Page 1

Compact Washer

Laveuse compactes

Use and Care Guide

Para una versión de estas instrucciones en español, visite www.amana.com

Table of Contents

WASHER SAFETY ...................................................................... 2

INSTALLATION REQUIREMENTS ............................................. 3

PERMANENT INSTALLATION INSTRUCTIONS ....................... 6

PORTABLE INSTALLATION INSTRUCTIONS......................... 10

CONTROL PANEL AND FEATURES ....................................... 13

USING YOUR WASHER ........................................................... 15

WASHER MAINTENANCE ....................................................... 18

TROUBLESHOOTING .............................................................. 20

WARRANTY .............................................................................. 25

ASSISTANCE OR SERVICE ..................................BACK COVER

Guide d’utilisation

et d’entretien

Table des matières

SÉCURITÉ DE LA LAVEUSE ................................................... 26

EXIGENCES D’INSTALLATION ............................................... 27

INSTRUCTIONS D’INSTALLATION PERMANENTE ............... 31

INSTRUCTIONS POUR L’INSTALLATION PORTATIVE .......... 35

TABLEAU DE COMMANDE ET CARACTÉRISTIQUES .......... 39

UTILISATION DE LA LAVEUSE ............................................... 42

ENTRETIEN DE LA LAVEUSE ................................................. 45

DÉPANNAGE ............................................................................ 48

GARANTIE ................................................................................ 54

ASSISTANCE OU SERVICE ............... COUVERTURE ARRIÈRE

W10778944B

W10778945B - SP

Designed to use only HE High Efficiency detergents.

Conçue pour utiliser un détergent haute efficacité seulement.

Page 2

Washer Safety

2

Page 3

Installation Requirements

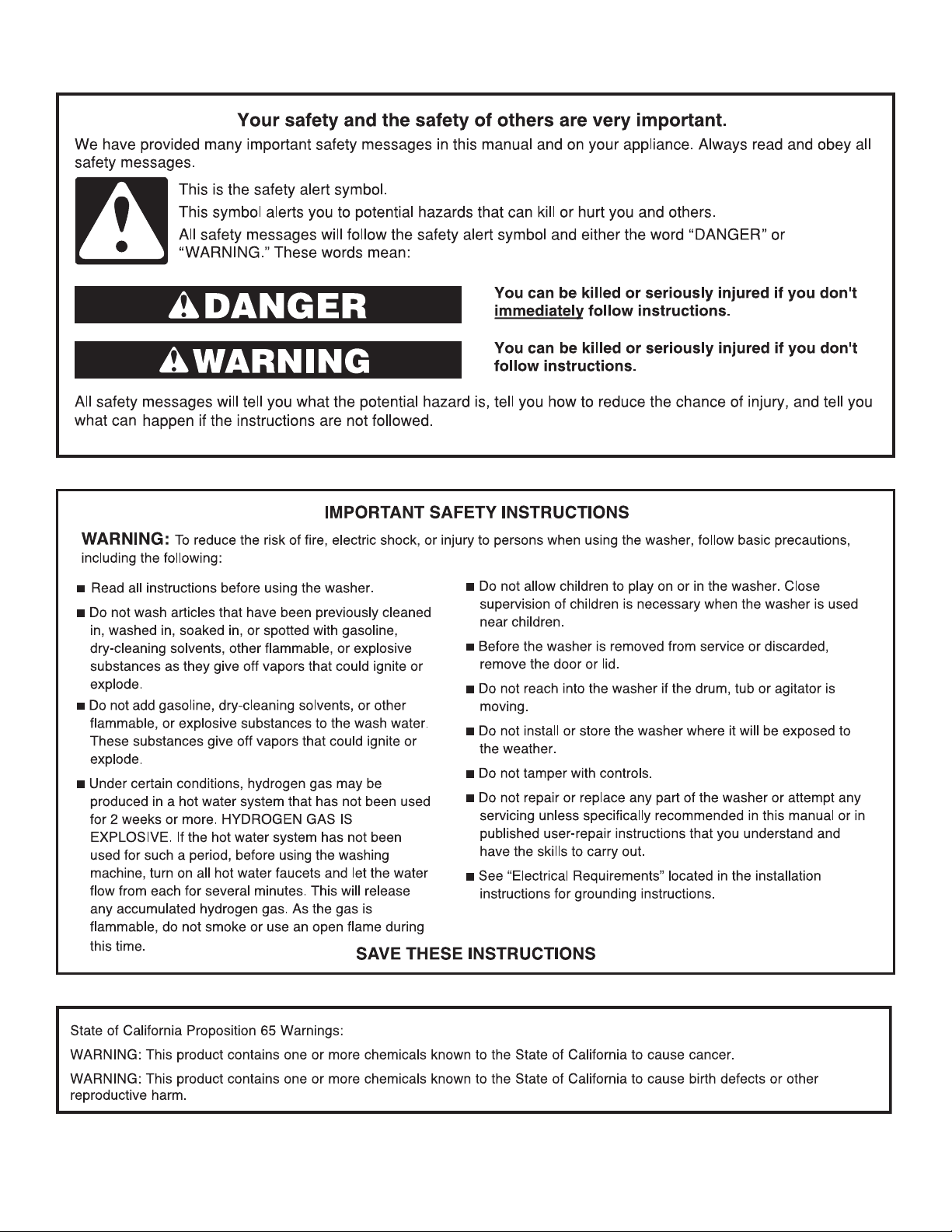

Tools and Parts

Gather the required tools and parts before starting installation.

The parts supplied are in the washer basket.

Portable Installation

Parts supplied:

Permanent Installation

Parts needed (not provided with washer):

NOTE: Replace inlet hoses

after 5 years of use to reduce

the risk of hose failure.

Record hose installation or

replacement dates for future

reference.

Inlet hoses with flat washers

Parts supplied:

Flat washers for faucet

adapter and fill hoses

Faucet adapter Fill-and-drain hose

Hose bracket

Tools needed for installation:

Silver, double-wire hose

clamp (for bottom of

drain hose)

Drain hose with clamp

Leveling feet (4)

Tools needed for installation

Pliers that open

9

to 1

⁄

" (3.95 cm)

16

Cable tie

Utility knife

Pliers that open

9

to 1

⁄

" (3.95 cm)

16

Flashlight (optional)

Utility knife

Flashlight (optional)

Measuring tape

Level

Adjustable or open-end

wrench

Phillips screwdriver

9

⁄

" (14 mm)

16

3

Page 4

Alternate Parts

Your installation may require additional parts. For information

on ordering, please refer to “Assistance or Service” on the

back cover of this manual.

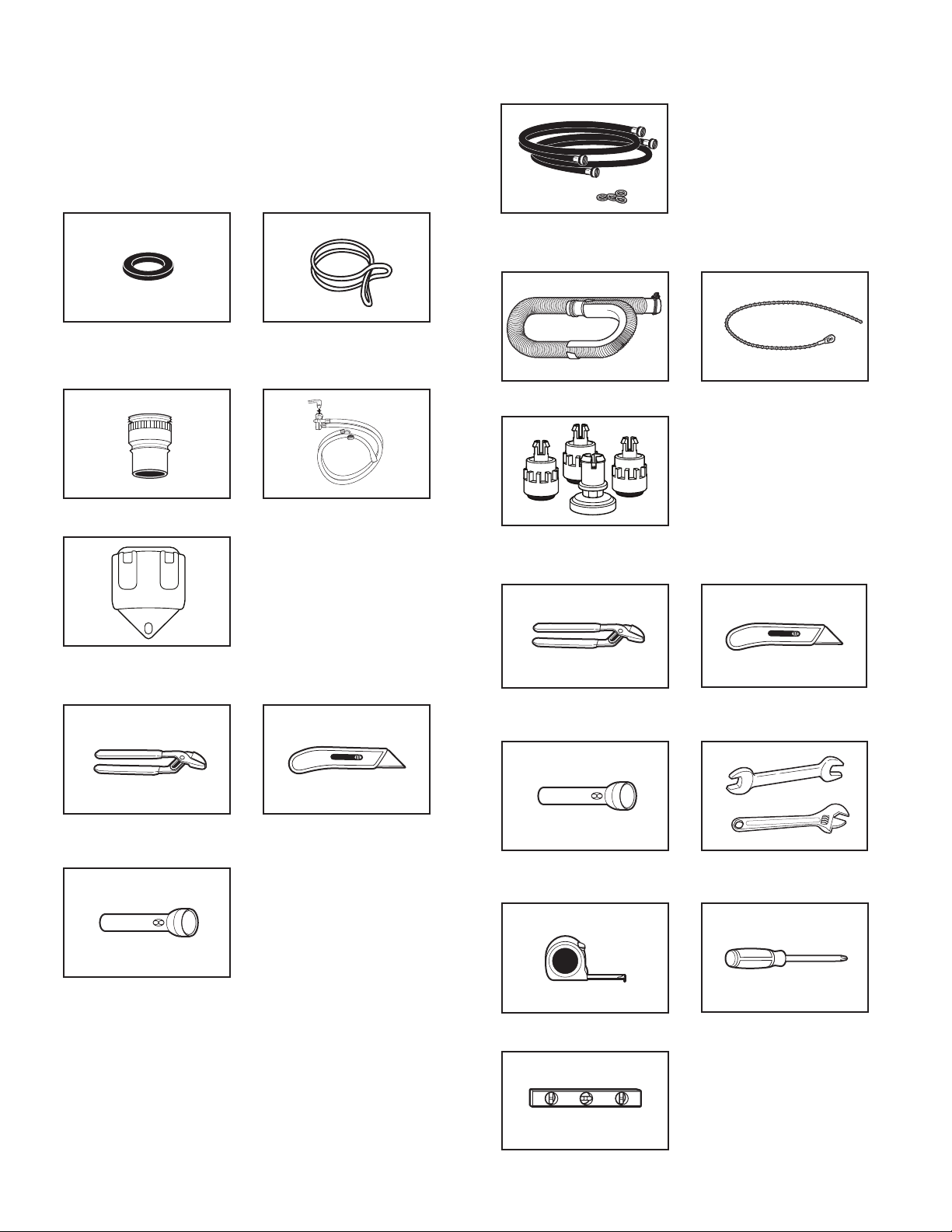

If You Have: You Will Need to Buy:

Laundry tub or standpipe

taller than 72" (183 cm)

1" (2.5 cm) diameter

standpipe

Sump pump system

(if not already available)

2" (5 cm) diameter to

1" (2.5 cm) diameter

standpipe adapter,

Part Number 3363920

Overhead sewer

Standard 20 gal (76 L)

39" (99 cm) tall drain tub or

utility sink, sump pump, and

connectors (available from

local plumbing suppliers)

Floor drain Siphon break, Part Number

285320; additional drain

hose, Part Number 3357090

and connector kit, Part

Number 285442

Water faucets beyond reach

of fill hoses

2 longer water fill hoses:

6 ft (1.8 m)

Part Number 76314

10 ft (3.0 m)

Part Number 350008

Drain hose too short

Drain hose, Part Number

388423 and hose kit,

Part Number 285442

Drain hose that is too long

Hose kit,

Part Number 285442

Lint clogged drain

Drain protector,

Part Number 367031

Location Requirements

Selecting the proper location for your washer improves

performance and minimizes noise and possible washer “walk.”

