Amana P1311102W, ESU15JW, P1311103W, ESU20JW, P1311104W Service Manual

...

Service

Upright Freezers

Models and manufacturing

numbers in this manual

ESU12JW P1311101W

ESU15JW P1311102W

ESU17JW P1311103W

ESU20JW P1311104W

ESUF15JW P1311105W

ESUF17JW P1311106W

ESUF20JW P1311107W

ESU12JW P1179615W

ESU15JW P1179616W

ESU17JW P1179617W

ESU20JW P1179618W

ESUF15JW P1179619W

ESUF17JW P1179620W

ESUF20JW P1179621W

AU120KW P1317701WW

AU120KW P1317714WW

AU150KW P1317702WW

AU150KW P1317715WW

AU170KW P1317703WW

AU170KW P1317716WW

AU200KW P1317704WW

AU200KW P1317717WW

AUF150KW P1317705WW

AUF150KW P1317718WW

AUF170KW P1317706WW

AUF170KW P1317719WW

AUF200KW P1317707WW

AUF200KW P1317720WW

This manual is to be used by qualified

appliance technicians only. Amana does not

assume any responsibility for property damage

or personal injury for improper service

procedures done by an unqualified person.

RS1500000

Revision 2

November 1999

Important Information

Pride and workmanship go into every product to provide our customers with quality products. It is possible,

however, that during its lifetime a product may require service. Products should be serviced only by a qualified

service technician who is familiar with the safety procedures required in the repair and who is equipped with

the proper tools, parts, testing instruments and the appropriate service manual. REVIEW ALL SERVICE

INFORMATION IN THE APPROPRIATE SERVICE MANUAL BEFORE BEGINNING REPAIRS.

Important Information

Important Notices for Consumers and Servicers

!

To avoid risk of serious injury or death, repairs should not be attempted by an unauthorized personal, dangerous

conditions (such as exposure to electrical shock) may result.

!

Amana will not be responsible for any injury or property damage from improper service procedures. If performing

service on your own product, assume responsibility for any personal injury or property damage which may result.

To locate an authorized servicer, consult your telephone book or the dealer from whom you purchased this product.

For further assistance, contact: 1 (800) 628-5782 first, if no answer call number listed below.

CONSUMER AFFAIRS DEPT. OR 1 (800) 843-0304

AMANA APPLIANCES CALL

AMANA, IOWA 52204

If outside the United States contact:

AMANA

ATTN: CONSUMER AFFAIRS DEPT

AMANA, IOWA 52204, USA

Telephone: (319) 622-5511

Facsimile: (319) 622-2180

TELEX: 4330076 AMANA

CABLE: "AMANA", AMANA, IOWA, USA

WARNING

CAUTION

Recognize Safety Symbols, Words, and Labels

DANGER

!

DANGER - Immediate hazards which WILL result in severe personal injury or death.

WARNING

!

WARNING - Hazards or unsafe practices which COULD result in severe personal injury or death.

CAUTION

!

CAUTION - Hazards or unsafe practices which COULD result in minor personal injury or product or property

damage.

