Figure 11

LO BACK RAIL SLIDE-IN MODEL

B. For electric and gas connection specifications refer to

instructions for installing automatic pilotless ignition

gas range.

C. On post formed (moulded) tops, shave the front

corner of cabinet opening flush with countertop in

area which will be underneath front corners of range

top (3/8"). (See Figure 12.)

Figure 12

D. On countertops with front metal trim, cut metal trim

back 3/8" from front corner of opening. (See Figure

--.)

and turned fully counterclockwise, the electrode between the flash tubes will start sparking and continue

as long as the knob is held in this position. After the

burner ignites, move the knob to the "ON" position of

the valve. At this time the sparking will cease. There

are no standing pilots that have to be lighted or

adjusted.

2. Top Burner Adjustment

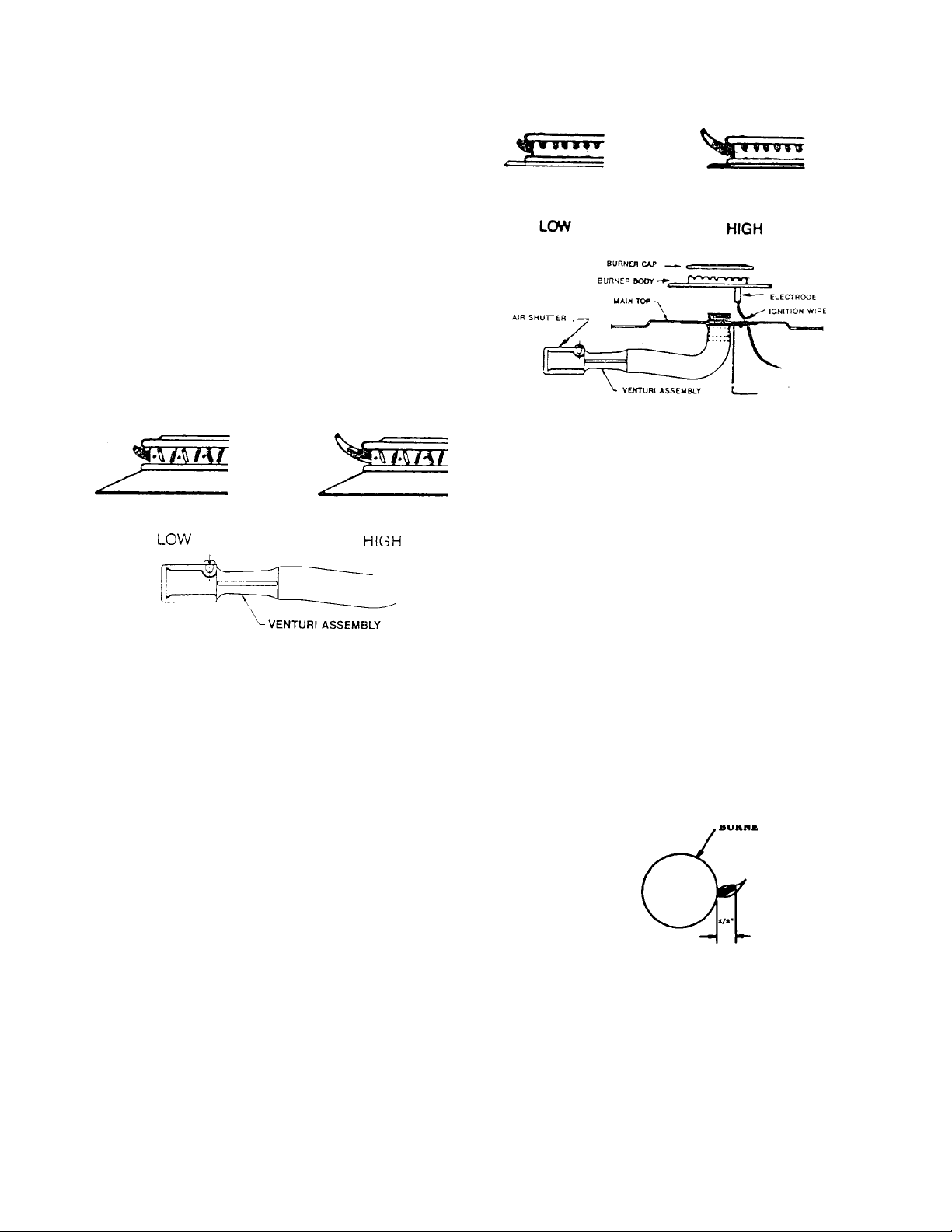

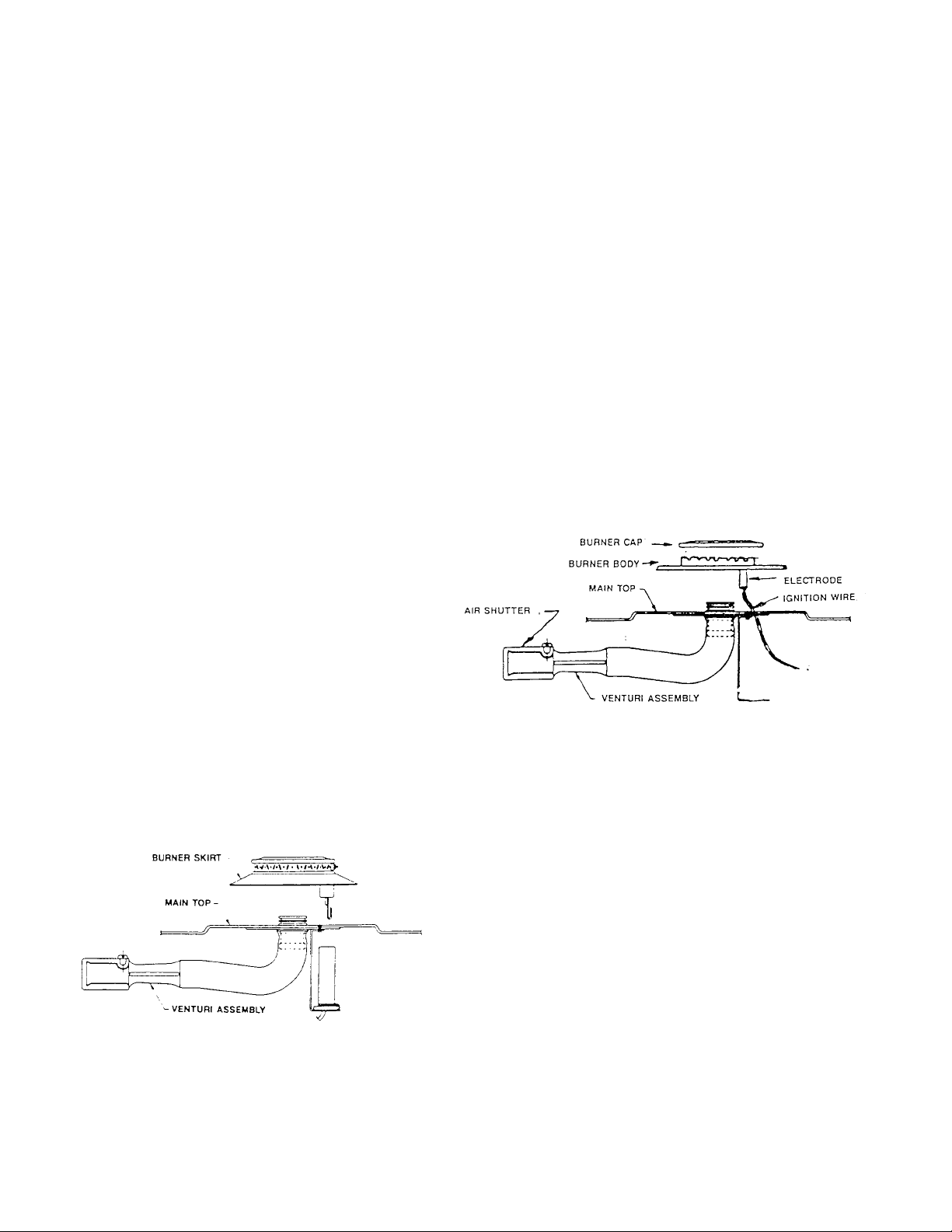

The air shutter (see Figure 5) should be adjusted to a

proper flame. Loosen the air shutter lock screw and

adjust the air shutter so the flame has an inner cone

of bluish-green and an outer mantle of dark blue. The

flame should be soft in character. Tighten the lock

screw when the adjustment is complete.

Figure 14

NATURAL GAS BURNER ADJUSTMENT

Models with Sealed Top Burners (Below Serial

Number F0430127550)

1. Top Burners

Whenever a top burner gas valve knob is depressed

and turned fully counterclockwise, the electrode built

into the burner cap will start sparking and continue as

long as the knob is held in this position. After the

burner lights, move the knob to the "HI" position of the

valve. At this time the sparking will cease. There are

no standing pilots that have to be lighted or adjusted.

2. Top Burner Adjustment

No gas input adjustment is necessary as the burner is

equipped with a fixed orifice. There is no shutter to

adjust.

Figure 13

ADJUSTMENTS AND LP CONVERSION

NATURAL GAS BURNER ADJUSTMENT

Models Without Sealed Top Burners

1. Top Burners

Whenever a top burner gas valve knob is depressed

RC231002 Rev. 3 12

Low burner flame may be adjusted by turning adjustment screw in center of valve stem. Normally, the low

flame should be adjusted to the minimum steady blue

flame. Check the adjustment by turning from high to

low several times to see that the burner does not go

out.

