®

Gas

Self-Clean

Owner's

Downdraft

an

anual

AG

* Additional alphanumeric characters representing

other models in series may follow each model

number,

Natural Gas Only

Please Read Manual Before installing and

Operating Range

e

important

Save for local electrical inspector's use.

installer

Leave this manual and other literature with consumer for

future use.

Customer

Keep these instructions for future reference. If appliance

changes ownership, be sure this manual accompanies

range.

Contents

Model Identification ................................................. 2

Parts and Accessories ............................................ 2

Service .................................................................... 2

Asure TM Extended Service Plan .............................. 2

Important Safety Information ....................................... 3

Installation .................................................................. 6

Packing Material ..................................................... 6

Cabinet Opening ..................................................... 6

Minimum Clearances to Combustible Surfaces ....... 7

Installing Side Trim ................................................. 7

Electrical Connection Requirements ....................... 8

Electrical Connection Clearance ............................. 8

Gas Supply Location ............................................... 8

Gas Supply Pressure .............................................. 9

Duct Requirements ................................................. 9

Duct Location ......................................................... 9

Duct Length ............................................................ 10

Duct Connection ..................................................... 12

Gas Connection Requirements ................................ 13

Pressure Regulator Location ................................... 13

Gas Connection ...................................................... 13

Testing for Gas Leaks ............................................. t4

Seal Openings ........................................................ 14

Anti-tip Bracket Installation ..................................... 14

Place and Level Range ............................................ 15

Removal and Replacement of Range ....................... 15

Test and Adjust Oven Burner Flame ........................ 15

Cartridges .................................................................. 16

Cartridge Features .................................................. 16

Installing Cartridges ................................................ 16

Removing Cartridges ............................................... 18

Adjusting Surface Burner Low Flame Size .............. 18

Testing and Adjusting Burner Flame Characteristics 19

Igniting Surface Burner without Electricity ............... 19

Features .................................................................... 20

Operation ................................................................... 23

Setting Clock .......................................................... 23

Setting Minute Timer ............................................... 23

Prepare to Bake ...................................................... 23

Baking .................................................................... 24

Timed Baking .......................................................... 24

Delayed Baking ....................................................... 25

Adjusting Oven Temperature .................................... 25

Broiling ................................................................... 25

Prepare for Self-clean and

Delayed Self-clean Cycle ........................................ 26

Self=cleaning ........................................................... 26

Delayed Self=clean Cycle ........................................ 26

Operating Surface Burners ...................................... 27

Cooking Utensils ..................................................... 28

Smoke Control Grill TM and Griddle .......................... 29

Cooking Guide ........................................................... 30

Care and Cleaning ...................................................... 32

Removing Oven Door ............................................... 32

Replacing Oven Light .............................................. 32

Removing Storage Drawer ....................................... 33

Removing Vent Filter ............................................... 33

Cleaning .................................................................. 34

BEFORE CALLING FOR SERVICE ............................ 36

VVarranty .................................................................... 37

Quick Reference Instructions ..................................... 38

Model Identification

Complete enclosed registration card and promptly return.

If registration card is missing, call Consumer Affairs

Department at 1-800-843-0304 inside U.S.A.

319-622-55tl outside U.S.A. When contacting Amana,

provide product information located on rating plate. Rating

plate is located on the oven frame. Record the following:

Model Number:

Manufacturing Number:

Serial or S/N Number:

Date of purchase:

Dealer's name and address:

Save Time and Money

If something seems unusual

PLEASE CHECK BEFORE CALLING

FOR SERVICE page 36,

Parts and Accessories

Purchase replacement parts and additional accessories

(e.g., refrigerator shelves, dryer racks, or cooktop

modules) over the phone. To order accessories for your

Amana product, call 1=800-843=0304 inside U.S.A. or

319=622=5511 outside U.S.A.

Service

Keep a copy of sales receipt for future reference or in

case warranty service is required. Any questions or to

locate an authorized servicer, call 1-800-NAT=LSVC

(1-800=628-5782) inside U.S.A. 319-622-5511 outside

U.S.A. Warranty service must be performed by an

authorized servicer. Amana Appliances also recommends

contacting an authorized servicer if service is required

after warranty expires.

Asure TM Extended Service Plan

Amana offers long=term service protection for this new

range. Asure TM Extended Service Plan is specially

designed to supplement Amana's strong warranty.

This plan covers functional parts, labor, and travel

charges. Call 1=800=528=2682for information.

2

iMPORTANT SAFETY iNFORMATiON

WARNING

To reduce the risk of the appliance tipping, it must be

secured by a properly installedanti-tip bracket. To

make sure bracket has been installedproperly, remove

the storage drawer or panel and look under the range

with a flashlight. Bracket must be engaged in the rear

corner of the range.

,, ALL RANGES CAN TIP

,, INJURY TO PERSONS

COULD RESULT

,, INSTALL ANTI-TIP

BRACKET PACKED

WITH RANGE

,, SEE INSTALLATION

INSTRUCTIONS

WARNING I

To avoid death, personal injury or property damage,

information in this manual must be followed exactly.

- Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any other

appliance.

- WHATTO DO IFYOU SMELL GAS

Do not try to light any appliance.

Do not touch any electrical switch; do not use

any phone in your building.

Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's

instructions.

If you cannot reach your gas supplier, call the fire

department.

Installation and service must be performed by a

qualified installer, service agency or the gas

supplier.

WARNING

To avoid personal injury or property damage from

smoke or fire, do not store combustible gasoline or

other combustible materials near range.

WARNING

To avoid risk of electrical shock, personal injury, or

death, make sure your range has been properly

grounded and always disconnect it from main power

supply before servicing.

WARNING

To avoid personal injuryor property damage from

smoke or fire, do not use grill or griddle iffan is not

operating. In the unlikely event that the fan is not

operating, contact an authorized service technician.

