Page 1

ACM4 Series

Access Power Controllers

Installation Guide

Models Include:

ACM4

- Four (4) Fuse Protected Outputs

ACM4E

- Four (4) Fuse Protected Outputs w/Enclosure

ACM4CB

- Four (4) PTC Protected Outputs

ACM4CBE

- Four (4) PTC Protected Outputs w/Enclosure

Rev. 082808

More than just power.

TM

Page 2

Overview:

These units convert one (1) 12 to 24 volt AC or DC input into four (4) independently controlled fused or PTC protected

outputs. These power outputs can be converted to dry form “C” contacts (ACM4/ACM4E only). Outputs are activated by

an open collector sink or normally open (NO) dry trigger input from an Access Control System, Card Reader, Keypad, Push

Button, PIR, etc. The units will route power to a variety of access control hardware devices including Mag Locks, Electric

Strikes, Magnetic Door Holders, etc. All interconnecting devices must be UL Listed. Outputs will operate in both Fail-Safe

and/or Fail-Secure modes. Units are designed to be powered by one common power source which will provide power for

both the board operation and locking devices, or two (2) totally independent power sources, one (1) providing power for

board operation and the other for lock/accessory power. The FACP Interface enables Emergency Egress, Alarm Monitoring,

or may be used to trigger other auxiliary devices. The fire alarm disconnect feature is individually selectable for any or all

of the four (4) outputs.