RS1500000 Rev 2 2

Table of Contents

Important Information ................................................. 2

Model Identification .................................................... 4

Installation Instructions

Unpacking ............................................................... 5

General ................................................................... 5

Location................................................................... 5

Electrical Connection ............................................... 5

Door Handle ............................................................ 6

Leveling ................................................................... 6

Test After Installation ............................................... 6

General Instructions

Electrical Requirements .......................................... 7

Asure Extended Service Plan .............................. 7

Proper Disposal of your Freezer .............................. 7

Model Identification ................................................. 7

Operating Instructions

Setting Controls ....................................................... 8

Temperature Control ............................................... 8

Audible Alarm (Some models) ................................. 8

Features .................................................................. 9

Reversible Rack (some models) ............................. 9

Freezing Guide ........................................................ 9

Care and Cleaning

General ................................................................. 10

Adhesives.............................................................. 10

Door Gaskets ........................................................ 10

Odor Removal ....................................................... 10

Defrosting .............................................................. 11

Light Bulb (some models) ...................................... 11

General Tips

Energy Tips ........................................................... 12

Vacation Tips ......................................................... 12

Normal Operating Sounds ..................................... 12

Before Calling For Service..................................... 12

Operating Sounds ................................................. 13

Component Testing

Refrigeration System Test Procedures .................. 14

Testing Main Condenser ........................................ 15

Testing for Leaks ................................................... 16

Electrical System ................................................... 16

Compressor Electrical Tests.................................. 16

Testing Compressor Direct .................................... 16

Capacitor ............................................................... 17

Overload Protector ................................................ 17

Testing Overload Protector .................................... 17

PTC Relay ............................................................. 18

Testing PTC Relay................................................. 18

Interior Light and Switch ........................................ 18

Checking Control Operation .................................. 18

Temperature Control ............................................. 19

Defrost Timer ........................................................ 19

Checking Timer ..................................................... 20

Defrost Heater and Thermostat

No Defrosting Models ............................................ 20

Freezer Fan No-Defrosting Models ....................... 21

Testing Freezer Fan Motor .................................... 21

Troubleshooting................................................... 23-25

Disassembly Procedures

Replacing Dryer..................................................... 26

Replacing Compressor .......................................... 26

Replacing Heat Exchanger

Refrigerated Shelf Model ....................................... 27

Replacing Heat Exchanger

No-Defrosting Models............................................ 28

Replacing Freezer Shelving

Refrigerated Shelf Models ..................................... 29

Replacing Freezer Coil No-Defrosting Models ....... 30

Replacing Light Switch .......................................... 31

Replacing Control .................................................. 31

Replacing Heater................................................... 32

Replacing Freezer Fan Motor ................................ 32

Cabinet Door Assembly ......................................... 33

Door Handle .......................................................... 34

Door Lock Assembly ............................................. 34

Removing Door Lock Assembly ............................ 35

Cabinet Door Alignment ........................................ 35

Checking Gasket Seal ........................................... 35

Improving Gasket Seal .......................................... 35

Hinge Adjustments ................................................ 35

Cabinet Assembly ................................................. 36

Service Information

System Operation.................................................. 37

Checking Operational Pressures ........................... 38

Operational Testing ............................................... 39

Service Hints ......................................................... 39

Refrigeration System Complaints .......................... 40

Refrigerant Leaks .................................................. 41

Evacuation and Charging Procedures ................... 42

HFC134a Service Information ............................... 43

Health, Safety, and Handling ................................. 44

Drier Replacement ................................................ 44

Replacement HFC134a Service Compressor........ 45

Refrigerant Charge ................................................ 45

Leak Testing .......................................................... 45

Evacuation and Charging ...................................... 45

Dehydrating Sealed Refrigeration System ............. 47

Brazing .................................................................. 47

Refrigerant Precautions ......................................... 47

Open Lines ............................................................ 47

Line Piercing Valves .............................................. 48

Altitude Adjustment ............................................... 48

Cabinet Shell ......................................................... 49

Cabinet Liner (Food) ............................................. 49

Drain System ......................................................... 49

Wiring Diagram and Schematic ........................... 50-52

3 RS1500000 Rev. 2

Model Identification

Upright freezer models vary in trim and accessories,

but all models have the same basic construction.

"Operating Instructions" and "Service Instructions"

apply to all cabinets unless stated otherwise.

1997 Model Identification

ESU F 15 J W

Color

W White

Series

H

J

Storage Capacity

12 Cubic Foot

15 Cubic Foot

17 Cubic Foot

20 Cubic Foot

Defrost Type

Blank Manual

F Free-O-Frost

Product

ESU Energy Saving Upright Freezer

For positive identifications of individual units, state

complete serial number, model, and type. This

information is found on the serial plate located on front

upper right hand corner of foodliner or on some

models, exterior back of the outer casing.

An explanation of coding contained in Type position is

shown below.

1998 and 1999 Model Identification

A U F 7 0 K W

Color

W White

Series

K

Feature Level

0 Good

Storage Capacity

7 Cubic Foot

10 Cu bic Foot

15 Cubic Foot

22 Cubic Foot

Defrost Type

Blank Manual

F Free-O-Frost

Product

U Upright Freezer

RS1500000 Rev. 2 4

Amana

Installation Instructions

Unpacking

Remove all protective packaging. Cardboard shipping

braces and/or protective tape used to prevent damage to

baskets, shelves, speciality racks, and compartment

dividers during shipment. Use soapy water to remove

any adhesive residue. Do not use alcohol or nail polish

remover.

Door/Lid, handles, and hinges:

Support and secure door lid before transporting or

moving the freezer.

Install freezer handle if applicable

Do not use door or handle for leverage to lift or push

unit.

Defrost drain plug and drain pan:

Verify drain plug is installed on non-frost-free

freezers

Before operating frost-free freezer verify frost drain

pan is installed behind toe grille located at bottom

front of freezer with drain hose placed in the pan.

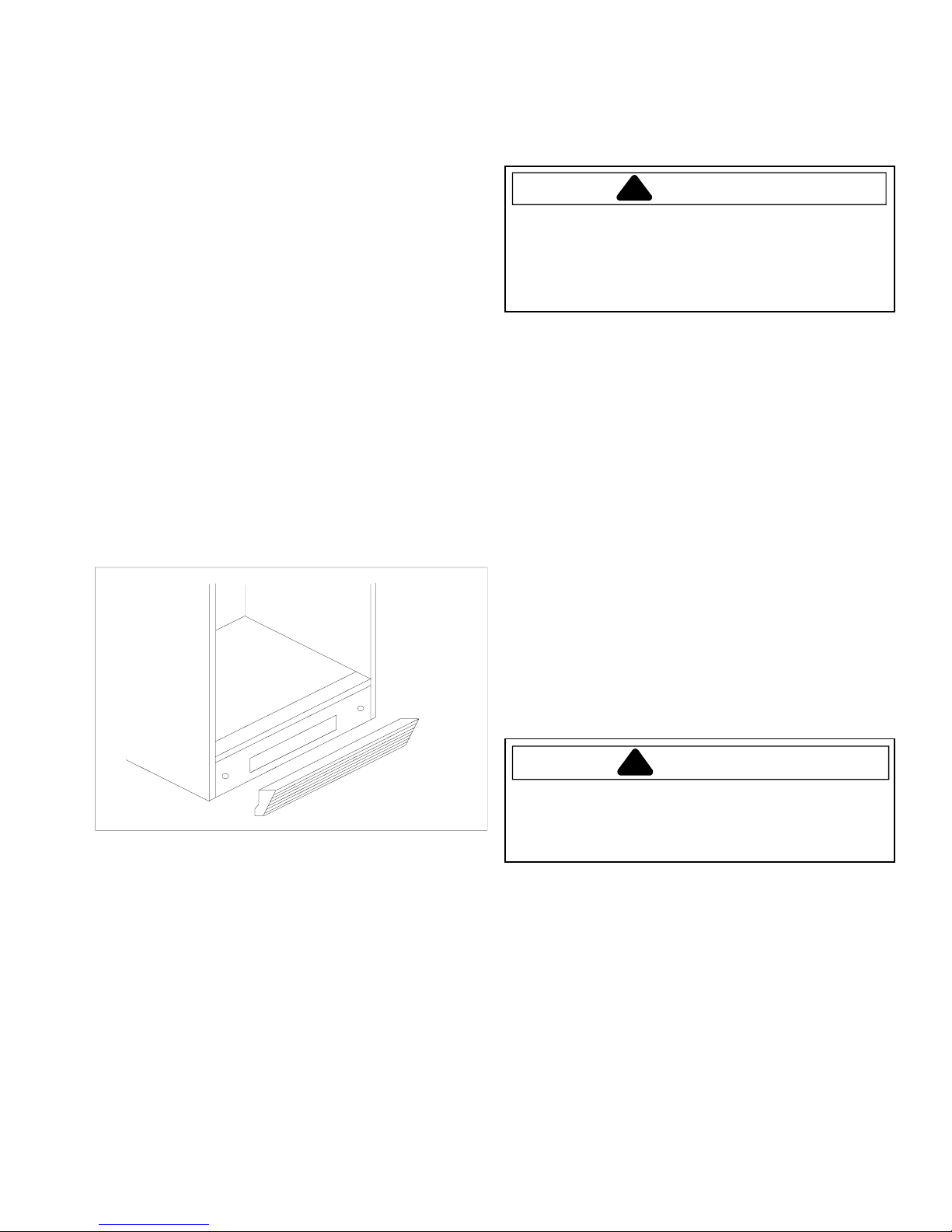

Toe grille:

Toe grille at bottom front of freezer can be removed

to locate drain tube and levelling gliders.