Figure 15

Top Burner Setting

OR

Page 14

INSTALLATION INSTRUCTIONS

Models with Sealed Top Burners (Above Serial

Number F0430127550)

The air shutters (see Figure 6) should be adjusted for a

proper flame. Adjust the air shutter so that the flame has

an inner cone of bluish-green and an outer mantle of dark

blue. The flame should be soft in character. To adjust the

air shutter to close the opening to decrease the air or

enlarge the opening for more air. Tighten the lock screw

when the adjustment is complete.

Low burner flame may be adjusted by turning adjustment

screw in center of valve stem. Normally, the low flame

should be adjusted to the minimum steady blue flame

(approximately 1/4" flame length). Check the adjustment

by turning from high to low several times to see that the

burner does not go out.

Figure 17

LOWER OVEN BURNER - RST

The appearance of properly adjusted oven burner flame is

a bluish-green inner cone and a dark blue mantle. The

flame characteristics should be clean and soft with no

yellow tips. Blowing or lifting of the flame should not occur.

Figure 16

Models with Cast Top Burners

The air shutters (See Figure 7) should be adjusted for a

proper flame. Adjust the air shutter so the flame has an

inner cone of bluish-green and an outer mantle of dark

blue.

For Access to the Air Shutters:

Lift off four (4) burner caps. Remove one (1) screw at each

burner body. Pull each burner body upwards and disconnect the ignition wire at the electrode. Remove one (1) flat

headed screw at each burner and lift off main top. Remove

plenum box covers (when so equipped).

To Adjust the Air Shutter:

Loosen the lock screw. Move the air shutter to close the

opening to decrease the air or enlarge the opening for more

air. Tighten the lock screw when the adjustment is complete.

Low burner flame may be adjusted by turning adjustment

screw in center of valve stem. Normally, the low flame

should be adjusted to the minimum steady blue flame

(approximately 1/4" flame length). Check the adjustment

by turning from high to low several times to see that the

burner does not go out. (See Figure 8.)

1. An electric ignitor is used to light the burner. DO NOT

attempt to insert any object into the opening of the protective shield surrounding the ignitor coil. Do not attempt to

clean this area.

2. The burner flame should be 1/2" long when the air

shutter is correctly adjusted. (See Figure 8.) The air

shutter is located at the lower right of the access area,

above the gas valve. To adjust the air shutter, loosen the

lock screw. Move the air shutter to close the opening to

decrease the air or enlarge the opening for more air.

Tighten the lock screw when the adjustment is complete.

Figure 18

UPPER OVEN BURNER ADJUSTMENT - RST

The burner flames should be 3/8" long when the air shutter

is correctly adjusted. The air shutter is located at the left

side of the upper oven burner. To adjust the air shutter,

loosen the lock screw. Move the air shutter to close the

opening to decrease the air or enlarge the opening to

increase the air. Tighten the lock screw when the adjustment is complete.

13 RC231002 Rev. 3

Page 15

INSTALLATION INSTRUCTIONS

BROIL BURNER

Burner Adjustment

1. No gas input adjustment is necessary as the infrared

burner is equipped with a fixed orifice. There is no air

shutter to adjust.

2. An electric ignitor is used to light the burner. DO NOT

attempt to insert any object into the openings of the

protective shield surrounding the ignitor coil. Do not

attempt to clean this area.

3. The burner may have a hazy or fuzzy appearance

when in operation. This haze may be 3/8" thick

maximum and is normal for this type of burner.

UPPER OVEN FLAME CHARACTERISTIC

ADJUSTMENT

The appearance of a properly adjusted gas flame is one

having an inner cone of bluish-green and an outer mantle

of dark blue. The length of the inner cone flame will be

about 3/8" when correctly adjusted. (See Figure 9.) Flame

characteristics should be clean but soft.

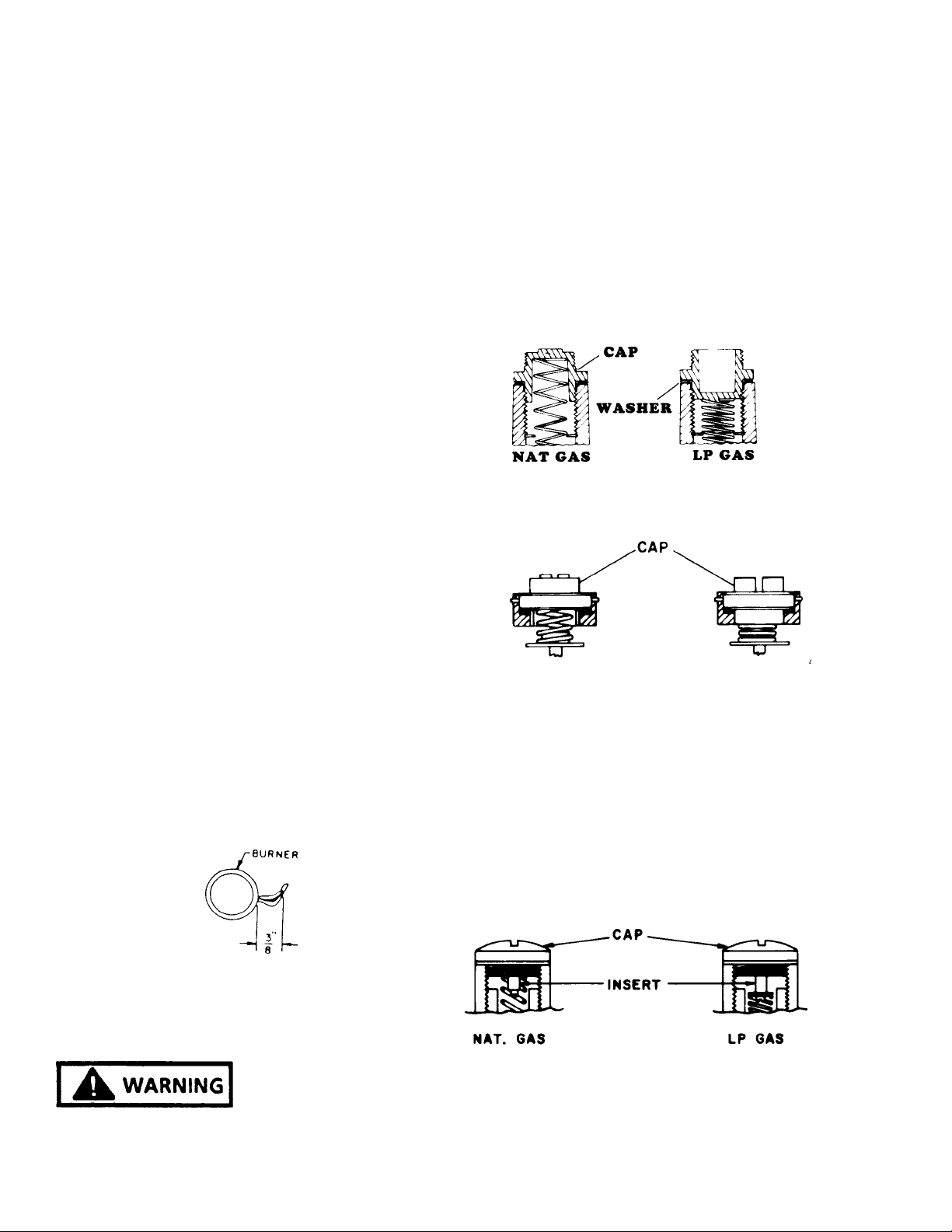

PRESSURE REGULATOR (On Range)

Remove the cap marked "Nat" and reverse it to read "LP".

Be sure not to disturb or remove the spring beneath the

cap. Also make sure the fiber washer is between the cap

and the body of the regulator. See Figure 10 for the

correction position of the cap.

Remove the cap with the screwdriver slot and replace

upside down. This plug will then have the marking "LPG10".

Be sure not to disturb or remove the spring beneath this

plug. See Figure 11 for correct position of plug.

Figure 20

OR

1. An electric ignitor is used to light the burner. DO NOT

attempt to insert any object into the openings of the

protective shield surrounding the ignitor coil. Do not

attempt to clean this area.

2. Oven Burner Adjustment

The burner flame should be 3/8" long when the air

shutter is correctly adjusted. (See Figure 9).

The air shutter is located at the left side of the upper oven

burner. To adjust the air shutter loosen the lock screw.

Move the air shutter to close the opening to decrease the

air or enlarge the opening to increase the air. Tighten the

lock screw when the adjustment is complete.

Figure 19

LP CONVERSION

Figure 21

OR

Remove the cap with the screwdriver slot. Remove the

black insert marked "Nat" from the cap. (This is a tight fit

in the cap.) Reverse this insert and carefully push it firmly

into the hole in the cap. The marking "LP" will now be

showing on the insert. Be sure the insert is pressed into the

shoulder. Also, be sure not to disturb the spring in the body

of the regulator.

Replace the cap in the body of the regulator and tighten.

See Figure 12 for the correct position of the insert.

NATURAL TO LP GAS CONVERSION

FIRE OR EXPLOSIION

HAZARD

THIS UNIVERSAL RANGE IS PREADJUSTED FOR

OPERATION ON "NATURAL" GAS AS SHIPPED FROM

THE FACTORY. TO USE THE APPLIANCE ON LP GAS,

YOU MUST DO THE FOLLOWING:

RC231002 Rev. 3 14

Figure 22

Remove the cap with screwdriver slot. Carefully remove

the spring and washer (washer will be at bottom of spring).