Your washer can be installed in a basement, laundry room,

closet, or recessed area. See “Drain System.”

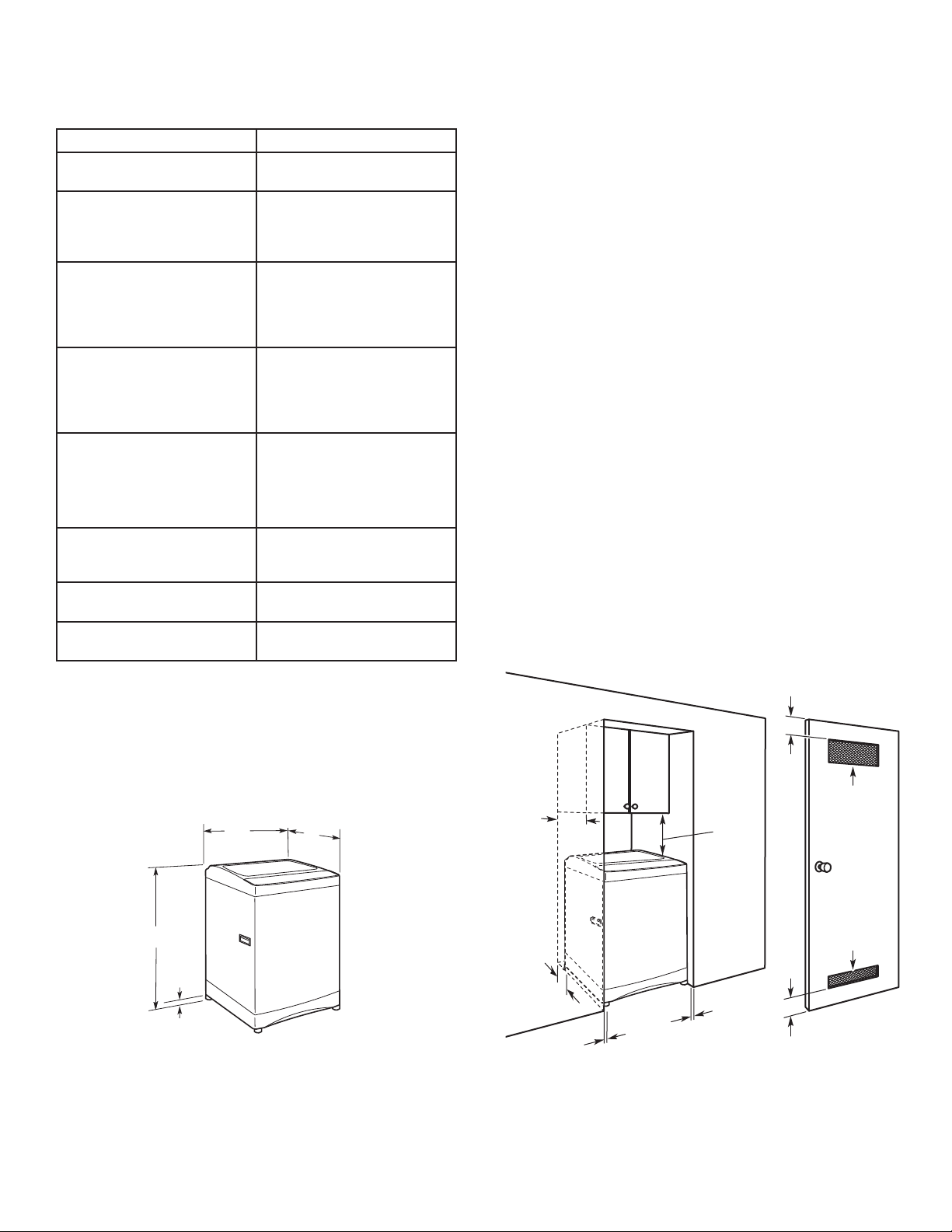

Washer Dimensions

21"

(533 mm)

23"

(584 mm)

You will need:

■ A water heater set to deliver 120°F (49°C) water to

the washer.

■ A grounded electrical outlet located within 5 ft (1.5 m) of

where the power cord is attached to the back of the washer.

See “Electrical Requirements.”

■ Hot and cold water faucets located within 3½ ft (1.1 m)

of the hot and cold water fill valves, and water pressure

of 5–100 psi (34.5–690 kPa).

■ A level floor with a maximum slope of ¾" (1.9 cm) under

entire washer. Installing the washer on carpeting is not

recommended.

■ A sturdy floor to support the washer weight (washer, water,

and load) of 225 lbs (102 kg).

Do not store or operate your washer in temperatures at or

below 32°F (0°C). Some water can remain in the washer and

can cause damage in low temperatures. See “Washer Care”

for winterizing information.

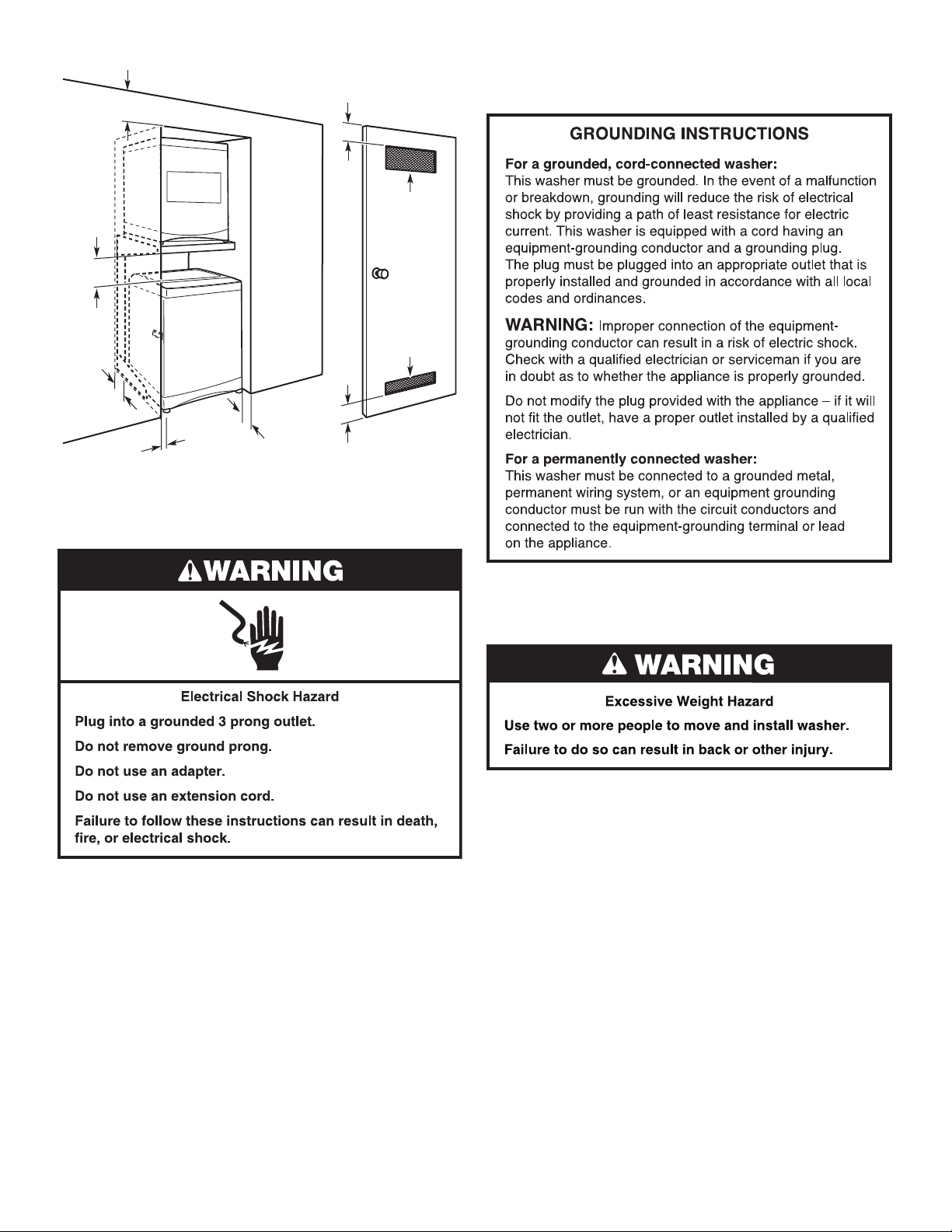

Recessed area or closet installation

The dimensions shown are for the recommended spacing

allowed, except the closet door ventilation openings. The

dimensions shown for the closet door ventilation openings

are the minimum required.

■ Additional spacing should be considered for ease of

installation and servicing.

■ Additional clearances may be required for wall, door, and

floor moldings.

■ Additional spacing of 1" (2.5 cm) on all sides of the washer

is recommended to reduce noise transfer.

■ If a closet door is installed, the minimum air openings in the

top and bottom of the door are required. Louvered doors

with air openings in the top and bottom are acceptable.

■ Companion appliance spacing should also be considered.

Washer Only

3"

(76 mm)

14" max.

(356 mm)

17"

(432 mm)

48 in.

(310 cm2)

2

37"

(940 mm)

3

/4"

(19 mm)*

*Minimum measurement with leveling feet installed.

IMPORTANT: Do not install or store the washer where it will

be exposed to the weather.

Proper installation is your responsibility.

4

4"

(102 mm)

1"

(25 mm)

Recessed area

1"

(25 mm)

2

24 in.

(155 cm2)

3"

(76 mm)

Closet door with vents

Page 5

Stacked

(305 mm)

12"

(305 mm)

3"

(76 mm)

■ Check with a qualified electrician if you are not sure if the

washer is properly grounded.

■ Do not have a fuse in the neutral or ground circuit.

DRYER

12"

WASHER

3"

(76 mm)

1"

(25 mm)

1"

(25 mm)

Recessed area

Electrical Requirements

2

48 in.

(310 cm2)

2

24 in.