Remove toe grille by grasping both ends and pulling

straight outward. Replace by pressing ends of toe

grille into slots on cabinet and snapping into place.

Location

These recommendations and explanations may help

customer receive maximum efficiency from freezer and

avoid service calls.

CAUTION

!

To avoid personal injury, wear gloves when installing

freezer.

To avoid property damage, protect soft vinyl or other

flooring with cardboard, rugs or other protective

material during installation or servicing.

If freezer is to be placed in basement, back porch, etc.,

place freezer on wooden slats up off floor.

1. Freezer is designed for installation as a

"freestanding" (not "built-in") unit.

2. Locate freezer with at least 3 inches of clearance on

both ends and back to provide adequate air

circulation to dissipate condenser heat.

3. Avoid locations near stoves, radiators, hot air ducts,

or where sun may cause excessive heat.

4. Do not locate where surrounding temperature could

drop below 32°F (0°C). Temperatures below 32°F

(0°C) cause compressor oil to thicken delaying

lubrication of sensitive components at compressor

start-up.

5. Avoid placing freezer on plush carpet which may

retard air flow over bottom, causing bottom sweating.

Toe grille

General

Secure door before moving freezer. Do not use door

or handle to lift or push freezer. If hinges must be

removed, check instruction label on rear of freezer

cabinet.

Amana freezers are currently rated for domestic use,

not designed for commercial application.

Confirm the following items are installed.

Free-O-Frost Upright Freezer Models

Defrost drain pan behind toe grille.

Standard Upright Freezer Models

Drain plug in bottom front of freezer liner.

(some models)

Electrical Connection

1. Electrical supply should be checked for proper

voltage and ground.

WARNING

!

Do not, under any circumstances, cut or remove the

round grounding prong from the plug. Freezer must

be grounded at all times. Do not remove warning tag

from power cord.

2. Avoid extension cords. If absolutely necessary, use

an Appliance Extension cord (at least

16 AWG) of less than 10 feet. If possible, have

freezer on separate circuit.

5 RS1500000 Rev. 2

Installation Instructions

Door Handle

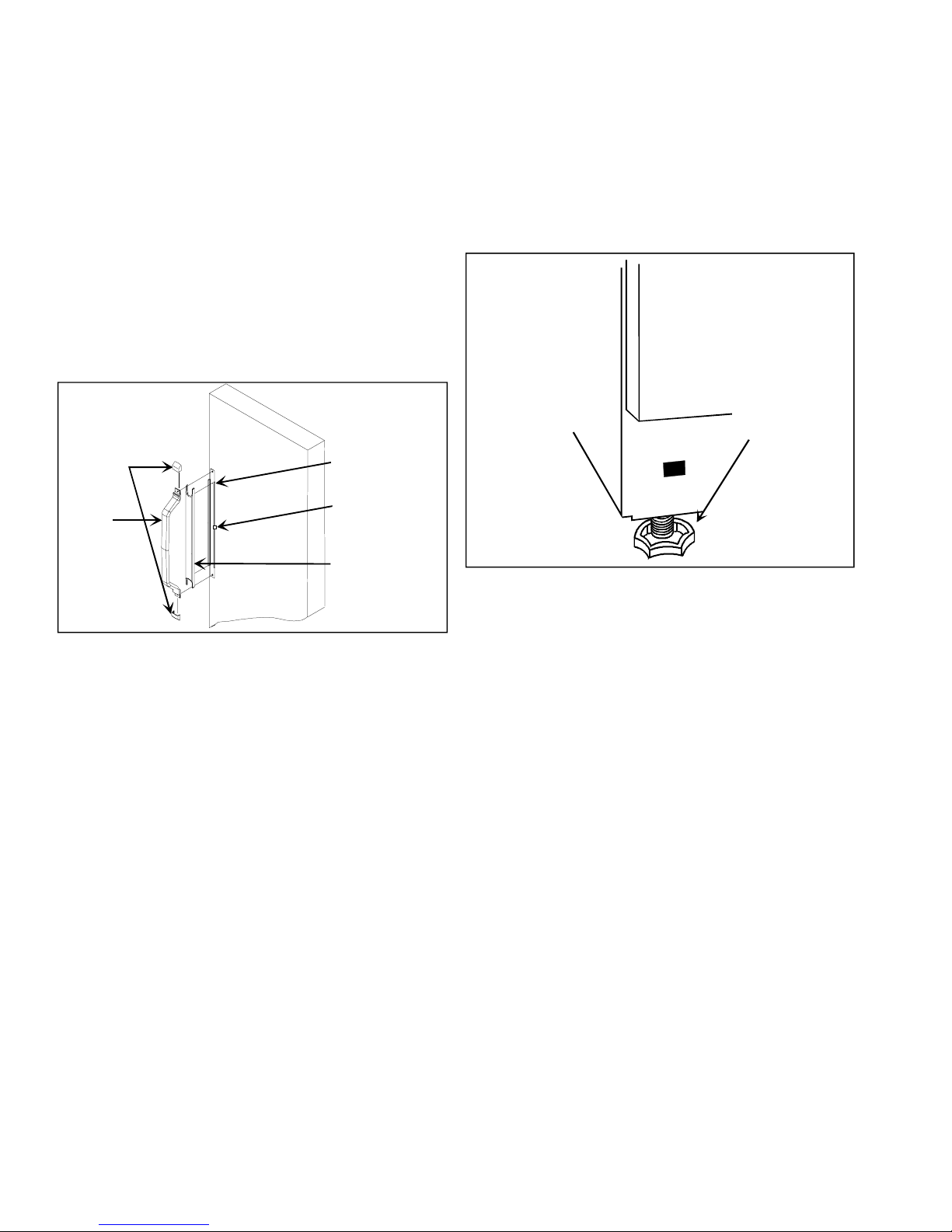

1. If handle trim has not been factory installed,

slide right edge of handle trim under right edge

of trim retainer. Verify rib on right inside edge of

handle trim fits into trim retainer notch. Snap outside

edge of handle trim over outside edge of trim

retainer.