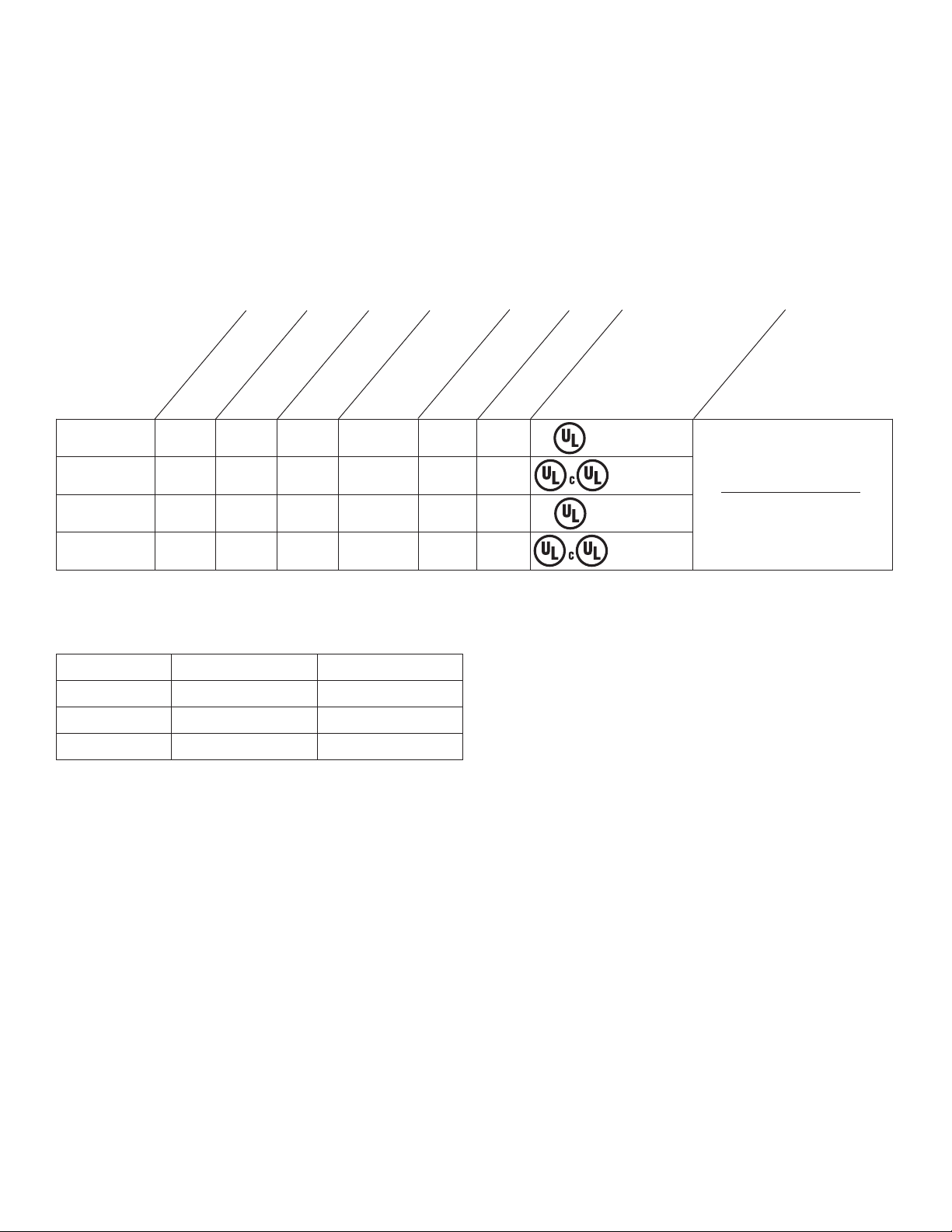

Configuration Reference Chart:

Altronix

Model

Number

ACM4 4 x ---- 3 amp - *

ACM4E 4 x ---- 3 amp - x

Outputs

Number of

Fuse Protected

Outputs

PTC Protected

Outputs

Output Ratings

(per output)

Class 2 Rated Power

Limited Outputs

Enclosure

Agency Listings

UL Listed

Sub-Assembly.

UL Listed

Accessory.

UL Listings and

File Numbers

UL File # BP6714

UL Listed for Access Control

System Units (UL 294).

ACM4CB 4 ---- x 2 amp x *

ACM4CBE 4 ---- x 2 amp x x

UL Listed

Sub-Assembly.

UL Listed

Accessory.

“Signal Equipment” Evaluated to

CSA Standard C22.2

No.205-M1983

*Install in Altronix Power Supply/Chargers AL300ULX, AL400ULX and AL600ULX only. Total output current when

ACM4/ACM4CB is utilized as a sub-assembly with power supply/chargers listed below (see Total Output Chart, below).

Note: The total for all outputs combined is not to exceed 8 amp for ACM4CBE and 10 amp for

ACM4E.

Total Output Chart:

Power Supply 12 volt DC Output 24 volt DC Output

AL300ULX 2.1 amp 2.3 amp

AL400ULX 2.8 amp 3.6 amp

AL600ULX 5.6 amp 5.8 amp

Note: ACM4/ACM4CB can only be utilized with the power supplies listed above.

Specifications:

• 12 to 24volt AC or DC operation (setting not required).

• Input Ratings (ACM4/ACM4CB only):

- 12VDC @ .4 amp or 24VDC @ .2 amp.

Input Ratings (ACM4E/ACM4CBE only):

- 12VDC @ .4 amp or 24VDC @ .2 amp.

- 12VAC @ .4 amp or 24VAC @ .3 amp.

• Power supply input options:

a) One (1) common power input (board and lock power).

b) Two (2) isolated power inputs (one (1) for board power and one (1) for lock/hardware power).

• Four (4) Access Control System trigger inputs:

a) Four (4) normally open (NO) inputs.

b) Four (4) open collector sink inputs.

c) Any combination of the above.

• Four (4) independently controlled outputs:

a) Four (4) Fail-Safe and/or Fail-Secure power outputs.

b) Four (4) dry form “C” 5 amp rated relay outputs (ACM4/ACM4E only).

c) Any combination of the above (ACM4/ACM4E only).

• Four (4) auxiliary power outputs (unswitched).

- 2 - ACM4 series

Page 3

• Output ratings:

- Fuses are rated 3 amp each.

- PTCs are rated 2.5 amp each.

• Main fuse is rated at 10 amp.

Note: The total for all outputs combined is not to exceed 8 amp for ACM4CBE and 10 amp for ACM4E.

(For Models ACM4/ACM4CB refer to the Total Output Chart on Page 2).

Note: Operating temperature range should be 0 to +49

o

C.

• Red LEDs indicate outputs are triggered (relays energized).

• Fire Alarm disconnect (latching or non-latching) is individually selectable for any or all of the four (4) outputs.

Fire Alarm disconnect input options:

a) Normally open (NO) or normally closed (NC) dry contact input.

b) Polarity reversal input from FACP signaling circuit.

• FACP output relay (form “C” contact rated @ 1 amp 28VDC not evaluated by UL).

• Green LED indicates when FACP disconnect is triggered.

• Removable terminal blocks facilitate ease of installation.