(155 cm2)

3"

(76 mm)

Closet door with vents

Remove Shipping Material

Before you install your washer, remove all shipping material.

■ A 120-volt, 60 Hz, AC-only, 15- or 20-amp, fused electrical

supply is required. A time-delay fuse or circuit breaker is

recommended. It is recommended that a separate circuit

serving only this appliance be provided.

■ This washer is equipped with a power supply cord having

a 3 prong grounding plug.

■ To minimize possible shock hazard, the cord must be

plugged into a mating, 3 prong, grounding-type outlet,

grounded in accordance with local codes and ordinances.

If a mating outlet is not available, it is the personal

responsibility and obligation of the customer to have the

properly grounded outlet installed by a qualified electrician.

■ If codes permit and a separate ground wire is used, it is

recommended that a qualified electrician determine that

the ground path is adequate.

■ Do not ground to a gas pipe.

To avoid damaging floor, use a large flat piece of cardboard

from the washer carton. Place cardboard under entire back

of the washer.

Firmly grasp the body of the washer and gently lay it on the

corner posts.

Remove plastic foam packaging from underneath the washer.

Stand the washer up.

Remove tape from washer lid. Open washer lid and remove

foam shipping piece, parts bag, and hoses from washer basket.

Close the lid.

5

Page 6

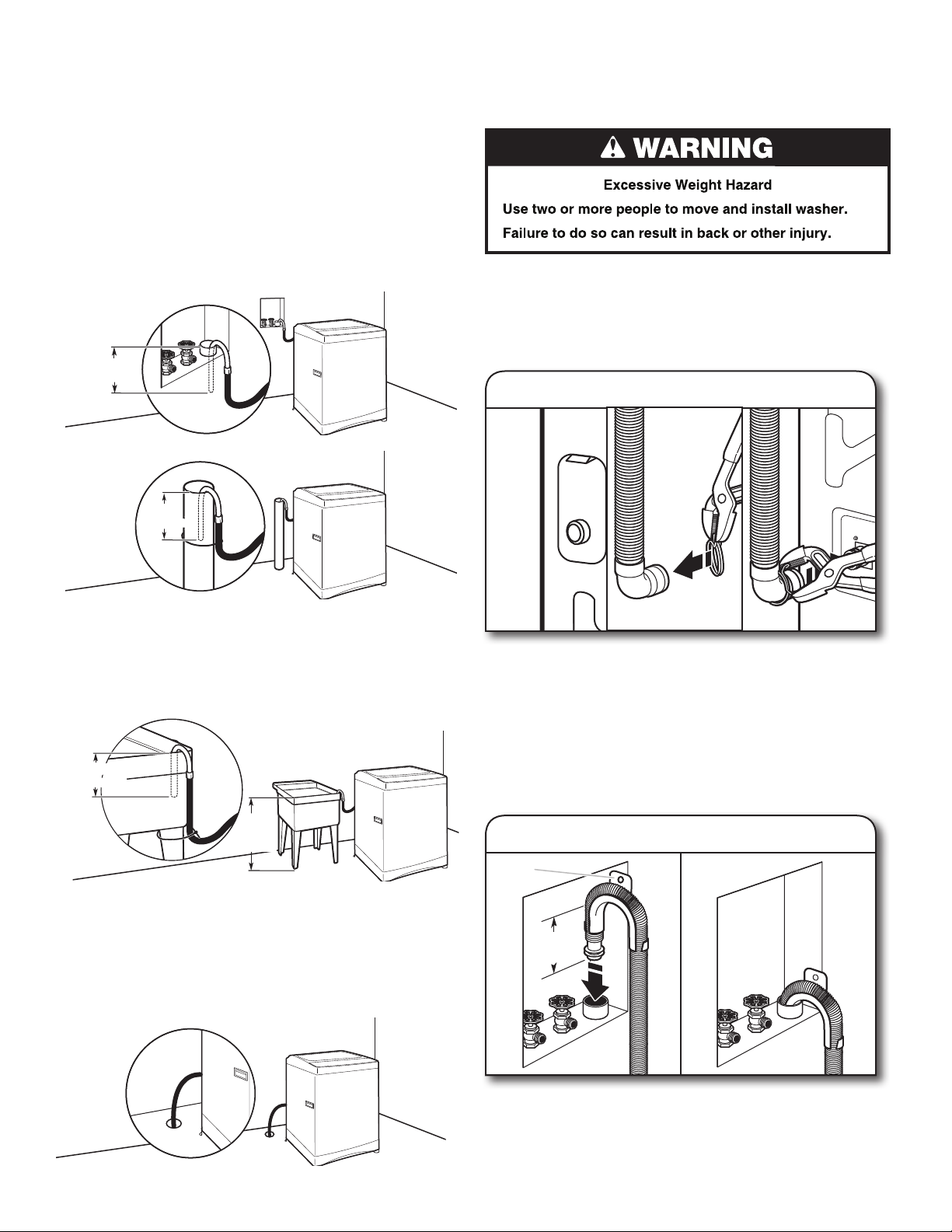

Drain System

(114 mm)

(114 mm)

The washer can be installed using the standpipe drain system

(floor or wall), the laundry tub drain system, or the floor drain

system. Select the drain hose installation method you need.

See “Tools and Parts.”

Standpipe drain system – wall or floor (views A & B)

The standpipe drain requires a minimum diameter standpipe

of 2" (50 mm). The minimum carry-away capacity (for permanent

installations) can be no less than 17 gal (64.5 L) per minute. A 2"

(50 mm) diameter to 1" (25 mm) diameter standpipe adapter kit

is available. See “Tools and Parts.”

The top of the standpipe must be at least 39" (990 mm) high

and no higher than 72" (183 cm) from the bottom of the washer.

Permanent Installation

Instructions

■ To avoid damage to the floor, set the washer onto cardboard

before moving across floor.

■ Move the washer to within approximately 3 ft (900 mm)

of the final location.

4.5"

(114 mm)

A

4.5"

4.5"

(114 mm)

(114 mm)

B

Laundry tub drain system (view C)

The laundry tub requires a minimum carry-away capacity

of 17 gal (64.5 L) per minute (for permanent installations).

The top of the laundry tub must be at least 39" (990 mm) above

the floor and no higher than 72" (183 cm) from the bottom of

the washer.

4.5"

4.5"

min.

min.

30"

39"

(762 mm)

(990 mm)

C

Floor drain system (view D)

The floor drain system requires a siphon break that may be

purchased separately. See “Tools and Parts.”

The siphon break must be a minimum of 28" (710 mm) from

the bottom of the washer. Additional hoses might be needed.

The minimum carry-away capacity (for permanent installations)

can be no less than 17 gal (64.5 L) per minute.

Connect Drain Hose

1. Attach drain hose to drain port

If clamp is not already in place on elbow end of drain hose,

slide it over end as shown. Squeeze clamp with pliers and slide

black elbow end of drain hose onto black drain port and secure

with clamp.

For a laundry tub or standpipe drain, go to Step 2.

For a floor drain, remove the preinstalled drain hose form as

shown in Step 3. You may need additional parts with separate

directions. See “Tools and Parts.”

Install Drain Hose

2. Place drain hose in standpipe

Drain

hose form

4.5"

(114 mm)

Place hose into standpipe (shown in picture) or over side of

laundry tub.

IMPORTANT: 4.5" (114 mm) of drain hose should be inside

standpipe; do not force excess hose into standpipe or lay on

D

bottom of laundry tub. Drain hose form must be used.

6

Page 7

3. Remove drain hose form

(floor drain installations only)

For floor drain installations, you will need to remove the

drain hose form from the end of the drain hose. You may

need additional parts with separate directions. See “Tools

and Parts.”

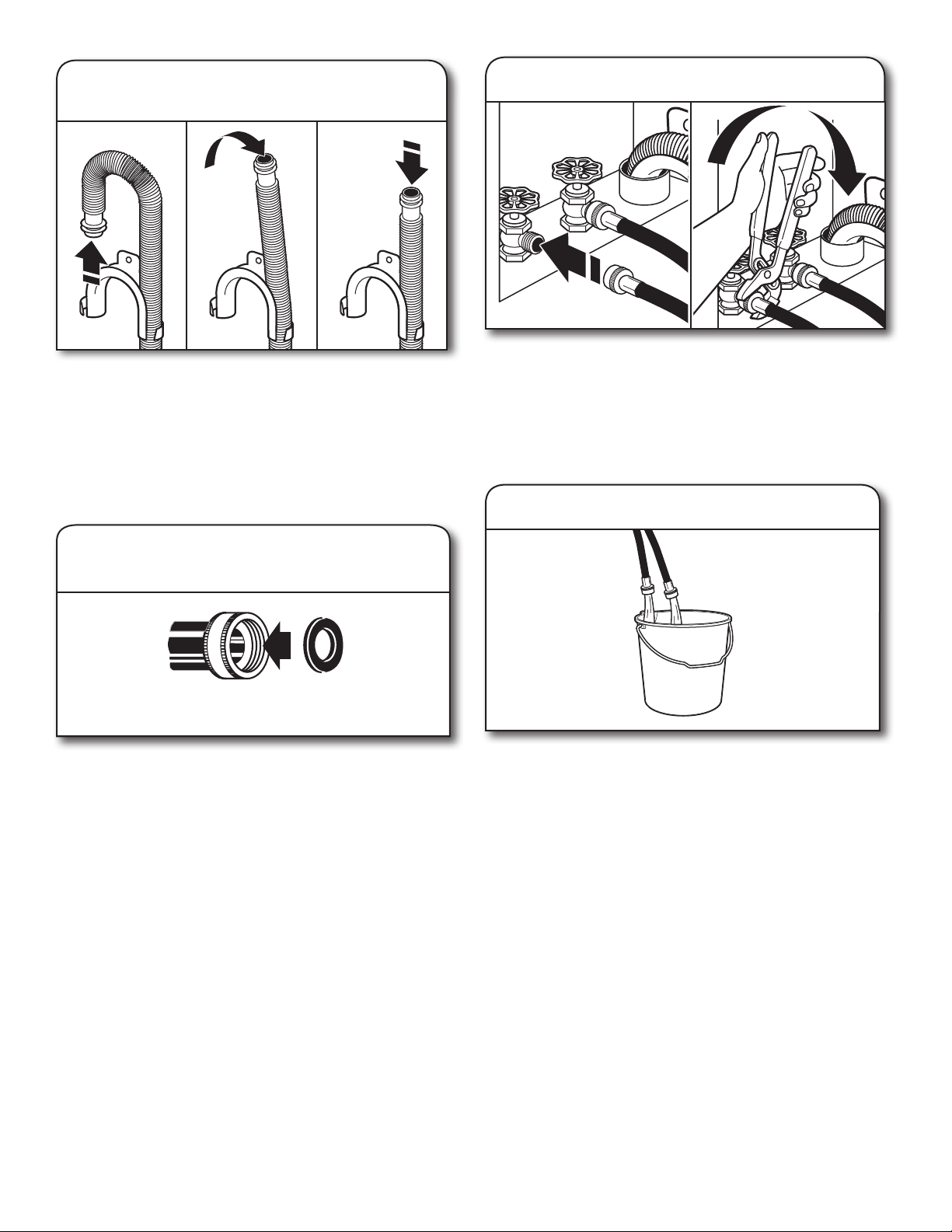

Connect Inlet Hoses

The washer must be connected to the water faucets using

new inlet hoses (not provided). Do not use old hoses.

