Amana P1142670N, P1143674N, P1143482N, P1143469N, ARR6400 User Manual

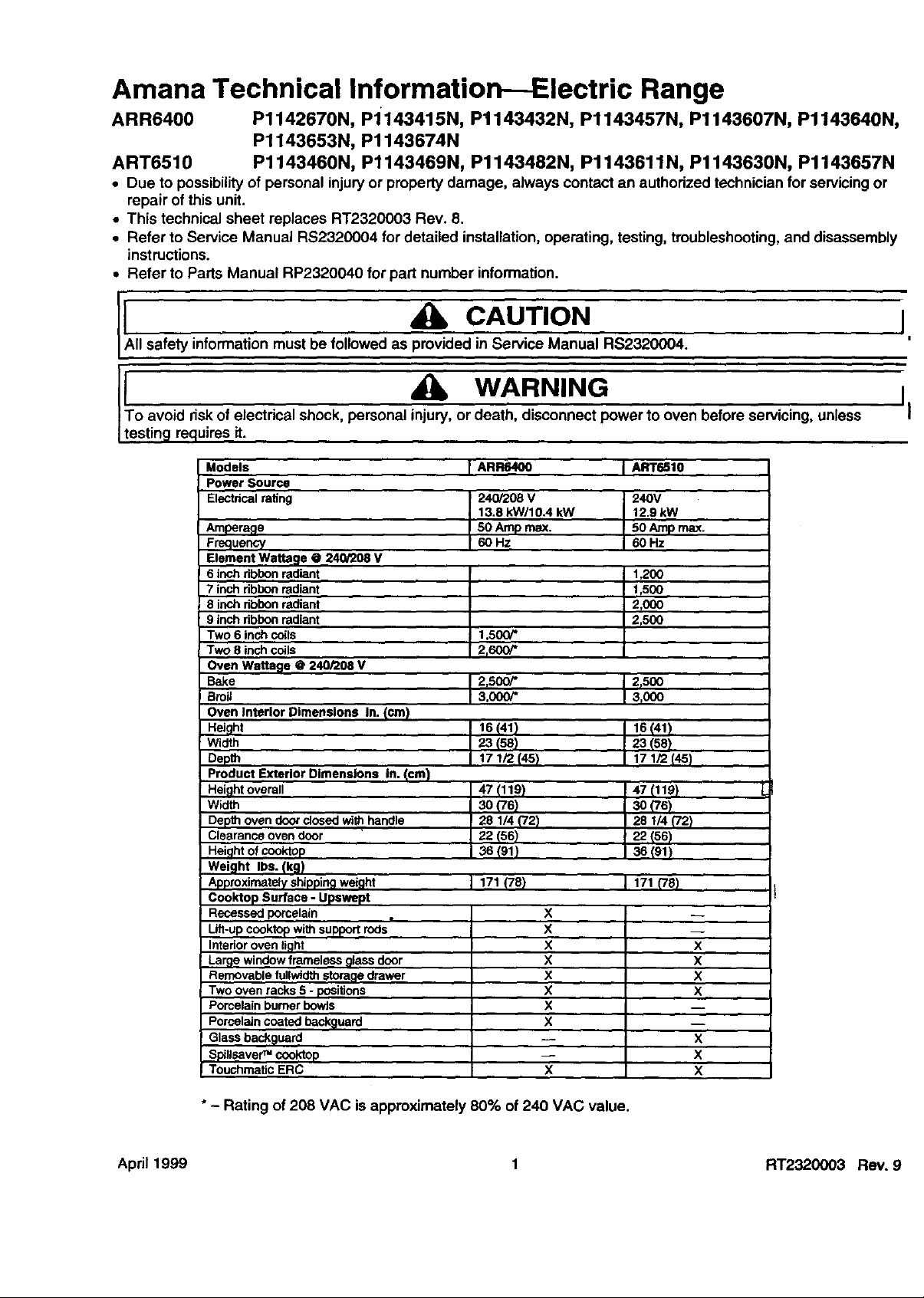

Amana Technical Information Electric Range

ARR6400 P1142670N, Pi143415N, P1143432N, P1143457N, P1143607N, P1143640N,

P1143653N, P1143674N

ART6510 P1143460N, P1143469N, P1143482N, P1143611N, P1143630N, P1143657N

• Due to possibilityof personal injuryor property damage, always contact an authorized technician for servicing or

repair of this unit.

• This technical sheet replaces RT2320003 Rev. 8.

• Refer to Service Manual RS2320004 for detailed installation, operating, testing, troubleshooting, and disassembly

instructions.

• Refer to Parts Manual RP2320040 for part number information.

CAUTION

MI safety information must be followed as provided in Service Manual RS2320004.

[ WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to oven before servicing, unless

testing requires it.

Models I ARR6400 I ART6510

I Power Source

Electrical rating 240/208 V 240V

Amperage

Frequency

Element Wattage @ 240/208 v

6 inch ribbon radiant

7 inch ribbon radiant

8 inch ribbon radiant

9 inch ribbon radiant

Two 6 inch coils

Two 8 inch coils

Oven Wattage @ 240/208 V

Bake

Broil

Oven Interior ,Dimensions In. (cm)

Height

Width

Depth

Product Exterior Dimensions In. (cm)

Height overall

Width

Depth oven door dosed with handle "

Clearance oven door

Height of cooktop

Weight Ibs. (kg)

Approximately shipping wel'ght

Cook'top Surface - Upswept

Recessed porcelain

Lilt-up cooktop with support rods

Interior oven light

La_e window frameless glass door

Removable fullwidth storage drawer

Two oven racks 5 - positions

Porcelain burner bowie

Porcelain coated baek_luard

Glass back_luard

S_llsaver TM cooktop

Touchmatic ERC

13.8 kW/10.4 kW 12,9 kW

50 Amp max. 50 Amp max.

60Hz 60Hz

1,200

t r500

2_000

2,500

1,500/*

2,600/*

2t500/* 2r500

3000/* 3r000

16 (41} 16 (41)

2"3(58) 23 (58)

t7 1/2 (45) 17 1/2 (45)

47(119) 47(110)

s0_76) 30(76)

20 1/4{72) 28 1/4('/2)

22(56) 22(56)

36(91) 36(91)

171 (78) 171 _78)

X

X

x

X

x

X

X

X

X

X

X

X

X

X"

X

X

I

!

II

"- Rating of 208 VAC is approximately 80% of 240 VAC value.

