Amana AMH80403ANBA, AMH80403ANBB, AMH80403AXBA, AMH80403AXBB, AMH80603ANBA Installation Manual

...

INSTALLATION INSTRUCTIONS FOR

TABLE OF CONTENTS

*M(H,S)8 / GD(H,S)8 / GHS8 / GME8

ADS(H,S)8 / AMEH8 G

(CA TEGOR Y I )

These furnaces comply with requirements embodied in

the American National Standard / National Standard of

Canada ANSI Z21.47·CSA-2.3 Gas Fired Central Furnaces.

ATTENTION INST ALLING PER SONNEL

As a professional installer, you have an obligation to know the

product better than the customer. This includes all safety precautions and related items.

Prior to actual installation, thoroughly familiarize yourself with

this Instruction Manual. Pay special attention to all safety warnings. Often during installation or repair, it is possible to place

yourself in a position which is more hazardous than when the

unit is in operation.

Remember, it is your responsibility to install the product safely

and to know it well enough to be able to instruct a customer in

its safe use.

Safety is a matter of common sense...a matter of thinking before

acting. Most dealers have a list of specific, good safety

practices...follow them.

The precautions listed in this Installation Manual are intended

as supplemental to existing practices. However, if there is a

direct conflict between existing practices and the content of

this manual, the precautions listed here take precedence.

RECOGNIZE THIS SYMBOL

AS A SAFETY PRECAUTION

NOTE: Please contact your distributor or our website listed

below for the applicable Specification Sheet referred to in this

manual.

AS FURNACE

Installer: Affix all manuals

adjacent to the unit.

PRODUCT APPLICATION............................................................5

LOCA TION REQUIREMENTS AND CONSIDERATIONS .................. 6

COMBUSTION AND VENTILA TION AIR REQUIREMENTS............. 8

CA TEGORY I VENTING (VERTICAL VENTING) ..............................9

EXTERIOR MASONRY CHIMNEYS

ELECTRICAL CONNECTIONS.....................................................14

GAS SUPPL Y AND PIPING ........................................................16

Safety Considerations......................................................3

Additional Safety Considerations ....................................4

Shipping Inspection .......................................................... 4

Electrostatic Discharge (ESD) Precautions ....................... 5

To The Installer..................................................................5

Clearances and Accessibility ...........................................7

Installation Positions .......................................................7

Horizontal Installation .....................................................7

Furnace Suspension .......................................................... 8

Existing Furnace Removal.................................................8

Thermostat Location .........................................................8

(CA TEGORY I FURNACES ONL Y) .........................................10

Checklist Summary ..........................................................10

Check 1 - Proper chimney termination ..........................11

Check 2 - Any solid or liquid fuel appliances

vented into this chimney channel ..............................11

Check 3 - Chimney Crown Condition...............................12

Check 4 - Debris in Cleanout...........................................1 2

Check 5 - Liner Condition. ...............................................12

Check 6 - Dilution Air . .....................................................12

Check 7 - Complete the Installation................................12

Fix 1 - Liner Termination .................................................13

Fix 2 -Change Venting Arr angemen t s ..............................13

Fix 3 - Rebuild the Crown ................................................13

Fix 4 - Relining ................................................................13

Wiring Harness ............................................................... 14

115 Volt Line Connections ..............................................14

Fossil Fuel Applications .................................................14

Junction Box Relocation .................................................1 4

24 Volt Thermostat W iring .............................................15

GME8 & AMEH8 Furnaces

with 2-Stage Condenser Field Wiring ........................1 5

Setting the Heat Anticipator............................................16

115 Volt Line Connection of Accessories ........................16

Electronic Air Cleaner .....................................................16

24 Vac Humidifier ...........................................................16

High Altitude Derate........................................................17

Propane Gas Conversion ................................................17

Gas Piping Connections..................................................17

Upflow Installations .......................................................18

Counterflow Installations ..............................................18

Gas Piping Checks...........................................................18

Propane Gas Tanks and Piping.......................................19

IO-446C

11/2015

5151 San Felipe Suite 500 • Houston, TX 77056

www.goodmanmfg.com • www .amana-hac.com

© 2011 - 2015 Goodman Manufacturing Company, L.P.

is a registered trademark of Maytag Corporation or its related companies and is used under license. All rights reserved.

CIRCULA TING AIR AND FILTERS ...............................................20

Ductwork - Air Flow.........................................................20

Filters - Read This Section Before

Installing The Return Air Ductwork ................................20

Upright Installations ......................................................20

Circulation Air Filters .....................................................20

Horizontal Installations .................................................21

SEQUENCE OF OPERA TION

(INTEGRA TED IGNITION CONTROL)..................................... 21

Power Up .........................................................................21

Heating Mode ..................................................................22

(Mode DIP switch is set to “1 STG” position) .................22

(Mode DIP Switch is set to “2 STG” position) .................22

Cooling Mode ..................................................................22

Fan Only Mode................................................................22

ST ART -UP PROCEDURE AND ADJUS TMENT ..............................23

Furnace Operation..........................................................23

Furnace Start-up .............................................................23

Furnace Shutdown ..........................................................23

Gas Supply Pressure Measurement................................23

Gas Manifold Pressure Measurement and Adjustment.2 5

Gas Input Rate Measurement (Natural Gas Only)..........27

T empera ture Rise.............................................................27

Circulator Blower Speed Adjustment..............................27

Circulator Blower Fan T iming Adjustment .....................28

Setting Furnace Operating Mode

(GDH8, GME8, *MH8, AMEH8 & ADSH8 models only) 28

OPERA TIONAL CHECKS............................................................28

Checking Duct Static .......................................................28

Burner Flame...................................................................29

SAFETY CIRCUIT DESCRIPTION................................................ 29

General............................................................................29

Integrated Control Module .............................................29

Primary Limit ...................................................................29

Auxiliary Limit .................................................................29

Rollout Limits ..................................................................29

Pressure Switches ...........................................................29

Flame Sensor...................................................................30

TROUBLESHOOTING ...............................................................30

Electrostatic Discharge (ESD) Precautions .....................30

Diagnostic Chart .............................................................30

Fault Recall .....................................................................30

(Furnaces equipped with

PCBBF132 Control Board only) ...................................30

Resetting From Lockout ...................................................30

MAINTENANCE........................................................................30

Annual inspection ...........................................................30

Filters ..............................................................................31

Filter Maintenance..........................................................31

Filter Removal .................................................................31

Induced Draft and Circulator Blower Motors ................31

Flame Sensor (Qualified Servicer Only) .........................31

Igniter (Qualified Servicer Only) ....................................31

Burners............................................................................31

CLEANING (QUALIFIED SERVICER ONL Y)..................................31

BEFORE LEA VING AN INST ALLA TION ........................................32

REP AIR AND REPLACEMENT PARTS..........................................32

Component ID..................................................................33

APPENDIX D TROUBLESHOOTING CHART ...............................34

PCBBF134 & PCBBF132 CONTROL BOARDS .................34

BLOWER PERFORMANCE DA T A ...............................................37

*M(H/S)8 .........................................................................37

GDS8/ADSS8 ....................................................................38

GHS8 ................................................................................38

GDH8 / ADSH8 .................................................................39

GME8 ...............................................................................40

AMEH8.............................................................................41

*(M, D, H)S8 / ADSS8 Wiring Diagram ..................................42

GME8 / AMEH8 Wiring Diagram ...........................................43

Honeywell Gas Valve .......................................................4 3

*(M,D)H8 / ADSH8 Wiring Diagram ......................................44

Honeywell Gas Valve .......................................................4 4

2

W ARN ING

G

OODMAN

DAMAGE ARISING FROM IMPROPER SERVICE OR SERVICE PROCEDURES

F YOU INSTALL OR PERFORM SERVICE ON THIS UNIT, YOU ASSUME

I

RESPONSIBI LITY FOR ANY PERSONAL INJURY OR PROPERTY DAMAGE

WHICH MAY RESULT

INSTALL OR SERVICE HEATING AND AIR CONDITIONING EQU IPMENT

S

AFETY

Adhere to the following warnings and cautions when installing,

adjusting, altering, servicing, or operating the furnace. To ensure

proper installation and operation, thoroughly read this manual

for specifics pertaining to the installation and application of this

product.

This furnace is manufactured for use with natural gas. It may be

field converte d to oper a t e on L.P. gas by using the appropriate L.P.

conversion kit liste d in the

LATIONS section of this manual

Install this furnace only in a location and position as specified in

LOCATION REQUIREMENTS & CONSIDERATIONS section and INSTALLATION POSITIONS section of this manual.

Provide adequate combustion and ventilation air to the furnace

as specified in COMBUSTION & VENTILATION AIR REQUIREMENTS

section of this manual.

Combustion products must be discharged to the outdoors. Connect this furnace to an approved vent system only, as specified in

CATEGORY 1 VENTING section of this manual.

Never test for gas leaks with an open flame. Use a commercially

available soap solution made specifically for the detection of

leaks to check all connections, as specified in GAS SUPPLY AND

PIPING section of this manual.

Always install a furnace to operate within the furnace’s intended

temperature-rise range with a duct system which has external

static pressure within the allowable range, as specified on the

furnace rating plate and OPERATIONAL CHECKS section of these

instructions.

When a furnace is installed so that supply ducts carry air circulated by the furnace to areas outside the space containing the

furnace, the return air shall also be handled by duct(s) sealed to

the furnace casing and terminating outside the space containing

the furnace.

A gas-fired furnace for installation in a residential garage must

be installed as specified in the LOCATION REQUIREMENTS AND

CONSIDERATIONS section of this manual.

WILL NOT BE RESPONSIBLE FOR ANY INJURY OR PROPERTY

. M

ANY JURISD ICTIONS REQ UIRE A LICENSE TO

C

ONSIDERA TIONS

PROPANE GAS/HIGH ALTITUDE INSTAL-

.

.

WARNING

TO

PREVENT PERSONAL INJURY OR DEATH DUE TO IMPROPER

INSTALLATION, ADJUSTMENT, ALTERA TI ON, SERVICE OR MAINTENANCE

REFER TO THIS MANUAL

INFORMATIO N, CONSULT A QUALIFIED INSTALLER, SERVICER AGENCY OR

THE GAS SUPPLIER

. FOR

ADDITIONAL ASSISTANCE OR

.