CAUTION

DO NOTTOUCH AREAS NEAR SURFACE

BURNERS--Areas near surface burners may become

hot enough to cause burns. During and after use, do

not touch, or let clothing touch or other flammable

materials contact surface burners or areas near

surface units until they have had enough time to cool.

These areas include the rangetop and backguard.

CAUTION

DO NOTTOUCH INTERIOR SURFACES OF OVEN--

Interior surfaces of an oven may become hot enough

to cause burns. During and after use, do not touch, or

let clothing or other flammable materials touch heating

interior surfaces of oven until they have had enough

time to cool. Other range surfaces that may become

hot enough to cause burns are the oven door and oven

vent under range backguard.

WARNING !

To avoid personal injury, do not sit, stand or lean on

oven door or oven drawer.

WARNING !

Gas leaks may occur in your system and result in a

dangerous situation. Gas leaks may not be detected by

smell alone. Gas suppliers recommend you purchase

and install an UL approved gas detector. Install and

use in accordance with manufacturer's instructions.

CAUTION l

This appliance contains or produces a chemical or

chemicals which can cause death or serious illness

and which are known to the state of California to

cause cancer, birth defects or other reproductive harm.

To reduce the risk from substances in the fuel or from

fuel combustion make sure this appliance is installed,

operated, and maintained according to the instructions

in this booklet.

CAUTION

Do not store items of interest to children in cabinets

above a range or behind the backguard of a range.

Children climbing on the range to reach items could

be seriously injured.

CAUTION 1

To avoid delayed or improper ignition, do not obstruct

the flow of combustion or ventilation air.

ALL APPLIANCES

1. Proper installation. Be sure your appliance is properly

installed and grounded by a qualified technician.

2. Never Use Your Appliance for Warming or Heating the

Room.

3. Do not leave children alone. Children should not be

alone or unattended in the area where the appliance

is in use. They should never be allowed to sit or stand

on any part of the appliance.

4. Wear proper apparel. Loose fitting or hanging

garments should never be worn while using appliance.

5. User Servicing--Do not repair or replace any part of

the appliance unless specifically recommended in the

manual. All other servicing should be referred to a

qualified technician.

6. Storage in oron appliance. Flammable materials

should not be stored in an oven or near surface units.

7. Do not use water on grease fires. Smother fire or

flame, or use dry chemical or foam-type extinguisher.

8. Use only dry potholders. Moist or damp potholders on

hot surfaces may result in burns from steam. Do not

let potholder touch flame. Do not use a towel or other

bulky cloth.

SURFACE COOKING UNITS

1. Use proper pan size. This appliance is equipped with

one or more surface units of different size. Select

utensils having flat bottoms large enough to cover the

surface unit heating element. The use of undersized

utensils will expose a portion of the burner to direct

contact and may result in ignition of clothing. Use of

oversized utensils concentrates heat on cooking

surface and can cause damage to range. Proper

relationship of utensil to burner improves efficiency.

2. Never leave surface units unattended. Boilover causes

smoking and greasy spillovers that may ignite.

3. Make sure drip bowls are in place. Absence of these

pans or bowls during cooking may subject wiring or

components underneath to damage.

4. Protective liners. Do not use aluminum foil to line drip

bowls or oven bottom. Improper installation of these

liners may result in a risk of fire.

5. Glazed cooking utensils--Only certain types of glass,

ceramic, earthware, or other glazed utensils are

suitable for rangetop service without breaking due to

sudden change in temperature.

6. Utensil handles should be turned inward and not

extend over adjacent surface units. To reduce the risk

of burns, ignition of flammable materials, and spillage

due to unintentional contact with the utensil, the

handle of a utensil should be positioned so that it is

turned inward, and does not extend over adjacent

surface units.

OVENS

1. Use care when opening door. Let hot air or steam

escape before removing or replacing food.

2. Do not heat unopened food containers. Build-up of

pressure may cause container to burst and result in

injury.

3. Keep oven vent ducts unobstructed.

4. Placement of oven racks. Always place oven racks in

desired location while oven is cool. If rack is removed

while oven is hot, do not let potholder contact burner

inoven.

SELF=CLEANING OVENS

1. Do not clean door gasket. The door gasket is

essential for a good seal. Care should be taken not

to rub, damage, or move the gasket.

2. Do not use oven cleaners. No commercial oven

cleaner or oven liner protective coating of any kind

should be used in or around any part of the liner.

3. Clean only parts listed in manual.

4. Before self-cleaning the oven, remove broiler pan,

oven racks, and other utensils.

5. Remove all items from rangetop and backguard.

4

VENTiLATiON DUCTS

1. Clean ventilation ducts frequently. Grease should not

be allowed to accumulate on hood or filter.

2. When flaming foods, turn fan on.

in Case of Fire

Fires can occur as a result of over cooking or excessive

grease. Though a fire is unlikely, if one occurs, proceed

as follows:

Surface Element Fire

1. Smother the fire with a nonflammable lid or baking

soda, or use a Class ABC or BC extinguisher. Not

water. Not salt. Not flour.

2. As soon as it is safe to do so, turn the surface

controls to OFF. Turn off power at main circuit breaker

or fuse box, and gas supply.

Oven Fires

1. Ifyou see smoke from your oven, do not open oven.

2. Press OVEN CANCEL pad to tum off oven.

3. As an added precaution, turn off power at main circuit

breaker or fuse box, and gas supply.

4. Turn on vent to remove smoke.

5. Allow food or grease to burn itself out in oven.

6. If smoke and fire persist, call fire department.

7. If there is any damage to components, call an

authorized servicer before using range.

Delayed ignition

Surface Burners

Burner should ignite within 4 seconds. If burner does not

ignite within 4 seconds turn control knob to OFF position

and follow directions for installing burner caps "Installing

Cartridges" section. Try burner again. If burner still does

not ignite in 4 seconds, contact an authorized servicer.

