Page 1

IC53

International

Top Mount

Refrigerator

Ice Maker Kit

Installation and

®

Operating

Instructions

Page 2

2

Page 3

Contents

Introduction ...............................................................3

Tools Required ..........................................................3

Safety Instructions ....................................................3

Materials Required ....................................................3

Parts .........................................................................5

Installation Instructions..............................................6

Operating Instructions ............................................. 10

Before Calling For Service ...................................... 10

Warranty ................................................................. 11

Safety Instructions

WARNING

To avoid electrical shock which can cause severe

personal injury or death, unplug power cord or open

household circuit breaker to refrigerator before

installing kit. After installing kit, reconnect power.

Introduction

Recognize this symbol as

a safety precaution.

Read entire manual before installing kit. All necessary

tools and materials must be available prior to

installation. Verify all listed parts are included in kit. If

parts are missing, contact source from whom kit was

purchased.

• Mechanical experience is required to install kit.

• Depending on installer’s knowledge and skill,

installation can take from 3 to 6 hours.

• If unable to solve a problem during installation,

contact an authorized Amana technician. Locate a

Factory Service Center or independent authorized

technician by calling 1-800-628-5782 inside U.S.A.

and 1-319-622-5511 outside U.S.A. Service is at

owner’s expense.

CAUTION

To avoid property damage, observe the following:

• Confirm water pressure to water valve is at

least 20 pounds per square inch.

• Start nuts by hand to avoid cross threading.

Finish tightening nuts using wrenches. Do not

overtighten.

• Check carefully for water leaks prior to

returning refrigerator to normal location and 24

hours after connection.

Materials Required

Important

• Before connecting ice maker, contact a plumber to

connect copper tubing to household plumbing in

compliance with local codes and ordinances.

• Amana recommends using a saddle valve. Do not

use self-piercing valve. Amana is not responsible

for property damage due to improper installation or

water connection.

Tools Required

• 9.65 mm (3/8") Electric drill (ground fault protected)

• 9.65 mm (3/8") Drill bit

• 6.35 mm (1/4") Hex nut driver

• 12.7 mm (1/2") Open-end wrenches (2)

• Bucket

• Tight fitting gloves

• Putty knife

• Masking tape

• Pliers

• Screwdriver

• Slip joint pliers

• Towel

6.35 mm (1/4") flexible copper tubing*.

*Length of copper tubing must reach from water supply

connection plus an additional 3 m (9.8') for service loop

behind refrigerator. Tubing should be soft instead of

rigid and ends should be free of burrs.