Reverse so that washer is at top of spring and reinstall

spring and washer.

Page 16

INSTALLATION INSTRUCTIONS

Remove the cap in the body of the regulator, over the

washer and spring, and tighten cap. See Figure 13 for the

correct position of the washer and spring.

Figure 23

OR

Figure 24

FLAME APPEARANCE

The air shutter (see Figure 17) should be adjusted for a

proper flame. Adjust the shutter so the flame has an inner

cone of bluish-green and an outer mantle of dark blue. The

flame should be soft in character.

NOTE: On LP gas a slight yellow tip will be visible on top

burner flames, but will not affect burner performance.

MODELS WITH SEALED TOP BURNERS

NOTE: Sealed Top Burner Models with Serial Number

Date Codes F006 through F009 are for use on Natural Gas

only and are not field convertible for use on LP gas.

TOP BURNER ADJUSTMENT (Below Serial Number

F0430127550)

ORIFICES

Universal Models (Natural or LP) are shipped from the

factory orificed for Natural Gas. IF THEY ARE TO BE

USED ON LP GAS, the burner orifice spuds must be

changed. They will be found wired to the inlet pipe behind

the storage drawer. The proper orifice for use on Bottled

(LP) Gas is red colored and stamped #68 (drill size). BE

SURE to use proper burner spud for the gas in use. Rewire

the Natural Gas orifice spuds to the inlet pipe for future

conversion.

MODELS WITHOUT SEALED TOP BURNERS

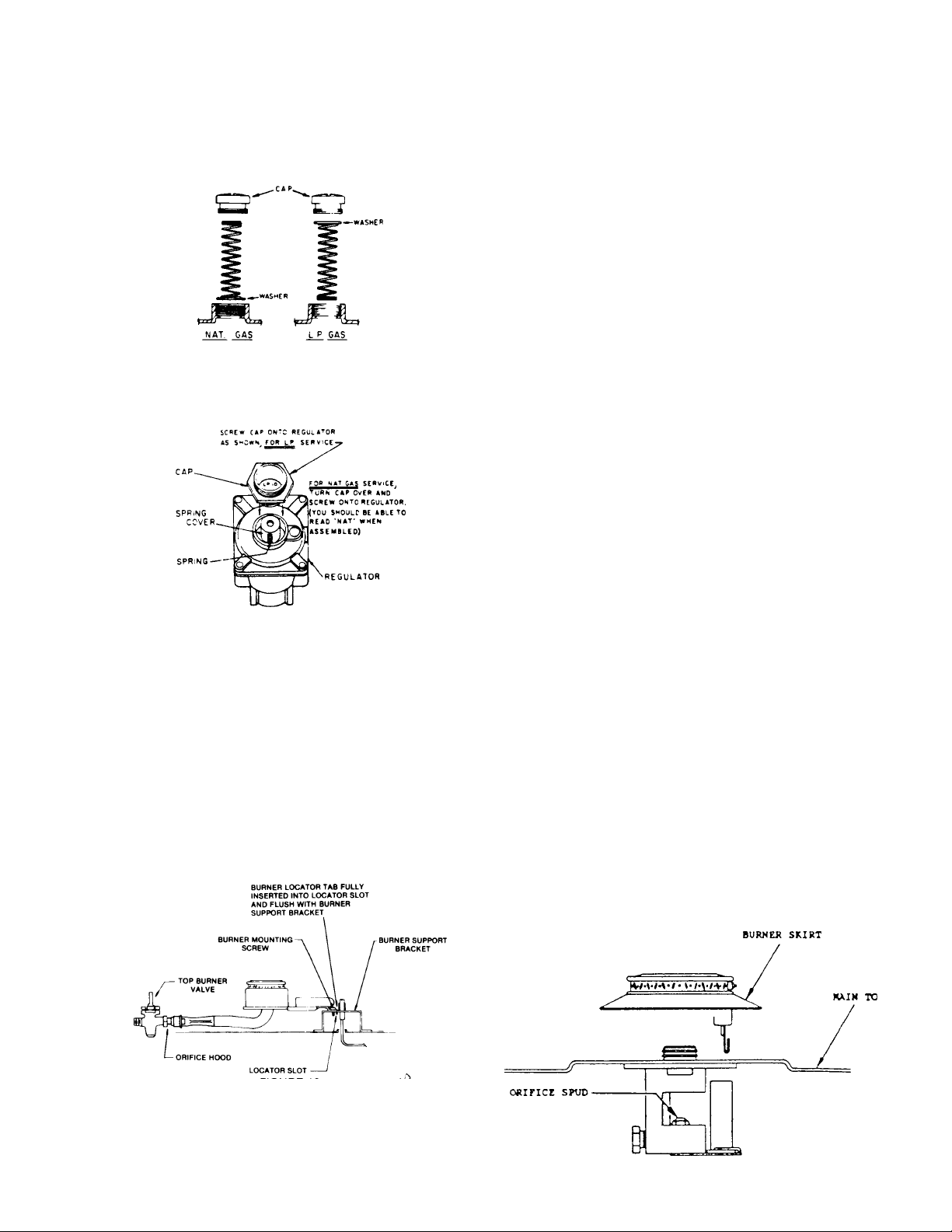

TOP BURNER ADJUSTMENT

ORIFICES

Remove four (4) top burners by removing the mounting

screws and lifting out of bracket. Then turn down the orifice

hoods onto the pins being careful not to drive pin into the

valve or to distort the hole through the center of the pin.

Reinstall the top burners and mounting screws. (See

Figure 15.)

FIGURE 25

Nat. Gas LP Gas

Burner Spud 54 68

(Red colored for

identification)

TO CONVERT

Remove four (4) top burners by pulling upwards. (See

Figure 26.) Remove the two (2) flat headed screws at each

burner and lift off main top. Replace the burner orifice

spuds using a 5/16" nut driver. Reinstall maintop and

burners. To replace the burners, position the ignitor over

the hole at the rear of each burner opening and push the

burner down onto the burner base until the skirt contacts

the maintop.

15 RC231002 Rev. 3

Figure 26

Page 17

INSTALLATION INSTRUCTIONS

BURNER ADJUSTMENT

No gas input adjustment is necessary as the burner are

equipped with fixed orifices. There are no shutters to

adjust. NOTE: On LP gas a slight yellow tip will be visible

on top burner flames, but will not affect burner performance.

OR

TOP BURNER ADJUSTMENT (Above Serial Number

F0430127550)

TO CONVERT

Lift off four (4) burner caps. (See Figure 27.) Remove one

(1) screw at each burner body. Pull each burner body

upwards and disconnect the ignition wire at the electrode.

Mark wires for identification on reassembly. Remove one

(1) flat headed screw at each burner and lift off main top.

Remove plenum box covers (when equipped). Remove

two (2) screws from each venturi mounting bracket and

remove venturi assemblies.

Turn the orifice hoods onto the pins. The orifices should be

turned snug onto the pins careful not to drive pin into the

valve or distort the hole through the center of the pin.

Reinstall the burner bodies and caps.

Remove one (1) flat headed screw at each burner and lift

off main top.

Remove plenum box covers. Remove two (2) screws from

each venturi mounting bracket and remove venturi assemblies.

Turn the orifice hoods onto the pins. The orifice should be

turned snug onto the pins careful not to drive pin into the

valve or distort the hole through the center of the pin.

Reinstall the burner bodies and caps.

The air shutters should be adjusted for a proper flame.

Adjust the air shutter so that the flame has an inner cone

of bluish-green and an outer mantle of dark blue. The

flame should be soft in character. To adjust the air shutter,

loosen the lock screw. Move the air shutter to close the

opening to decrease the air or enlarge the opening for more

air. Tighten the lock screw when the adjustment is complete. Reinstall the plenum box covers, main top and main

top burners in reverse order of removal. NOTE: On LP

gas a slight yellow tip will be visible on top burner

flames, but will not affect burner performance.

The air shutters should be adjusted for a proper flame.

Adjust the air shutter so that the flame has an inner cone

of bluish-green and an outer mantle of dark blue. The

flame should be soft in character. To adjust the air shutter,

loosen the lock screw. Move the air shutter to close the

opening to decrease the air or enlarge the opening for more

air. Tighten the lock screw when the adjustment is complete. Reinstall the plenum box covers, main top and main

top burners in reverse order of removal. NOTE: On LP

gas a slight yellow tip will be visible on top burner

flames, but will not affect burner performance.

Figure 27

MODELS WITH CAST BURNERS

TO CONVERT

Lift off four (4) burner caps. (See Figure 28.) Remove one

(1) screw at each burner body. Pull each burner body

upwards and disconnect the ignition wire at the electrode.

RC231002 Rev. 3 16

Figure 28

OVEN BURNER (Upper and Lower Oven) (RST)

ORIFICES

Turn down the orifice hood onto the pin. The orifice should

be turned snug onto the pin being careful not to drive pin

into the valve or to distort the hole through the center of the

pin.

LOWER OVEN FLAME CHARACTERISTIC

ADJUSTMENT

The appearance of a properly adjusted oven burner flame

is a bluish-green inner cone and a dark blue mantle. The

flame characteristics should be clean and soft with no

yellow tips. Blowing or lifting of the flame should not occur.