Bake and Broil Burner Flame

Allow no more than 40-60 seconds before burner ignites

and heat is felt. To check for heat, open oven door to first

stop and place hand over oven door. If heat is not felt,

press OVEN CANCEL pad to turn offoven. If burner

repeatedly fails to ignite, contact an authorized servicer.

Precautions

• Do not cook food directly on rangetop surface, always

use cookware.

• Do not mix household cleaning products. Chemical

mixtures may interact with objectionable or even

hazardous results.

• Do not put plastic items on warm cooking areas. They

may melt and stick.

• Do not slide rough metal objects across rangetop

surface. Scratching or metal marking can result.

• Do not leave fat heating unless you remain nearby. Fat

can ignite if overheated by spilling onto hot surfaces.

• Do not allow pots to boil dry as this can cause damage

to cooking surface and pan.

• Do not use rangetop surface as a cutting board.

• Do not use range for storage or as adisplay counter.

Installation

Packing Material

Remove protective packing materials from range. Tape

residue can be cleaned with a soft cloth and alcohol.

Duct pieces are in range storage drawer and oven cavity.

Remove all protective plastic and any residue on stainless

steel models. Any left on unit may cause spotting.

Cabinet Opening

Using dimensions, prepare cabinet opening.

Range extends beyond cabinet when installed.

WARNING

To avoid risk of burns or fire by reaching over surface

burners, cabinet storage space located above range

should be avoided. Ifcabinet storage isprovided,

install a range hood that projects horizontally a

minimum of 5 inches beyond the cabinet bottom to

reduce the risk.

E

A_30I/s to 30 inches

B--36 inches standard

C--35 inches standard

D_24 inches standard

E 25 inches standard

A--13/4 inches minimum

B--36 inches standard

C--35 inches standard

D--24 inches standard

E--30I/8 to 30 inches

F_25 inches standard

Standard Cabinet and Countertop with Backsplash

Standard Cabinet and Countertop without Backsplash

F

B

A_301/8 to 30 inches

B--36 inches standard

C--35 inches standard

D_24 inches standard

E 23_/2inches

F 25 inches minimum

Standard Cabinet and Countertop in island

Minimum Clearances to Combustible

Surfaces

Using dimensions, prepare cabinet opening.

• Minimum clearance to rearwall is 0 inches.

• Minimum clearance to a vertical right or left side wall is

3 inches.

• Minimum clearance to countertop/cabinet on each side

is 0 inches.

• Minimum of 30 inches between top of cooking surface

and bottom of an unprotected wood or metal cabinet.

• Minimum of 24 inches between cooking surface and

protected wood or metal cabinet above range. Cabinet

bottom must be protected by at least ¼ inch thick

millboard with not less than No. 28 MSG sheet steel,

.015 inch thick stainless steel, .024 inch thick

aluminum, or .020 inch thick copper.

Installing Side Trim

If desired, optional side trim provided can be installed on

range. Side trim must be installed above counter top level and

tapped down into place.

Side trim can be mounted in several different positions

depending on counter top opening, cabinet structure, and

range features.

Freestanding with Backsplash

To mount trim flush with front of counter top, use #3 trim

holes and "A" range holes. Trim does not extend the full

length of the cooking surface.

Optional Mounting

"A" range holes allow an extra 3/8-inchforward

adjustment. Trim holes #1, #2, and #3 allow a 72-inch

adjustment. Trim can be mounted in any desired location

using holes provided.

E

_30 inches minimum

B 30 inches unprotected/24 inches protected minimum

C 13inches maximum

D 3 inches minimum (Both Sides)

E 18 inches minimum

Minimum Clearances to Combustible Surfaces

Side of Range

Side Trim

Side Trim

A

23

2

2

3.

Left

A If the countertop is roll formed, notch the countertop to allow

for overlapping trim.

B Side trim

Roll Formed Countertop

Electrical Connection Requirements

WARNING 1

To avoid the risk of serious electrical shock or property

damage, do not cut or remove the third (ground) prong

from the power plug. A 3-wire grounded conductor

system must be used. Relying on the flexible

connector, hard piping or any other part of the gas

supply line as a ground may cause fire, electrical

shock and/or erratic control operation.

Electrical Connection Clearance

Electrical connection must be located in the shaded area

shown. Electrical connection must not interfere with gas

connection.

Range must be electrically grounded in accordance with

local codes or in the absence of local codes, with the

National Electrical Code, ANSI/NFPA No. 70-Latest

Edition.

In Canada, electrical connections are to made in

accordance with CSA C22.1 Canadian Electrical Code.

All electrical connections are to be made in accordance

with CSA standards Z240.6.1 electrical requirements for

mobile homes.

Use a dedicated 120 volt, 60 hertz, 3-prong receptacle

protected by a 15 amp circuit breaker or time delay fuse.

A qualified electrician should confirm the outlet is properly

grounded and polarized.

If a 2-prong outlet is encountered, range owner must

replace outlet before using range. Do not cut off cord, use

plug adapter or extension cord, or remove grounding plug.

L1 Neutral

Neutral

side 115 ± 1:

C

_18 inches (45,2 cm)

B_0 inches (50,8 cm)

C 5 inches (12,7 cm)

D 10inches (25,4cm)

_301/4 inches(76,5cm)

Electrical Connection Location

C

Gas Supply Location

Gas supply must be located in the shaded area shown.

Gas connection must not interfere with the electrical

connection.

prong

Standard 120 Volt, 60 Hertz

\

A_4 inches (10,2 cm)

B 2inches (5 cm)

C 2inches (5 cm)

Gas Supply Location

Gas Supply Pressure

1 CAUTION

To avoid property damage, maximum gas supply

pressure must not exceed 14" WCP.

• Appliance and individual shutoff valve must be

disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in

excess of ½ psig (3.5kPa) (14" WCP).

• Appliance must be isolated from gas supply piping

system by closing manual shutoffvalve during any

pressure testing of the gas supply piping system at

test pressures equal to or less than ½ psig (3.5kPa)

(14" WCP).