3

Page 4

7

16

14

11

20

6

9

19

5

3

8

1

2

13

12

4

10

15

18

17

4

Page 5

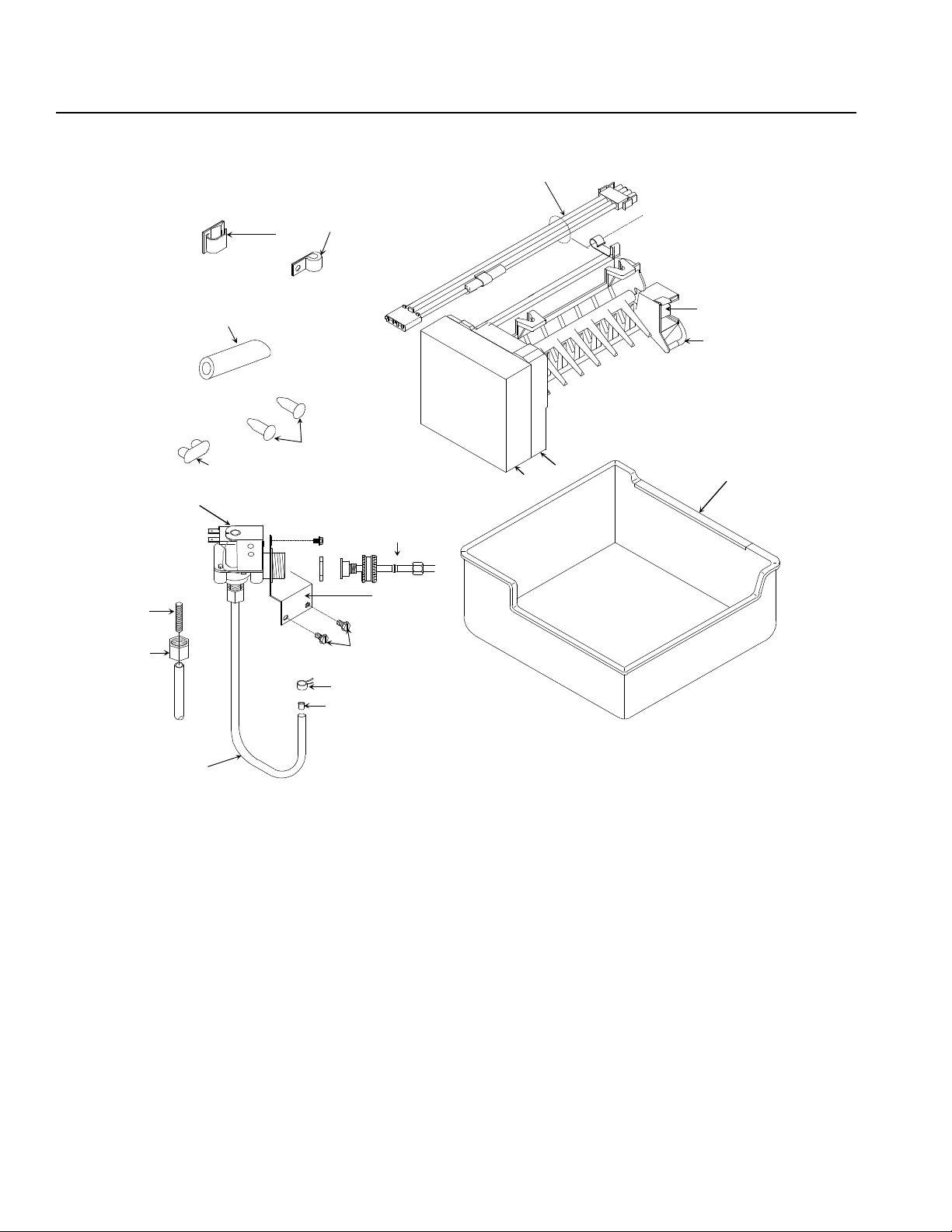

Parts

Use listed part numbers only when ordering replacement parts. Part numbers are not used in installation

instructions.

Item Description Part number Quantity

1 Ice maker D7846302 1

2 Ice maker cover B5724506 1

N/S Ice maker cover label 10285801 1

N/S Warning label A3036901 1

N/S Water pressure label B8361202 1

3 Ice maker arm 10884401 1

N/S Ice maker shield D7846203 1

4 9 mm (3/8”) long cutting screw M0251015 4

5 Stainless steel clip B5720302 1

6 Water fill tube extension A3127401 1

7 Ice maker wire harness 10179201 1

N/S Ice maker power cable C8949201 1

N/S Thermal fuse clip (attached to ice maker) 10319801 2

N/S 15 mm (5/8”) long sheet metal screw M0211018 2

8 Button plug M0311301 2

9 Oblong plug A3124301 2

10 Ice storage bucket D7621116 1

11 Water valve D7847801 1

N/S Water valve cable 10179101 1

12 Water valve mounting bracket D7701602 1

13 Water valve adaptor assembly 10244902 1

14 Nylon nut and sleeve M0753001 1

N/S 9 mm (3/8”) long sheet metal screw M0211016 3

15 6.35 mm (1/4”) O.D. plastic tubing B5705308 1

16 Anti-kink spring A1055101 1

17 Stainless steel insert A3223101 1

18 Hose clamp M0114003 1

19 “P” clamp M0108001 1

20 Plastic clamp M0104101 1

N/S Plastic clip M0104102 2

N/S Installation instructions 10527016 1

5

Page 6

Installation Instructions

1.Turn off water supply to refrigerator.

CAUTION

To avoid property damage, protect flooring with

cardboard, rugs, or other protective material when

moving refrigerator.

2. Move refrigerator away from wall.

3. Seal open end of copper tubing with tape to keep

inside of tubing clean. Route copper tubing up to

refrigerator through floor or interior wall behind

refrigerator providing 9 mm (3/8") holes as

required. Copper tubing route must be above 2°C

(35°F) to prevent water line from freezing.

4. Secure water valve mounting bracket behind

square collar on water valve inlet.

Water valve

inlet collar

Earthing

wire

Mounting

bracket

5. Slide plastic tubing through nut. Insert spring into

plastic tubing. Large coil must face out. Do not

force large coil into plastic tubing. Large coil

prevents spring from slipping through plastic tubing.