The burner flame should be 1/2" long when the air shutter

is correctly adjusted. (See Figure 18.)

An electric ignitor is used to light the burner. DO NOT

attempt to insert any object into the openings of the

protective shield surrounding the ignitor coil. Do not

attempt to clean this area.

Page 18

INSTALLATION INSTRUCTIONS

found under the plate in the center of the burner box. BE

SURE to use the proper burner spud for the gas in use.

Reinsert Nat. Gas orifice in burner box with louvers facing

to rear of unit.

Nat. Gas LP Gas

Burner Spud 50 58

(Silver colored for identi-

Figure 29

fication)

The air shutter is located in the lower access area. To

adjust the air shutter, loosen the lock screw. Move the air

shutter to close the opening to decrease the air or enlarge

the opening for more air. Tighten the lock screw when the

adjustment is complete.

OVEN BURNER (RSS)

1. Orifices

Turn down the orifice hood onto the pin. The orifice

should be turned snug onto the pin being careful not

to drive pin into the valve or to distort the hole through

the center of the pin.

2. Low Oven Flame Characteristic Adjustment

a. The appearance of a properly adjusted oven burner

flame is a bluish-green inner cone and a dark blue

mantle. The flame characteristics should be clean

and soft with no yellow tips. Blowing or lifting of the

flame should not occur. The burner flame should be

1/2" long when the air shutter is correctly adjusted.

b. An electric ignitor is used to light the burner. DO

NOT attempt to insert any object into the openings of

the protective shield surrounding the ignitor. Do not

attempt to clean this area.

MODELS WITH SEALED TOP BURNERS

Universal models (Nat. or LP) are shipped from the factory

orificed for Nat. Gas. IF THEY ARE TO BE USED ON LP

GAS, the burner orifice spud must be changed. This will be

found wired to the inlet pipe behind the storage drawer.

The proper orifice for use on Bottled (LP) gas is silver

colored (Nickel plated) and stamped #58 (drill size). BE

SURE to use the proper burner spud for the gas in use.

Rewire the Natural Gas orifice spuds to the inlet pipe for

future conversion.

TO CONVERT

Remove oven door and storage drawer. Shut off valve on

gas line that runs from the pressure regulator to the gas

valve.

Remove the two (2) screws fastening the broiler burner to

the oven tank at front of burner. Remove the burner by

pulling front end down to expose the burner orifice spud in

the rear wall. Be careful not to break the ignitor. Lay the

burner aside carefully with the screen side up. Replace the

burner orifice spud using a 5/16" nut driver. Reverse the

procedure to reinstall the burner.

BURNER ADJUSTMENT

c. The air shutter is located in the lower accessed

area. To adjust the air shutter, loosen the lock screw.

Move the air shutter to close the opening to decrease

the air shutter to close the opening to decrease the air

or enlarge the opening for more air. Tighten the lock

screw when the adjustment is complete.

ULTRA-RAY® BROILER BURNER

An electric ignitor is used to light the burner. DO NOT

attempt to insert any object into the openings of the

protective shield surrounding the ignitor element. Do not

attempt to clean this area.

MODELS WITHOUT SEALED TOP BURNERS

Universal models (Nat or LP) are shipped from the factory

orifices for Nat gas. IF THEY ARE TO BE USED ON LP

GAS, the burner orifice spud must be changed. This will be

17 RC231002 Rev. 3

No gas input adjustment is necessary as the infrared

burner is equipped with a fixed orifice. There is no shutter

to adjust.

The burner may have a hazy or fuzzy appearance when in

operation. This haze may be 3/8" thick, maximum and is

normal for this type of burner.

RANGE FEATURE CHECKOUT

Check all range features, including lights, clocks, etc. for

proper operation.

Page 19

INSTALLATION INSTRUCTIONS

CHECKOUT PROCEDURE OF CLEAN CYCLE

OPERATION - RSS (WITH MECHANICAL TIMER;

FOR OTHER MODELS FOLLOW TIMER

INSTRUCTIONS)

REMOVE OVEN RACKS, BROILER PAN AND GRID.

MAINTENANCE INSTRUCTIONS

1. Keep appliance clear and free from combustible

materials, gasoline, cleaning fluids, and other flammable vapors and liquids.

A. Set the range clock to the correct time of day. (If not

set properly).

B. Push the turn the start dial on the backguard to the

approximate time of day until set stem pops out.

C. To establish length of clean time, turn the stop dial 1

1/2 hours to 2 hours ahead of start time. On electronic

clock models push clean button on timer for 3-hour

clean time.

D. Close and latch oven door, moving the latch arm to

the far right. (clean position).

E. Turn the oven heat control, on control panel, clock-

wise to "CLEAN" position. Then, turn selector switch

to the "CLEAN" setting.

F. A 15-20 second delay should occur, and the oven

indicator light should then come on.

G. After the cycle begins, the oven should reach a

temperature in excess of normal broiling (approximately 700°). The "CLEAN" indicator light should

come on, and the terminal lock system should lock

and secure the oven door.

H. Turn selector switch from "CLEAN" to "OFF" and heat

control to "OFF".

I. When oven temperature has lowered to approxi-

mately 700° or less, the lock system should unlock the

oven door allowing the latch handle to move freely.

2. Gas burners need sufficient air to operate. Objects

should not be placed in front of or on maintop rear of

range while in use. This could obstruct the air flow

needed for combustion and vent for flue products.

BURNER CLEANING -

The burner heads are made of aluminum and should not be

subjected to scouring or abrasive pads. Never not be

subjected to scouring or abrasive pads. Never use steel

wool or oven cleaners on the burner heads or they will dull

and not regain their original luster.

To clean the burners, remove the burner grates and push

the main top towards the rear of the range until the front

tabs are free. Then raise the main top and remove or

engage the main top support. This will support the main top

while the burners are removed for cleaning.

Before attempting to remove the burners, be certain the

four (4) burner mounting screws which retain the burners to

the burner supports are removed. If the screws are still

secured, they can be removed with a Phillips screwdriver.

To remove the burners, release the burner head brackets

from the burner support, lift up and pull towards the rear of

the range.

To replace the burners slip the Venturi (long, thin end) over

the burner orifice and then position the burner locating

brackets into the burner support channel. Reinstall the

burner mounting screws.

DEFECTS

Any defects or faulty or damaged parts must be reported

immediately and steps taken to correct them through

normal dealer service channels.

POWER FAILURE

In the event of a power failure, safe manual lighting of the

top burners is possible. To do this, hold a lighted match at

the desired burner head (the part projecting above the

main top), turn the top burner control knob to the light

position.

The flame height can now be adjusted to the desired size.

The broil and oven burners cannot be operated during a

power failure and no attempt should be made to do so.

RC231002 Rev. 3 18

Wiping the burners following each use will remove spillover

deposits and grease spatters before these soils get a

chance to harden on the surface. Burnt soil can be cleaned

by soaking the burners in warm water and a dishwashing

liquid detergent such as "Dove" or "Lux". A dishcloth or

nonabrasive pad (such as Dobie pad) should be used to rub

the burner caps after the soaking period. Be sure the

burners are dry, as water lodged in the burner parts might

cause an uneven flame or interfere with automatic lighting.

If stains still remain after soaking, you can soak any heavily

soiled burners in a solution of two tablespoons of "Dip-it"

per quart of water. Use a large pan and enough water so

the cap and base part of the burner assembly can be

completely immersed; bring water to a boil, remove vessel

from burner, and add measured amount of "Dip-it". Immerse the burner in the hot solution and soak for 20

Page 20

INSTALLATION INSTRUCTIONS

minutes, no longer. Be sure the liquid completely covers

the cap and base portion of the assembly. After 20

minutes, remove burner, cool slightly and rinse thoroughly

with cold water. Be sure hands are protected to prevent

burns from hot water. Be sure all the solution is completely

rinsed off both the inside and outside of the burner. If some

stains still remain, rub with a "Dobie" pad.

The burner may then be left to dry at room temperature or

be placed in the oven at 170° for 1/2 hour. BE SURE TO

PROTECT YOUR HANDS WHEN REMOVING DRIED

BURNERS FORM THE OVEN.

Figure 31

NOTE: These thermostats (Robertshaw) have a cement

coating over the adjusting screw. Evidence of attempts to

adjust these thermostat nullifies the warranty.