2. Install handle on freezer door as shown. Verify

freezer handle is angled inward towards opposite

side of freezer. Secure handle to freezer door with

screws provided. Verify screws are secure.

3. Slide end caps over ends of handle until end

caps snap in place. End cap marked L goes on

top end of handle. End cap marked R goes on

bottom end of handle.

End

caps

Handle

Trim

retainer

Trim retainer

notch

Leveling

1. Install leveling legs under front corners behind toe

grille.

2. Level freezer side to side and tilt freezer 1/4" from

front to back. Turn legs clockwise to raise freezer and

counterclockwise to lower freezer. If freezer cannot

be level due to flooring, use shims under rear of

freezer cabinet to level freezer.

Leveling

foot

Handle trim

3. Check freezer 2 or 3 weeks after loading with food

and confirm freezer is level.

Test After Installation

1. For proper compressor operation, voltage must be

measured at the compressor terminals at the

moment of starting. Voltage must be in the range

shown on Freezer Wiring Diagram.

2. Check freezer is reasonably level.

3. Check lid gasket seal.

4. Be sure light(s) work.

5. Check lock.

6. Wipe off any dirt and smudges.

RS1500000 Rev. 2 6

6 RS1500000 Rev. 0

General Instructions

Electrical Requirements

WARNING

!

Electrical Grounding InstructionsThis freezer is

equipped with a three-prong (grounding) plug for

protection against possible shock hazards. If a twoprong wall receptacle is encountered, contact a

qualified electrician and have the two-prong wall

receptacle replaced with a properly grounded

three-prong wall receptacle in accordance with the

National Electrical Code.

Freezers are designed to operate on a separate

103 to 126 VAC, @ 15 A., with a 60 Hz cycle.

Do not under any circumstances cut or remove the

round grounding prong from the plug. Freezers must

be grounded at all times. Do not remove warning tag

from power cord.

Do not use a two-prong adapter. Do not use an

extension cord.

Asure Extended Service Plan

Amana offers long-term service protection for this new

freezer. Asure Extended Service Plan is specially

designed to supplement Amanas strong warranty. This

plan covers parts, labor, and travel charges.

Call 1-800-528-2682 for information.

Proper Disposal of your Freezer

NOTE: Child entrapment and suffocation are not

problems of the past. Junked or abandoned

freezers are still dangerouseven if they sit for

"just a few days". When you get rid of your old

freezer, please follow the instructions below to

help prevent accidents.

Model Identification

Read the Owner's Manual thoroughly. This manual

provides proper maintenance information for consumers.

Any questions, call the Consumer Affairs Department at

1-800-843-0304 inside U.S.A. and 1-319-622-5511

outside U.S.A.

Complete enclosed registration card provided in

owners manual and promptly return. If registration card is

missing, call the Consumer Affairs Department.

When contacting Amana, provide product information.

Locate product information on the serial plate. Chest

freezer serial plate is located on upper right wall. Record

the following information:

Model Number:

Manufacturing Number:

S/N or Serial Number:

Date of purchase:

Dealers name and address:

Keep a copy of sales receipt for future reference.

Locate an authorized servicer by calling

1-800-NATLSVC (628-5782) inside U.S.A. and

319-622-5511 outside U.S.A. Warranty service must be

performed by an authorized servicer. Amana also

recommends contacting an authorized servicer if service

is required after warranty expires.

Amana offers a complete line of appliances,

refrigerators, freezers, ranges, cooktops, wall ovens,

microwave ovens, dishwashers, washers and dryers.

Amana also manufactures a complete selection of high

efficiency gas furnaces plus both central and room air

conditioners.

Enjoy this new Amana freezer.

Before Throwing Away Old Freezers:

Take off the doors.

Leave the shelves in place to prevent children from

easily climbing inside unit.

7 RS1500000 Rev. 2

Operating Instructions

Setting Controls

This freezer operates most efficiently in normal

household temperatures of 65° to 90°F.