5. Connect inlet hoses to water faucets

Check that the washer basket is empty.

Attach hose to hot water faucet. Screw on coupling by hand

until it is seated on washer. Use pliers to tighten couplings an

additional two-thirds turn. Repeat this step with second hose

for cold water faucet.

IMPORTANT: Do not overtighten or use tape or sealants on

valve when attaching to faucets or washer. Damage can result.

6. Clear water lines

4. Insert new flat washers into

inlet hoses

Coupling Washer

Insert new flat washers (not provided) into each end of the inlet

hoses. Firmly seat the washers in the couplings.

Run water for a few seconds through hoses into a laundry tub,

drainpipe, or bucket to avoid clogs. Water should run until clear.

Make note of which hose is connected to hot water to help in

attaching hoses to washer correctly.

7

Page 8

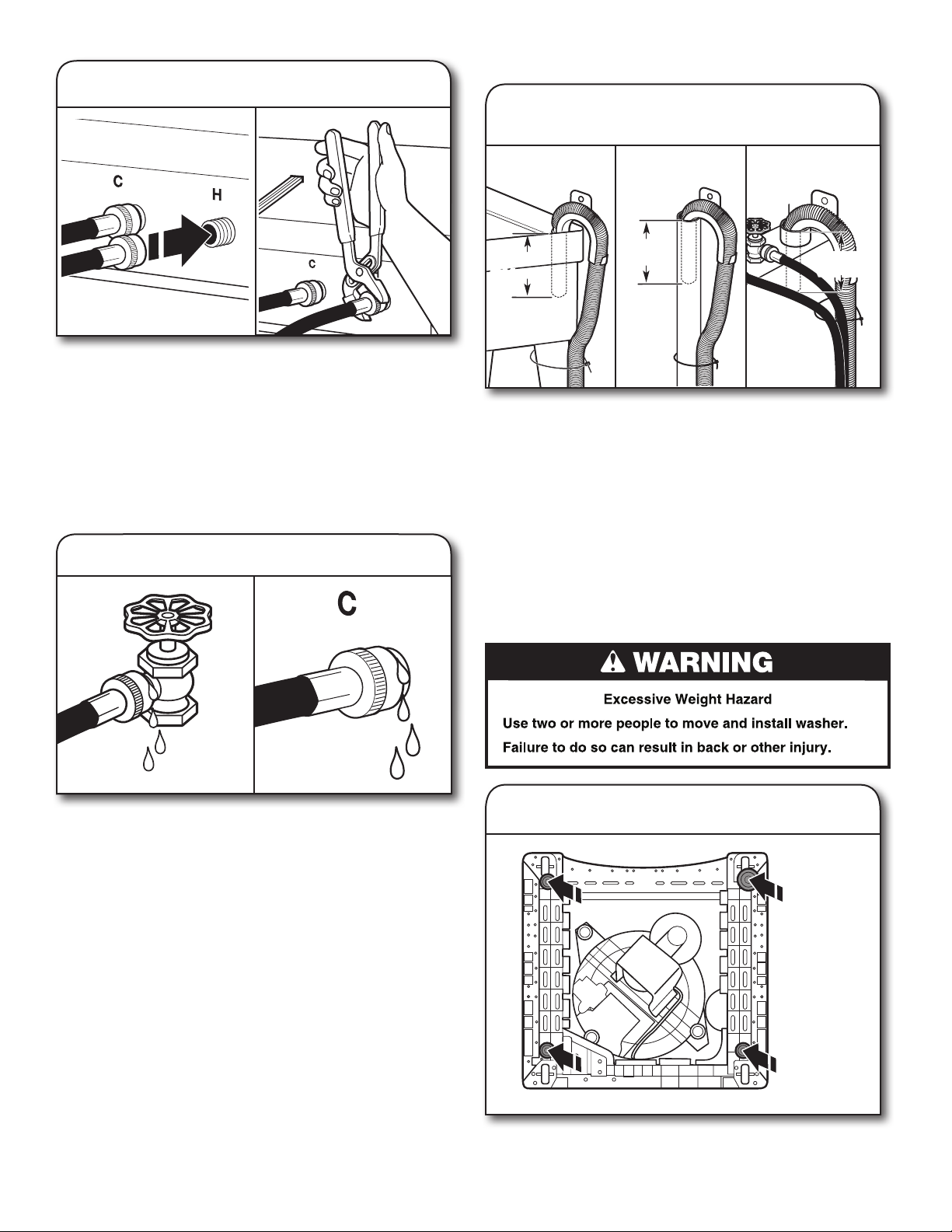

7. Connect inlet hoses to washer

Secure Drain Hose

9. Secure drain hose to laundry tub,

standpipe, or wall

Laundry Tub Standpipe Wall

Remove inlet cap and attach hot water hose to hot water (right)

inlet valve. Screw coupling by hand until it is snug. Use pliers

to tighten couplings an additional two-thirds turn. Repeat with

cold water (left) inlet valve.

IMPORTANT: To reduce risk of hose failure, replace the hoses

every 5 years. Record hose installation or replacement dates

for future reference.

■ Periodically inspect and replace hoses if bulges, kinks, cuts,

wear, or leaks are found.

8. Check for leaks

4.5"

4.5"

(114 mm)

(114 mm)

Secure drain hose to laundry tub leg, drain standpipe, or inlet

hoses for wall standpipe with cable tie (provided).

■ Do not force excess drain hose back into the rear of

the washer.

■ To avoid siphoning, do not seal or put more than 4½"

(114 mm) of the drain hose into drainpipe or standpipe.

4.5"

(114 mm)

4.5"

4.5"

(113 mm)

(114 mm)

Install Leveling Feet – Optional

(for permanent installation only)

IMPORTANT: Installation of the leveling feet is permanent.

Once the leveling feet are installed into the base of the washer

they cannot be removed.

Turn on water faucets to check for leaks. A small amount of

water may enter washer. It will drain later.

■ If you connect only one water hose, you must cap (supplied)

off the remaining water inlet port.

8

10. Install leveling feet

Front

Large

black

rubber

foot

Lay washer on its back. Push in to snap the large black rubber

foot into the right front corner of the washer base. Repeat to

install the remaining leveling feet on the other 3 corners.

Page 9

Level the Washer

IMPORTANT: Level washer properly to reduce excess noise

and vibration.

For Permanent Installations:

11. Check levelness of washer

Move the washer to its final location. Place a level on top

edges of washer. Use side seam as a guide to check levelness

of sides. Check levelness of front using lid, as shown. Rock

washer back and forth to make sure all 4 feet make solid

contact with floor.

13. Plug into a grounded 3 prong outlet

Not Level

LEVEL

Not Level

12. Adjust leveling foot

If the washer is not level, lay washer on its back to adjust the

large black rubber leveling foot. If the washer is against a wall,

move the washer out slightly before laying on its back.

Use a crescent wrench to adjust the large black rubber leveling

foot up or down as necessary.

NOTE: The 3 smaller leveling feet are not adjustable.

For Portable Installations:

Check the levelness of the floor.

Complete Installation Checklist

Check electrical requirements. Be sure you have correct

q

electrical supply and recommended grounding method.

Check that all parts are now installed. If there is an extra

q

part, go back through steps to see what was skipped.

Check that you have all of your tools.

q

Check that shipping materials were completely

q

removed from washer.

Check that water faucets are on.

q

Check for leaks around faucets and inlet hoses.

q

Remove protective film from console and any tape

q

remaining on washer.

Check that washer is plugged into a grounded

q

3 prong outlet.

Dispose of/recycle all packaging materials.

q

Read “Washer Care” in your Use and Care Guide.

q

To test and clean your washer, measure ½ of normal

q

recommended amount of powdered or liquid detergent

and pour it into washer basket or detergent dispenser

(on some models). Close lid. Select any cycle. Start

washer and allow to complete full cycle.

9

Page 10

Portable Installation

Instructions

Drain System

The washer must drain into a sink or laundry tub with a

carry-away capacity of 17 gal (64.5 L) per minute (for portable

installations). The top of the tub must be at least 27" (68.6 cm)

above floor and no higher than 48" (121.9 cm) from the bottom

of the washer.

27"

(68.6 cm)

1. Attach hose bracket

3. Connect fill hose

Attach the fill hose to the cold water (left) inlet valve.

Tighten coupling by hand. Use pliers to make an additional

two-thirds turn.

NOTE: Do not overtighten. Damage to the valves can result.

Hot water (right) inlet valve is capped. Leave this valve capped.

4. Connect drain hose

Slot

Post

Place the hose bracket over the post on the back of the

washer and position the the tab so it will insert into the slot.

Push down to lock into place.

Connect Fill-And-Drain Hose

Proper connection of the fill-and-drain hose will protect your

floors from damage due to water leakage.

2. Insert new flat washer into inlet hose

1

/4"

(6 mm)

To keep the fill-and-drain hose from leaking, it must be

installed according to the following instructions.

IMPORTANT: To ensure proper installation, this procedure

must be followed exactly.

Remove permanent installation drain hose. Wet inside end

of the drain hose with tap water.

IMPORTANT: Do not use any lubricant other than water.

Squeeze ears of double-wire clamp with pliers to open. Place

clamp over the straight end of the drain hose ¼" (6 mm) from

the end. Twist hose back and forth while pushing down onto

drain connector at the bottom of the washer. Continue until

hose contacts the cabinet.

Coupling Washer

Insert new flat washer (supplied) into the end of the inlet hose.

Firmly seat the washer in the coupling.

10

Page 11

5. Secure drain hose

8. Set wash TEMP to COLD

Cabinet

Drain hose

Clamp

¼"

(6 mm)

¼"

(6 mm)

Place clamp over area marked “CLAMP.” Release clamp.