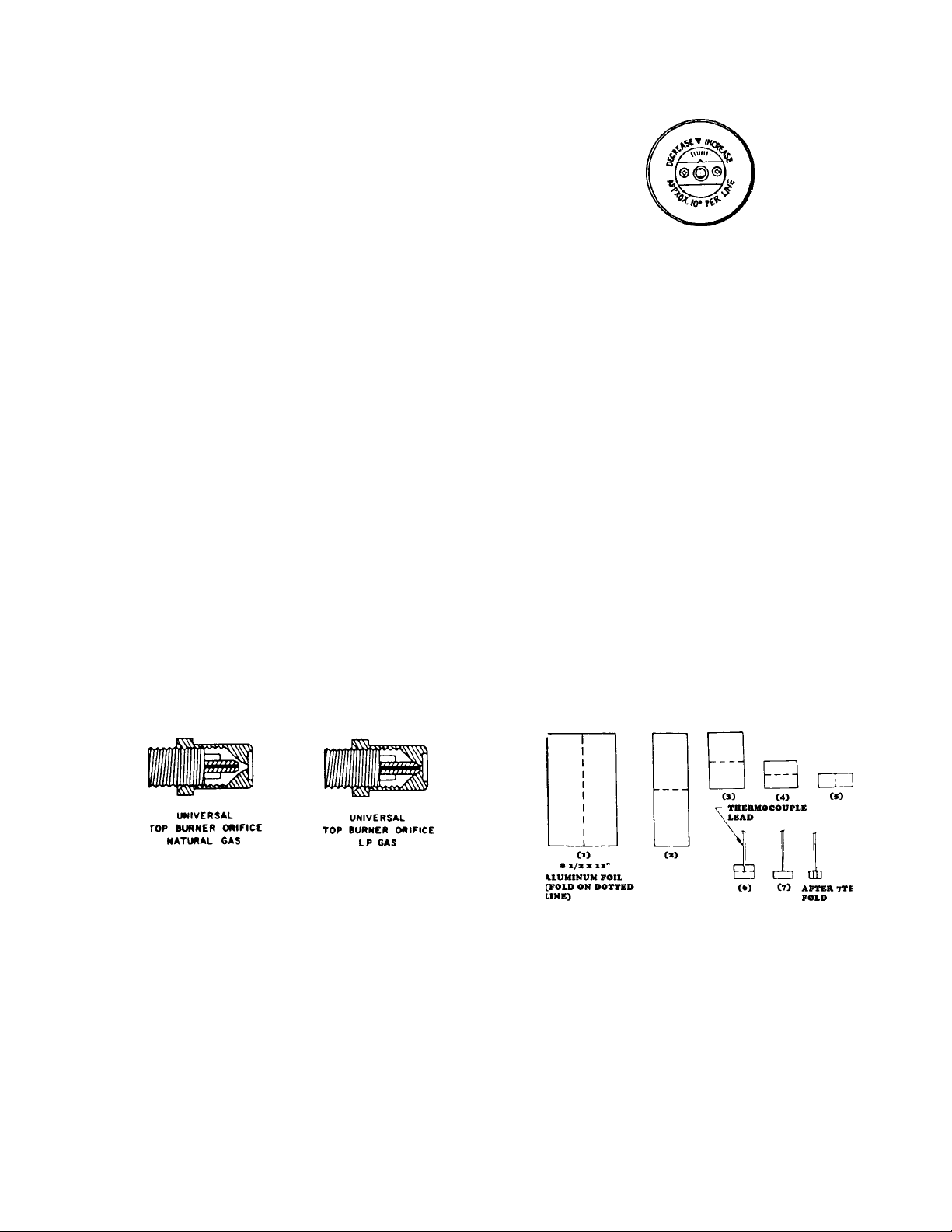

UNIVERSAL GAS ORIFICES

With the exception of the Broiler Burner and Sealed Top

Burner, orifices for these models are of the coaxial type.

They contain a double coaxial orifice hood and universal

pin. The hood orifice is sized for Natural Gas (6 inches

water column pressure). The pin orifice is sized for LP Gas

(11 inches water column pressure).

The orifice is adjusted for Natural gas as shipped from the

factory. It must be adjusted for use on LP gas. This

requires that the orifice hood be screwed or turned down

approximately two (2) turns onto the pin. The hood should

be turned down snug but not tight to the point where it

damages or distorts the pin. (See Figure 19.)

When set up for Natural Gas, gas flows around the pin and

through the orifice of the hood which is sized for Natural

Gas. When the hood is screwed down for LP gas, the gas

flow is only through the hollow pin which is sized for LP gas.

For Thermostat Calibration on models with the Electronic Range Control (ERC), see section on ERC

Operating and Testing Procedures.

When making any temperature adjustments, a reliable test

instrument should be used to accurately determine the

oven temperature.

A reliable test instrument of the thermocouple type is

preferred which will allow temperature readings with the

door closed.

Position the thermocouple clip of the test instrument on the

center of the oven rack that is positioned in the center of the

oven cavity. The thermocouple of the test instrument

should be "weighted" or "loaded" in order to represent more

closely the average cooking temperature of the oven

versus the on-off cycling of the thermostat with the full rate

gas valve. The procedure for loading a thermocouple is

illustrated in Figure 20.

Figure 30 - Universal Orifice

OVEN THERMOSTAT KNOB ADJUSTMENT

Models without electronic Range Control (ERC)

Cooking recipes are written to take into consideration that

oven thermostats have manufacturing tolerances, and

may not provide an average temperature exactly on the

thermostat setting. If the temperature average reading is

beyond the ±25° tolerance range, a limited adjustment can

be made with the adjustable skirt on the knob. The

adjusting screw on the thermostat is sealed and no adjustment can or should be attempted. The rear of the adjustable skirt shown here is self-explanatory.

19 RC231002 Rev. 3

Figure 32 - "Loading" A Thermocouple

An 8 1/2 x 11-inch piece of aluminum foil should be folded

five (5) times, doubling the thickness with each fold. After

the fifth fold, place the thermocouple in the center of the

aluminum piece as shown and fold once more. Finally, fold

the sides so the foil clings to the thermocouple. The loaded

thermocouple will then provide temperature readings on

the thermometer that more closely resemble the mean or

average temperature of the oven as it cycles on and off

above and below the temperature setting.

With all the controls properly set for "Bake", turn the oven

thermostat to 350°.

Page 21

INSTALLATION INSTRUCTIONS

After the oven has cycled for 25 to 30 minutes, note the

temperature that the oven cycles ON and OFF. For

example, at 350° setting the oven cycles between 335° and

355°. This provides a mean or average temperature of

345°F., well within the ±25°F specification.

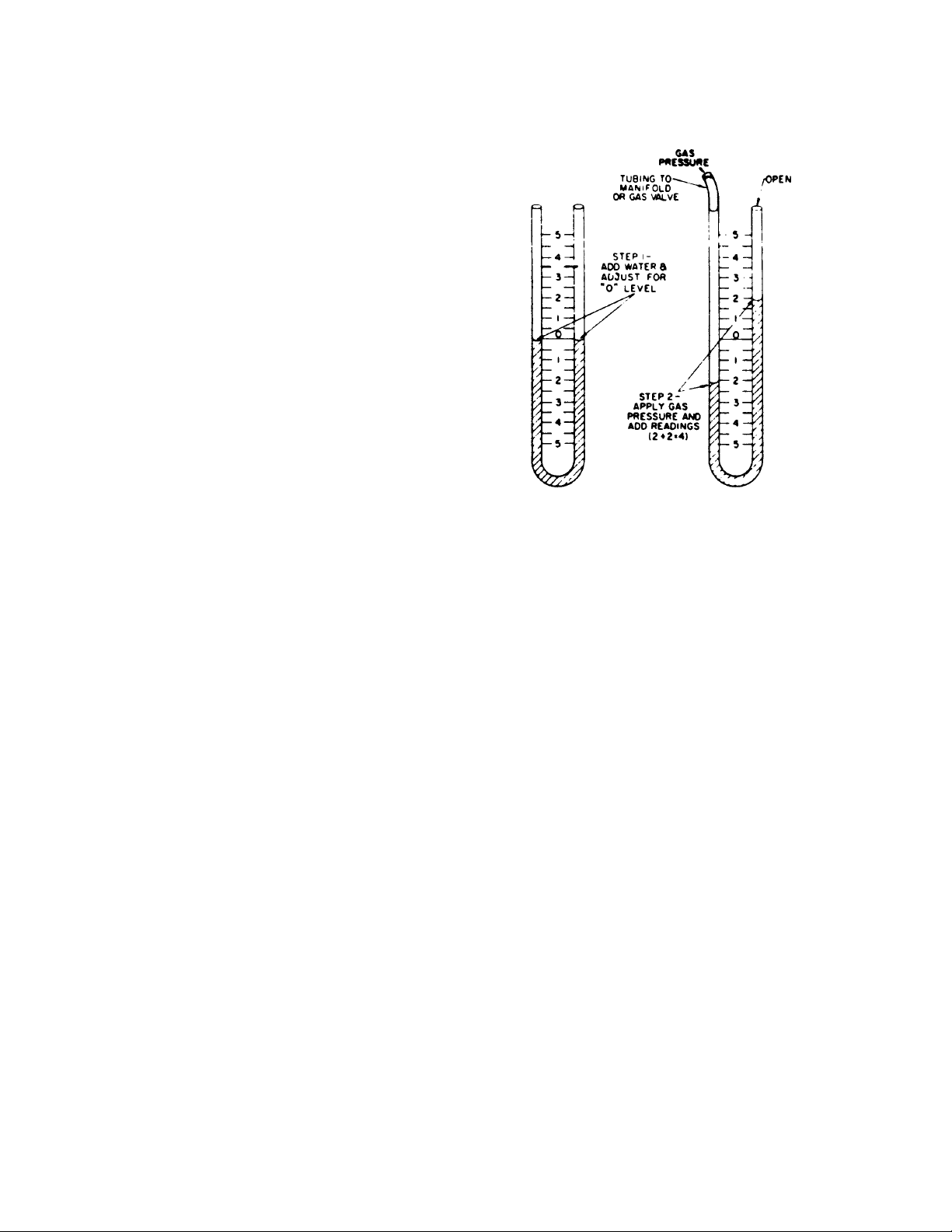

GAS PRESSURE

Correct ignition and operation of the burners are dependent

upon adequate gas pressure. The regulator is designed to

provide pressure of approximately six (6) inches water

column pressure (WCP) for natural gas and approximately

eleven (11) inches for WCP for liquid propane (LP) gas,

provided the universal type gas regulator and gas valves

have been correctly set up for the type gas employed.