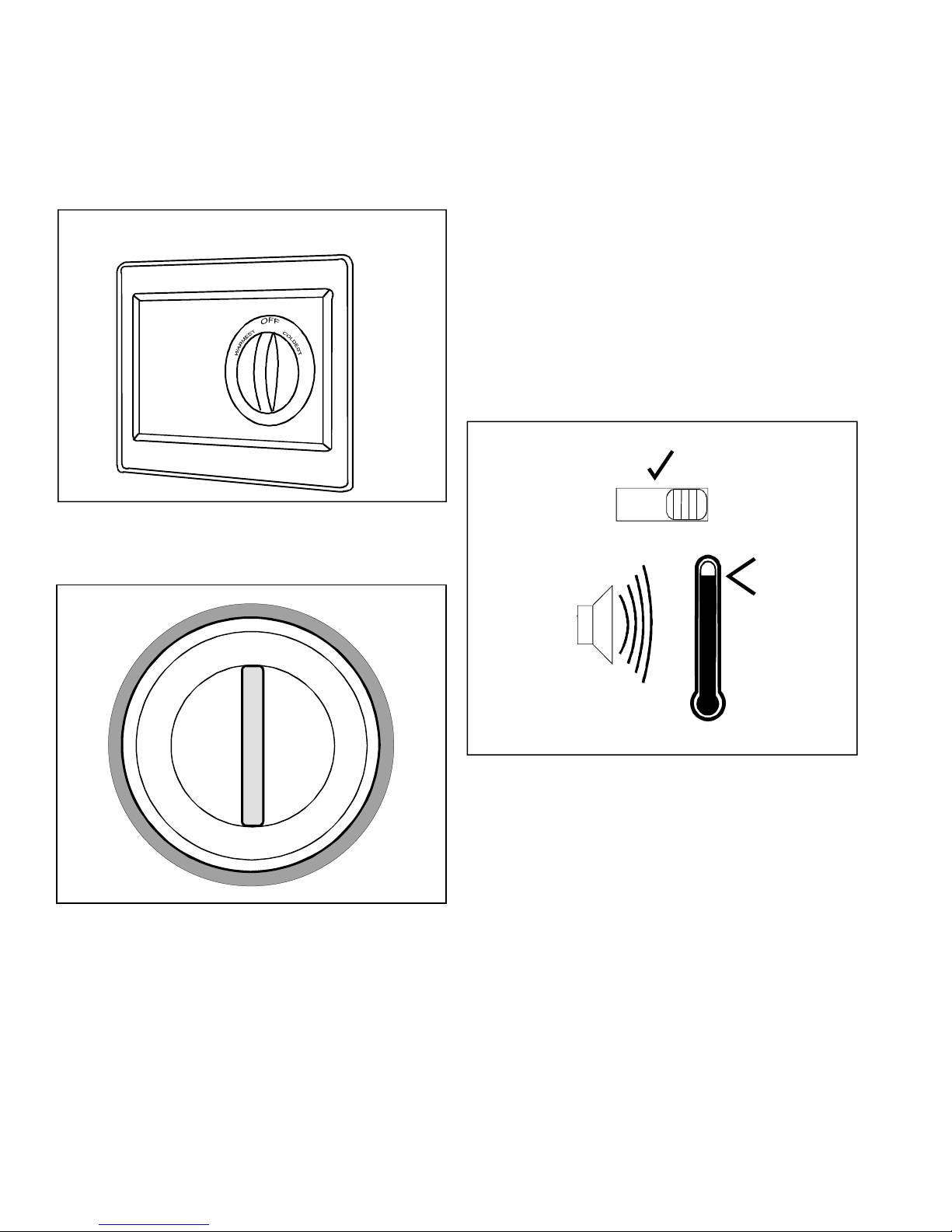

Temperature Control

1

Locate temperature control on right side of interior

freezer cabinet wall.

7

Audible Alarm (Some models)

Locate audible alarm on right side of freezer cabinet near

bottom right corner.

Alarm sounds if temperature in freezer rises 10°F or

more above normal for selected setting. Alarm may

sound if temperature control dial is turned to a much

lower/colder setting or if a large amount of unfrozen food

is added at one time.

Alarm is controlled by a three-position switch.

0 prevents alarm from sounding when freezer is

warm, such as during initial start-up or defrosting.

Ö sounds alarm regardless of temperature. Alarm

system should be tested at least once a month.

1 is proper setting for normal freezer use. Return

switch to 1 after defrosting.

0

1

OFF

C

7

ST

1

E

M

R

A

W

2

3

O

L

D

E

S

T

6

5

4

When control is set to OFF, freezer will not cool. Initially,

set control to 4. Wait 3 hours after connecting power for

freezer to reach desired temperatures, then add food.

After 24 hours, adjust control as desired. 1 is warmest

setting and 7 is coldest.

Set temperatures precisely using a household

thermometer that includes temperatures between -5° to

50°F. Put thermometer snugly between frozen packages

in freezer. Wait 58 hours. If freezer temperature is not

0° to 2°F, adjust control, one number at a time. Check

again after 58 hours.

RS1500000 Rev. 2 8

Operating Instructions

Features

Door Lock

Lock freezer door by completing the following:

1. Insert key into lock approximately 1/4".

2. Turn key clockwise to lock door and counterclockwise

to unlock door.

WARNING

!

To help prevent child entrapment keep key out of

reach of children and away from cabinet.

Reversible Rack (some models)

Racks separates food for more storage space.

Remove rack by releasing rack from shelf wires. Pull

down if located under shelf or lift up if located above

shelf.

Replace rack by positioning on top or underneath shelf

wires. Slide rack until rack locks in place.

Freezing Guide

Wrapping

Use moisture-vapor-proof materials and seal tightly.

When lids are furnished, follow manufacturer's

directions for best results.

Choose materials which are labeled for freezer use.

Ordinary waxed paper or butcher paper does not

provide proper protection for frozen food. Materials not

designed for freezer use may give off odors.

Freezing Guidelines

Item Recommended storage

times at 0° F. (Months)

Meat

Beef roast or steak

(fresh)

Meat casserole

(cooked)

Hamburger 3–4

Pork (cured) 1–3

Pork chop or roast

(fresh)

Roast (fresh) 4–8

Sausage 1–3

Veal 8–9

Lamb

Poultry

Chicken (fresh) 9–12

Chicken (cooked) 1–3

Duck 6

Goose 6

Turkey (fresh) 6–12

Turkey (cooked) 1–3

Fish

Vegetables

Fruits

Bread and Pastries

Bread 1–3

Yeast Rolls 1–3

Layer Cake 2–4

Fruit Pie (unbaked) 8

Ice Cream, Sherbert

9–12

3–6

4–8

9–12

3–6

8

12

1–2

9 RS1500000 Rev. 2

Care and Cleaning

WARNING

!

To avoid electrical shock which can cause severe

personal injury or death, disconnect power to freezer

before cleaning. After cleaning, restore power.

CAUTION

!

To avoid personal injury or property damage, read and

follow all cleaning product manufacturer's directions.

General

1. Wash surfaces with four tablespoons baking soda

dissolved in one quart warm water and a soft, clean

cloth.

2. Rinse surfaces with warm water. Dry surfaces

with a soft, clean cloth.

NOTE:

Do not use the following items:

abrasive or harsh cleaners, ammonia,

chlorine bleach, etc.

concentrated detergents or solvents

metal scouring pads

These items can scratch, crack and discolor

surfaces.

Do not place shelves or accessories in dish-

washer.

Odor Removal

1. Remove all food.

2. Wash all interior surfaces including door, floor and

walls according to "General" instructions. Pay special

attention to corners, crevices and grooves. Include all

accessories, shelves and gaskets.

3. Rinse and dry thoroughly.

4. Wrap foods in tightly sealed wrap or containers to

prevent further odor. After 24 hours, check if odor

was eliminated.

If odor was not eliminated, do the following:

1. Complete procedures in steps 13 above.

2. Pack freezer with crumpled sheets of black and white

newspaper.

3. Place charcoal briquettes randomly throughout

newspaper.

4. Close door and let stand 2448 hours.

5. Remove charcoal briquettes and newspapers.

Wash all interior surfaces including door, floor and

walls according to "General" instructions. Pay special

attention to corners, crevices and grooves. Include all

accessories, shelves and gaskets.

6. Wrap foods in tightly sealed wrap or containers to

prevent further odor. After 24 hours, check if odor

was eliminated.