6. Attach faucet kit adapter to faucet

Washer

Adapter

Proper connection of your faucet adapter kit will allow hot and

cold water to enter your washer properly. It also helps avoid

water damage due to leaks.

Attach the faucet adapter kit from the parts bag to your

faucet. A standard faucet adapter and washer are supplied.

Customized adapters are available from traditional plumbing

supply sources.

Set the temperature setting on your washer to COLD. Set

the water temperature for the wash cycle by adjusting the

Hot and Cold water faucets.

To test the water, press the red water-flow button on the

hose connector.

NOTE: If desired, you can change the water temperature for

the rinse cycle by adjusting the Hot and Cold water faucets.

Keep the temperature setting on your washer set at COLD.

7. Attach fill-and-drain hose connector

to faucet

Red water-flow

button

Roll washer to sink area. It rolls and operates on wheels.

The wheels do not roll from side to side. Be sure your washer

is on a level floor to help avoid movement during spin.

Attach fill-and-drain hose connector to a single-spout

hot/cold water faucet. Move the locking collar down while

lifting the connector until it snaps into place.

9. Plug into a grounded 3 prong outlet

11

Page 12

Disconnect Washer

1. Remove fill-and-drain hose connector

from faucet

Red water-flow

button

Turn off water faucets and unplug the power cord. Press the

red water-flow button to release water pressure in the hose.

Pull the locking collar down to remove the connector from

the faucet.

2. Replace fill-and-drain hose on storage

bracket

Complete Installation Checklist

Check electrical requirements. Be sure you have correct

q

electrical supply and recommended grounding method.

Check that all parts are now installed. If there is an extra

q

part, go back through steps to see what was skipped.

Check that you have all of your tools.

q

Check that shipping materials were completely

q

removed from washer.

Check that water faucets are on.

q

Check for leaks around faucets and inlet hoses.

q

NOTE: If the washer is attached to a faucet equipped

with a spray hose, the constant water pressure may

cause the spray hose to leak. To avoid possible failure,

the spray hose should be disconnected or replaced with

a high-pressure hose.

Remove protective film from console and any tape

q

remaining on washer.

Check that washer is plugged into a grounded

q

3 prong outlet.

Dispose of/recycle all packaging materials.

q

Read “Washer Care” in your Use and Care Guide.

q

To test and clean your washer, measure ½ of normal

q

recommended amount of powdered or liquid detergent

and pour it into washer basket or detergent dispenser

(on some models). Close lid. Select any cycle. Start

washer and allow to complete full cycle.

Pour water out of the faucet connector. Place fill-and-drain

hose on the plastic holder in the back of the washer.

12

Page 13

Control Panel and Features

2 3

1

4

LED TIME/STATUS DISPLAY

1

The Remaining Time display shows the time required for

the cycle to complete. Factors such as load size and water

pressure may affect the time shown in the display. Tightly

packed loads, unbalanced loads, or excessive suds may

cause the washer to adjust the cycle time as well.

2

LID LOCK LIGHT

The Lid Lock indicator lights up when the lid is locked and

cannot be opened. If you need to open the lid, press and

hold START/PAUSE. The lid will unlock once the washer

movement has stopped. This may take several minutes if

the load was spinning at high speed. Press the Start/Pause

button again to restart the cycle.

3

START/PAUSE

After selecting a wash cycle, press START/PAUSE to start

the cycle. Press once to pause a cycle. The flashing lights

indicate the selected cycle and the current process.

4

CYCLE TIME (+ or -)

■ Press “+” or “-” to adjust the duration of a wash cycle.

■ Press “+” or “-” to adjust the duration of a spin cycle.

■ LED display will show the time remaining for the cycle

to complete.

■ If an out-of-range adjustment is made, a buzzer

will sound.

End-of-Cycle Signal

Press and hold the plus (+) button for 3 seconds

to enable or disable the end-of-cycle signal.

5

4 6

CYCLE

5

Press CYCLE to select a wash cycle. Choose from Normal,

Delicate, Heavy, Rinse, Spin, or Clean Washer.

NOTE: The washer will remember the last cycle used, with

a default load size of Medium.

LOAD SIZE

6

Press to select the water level based on the amount of

garments to wash.

When the Medium water level is selected with the Normal

or Heavy cycle, the washer will sense the size of the load

and adjust if required.

7

TEMP

Select a wash temperature based on the type of fabric

and soils being washed. For best results and following

the garment label instructions, use the warmest wash

water safe for your fabric.

For Portable Installations: If desired, you can change the

water temperature for the rinse cycle by adjusting the Hot

and Cold water faucets. Keep the temperature setting on

your washer set at COLD.

7

8

CONTROL LOCK

Press and hold TEMP for 4 seconds to lock the controls.

Press and hold for 4 seconds to unlock. You may still press

POWER ON/OFF to turn off the washer.

8

POWER ON/OFF

Press POWER ON/OFF to turn on or off the washer.

Press once while a cycle is running to stop the washer.

13

Page 14

Dispensers

B

A

C

Liquid fabric softener dispenser

A

Pour measured liquid fabric softener into the liquid fabric

softener dispenser if desired. It will dispense automatically

at the optimum time.

■ Use only liquid fabric softener in this dispenser.

NOTE: The fabric softener dispenser rotates around the

wash basket and may not be in the same spot each time.

High Efficiency “HE” powdered detergent dispenser

B

Add only powdered HE detergent product to this dispenser

for your main wash cycle.

Use only High Efficiency (HE) detergent.

NOTES:

■ Follow the manufacturer’s instructions to determine

the amount of detergent to use.

■ Add liquid HE detergent or single-dose packets

to the basket prior to adding laundry.

Liquid chlorine bleach dispenser

C

This dispenser holds up to ¾ cup (180 mL) liquid chlorine

bleach. The bleach will be automatically diluted and

dispensed at the optimum time during the wash cycle.

This dispenser cannot dilute powdered bleach.

NOTE: Fill dispenser with only liquid bleach.

Choosing the Right Detergent

Use only High Efficiency detergents. The package will be

marked “HE” or “High Efficiency.” Low-water washing creates

excessive sudsing with a non-HE detergent. Using non-HE

detergent will likely result in longer cycle times and reduced

rinsing performance. It may also result in component failure and,

over time, buildup of mold or mildew. HE detergents should be

low-sudsing and quick-dispersing to produce the right amount

of suds for the best performance. They should hold soil in

suspension so it is not re-deposited onto clean clothes. Not all

detergents labeled as High Efficiency are identical in formulation

and their ability to reduce suds. For example, natural, organic,

or homemade HE detergents may generate a high level of suds.

Follow the manufacturer’s instructions to determine the amount

of detergent to use.

Cycle Guide

This section describes the available wash cycles and will help

you make the best cycle selections for your wash loads. Each

cycle is designed for different types of fabric and soil levels.

Always read and follow fabric care label instructions to avoid

damage to your items.

Normal

Use this cycle for normally soiled cottons and linens. Wash

combines medium-speed agitation and high-speed spin to

shorten drying time.

Delicate

Use this cycle for lingerie and loosely knit items. Wash combines

low-speed agitation for gentle soil removal, and high-speed spin

to shorten drying time.

Heavy

Use this cycle for sturdy or heavily soiled loads. Wash combines

high-speed agitation and high-speed spin for maximum soil

removal.

Rinse

Use this cycle for additional rinsing of the washer load

or hand-washed items.

Spin

Use this cycle to remove excess water from the washer load

or hand-washed items.

Clean Washer

Use this cycle every 30 washes to keep the inside of your

washer fresh and clean. This cycle uses a higher water level.

Use with affresh® Washer Cleaner tablet or liquid chlorine bleach

to thoroughly clean the inside of your washer. This cycle should

not be interrupted.

IMPORTANT: Do not place garments or other items in the

washer during the Clean Washer cycle. Use this cycle with

an empty washtub.

End-of-Cycle Signal

The End-of-Cycle signal may be turned on and off by pressing

and holding the Cycle “+” button for 3 seconds.

14

Page 15

Using Your Washer

1. Sort and prepare your laundry

2. Add laundry products

■ Empty pockets. Loose change, buttons, or any small

object can pass under the washplate and become

trapped, causing unexpected sounds.

■ Sort items by recommended cycle, water temperature,

and colorfastness.

■ Separate heavily soiled items from lightly soiled.

■ Separate delicate items from sturdy fabrics.

■ Do not dry items if stains remain after washing; heat

can set stains into fabric.

■ Treat stains promptly.

■ Close zippers, fasten hooks, tie strings, and sashes.

Remove non-washable trim and ornaments.

■ Mend rips and tears to avoid further damage to items

during washing.

Helpful Tips:

■ For best performance, use HE liquid detergent when washing

bulky items.

■ Use mesh bags to help avoid tangling when washing

delicate or small items.

■ Turn knits inside out to avoid pilling. Separate lint-takers

from lint-givers. Synthetics, knits, and corduroy fabrics will

pick up lint from towels, rugs, and chenille fabrics.

NOTE: Always read and follow fabric care label instructions

to avoid damage to your items.

IMPORTANT: If you are using the Compact Dryer Stack Stand

(Part Number 49971), pull the washer forward before lifting

the washer lid.

If you are using liquid laundry detergent, single-dose laundry

packets, color-safe bleach, Oxi-type boosters, or fabric softener

crystals, add to the wash basket prior to adding laundry.

NOTE: Always follow manufacturer’s instructions.

3. Load laundry into washer

Max

For best performance, load items

in loose heaps evenly around the

washplate. Try mixing differentsized items to reduce tangling.

IMPORTANT: Items need to move

freely for best cleaning and to reduce wrinkling and tangling.

NOTE: The maximum volume is about 1.52 cubic ft. (4.4 lb max.

load size per cubic ft.).

load

level

15

Page 16

Using Laundry Product Dispensers

NOTE: Do not add liquid laundry detergent, single-dose

laundry packets, color-safe bleach, Oxi-type boosters, or

fabric softener crystals to dispensers. They will not dispense

correctly. Add to the basket prior to adding laundry.

4. Add powdered HE detergent

IMPORTANT: Use only High Efficiency detergents. The

package will be marked “HE” or “High Efficiency.” Low-water

washing creates excessive sudsing with a regular non-HE

detergent. Using regular detergent will likely result in longer

cycle times and reduced rinsing performance. It may also

result in component failures and noticeable mold or mildew.

HE detergents are made to produce the right amount of

suds for the best performance. Follow the manufacturer’s

instructions to determine the amount of detergent to use.

NOTES:

■ Use only powdered HE detergent in the detergent

dispenser. Add liquid HE detergent or single-dose packets

to the basket prior to adding laundry.