WARNING

IF

THE INFORMATION IN THESE INSTRUCTIONS IS NOT FOLLOWED

EXACTLY, A FIRE OR EXPLOSION MAY RESU LT CAUSING PROPERTY

DAMAGE

,

PERSONAL INJURY OR LOSS OF LIFE

DO

NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND

LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE

.

.

WHAT TO DO IF YOU SMELL GAS:

D

O NOT TRY TO LIGHT ANY APPLIANCE

D

O NOT TOUCH ANY ELECTRICAL SWITCH; DO NOT USE ANY PHONE

IN YOUR BUILDING

I

MMEDIATELY CALL YOUR GAS SUPPLIER FROM A NEIGHBOR’S

PHONE

. F

I

F YOU CANNOT REACH YOUR GAS SUPPLIER, CALL THE FIRE

DEPARTMENT

I

NSTALLATION AND SERVICE MUST BE PERFORMED BY A QUALIFIED

INSTALLER, SERVICE AGENCY OR THE GAS SUPPLIER

.

OLLOW THE GAS SUPPLIER’S INSTRUCTIONS

.

.

.

.

WARNING

T

HIS PRODUCT CONTAI NS OR PRODUCES A CHEMICAL OR CHEMICALS

WHICH MAY CAUSE SERIOUS ILLNESS OR DEATH AND WHICH ARE

KNOWN TO THE STATE OF CALIFORNIA TO CAUSE CANCER, BIRTH

DEFECTS OR OTHER REPRODUCTIV E HARM

.

WARNING

H

EATING UNIT SHOULD NOT BE UTILIZED WITHOUT REASONABLE

ROUT INE, INSPECTION, MAINTENANCE AND SUPERVISION

BUILDING IN WHICH ANY SUCH DEVICE IS LOCATED WILL BE VACAN T

CARE SHOULD BE TAKEN THAT SUCH DEVICE IS ROUT INELY INSPECTED

MAINTAINED AND MONITORED. IN THE EVENT THAT THE BUILDING

MAYBE EXPOSED TO FREEZING TEMPERATURES AND WILL BE VACAN T

ALL WATER-BEARING PIPES SHOULD BE DRAINED, THE BUILDING SHOULD

BE PROPERLY WINTERIZED, AND THE WATER SOURCE CLOSED. IN THE

EVENT THAT THE BUILDING MAY BE EXPOSED TO FREEZING

TEMPERATURES AND WILL BE VACAN T, ANY HYDRONIC COIL UNITS

SHOULD BE DRAINED AS WELL AND, IN SUCH CASE, ALTERNATIVE HEAT

SOURCES SHOULD BE UTILIZED

.

. IF

THE

,

,

,

,

WARNING

TO

PREVENT POSSIBLE PROPERTY DAMAGE, PERSONAL INJURY OR

DEATH DUE TO ELECTRICAL SHOCK, THE FURNACE MUST BE LOCATED TO

PROTECT THE ELECTRICAL COMPONENTS FROM WATER

.

,

This furnace may be used as a construction site heater only if

certain conditions are met. These conditions are listed in the PROD-

UCT APPLICATION section of this manual.

3

Advertenci a e spe cia l p ara la instalación de calent adores ó manejadoras

de aire en áreas cerradas como estacionamientos ó cuartos de servicio.

RISQUE D'E MPO ISO N NEM EN T AU

MONOXYDE DE CARBONE

Las emis ion es de monóxido de carbono pue de n c irc ular a través

del aparat o c uando se opera en cualquier modo.

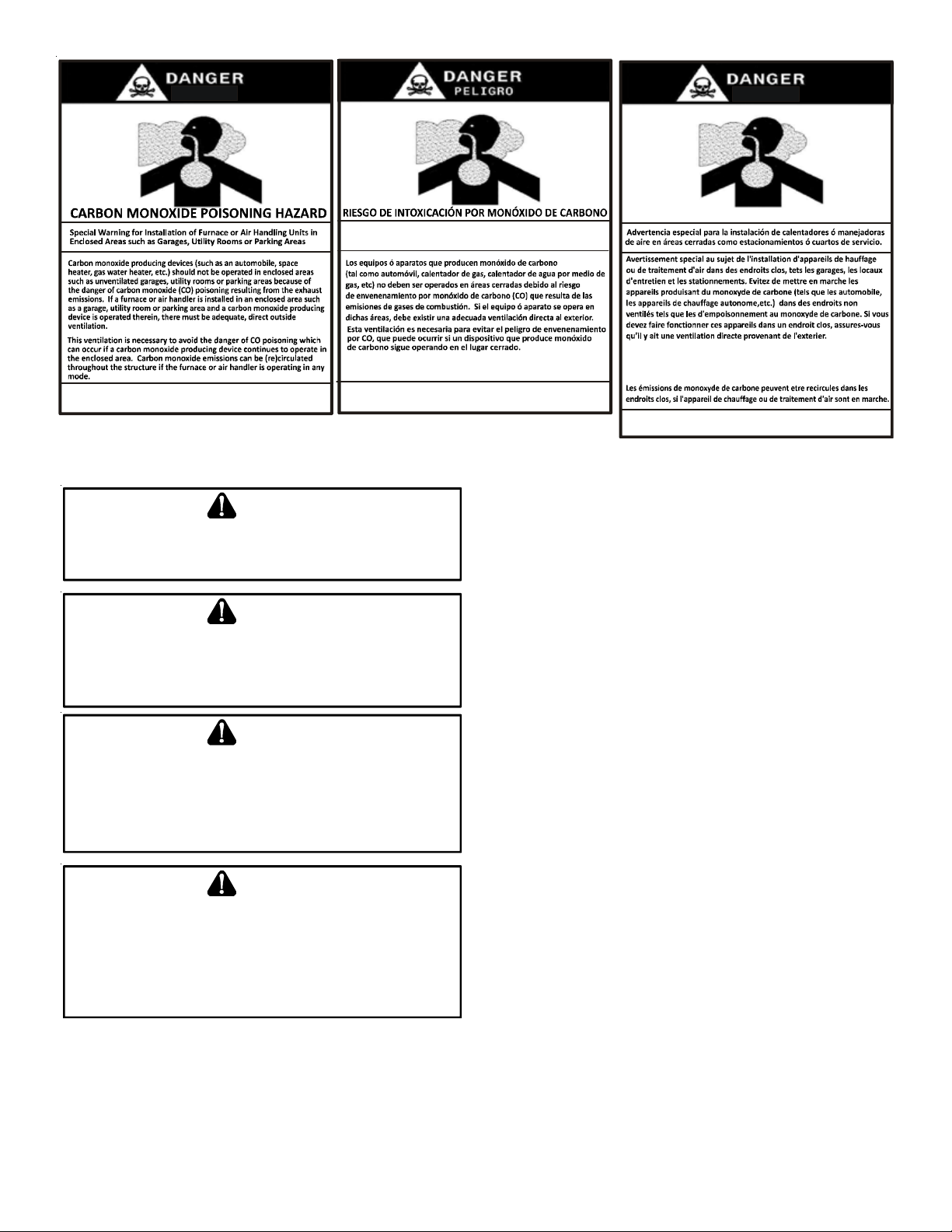

CO can cause serious illness including permanent brain

damag e or death.

B10259-216

El monóx i do de carbono puede causar e nfermedades se ve ras

como daño cerebral permanente ó muerte.

WARN ING

S

HOULD OVERHEAT ING OCCUR OR THE GAS SUPPLY FAIL TO SHUT OFF

TURN OFF THE MANUAL GAS SHUTOFF VALVE EXTERNAL TO THE

FURNACE BEFORE TURNING OFF THE ELECTRICAL SUPPLY

.

WARN ING

P

OSSIBLE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH DUE TO

FIRE, EXPLOSION, SMOKE, SOOT, COND E NSATION, ELECTRICAL SHOCK

OR CARBON MONOXIDE MAY RESULT FROM IMPROPER INSTALLATION

REPAIR OPERATION, OR MAINTENANCE OF THIS PRODUCT

.

WARN ING

TO

PREVENT PERSONAL INJURY OR DEATH DUE TO IMPROPER

INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR MAINTENANCE

REFER TO THIS MANUAL

INFORMATIO N, CONSULT A QUALIFIED INSTALLER, SERVICER AGENCY OR

THE GAS SUPPLIER

. FOR

ADDITIONAL ASSISTANCE OR

.

WARN ING

TO

PREVENT PERSONAL INJURY OR DEATH DUE TO ASPHYXIATION, THIS

FURNACE MUST BE CATEGORY

ATEGORY

C

P

ROVIS IONS MUST BE MADE FOR VENTI NG COMBUSTION PRODUCTS

OUTDOORS THROUGH A PROPER VENTI NG SYSTEM

FLUE PIPE COUL D BE A LIMITING FACTOR IN LOCATING THE FURNACE

III

VENTI NG

I

VENTED

. DO

NOT VENT USING

.

. THE

LENGTH OF

ADDITIONAL SAFETY CONSIDERATIONS

• This furnace is approved for Category I Venting only.

• Provisions must be made for venting combustion

products outdoors through a proper venting system. The

length of flue pipe could be a limiting factor in locating

the furnace.

Cett e v entilation es t nécessaire po ur év iter le danger d ' intoxication

au CO pouvant survenir si un appareil produisant du monoxyde

de carbon e continue de fonctionne r au sei n de la zone confi né e .

B10259-216

Le monoxyde de

des

dommages permanents au cerveau et meme la mort.

carbone peut causer des maladies graves telles que

B10259-216

SHIPPING INSPECTION

All units are securely packed in shipping containers tested ac-

,

cording to International Safe Transit Association specifications.

The carton must be checked upon arrival for external damage. If

damage is found, a request for inspection by carrier’s agent must

be made in writing immediately.

.

The furnace must be carefully inspected on arrival for damage

and bolts or screws which may have come loose in transit. In the

event of damage the consignee should:

,

1. Make a notation on delivery receipt of any visible damage

to shipment or container.