If odor was still not eliminated, contact Consumer Affairs

Department at 1-800-843-0304.

Adhesives

Remove glue residue by dabbing toothpaste over

adhesive. Rub toothpaste into adhesive with fingers until

adhesive loosens. Rinse surface with warm water. Dry

surface with a soft, clean cloth.

Door Gaskets

1. Clean door gaskets every three months or more

frequently if necessary.

2. Rinse and dry gaskets thoroughly.

3. Apply a light film of petroleum jelly on cabinet hinge

side to keep gaskets pliable.

RS1500000 Rev. 2 10

Care and Cleaning

Defrosting

WARNING

!

To avoid electrical shock which can cause severe

personal injury or death, disconnect power to freezer

before defrosting. After defrosting, restore power.

Defrost freezer when frost has accumulated to 1/4".

Upper section of freezer will normally have more frost

than lower section.

1. Transfer food to an alternate cooling source.

2. Remove toe grille by pulling forward.

3. Remove interior drain plug from freezer.

4. Verify drain pan is beneath drain opening to catch

defrost water.

5. Place pans of hot water in freezer.

6. Wash all interior surfaces including door, floor and

walls.

7. Replace inside drain plug. Drain plug must be

properly installed for efficient operation.

Light Bulb (some models)

WARNING

!

To avoid electrical shock which can cause severe

personal injury or death, disconnect power to freezer

before replacing light bulb. After replacing light bulb,

restore power.

CAUTION

!

To avoid personal injury or property damage, observe

the following:

Allow light bulb to cool.

Wear gloves when replacing light bulb.

Remove light bulb cover by pressing front and back of

light bulb cover together. Replace light bulb with 15-watt

appliance bulb, Amana part # A3073101.

11 RS1500000 Rev. 2

General Tips

Energy Tips

This freezer is designed to be one of the most

energy efficient freezers available. Reduce energy

use by doing the following:

Operate in normal room temperatures away from heat

sources and direct sunlight.

Set controls no colder than necessary.

Keep freezer full.

Keep door gaskets clean and pliable. Replace gaskets

if worn.

Vacation Tips

For long vacations, do the following:

1. Empty freezer.

2. Unplug freezer.

3. Clean freezer including door gaskets.

4. Prop doors open, so air can circulate inside.

Normal Operating Sounds

Todays freezers have new features and are more energy

efficient. As a result, certain sounds may be unfamiliar.

These sounds are normal and will soon become familiar.

These sounds also indicate freezer is operating and

performing as designed.

1. Temperature Control

Temperature control clicks when starting or

stopping compressor.

2. Evaporator

Evaporator refrigerant flow gurgles, pops or sounds

like boiling water.

3. Evaporator Fan Motor

Makes a whirring noise or sounds like rushing air.

4. Compressor

Compressor has a high pitched hum or pulsating

sound.

5. Defrost Heater

Sizzling, hissing, or popping sounds are caused by

water dropping on the defrost heater during the

defrost cycle.

6. Defrost Drain Pan

Dripping sounds is defrost water falling onto drain

pan.

7. Defrost Timer

Automatic timer sounds like an electronic clock that

snaps in and out of the defrost cycle.

8. Insulation

Foam insulation is very energy efficient and has

excellent insulating capabilities. However, foam

insulation is not as sound absorbent as previously

used fiberglass insulation.

Before Calling For Service

Freezer does not operate.

Confirm temperature control is on.

Confirm freezer is plugged in.

Check fuse or circuit breaker. Plug in another

item at that wall outlet.

Wait 20 minutes to see if freezer restarts. If

freezer control is on, freezer may be in defrost

cycle.

Freezer still wont operate.

Unplug freezer. Transfer food to another unit or

place dry ice in freezer to preserve food.

Call 1-800-NATLSVC (628-5782) inside U.S.A.

and 319-622-5511 outside U.S.A. to locate an

authorized servicer.

Food temperature appears too warm.

See above sections.

Allow time for recently added food to reach

freezer temperature.

Check gasket for proper seal.

Adjust temperature control.

Freezer runs too frequently.

It may be normal to maintain an even temperature.

Doors may have been opened frequently or for

an extended period of time.

Adjust temperature control.

Check gaskets for proper seal.

Confirm freezer has proper clearance on each side.

Water droplets form on outside of freezer.

Check door gaskets for proper seal.

Water is on floor beneath freezer.

Confirm drain plugs are properly positioned.

Empty drain pan .

Freezer has an odor.

See "Odor Removal" instructions in "Care and Cleaning"

section.

Freezer makes unfamiliar sounds or seems too loud.

It may be normal. See "Normal Operating Sounds"

section, this page.

RS1500000 Rev. 2 12

General Tips

Operating Sounds

Todays freezers are designed for economical operation and energy efficiency. New features and designs may create

sounds which are different. Following is normal operating sounds which may be encountered, no service call is

required.

Defrost heater:*

Sizzling, hissing, or popping sounds are cause d by water

dropping on the defrost heater during the defrost cycle.

Temperature control:

Clicks when the compressor

starts or stops.

Defrost timer:*

Automatic timer sounds like an

electric clock that snaps in and

out of the defrost cycle.

Evaporator:

Gurgling sound, like boiling

water, when refrigerent flows

through the freezer cooling

coil.

Insulation:

High-efficiency foam is used for

its excellent energy insulation

capacity, even though it does not

offer the same level of sound

insulation as less energy-efficient

fiberglass insulation once foun d

in freezers.

* Frost-free models only

Freezer fan:*

Makes a whirring noise

or sounds like rushing

air as cold air ciculates in

the freezer compartment.

Compressor:

Runs faster for higher

efficiency and has

a higher pi tched hum

or pulsating sound.

Defrost drain pan:*

Dripping sound is defrost

water fa lling ont o dr a in pan.

13 RS1500000 Rev. 2

Component Testing

To avoid risk electrical shock, personal injury, or death,

WARNING

!

power to be connected. When removing any wiring from terminals they must be replaced on the same terminals.

Ensure all ground wires are connected before certifying unit as repaired and/or operational.