• Gas supply pressure for checking regulator setting

must be at least 1"WCP above manifold pressure

shown on rating label.

Duct Requirements

• Duct should be 6-inch round metal ducting. Island or

peninsula installations may require 31/4X 10 inch duct.

• To ensure proper ventilation, duct work must not exceed

60 equivalent feet.

• Curved fittings should not account for more than 50% of

duct length.

• Flexible duct is not recommended because of irregular

interior surface. Ifflexible duct is to be used, one foot is

equal to 2 feet of metal duct. NEVER USE PLASTIC

TYPE DRYER DUCTING.

• Do not vent into an attic or crawl space. Vent range

outside.

• Flexible duct elbows are equal to twice as many feet as

smooth metal elbows.

• Never install two elbow fittings next to each other. Two

elbows installed together create a poor vent path and

insufficient ventilation.

• Seal all duct joints tightly using duct tape. Openings left

in ducting allow smoke and odor to escape inside

house.

• For best performance, do not use more than three 90°

elbows.

• 6-inch transition duct provided must be mechanically

secured to exhaust blower outlet. Secure transition duct

using two screws provided.

Duct Location

Backwall

1. Locate studs inwall.

2. Measure and cut an opening for thimble as illustrated

in figure below. Cutout should be 6%-inch diameter

circle.

3. Ducting is completed in Duct Connection section.

q

C_

_8 inches

B 45/16inches

Backwall Duct Location

Floor

1. Locate studs in floor.

2. Measure to locate center of floor duct location. See

figure below.

3. Cut anopening for floor transition piece as illustrated

in figure below. Cutout should be 71/4x 71/4inches

square. If opening is not correctly aligned, duct does

not connect properly.

4. Ducting is completed in Duct Connection section.

Duct Length

Ducting design is in terms of maximum length of straight

metal duct. To ensure proper air movement, limit fittings,

other than straight, to 50% of total duct length. Maximum

allowable calculated duct length is 60 equivalent feet.

• Use Duct Length Piece Equivalents section to calculate

duct length.

• Flexible duct is not recommended because it can

create a fire hazard. However, if it is used, one foot of

flexible duct is equal to two feet of smooth metal duct.

C

A

_107/s inches

B 131/sinches for installation with counter top or backsplash

behind range. 11% inches for installation without counter top

or backsplash behind range.

Floor Duct Location

Transition

Piece 0'

90° Elbow 5'

10' of Duct 10'

Wall Cap 0'

Total Feet 15'

Duct Length Example

10

Duct Length Piece Equivalents

1 foot of 31¼x 10 inch duct = 1 equivalent foot

I

1 foot of 6 inch pipe = 1 equivalent foot

31/4x 10 inch to 6 inch

transition = 4½ equivalent

feet

31/4x 10 inch to 6 inch 90

degree transition =

5 equivalent feet

31Ax 10 inch 90 degree

elbow = 5 equivalent feet

31/4x 10 inch flat elbow =

12 equivalent feet

6 inch to 31/4x 10 inch

transition =

1 equivalent foot

6 inch to 31/4x 10 inch 90

degree transition =

5 equivalent feet

6 inch 90 degree elbow =

5 equivalent feet

6 inch 45 degree elbow =

2½ equivalent feet

31/4x 10 inch wall cap

(Unrestricted) =

0 equivalent feet

6 inch wall cap

(Unrestricted) =

0 equivalent feet

11

Duct Connection

Floor

1. Attach rubber gasket around edge of transition piece.

• Flat side of rubber gasket must be on under side of

transition piece, See figure below,

A

%

%

A Transition piece

B Gasket

.

Remove blower transition from blower.

5.

Attach floor elbow duct to blower using 2 screws

provided.

• Floor elbow duct should be inside blower.

.

Connect electrical supply.

7.

Push range into position.

• Tilt range slightly while pushing in range. Tilting

range allows floor plate to clear gasket.

• Make sure that floor elbow duct is directly over

transition piece and rubber gasket.

• Rubber gasket provides a seal between floor elbow

and transition piece.

Backwall

1. Remove screw in front of blower transition separating

blower transition from blower housing.

2. Place hose clamp around round end of blower

transition and attach flex duct to blower transition

using hose clamp.

Floor Connection

.

Place round end of transition piece into floor. Secure

transition piece using 8 screws provided in kit.

• Lift edge of rubber gasket to install screws.

• Make sure round edge of gasket isfacing up.

.

Insert floor plate into elbow duct and attach using 2

screws provided.

• Tighten only front screw.

• When installed, wide flange of floor plate must face

toward back of range.

A \

\ B

I

_Blower

B Floor elbow duct

C_loor plate

D_ransition piece and gasket

E_lower transition

A \

• \

D

A Blower and transition piece

B_ose clamps

_Flex duct

D Thimble

Baclcwall Connection

3. Place long end of thimble into wall and secure

thimble using four screws provided, one in each

corner.

4. Place hose clamp provided around short end of

thimble. Attach opposite end of flex duct to short

end of thimble using hose clamp.

5. Connect electrical supply.

6. Carefully push range back into position. Avoid

pinching transition piece or flex duct.

Insert Floor Plate into Elbow Duct and Attach

12

7. Usingguidescrewtolocateholeinrearofblower

housingpositiontransitioninsideblowerhousing.

Rotatetransitionuntilholeinfrontofblowerhousing

isaligned.Securetransitionwithscrewprovided.

8. Sealallductjointswithducttape.

9. Checkunderrangetobesurelevelinglegisfully

engaged in the anti-tip bracket.

10. Instafl storage drawer.

Gas Connection Requirements

Before connecting this appliance to the gas supply piping

system, confirm installationmeets the requirements of local

codes, or in the absence of local codes, with the National

Fuel Gas Code, ANSi Z223.1 -Latest Edition.