2. Notify carrier promptly and request an inspection.

3. With concealed damage, carrier must be notified as soon

as possible - preferably within five days.

,

4. File the claim with the following support documents within

a nine month statute of limitations.

• Original or certified copy of the Bill of Lading, or

indemnity bond.

• Original paid freight bill or indemnity in lieu thereof.

• Original or certified copy of the invoice, showing trade

and other discounts or reductions.

• Copy of the inspection report issued by carrier’s

represen tative at the time damage is reported to carrier.

The carrier is responsible for making prompt inspection of damage and for a thorough investigation of each claim. The distributor or manufacturer will not accept claims from dealers for transportation damage.

Keep this literature in a safe place for future reference.

4

ELECTROSTATIC DISCHARGE (ESD) PRECAUTIONS

NOTE: Discharge body’ s st atic electricity bef or e touching unit. An

electrostatic discharge can adversely affect electrical components.

Use the following precautions during furnace installation and ser-

vicing to protect the integrated control module from damage. By

putting the furnace, the control, and the person at the same electrostatic potential, these steps will help avoid exposing the integrated control module to electrostatic discharge. This procedure

is applicable to both installed and non-installed (ungrounded)

furnaces.

1. Disconnect all power to the furnace. Do not touch the

integrated control module or any wire connected to the

control prior to discharging your body’s electrostatic

charge to ground.

2. Firmly touch a clean, unpainted, metal surface of the

furnaces near the control. Any tools held in a person’s

hand during grounding will be discharged.

3. Service integrated control module or connecting wiring

following the discharge process in step 2. Use caution not

to recharge your body with static electricity; (i.e., do not

move or shuffle your feet, do not touch ungrounded objects,

etc.). If you come in contact with an ungrounded object,

repeat step 2 before touching control or wires.

4. Discharge your body to ground before removing a new

control from its container. Follow steps 1 through 3 if

installing the control on a furnace. Return any old or new

controls to their containers before touching any ungrounded

object.

TO THE INSTALLER

Before installing this unit, please read this manual thoroughly to

familiarize yourself with specific items which must be adhered to,

including but not limited to: unit maximum external static pressure, gas pressures, BTU input rating, proper electrical connections, circulating air temperature rise, minimum or maximum CFM,

and motor speed connections, and venting. These furnaces are

designed for Category I venting only.

WARN ING

TO

PREVENT PROPERTY DAMAGE, PERSONAL INJURY OR DEATH DUE TO

FIRE, DO NOT INSTALL THIS FURNACE IN A MOBILE HOME, TRAILER, OR

RECREATIONAL VEHICL E

P

RODUCT APPLICA TION

This furnace is primarily designed for residential home-heating

applications. It is NOT designed or certified for use in mobile

homes, trailers or recreational vehicles. Neither is it designed or

certified for outdoor applications. The furnace must be installed

indoors (i.e., attic space, crawl space, or garage area provided the

garage area is enclosed with an operating door).

This furnace can be used in the following non-industrial commercial applications:

Schools, Office buildings, Churches, Retail stores,

Nursing homes, Hotels/motels, Common or office areas

.

In such applications , the furnace must be installed with the following stipulations:

• It must be installed per the installation instructions

provided and per local and national codes.

• It must be installed indoors in a building constructed on

site.

• It must be part of a ducted system and not used in a free

air delivery application.

• It must not be used as a “make-up” air unit.

• All other warranty exclusions and restrictions apply.

This furnace may be used as a construction sit e he a ter ONLY if the

following conditions are met:

• The vent system is permanently installed per these

installation instructions.

• A room thermostat is used to control the furnace. Fixed

jumpers that provide continuous heating CANNOT be used

and can cause long term equipment damage. Bi-metal

thermostats, or any thermostat affected by vibration must

not be used during construction.

• Return air ducts are provided and sealed to the furnace.

• A return air temperature range between 60ºF (16ºC) and

80ºF (27ºC) is maintained.

• Air filters are installed in the system and replaced daily

during construction and upon completion of

construction.

• The input rate and temperature rise are set per the furnace

rating plate.

• 100% outside air must be used for combustion during

construction. Temporary ducting may be used to supply

outside air to the furnace for combustion – do not connect

this duct directly to the furnace. Size this duct according

to NFPA 54/ANSI Z223.1 section for Combustion and

Ventilation Air.

• The furnace heat exchanger, components, duct system,

air filters and evaporator coils are thoroughly cleaned

following final construction clean up by a qualified

person.

• All furnace operating conditions (including ignition,

input rate, temperature rise and venting) are verified by

a qualified person according to these installation

instructions.

• Furnace doors must be in place on the furnace while the

furnace is operating in any mode.

Damage or repairs due to failure to comply with these requirements are not cov ere d under the w arr an ty.

NOTE: The Commonwealth of Massachusetts requires that the

following additional requirements must also be met:

• Gas furnaces must be installed by a licensed plumber or

gas fitter.

• A T-handle gas cock must be used.

• If the unit is to be installed in an attic, the passageway to

and the service area around the unit must have flooring.

5

WARN ING

TO

PREVENT PROPERTY DAMAGE, PERSONAL INJURY OR DEATH DUE TO

FIRE, DO NOT INSTALL THIS FURNACE IN A MOBILE HOME, TRAILER, OR

RECREATIONAL VEHICL E

.

WARNING

TO

PREVENT POSSIBLE EQUIPM EN T DAMAGE, PROPERTY DAMAGE

PERSONAL INJURY OR DEATH, THE FOLLOWING BULLET POINTS MUST BE

OBSERVED WHEN INSTALLING THIS UNIT

.

,

T o ensure proper furnace oper ation, install, opera te and maintain

the furnace in accordance with these installation and operation

instructions, all local building codes and ordinances. In their ab-

sence, follow the lates t edition of the National Fuel Gas Code (NFP A

54/ANSI Z223.1), and/or CAN/CSA B149 Installation Codes, local

plumbing or waste water codes, and other applicable codes.

A copy of the National Fuel Gas Code (NFP A 54/ANSI Z223.1) can be

obtained from any of the following:

American National Standards Institute

25 West 43rd Street, 4th Floor

New Y ork, NY 10036

National Fire Protection Association

1 Batterymarch Park

Quincy, MA 02169-7471

CSA International

8501 East Pleasant Valley

Cleveland, OH 44131

The rated heating capacity of the furnace should be greater than

or equal to the total heat loss of the area to be heated. The total

heat loss should be calculated by an approved method or in accordance with “ASHRAE Guide” or “Manual J-Load Calculations”

published by the Air Conditioning Contractors of America.

In the USA, this furnace MUST be installed in accordance with the

latest edition of the ANSI Z223.1 booklet entitled “National Fuel

Gas Code” (NFPA 54), and the requirements or codes of the local

utility or other authority having jurisdiction. Additional helpful

publications available from the NFPA are, NFPA 90A - Installation

of Air Conditioning and Ventilating System and NFPA 90B - Warm

Air Heating and Air Conditioning System.

All venting shall be in accordance with the National Fuel Gas

Code, ANSI Z223.1, or applicable local building and/or air conditioning codes.

NOTE: Furnaces with NOx screens meet the California NOx emission standards and California seasonal efficiency standards. ANNUAL inspections of the furnace and its vent system is strongly

recommended.

L

OCATION REQUI

REMENTS AND CONSIDERATIONS

Your unit model type determines which installation procedures

must be used. For *MH8, *MS8, and GHS8 models, you must follow

instructions for Horizontal Left, Horizontal Right or Upflow installations only. These furnaces are not approved for Downflow installations.

Downflow models GD(H,S) ARE NOT APPRO VED FOR HORIZONT AL

OR UPFLOW INSTALLATIONS. For these models, use only the instructions for downflow installation only.

Follow the instructions listed below when selecting a furnace location. Refer also to the guidelines provided in Combustion and

Ven tilation Air Requirements.

• Centrally locate the furnace with respect to the proposed

or existing air distribution system.

• Ensure the temperature of the return air entering the

furnace is between 55°F and 100°F when the furnace is

heating.

• If the furnace is installed in an application where the

typical operating sound level of a furnace is deemed

objectionable, an optional sound reduction kit is

available. Consult your local distributor for more details.

• Provisions must be made for venting combustion

products outdoors through a proper venting system. The

length of flue pipe could be a limiting factor in locating

the furnace.

• Ensure adequate combustion air is available for the

furnace. Improper or insufficient combustion air can

expose building occupants to gas combustion products

that could include carbon monoxide. Refer to Combustion

and Vent ilation Air Requirements.

• The furnace must be level. If the furnace is to be set on a

floor that may become wet or damp at times, the furnace

should be supported above the floor on a concrete base

sized approximately 1-1/2" larger than the base of the

furnace.

• Ensure upflow or horizontal furnaces are not installed

directly on carpeting, or any other combustible material.

The only combustible material allowed is wood.

• Exposure to contaminated combustion air will result in

safety and performance-related problems. Do not install

the furnace where the combustion air is exposed to the

following substances:

chlorinated waxes or cleaners

chlorine-based swimming pool chemicals

water softening chemicals

deicing salts or chemicals

carbon tetrachloride

halogen type refrigerants

cleaning solutions (such as perchloroethylene)

printing inks

paint removers

varnishes

hydrochloric acid

cements and glues

antistatic fabric softeners for clothes dryers

and masonry acid washing materials

• If the furnace is used in connection with a cooling unit,

install the furnace upstream or in parallel with the

cooling unit coil. Premature heat exchanger failure will

result if the cooling unit coil is placed ahead of the

furnace.

6

For vertical (upflow or downflow) applications, the

V

minimum cooling coil width shall not be less than furnace

width minus 1”. Additionally, a coil installed above an

upflow furnace or under a counterflow furnace may be

the same width as the furnace or may be one size larger

than the furnace. Example: a “C” width coil may be

installed with a “B” width furnace.

For upflow applications, the front of the coil and furnace

must face the same direction.

• If the furnace is installed in a residential garage, position

the furnace so that the burners and ignition source are

located not less than 18 inche s (457 mm) abov e the floor.

Protect the furnace from physical damage by vehicles.

