Page 1

Amana Technical Information—Electric Range

ARR6400 P1142670N, P1143415N, P1143432N, P1143457N, P1143607N, P1143640N,

P1143653N, P1143674N

ART6510 P1143460N, P1143469N, P1143482N, P114361 IN, P1143630N, P1143657N

• Due to possibility of personal injury or property damage, always contact an authorized technician for servicing or

repair of this unit.

• This technical sheet replaces RT2320003 Rev. 8.

• Refer to Service Manual RS2320004 for detailed installation, operating, testing, troubleshooting, and disassembly

instructions.

• Refer to Parts Manual RP2320040 for part number information.

A CAUTION

All safety information must be followed as provided in Service Manual RS2320004.

^

_________________

To avoid risk of electrical shock, personal injury, or death, disconnect power to oven before servicing, unless

testing requires it.

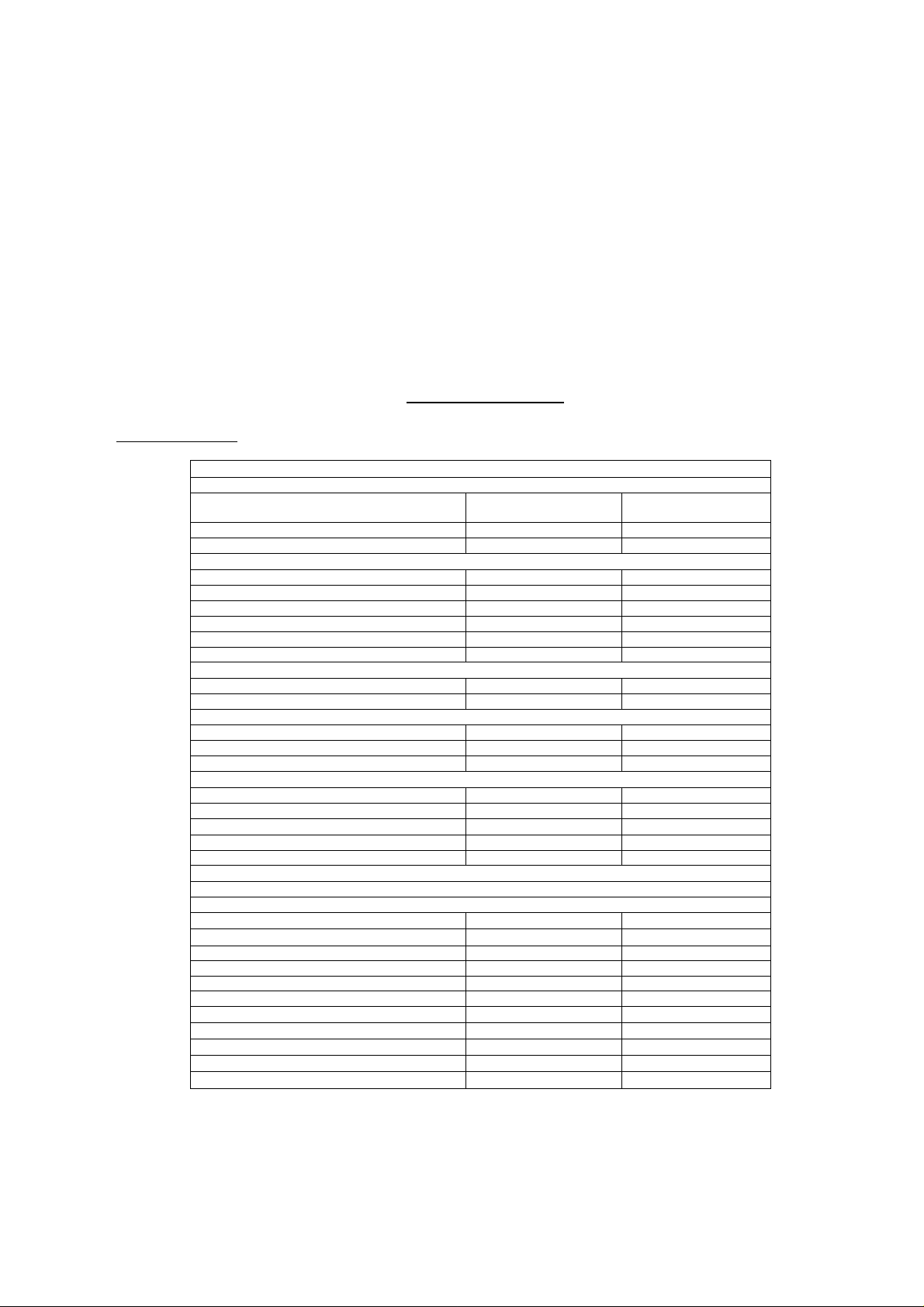

Models TÂRR64ÔÔ | ART6510

Power Source

Electrical rating

Amperage 50 Amp max.