April 1999 1 RT2320003 Rev. 9

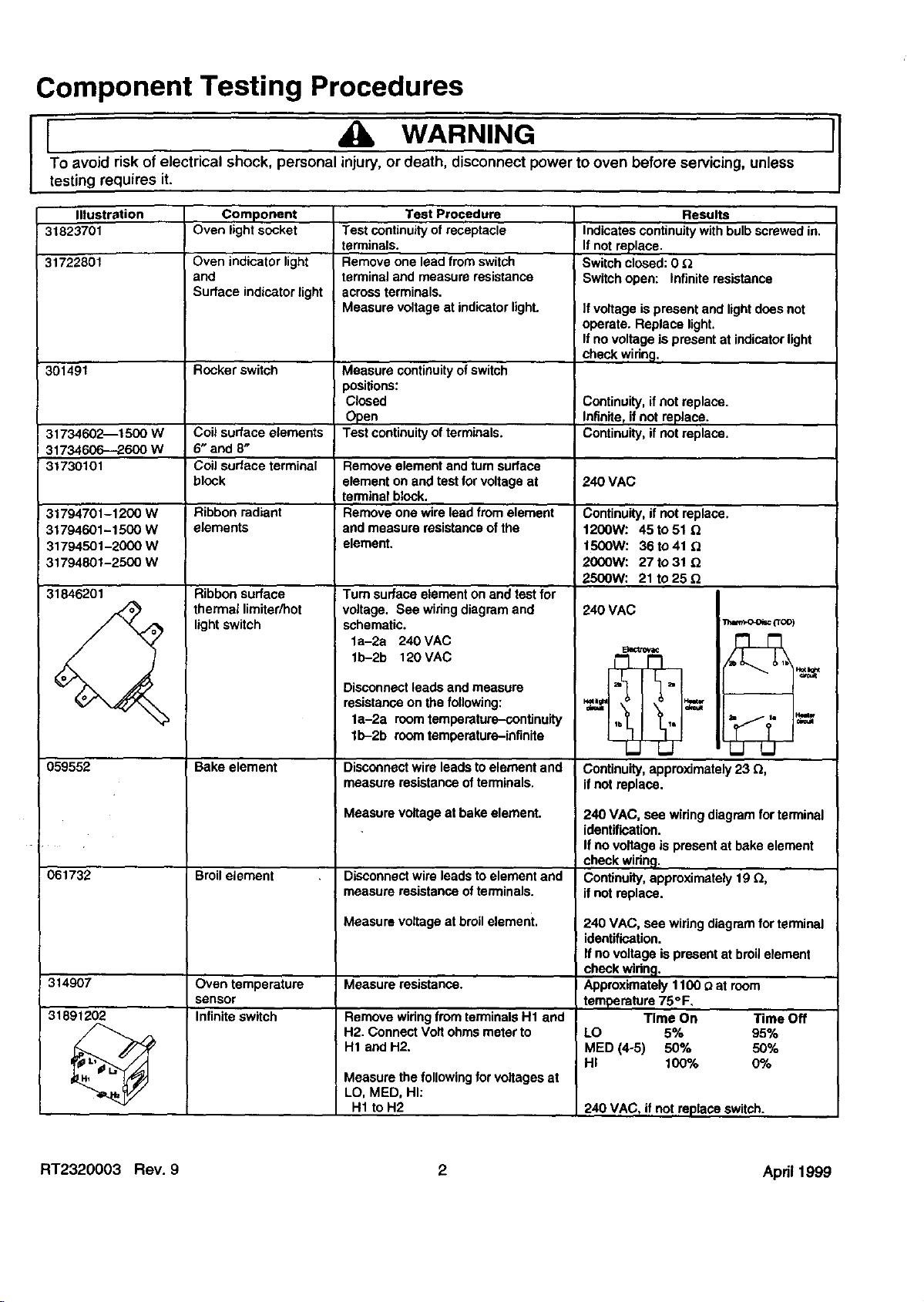

Component Testing Procedures

To avoid risk of electrical shock, personal injury, or death, disconnect power to oven before servicing, unless

f WARNING

testing requires it.

'1

nlustration

31823701

31722801

301491

31734606--2600 W 6" and 8"

31730101 Coilsurface terminal Remove element and turn surface

31794701-1200 W Ribbon radiant Remove one wire lead from element Continuity,if not replace.

31794601-1500 W elements and measure resistanceof the 1200W: 45 to 51

31794501-2000 W element, t50OW: 36 to 41

31794801-2500 W 200OW: 27 to 31

31846201

Component

Oven light socket

Oven indicator light

and

Surface indicator light

Rocker switch

block element on and test for voltage at 240 VAC

Ribbon surface

thermal limiter/hot

lightswitch

Test continuityof receptacle

terminals.

Remove one lead from switch

terminal and measure resistance

acrossterminals.

Measure voltage at indicatorlight.

Measure continuityofswitch

positions:

Closed

Open

Test continuityofterminals.

terminal block.

Tum surface element on and test for

voltage. See wiring diagram and

schematic.

la-2a 240 VAC

lb-2b 120 VAC

Test Procedure

Results

Indicates continuitywith bulbscrewed in.

If not replace.

Switchclosed: 0

Switchopen: Infinite resistance

]f voltage is present and lightdoes not

operate. Replace light.

If no voltage is present at indicatorlight

checkwidng.

Continuity, if not replace.

Intinife,if notreplace.

Continuity, if notreplace.31734602--1500 W Coil surface elements

2500W: 21 to 25

240 VAC

Etectmv_

059552

061732

314907

31891202

I Bake element

Broil element

Oven temperature

sensor

Infinite switch

Disconnect leads and measure

resistanceon the following:

la-2a roomtemperature-continuity

lb-2b room temperature-infinite

Disconnectwire leads to element and

measure resistance of terminals.

Measure voltage at bake element.

Disconnectwire leads to element and

measure resistance of terminals.

Measure voltage at broilelement.

Measure resistance.

Remove wiring fromterminalsH1 and

H2. Connect Volt ohms meter to

H1 and H2.

Measure the followingfor voltages at

LO, MED, HI:

H1 to H2

Continuity,approximately 23 Q,

ifnot replace.

240 VAC, see wiring diagram forterminal

identification.

Ifno voltage is presentat bake element

check widng.

Continuity, approximately 19 £_,

if not replace.

240 VAC, see wiringdiagram for terminal

identification.

If novoltage is present at broilelement

checkwidng.

Approximately1100 _ at room

temperature 75°F.