Gas Connection (Natural Gas Only)

Connect gas supply to regulator using hard pipe or flexible

connector (Check local codes). Pressure regulator

supplied with this appliance has al/2 inch NPT female

connection. If gas union is used, remove storage drawer,

slide range into place, and connect union.

® A manuN shutoff, not supplied with range, must be

installed in an accessible location outside of range.

® Use joint compound on all male pipe threads.

® Use supplied pressure regulator only.

® Do not overtighten gas fitting when attaching to

pressure regulator. Overtightening may crack regulator.

® Support pressure regulator with wrench when instNling

gas fitting.

When installed in mobile housing, installation is to be in

accordance with CSA standard Z241.1 gas equipped

mobile housing.

The installation of appliances designed for manufactured

(mobile) home installation must conform with

Manufactured Home Construction and Safety Standard,

Title 24 CFR, Part 3280, or when such standard is not

applicable, the Standard for Manufactured Home

Instaflation, ANSI225.1/NFPA 501 A-Latest Edition, or with

local codes or the standard CAN/CSA-z240MH, "Mobile

Homes", and with local codes where applicable.

The instNlation of appliances is to be in accordance with

CAN1 =B149.1 or B149.2 installation code for gas burning

appliances and equipment and/or local codes. Part 1 and/

or local codes.

Pressure Regulator Location

Remove the storage drawer and locate regulator under

oven cavit'r inrear.

,/

1

WARNING !

To avoid property damage or personal injury, only use

a new flexible connector that is AGA/CGA design

certified.

• Do not use an old connector.

• Do not reuse a connector after moving appliance.

A B

A Regulator

B_Flexibte Connector

C_Manual Shut Off Valve

D_Adaptor

Flexible Connection

Pressure Regulator Location

insure red tab

REMAINS in the

OPEN or On

position during

installation.

13

A B C

F

_Union

B_anual Shut OffValve

C_educing Elbow (3/4-inch to l/2-inch)

D 3/4-inch Stub

E 1/2-inch Nipple

F Regulator

Hardpipe Connection

Testing for Gas Leaks

Leak Testing of the appliance shall be conducted

according to the manuafacturer's instructions. After final

gas connection is made, turn on manual gas valve and

test all connections in gas supply piping and range for

gas leaks,

E

WARNING

Seal Openings

Openings in wall behind the range or on floor under range

must be sealed before sliding range into position.

Anti=tip Bracket Installation

To reduce risk of range tipping, secure range with a

properly installed anti-tip bracket.

1. Measure (A)from back wall on right and left side of

cabinet cutout. Mark measurements on floor and draw

a straight line connecting marks.

• Measure 31/2inches when installed with

backsplash.

• Measure 13/4inches when installed without

backsplash.

• Drop vertical line from back of cutout and measure

1_/2inches when installed in island.

2. Position anti-tip bracket.

• If range is installed beside cabinet(s), place anti-tip

bracket with back edge on line drawn on floor and

side of bracket against cabinet.

• If range is not installed beside cabinet(s), position

range where it will be installed. Draw a line along

side of range on floor from front to back. Remove

range. Place anti-tip bracket with back edge over

line drawn from back wall and side of bracket over

line drawn along side of range on floor.

• Anti-tip bracket can be installed on either right or

left side.

Toavoid property damage or serious personal injury,

never use a lighted match to test for gas leaks.

Place soap suds on connection.

• Bubbles appear if leak is present.

2. Ifbubbles appear, shut off gas supply valve.

3. Tighten joint if leak is at factory fitting.

• If leak is not at factory fitting, unscrew, apply more

joint compound, and tighten to correct leak.

4. Retest connection for leak after tightening.

• Retest any connections that were disturbed.

Test for Gas Leaks

or

\\\\\

/ \ A

i

Anti-tip Bracket Installation

3. Mark 2 hole locations in anti-tip bracket.

4. Drill 2 holes.

• If drilling into wood, use a 3/32-inchdrill bit.

• If drilling into concrete, use a 3/16-inchmasonry drill

bit and insert plastic anchors.

5. Secure bracket to floor using screws supplied. Slide

range into position.

6. Remove range storage drawer or panel and confirm

anti-tip bracket is engaged with range leveling leg.

• See "Removing Storage Drawer" or "Removing

Panel" section.

14

Place and Level Range

CAUTION I

To avoid damaging oven door, do not lift or move range

by oven door handle. Glass can break.

Plug in range. Slide range into place. Carefully level range

using legs provided. Range must be level to cook and

bake uniformly.

• Place a level on top oven rackoron top of range when

leveling.

• Leveling legs must be extended out 1¼inch to engage

anti-tip bracket.

Removal and Replacement of Range

1. Turn offgas, and disconnect gas and power to range.

2. Slide range forward.

3. Unplug range cord and place range aside.

4. Remove anti-tip bracket.

5. Install anti-tip bracket into new location using

instructions provided with bracket or see Anti-tip

Bracket Installation section in this manual.

6. Toreinstall range, follow instructions in Installation

section of this manual.

Adjust Oven Burner Flame

1. Remove storage drawer.

• See "Removing Storage Drawer" section.

2. Locate air shutter behind downdraft vent.

3. Loosen air shutter lock screw and open or close air

shutter.

• Tighten air shutter lock screw after adjusting.

4. Replace cover plate and storage drawer.

A

B

A Air Shutter Lock Screw

B_)rifice Hood

C_ir Shutter

Adjust Air Shutter

Test and Adjust Oven Burner and Broiler

Flame

Turn on oven burner and broiler. See "Baking" and

"Broling" sections for operating instructions. Properly

adjusted flames are blue with a distinct deep blue inner

cone approximately ½ inch long. Flame should not have

any yellow flame when burning.

Bake burner flame should not be visible in the oven cavity

when burning and should not extend into the oven cavity

beyond the removable oven bottom.

• If burnerflame is blowing or noisy, reduce airflow to

burner.