• If the furnace is installed horizon t ally, the furnace access

doors must be vertical so that the burners fire horizontally

into the heat exchanger. Do not install the unit with the

access doors on the “up/top” or “down/bottom” side of

the furnace.

• Do not connect this furnace to a chimney flue that serves

a separate appliance designed to burn solid fuel.

• For counterflow installations, the air conditioning coil

must be downstream from the heat exchanger of the

furnace.

• Counterflow installation over a noncombustible floor.

Before setting the furnace over the plenum opening,

ensure the surface around the opening is smooth and

level. A tight seal should be made between the furnace

base and floor by using a silicon rubber caulking

compound or cement grout.

• Counterflow installation over a combustible floor. If

installation over a combustible floor become s necessary,

use an accessory subbase (see Specification Sheet

applicable to your model for details). A special accessory

subbase must be used for upright counterflow unit

installations over any combustible material including

wood. Follow the instructions with the subbase for proper

installations. Do not install the furnace directly on

carpeting, tile, or other combustible material other than

wood flooring. (NOTE: The subbase will not be required

if an air conditioning coil is installed between the supply

air opening on the furnace and the floor.

ent Pipe Clearance to Combustibles6" using Single Wall Connector or 1"

using B-1 vent.

Top - 1"

Back - 0"

• Adequate combustion/ventilation air must be supplied

to the closet.

• Furnace must be completely sealed to floor or base.

Combustion/ ventilation air supply pipes must terminate

12" from top of closet and 12" from floor of closet. DO

NOT remove solid base plate for side return.

• Return air ducts must be completely sealed to the furnace

and terminate outside the enclosure surfaces.

CLEARANCES AND ACCESSIBILITY

Unobstructed front clearance of 24" for servicing is recommended.

VENT

B1-VENT SINGLE

1" 6" 1" 3" 0" 1"

Top clearance for horizontal configuration - 1"

SIDES FRONT BACK

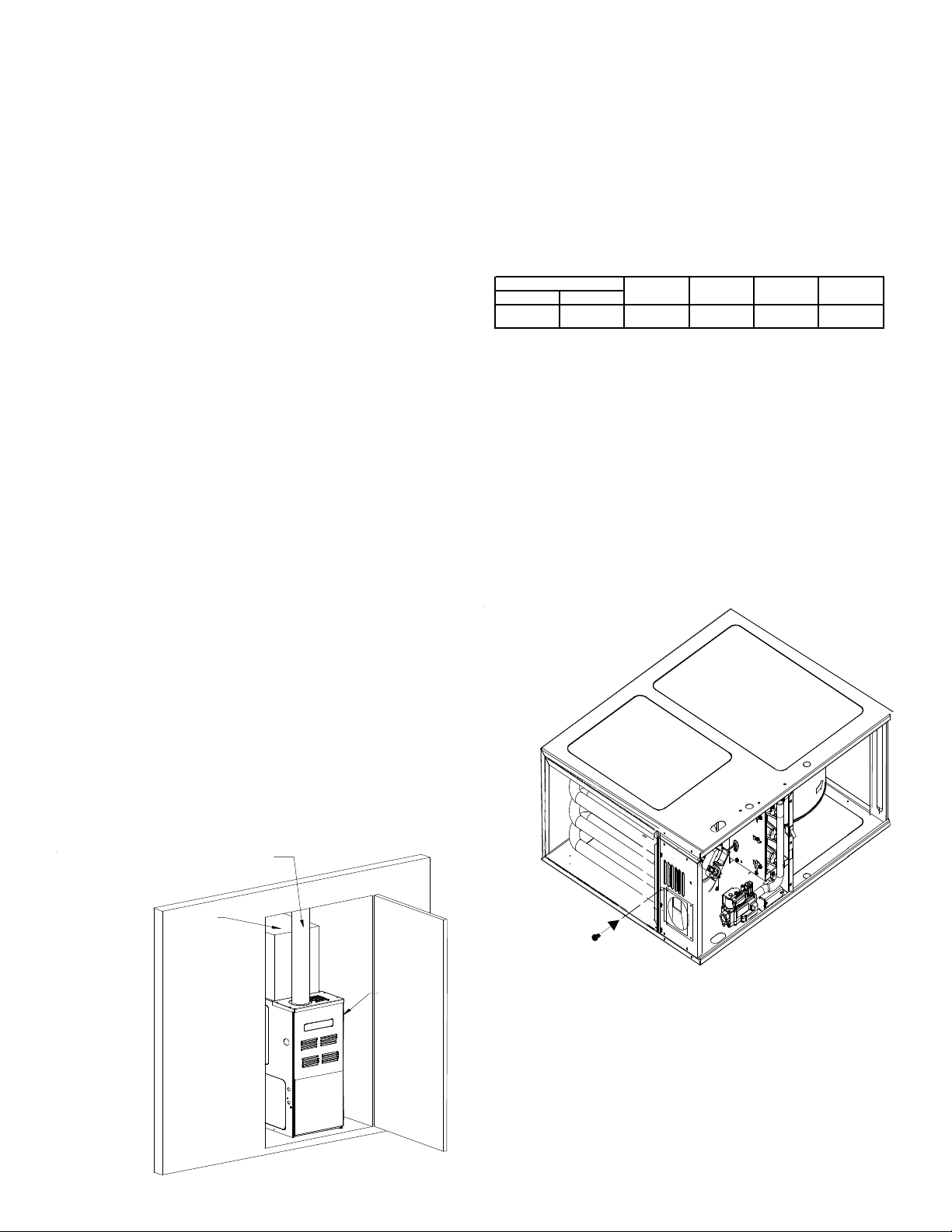

INSTALLATION POSITIONS

An upflow furnace may be installed in an upright position or horizontal on either the left or right side panel. Do not install this

furnace on its back. For vertically installed upflow furnaces, return air ductwork may be attached to the side panel(s) and/or

basepan. For horizontally installed upflow furnaces, return air

ductwork must be attached to the basepan. For counterflow fur-

naces, return ductwork must be attached to the top end of the

blower compartment.

NOTE: Ductwork must never be attached to the back of the furnace.

HORIZONTAL INSTALLATION

horizontal installations,

For

insert the

#8 x 5/8 screw

from the

literature package.

TOP

(PLENUM)

Side

Clearance - 1"

Line contact to framing is permitted when installed in the horizontal configuration. Line contact is defined as the portion of the

cabinet that is formed by the intersection of the top and side.

ACCESSIBILITY CLEARANCE, WHERE GREA TER, SHOULD T AKE PRECE DENCE OVER MINIMUM FIRE PROTECTION CLEARANCE. A gas-fired

furnace for installation in a residential garage must be installed

Front Clearance - 3"

7

so that the ignition source and burners are located not less than

eighteen inches (18") above the floor and is protected or located to

prevent physical damage by vehicles. A gas furnace must not be

installed directly on carpeting, tile, or other combustible materials other than wood flooring.

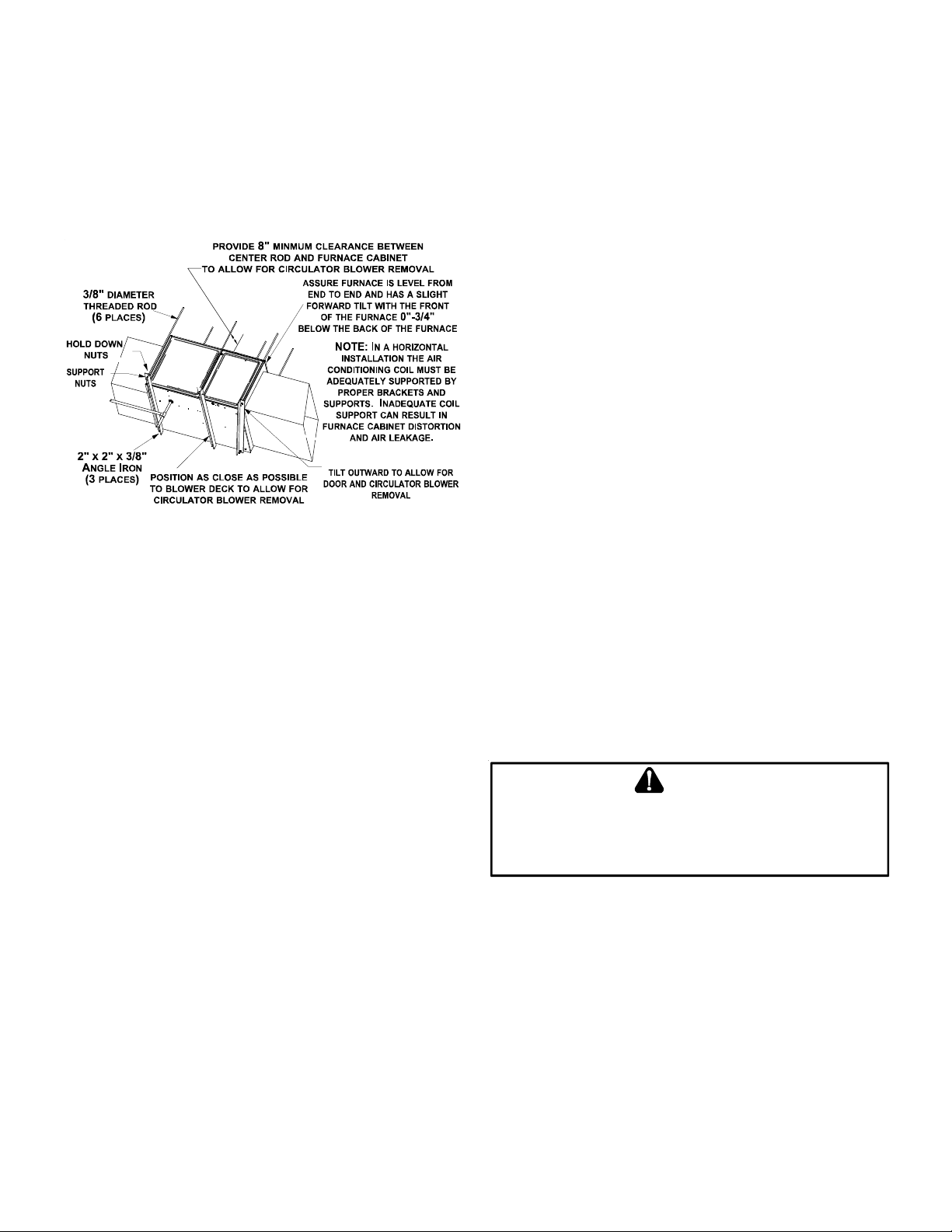

FURNACE SUSPENSION

If suspending the furnace from rafters or joist, use 3/8" threaded

rod and 2”x2”x3/8” angle iron as shown below. The length of rod

will depend on the application and the clearances necessary.