■ See “Washer Maintenance” for information on

recommended method of cleaning washer dispensers.

6. Add liquid fabric softener

Pour a measured amount of liquid fabric softener into

dispenser; always follow manufacturer’s directions for correct

amount of fabric softener based on your load size. Fabric

Softener is added during rinse.

IMPORTANT: Do not overfill or dilute. Overfilling dispenser

will cause fabric softener to immediately dispense into washer.

It is normal for a small amount of water to remain in the

dispenser at the end of a cycle.

NOTE: The fabric softener dispenser rotates around the wash

basket and may not be in the same spot each time.

7. Press POWER to turn on washer

5. Add liquid chlorine bleach

to dispenser

Bleach will be dispensed automatically during the wash part

of the cycle. Do not overfill, dilute, or use more than 1 cup

(250 mL). Do not use color-safe bleach or Oxi products in

the same cycle with liquid chlorine bleach.

16

Close the washer lid. Washer will not fill, agitate, or spin

with the lid open. Make sure the dispenser drawer is closed

completely; then press POWER to turn on the washer.

8. Select LOAD size

Press the Load button to select the correct setting for

your wash load and the type of fabric being washed.

Choose a water level that allows the load to move freely

for best fabric care.

Page 17

When Medium is selected with the Normal or Heavy

cycles, the washer will sense the size of the load and

adjust if required.

You may change the load size setting while the washer is

filling. If you change from Large to Medium but the water has

filled past Medium, you will get Medium with the next fill.

9. Select wash TEMP

Set the water temperature for the type of fabric and soils

being washed. Use the warmest wash water safe for fabric.

Follow garment label instructions.

For Portable Installations

Open the faucets connected to the water supply hoses.

Wash and Rinse water temperatures are set at your faucet.

The Temperature control does not set the temperature.

Adjust the Hot and Cold water faucets to desired wash

temperature. Keep the temperature control set at COLD.

NOTE: The Cold setting allows water from the faucet to

enter the washer, but does not control the incoming water

temperature.

For a Rinse temperature that is different from the wash

temperature, you must adjust the water temperature at

the faucet after the washer has completed its initial fill.

To test the water temperature, press the red water-flow

button on the hose connector.

For Permanent Installations

The Rinse and Spin cycles default to a cold rinse, all other

cycles default to a warm rinse. Press the Temp button to

choose a different wash temperature.

Selecting Water Temperatures

NOTE: Always read and follow fabric care labels instructions

to avoid damage to your items.

Water Temperature Suggested Fabrics

Hot

Warm

Cold

NOTE: In wash water temperatures colder than 60ºF (15.6ºC),

detergents do not dissolve well. Soils can be difficult to

remove. Some fabrics can retain wear wrinkles and have

increased pilling (the formation of small lint-like balls on the

surface of garments).

Whites and pastels

Durable items

Heavy soils

Bright colors

Moderate to light soils

Colors that bleed or fade

Light soils

10. Select CYCLE

Press the Cycle button to select your wash cycle. See “Cycle

Guide” for details on cycle features.

11. Press Start/Pause button

to begin wash cycle

Press the Start/Pause button to start the wash cycle. When

the cycle has finished, the end-of-cycle signal will sound

(if set). Promptly remove items when cycle is done to avoid

odor, reduce wrinkling, and reduce rusting of metal hooks,

zippers, and snaps.

Unlocking the lid to add items

If you need to open the lid to add 1 or 2 missed items:

Press the Start/Pause button to pause washer; the lid will

unlock once the washer movement has stopped. This may

take several minutes if the load was spinning at a high speed.

Then close lid and press the Start/Pause button again to

restart the cycle.

To stop or restart your washer:

■ To stop the washer at any time, press the

button and the cycle will pause.

■ To restart the washer,

and the cycle will resume.

press the

Start/Pause

Start/Pause

button

17

Page 18

Washer Maintenance

WATER INLET HOSES

Replace inlet hoses after 5 years of use to reduce the risk

of hose failure. Periodically inspect and replace inlet hoses

if bulges, kinks, cuts, wear, or leaks are found.

When replacing your inlet hoses, mark the date of

replacement on the label with a permanent marker.

WASHER CARE

Recommendations to Help Keep Your Washer Clean

and Performing at Its Best

1. Always use High Efficiency (HE) detergents and follow the

HE detergent manufacturer’s instructions regarding the

amount of HE detergent to use. Never use more than the

recommended amount because that may increase the

rate at which detergent and soil residue accumulate inside

your washer which, in turn, may result in undesirable odor.

2. Use warm and hot wash water settings sometimes (not

exclusively cold water washes), because they do a better

job of controlling the rate at which soils and detergent

accumulate.

3. Always leave the washer lid open between uses to

help dry out the washer and prevent the buildup of

odor-causing residue.

Cleaning Your Top Loading Washer

Read these instructions completely before beginning the

routine cleaning processes recommended below. This

Washer Maintenance Procedure should be performed,

at a minimum, once per month or every 30 wash cycles,

whichever occurs sooner, to control the rate at which soils

and detergent may otherwise accumulate in your washer.

Cleaning the Inside of the Washer

To keep your washer odor-free, follow the usage instructions

provided above, and use this recommended monthly

cleaning procedure:

Clean Washer Cycle

This washer has a special cycle that uses higher water

volumes in combination with affresh® Washer Cleaner

or liquid chlorine bleach to clean the inside of the washer.

Begin procedure

1. affresh® Washer Cleaner Cycle Procedure

(Recommended for Best Performance):

a. Open the washer lid and remove any clothing or items.

b. Place an affresh® Washer Cleaner tablet in the bottom

of the washer basket.

c. Do not place an affresh® Washer Cleaner tablet

in the detergent dispenser.

d. Do not add any detergent or other chemical to the

washer when following this procedure.

e. Close the washer lid.

f. Select the Clean Washer cycle.

g. Press the Start/Pause button to begin the cycle.

The Clean Washer Cycle Operation is described below.

NOTE: For best results, do not interrupt cycle. If cycle

must be interrupted, press POWER. (For models with no

Power/Cancel button, press and hold START/PAUSE for

three seconds). After the Clean Washer cycle has stopped,

run a Rinse cycle to rinse cleaner from washer.

WASHER CARE (cont.)

Begin procedure

2. Chlorine Bleach Procedure (Alternative):

a. Open the washer lid and remove any clothing

or items.

b. Add 1 cup (236 mL) of liquid chlorine bleach

to the bleach compartment.

NOTE: Use of more liquid chlorine bleach than is

recommended above could cause washer damage

over time.

c. Close the washer lid.

d. Do not add any detergent or other chemical

to the washer when following this procedure.

e. Select the Clean Washer cycle.

f. Press the

The Clean Washer Cycle Operation is described below.

NOTE: For best results, do not interrupt cycle. If cycle

must be interrupted, press POWER. (For models with

no Power/Cancel button, press and hold START/PAUSE

for 3 seconds). After the Clean Washer cycle has stopped,

run a Rinse cycle to rinse cleaner from washer.

Description of Clean Washer Cycle Operation:

1. This cycle will fill to a water level higher than in normal

wash cycles to provide rinsing at a level above the water

line for normal wash cycle.

2. During this cycle, there will be some agitation and

spinning to increase the removal of soils.

After this cycle is complete, leave the lid open to allow

for better ventilation and drying of the washer interior.

Cleaning the Dispensers

After a period of using your washer, you may find some

residue buildup in the washer’s dispensers. To remove

residue from the dispensers, wipe them with a damp cloth

and towel dry. Do not attempt to remove the dispensers or

trim for cleaning. The dispensers and trim are not removable.

If your model has a dispenser drawer, however, remove the

drawer and clean it before or after you run the Clean Washer

cycle. Use an all-purpose surface cleaner, if needed.

Cleaning the Outside of the Washer

Use a soft, damp cloth or sponge to wipe away any spills.

Use only mild soaps or cleaners when cleaning external

washer surfaces.

IMPORTANT: To avoid damaging the washer’s finish, do not

use abrasive products.

Start/Pause

button to begin the cycle.

18

Page 19

WASHER CARE (cont.)

NON-USE AND VACATION CARE

Cleaning The Lint Filter

Clean filter after every load.

1. Press down, then out, to remove the lint filter.

2. Open the lint filter and clean with water.

3. Insert the lint filter bottom first; then press down and in

to replace the fliter.

Operate your washer only when you are home. If moving,

or not using your washer for a period of time, follow

these steps:

1. Unplug or disconnect power to washer.

2. Turn off water supply to washer to avoid flooding due

to water pressure surges.

3. Clean the dispensers. See “Cleaning the Dispensers.”

WINTER STORAGE CARE

IMPORTANT: To avoid damage, install and store washer

where it will not freeze. Because some water may stay in

hoses, freezing can damage washer. If storing or moving

during freezing weather, winterize your washer.

To winterize washer:

1. Shut off both water faucets, disconnect and drain water

inlet hoses.

2. Put 1 qt (1 L) of R.V.-type antifreeze in washer basket

and run washer on Normal cycle for about 2 minutes

to mix antifreeze and remaining water.

3. Unplug washer or disconnect power.

REINSTALLING/USING WASHER AGAIN

To reinstall washer after non-use, vacation, winter storage,

or moving:

1. Refer to Installation Instructions to locate, level, and

connect washer.

2. Before using again, run washer through the following

recommended procedure:

To use washer again:

1. Flush water pipes and hoses. Reconnect water inlet

hoses. Turn on both water faucets.

TRANSPORTING YOUR WASHER

1. Shut off both water faucets. Disconnect and drain water

inlet hoses.

2. If washer will be moved during freezing weather, follow

“Winter Storage Care” directions before moving.

3. Disconnect drain hose from drain system and from back

of washer.

4. Unplug power cord.

5. Place inlet hoses and drain hose inside washer basket.

6. Bundle power cord with a rubber band or cable tie to

keep it from hanging onto the ground.

IMPORTANT: Call for service to install new transport bolts.

Do not reuse transport bolts. Washer must be transported

in the upright position. To avoid structural damage to

your washer, it must be properly set up for relocation

by a certified technician.

2. Plug in washer or reconnect power.

3. Run washer through Heavy Duty cycle to clean washer

and remove antifreeze, if used. Use only HE detergent.

Use half the manufacturer’s recommended amount for

a medium-size load.

19

Page 20

Troubleshooting

First try the solutions suggested here or visit our website at www.amana.com –

In Canada www.amanacanada.ca for assistance and to possibly avoid a service call.