• If burner flame is yellow and does not hold its shape,

increase airflow to burner.

[

Burner Flame

Broiler Flame

1. Open oven door and locate air shutter on ceiling of

oven cavity.

2. Loosen air shutter lock screw and open or close air

shutter.

• Tighten air shutter lock screw after adjusting.

15

Cartridge Features

This range features a choice of different cartridges, shown below. Range is shipped with 1 sealed burner cartridge. Call

your localauthorized dealer or Amana at 1-800-843-0304 inside U.S.A. or 319-622-5511 outside U.S.A. to purchase

additional accessories. Only use cartridges that are approved for range. See label in cartridge well for approved

cartridges.

D

A Left Cartridge Position

B_ight Cartridge Position

C Sealed Burner Cartridge

D Smoke Control Grill TM Cartridge. Installs on right side only.

E Griddle Accessory. Griddle accessory installs on right side only.

Cartridge Features

Installing Cartridges

WARNING 1

To avoid risk of personal injury, all controls must be in

OFF position before removing or installing.

Burner Cartridge

Burner cartridge installs on either side.

1. Turn controls to OFF position.

2. Remove grate and burner caps from cartridge.

3. Place end of cartridge into range well with air

shutters facing rear of well.

• If drip pan from grill or griddle cartridge is in well,

remove before installing burner cartridge.

• Do not tilt cartridge too high. Lifting cartridge over

45 ° can cause damage to orifices.

Installing Burner Cartridge

16

4. Slide cartridge towards rear of range until cartridge

engages range. Lower front of cartridge into well.

5. Place burner caps on burner base.

To make sure cap is properly aligned and leveled, move

burner cap around on burner base. Pegs in the burner

base fit into recess in underside of burner cap. Burner cap

must be correctly seated on burner base for proper

operation of burner.

A D

B/

_Burner Grate

B_urner Bowl

C Burner Cap

D Burner Base

Place Burner Caps and Grate

C

Make sure proper cap size is on each burner base.

Burner does not burn properly ifwrong size burner cap is

placed on burner base.

Correct

Not centered Too small

Too large

Position Burner Caps

6. Ignite burner. Properly adjusted burner flames are

clean and blue with a distinct inner cone

approximately ½ inch long.

• If burnerflame is blowing or noisy, or if burner flame

is yellow and does not hold its shape, see

"Adjusting Burner Flame Characteristics" section.

7. Replace burner grate when flame is properly adjusted.

17

SmokeControlGrill TM

Install on right side only.

1. Turn controls to OFF position.

2. Remove grill from cartridge.

3. Place drip pan in well.

4. Place end of cartridge into range well with air

shutters facing rear of well. Lower front of cartridge

into well.

• Do not tilt cartridge too high. Lifting cartridge over

45° can cause damage to orifices.

5. Place grill grate on cartridge.

Grill

Drip pan

Removing Cartridges

1. Turn all controls to OFF. Make sure cartridge is cool.

2. Using tab on front of cartridge, lift up cartridge until

the bottom clears the range.

• Do not tilt cartridge too high. Lifting cartridge over

45 ° can cause damage to orifices.

3. Pull cartridge toward the front of range and carefully

lift it out.

Adjusting Surface Burner Low Flame Size

1. Push and turn burner control knob to LITEposition.

• Burner sparks until turned from LITE.

2. Set burner control knob to low setting.

3. Remove burner control knob.

4. While holding valve stem stationary, turn screw in

center of burner control stem until flame is adjusted.

• Use small blade screwdriver.

5. Replace burner control knob.

6. Turn surface burner control on and off to test burner

flame.

7. Ifflame is adjusted too low, flame may be easily

extinguished. Flame may be extinguished by drafts,

door opening or closing, heating and cooling vents,

ceiling fans, etc.

Installing Smoke Control Grill TM

Installing Griddle

1. Turn controls to OFF position.

2. Install cartridge according to "Installing Smoke

Control Grill TM Cartridge" section.

3. With grease trap toward rear of range, place griddle

pan over burner.

• To remove griddle cartridge turn all controls to OFF

and reverse steps above.

Grease

Trap

Adjusting Low Burner Flame Size

Installing Griddle

18

Testing and Adjusting Burner Flame

Characteristics

Surface burner should ignite within 4 seconds. Properly

adjusted surface burner flames are clean and blue with a

distinct inner cone approximately 1/4inch to 1/2inch long.

Flames will not be a uniform size around the cap. This

distribution around the cap and grate allows for optimal

heating.

* If burner flame is blowing or noisy, reduce airflow to

burner.

* If burner flame does not hold its shape, increase airflow

to burner.

Adjusting Surface Burner Flame

1. Turn controlsto OFF position.

2. Remove grate and burner caps from cartridge.

3. Remove cartridge according to "Removing Cartridge"

section.

4. Locate air shutters on rear of cartridge.

5. Adjust each air shutter using small screw driver.

* Slide air shutter until shutter isapproximately

1/8inchopen.

6. Replace cartridge according to "Installing Burner

Cartridge" section and check for proper flame.

7. Replace burner grate when flame isproperly adjusted.

Adjusting Grill Cartridge Burner Flame

1. Turn controlsto OFF position.

2. Remove grill or griddle from cartridge ifnecessary.

3. Remove cartridge according to "Removing Cartridge"

section.

4. Locate air shutters on rear of cartridge, loosen air

shutter lock screw, and open or close air shutter.

• Tighten air shutter lock screw after adjusting.

5. Replace cartridge according to"lnstalling Burner

Cartridge" section and check for proper flame.

Adjusting Air Shutter

Adjust Grill Cartridge Burner Flame

igniting Surface Burner without Electricity

If power is not available, ignite surface burner with a

match.

WARNING

To avoid risk of personal injury, property damage, due

to excessive smoke or fire, do not attempt to use grill

or griddle, when power is not available. Fan must be

running to exhaust smoke and fumes.