Spring will prevent plastic tubing from kinking.

Large coil

Plastic nut

Plastic tubing

6. Push end of plastic tubing with spring into bottom

water valve fitting. Tighten nut with a pliers.

7. Remove lower horizontal and top vertical covers on

rear of refrigerator cabinet by removing screws with

a 6.4 mm (1/4") hex nut driver.

8. Connect electrical wiring plug to water valve spade

terminals. Connect earthing wires to water valve

and water valve bracket.

Electrical

wiring plug

Water

valve

WARNING

To avoid electrical shock which can cause severe

personal injury or death, earthing wire must be

properly attached to both bracket and water valve.

9. Secure water valve to two predrilled holes in lower

rail of refrigerator cabinet with two 9 mm long

cutting screws and 6.4 mm (1/4") hex nut driver.

10. Remove cap from bottom of water inlet fitting

located on back upper right corner of cabinet.

6

Page 7

11. Push stainless steel insert into open end of plastic

tubing. Stainless steel insert must be flush with end

of plastic tubing. Hold hose clamp open with pliers

and slide hose clamp over stem of water fitting.

Push end of plastic tubing 15 mm (5/8") into water

fitting stem and release hose clamp. Confirm

plastic tubing is secure by pulling on plastic tubing.

Water inlet

fitting

Hose clamp

Stainless steel

insert

13. Connect three terminals of water valve electrical

cable to terminal block: green/yellow to ground,

blue to neutral, and red to power. Remove bottom

screws that hold cable restraint. Reinstall terminal

cover by reversing procedure in step 18.

Green/Yellow

Red

Blue

12. Remove top two terminal cover screws using 6.35

mm (1/4") hex socket and driver. Pull terminal

cover upwards and remove. Terminal is located on

back of refrigerator near lower left corner.

6.35 mm

(1/4") screws

Terminal

block

14. Remove tape from copper tubing. Put other end of

copper tubing into sink or bucket. Open saddle

valve slightly. Water will be under considerable

pressure. Allow water to run through copper tubing

for 1 minute to flush out saddle valve and copper

tubing. Turn off saddle valve when flushing is

complete.

15. Slide brass nut and sleeve over end of copper

tubing. Insert copper tubing completely into adapter

fitting. Confirm hose washer is in place by checking

fitting. Tighten adapter fitting nut by hand as much

as possible. Carefully tighten an additional 1/3 turn

with pliers. Tighten brass nut on copper tubing to

adapter fitting with 2 wrenches. Confirm copper

tubing is secure by pulling on copper tubing.

Adaptor fitting

nut

Brass

nut

Hose

washer

Brass

sleeve

16. Open saddle valve 1 turn counterclockwise and

check for leaks. If water leaks, turn off water valve

and correct leaks. Repeat this process until no

leaks are found, then completely open saddle

valve.

7

Page 8

17. Slide ice service rack in freezer toward front of

freezer until screws are in middle of mounting

holes. Gently pull ice service rack away from

freezer. Remove screws with 6.4 mm (1/4") hex nut

driver. Insert plugs into screw holes.

18. Remove freezer shelf.

19. Remove button plugs from side wall with a putty

knife covered with masking tape. Discard button

plugs.

20. Remove back panel screws and button plug.

21. Remove ice maker from shipping carton. Discard

packing material.

22. Models with Four Wire Connector Behind Back

Wall

Insert ice maker receptacle into opening in back

wall. Snap ice maker receptacle in place. Discard

four wire connectors. Reinstall back wall by

reversing procedure in step 20.

23. Top Freezer Models

Slide water fill tube extension over water inlet tube

on rear wall. Water fill tube extension must fit

tightly and be even with hole in rear wall so water

cannot leak into freezer.

Water fill tube

extension

Ice maker

receptacle

Snap in place

here

Models without Four-Wire Connector Behind

Back Wall

Attach 6.35 mm (1/4") terminals to terminal board.

Insert ice maker receptacle into opening in back

wall. Snap ice maker receptacle in place. Discard

four wire connectors. Reinstall back wall by

reversing procedure in step 20.

24. Remove ice maker from shipping carton and

discard packing material.

25. Install straight end of ice maker arm in round hole

in water cup. Insert other end in elongated hole

only; not into round holes in black ice maker

housing. Ice maker arm must be even with ice

maker surface.

Ice maker arm

insertion

8

Page 9

26. Hold ice maker in position. Insert wire harness plug

into receptacle on rear wall. Ice maker can only be

installed one way. Do not drill additional holes.