Frequency 60 Hz 60 Hz

Element Wattage 9 240/208 V

6 inch ribtmn radiant

7 inch ribtxm radiant

8 inch ribbon radiant

9 inch ribbon radiant

Two 6 inch coils

Two 8 inch coiis

Oven Wattage 9 240/208 V

Bake 2,500r

Broil 3.000/* 3,000

Oven Interior Dimensions in. (cm)

Height 16(41)

Width

Depth

Product Exterior Dimensions in. (cm)

Height overatl 47(119)

Width

Depth oven door closed with handle

Clearance oven door ' 22(56)

Height of cooktop 36(91)

Weight lbs. (kg)

Approximatelv shipping weight I 171(78) I 171(78)

Cooktop Surface - Upswept

Recessed porcelain .

Lift-up cooktop with support rods

Interior oven light X

Large window frameless glass door

Removable fullwidth storage drawer X

Two oven racks 5 - positions

Porcelain burner bowls X

Porcelain coated backguard X

Glass backguard

Spillsaver™ cooktop

Touchmatic ERC

A WARNING

240/208 V

13.8 kW/10.4 kW

1.500r

2,600r

23(58)

17 1/2 (45) 17 1/2 (45)

30(76) 30(76)

28 1/4 (72) 28 1/4 (72)

X

X

X

X

—

—

X

____________

240V

12.9 kW

50 Amp max.

1.200

1,500

2,000

2,500

2,500

16(41)

23 (58)

47(119) L

22(56)

36(91)

:

-

-

-

X

X

X

X

—

—

X

X

X

_

April 1999

* - Rating of 208 VAC is approximately 80% of 240 VAC value.

RT2320003 Rev. 9

Page 2

Component Testing Procedures

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to oven before servicing, unless

testing requires it.