These pressures therefore require that the minimum supply

pressure to the regulator must be at least six (6) inches

WCP for natural gas and eleven (11) inches WCP for LP

gas, with maximum pressure not to exceed fourteen (14)

inches WCP.

MEASURING GAS PRESSURE

Equipment for measurement of gas pressure varies from

pressure meters and gauges to the relatively simply and

most commonly used manometer. If it is used, follow the

directions supplied with the unit. The following informations

covers the use of a manometer.

zero level.

Figure 33 - The Mannometer

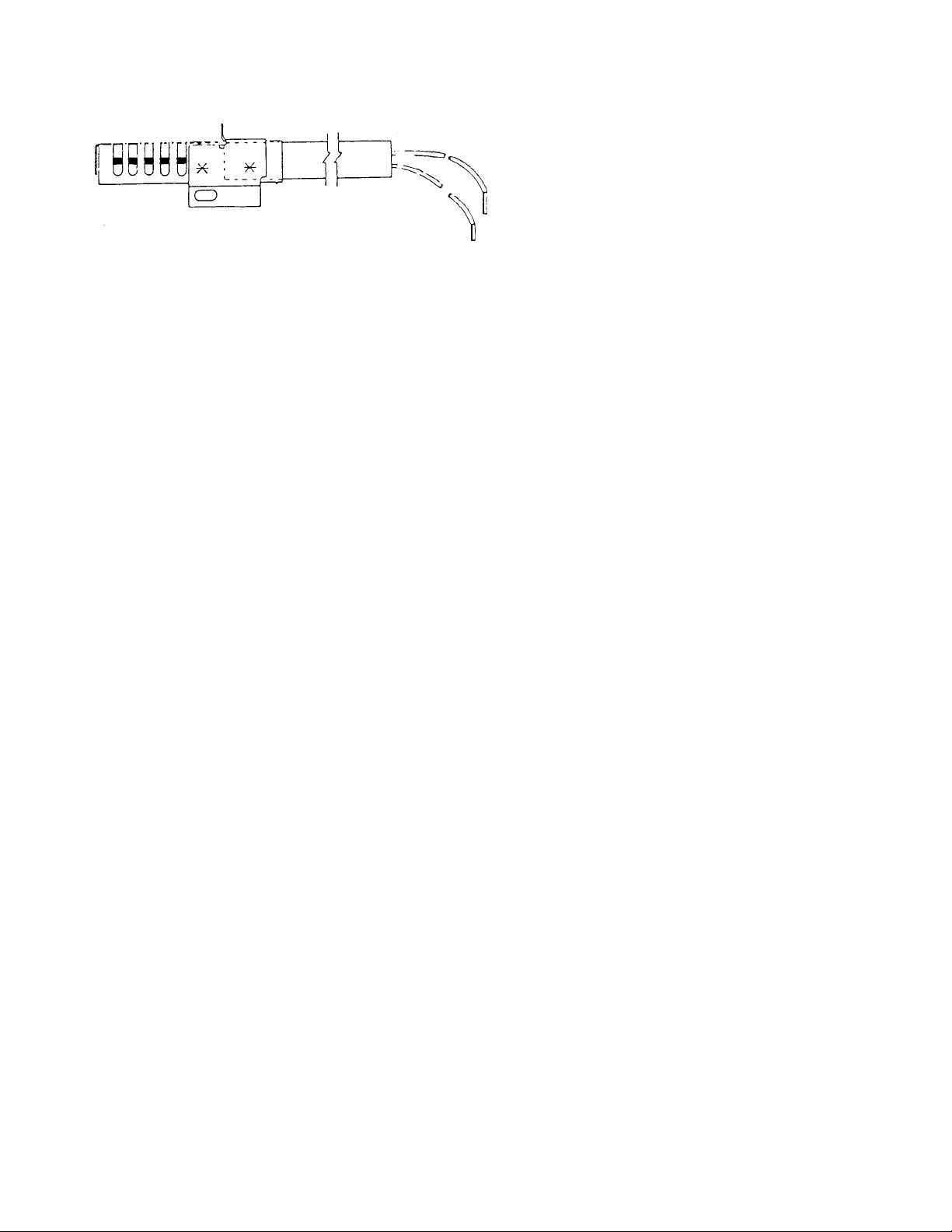

A manometer is simply a U-shaped tube of clear plastic or

glass (see illustration). A scale in inches is located between

the two (2) legs of the "U". In use, the tube is filled with

sufficient water to achieve a level at "0" inches. One end

of the tube is connected to the range manifold or gas valve

orifice while the other end of the tube or leg is open. When

gas pressure is applied, the water on the gas side of the tube

is pushed down and the water in the other leg rises up

against the atmospheric pressure on the open end. The

sum of the readings below the zero level and above the

level will provide the gas pressure in inches water column,

or the water column height which the gas pressure will

support against the atmospheric pressure on top of the

water column. The manometer therefore indicates gas

pressure in inches water column. This conforms with the

gas specifications for gas appliances which are given as

inches WCP or inches water column pressure.

USING THE MANOMETER

The usual procedure for taking the pressure reading is to

connect the tubing to one of the gas valve orifice hoods and

turn on the valve. A full load reading should be taken by

turning on all of the top burners and the oven burner to

assure that the pressure under a full load is adequate.

Figure 33 shows four (4) inches water column pressure

(WCP), two (2) inches above and two (2) inches below the

RC231002 Rev. 3 20

Page 22

SAFE OPERATING PROCEDURES

SAFETY PRECAUTIONS READ BEFORE OPERATING

THE RANGE.

are easily hit. UTENSIL HANDLES SHOULD BE

TURNED INWARD AND NOT EXTEND OVER ADJACENT SURFACE BURNERS to minimize burns,

ignition of flammable materials, and spillage due to

unintentional contact with the utensil.

Accidents are always tragic, especially because so many

of them could have been prevented with a little care and

judgement. Here are some basic good practices to follow

for safe use of the gas range.

1. Be sure the range is installed by a qualified technician

and is properly grounded.

2. Never use the range for warming or heating the room.

This warning is based on safety considerations.

3. Wear proper apparel - loose fitting or hanging

garments should never be worn when operating the

range.

4. Do not repair or replace any part unless specifically

recommended in the manual. All other servicing

should be referred to a qualified service technician.

5. Flammable materials should not be stored near the

range.

6. Do not use water on grease fires. Smother fire or

flame or use dry chemical (such as baking soda) or

foam type extinguisher.

7. Use only dry potholders. Moist or damp potholders on

hot surfaces may result in burns from steam. Do not

use a towel or other bulky cloth.

8. Children should not be left alone or unattended in

area when the range is in use. They should never be

allowed to sit or stand on any part of the range.

9. Select utensils large enough to properly contain food

and avoid boil-overs or spillovers. This will both save

cleaning and prevent hazardous accumulations of

food, since heavy splattering or spillovers left on a

range can ignite. Pan size is especially important in

deep-fat frying.

12. Never leave range burners at high heat settings. Boilover causes smoking and greasy spillovers that may

ignite.

13. Clean range with caution. If a wet sponge or cloth is

used to wipe spills on a hot cooking area, be careful

to avoid steam burns. Some cleansers can produce

noxious fumes if applied to hot surfaces.

14. Do not touch surface area near burner units and

burner caps. During and after use, these areas may

be hot enough to cause burns. Avoid contact with

these areas by clothing or other flammable materials

until they have had sufficient time to cool.

15. Do not heat unopened food containers - build-up of

pressure may cause container to burst and result in

injury.

16. Do not store items of interest to children in

cabinets above the range. Children climbing on

the range to reach items could be seriously injured.

17. GREASE - Grease is flammable and should be

handled carefully. Never leave any cooking operation unattended. Let fat cool before attempting to

handle it. Wipe spillovers immediately.

18. Burner flame should be adjusted so that they do not

extend beyond the edge of the utensil. This warning

is based on safety considerations.

19. Never sit, step, or stand on any part of the range or

injury may result.

10. TYPE OF UTENSILS - Avoid pans that are unstable

and easily tipped. In choosing pans, look for easily

grasped handles that will stay cool. Pans that are too

heavy when filled with food can also be a hazard. If

pan handles twist and cannot be tightened, discard

the pan.

11. HANDLES - Always turn pan handles to the side or

back of the range - not out into the room where they

21 RC231002 Rev. 3

Page 23

SAFE OPERATING PROCEDURES

OPERATING INSTRUCTIONS

SAFETY TIPS

Some "common sense" rules to remember:

· Always be certain that the oven parts are cool before

touching them when hands are not protected by a

potholder.

· Always use a dry potholder, never a moist one, nor a

trailing cloth, to avoid possible burns from steam.

· Pulling out oven racks is a convenience when lifting

heavy foods, but caution should be used against

possible burns from touching hot surface.

· For your safety, never use the range as a space

heater.

· Do not heat unopened containers such as jars, cans,

etc., in the oven. The build-up of pressure may cause

the container to burst and can cause serious personal

harm or damage the range.

· Do not use aluminum foil on the racks or oven bottom.

This will hinder heat circulation.

· Do not use aluminum foil on the racks or oven bottom

when cleaning. The self-cleaning feature makes this

unnecessary.