Secure ice maker with two 15 mm long sheet metal

screws and a 6.35 mm (1/4") hex nut driver.

Wire harness

plug

Sheet metal

screw

Ice maker

hanger

Wire harness

receptacle

28. Replace freezer shelf. Position ice storage bucket

on freezer shelf under ice maker. Slide freezer shelf

on ice storage bucket.

29. Check for leaks at water valve and saddle valve.

Correct any leaks. Carefully tuck wires inside cover

to avoid pinching wires. Replace lower back and

top vertical cover by placing cover on refrigerator

cabinet. Insert and tighten screws with a 6.4 mm

(1/4") hex nut driver.

30. Create service loop with copper tubing using

extreme care to avoid kinks. Secure copper

tubing at back horizontal cover using “P”

clamp. Copper tubing must not extend 9 mm

(3/8") beyond back.

Service

loop

27. Push down on water fill tube extension until water

fill tube extension fits securely into “U” opening.

Place free end of water fill tube extension under

stainless steel clip. Water fill tube extension must

extend 13 mm (1/2") into “U” opening without

kinking.

13 mm (1/2")

Stainless steel

clip

Water fill tube

extension

"P" clamp

CAUTION

To avoid property damage, all covers must be in

place.

31. Move refrigerator in place and level if necessary.

CAUTION

To avoid property damage, protect flooring with

cardboard, rugs, or other protective material when

moving refrigerator.

9

Page 10

Operating Instructions

Before Calling For Service

• Confirm ice bucket is in place and ice maker arm is

down.

Off position

On position

• After freezer section reaches normal temperature,

ice maker fills with water and begins operating.

Allow 24-48 hours after installation before first

harvest of ice. Ice maker produces 6 to 7 harvests

of ice in a 24-hour period under ideal conditions.

• After ice is formed, ice maker drops ice cubes into

ice storage bucket. During ice production, ice

maker arm raises and lowers. When ice storage

bucket is full, ice maker arm turns ice maker off.

Discard first 3 harvests of ice after initially

connecting refrigerator to household water supply

and after extended periods of non-use.

• Stop ice production by lifting ice maker arm. A

definite click is heard when proper position is

reached. Ice maker arm will remain in that position

until pushed down.

Allow ice maker 1 overnight period to make ice before

assuming a difficulty exists.

If ice maker is not producing ice

• Check electrical connections to water valve coil and

connector block on refrigerator cabinet.

• Confirm freezer is operating at proper temperature.

• Confirm ice maker arm is down.

• Confirm household water supply is reaching water

valve.

• Confirm ice maker wiring harness is completely

inserted into proper electrical contacts.

• Check for kinks in copper or plastic tubing.

Remove kinks or replace tubing.

If ice maker is not producing enough ice

• Ice maker produces 6 to 7 harvests of ice in a

24-hour period under ideal conditions.

• See above section.

If ice maker makes unfamiliar sounds.

• These may be normal. Refer to “Normal Operating

Sounds” section in Owner's Manual.

CAUTION

To avoid damage to ice maker, observe the

following:

• Do not force ice maker arm down or up.

• Do not place or store anything on ice maker or

in ice storage bucket.

10

Page 11

Warranty

First Year

Manufacturer will provide a free replacement part, f.o.b. Amana, Iowa, U.S.A., for any part which is

defective due to workmanship or materials.

Ice Maker

Limited One Year Warranty

Warranty Limitations

• Begins at date of original purchase.

• Service must be performed by an authorized

Amana® technician.

Warranty Is Void If

• Product is used on a commercial, rental or

leased basis.

• Product has defect or damage due to an

accident, fire, flood, connection to an improper

electrical or water supply, lightning, product

alteration, shipping and handling, or other

conditions beyond the control of Amana.

• Product is improperly installed or used.

Owner's Responsibilities

• Provide proof of purchase (sales receipt).

• Provide normal care and maintenance. Replace

owner replaceable items where directions appear

in Owner's Manual and Installation Instructions.

• Make product reasonably accessible for service.

• Pay for premium service costs for service

outside technician's normal business hours.

• Pay for service calls related to product

installation or usage.

In no event shall Amana be liable for incidental

or consequential damages

11

Page 12

Part No. 10527016

Printed in U.S.A.

1996 Raytheon Appliances

Amana, Iowa 52204

Loading...

Loading...