________________

______________________________

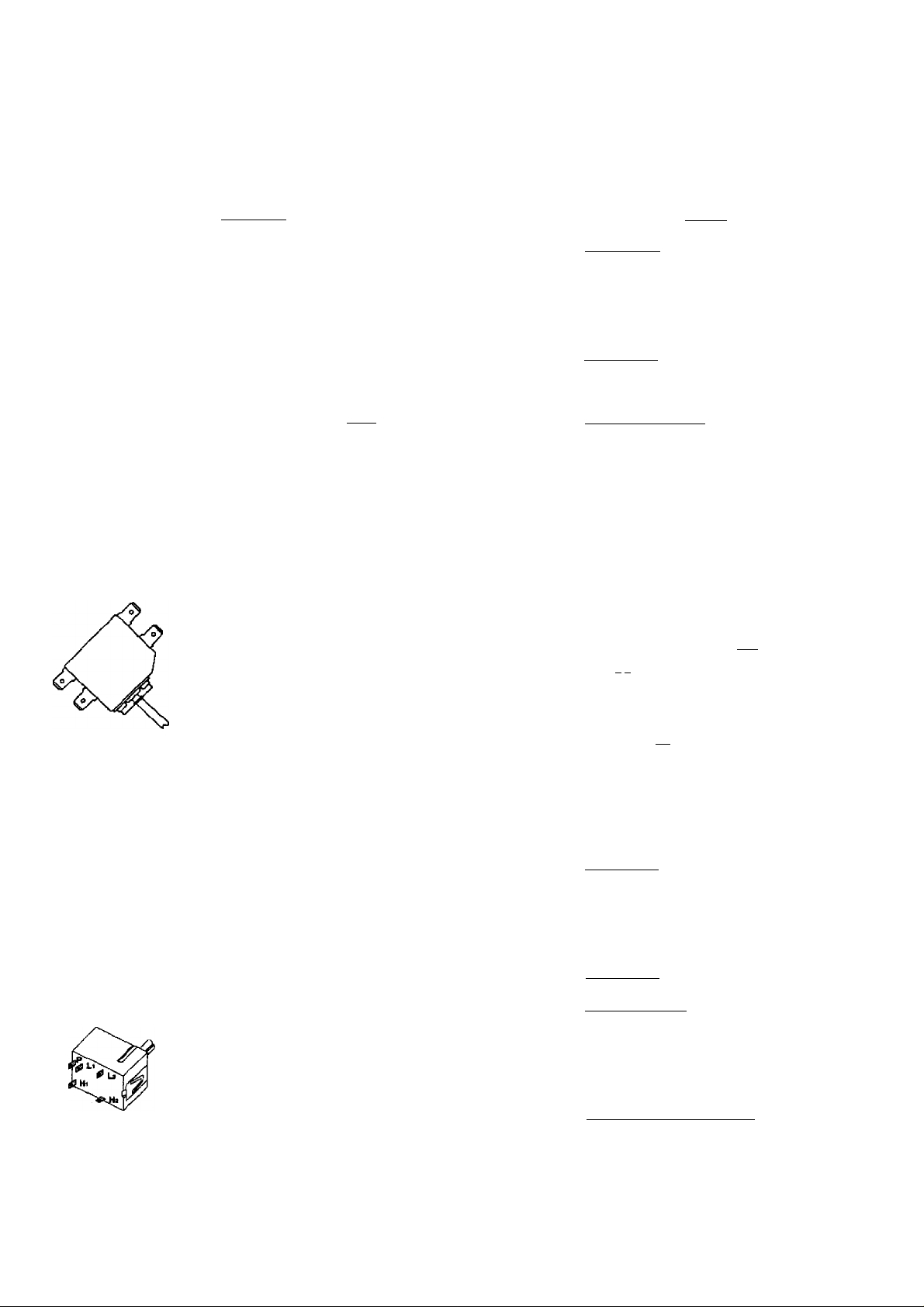

Illustration Component Test Procedure

31823701

31722801

301491

31734602—1500 W

31734606-^600 W

31730101 Coil surface terminal

31794701-1200 W

31794601-1500 W

31794501-2000 W

31794801-2500 W

31846201

059552

Oven light socket

Oven indicator light

and

Surface indicator light

Rocker switch

Coil surface elements

6" and 8"

block

Ribbon radiant

elements

Ribbon surface

thermal limiter/hot

light switch

Bake element

Test continuity of receptacle

terminals.

Remove one lead from switch

terminal and measure resistance

across terminals.

Measure voltage at indicator light.

Measure continuity of switch

positions;

Closed

Open

Test continuity of terminals. Continuity, if not replace.

Remove element and turn surface

element on and test for voltage at

terminal block.

Remove one wire lead from element

and measure resistance of the

element.

Turn surface element on and test for

voltage. See wiring diagram and

schematic.

1a-2a 240 VAC

1b-2b 120 VAC

Disconnect leads and measure

resistance on the foNoviring:

1a-2a room temperature-continuity

1b-2b room temperature-infinite

Disconnect wire ieads to element and

measure resistance of terminals.

_______________

Indicates continuity with bulb screwed in.

If not replace.

Switch closed; 0 il

Switch open; Infinite resistance

If voltage is present and light does not

operate. Replace light.

If no voltage is present at indicator light

check wiring.

Ccmtinuity, if not replace.

Infinite, if not replace.

240 VAC

Continuity, if not replace.

1200W: 45 to 51 n

1500W: 36 to 41 Cl

Results

______________

_________________________

_________________________

2000W: 27 to 31 Q

2500W: 21 to 25 n

240 VAC

EtotirovM

q.n

TTl

uwbA

V‘

■u a

Continuity, approximately 23 Q,

if not replace.

Th«mwO>Oisc (TOO)

n n

Might

to la

r Î

trxr

061732

314907

31891202

RT2320003 Rev. 9

Broil element

Oven temperature

sensor

Infinite switch

Measure voltage at bake element.

Disconnect wire leads to element and

measure resistance of terminals.

Measure voltage at broil element.

Measure resistance.

Remove wiring from terminals HI and

H2. Connect Volt ohms meter to

HI and H2.

Measure the following for voltages at

LO, MED, HI;

HI to H2

240 VAC, see wiring diagram for terminal

identification.

If no voltage is present at bake element

check wiring.

Continuity, approximately 19 il,

if not replace.

240 VAC, see wiring diagram for terminal

identification.

