Page 1

PTAC

NSTALLA TION INSTRUCTIONS

I

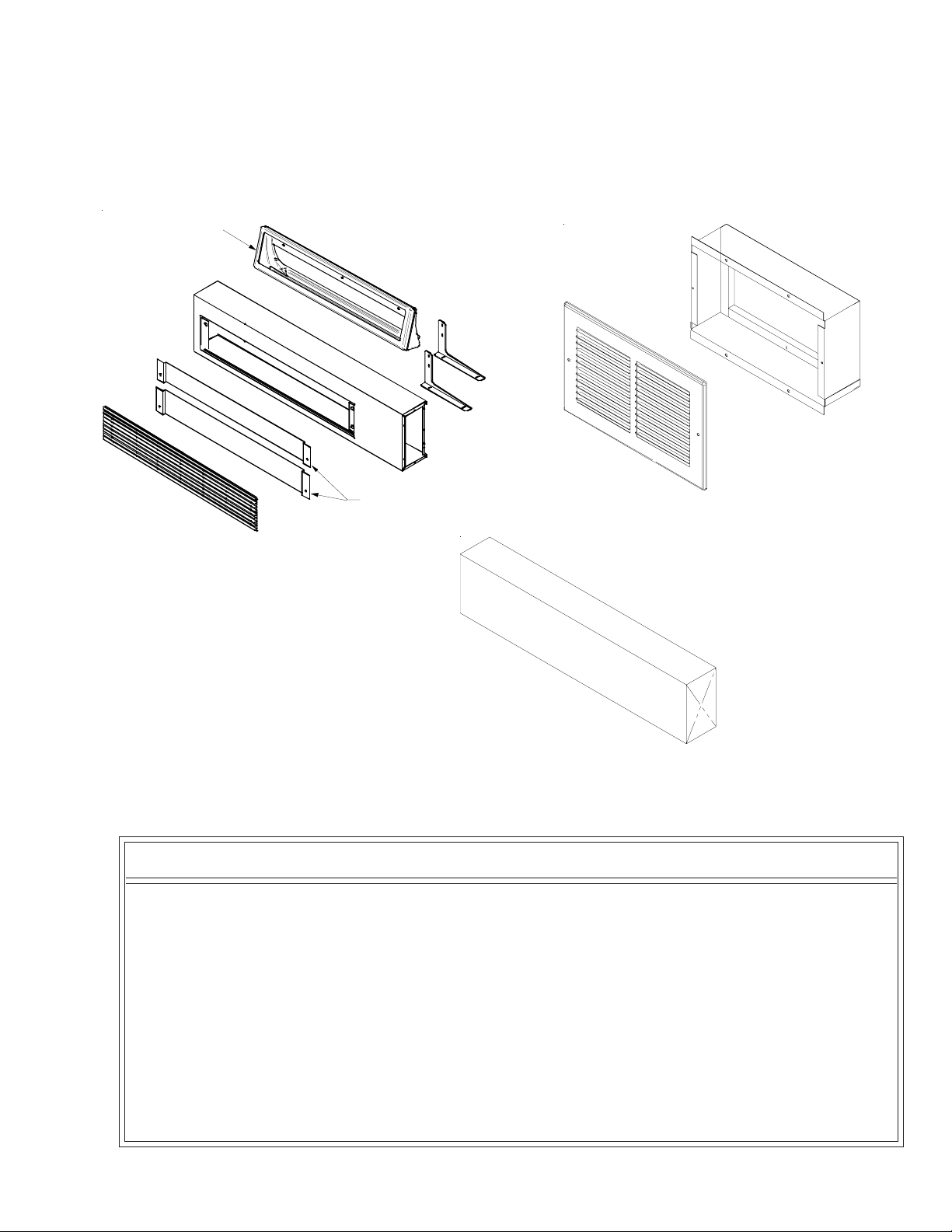

Extends air distribution to an adjoining room.