Board Dimensions (approximate): 5.125”L x 3.625”W x 1.25”H (ACM4 and ACM4CB).

Enclosure Dimensions (approximate): 8.5”H x 7.5”W x 3.5”D (ACM4E and ACM4CBE).

Installation Instructions:

Wiring methods shall be in accordance with the National Electrical Code/NFPA 70/ANSI, and with all local codes and

authorities having jurisdiction. Product is intended for indoor use only.

1. For ACM4/ACM4CB sub-assembly boards, use stand-offs to mount only in AL300ULX, AL400ULX or

AL600ULX enclosures (Figs. 8-9, pg. 8). For ACM4E/ACM4CBE units, mount in desired location.

The enclosure door for the ACM4E/A

Mark and predrill holes in the wall to line up with the top two keyholes in the enclosure. Install three upper

fasteners and screws in the wall with the screw heads protruding. Place the enclosure’s upper keyholes over the two

upper screws, level and secure. Mark the position of the lower three holes. Remove the enclosure. Drill the lower

holes and install the two fasteners. Place the enclosure’s upper keyholes over the two upper screws. Install the

two lower screws and make sure to tighten all screws (Enclosure Dimensions, pg. 7).

Carefully review:

Typical Application Dia

gram (pg. 4) Terminal Identification Table (pg. 5)

LED Diagnostics (pg. 5) Hook-up Diagrams (pg. 6)

2. Power supply input:

The units can be powered with one (1) Listed Access Control Power Supply which will provide power for both

board operation and the locking devices or two (2) separate Listed Access Control Power Supplies, one (1) to provide

po

wer for the board operation and the other to provide power for the locking devices and/or access control hardware.

Note: The input power can be either 12 to 24 volts AC or DC operation.

Input Ratings (ACM4/A

CM4CB only):

- 12VDC @ .4 amp or 24VDC @ .2 amp.

Input Ratings (ACM4E/ACM4CBE only):

- 12VDC @ .4 amp or 24VDC @ .2 amp.

- 12VAC @ .4 amp or 24VAC @ .3 amp.

(a) Single power supply input:

If the unit and the locking devices are to be powered using a single Listed Access Control Power Supply, connect

the output (12 to 24 v

(b) Dual po

wer supply inputs (Fig. 1, pg. 4):

olts AC or DC) to the terminals marked [- Control +].

When the use of two Listed Access Control P

of the power/control terminals) must be cut. Connect power for the unit to the terminals marked [- Control +]

and connect power for the locking devices to the terminals marked [- Power +].

Note: When using DC Listed Access Control Power Supplies polarity must be observed. When using AC Listed

Access Control P

ower Supplies polarity need not be observed.

Note: For UL compliance the power supplies must be UL Listed for Access Control Systems and accessories.

3. Output options (Fig. 1, pg. 4):

The ACM4/ACM4E will provide either four (4) switched power outputs, four (4) dry form “C” outputs, or

an

y combination of of both switched power and form “C” outputs, plus four (4) unswitched auxiliary power outputs.

The ACM4CB/ACM4CBE will provide four (4) switched power outputs or four (4) unswitched auxiliary power outputs.

(a) Switched Power outputs:

Connect the negative (-) input of the device being powered to the terminal marked [COM]. For Fail-Safe operation

ACM4 series - 3 -

CM4CBE can be fastened by using either a cam lock or screws (both supplied).

ower Supplies is desired, jumpers J1 and J2 (located to the left

Page 4

connect the positive (+) input of the device being powered to the terminal marked [NC]. For Fail-Secure operation

NC C NO COM

OUTPUT1

NC C NO COM

OUTPUT2

NO C NC

FACP

--- + --- +

Power Control

+ INP --- T + RET ---

INTERFACE

L

ED1

S

W1 SW2 SW3

S

W4

L

ED2 LED3 LED4

TRIGGER

INPUT

T

RG

NC C NO COM

OUTPUT3

NC C NO COM

OUTPUT4

J2 J1

J

3

ACM4

A

CCESS POWER

CONTROLLER

LED1

SW1 SW2

LED2

IN GND

2

IN GND

1

IN GND

3

IN GND

4

NC

NO

C

KEYPAD

NORMALLY OPEN

N.O. DOOR

RELEASING

DEVICE

ACCESS CONTROL

PANEL

OUTPUT

RELAY

MAG.

