Amana PTC154G35CXXX, PTH153G50CXXX, PTH153G25CXXX, PTC153G25CXXX, PTC153G35CXXX Owner's Guide

...

PACKAGE TERMINAL

AIR CONDITIONER/HEAT PUMP

INSTALLATION INSTRUCTIONS & OWNER’S MANUAL

Standard and Remote Applications with LED Control

ATTENTION INSTALLING PERSONNEL

As a professional installer you have an obligation to know the

product better than the customer. This includes all safety precautions and related items.

Prior to actual installation, thoroughly familiarize yourself with

this Instruction Manual. Pay special attention to all safety warnings.

Often during installation or repair it is possible to place yourself

in a position which is more hazardous than when the unit is in

operation.

This manual must be left with the owner of the equipment.

IO-447B

03/2017

5151 San Felipe, Suite 500 • Houston, TX 77056 • www.amana-ptac.com

is a registered trademark of Maytag Corporation or its related companies and is used

under license to Goodman Company, L.P., Houston, TX, USA. All rights reserved.

© 2014 - 2015, 2017 Goodman Company, L.P.

Remember, it is your responsibility to install the product safely

and to know it well enough to be able to instruct a customer in

its safe use.

Safety is a matter of common sense...a matter of thinking before

acting. Most dealers have a list of specific good safety

practices...follow them.

The precautions listed in this Installation Manual are intended as

supplemental to existing practices. However, if there is a direct

conflict between existing practices and the content of this manual,

the precautions listed here take precedence.

Contents

Unit Features.................................................. 2

Installation Instructions ..................................... 5

Wiring ........................................................... 7

Operating Instructions....................................... 8

Maintenance and Cleaning................................ 12

Obtaining Service........................................... 14

Normal Operating Sounds and Conditions ............. 14

Configuration Settings ..................................... 14

IMPORTANT NOTE TO THE SERVICER

Read this manual and familiarize yourself with the specific items

which must be adhered to before attempting to service this unit.

The precautions listed in this Installation Manual are intended as

supplemental to existing practices. However, if there is a direct

conflict between existing practices and the content of this

manual, the precautions listed here take precedence.

RECOGNIZE THIS SYMBOL

AS A SAFETY PRECAUTION.

WARNING

G

OODMAN WILL NO T BE RESP ONSIBLE FOR A NY INJURY OR PROPERTY

DAMAGE ARISING FROM IMPROPER SERVICE OR SERV ICE PROCEDURES.

I

F YOU INSTALL OR PERFO RM SERVICE ON THIS UNIT, YOU ASSUME

RESPONSIBILITY FOR ANY PERSO NAL INJURY OR PROPERTY DAM AGE WHICH

MAY RESULT.

SERVICE HEATING AND AIR C ONDITIONING EQUIPMENT.

M

ANY JURISDICTIONS REQUIRE A L ICENSE TO INSTALL OR

Configuration Chart ........................................ 15

Diagnostic Maintenance & Status Report .............. 16

Diagnostic Codes............................................ 17

IMPORTANT NOTE TO THE OWNER

This manual is to be used by qualified, professionally trained

HVAC technicians only. Goodman does not assume any responsibility for property damage or personal injury for improper

service procedures or services performed by an unqualified

person.

IMPORTANT NOTES:

Your warranty certificate is also supplied with the unit.

Read the warranty carefully and note what is covered.

Keep the warranty certificate in a safe place, so you can

find it, if necessary.

Before using this manual, check the serial plate for

proper model identification.

THE INSTALLATION AND SERVICING OF THIS EQUIPMENT

MUST BE PERFORMED BY QUALIFIED, EXPERIENCED TECHNICIANS ONLY.

Due to policy of continual product improvement, the

right is reserved to change specifications and design

without notice.