· Do not attempt to clean the oven or broiler burner

ignitor assembly. The ignitors are electrically operated and the danger of electric shock is present.

· Do not place baking utensils directly on the oven

bottom.

· Do not use disposable or substitute broiler pans. The

broiler pan and grid provided with the range have

been scientifically designed to keep drippings cool so

they will not become hot enough to ignite.

· Always remove the broiler pan and grid from the oven

when baking and roasting. A possible fire hazard

could exist if a soiled pan and grid are left in the oven.

Also, any drippings on the grid will become baked on

and will be very difficult to remove.

· Never cover the broiler grid with aluminum foil. It may

trap grease and cause it to smoke. If desired, place

a sheet of aluminum foil to line the broiler pan

underneath the broiler grid to ease clean up. (A cup

of water placed in the broiler pan will also minimize

clean up.)

· Never use the range as storage space.

· Never store flammable items in the storage drawer.

all broiling is done with a fast, searing heat, no temperature

selection is used except with certain recipes). The burner

lights automatically in 50 - 60 seconds. During the broil

cycle the burner will cycle on and off. For programming

information on models with the Electronic Range Control,

see Section III, Operation and Troubleshooting, ERC

Control.

Things to Remember:

CLOSE THE DOOR COMPLETELY FOR ALL BROILING.

Ultra-Ray® consumes most smoke and spatter. Kitchen

stays cleaner, cooler.

DO NOT PRE-HEAT THE BROILER BEFORE USING.

BAKING

For best results preheat the oven first. Turn the selector

dial to "Manual" and the thermostat dial to the desired

temperature. The oven will light automatically. Allow the

oven to heat to temperature, approximately fifteen (15)

minutes. For programming information on models with the

Electronic Range Control, see Section III, Operation and

Troubleshooting, ERC Control.

The range is equipped with tilt proof oven racks with

automatic stops. The oven racks are removable and can

be inserted at various levels. They can be pulled to the

"STOP" position without danger of tipping. To remove the

racks, pull to the stop position, raise the forward edge, and

lift. Reverse the procedure to install racks. One or both

oven racks can be used during baking.

Always keep in mind that heated air in the oven must be

allowed to circulate freely. Leave at least 1 1/2" between

utensils and between utensils and the oven walls. For

example, never place one cake layer directly over another

- stagger them within the oven.

BROILING

The Ultra-Ray® Broiler

To use the Ultra-Ray® broiler, set the selector dial to

"Manual" and the temperature control dial to "Broil" (since

RC231002 Rev. 3 22

FIGURE 34

Page 24

SAFE OPERATING PROCEDURES

OPERATING THE TOP BURNERS

MODELS WITHOUT SEALED BURNERS

The top burners of some models are equipped with Tri-Set

top burner valves. These valves provide flame adjustment

for any size flame which is desired as well as "click"

positions for "LO", "MED", and "HI" settings. Depress the

knob and turn the knob counterclockwise as far as it will go.

When the burner lights, turn the knob back to the desired

flame height.

The "HI" position provides a flame which will bring water to

a full boil quickly. This is the "full on" position of the valve.

If the burner flame is turned down, an audible "click" can be

heard as the valve reaches the "MEDIUM" position. This

flame is sufficient to keep water boiling in a covered pan.

When the flame is turned down lower, a second "click" can

be heard. This is a very low or "Keep Warm" flame setting

which is the "LO" position on the valve. The low flame

provides a warming heat to keep food which is already

cooked ready to serve.

The "HI" position provides a flame which will bring water to

a full boil quickly. This is the "full on" position of the valve.

If the burner flame is turned down, an audible "click" can be

heard as the valve reaches the "MEDIUM" position. This

flame is sufficient to keep water boiling in a covered pan.

When the flame is turned down lower, a second "click" can

be heard. This is a very low or "Keep Warm" flame setting

which is the "LO" position on the valve. The low flame

provides a warming heat to keep food which is already

cooked ready to serve.

The low burner flame may be adjusted by turning adjustment screw in center of valve stem. Normally, the low

flame should be adjusted to the minimum steady blue

flame. Check the adjustment by turning from high to low

several times to see that the burner does not go out.

NOTE: When adjusting the low burner flame, the valve

stem should be held in the "LOW" position.

The Tri-Set valves are equipped with metered, fixed

orifices, and the low setting cannot be adjusted. As there

are air shutters, the burner flames can be adjusted in

accordance with the Adjustment and Calibration Instructions.

The HI-LOW valves on other models are similar but

without the "click" stops.

TOP BURNERS

The top burners consists of a burner and integral cap, a

flash tube and support, a gas delivery tube including

venturi and an adjustment air shutter. These burners are

designed for trouble free operation with a minimum of

parts.

MODELS WITH SEALED BURNERS

The top burners of these models are equipped with Tri-Set

top burner valves. These valves provide flame adjustment

for any size flame which is desired as well as "click"

positions for "LO", "MED", and "HI" settings.

Whenever a top burner gas valve knob is depressed and

turned fully counterclockwise, the electrode built into the

burner cap will start sparking and continue as long as the

knob is held in this position. After the burner lights, move

the knob to the "HI" position of the valve. At this time the

sparking will cease. There are no standing pilots that have

to be lighted or adjusted.

23 RC231002 Rev. 3

Page 25

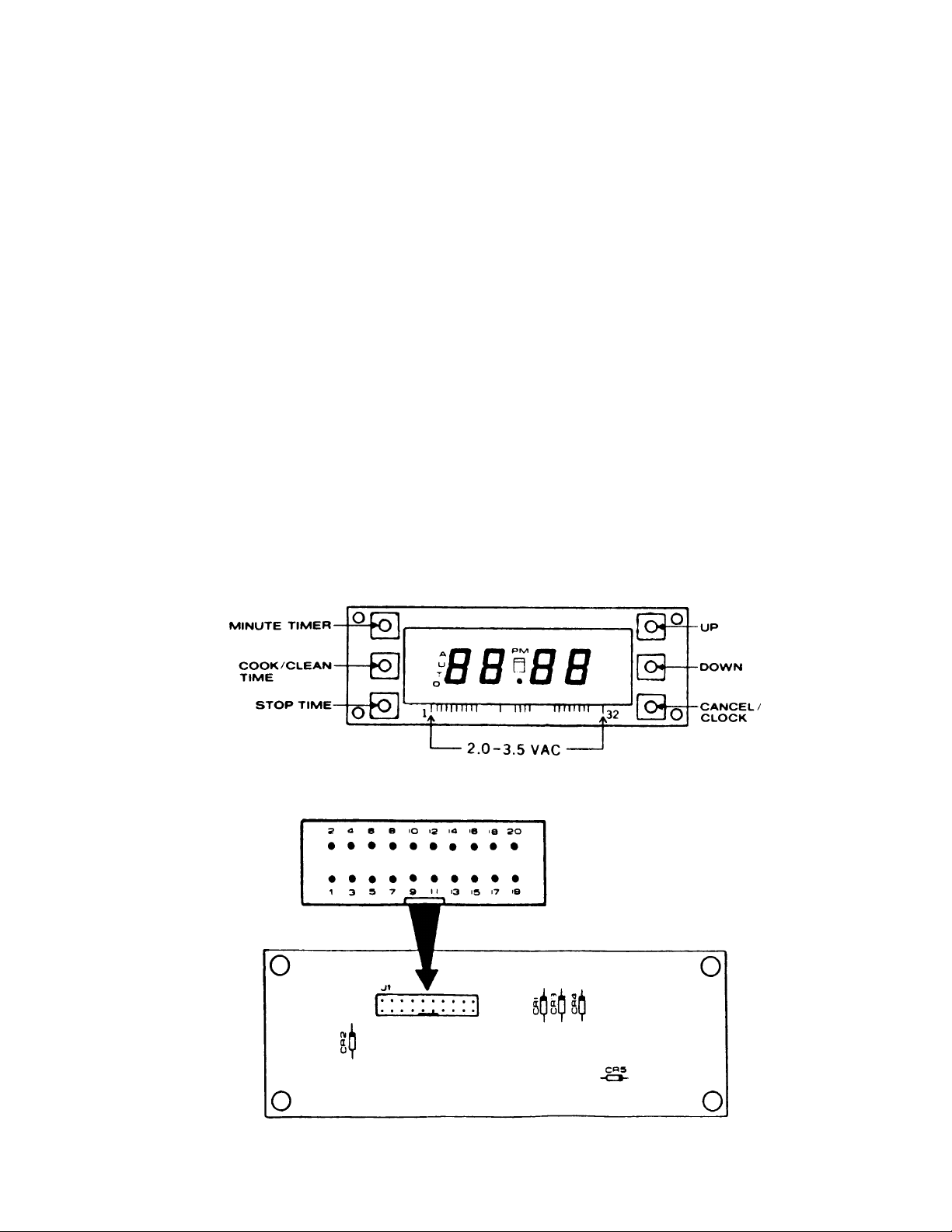

OPERATION AND SERVICE PROCEDURES

(SLIDE IN MODELS)