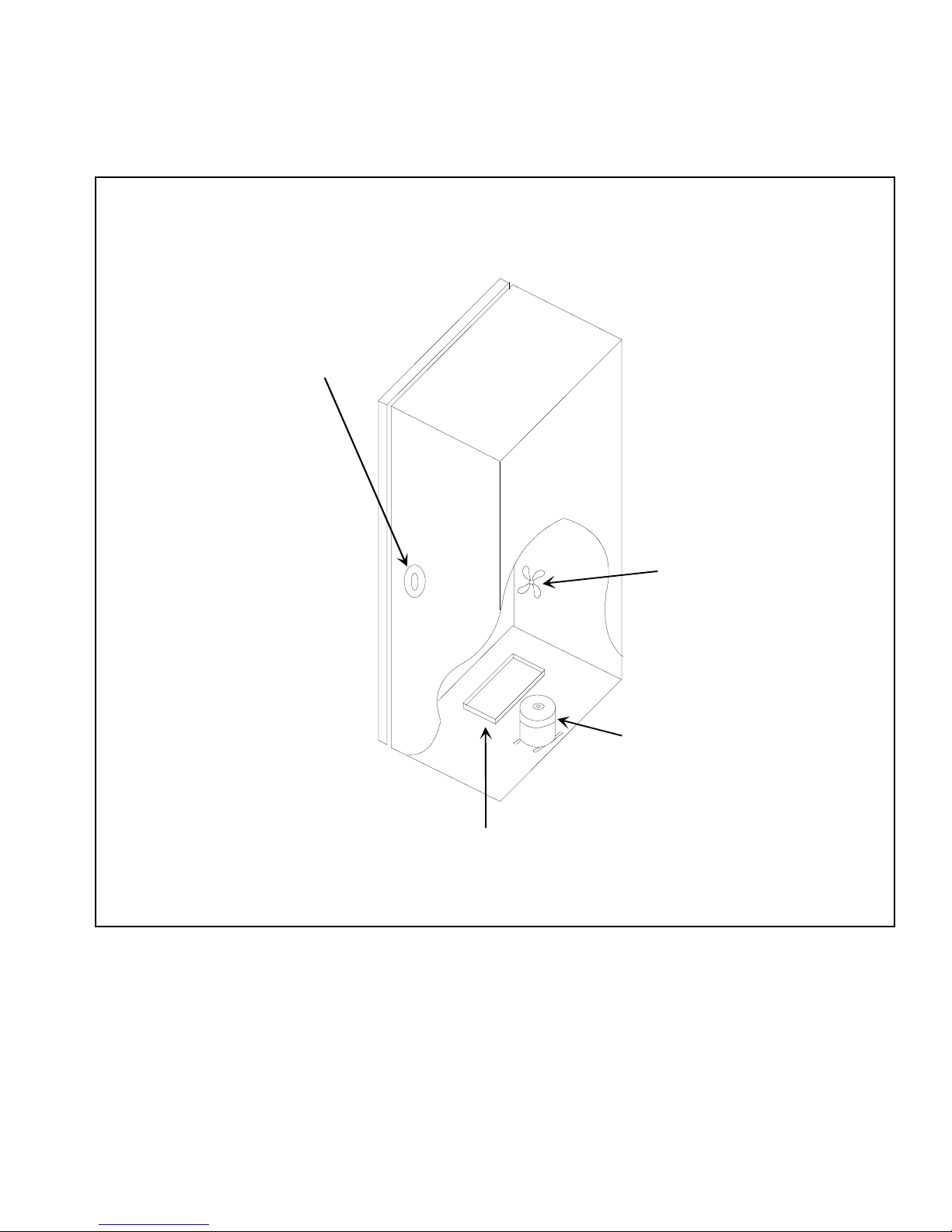

Refrigeration System Test Procedures

Careful testing of the refrigeration system is essential in determining if a malfunction is present.

Temperature testing is accomplished by using a three lead thermocouple temperature tester in specific locations.

1. Test point 1, is attached to inlet on the evaporator coil

2. Test point 2, is attached to outlet on the evaporator coil.

3. Test point 3, is approximately 68 inches from suction port of compressor on the suction line.

4. Thermocouple tips should be attached securely to the locations specified.

5. Do not test during initial pull down, Allow one complete OFF cycle or a balanced temperature condition to

occur before proceeding.

6. Unit must operate a minimum of 20 minutes after thermocouples are installed.

NOTE: It may be necessary to turn control colder to maintain required operating time.

7. Wattage reading must be recorded with temperature test to confirm proper operation.

8. Suction and Head pressures are listed in the specification chart.

always disconnect electrical power source to the freezer

before attempting to service, unless test procedures require

Evaporator

Heat

exchanger

Compressor

Refrigerant Flow Diagram

Condenser

Manual Defrost

Dryer

Discharge

line

Suction

line

Condenser

Heat

exchanger

Suction

line

Drier

Discharge

line

Compressor

Evaporator

Refrigerant Flow Diagram

Automatic Defrost

RS1500000 Rev. 2 14

Component Testing

To avoid risk electrical shock, personal injury, or death,

WARNING

!

power to be connected. When removing any wiring from terminals they must be replaced on the same terminals.

Ensure all ground wires are connected before certifying unit as repaired and/or operational.