Suspended Furnace

EXISTING FURNACE REMOVAL

NOTE: When an existing furnace is removed from a venting system

serving other appliances, the venting system may be too large to

properly vent the remaining attached appliances.

The following vent testing procedure is reproduced from the Ameri-

can National Standard/National Standard of Canada for Gas-Fired

Central Furnaces ANSI Z21.47-Latest Edition, CSA-2.3-Latest Edition Section 1.23.1. The following steps shall be followed with

each appliance connected to the venting system placed in operation, while any other appliances connected to the venting system

are not in operation:

a. Seal any unused openings in the venting system;

b. Inspect the venting system for proper size and horizontal

pitch, as required by the National Fuel Gas Code, ANSI

Z223.1 or the CAN/CSA B149 Installation Codes and these

instructions. Determine that there is no blockage or

restriction, leakage, corrosion and other deficiencies

which could cause an unsafe condition;

c. In so far as practical, close all building doors and

windows and all doors between the space in which the

appliance(s) connected to the venting system are located

and other spaces of the building. Turn on clothes dryers

and any appliance not connected to the venting system.

Turn on any exhaust fans, such as range hoods and

bathroom exhausts, so they shall operate at maximum

speed. Do not operate a summer exhaust fan. Close

fireplace dampers;

d. Follow the lighting instructions. Place the appliance being

inspected in operation. Adjust thermostat so appliance

shall operate continuously;

e. Test for draft hood equipped appliance spillage at the

draft hood relief opening after 5 minutes of main burner

operation. Use the flame of a match or candle;

f. After it has been determined that each appliance

connected to the venting system properly vents when

tested as outlined above, return doors, windows, exhaust

fans, fireplace dampers and any other gas burning

appliance to their previous conditions of use;

g. If improper venting is observed during any of the above

tests, the common venting system must be corrected.

Corrections must be in accordance with the latest edition of the

National Fuel Gas Code NFP A 54/ANSI Z223.1 and/or CAN/CSA B149

Installation Codes.

If resizing is required on any portion of the venting system, use the

appropriate table in the latest edition of the National Fuel Gas

Code ANSI Z223.1 and/or CAN/CSA B149 Installation Codes.

THERMOSTAT LOCATION

In an area having good air circulation, locate the thermostat about

five feet high on a vibration-free inside wall. Do not install the

thermostat where it may be influenced by any of the following:

• Drafts, or dead spots behind doors, in corners, or under

cabinets.

• Hot or cold air from registers.

• Radiant heat from the sun.

• Light fixtures or other appliances.

• Radiant heat from a fireplace.

• Concealed hot or cold water pipes, or chimneys.

• Unconditioned areas behind the thermostat, such as an

outside wall.

Consult the instructions packaged with the thermostat for mounting instructions and further precautions.

C

OMBUSTION AND VENTILA TION AIR REQUIREMENTS

WARN ING

TO

AVOID PROPERTY DAMAGE, PERSONAL INJURY OR DEATH

SUFFICIEN T FRESH AIR FOR PROPER COMBUSTION AND VENTILATION OF

FLUE GASES MUST BE SUPPLIED

SUPPLIED INTO THE FURNACE AREA

. M

OST HOMES REQUIRE OUTSIDE AIR BE

.

Improved construction and additional insulation in buildings have

reduced heat loss by reducing air infiltration and escape around

doors and windows. These changes have helped in reducing heating/cooling costs but have created a problem supplying combustion and ventilation air for gas fired and other fuel burning appliances. Appliances that pull air out of the house (clothes dryers,

exhaust fans, fireplaces, etc.) increase the problem by starving

appliances for air.

House depressurization can cause back drafting or improper combustion of gas-fired appliances, thereby exposing building occupants to gas combustion products that could include carbon monoxide.

,

8

If this furnace is to be installed in the same space with other gas

appliances, such as a water heater, ensure there is an adequate

supply of combustion and ventilation air for all appliances. Refer

to the latest edition of the National Fuel Gas Code NFPA 54/ANSI

Z223.1 or CAN/CSA B149 Installation Codes or applicable provisions of the local building codes for determining the combustion

air requirements for the appliances.

This furnace must use indoor air for combustion. It cannot be installed as a direct vent (i.e., sealed combustion) furnace.

Most homes will require outside air be supplied to the furnace

area by means of ventilation grilles or ducts connecting directly

to the outdoors or spaces open to the outdoors such as attics or

crawl spaces.

C

ATEGORY

I V

ENTING

(V

ERTICAL VENTING

)

WARN ING

TO

PREVENT POSSIBLE PERSONAL INJURY OR DEATH DUE TO

ASPHYXIATION, THIS FURNACE MUST BE CATEGORY

VENT USING CATEGORY

III

VENTI NG

.

I

VENTED

. DO

NOT

Category I V enting is venting a t a non-positive pre ssure. A furnace

vented as Category I is considered a fan-assisted appliance and

the vent syst em does not have to be “ ga s tight. ” NOTE: Single st age

gas furnaces with induced draft blowers draw products of combustion through a heat exchanger allowing, in some instances,

common venting with natural draft appliances (i.e. water heaters). All installations must be vented in accordance with National

Fuel Gas Code NFP A 54/ANSI Z223.1 - lat est e dition. In Cana da, the

furnaces must be vented in accordance with the National Standard of Canada, CAN/CSA B149.1 and CAN/CSA B149.2 - latest editions and amendments.

NOTE: Masonry vent kit (MVK-01 and MVK-02) is to only be used

on interior masonry chimneys or qualifying exterior masonry

chimney applications identified in the MVK kit installation

instructions. To ensure safe and reliable operation, use only the

kit listed for your model.

Kit Inp ut KBTU Range L imit Sett i ng

MVK-01 40-100 250°F

MVK-02 120-140 290°F

This kit is for use on Amana

Note :

33” tall “H” and “S” model furnaces installed in the upflow position only.

®

brand and Goodman® brand 80% AF UE,

NOTE: The vertical height of the Category I venting system must be

at least as great as the horizontal length of the venting system.

WARNING

TO

PREVENT POSSIBLE PERSONAL INJURY OR DEATH DUE TO

ASPHYXIATION, COMMON VENTI NG WITH OTHER MANUFACTURER’S

INDUCED DRAFT APPLIANCES IS NOT ALLOWED

.

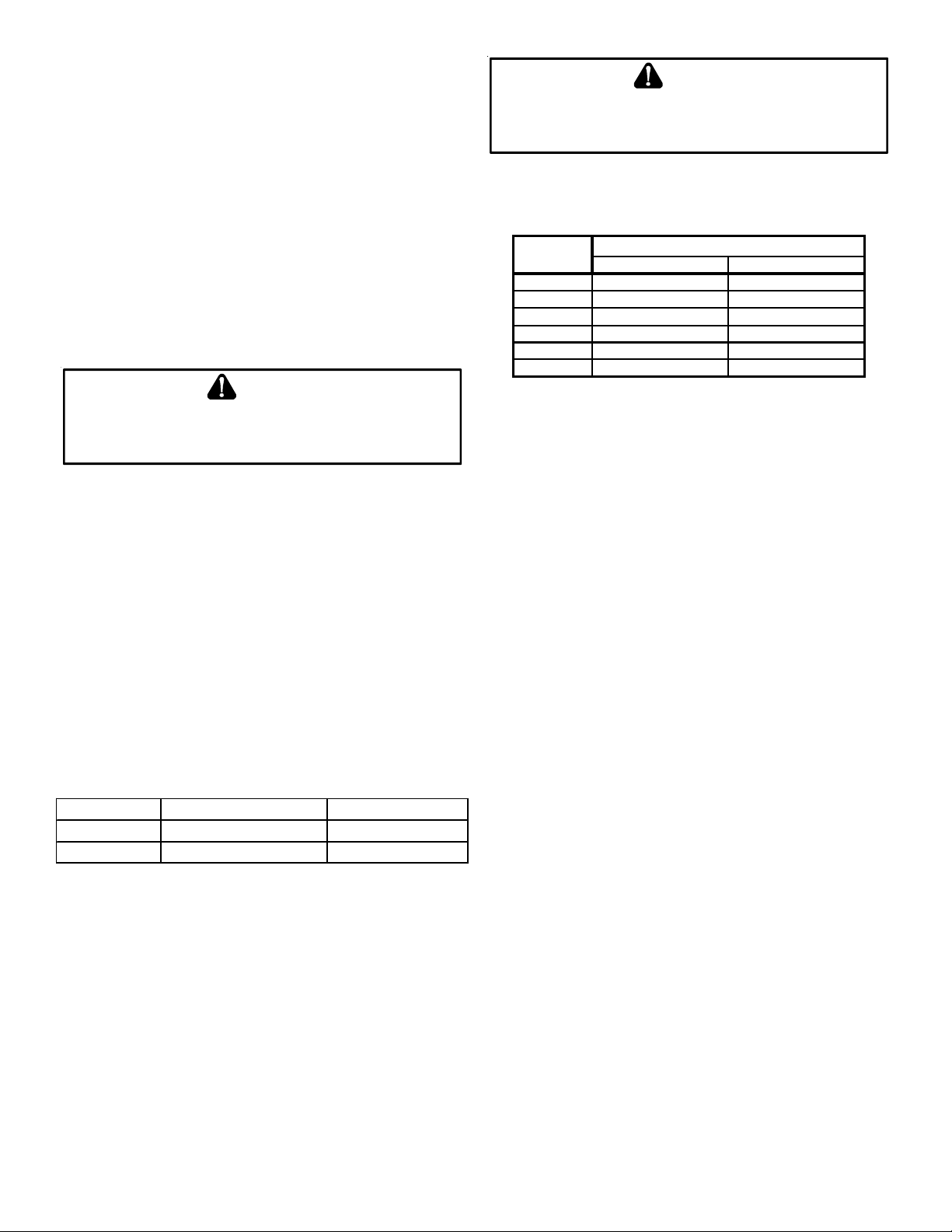

The minimum vent diameter for the Category I venting system is as

shown:

MODEL

40 4 Inch 4 Inch

60 4 Inch 4 Inch

80 4 Inch 4 Inch

100 5 Inch 5 Inch

120 5 Inch N/A

140 5 Inch N/A

UPFLOW COUNTERFLOW

MINIMUM VENT

Under some conditions, larger vents than those shown above may

be required or allowed. When an existing furnace is removed from

a venting system serving other appliances, the venting system may

be too large to properly vent the remaining attached appliances.