ELECTRONIC CLOCK/TIMER

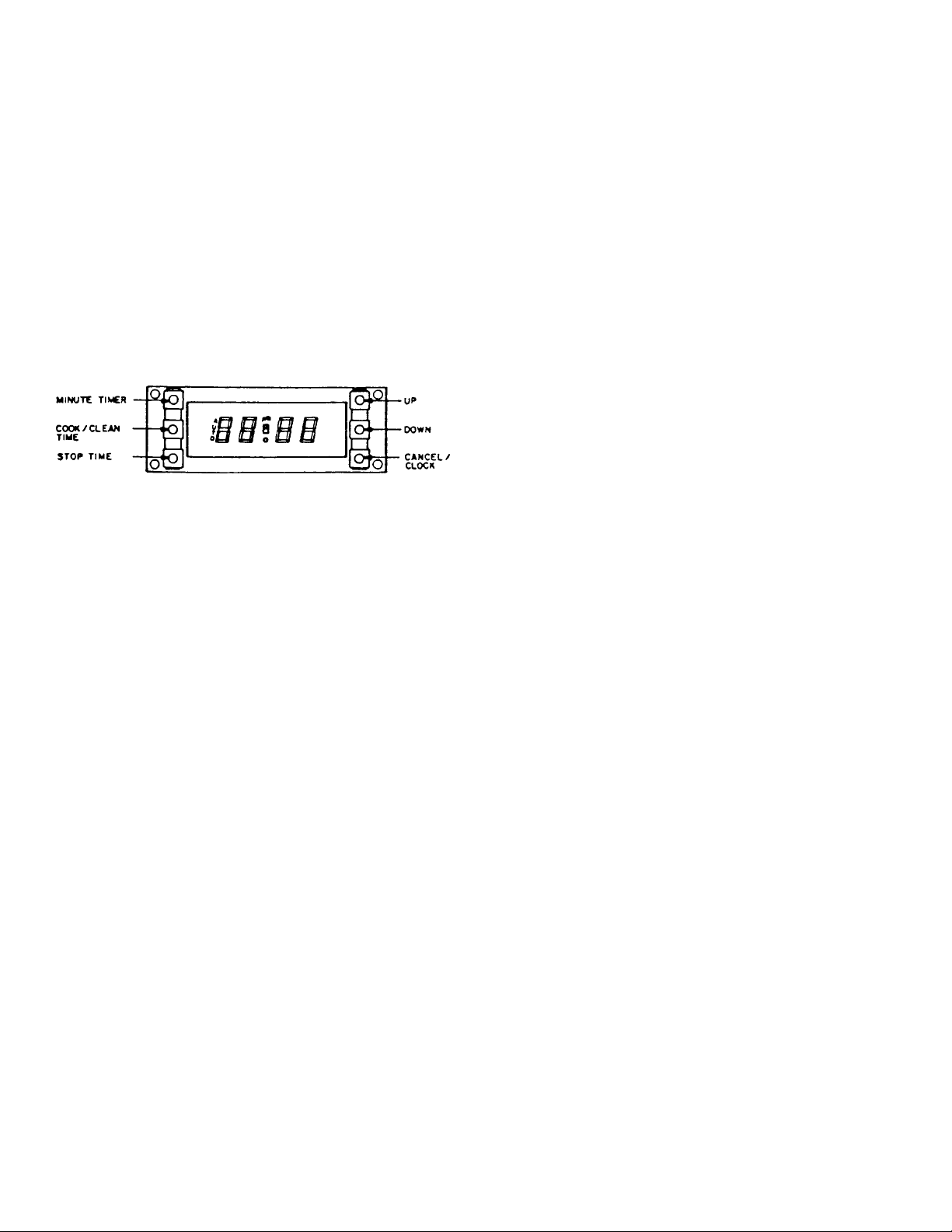

The Clock/Timer offers a time-of-day clock with a PM

designation, a Minute Timer with up to nine (9) hours and

fifty-nine (59) minutes, and cook and stop functions. The

clock and timer are set up with up and down variable speed

"slew" entry.

The display board consists of a vacuum fluorescent display

(VFD) with pushbutton entry. There are six (6) pushbuttons:

"MINUTE TIMER", "COOK/CLEAN TIME", "STOP TIME",

"UP" and "DOWN" and "CANCEL/CLOCK". The "UP" and

"DOWN" pushbuttons are for time setting.

Figure 56 - Electronic Clock/Timer

The Clock/Timer is a digital clock with a minute timer and

automatic control cooking cycle. The clock is set via the

function setting and slew controls. When power is connected to the unit, or a power failure of longer than three (3)

seconds occur, the display will show "12:00" flashing at the

rate of 1/2 second ON and 1/2 second OFF.

Setting the Time-of-Day

To Set the Minute Timer:

1. Display the "MINUTE TIMER" button. The timer will

display "0:00".

2. Press the "UP" button until the desired time period is

displayed, and release the "UP" button.

The minute timer is now programmed. After approximately five (5) seconds the timer display will revert

back to the Time-of-Day while continuing to count

down the programmed time. An alarm will sound

when the timer reaches "0:00". Press the "MINUTE

TIMER" button to silence the alarm. To check the

remaining time in the program, simply press the

"MINUTE TIMER" button.

The Minute Timer can also be used when the Clock/

Timer is programmed for a Timed Bake or Self-Clean

operation. NOTE: The Minute Timer does not control

oven operation.

SETTING TIMER FOR TIMED BAKE (Bake Cycle

Only)

SEMI-AUTOMATIC OPERATION

Oven starts at once and shuts off at the end of the cooking

cycles.

The clock setting is achieved by depressing the "CANCEL/

CLOCK" pushbutton first. Then key in the desired time of

day by using the "UP" and "DOWN" pushbutton keys. The

clock has a PM designation on the VFD for the PM time

setting.

The Clock/Timer also incorporates military timing capabilities. In order to change from the standard AM/PM clock

operation to military time clock operation or vice versa,

simultaneously press "COOK/CLEAN TIME" button and

the "STOP TIME" button. NOTE: The "UP" and "DOWN"

buttons must be pressed within five (5) seconds after

selecting or pressing any timing function button ("CANCEL/CLOCK", "MINUTE TIMER", "COOK/CLEAN TIME",

"STOP TIME"). If the "UP" and "DOWN" buttons are not

pressed within the five (5) second period, incorrect or no

programming will occur.

Setting the Minute Timer

The minute timer can be used for precisely time baking or

broiling operations in the oven. It can be used for timing

from one (1) minute up to nine (9) hours and fifty-nine (59)

minutes.

1. Turn selector switch knob to "AUTO".

2. Turn oven control knob to the desired baking temperature.

3. Press the "STOP TIME" button. The display will show

"0:00".

4. Press the "UP" button to set the desired stop time, and

then release the "UP" button. After approximately

five (5) seconds, the display reverts back to the Timeof-Day, "AUTO" appears on the left of the display

along with the oven indicator in the center of the

display signifying that the timed bake cooking cycle

has started. When the desired stop time is reached,

the oven indicator light goes out and an alarm will

sound for approximately ten (10) seconds. The oven

will automatically shut off. "AUTO" will continue to

blink ON and OFF indicating that the clock timer was

set for an automatic timed function and is completed.

5. Turn the selector switch to "MANUAL", oven control

to the OFF position and press the "CANCEL/CLOCK"

button.

RC231002 Rev. 3 24

Page 26

OPERATION AND SERVICE PROCEDURES

(SLIDE IN MODELS)

DELAYED TIME BAKE

Oven starts at a later time and shuts off at the end of the

cooking cycle.

1. Turn selector switch knob to "AUTO".

2. Turn oven control knob to the desired baking temperature.

3. Press "COOK/CLEAN TIME" button. The display will

show "0:00".

4. Press the "UP" button to set the desired length of

baking time. EXAMPLE: To time bake for three (3)

hours press and hold the "UP" button until "3:00"

appears on the display, then release the UP button.

5. Press the "STOP TIME" button.

6. Press the "UP" button to set the desired stop time. To

have the time bake cycle finish at five o-clock (5:00),

press and hold the "UP" button until "5:00" appears on

the display, then release the "UP" button. After

approximately five (5) seconds, the display reverts

back to the Time-of-Day and "AUTO" appears on the

left of the display indicating that the Clock/Timer is

programmed for an automatic timed function. The

clock will automatically calculate the start time. When

the starting time is reached, the oven indicator in the

center of the display will come on indicating that the

timed bake cycle has started.

When the stop time is reached, the oven indicator

turns off and an alarm will sound for approximately

ten (10) seconds. The oven will automatically turn off

and AUTO will continue to blink ON and OFF indicating that the Clock/Timer was set for an automatic

timed mode and it is completed.

7. Turn the selector switch to "MANUAL", the oven

control to the OFF position, and press the "CANCEL/

CLOCK" button.

SETTING THE TIME FOR SELF-CLEAN

4. Press the "COOK/CLEAN TIME" button. The display

will show "0:00".

5. Press the "UP" button to set the desired length of the

clean time. EXAMPLE: To self-clean the oven for

three (3) hours, press and hold the UP button until

"3:00" appears on the display, then release the "UP"

button.

After approximately five (5) seconds, the display

reverts back to the Time-of-Day and "AUTO" appears

on the left of the display along with the oven indicator

in the center of the display signifying that the clean

cycle has started.

The oven indicator light on the control panel will come

on and cycle ON and OFF with the thermostat.

6. At the end of the clean cycle the oven indicator light

and oven indicator (clock) will turn OFF, and an alarm

will sound for approximately ten (10) seconds. The

oven will automatically turn off and "AUTO" will

continue to blink ON and OFF indicating that the

Clock/Timer was set for an automatic timed mode

and it is now completed.