If no voltage is present at broil element

check wiring.

Approximately 1100 o at room

temperature 75° F.

LO 5%

MED (4-5) 50%

HI 100%

240 VAC, if not replace switch.

__________________________

____________

Time On

Time Off

95%

50%

0%

April 1999

Page 3

Component Testing Information

A WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to oven before servicing, unless testing requires it.

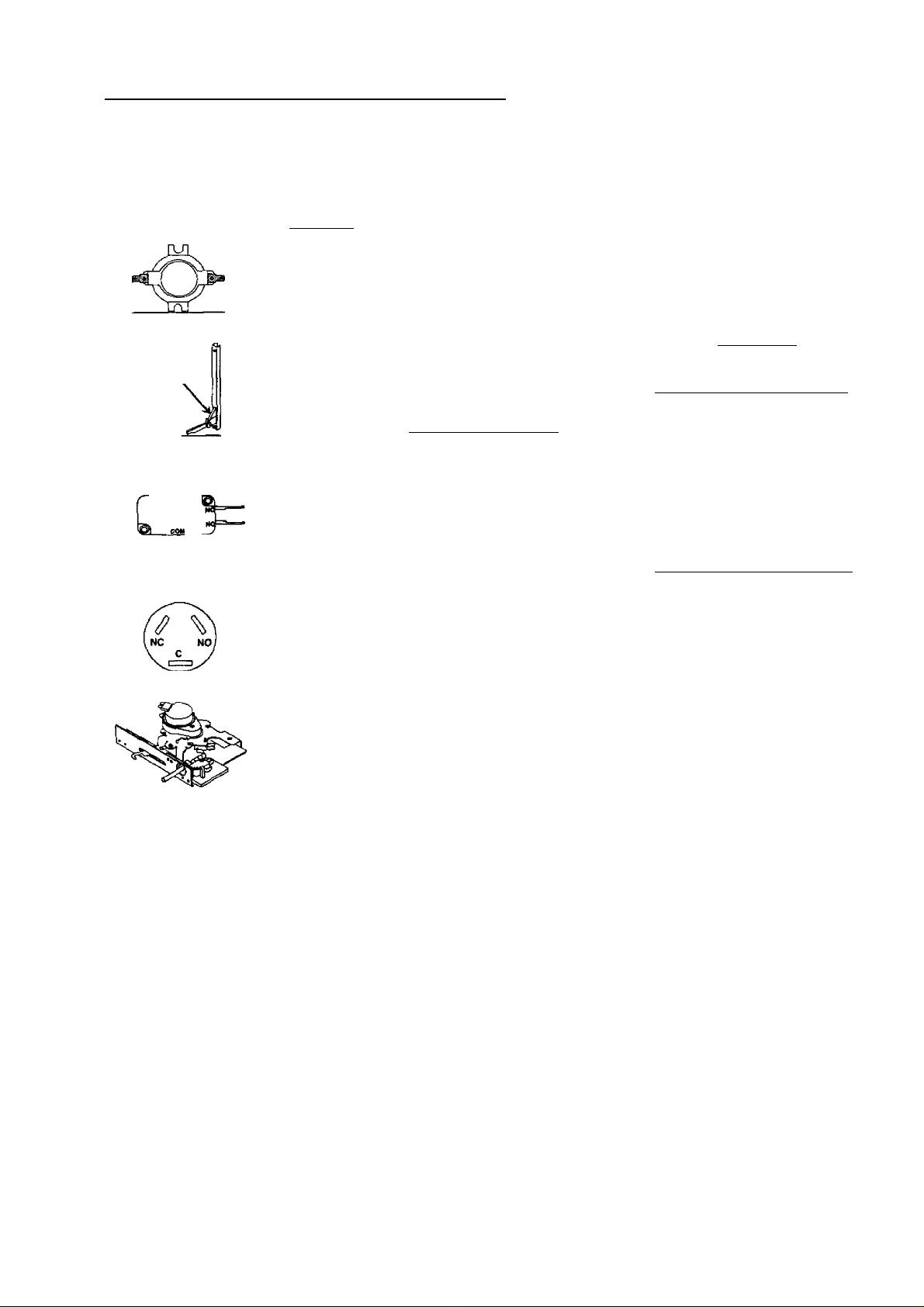

Illustratiort

053584

31715201— LH

31715202— RH

Opening

065780

305797

Component

Control limit

Hinge Carefully open the hinge fully, and

Door lock switch

Door plunger switch Remove switch from unit and measure

Normally Closed

Verify proper operation.