Upflow or Horizontal units are shipped with the induced draft

blower discharging from the top of the furnace. (“T op” is as viewed

for an upflow installation.) The induced draft blower can be rotated 90 degrees with the (0270F01119) chimney transition bottom kit for Category I venting. For upflow models installed vertically or horizontally, a four inch single wall pipe can be used to

extend the induced draft blower outlet 1/2” beyond the furnace

cabinet. THIS PRODUCT IS NOT DESIGNED FOR COUNTERCLOCK-

WISE INDUCED DRAFT BLOWER ROT A TION.

Vent the furnace in accordance with the National Fuel Gas Code

NFPA 54/ANSI Z223.1 - latest edition.

Venting - F urnace Installed in Horiz ont al Position

THIS FURNACE IS NOT DESIGN CERTIFIED TO BE HORIZONTALLY

VENTED THROUGH AN EXTERIOR SIDE W ALL.

The following describes an optional venting procedure when the

furnace is installed in the horizontal left discharge position.

To rotate the induced draft blower clockwise, you will need to

purchase one (0270F01119) chimney transition bottom kit.

1. Disconnect electrical power from the furnace.

2. Disconnect the induced draft blower power leads, flue pipe,

and pressure switch tubing.

3. Remove the round cutout fr om the right side of the wrapper.

4. Remove and save the four screws that fasten the induced

draft blower to the flue collector box.

5. Remove and save the three screws that hold the chimney

assembly to the induced draft blower.

6. Remove and save the four screws that fasten the chimney

top to the chimney bottom.

9

7. Remove the chimney transition bottom from the transition

bottom kit.

8. Install the chimney top with the four screws retained from

step 6 onto the new chimney transition bottom from the

transition bottom kit.

9. Remove the induced draft blower and install the new

chimney assembly to it using the three screws retained

from step 5.

10. Rotate the induced draft blower 90 degrees to the right,

feed the flue pipe through the round cutout from the outside

of the wrapper, and fit onto the chimney top assembly.

Secure the pipe to the chimney top from the front, top, and

bottom using (3) screws and rotating the induced draft

blower to properly orient the assembly. NOTE: If the pipe

section is less than 18” , then att ach it directly to the chimney

top on 3 sides and feed it through the round cutout from the

inside of the wrapper.

11. Reattach the induced draft blower using the (4) screws

retained from step 3. Ensure the gasket located between

the induced draft blower and collector box is rotated

accordingly.

12. Reconnect the induced draft blower power leads. NOTE: If

the wires are not long enough, pull extra wire from the wire

bundle in the blower compartment.

13. Reconnect the remaining flue pipe, and the pressure switch

tubing. Ensure that all wires and the pressure switch tubing

is at least one inch from the flue pipe, or any other hot

surface.

14. Restore power to furnace.

NOTE: In a horizontal installation the air conditioning coil must

be adequately supported by proper brackets and supports.

Inadequate coil support can result in furnace cabinet distortion

and air leakage.

Counterflow units are shipped with the induced draft blower discharging from the top of the furnace. (“T op” a s viewed for a counterflow installation.)

Vent the furnace in accordance with the National Fuel Gas Code

NFPA54/ANSI Z223.1-latest edition.

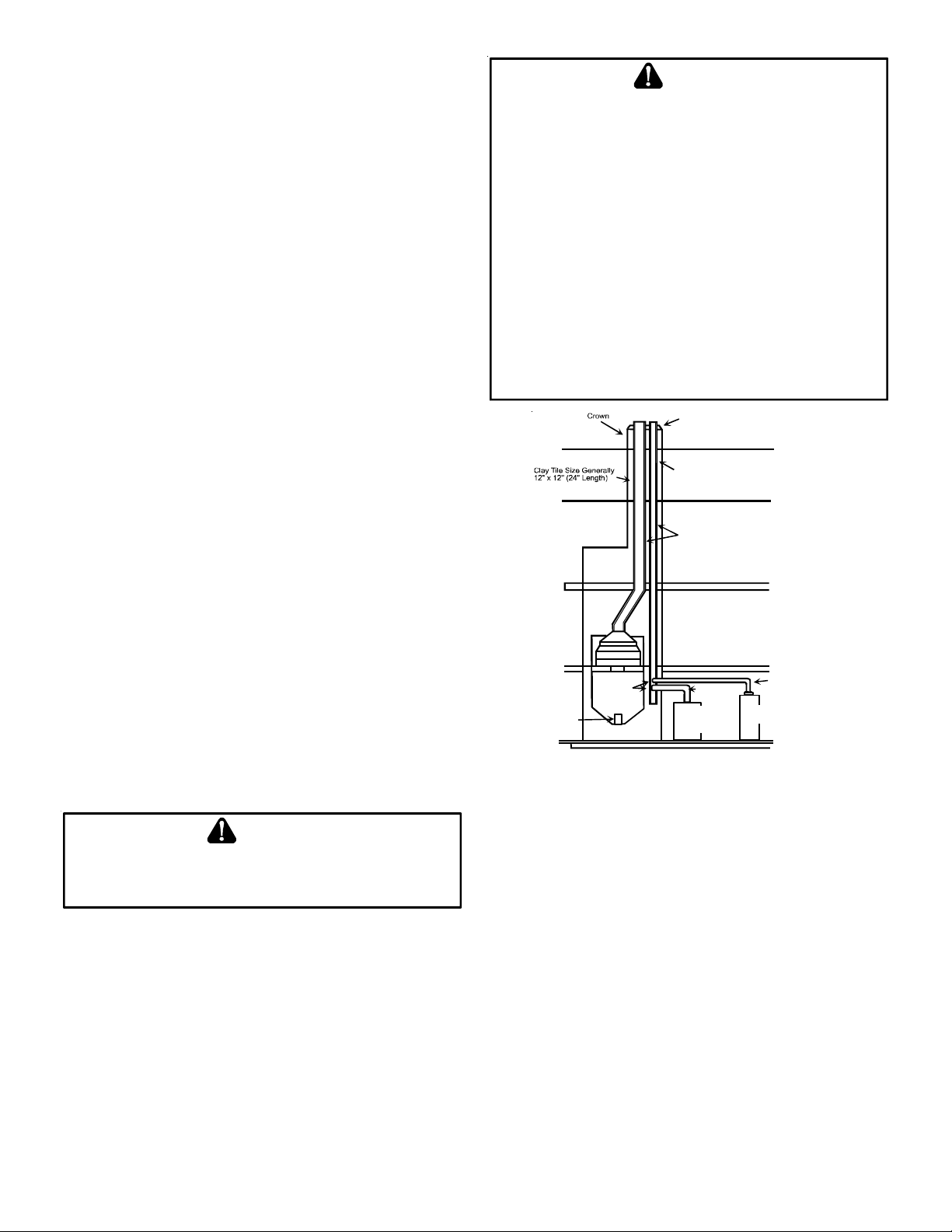

WARNING

P

OSSIBILITY OF PROPERTY DAMAGE, PERSONAL INJURY OR DEATH

DAMAGING COND ENSATION CAN OCCUR INSIDE MASONRY CHIMNEYS

WHEN A SINGLE FAN-ASSISTED CATEGORY

FURNACE) IS VENTED WITHOUT ADEQUATE DILUTION AIR

CONNECT AN

FURNACE IS COMMON VENTED WITH A DRAFT HOOD EQUIPPED

APPLIANCE OR THE CHIMNEY IS LINED WITH A METAL LINER OR TYPE

METAL VENT

SIZED IN ACCORDANCE WITH THE APPROPRIATE VENTI NG TABLES

80%

APPLIANCE, THE POTENTIAL FOR COND E NSATION DAMAGE MAY STILL

EXIST WITH EXTREMELY COLD CONDITION S, LONG VENT CONNECTORS

EXTERIOR CHIMNEYS, OR ANY COMBIN ATIO N OF THESE CONDITIONS

HE RISK OF COND ENSATION DAMAGE IS BEST AVOIDED BY USING

T

MASONRY CHIMNEY AS A PATHWAY FOR PROPERLY SIZED METAL LINER

OR TYPE

80%

FURNACE TO A MASONRY CHIMNEY UNLESS THE

. ALL

INSTALLATIONS USING MASONRY CHIMNEYS MUST BE

FURNACE IS COMMON VENTED WITH A DRAFT HOOD EQUIPPE D

B

METAL VENT

Clean Out

Typical Multiple Flue Clay Tile Chimney

Throat

Damper

Breech

.

Clay Tile Size: 8" x 8" x12 "

I

APPLIANCE

Wash

(Each x 24" Length)

1/2" to 1" Air Space

F.A .F. Vent

Connector

Fan Assisted

Forced Air

Furnace

Roof Line

Attic Floor

Second Floor

First Floor

Water Heater

Vent Connector

Natural Draft

Water Heater

Basement Floor

(80% AFUE

. DO

NOT

CHECKLIST SUMMARY

B

. IF AN

,

.

WARN ING

N

EVER ALLOW THE PRODUCTS OF COMBUSTION, INCLUDING CARBON

MONOXIDE, TO ENTER THE RETURN DUCTWORK OR CIRCULATION AIR

SUPPLY

.