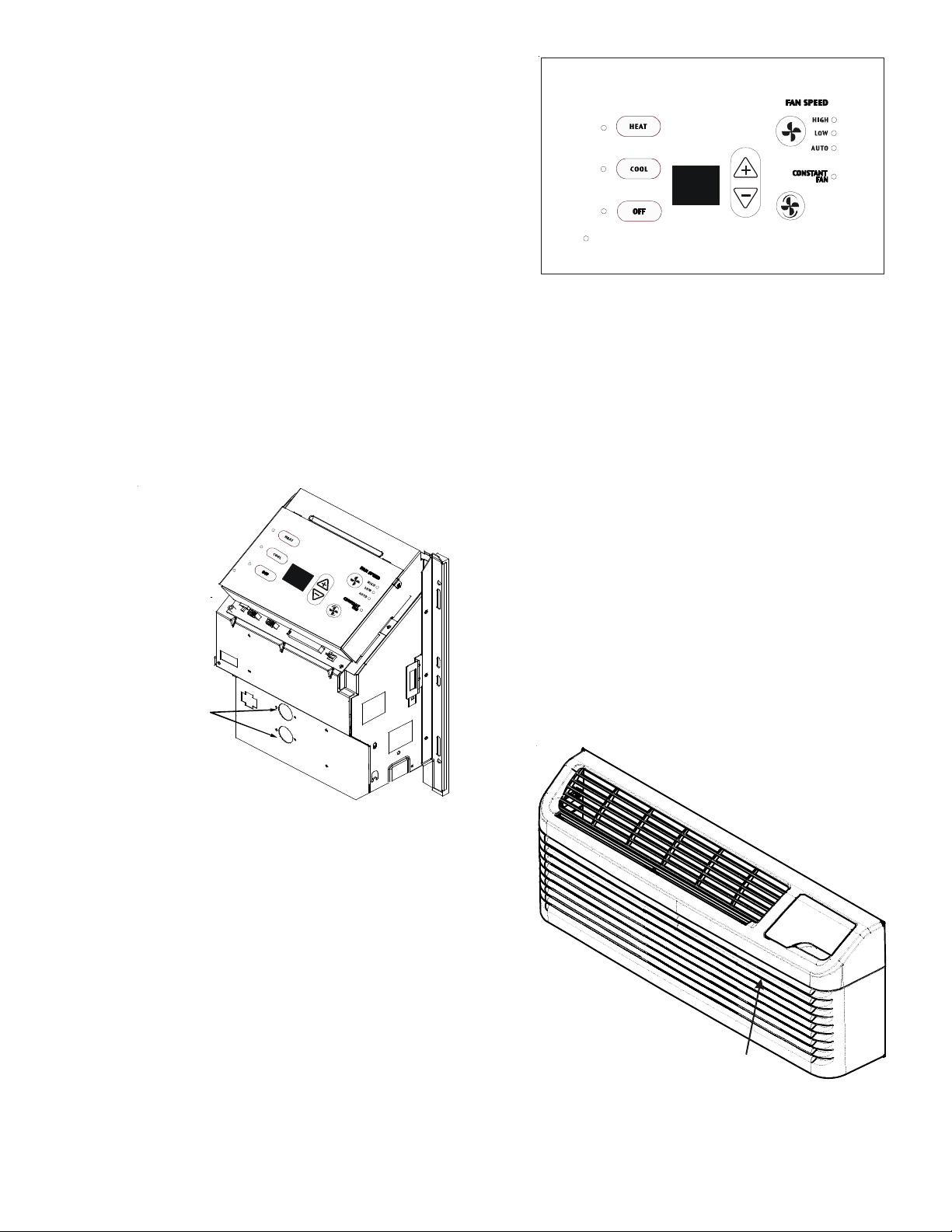

UNIT FEATURES

This unit has many features which are different than those found

on conventional PTAC units. The servicer must be familiar with

these features in order to properly service the unit.

• LCDI or AFCI Power Cords - Underwriters Laboratories

and the National Electric Code (NEC) now require power

cords that sense current leakage and can open the electrical circuit to the unit on units rated at 250 volts or

less. In the event that unit does not operate, check the

reset button located on or near the head of the power

cord as part of the normal troubleshooting procedure.