Hold burning match 1/2 inch from burner head.

2. Push and turn burner control knob to LITEposition.

• Remove hand when burner ignites.

3. Turn burner control knob to OFF position

when finished.

19

Features

A

, B

\

\

\

\

\

\

\

C

\\

\

\\\

\\

\

\

\

\

\

D

K

\

\

\\

\

\

\\

\

\

\\

\

AOven Light Switch

B Surface burner Control Knob

C Surface Burner Module

D Exhaust Vent

E_)ven Vent

F Smoke Control TM Grill Module

G Exhaust Fan Speed Control

H_lectronic Range Control

J Storage Drawer

K Oven Window

\

\\

\

\\

\

\\

'\

F

H

Range Features

2O

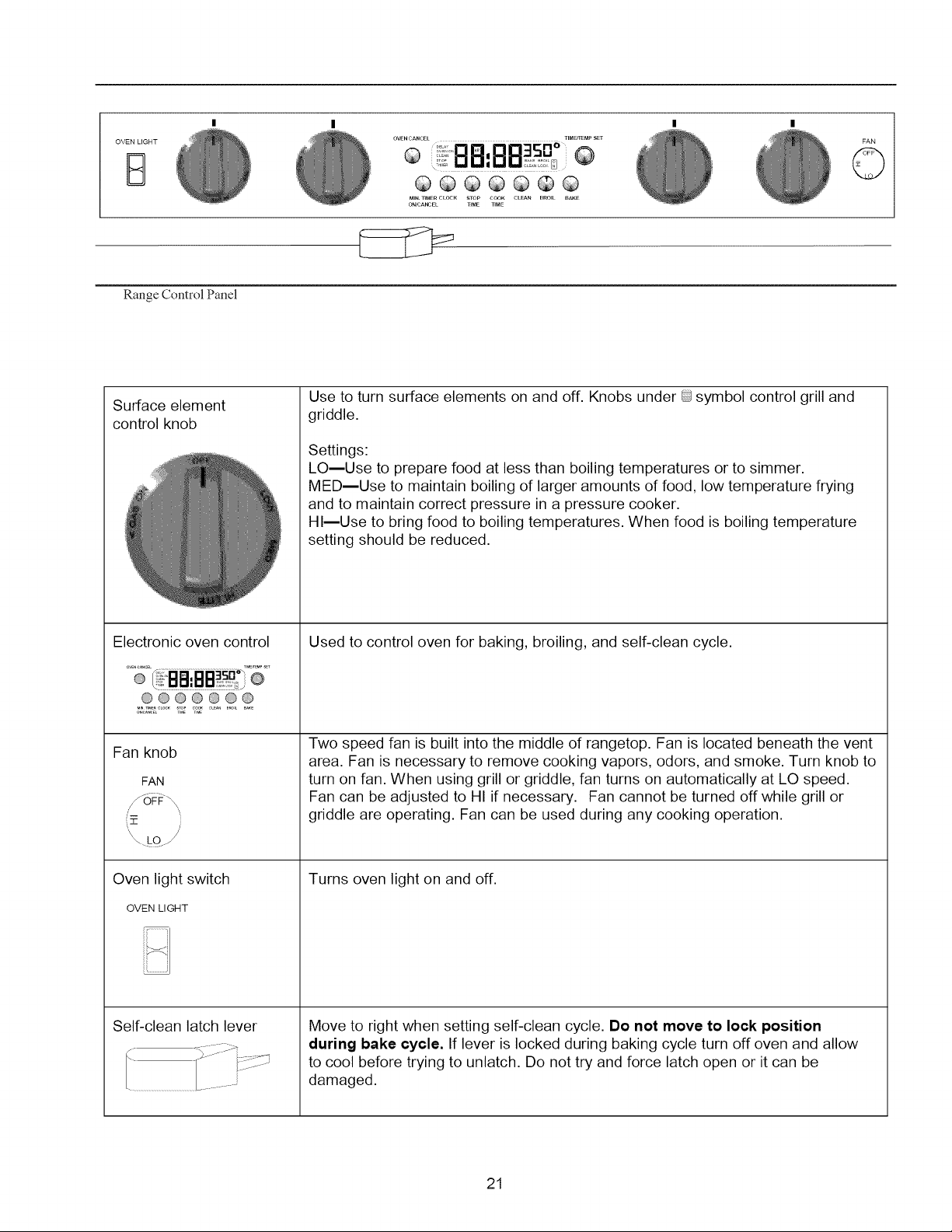

OVEN LIGHT

I I I I

OVENCANCEL TIME_EMPSET

FAN

S

Range Control Panel

Surface element

control knob

@@@@@@@

MIN. 11MER CLOCK STOP COOK CLBN BROIL BAKE

_/CANCEL TIME TIME

Use to turn surface elements on and off. Knobs under @symbol control grill and

griddle.

Settings:

LO--Use to prepare food at less than boiling temperatures or to simmer.

MED--Use to maintain boiling of larger amounts of food, low temperature frying

and to maintain correct pressure in a pressure cooker.

HI--Use to bring food to boiling temperatures. When food is boiling temperature

setting should be reduced.

©

Electronic oven control

@@@@@@@

Fan knob

FAN

i,::z: /

Oven light switch

OVEN LIGHT

Self-clean latch lever

Used to control oven for baking, broiling, and self-clean cycle.

Two speed fan is built into the middle of rangetop. Fan is located beneath the vent

area. Fan is necessary to remove cooking vapors, odors, and smoke. Turn knob to

turn on fan. When using grill or griddle, fan turns on automatically at LO speed.

Fan can be adjusted to HI if necessary. Fan cannot be turned off while grill or

griddle are operating. Fan can be used during any cooking operation.

Turns oven light on and off.

Move to right when setting self-clean cycle. Do not move to lock position

during bake cycle. If lever is locked during baking cycle turn off oven and allow

to cool before trying to unlatch. Do not try and force latch open or it can be

damaged.