Time On Time Off

LO 5% 95%

MED (4-5) 50% 50%

HI 100% 0%

240 VAC, if notreplace switch.

RT2320003 Rev. 9 2 Apd11999

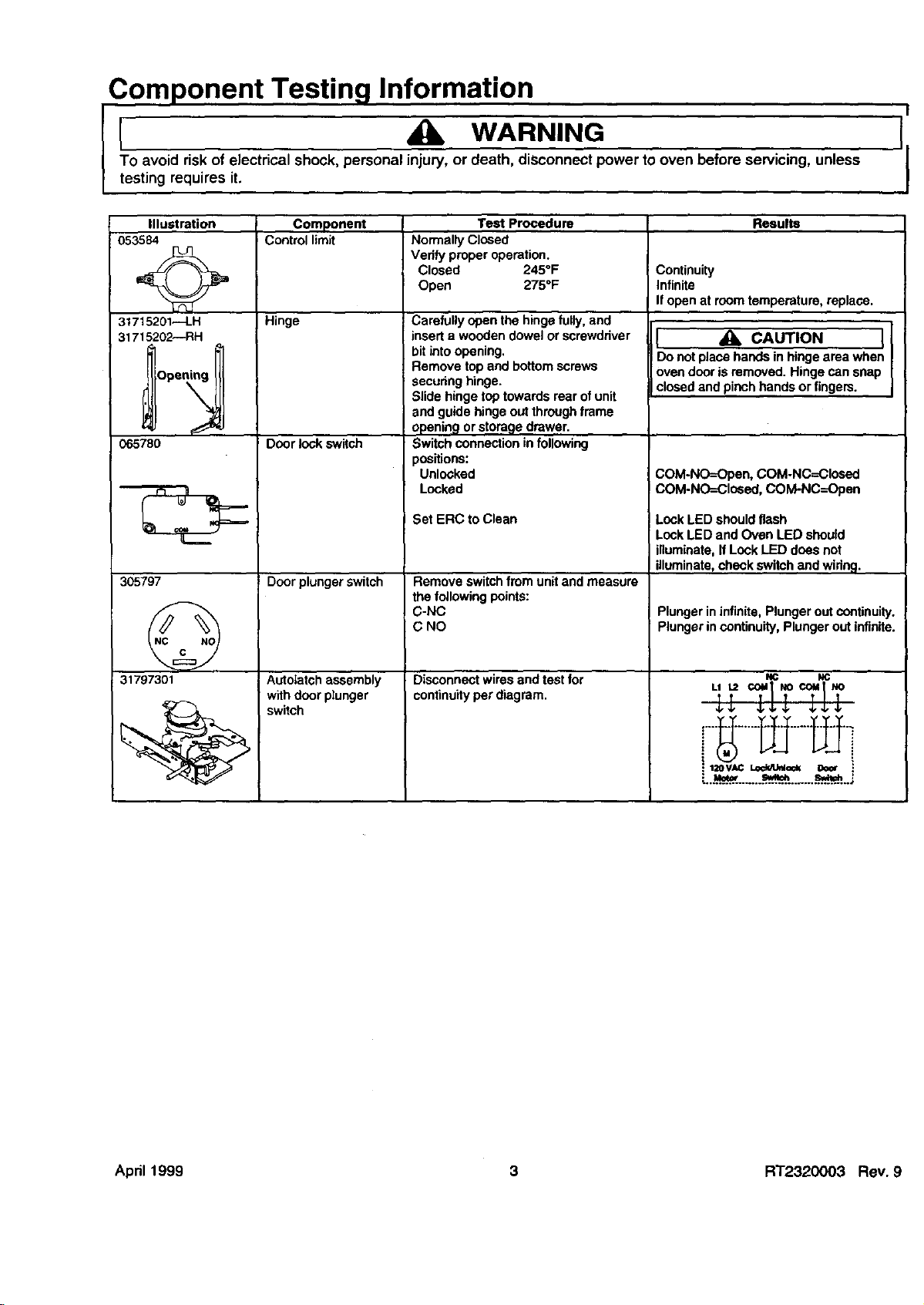

Component Testing Information

To avoid risk of electrical shock, personal injury, or death, diSconnect power to oven before servicing, unless

I I WARNING

testing requires iL

I

Illustration

053584

31715201--LH

31715202--RH

065780

305797

Component Test Procedure Results

Control limit Normally Closed

Verify proper operation.

Closed 245°F Continuity

Open 275°F Infinite

If open at roomtemperature, replace.

Hinge

Door lock switch

Door plungerswitch

Carefully open the hinge fully, and

insert a wooden dowelor screwdriver

bitinto opening.

Remove top and bottom screws

: securing hinge.

Slide hinge top towards rear of unit

and guide hinge out throughframe

opening or storage drawer.

Switch connectionin following

positions:

Unlooked

Looked

;et ERC to Clean

Remove switchfrom unit and measure

the following points:

C-NC

C NO

I 4_ CAUTION II

Do notplace hands in hinge area when

Ovendooris removed. Hinge can snap

closed and pinch hands or fingers.

COM-NO=Open, COM-NC=Closed

COM-NO=Clceed, COM-NC--Open

Lock LED should flash

LookLED and Oven LED should

illuminate,If LockLED does not

illuminate,check switch and widng.

Plunger ininfinite, Plunger out continuity.

Plunger incontinuity, Plunger out infinite.

I

31797301

Autotatch assembly

withdoor plunger

switch

Disconnect wires and test for

continuityperdiagram

NC NC

__, ,_

,:....a_H.__.....___.o_ _.. ;

April 1999 3 RT2320003 Rev 9

Loading...

Loading...