LOCK

MAG.

LOCK

ELECTRIC

STRIKE

ELECTROMAGNETIC

DOOR HOLDERS

LISTED

AC or DC

ACCESS CONTROL

POWER SUPPLY

(optional)

FACP

(Fire Alarm

Control Panel)

LISTED

AC or DC

ACCESS CONTROL

POWER SUPPLY

(req’d)

UL Listed Power-Limited Power Supply

For this application

corresponding fuse

must be removed.

(ACM4 and ACM4E only)

FACP Interface Enabled

FACP Interface Disabled

SW1-SW4

ACM4CB

FACP Dry

Form "C"

Output

NO C NC

FACP

3A

1

0A

3A3A3A

Keep power limited wiring separate from non-power limited.

Use minimum .25" spacing.

connect the positive (+) input of the device being powered to the terminal marked [NO].

(b) Form “C” outputs (ACM4/ACM4E):

When form “C” outputs are desired the corresponding output fuse (1-4) must be removed. Connect negative (-) of

the po

wer supply directly to the locking device. Connect the positive (+) of the power supply to the terminal marked

[C]. For Fail-Safe operation connect the positive (+) of the device being powered to the terminal marked NC]. For

Fail-Secure operation connect the positive (+) of the device being powered to the terminal marked [NO].

(c) Auxiliary Power outputs (unswitched):

Connect positive (+) input of the device being powered to the terminal marked [C] and the negative (-) of the device

being po

wered to the terminal marked [COM]. Output can be used to provide power for card readers, keypads etc.

Note: When wiring for power-limited outputs utilize a knockout separate from the one used for

non po

wer-limited wiring.

4. Input trigger options (Fig. 1, pg. 4):

(a) Normall

y Open [NO] input trigger:

Inputs 1-4 are activated by normally open or open collector sink inputs.

Connect de

vices (card readers, keypads, request to exit buttons etc.) to terminals marked [IN] and [GND].

(b) Open Collector Sink inputs:

Connect the access control panel open collector output to the terminal marked [IN] and the

common (ne

gative) to the terminal marked [GND].

Typical Application Diagram:

Fig. 1a

Fig. 1

- 4 - ACM4 series

Page 5

5. Fire Alarm Interface options (Figs. 3 through 7, pg. 6):

A nor

mally closed [NC], normally open [NO] input or polarity reversal input from FACP signaling circuit will

trigger selected outputs. To enable FACP Disconnect for an output open the corresponding switch [SW1-SW4].

To disable FACP disconnect for an output close the corresponding switch [SW1-SW4].

(a) Normally Open [NO] input:

For non-latching hook-up (Fig. 4, pg. 6). For latching hook-up (Fig. 5, pg. 6).

(b) Normally Closed [NC] input:

For non-latching hook-up (Fig. 6, pg. 6). For latching hook-up (Fig. 7, pg. 6).

(c) FACP Signaling Circuit input trigger:

Connect the positive (+) and negative (-) from the FACP signaling circuit output to the terminals marked [+ INP -].

Connect the F

ACP EOL to the terminals marked [+ RET -] (polarity is referenced in an alarm condition).

Jumper J3 must be cut (Fig. 3, pg. 6).

6. FACP Dry form “C” output (Fig. 1a, pg. 4):

Connect desired device to be triggered by the unit’s dry contact output to the terminals marked [NO] and [C]

F

ACP for normally open output or the terminals marked [NC] and [C] FACP for normally closed output.

7. Installation of tamper switch (Not Included):

Mount UL Listed tamper switch (Sentrol model 3012 or equivalent) at the top of the enclosure. Slide the tamper

switch brack

et onto the edge of the enclosure approximately 2” from the right side.

Connect tamper switch wiring to the Listed Access Control Panel input or the appropriate UL Listed reporting device,

to activate alarm signal when the door of the enclosure is open.

Maintenance:

Unit should be tested at least once a year for the proper operation. Voltage on each output has to be tested for both

trigger and non-trigger states and operation of FACP interface has to be simulated.

LED Diagnostics:

LED ON OFF

LED 1 - LED 4 (Red) Output relay(s) energized. Output relay(s) de-energized.

TRG (Green) FACP input triggered (alarm condition). FACP normal (non-alarm condition).

Terminal Identification Tables:

Terminal Legend Function/Description

-- Power + 12VDC to 24VDC input from UL Listed Access Control Power Supply.