The kit consists of a main duct for the room of origin and an extension duct to reach the adjoining room, and terminal

duct. NOTE: All required hardware is provided within kit.

TRANSITION

BAFFLES

DUCT KIT

*

*

*

*

*

*

*

*

Terminal Duct Kit - TDK02

Main Duct Kit - MDK02

Extension Duct Kit - EDK02

ATTENTION INSTALLING PERSONNEL

As a professional installer you have an obligation to know the product better than the customer. This

includes all safety precautions and related items.

Prior to actual installation, thoroughly familiarize yourself with this Instruction Manual. Pay special

attention to all safety warnings. Often during installation or repair it is possible to place yourself in a

position which is more hazardous than when the unit is in operation.

Remember, it is your responsibility to install the product safely and to know it well enough to be able to

instruct a customer in its safe use.

Safety is a matter of common sense...a matter of thinking before acting. Most dealers have a list of

specific good safety practices...follow them.

The precautions listed in this Installation Manual are intended as supplemental to existing practices.

However, if there is a direct conflict between existing practices and the content of this manual, the

precautions listed here take precedence.

Part No. 1 1 1 13404

Printed in USA

September 2004

Page 2

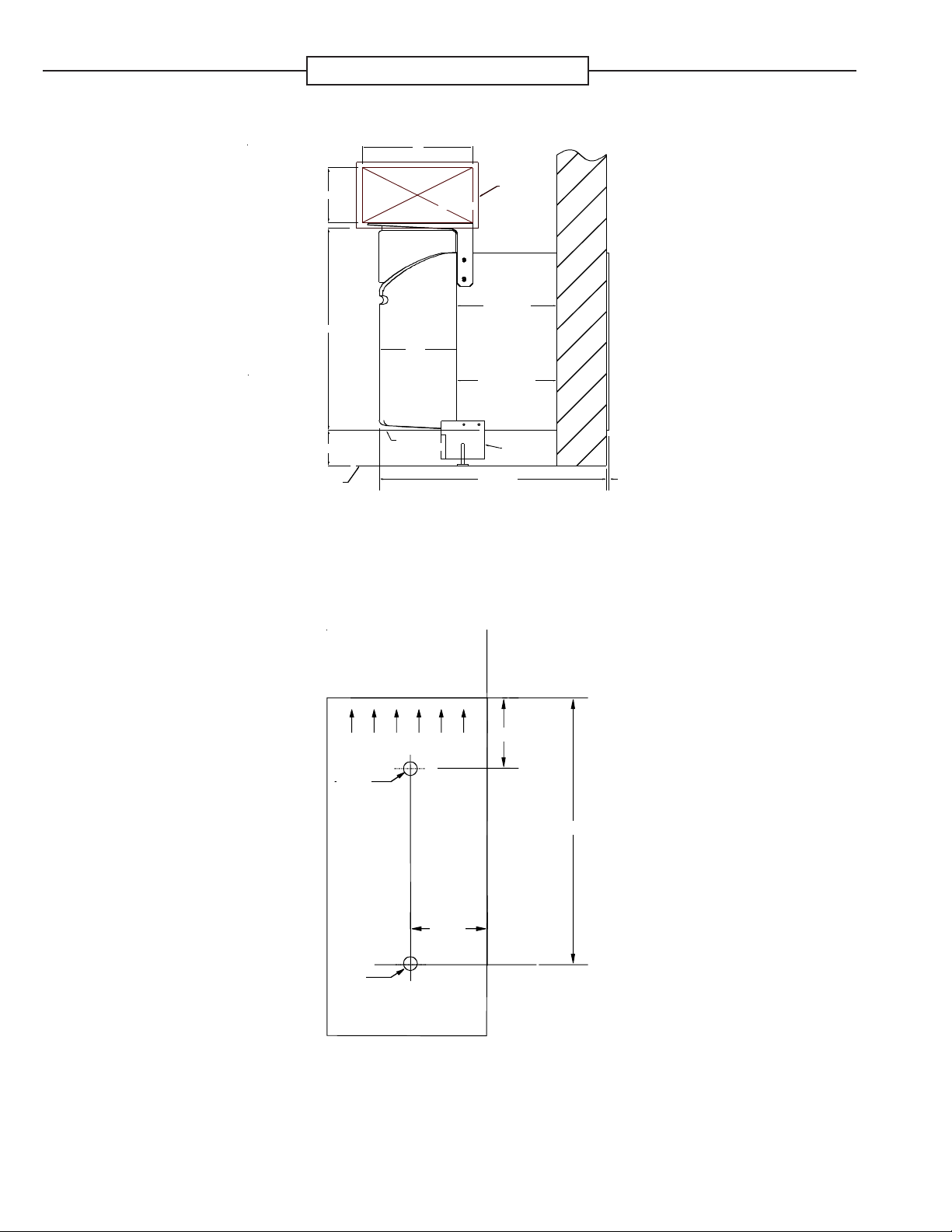

Installation Dimensions

10"

END OF

UNIT FRONT

7-1/2"

BOTTOM OF

WALL SLEEVE

DUCT

EXTENSION

5"

1/2"

TRANSITION

18-3/8"

3-1/4" MIN

FLOOR LINE

Installation Dimensions

INNER WALL

CUT-OUT

2-3/8" MIN

(FOR DUCT KIT)

WALL SLEEVE

2-3/4" MIN

(FOR SUBBASE KIT)

SUBBASE KIT

20-1/2" MAX

OUTSIDE

WALL

1/4" MIN

TOP

5/8"

Ø 1/8"

11/16"

Ø 1/8"

Hole Placement Template

2 3/8"