LCDI power Cord

• Automatic 3-minute compressor lockout - After the compressor cycles off, it will not restart for three minutes.

nd

• Automatic 2

ture falls to 4°F below the set point temperature, the

reverse cycle heat is shut off and the electric strip heat is

turned on.

stage electric heat - If the room tempera-

2

• Automatic freeze protection - Whenever power is supplied to the unit and the master switch is in the ON position, automatic freeze protection is active. If the unit

senses temperature below 40°F, the fan motor and electric strip heat are turned on. Freeze protection can be

turned off, if required.

• Random restart delay - To help eliminate power surges

after a power outage, the unit is equipped with a two to

four minute random restart delay feature. Whenever the

unit is plugged in with the master switch turned on and

the mode switch set in the cool or heat mode, a random

restart will occur. A random restart condition can be

avoided by setting the mode switch in the fan only or off

position before applying power to the unit.

• Fuse holder - On all 265 volt units, fuse holders are factory installed. Check for blown fuse if unit does not operate. Fuse holder is located behind the front. Replacement

fuses may be purchased from the Parts Department or

contact your sales representative for part numbers.

7 Button Touch Pad With Display

• Load shedding - When input terminals have been configured for load shedding operations. If at any time a switch

is closed between the IN1 and COM or IN2 and COM terminals as configured, the compressor and electric heater

will lockout until the switch is opened.

NOTE: The PTAC Wire Harness Kit (PWHK01G70) is required when

using or load shedding option.

• Transfer fan - A daughter board allows for an external

(transfer) fan connection. A user-supplied relay is required

and, depending upon the type used, an approved external

transformer kit may be required for installation.

FUSE

HOLDERS

Control Panel

• Indication LEDs - The touch pad has LEDs that correspond

to fan operation and to indicate unit status. The LEDs

next to the selections OFF, COOL, and HEAT indicate which

operational mode is active. The LED located in the lower

left corner is a status LED. This LED indicates the status of

the unit. See Diagnostic Maintenance & Status Report section for further details.

• Front mounting hole - A mounting hole location is provided to give the owner the option of securing the front to

the chassis. The mounting hole must be drilled at the

dimple indicating the correct location below a louver . The

owner must supply one 1/2 inch long #8 sheet metal screw

per unit. The screw must be removed before the front can

be removed.

Front Mo unting Screw accessed

through louvers.

Chassis Front

3

• Energy Management System Features

b. Original paid freight bill or indemnity in lieu thereof.

Temperature Setback - This option can save energy dollars for unrented or unoccupied rooms by automatically

setting back the operational temperatures. This mode of

operation is selected through the configuration routine

(see Configuration Settings section). NOTE: T emperature

setback does not work with a wired remote thermostat.

Door Switch and Motion Sensor Low Voltage Terminals (IN1,

IN2, COM) - The door switch and motion sensor operate as

a unit, the terminals allow for wired connection of a door

sensor to the control board. The motion sensor interprets

any door movement as a signal of occupancy . If the switch

between IN* and COM is closed, the door control will interpret the room door as closed. If the switch between

IN* and COM terminals is opened (or closed if unit is configured for normally open) the control will interpret the

action as a signal of occupancy . If thirty minutes pass without any door activity, Energy Management Temperature

setback activates.

Serial Port Interfaces - A serial port, located on the control board, provides easy access for two-way communications to the control board from an optional RF antennae

can be attached for wireless communications.

TRANSPORTATION DAMAGE

All units are securely packed in shipping containers tested

according to International Safe Transit Association specifications. The carton must be checked upon arrival for external

damage. If damage is found, a written request for inspection by

the carrier’s agent must be made immediately.

In the event of damage, the consignee must:

1. Make notation on delivery receipt of any visible damage to

shipment or container.

c. Original invoice or certified copy thereof, showing

trade and other discounts or reductions.

d. Copy of the inspection report issued by carrier’s

representative at the time damage is reported to the

carrier.

The carrier is responsible for making prompt inspection of

damage and for a thorough investigation of each claim. The

distributor or manufacturer will not accept claims from dealers

for transportation damage.

UNIT ACCESSORIES

This unit is designed for through-the-wall installation in new or

existing buildings. To complete the installation of this PTAC, an

insulated wall sleeve and an outdoor grille (either the stamped

aluminum grille, the architectural grille or polymer grille) are

required.