If you experience Possible Causes Solution

Vibration or Off-Balance

Vibration, rocking, or

“walking”

Vibration during spinning

or washer stopped

Noises

Clicking or metallic

noises

Gurgling or humming Washer may be draining water. It is normal to hear the pump making a continuous humming

Humming Load sensing may be occurring. You may hear the hum of the sensing spins after you have

Whirring Basket may be slowing down. You may hear the whirring sound of the basket slowing down.

Water Leaks

Check the following for

proper installation:

Washer not performing as expected

Not enough water

in washer

Feet may not be in contact with

the floor and locked.

Washer may not be level.

Load could be unbalanced. Load items in loose heaps evenly around the washplate. Adding

Objects may be caught in washer

drain system.

Washer not level. Water may splash off basket if washer is not level.

Fill hoses not attached tightly. Tighten fill-hose connection.

Fill hose washers Make sure fill hose flat washers are properly seated.

Drain hose connection Properly secure drain hose to drainpipe or laundry tub.

Check household plumbing for leaks

or clogged sink or drain.

Washer not loaded as

recommended.

Load not completely covered

in water.

Front and rear feet or casters must be in firm contact with floor,

and washer must be level to operate properly.

Check floor for flexing or sagging. If flooring is uneven,

a ¾" (19 mm) piece of plywood under your washer will

reduce sound.

See “Level the Washer” in the Installation Instructions.

wet items to washer or adding more water to basket could

unbalance washer.

Avoid washing single items. Balance a single item such as a

rug or jeans jacket with a few extra items. Redistribute the load,

close the lid, and press START/PAUSE.

Item or load not suitable for selected cycle. See “Cycle Guide”

and “Using Your Washer.”

Empty pockets before washing. Loose items such as coins

could fall between basket and tub or may block pump. It may be

necessary to call for service to remove items.

It is normal to hear metal items on clothing such as metal snaps,

buckles, or zippers touch against the stainless steel basket.

sound with periodic gurgling or surging as final amounts of water

are removed during the spin/drain cycles.

started the washer. This is normal.

This is normal.

Do not place tape over drain opening.

Water can back up out of a clogged sink or drainpipe. Check all

household plumbing for leaks (laundry tubs, drain pipe, water

pipes, and faucets.)

An unbalanced load can cause basket to be out of alignment

and cause water to splash off tub. See “Using Your Washer” for

loading instructions.

This is normal operation for an HE low-water washer. The load

will not be completely underwater. The washer senses load

sizes and adds correct amount of water for optimal cleaning.

IMPORTANT: Do not add more water to washer. Adding

water lifts the items off the washplate, resulting in less effective

cleaning.

Run Clean Washer cycle to optimize the water level and

wash performance.

20

Page 21

Troubleshooting

First try the solutions suggested here or visit our website at www.amana.com –

In Canada www.amanacanada.ca for assistance and to possibly avoid a service call.

If you experience Possible Causes Solution

Washer not performing as expected (cont.)

Washer won’t run or fill,

washer stops working

Check for proper water supply. Hose(s) must be attached and have water flowing to inlet valve.

Water faucet(s) must be turned on.

Check that inlet valve screens have not become clogged.

Check for any kinks in inlet hoses, which can restrict water flow.

Washer won’t run or fill,

washer stops working

(cont.)

Washer not draining/

spinning, loads are

still wet

Check proper electrical supply. Plug power cord into a grounded 3-prong outlet.

Do not use an extension cord.

Ensure there is power to outlet.

Reset a tripped circuit breaker. Replace any blown fuses.

NOTE: If problems continue, contact an electrician.

Normal washer operation. Lid must be closed for washer to run.

Washer will pause during certain phases of cycle. Do not

interrupt cycle.

Washer may be stopped to reduce suds.

Washer may be tightly packed.

Not using HE detergent or using too

much HE detergent.

Small items may have been caught

in pump or between basket and tub,

which can slow draining.

Using cycles with a lower spin speed. Cycles with lower spin speeds remove less water than cycles

Washer may be tightly packed or

unbalanced.

Remove several items, rearrange load evenly around the

washplate. Close lid, press Start/Pause button.

Add only 1 or 2 additional items after washer has started.

Do not add more water to the washer.

Only use HE detergent. Suds from regular detergents can slow or

stop the washer. Always measure detergent and follow detergent

directions based on your load requirements.

To remove suds, cancel cycle. Select RINSE then SPIN. Do not

add more detergent.

Empty pockets and use garment bags for small items.

with high spin speeds. Use the recommended cycle/speed spin

for your item.

Tightly packed loads may not allow the washer to spin correctly,

leaving the load wetter than normal. Evenly arrange the wet load

for balanced spinning. Select SPIN to remove excess water. See

“Using Your Washer” for loading recommendations.

21

Page 22

Troubleshooting

First try the solutions suggested here or visit our website at www.amana.com –

In Canada www.amanacanada.ca for assistance and to possibly avoid a service call.

If you experience Possible Causes Solution

Washer not performing as expected (cont.)

Washer not draining/

spinning, loads are

still wet (cont.)

Incorrect or wrong wash

or rinse temperatures

Load not rinsed Check for proper water supply. For permanent installations, make sure hot and cold inlet hoses

Sand, pet hair, lint, etc.

on load after washing

Load is tangling Washer not loaded

Not cleaning or

removing stains

Load off balanced.

Check plumbing for correct drain

hose installation. Drain hose extends

into standpipe farther than 4.5"

(114 mm).

Not using HE detergent or using

too much HE detergent.

Check for proper water supply. For permanent installations, make sure that hot and cold inlet

Not using HE detergent or using

too much HE detergent.

Washer may be tightly packed.

Heavy sand, pet hair, lint, and

detergent or bleach residues may

require additional rinsing.

as recommended.

Wash action and/or spin speed

too fast for load.

Wash load not completely

covered in water.

Added more water to washer. Do not add more water to washer. Adding water lifts the items

Washer not loaded

as recommended.

See “Vibration or Off-Balance” in “Troubleshooting” section for

more information.

Check drain hose for proper installation. Use drain hose

form and securely attach to drainpipe or tub. Do not tape

over drain opening. Lower drain hose if the end is higher than

96" (2.4 m) above the floor. Remove any clogs from drain hose.

Suds from regular detergent or using too much detergent can

slow or stop draining or spinning. Use only HE detergent. Always

measure and follow detergent directions for your load. To remove

extra suds, select RINSE. Do not add detergent.

hoses are not reversed. For portable installations, adjust water

temperature at faucet.

For permanent installations, both hoses must be attached to

both washer and faucet, and have both hot and cold water

flowing to inlet valve.

Check that inlet valve screens are not clogged.

Remove any kinks in hoses.

are not reversed.

Hoses must be attached and have water flowing to the inlet

valves or faucet.

For permanent installations, both hot and cold water faucets

must be on. For portable installations, sink faucet must be on.

Inlet valve screens on washer may be clogged.

Remove any kinks in the inlet hose.

The suds from regular detergent can cause the washer to

operate incorrectly.

Use only HE detergent. Be sure to measure correctly.

Always measure detergent and follow detergent directions based

on load size and soil level.

The washer is less efficient at rinsing when load is tightly

packed.

Load items in loose heaps evenly around the washplate.

Use cycle designed for the fabrics being washed.

Add only 1 or 2 additional items after washer has started.

Run an additional Rinse cycle.

Load items in loose heaps evenly around the washplate.

Reduce tangling by mixing types of load items. Use the

recommended cycle for the type of items being washed.

Select a cycle with a slower wash action and slower spin speed.

Note that items will be wetter than when using a higher speed spin.

Washer senses load size and adds correct amount of water.

This is normal and necessary for clothes to move.

off the washplate, resulting in less effective cleaning.

Load items in loose heaps evenly around the washplate.

Add only 1 or 2 additional items after washer has started.

22

Page 23

Troubleshooting

First try the solutions suggested here or visit our website at www.amana.com –

In Canada www.amanacanada.ca for assistance and to possibly avoid a service call.

If you experience Possible Causes Solution

Washer not performing as expected (cont.)

Not cleaning or

removing stains (cont.)

Odors Monthly maintenance not done

Fabric damage

Not using HE detergent or using too

much HE detergent.

Not using correct cycle for

fabric type.

Not using dispensers. Use dispensers to avoid chlorine bleach and fabric

Not washing like colors together. Wash like colors together and remove promptly after the cycle

as recommended.

Not using HE detergent or using

too much HE detergent.

Sharp items were in pockets

during wash cycle.

Strings and straps could

have tangled.

Items may have been damaged

before washing.

Fabric damage can occur if the

load is tightly packed.

Garment care instructions may

not have been followed.

Liquid chlorine bleach may have

been added incorrectly.

The suds from regular detergent can keep washer from

operating correctly.

Use only HE detergent. Be sure to measure correctly.

Always measure detergent and follow detergent directions

based on load size and soil level.

Use a higher soil level cycle option and warmer wash

temperature to improve cleaning.

Use Heavy cycle for tough cleaning.

See the “Cycle Guide” to match your load with the best cycle.

softener staining.

Load dispensers before starting a cycle.

Avoid overfilling.

Do not add products directly onto load.

is complete to avoid dye transfer.

Run the Clean Washer cycle after every 30 washes.

See “Washer Care.”

Unload washer as soon as cycle is complete.

Use only HE detergent. Be sure to measure correctly.

Always follow the detergent directions.

See “Washer Care” section.

Empty pockets, zip zippers, and snap or hook fasteners before

washing to avoid snags and tears.

Tie all strings and straps before starting wash load.

Mend rips and broken threads in seams before washing.

Load items in loose heaps evenly around washplate.

Load items should move freely during wash cycle to avoid

damage.

Use cycle designed for the fabrics being washed.

Add only 1 or 2 additional items after washer has started.

Always read and follow garment manufacturer’s care label

instructions. See the “Cycle Guide” to match your load with

the best cycle.

Do not pour liquid chlorine bleach directly onto load. Wipe up

bleach spills.

Undiluted bleach will damage fabrics. Do not use more than

recommended by manufacturer.

Do not place load items on top of bleach dispenser when

loading and unloading washer.

23

Page 24

Troubleshooting

First try the solutions suggested here or visit our website at www.amana.com –

In Canada www.amanacanada.ca for assistance and to possibly avoid a service call.

If you experience Possible Causes Solution

Washer not performing as expected (cont.)

Incorrect dispenser

operation

Powdered detergent not

dissolving completely

in load

Single-dose laundry

packet not dissolving

Error Code Appears in Display

E1 – Water inlet alarm

E2 – Draining alarm

E3 – Unbalanced alarm

E4 – Open lid alarm Opening the lid during the Spin cycle.