EXTERIOR MASONRY CHIMNEYS (CATE GORY I FURNACES ONL Y)

An exterior masonry chimney is defined as a “Masonry” chimney

exposed to the outdoors on one or more side s below the roof line. ”

The ability to use a clay lined masonry chimney depends on a

parameter not associated with interior chimneys. This variable is

the geographic location of the installation. Researchers have discovered that the winter design temperatures have a direct impact

on the suitability of this type of venting. In most situations, the

existing masonry chimneys will require a properly sized metallic

liner.

This checklist serves as a summary of the items to be checked

before venting an 80+ furnace into a masonry chimney. In addition, we recommend that a qualified serviceman use this checklist

to perform a yearly inspection of the furnace venting system.

This checklist is only a summary. For detailed information on

each of the procedures mentioned, see the paragraph referenced

with each item.

10

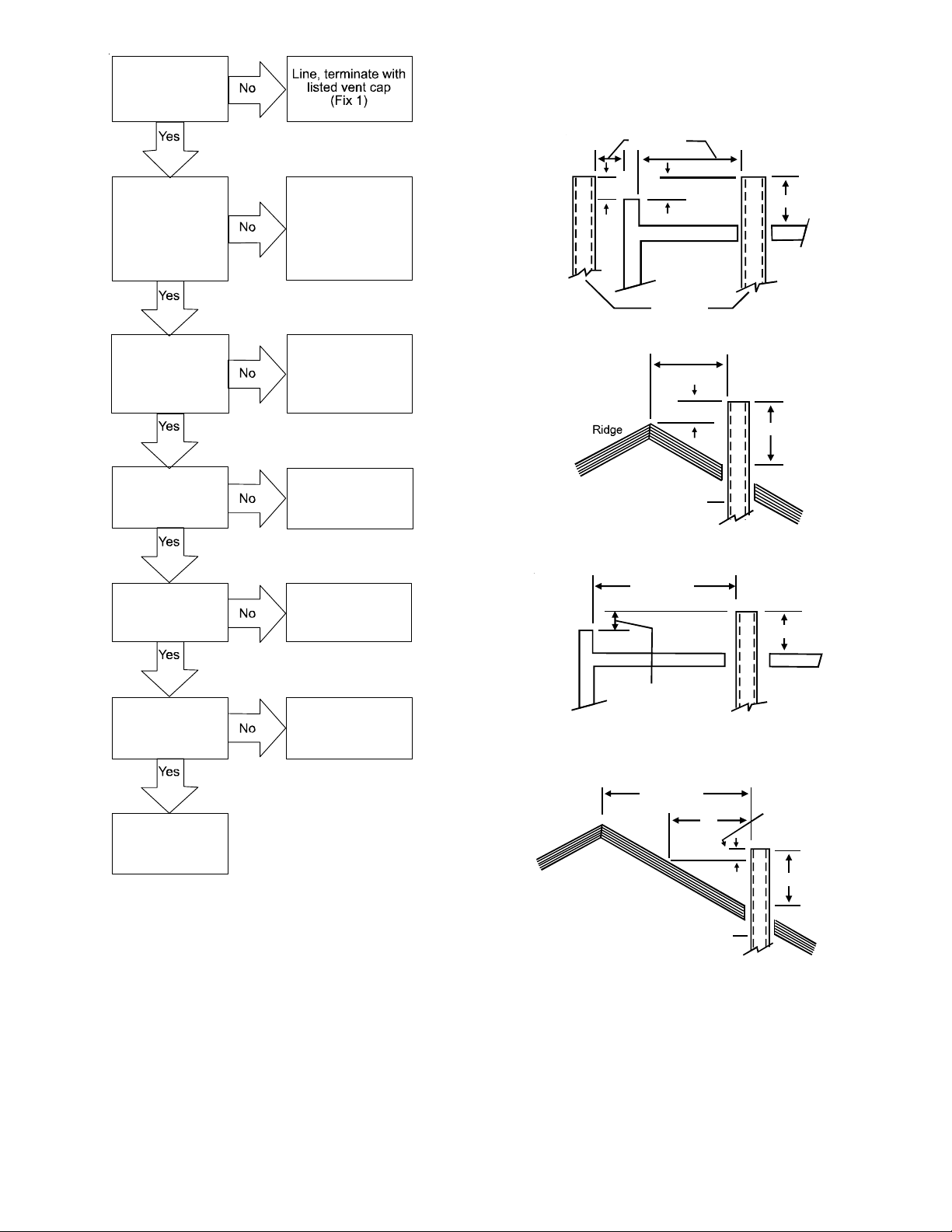

Proper Chimney

Termination?

(Check 1)

If the chimney does not meet these termination requirements, but

all other requirements in the checklist can be met, it may be possible for a mason to extend the chimney. If this will not be practical, see Fix 1.

10' or Less

Chimney channel

free of solid and

liquid fuel

appliances?

(Check 2)

Crown in good

condition

(Check 3)

Cleanout free of

debris?

(Check 4)

Liner in good

condition?

(Check 5)

Change venting

arrangements

(Fix 2)

Rebuild crown

(Fix 3)

and/or Reline

(Fix 4)

Reline

(Fix 4)

Reline

(Fix 4)

2' Min.

Termination 10 Feet Or Less From Ridge, Wall or Parapet

2' Min.

Wall o r

Parapet

Chimney

10' or Less

2' Min.

Chimney

More than 10’

3' Min.

3' Min.

3’ Min.

Dilution air

available?

(Check 6)

Reline

(Fix 4)

Complete the

installation.

(Check 7)

CHECK 1 - PROPER CHIMNEY TERMINATION.

A masonry chimney used as a vent for gas fired equipment must

extend at least three feet above the highest point where it passes

through the roof. It must extend at least two feet higher than any

portion of a building within a horizontal distance of 10 feet. In

addition, the chimney must terminate at least 3 feet above any

forced air inlet located within 10 feet. The chimney must extend at

least five feet above the highest connected equipment draft hood

outlet or flue collar.

NOTE:

No Height

above parapet

Wall or

Parapet

Ridge

Termination More Than 10 Feet From Ridge, Wall or Parapet

required when distance

from walls or parapet is

more than 10 feet.

More than 10’

Chimney

10’

2” Min.

Chimney

Height above any

roof surface within

10 feet horizontally.

3’ Min.

CHECK 2 - ANY SOLID OR LIQUID FUEL APPLIANCES VENTED INTO THIS

CHIMNEY

Solid fuel appliances include fireplaces, wood stoves, coal furnaces, and incinerators.

Liquid fuel appliances include oil furnaces, oil-fired boilers and

oil-fired water heaters.

CHANNEL

11

Appliances which burn propane (sometimes referred to as LP (liquefied petroleum)) gas are considered gas-fired appliances.

CHECK 3 - CHIMNEY CROWN CONDITION.

Damage from condensate usually shows up first in the crown. If

any of the following trouble signs are present, the condition of the

crown is not satisfactory:

a) Crown leaning

b) Bricks missing

c) Mortar missing

d) T ile liner cracked

e) No tile liner

f) Salt staining at mortar joints. (White stains, and mortar

becomes sandy and/or erodes.)

For problems a, b, or c, see Fix 3. If problems d, e, or f are present,

see Fix 4. IMPORT ANT : It may be nece ssary to follow both Fix 3 and

Fix 4.

CHECK 4 - DEBRIS IN CLEANOUT

A cleanout (dropleg) must be present such that the upper edge of

the cleanout cover is at least 12 inches below the lower edge of the

lowest chimney inlet opening.

A chimney without a cleanout could become partially blocked by

debris. If no cleanout is present, the chimney must be relined (Fix

4). Remove the cleanout cover, and examine the cleanout for debris. If significant amounts of any of the following are found:

• Fuel oil residue

• Bricks

• Mortar or sand

• Pieces of the tile liner

• Rusted pieces of the metallic liner - reline the chimney

(Fix 4).

CHECK 5 - LINER CONDITION.

If a metal liner is present, it must be checked. It cannot be assumed that all existing metal liners are correctly installed and in

good condition.

Remove the lowe st existing ven t connector , and e xamine the inside

of the elbow or tee at the base of the liner. A small amount of soot

may be considered acceptable, provided the installer vacuums it

away. If rusted pieces of the liner have collected here, the metal

liner must be removed and replaced (Fix 4).

Next, gently tap the inside of the liner with a Phillips screwdriver.

If the screwdriver perforates the liner, or if the tapping does not

sound like metal hitting metal, the liner must be removed and

replaced (Fix 4).

Remember that all appliances must be vented inside the liner.

Venting one appliance inside the liner and another appliance outside the liner is not acceptable.

Next, use a flashlight and small mirror to sight up the liner. B vent

must be supported so as to not come into direct contact with the

chimney walls or tile liner. If it is not, it can probably be rehung so

as to be acceptable. A thimble or fire stop may be helpful here.

Flexible liners should be hung straight or nearly straight. If it is

spiraled in the chimney and in good condition, it should be rehung.

To do this, break the top seal; pull up and cut off the excess liner

length, and refit the top seal. Use caution when doing this, as the

cut edges of flexible liners may be sharp.

The surfaces of the liner must be physically sound. If gaps or holes

are present, the metal liner must be removed and replaced (Fix 4).

Finally, confirm that the metal liner is the correct size for the

appliances to be installed. Use the GAMA tables and rules.

If a metal liner is not present, a clay tile liner must be present, or

the chimney must be lined (Fix 4).

Use a flashlight and small mirror at the cleanout or vent connector to inspect the clay tile liner. If any of the following problems

are present:

• T ile sections misaligned

• T ile sections missing

• Gaps between tile sections

• Signs of condensate drainage at the cleanout or vent

connectors

• Mortar protruding from between tile sections

• Use of sewer pipe or drainage pipe rather than an

approved fire clay tile reline the chimney (Fix 4).

Next, measure the size of the liner. It may be possible to do this

from the cleanout. The liner must be at least as large as the minimum size established by the tables in National Fuel Gas Code

NFPA 54/ANSI Z223.1 - latest edition and in the National Standard

of Canada, CAN/CSA B149.1 and CAN/CSA B149.2 - latest editions

and amendments. If the liner is too small or too large, then the

chimney must be relined (Fix 4).

CHECK 6 - DILUTION AIR.

If gas-fired appliances are to be vented into a clay tile liner, a

source of dilution air is required.