Closed 245°F

Open 275“F

insert a wooden dowel or screwdriver

bit into opening.

Remove top and bottom screws

securing hinge.

Slide hinge top towards rear of unit

and guide hinge out through frame

opening or storage drawer.

Switch connection in following

positions:

Unlocked

Locked

Set ERC to Clean

the following points:

C-NC

C NO

Test Procedure Results

Continuity

Infinite

If open at room temperature, replace.

A CAUTION

Do not place hands in hinge area when

oven door is removed. Hinge can snap

closed and pinch hands or fingers.

COM-NO=Open, COM-NC=Closed

COM-NO=Closed, COM-NC=Open

Lock LED should flash

Lock LED and Oven LEO should

illuminate, If Lock LED does not

illuminate, check switch and wiring.

Plunger in infinite. Plunger out continuity.

Plunger in continuity, Plunger out infinite.

31797301

Autolatch assembly

with door plunger

switch

Disconnect wires and test for

continuity per diagram.

NC NC

LI L2 COMI PM com! no

X ■ I' Jr >L i

120 VAC LedVUntocfc

Motor

Door

Switch

April 1999

RT2320003 Rev. 9

Page 4

Component Testing Procedures

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to oven before servicing, unless

testing requires it.

____________

_______________________

____________________________________________

Illustration

Blr30D.-jH

ээшшвввв

ERC3 Controlled Oven temperature

ERC3 Controlled

ERC3 Controlled

ERC3 Controlled

Component

ERC3 - Touchmatic

electronic range

control

adjustment

Twelve hour off Control will automatically cancel any

Child lock out Control input features will be disabled

Drive requirements

Based on a 60

second cycle.

Test Procedure

FI—Shorted pad button.

F2—Oven cavity over temperature.

F3—Open circuit in oven temperature

sensor circuit.

F4—Shorted circuit in oven

temperature circuit.

F^-Defective watchdog circuit in

control.

F7—Failure of door lock switch sensing

with door locked.

F9—Failure of door lock switching

sensing with door unlocked.

DOOR—Lock status is not sensed

within 20 seconds of energizing door

lock relay.

Push BAKE pad.

Push SLEW pad until an oven

temperature greater than 500“F

displays.

Immediately push and hold BAKE pad

until "00” displays, approximately 5

seconds.

To decrease oven temperature (for a

cooler oven). Push SLEW pad until

negative numbers appear. Oven can be

adjusted from -05" to -35° lower. To

avoid over adjusting oven move

temperature -5° each time.

To increase oven temperature (for a

warmer oven), Push SLEW pad until

positive numbers appear. Oven can be

adjusted from 5* to 35° higher. To avoid

over adjusting oven move temperature

5° each time.

Push OVEN CANCEL button.

Temperature adjustment will be

retained even through a power failure.

cooking operation and remove all relay

drives 12 hours after the last pad touch.

and display will indicate “OFP, when

BAKE and CLOCK are pushed

simultaneously and held for 5 seconds.

Control wiItVetum to normal operation

by repeating the procedure.

Bake

Broil

Clean

Stage 1

Stage 2

Lock light

____________

Results

Verify actuator operation.

Check sensor wiring, sensor, and

temperature limiter.

Check sensor resistance and wiring.

Check sensor resistance and wiring.

Replace ERC3.

Check latch switch and door motor.

Check latch switch and door motor.

Verify operation of door latch switches.

While increasing or decreasing oven

temperature, this does not affect self

cleaning temperature.

100% bake

0% bake 100% broil

0% bake

0% bake

0% bake

0% bake

0% bake

Time controlled 15 minutes 0% bake

100% broil.

Time controlled 100% bake 10% broil.

On at the start of the clean cycle.

Off at approximately 400°F ± 25°F.

10% broil

93% broil 5

87% broil 4

80% broil

73% broil 2

67% broil 1

HI

3

RT2320003 Rev. 9

April 1999

Page 5

Wiring Diagram and Schematic

A WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to oven before servicing, unless testing requires it.