21

OVENCANCEL

TIME/TEMP SET

TIMER _ CLEAN

MIN. TIMER CLOCK STOP COOK CLEAN BROIL BAKE

ON/CANCEL TIME TIME

Electronic Range Control

Pad Description

OVEN CANCEL Cancels any cooking or cleaning function except timer.

MIN. TIMER Use to time any kitchen function or cancel timer. Does not control bake, broil, or

ON / CANCEL clean function.

CLOCK Use to set time of day.

STOP TIME Use to set delayed bake and self-clean.

COOK TIME Use to set timed baking.

CLEAN Use to select self-clean cycle.

BROIL Use to select broil.

BAKE Use to select bake.

,, U U

TIME / TEMP SET Use to set temperature or time.

Display Glossary

TIME or HR TIME displays while time-of-day is entered. TIME HR displays when time is

entered for timed or delayed baking or delayed self-cleaning.

TIMER TIMER displays while setting timer.

BAKE BAKE displays while bake oven temperature is entered and when oven bakes.

ON Displays when oven is heating.

STOP Displays when setting the stop time for a delayed baking or self-clean cycle.

BROIL Displays when broil is set and is broiling.

CLEAN Displays when self-clean cycle is entered and set.

LOCK LOCK flashes while oven door is locking and remains in display while door is

locked. After cycle is complete and oven has cooled to a safe temperature, LOCK

no longer displays and door can be opened.

22

Oven Signals

Timer signal When time elapses, timer beeps 3 times then approximately once every 6-8

seconds.

Preheat signal After setting oven to bake and selecting a temperature, oven preheats. When

oven reaches set temperature, 1-second signal sounds.

End-of-Cycle signal When a timed cooking cycle is complete, three long signals sound. End of cycle

signal continues to sound until OVEN CANCEL pad is pushed.

If minute timer end of cycle signal is sounding, push TIMER ON/OFF pad.

Other Features

12-hour automatic Cancel This safety feature prevents oven from continuing to operate if it has been left on

for over 12 hours. If a cooking function continues longer than 12 hours without

any options on oven control being touched, this feature turns oven off. Any time

an option is touched, 12-hour automatic cancel is reset.

Service Codes and Tones

Electronic range control is equipped with a self diagnostic system. Self diagnostic

system alerts you if there is a error or problem in the control. If electronic range

control sounds a series of short, rapid beeps for over 16 seconds and display

shows a F-code, record the F-code shown. Some F-codes can be cleared by

touching CANCEL or disconnecting power to the range. If the code continues to

reoccur call an authorized servicer. Disconnect electrical supply to range and

contact an authorized servicer.

Operation

Setting Clock

1. Press CLOCKpad.

2. Turn TIME/TEMP SET knob until correct time of day

is displayed.

3. PressOVEN CANCEL pad.

Setting Minute Timer

1. PressTIMER ON/OFF pad.

2. Turn TIME/TEMP SET knob until desired amount of

time is displayed. Timer can be set from 5 seconds

to 9 hours and 55 minutes.

Canceling Minute Timer

Press and hold the TIMER ON/OFF pad for 3 seconds.

• When canceling minute timer do not press OVEN

CANCEL pad. Pressing OVEN CANCEL pad cancels

cooking function.

Prepare to BaRe

CAUTION

To reduce risk of food poisoning due to bacterial

growth and production of toxins, never hold meat, milk,

fish or eggs for more than 2 hours before cooking.

Remove items Stored in Oven

Remove any pans and other cooking utensils stored in

oven.

23

Remove Items Storedin Oven

Oven Rack Placement

Position oven rack before turning oven on.

WARNING 1

To avoid damaging oven liner or creating fire, do not

line oven bottom or oven racks with foil.

1. Pull rack forward to stop position.

2. Raise front edge of rack and pull until rack is out of

oven.

3. Place rack in new rack position.

• Curved edge of rack must be toward rear of oven.

Oven Rack Placement

Bake Pan Placement

• Keep pans and baking sheets 2 inches from oven walls.

• Stagger pans placed on different racks so one is not

directly over the other.

7

=#

Pan Placement

Baking

Open oven door to confirm nothing is stored in oven cavity

and set racks to proper height before baking. Preheat

approximately 10-15 minutes before placing food inside

oven.

1. Press BAKE pad.

2. Turn TIME/TEMP SET knob until desired temperature

is displayed.

• Temperature can be set from 170°F to 550°F in 5

degree increments.

• Temperature starts at 100°F and increases in 5°

increments until reaching set temperature. Some

minor smoking is normal when using oven for first

time.

• When cook temperature is reached oven signal

sounds for approximately I second.

3. Press OVEN CANCEL pad when finished.

• Remove food from oven when cooking time has

elapsed. Food left in oven can overcook.

Timed Baking

Set oven to cook for desired amount of time. Oven

automatically stops heating after time elapses.

1. Place food in oven.

2. Press COOK TIME pad.

3. Turn TIME/TEMP SET knob until cooking time is

displayed.

• Cook time can be set up to 11 hours and 55

minutes.

• 10 minutes minimum cooking time.

4. Press BAKE pad.

5. Turn TIME/TEMP SET knob until desired temperature

is displayed.

• Temperature can be set from 170°Fto550°F in 5°

increments.

• Temperature display increases in 5°F increments

starting at 100°F until reaching set temperature.

Some minor smoking is normal when using oven for

first time. When cook temperature is reached oven

signals.

• To view cook time, press and hold COOK TIME

pad.

• When cooking time has elapsed, an end of cycle

signal sounds, oven automatically turns off and

display returns to time of day. Oven signal sounds 3

times, then once, approximately every 5 seconds

for 5 minutes or until OVEN CANCEL pad is

pressed.

To Cancel Remaining Cooking Time

Press OVEN CANCEL pad.

24