2

Page 3

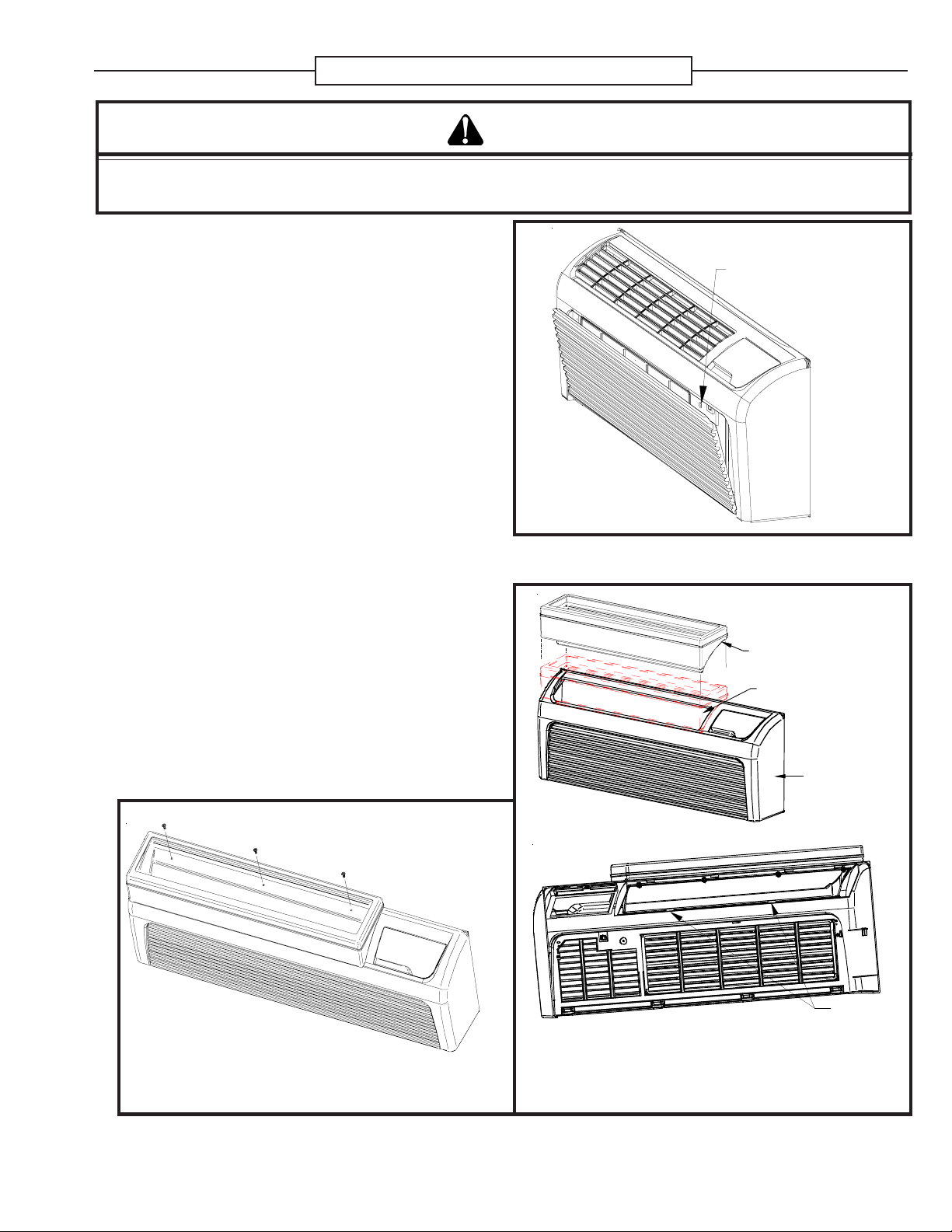

MDK Installation Instructions

WARNING

T o avoid the risk of personal injury or death due to electrical shock, disconnect power

source before removing the chassis.

PRE-ASSEMBLY [TRANSITION/FRONT]

1. If the cabinet front is screwed to the chassis, remove

the screw located behind the inlet grille. Pull the inlet

grille forward from the top of the grille to access two

screws.

2. Remove cabinet front from chassis by tilting the bottom of the front forward, lifting slightly up and forward.

3. Disengage discharge grille from cabinet front by removing four pal nuts from under the front

FRONT MOUNTING

HOLE

4. Place transition in air discharge opening of cabinet

front and secure with the provided U-clip.

5. Using 1/8” drill bit, pre-drill holes in front using the actual transition as a template. Fasten with three

screws. Do not overtighten.

Cabinet Front Removal

TRANSITION

AIR DISCHARGE

OPENING

CABINET

FRONT

`

Transition Assembly

3

U-CLIP

Page 4

MDK Installation Instructions

PRE-ASSEMBLY

(WALL SLEEVE) HOLE DIMENSION AND PLACEMENT

1. Unplug and remove chassis from wall sleeve. Drill two

1/8” holes on left and right sides of wall sleeve in

proper locations (see template on page 2).

2. Install chassis back into wall sleeve.

3. Install transition/front assemby on to chassis. Make

sure top of cabinet front catches metal flange on

chassis.

NOTE: If there is not enough clearance between

sleeve and partition wall to drill the holes, layout

and drill the holes from inside the sleeve.

1/8" HOLES

WALL

1/8" HOLES

WALL

SLEEVE

5/8"

2-3/8"

11/16"

INDOOR

5/8"

2-3/8"

11/16"

INDOOR

SLEEVE

Wall Sleeve Hole Placement

MDK ASSEMBLY

Determine if the duct is to be extended to the right of the

unit (where controls are located) or to the left of the unit

(opposite the controls).

For left side extensions remove the main duct end cap

and reinstall on the right end of the duct. Using the four

painted sheetmetal screws, secure the two mounting

brackets to the main duct.

Two mounting slots are provided in each bracket. To

mount extension on right side, adjust bracket so the

screws are in left side of bracket slots; for mounting

extension on the left, adjust brackets so the screws are

in right side of slots.

On right side extensions shift the brackets to the right.

For left side extensions shift the brackets to the left.