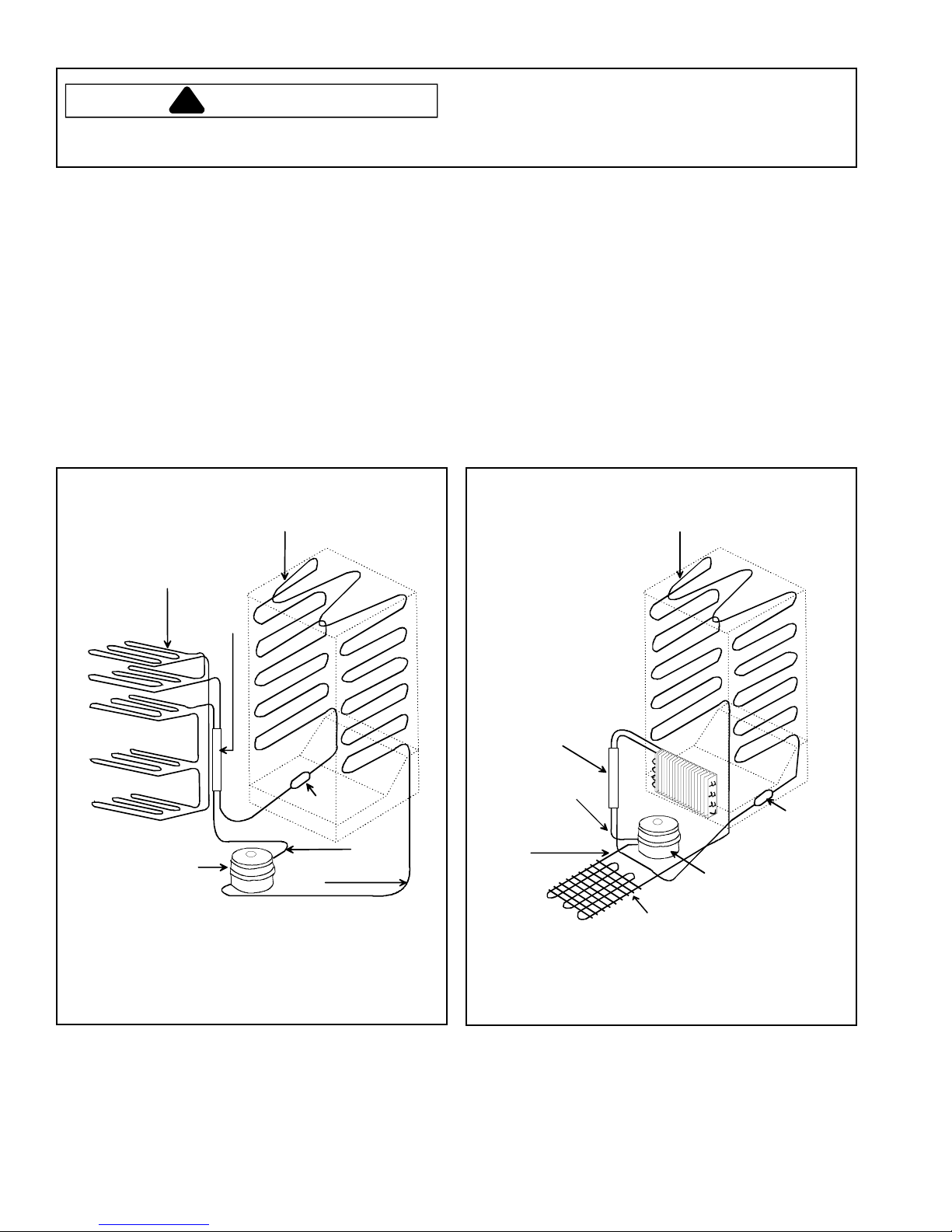

Testing Main Condenser

Before testing condenser, verify no leaks exist

elsewhere.

Condenser loop must be disconnected from the system

and tested separately. The following illustration shows

the tubing as it is routed and fastened in the freezer

cabinet flange.

NOTE: Verify a leak is not present in any external

tubing or joints before performing the following

test.

Following equipment is required to test.

An access fitting

A drum of oil pumped nitrogen.

Pressure regulator.

Two gauges.

Line valve and tubing.

Access fitting should be prepared as follows:

always disconnect electrical power source to the freezer

before attempting to service, unless test procedures require

Condensor

bottom

external

Suction

To

condensor

To

evaporater

Discharge

From

condensor

Gauges

Pressure

regulator

Line

valve

Nitrogen Tank and Fittings

To

condensor

Process From

Discharge

Suction

condensor

Tube

process

Compressor Cutting or Unsoldering

Points No Defrost Models

Prepare equipment as required and test condenser as

follows:

1. Cut tubing at arrow to condenser and from

condenser as shown in the previous illustration.

2. Crimp and solder the end to condenser that enters

into the cabinet.

3. Silver solder access fitting of test equipment to the

end from condenser tube that emerges from the

cabinet.

4. Pressurize the system to 250 pounds with dry

nitrogen. Test all connections for leaks with a soap

solution.

5. Check the pressure gauge. If pressure drops, there is

a leak. However, it may be necessary to allow as

much as 24 hours for test results to verify no leaks

exist. If there are no leaks, reconnect the tubing.

Evacuate and recharge the system.

Tube

process

Compressor Cutting or Unsoldering

Points Refrigerated Shelf Models

15 RS1500000 Rev. 2

Component Testing

To avoid risk electrical shock, personal injury, or death,

WARNING

!

power to be connected. When removing any wiring from terminals they must be replaced on the same terminals.

Ensure all ground wires are connected before certifying unit as repaired and/or operational.

always disconnect electrical power source to the freezer

before attempting to service, unless test procedures require

Testing for Leaks

DANGER

!

Free oxygen will explode on contact with oil.

Acetylene will explode spontaneously when put under

pressure.

To prevent violent explosions that may result in

serious injury or death to persons in or near the

immediate vicinity, NEVER use oxygen or acetylene

for pressure testing or cleanout of refrigeration

systems.

WARNING

!

To avoid severe personal injury or death from fire,

keep system free from contamination due to presence

of air. Follow instructions exactly.

Electrical System

WARNING

!

To avoid possible electric shock, personal injury or

death disconnect power before servicing. Follow

specific steps listed in this manual for testing or

replacement of a suspected failed component.

Compressor Electrical Tests

Compressor terminals on all models can be reached only

from the rear of the cabinet.

If freezer does not operate, do not assume compressor

has failed until all other possibilities are eliminated.

Is current entering the compressor through the power

cord?

Check for low voltage at the compressor terminals, a

minimum of 100 volts is required for compressor to

start.

If the necessary voltage is available, check for failures

in:

Over load protector

Starting relay

Temperature control,

Cabinet wiring harness.

Testing Compressor Direct

To test compressor with no other wiring in the circuit is

called DIRECT TEST. Safest way to check the

compressor is by using a compressor tester.

Run

Common

Start

Switch

All electrical components are grounded to the cabinet.

The green center conductor of three wire lead cord is

also attached to the cabinet to provide a grounding circuit

when the lead cord is plugged into a properly grounded

electrical outlet. After replacing an electrical component,

always verify the ground wire is reconnected.

The electrical outlet from which the appliance is to

receive its power should always be checked to verify it is

properly wired.

RS1500000 Rev. 2 16

Power

cord

Capacitor

connections

Compressor Tester

Loading...

Loading...