The chassis and the cabinet front are shipped in one carton.

Optional accessories to complete a particular installation are

the following:

OPTIONAL ACCESSORIES

Power Switch Kit Wire Harness Kit

Wall Sleeve Kit Circuit Breaker Kit

Key Lock Kit Architectural Grille Kit

Drain Kit Remote Escutcheon Kit

Filter Kit External Transformer Kit

Subbase Kit Water or Steam Valve Kit

Hard Wire Kit Condensate Disposal Pump Kit

Main Duct Kit Remote Temperature Sensor Kit

Power Door Kit Wireless RF Antenna

Leveling Legs Kit Wireless RF Thermostat

Hydronic Heat Kit Wireless Motion Sensor

Stamped Grille Kit Wireless Door Switch

Curtain Guard Kit Extra Deep Sleeves

Polymer Grille Kit Wall Thermostat Kit

Extension Duct Kit Fuse Holder Kit

NOTE: Consult sales literature for the appropriate voltage and

amperage selections, if applicable. For additional details and

illustrations of the accessories, refer to the Architect’s and

Engineer’s Manual.

2. Notify carrier promptly and request an inspection.

3. In case of concealed damage, carrier should be notified as

soon as possible—preferably within 5 days.

4. File the claim with the following supporting documents

within the 6 month statute of limitations.

a. Original Bill of Lading, certified copy, or indemnity

bond.

4

INSTALLATION INSTRUCTIONS

r

Sleeve

Stiffene

To ensure that the unit operates safely and efficiently, it must

be installed, operated and maintained according to these installation and operating instructions and all local codes and ordinances or, in their absence, with the latest edition of the

National Electric Code. The proper installation of this unit is

described in the following sections. Following the steps in the

order presented should ensure proper installation. Rated performance is achieved after 72 hours of operation.