A

April 1999

COLOR

color

RED

orange OR

YELLOW

GREEN

BLUE

VIOLET

BLACK BK

8R0* N

GRAY

HUE

NO TES :

.AU INT[*NAl » lfi[S AB£ laCA. liO 'C XL UIILESS 01HESKISE «0U D

? All RE PLACE Wm » IBES UUSl HAVE SAKE BATING AS

ORIGINAMI) IRES. •

J. SEE SERIAL PLATE FOR INPUT VOLTAGE/* ATIAOE rating.

4. DiNOFES optional EOUIPNEHT AND RELATE 0 * IRINC N01

supplied on sone uooees.

b.ELENENT WATlAGESVASr Bi MODEL. BEPLACENENl ELENEH15

RUST HAVE SAMI iATTACE AS ORIGINAL ELEMENTS,

6. FOR RANGE INST AELAT ION, USE COPPER * IRE ONLY.

i.CROUNDSIRAPNOTUSED for four* IRE INSTALLATIONS.

\kl ADMlKir -ELECIRICAl SHOCK HAZARD

W A KIN IN b -disconnect POWER Al MAIN

FUSE OR CIRCUIT BREAKER BEFORE SERVICING

FAILURE TO DO SO COULD RESULT IN SERIOUS

INJURY OR DEATH.

lOULEUa

SYMBOL

RD ROUGE

ORANGE

YL JAUNE

GN

BU DIEU

VT

MARRON

OR

CY GRIS

H H BLANC

VERT

VIOLET

HOIR

DI AGR AM

DANGER -DEBRANCHER L’ALIMENTATION ELECTRIQUE.

LE MANQUE DE RESPECT DE CETTE CONSIGNE POUR RA IT

AVOIR COMME RESULTAT UNE BLESSURE GRAVE OU MORTELLE.

ARR6400

-RISQUE DE CHOC ELECTRIQUE

AVANT D'ENTRETENIR CETTE UNITE.

RT2320003 Rev. 9

Page 6

Wiring Diagram and Schematic

A WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to oven before servicing, unless

testing requires it. ____________________________________________________

RT2320003 Rev. 9

ARR6400

6

April 1999

Page 7

Wiring Diagram and Schematic

A WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to oven before servicing, unless testing requires it.

April 1999

COLOR

COLOR

RED

ORANGE OR

YELLOW

GREEN

blue

VIOLET

BLACK

BROWN BR

GRAY

[white

NO TEWHS :

ALL INTERNAL WIRES ARE 1BGA . I50tC XL UNLESS

OTHERWISE NOTED. SF2 IS SEW-2/SF3 200tC .

ALL REPLACEMENT WIRES UUST HAVE SAME RATING AS

original wires -

SEE SERIAL PLATE FOR INPUT VOLTACE/WATTAGE RATING

*OR (-------------)DENOTES OPTIONAL EOlflPMENT A

SUPPLIED ON SOME MODELS.

ELEMENT WATTAGES VARY BY MODEL. REPLACEMENT ELEMENTS

MUST HAVE SAME WATTAGE AS ORIGINAL ELEMENTS.

FOR RANGE INSTALLATION. USE COPPER WIRE ONLY.

CftOUNO STRAP NOT USED FOR FOUR WIRE INSTALLATIONS

WARN ING

A

COULEUR

SYMBOL

RD ROUGE

ORANGE

YL JAUNE

VERT

GN

BLEU

BU

VIOLET

VT

BK NOIR

MARRON

GRIS

GY

[ BLANC P

ANO RELATED WIRING NOT BLOCK

- electrical shock hazard

FUSE OR Ciftcun breaker BEFORE SERVICING.

failure to 00 SO COULO RESULT IN SERIOUS

INJURY OR DEATH.

- DISCONNECT POWER AT MAIN

MAIN ^

TERMINAL

* POWER CORÇ

DIAGRAM

„ ^ - RISQUE DE CHOC ELECTRIQUE

DANGFR- DEBRANCHER L'ALIMENTATION ELECTRIQUE

LE MANQUE DE RESPECT DE CETTE CONSIGNE POURRAIT

AVOIR COMME RESULTAT UNE BLESSURE GRAVE OU MORTELLE.

ART6510

AVANT D'ENTRETENIR CETTE UNITE.

CHASSIS

GND

RT2320003 Rev. 9

Page 8

Wiring Diagram and Schematic

;

__________________

To avoid risk of electrical shock, personal injury, or death, disconnect power to oven before servicing, unless

testing requires it.

A WARNING

___________________

RT2320003 Rev, 9

ART6510

8

April 1999

Loading...

Loading...