Dilution air cannot be obtained through:

• Induced draft appliances

• Natural draft appliances with vent dampers

Sufficient dilution air can ordinarily be obtained through the draft

hood of a natural draft appliance only if the appliance’s vent

connector does not include a vent damper. If dilution air wi ll not

be available, the chimney must be relined (Fix 4).

CHECK 7 - COMPLETE THE INSTALLATION.

If Checks 1 through 6 have been satisfactory, and the liner is an

acceptable size as determined by the tables in National Fuel Gas

Code NFPA 54/ANSI Z223.1 - latest edition and in the National

Standard of Canada, CAN/CSA B149.1 and CAN/CSA B149.2 - latest

editions and amendments, then the clay tile liner can probably be

used as a vent for the gas appliances. However, the installer must

keep in mind the following factors which may render the tile liner

unsuitable for use as a vent:

12

• Extremely cold weather

• Long vent connectors

• Masonry chimneys with no air gap between the liner and

the bricks. (In practice, this can be difficult to detect.)

• Exterior chimneys (The tables in National Fuel Gas Code

NFPA 54/ANSI Z223.1 - latest edition and in the National

Standard of Canada, CAN/CSA B149.1 and CAN/CSA B149.2

- latest editions and amendments assume interior

chimneys.)

If, in the judgment of the local gas utility, installer, and/or local

codes; one or more of the above factors is likely to present a

problem, the chimney must be relined (Fix 4).

FIX 1 - LINER TERMINATION

Any cap or roof assembly used with a liner must be approved by

the liner manufacturer for such use. The liner and cap/roof assembly must then terminate above the roof in accordance with the

manufacturer’s instructions.

In some cases, a shorter extension above the roof may be possible

with a liner than would be required with a masonry chimney.

For further information on relining, see Fix 4.

FIX 2 -CHANGE VENTING ARRANGEMENTS

If the masonry chimney has more than one channel, it may be

possible to vent the gas appliances into one channel and vent the

solid or liquid fuel appliance(s) into another channel(s). Do not

vent an 80+ Furnace inside of a metal liner with other appliances

vented outside the liner.

Alternatively, the homeowner may agree to discontinue use of the

fireplace (solid fuel appliance). If so, the tile liner must be cleaned

to remove creosote buildup. The fireplace opening must then be

permanently sealed.

If oil-fired appliance(s) are being replaced by gas-fired

appliance(s), the tile liner must first be cleaned to remove the fuel

oil residue.

If none of the above options is practical, the furnace may need to

be vented vertically with a B Vent.

Under some conditions, a 90%+ furnace could be installed rather

than an 80% furnace. The 90%+ furnace can be vented horizontally

or vertically through PVC pipe.

FIX 3 - REBUILD THE CROWN

If the chimney crown is damaged, a qualified mason must repair it

in accordance with nationally recognized building codes or standards. One such standard which may be referenced is the Standard for Chimneys, Fireplaces, Vents, and Solid Fuel Burning Appliances, ANSI/NFPA 211.

FIX 4 - RELINING

Relining options include B vent and flexible liners.

If the chimney has diagonal offsets, B vent probably cannot be

used.

If B vent is to be used, it must be supported adequately. Supports

(such as fire stops or thimbles) must be used to prevent the B vent

from coming into direct contact with the tile liner or chimney

walls. Direct contact would result in higher heat loss, with an

increased possibility of poor venting system performance.

It is not acceptable to vent one appliance inside the B vent and

other appliances outside. The excess space between the B vent and

the chimney walls must be covered at the top of the chimney by a

weatherproof, corrosion resistant flashing.

The B vent should then be topped with a listed vent cap. The listed

vent cap will, when installed per the manufacturer ’s instructions,

prevent problems due to rain, birds, or wind effects.

A B-vent installed as described in this section is considered to be

an enclosed vent system, and the sizing tables in National Fuel

Gas Code NFPA 54/ANSI Z223.1 - latest edition and in the National

Standard of Canada, CAN/CSA B149.1 and CAN/CSA B149.2 - latest

editions and amendments may be used.

If a flexible liner is to be used, it must be made of the proper

materials:

• For most residential applications, an aluminum liner

should be acceptable.

• If the combustion air supplied to the furnace will be

contaminated with compounds containing chlorine or

fluorine, a liner of AL 29-4C stainless steel should be

used. Common sources of chlorine and fluorine

compounds include indoor swimming pools and chlorine

bleaches, paint strippers, adhesives, paints, varnishes,

sealers, waxes (which are not yet dried) and solvents

used during construction and remodeling. Various

commercial and industrial processes may also be sources

of chlorine/fluorine compounds.

• Heavier gauge 300 and 400 series stainless steel liners

were developed for use with oil or solid fuel appliances.

They are not suitable for use with gas-fired appliances.

Flexible liners specifically intended and tested for gas

applications are listed in the UL “Gas and Oil Equipment

Directory”. (UL Standard 1777).

For sizing of flexible liners, see the tables in the National Fuel Gas

Code NFPA 54/ANSI Z223.1 - latest edition and in the National

Standard of Canada, CAN/CSA B149.1 and CAN/CSA B149.2 - latest

editions and amendments.

To install the liner, read and follow the liner manufacturer’s instructions and your local codes. Excess liner length should be

pulled out of the chimney and cut off . U se caution when doing this,

as the cut edges of flexible liners may be sharp. Do not spiral

excess liner inside of the chimney. Support the liner as recommended by the liner manufacturer.

Some manufacturers of flexible liners offer an insulation sleeve

designed to be added to the liner before it is installed in the chimney. (Poured insulation, either vermiculite or other materials, is

no longer recommended.) Insulation will need to be added to the

flexible liner if:

• It is required by the liner manufacturer’s instructions.

13

• The previous liner was properly sized and installed, and

suffered from condensation damage.

• It is required by your local building codes.

Even if none of those three conditions exist which require additional liner insulation, the installer may wish to consider it if:

• The local climate is very cold.

• The chimney is very tall.

• The vent connectors used are very long or have a large

number of elbows.

• Local experience indicates that flexible liners installed

without insulation are likely to have condensation

problems.

Insulation must be selected and installed in accordance with the

liner manufacturer’s instructions.

Finally, cap the chimney and terminate the liner in accordance

with the liner manufacturer’s instructions.

E

LECTRICAL CONNECTIONS

115 VOLT LINE CONNECTIONS

Before proceeding with electrical connections, ensure that the supply voltage, frequency, and phase correspond to that specified on

the unit rating plate. Power supply to the furnace must be NEC

Class 1, and must comply with all applicable codes. The furnace

must be electrically grounded in accordance with local codes or,

in their absence, with the latest edition of The National Electric

Code, ANSI NFP A 70 and/ or The Canadian Electric Code CSA C22.1.

Use a separate fused branch electrical circuit containing properly

sized wire, and fuse or circuit breaker. The fuse or circuit breaker

must be sized in accordance with the maximum overcurrent protection specified on the unit rating plate. An electrical disconnect

must be provided at the furnace location.

Line voltage wiring must enter into the junction box provided with

the furnace.

NOTE: Line polarity must be observed when making field

connections.

FOSSIL FUEL APPLICATIONS

WARN ING

HIGH VOLTAGE !

TO

AVOID THE RISK OF ELECTRICAL SHOCK, WIRING TO

THE UNIT MUST BE POLARIZED AND GROUNDED

.

WARN ING

HIGH VOLTAGE !

TO

AVOID PERSONAL INJURY OR DEATH DUE TO

ELECTRICAL SHOCK, DISCONNECT ELECTRICAL POWER

BEFORE SERVICING OR CHANGING ANY ELECTRICAL

WIRING

.

CAUTION

L

ABEL ALL WIRES PRIOR TO DISCONNECTION WHEN SERVICING

CONTROLS

OPERATION

. W

IRING ERRORS CAN CAUSE IMPROPER AND DANGEROUS

. V

ERIFY PROPER OPERATION AFTER SERVICING

WARN ING

HIGH VOLTAGE !

TO

AVOID THE RISK OF INJURY, ELECTRICAL SHOCK OR

DEATH, THE FURNACE MUST BE ELECTRICALLY

GROUNDED IN ACCORDANCE WITH LOCAL CODES OR IN

THEIR ABSENCE, WITH THE LATEST EDITION OF THE

N

ATIONAL ELECTRIC CODE

.

This furnace can be used in conjunction with a heat pump in a

fossil fuel application. A fossil fuel application refers to a combined gas furnace and heat pump installation which uses an outdoor temperature sensor to determine the most cost efficient means

of heating heat pump or gas furnace.

A heat pump thermostat with two stages of heat is required to

properly use a furnace in conjunction with a heat pump. Refer to

the fossil fuel kit installation instructions for additional thermostat requirements.

Strictly follow the wiring guidelines in the fossil fuel kit installation instructions. All furnace connections must be made to the

furnace integrated control module and the FURNACE terminal strip

on the fossil fuel control board.

JUNCTION BOX RELOCATION

.

E

DGES OF SHEET METAL HOLES MAY BE SHARP

PRECAUTION WHEN REMOVING HOLE PLUGS

Line voltage connections can be made through either the right or

left side panel. The furnace is shipped configured for a right side

electrical connection. To make electrical connections through the

opposite side of the furnace, the junction box must be relocated to

the left side prior to making electrical connections. To relocate

the junction box, perform the following steps.

WARNING

.

. USE

GLOVES AS A

WIRING HARNESS

The wiring harness is an integral part of this furnace. Field alteration to comply with electrical codes should not be r equired. Wires

are color coded for identification purposes. Refer to the wiring

diagram for wire routings. If any of the original wire as supplied

with the furnace must be replaced, it must be replaced with wiring

material having a temperature rating of at least 105° C. Any replacement wiring must be a copper conductor.

WARNING

TO

PREVENT PERSONAL INJURY OR DEATH DUE TO ELECTRIC SHOCK

DISCONNECT ELECTRICAL POWER BEFORE INSTALLING OR SERVICING THIS

UNIT

.

1. Remove both doors from the furnace.

2. Remove and save the screws holding the junction box to

the right side of the furnace.

14

,

Loading...

Loading...