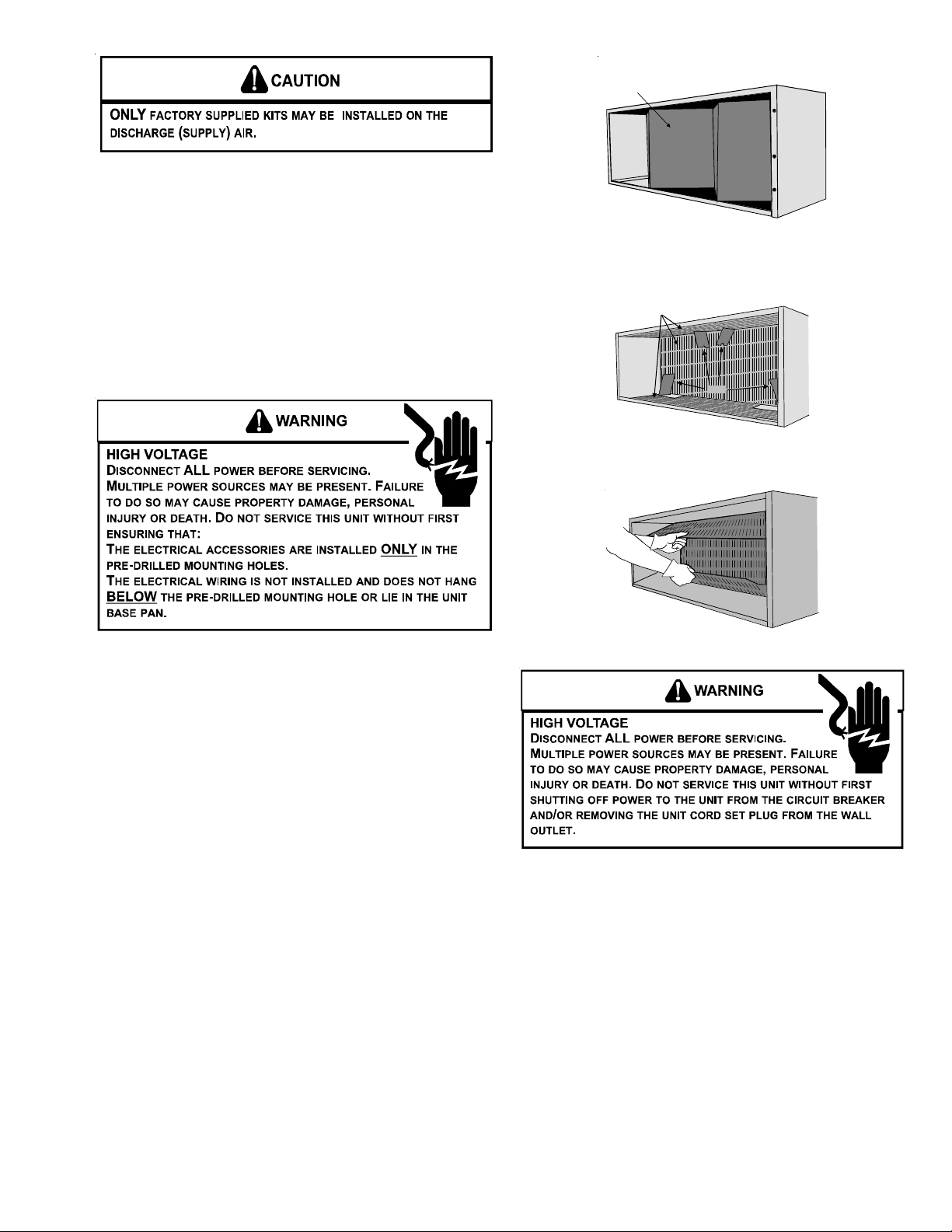

SLEEVE STIFFENER AND REAR CLOSURE PANEL

REMOVAL

Before the chassis can be installed in the wall sleeve, the sleeve

stiffener and the rear closure panel must be removed.

Wall Sleeve with Stiffener

Rear Closure

Panel

Flaps

Stiffener Removal

Rear Enclosure Panel Removal

1. Remove the zigzag folded cardboard sleeve stiffener.

2. Remove the rear closure panel by folding the four flaps.

3. Grasping the top and bottom flanges of the rear closure

panel pull the entire panel out diagonally from one side.

DRAIN KIT INSTALLATION (OPTIONAL ACCESSORY)

During normal reverse cycle heating operation, condensate

water will drain out of the rear of the wall sleeve. If this water

is objectionable, a drain kit should be installed. The drain kit has

provisions for draining the water from either the right or left side

of the sleeve externally or from the bottom of the sleeve

internally. The drain kit must be installed before the outdoor

grille is installed. Refer to the Installation Instructions supplied

with the drain kit for a complete description of the installation

procedure.

SLEEVE INSTALLATION

In order for condensate water to drain properly inside the unit,

the sleeve must be installed properly:

• Level from right to left.

• A slight downward pitch from the indoor side to the outdoor side as shown below.

Refer to the Installation Instructions supplied with the PTAC wall

sleeve for a complete description of the installation procedure.

5

OutsideInside

Level

Wall

Sleeve

Outside

Wall

1/4 Bubble

Tilt To

Outside

Proper Sleeve Tilt

OUTDOOR GRILLE

An outside grille must be installed to direct air flow for proper

unit operation and also protect the outdoor coil. The grille must

be installed before installing the chassis. Refer to the Installation Instructions supplied with the outdoor grille kit for a

complete description of the installation procedure.

This model requires either a Stamped Grille Kit (Model SGK--B),

a Polymer Grille Kit (Model PGK) or an Architectural Grille Kit

(Model AGK--B). When replacing an old chassis with an existing

grille or using a specialized grille in a new installation, please

check with your sales representative to determine if the new

chassis should be used with the non-standard specialized grille.

An improper outdoor grille can decrease cooling or heating

capacity, increase energy usage and shorten compressor life and

possibly void the warranty.