EA or EC – Other errors

Clogged dispensers or laundry

products dispensing too soon.

Liquid chlorine bleach not used

in dispenser.

Using too much HE detergent. Follow the manufacturer’s instructions to determine the amount

Water temperature is very cold. Select a warmer wash temperature.

Adding laundry packet incorrectly. Be sure laundry packet is added to washer basket before adding

Water level not reached after

20 minutes.

Washer is still detecting water after

draining for 8 minutes.

Washer may be tightly packed or

clothes are not evenly distributed.

Other

Do not overfill dispenser. Overfilling causes immediate dispensing.

Load dispensers before starting a cycle.

It is normal for small amounts of water to be remain in dispenser

at the end of the cycle.

Fabric softener thickens as it gets older. If there becomes an

increase of fabric softener in the dispenser after a cycle, check

the age of the fabric softener and replace if needed.

Homes with low water pressure may result in residual powder

in the dispenser. To avoid, select a warmer wash temperature

if possible, depending on your load. Do not use single-dose

laundry packets in the dispenser. They may not dissolve properly

and clog the dispenser.

Use only liquid chlorine bleach in the bleach dispenser.

of detergent to use.

Try adding the detergent to the basket prior to adding laundry,

rather than using the detergent dispenser.

clothes. Follow the manufacturer’s instructions to avoid damage

to your items.

Check that the water faucets are not closed.

Check that the water pressure in the house is over 20kPa.

Clean the inlet hose filter screens.

Check that the drain hose is not below 27½" (700 mm) from

the floor.

Check that the drain hose is not more than 39

the floor.

Remove any clogs from the drain hose.

Remove several items, rearrange load evenly around the

washplate, and restart the Spin cycle.

Close the lid.

Call for technical assistance – see “Assistance or Service” on the

back cover.

1

⁄3"

(100 cm) from

24

Page 25

ATTACH YOUR RECEIPT HERE. PROOF OF PURCHASE IS REQUIRED

usthelp.com

AMANA®

MAJOR APPLIANCE

LIMITED WARRANTY

TO OBTAIN WARRANTY SERVICE.

Please have the following information available when you call the

Customer eXperience Center:

■ Name, address and telephone number

■ Model number and serial number

■ A clear, detailed description of the problem

■ Proof of purchase including dealer or retailer name and address

IF YOU NEED SERVICE:

1. Before contacting us to arrange service, please determine whether your product requires repair. Some

questions can be addressed without service. Please take a few minutes to review the Troubleshooting or

Problem Solver section of the Use and Care Guide, scan the QR code on the right to access additional

resources, or visit http://amana.custhelp.com.

2. All warranty service is provided exclusively by our authorized Amana Service Providers

direct all requests for warranty service to:

Amana Customer eXperience Center

In the U.S.A., call 1-800-843-0304. In Canada, call 1-800-807-6777.

If outside the 50 United States or Canada, contact your authorized Amana dealer to determine whether another warranty applies.

ONE YEAR LIMITED WARRANTY

WHAT IS COVERED WHAT IS NOT COVERED

For one year from the date of purchase, when

this major appliance is installed, operated and

maintained according to instructions attached to

or furnished with the product, Amana brand of

Whirlpool Corporation or Whirlpool Canada LP

(hereafter “Amana”) will pay for Factory Specified

Replacement Parts and repair labor to correct

defects in materials or workmanship that existed

when this major appliance was purchased, or at

its sole discretion replace the product. In the

event of product replacement, your appliance will

be warranted for the remaining term of the

original unit's warranty period.

YOUR SOLE AND EXCLUSIVE REMEDY UNDER

THIS LIMITED WARRANTY SHALL BE

PRODUCT REPAIR AS PROVIDED HEREIN.

Service must be provided by a Amana

designated service company. This limited

warranty is valid only in the United States or

Canada and applies only when the major

appliance is used in the country in which it was

purchased. This limited warranty is effective from

the date of original consumer purchase. Proof of

original purchase date is required to obtain

service under this limited warranty.

1. Commercial, non-residential, multiple-family use, or use inconsistent with published user,

operator or installation instructions.

2. In-home instruction on how to use your product.

3. Service to correct improper product maintenance or installation, installation not in

accordance with electrical or plumbing codes or correction of household electrical or

plumbing (i.e. house wiring, fuses or water inlet hoses).

4. Consumable parts (i.e. light bulbs, batteries, air or water filters, preservation solutions, etc.).

5. Defects or damage caused by the use of non-genuine Amana parts or accessories.

6. Conversion of products from natural gas or L.P. gas.

7. Damage from accident, misuse, abuse, fire, floods, acts of God or use with products not

approved by Amana.

8. Repairs to parts or systems to correct product damage or defects caused by unauthorized

service, alteration or modification of the appliance.

9. Cosmetic damage including scratches, dents, chips, and other damage to the appliance

finishes unless such damage results from defects in materials and workmanship and is

reported to Amana within 30 days.

10. Discoloration, rust or oxidation of surfaces resulting from caustic or corrosive environments

including but not limited to high salt concentrations, high moisture or humidity or exposure

to chemicals.

11. Food or medicine loss due to product failure.

12. Pick-up or delivery. This product is intended for in-home repair.

13. Travel or transportation expenses for service in remote locations where an authorized

Amana servicer is not available.

14. Removal or reinstallation of inaccessible appliances or built-in fixtures (i.e. trim, decorative

panels, flooring, cabinetry, islands, countertops, drywall, etc.) that interfere with servicing,

removal or replacement of the product.

15. Service or parts for appliances with original model/serial numbers removed, altered or not

easily determined.

The cost of repair or replacement under these excluded circumstances shall be borne by

the customer.

. In the U.S. and Canada,

http://amana.c

DISCLAIMER OF IMPLIED WARRANTIES

IMPLIED WARRANTIES, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR IMPLIED WARRANTY OF FITNESS FOR A

PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR OR THE SHORTEST PERIOD ALLOWED BY LAW. Some states and provinces do not allow

limitations on the duration of implied warranties of merchantability or fitness, so this limitation may not apply to you. This warranty gives you

specific legal rights, and you also may have other rights that vary from state to state or province to province.

DISCLAIMER OF REPRESENTATIONS OUTSIDE OF WARRANTY

Amana makes no representations about the quality, durability, or need for service or repair of this major appliance other than the representations

contained in this warranty. If you want a longer or more comprehensive warranty than the limited warranty that comes with this major appliance,

you should ask Amana or your retailer about buying an extended warranty.

LIMITATION OF REMEDIES; EXCLUSION OF INCIDENTAL AND CONSEQUENTIAL DAMAGES

YOUR SOLE AND EXCLUSIVE REMEDY UNDER THIS LIMITED WARRANTY SHALL BE PRODUCT REPAIR AS PROVIDED HEREIN. AMANA

SHALL NOT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES. Some states and provinces do not allow the exclusion or limitation

of incidental or consequential damages, so these limitations and exclusions may not apply to you. This warranty gives you specific legal rights, and

you also may have other rights that vary from state to state or province to province.

11/14

25

Page 26

Assistance or Service

Before calling for assistance or service, please check “Troubleshooting” or visit www.amana.com/help.

It may save you the cost of a service call. If you still need help, follow the instructions below.

When calling, please know the purchase date and the complete model and serial number of your appliance.

This information will help us to better respond to your request.

If you need replacement parts or to order accessories

We recommend that you use only FSP® Factory Specified Parts.

These parts will fit right and work right because they are made with the same precision

used to build every new AMANA

To locate FSP® replacement parts or accessories go to www.amanapartsonline.com.

Questions? Call us toll free at 1-866-616-2664 or in Canada call 1-866-587-2002.

Our consultants provide assistance with

In the U.S.A.

■ Features and specifications on our full line of appliances.

■ Installation information.

■ Specialized customer assistance (Spanish speaking,

hearing impaired, limited vision, etc.).

You can write with any questions or concerns at:

Amana Brand Appliances

Customer eXperience Center

553 Benson Road

Benton Harbor, MI 49022-2692

1-866-616-2664

Please include a daytime phone number in your correspondence.

®

appliance.

In the U.S.A. and Canada

■ Use and maintenance procedures.

■ Accessory and repair parts sales.

■ Referrals to local dealers, repair parts distributors,

and service companies. Whirlpool designated service

technicians are trained to fulfill the product warranty and

provide after-warranty service, anywhere in the United

States and Canada.

Amana Brand Appliances

Customer eXperience Centre

Unit 200-6750 Century Ave

Mississauga, Ontario L5N 0B7

1-866-587-2002

Assistance ou Service

Avant de faire un appel pour obtenir de l’assistance ou un entretient, vérifier la section “Dépannage” ou consulter

www.amana.com/help. Cette vérification peut vous faire économiser le coût d’une visite de réparation.

Lors d’un appel, garder à portée de main la date d’achat et les numéros de modèle et de série de votre appareil.

Pour commander des pièces de rechange ou des accessoires

Pour commander des pièces de rechange, nous vous recommandons d’utiliser seulement

des pièces spécifiées par l’usine. Ces pièces conviendront et fonctionneront bien parce qu’elles sont fabriquées selon

les mêmes spécifications précises utilisées pour construire chaque nouvel appareil AMANA

Pour trouver des pièces de rechange FSP

Nos consultants fournissent

l’assistance pour :

■ Procédés d’utilisation et d’entretien.

■ Vente d’accessoires et de pièces de rechange.

■ Références aux concessionnaires, compagnies de service

de réparation et distributeurs de pièces de rechange

locaux. Les techniciens de service désignés par Whirlpool

sont formés pour remplir la garantie des produits et fournir

un service après la garantie, partout au Canada.

Si vous avez encore besoin d’aide, suivre les instructions ci-dessous.

Ces renseignements nous aideront à mieux répondre à votre demande.

®

ou des accessoires, visiter le www.amanacanada.ca.

Des questions? Composer le numéro sans frais 1-866-587-2002.

Pour plus d’assistance

Vous pouvez nous soumettre toute question ou toute

problème en écrivant à l’adresse ci-dessous :

Amana Brand Appliances

Centre pour l’eXpérience de la clientèle

Unit 200-6750 Century Ave

Mississauga, Ontario L5N 0B7

1-866-587-2002

Dans votre correspondance, veuillez indiquer un numéro

de téléphone où nous pouvons vous joindre dans la journée.

®

.

W10778944B

W10778945B - SP

®/TM

© 2016. All rights reserved. Used under license in Canada.

®/TM

© 2016. Tous droits réservés. Emploi sous licence au Canada.

02/16

Loading...

Loading...