Mounting Brackets Installation

LEFT SHIFT

RIGHT SH IFT

4

Page 5

Air Baffle Installation Instructions

1. Determine amount of air desired at main duct and at

extension duct. Using the table provided, select the

appropriate baffle.

DISCHARGE

AIR GRILLE

BAFFLE DIMENSIONS

AIRFLOW

MAIN DUCT EXT. DUCT

Small 3 11/16" x 31 3/4" 80% 20%

Large 4 5/16" x 31 3/4" 65% 35%

Table 1

2. Place baffle on grille support brackets on main duct.

Ensure the two extruded holes of the baffle are on top

of the front bracket holes.

3. Install discharge air grille on top of the air baffle. Secure the grille to the duct with pal nuts (provided) by

reaching through the opening in the bottom of the

duct.

4. Place main duct assembly on the transition. Secure

the brackets to the wall sleeve with four #10 hex head

screws. Do not apply pressure on top of duct during

this installation!

SUPPORT

BRACKETS

Air Grille Installation

M

D

K

T

R

A

AIR BAFFLE

A

S

S

E

M

B

L

Y

N

S

I

T

I

O

N

5. Install two Phillips head screws into the top flange of

the main supply duct at extension duct connection.

Do not tighten screws. Leave space for one thickness

of the duct sheet metal between screw head and

main duct flange.

NOTE: Total length of duct extension assembly, including field

supplied duct between main and extension duct, should not exceed

15 effective feet (according to ASHRAE standards). For additional

dimensions, refer to Main Duct and Duct Extension Dimensions

illustration.

MDK Installation Onto Transition Assembly

Main Supply Duct Top Flange

5

Page 6

Air Baffle Installation Instructions

6. In the room where the main duct kit is attached to the

chassis, cut a hole in the wall at the same height from

the floor that the main duct is located. Cut the hole 1/

8” larger than the width and height (10” x 5”) dimensions of the extension duct.

7. Measure from the end of the main duct where the extension duct will be connected to the hole in the wall.

If necessary cut the extension duct to a length where

the cut end protrudes into the wall’s inner space and

one inch from the adjoining room’s wall surface.

8. Insert the extension duct into the opening in the wall.

Install the extension duct by placing the slotted flange

over the two screws in the main duct. Using two #8

round Phillips head screws, mount bottom of extension duct to mounting bracket through the bracket slot

(see Main Supply Duct Top Flange illustration).

NOTE: The EDK02 can be cut into two sections and

used with two MDK02s if the needed length does not

exceed 21-1/4”.

PARTITION

WALL

DUCT

TERMINATION

AIR FLOW

1" to

adjoining

wall

surface

KIT

BRACKET

42-27/32" 6" TO 42-1/2"

AIR FLOW

5"

TRANSITION

DUCT

MAIN DUCT

DUCT EXTENSION

BRACKET

MINIMUM

5"

BOTH SIDES

Main Duct and Duct Extension Dimensions

6

Page 7

TDK Installation Instructions

IMPORTANT NOTE

ANY FIELD-SUPPLIED GRILLE, MUST HAVE FIXED LOUVERS THAT CANNOT BE CLOSED.

The sheet metal collar of the terminal duct kit must be mounted in the wall of the adjoining room opposite the room

where the main duct kit is attached to the PTAC chassis.

1. Cut a hole in the wall of the adjoining room such that

the hole is centered on the extension duct that is currently in the wall of the opposite room. See wall hole

dimensions illustration for sheet metal collar.

2. Insert the sheet metal collar into the wall so that the

flanges will mount flush to the wall after the collar is

pushed all the way into the wall. While pushing the

collar into the wall make sure the extension duct is inside the collar. Use four #8 screws to attach metal

collar to wall.

11-1/4"

6-1/4"

Wall Hole Dimension

11"

GASKET

6"

3. Center the metal grille over the sheet metal collar and

use two #8 screws (provided) to attach the grille to

the metal collar .

Sheet Metal Collar

USE

TWO

#8 SCREWS

Metal Grille

7

Loading...

Loading...