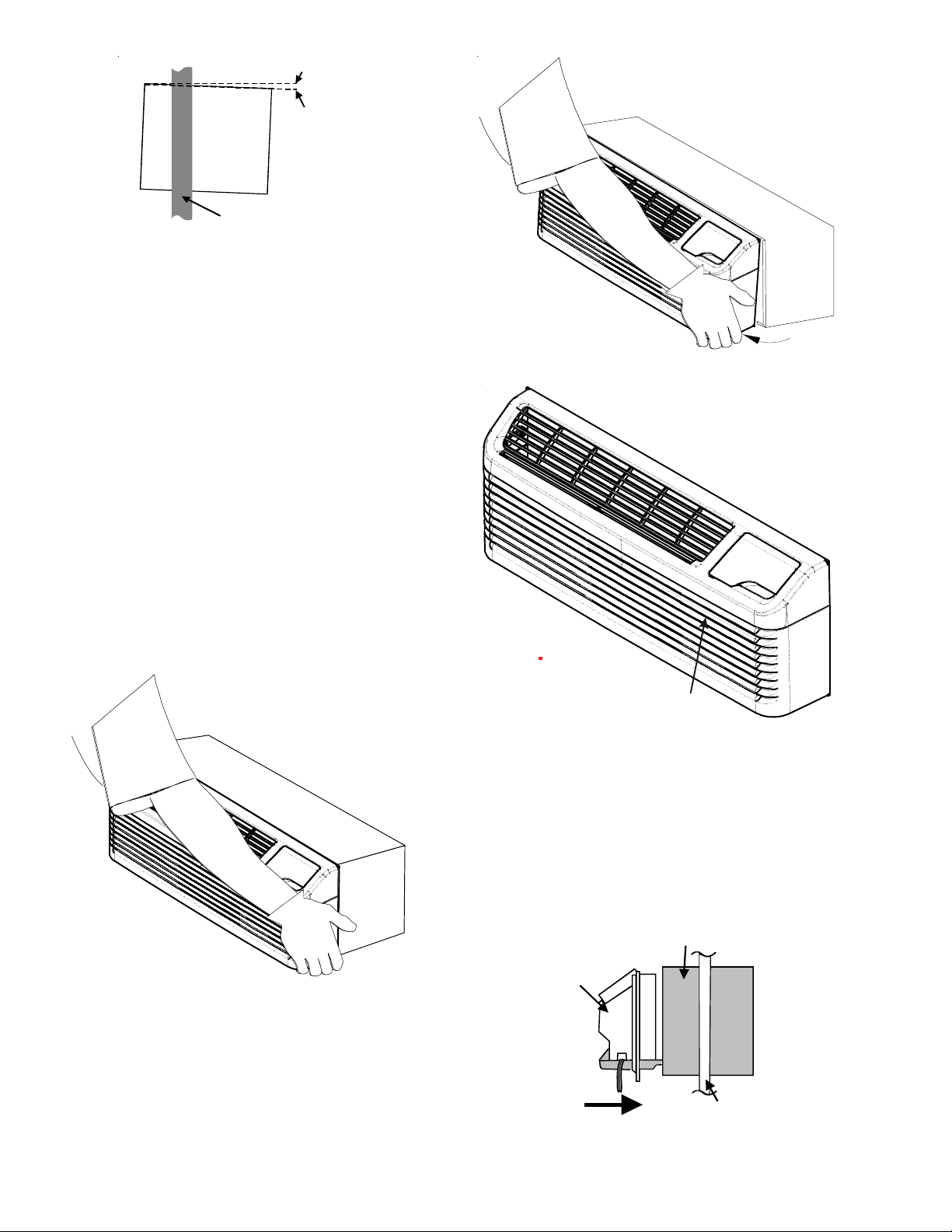

Cabinet Front Removal View 2

FRONT REMOVAL

1. Grasp the cabinet front.

Cabinet Front Removal View 1

2. Pull the bottom of the cabinet front away from the chassis

until the retaining clips disengage. NOTE: If front is secured with a screw, remove front mounting screw, then

follow front removal procedure.

Front Mo unting Screw accessed

through louvers.

Front Mounting Screw

3. Lift the cabinet front off the chassis. Reverse this procedure

to reinstall the cabinet front.

CHASSIS INSTALLATION

1. Remove the cabinet front from the chassis as described in

Front Removal.

2. Insert the chassis into the wall sleeve.

Wall Sleeve

Chassis

Slide Chassis In

Outside

Wall

Chassis Installation View 1

6

Loading...

Loading...