These terminals can be connected to a separate, UL Listed Access Control Power Supply to

-- Control +

TRIGGER

INPUT 1 - INPUT 4

IN, GND

OUTPUT 1 - OUTPUT 4

NC, C, NO, COM

provideisolated operating power for the ACM4/ACM4E/ACM4CB/ACM4CBE (jumpers

J1and J2 Must be removed).

From normally open and/or open collector sink trigger inputs

(request to exit buttons, exit pir’s, etc.).

12 to 24 volts AC/DC trigger controlled outputs:

Fail-Safe [NC positive (+) & COM Negative (-)],

Fail-Secure [NO positive (+) & COM Negative (-)],

Auxiliary output [C positive (+) & COM Negative (-)]

(When using AC power supplies polarity need not be observed),

NC, C, NO become form “C” 5 amp 24VAC/VDC rated dry outputs when fuses are

removed (ACM4/ACM4E). Contacts shown in a non-triggered state.

FACP INTERFACE

T, + INPUT --

FACP INTERFACE

NC, C, NO

ACM4 series - 5 -

Fire Alarm Interface trigger input from FACP. Trigger inputs can be normally open,

normally closed from an FACP output circuit (Fig. 3 through 7, pg. 6).

Form “C” relay contact rated @ 1 amp 28VDC for alarm reporting.

(This output has not been evaluated by UL).

Page 6

NO C NC

FACP

+ INP --- T + RET ---

INTERFACE

TRG

J3

JUMPER

N.C. DRY

TRIGGER

INPUT

NO C NC

FACP

+ INP --- T + RET ---

INTERFACE

TRG

J3

N.C. TRIGGER

INPUT

N.C. RESET

SWITCH

JUMPER

Fig. 2 Optional hook-up using two (2) isolated

CUT JUMPERS

J1 AND J2

ISOLATED POWER INPUT

1

2 OR 24VAC OR VDC

(LOCK POWER)

ISOLATED POWER INPUT

1

2 OR 24VAC OR VDC

(ACM4 POWER)

--- + --- +

Power Control

J2 J1

CUT

JUMPER J3

FROM FACP

CONTROL

CIRCUIT

+

--

FACP

CONTROL

CIRCUIT EOL

(if employed)

NO C NC

FACP

+ INP --- T + RET ---

INTERFACE

TRG

J3

NO C NC

FACP

+ INP --- T + RET ---

INTERFACE

TRG

J3

N.O. TRIGGER

INPUT

NO C NC

FACP

+ INP --- T + RET ---

INTERFACE

TRG

J3

N.C. RESET

SWITCH

N.O.

TRIGGER

INPUT

JUMPER

po

wer supply inputs:

Hook-up Diagrams:

. 3 Polarity reversal input from FACP signaling circuit

Fig

output (polarity is referenced in alarm condition):

(This output has not been evaluated by UL)

Fig. 4 Normally Open - Non-Latching FACP

trigger input:

Fig. 6 Normally Closed - Non-Latching FACP

trigger input:

Fig. 5 Normally Open FACP Latching trigger input

with reset:

(This output has not been evaluated by UL)

Fig. 7 Normally Closed - Latching FACP trigger input

with reset:

(This output has not been ev

aluated by UL)

Note: Keep power limited wiring separate from non-power limited. Use minimum .25" spacing.

- 6 - ACM4 series

Page 7

• ACM4E and ACM4CBE

8.5"H x 7.5"W x 3.5"D

Enclosure Dimensions:

ACM4 series - 7 -

Page 8

UL Listed Sub-Assembly Installation Instructions:

NC C NO COM

OUTPUT1

NC C NO COM

OUTPUT2

NO C NC

FACP

--- + --- +

Power Control

+ INP --- T + RET ---

INTERFACE

LED1

SW1 SW2

SW3

SW4

LED2 LED3 LED4

10A

3A3A3A3A

TRIGGER

INPUT

TRG

NC C NO COM

OUTPUT3

NC C NO COM

OUTPUT4

J2 J1

J3

IN GND

2

IN GND

1

IN GND

3

IN GND

4

--- DC

+

L G N

NC C NO NC C NO

+ BAT ---

AC FAIL

BAT FAIL

S

ub-Assembly

M

ounting

Holes

Divider

Red Lead

Black Lead

P

ower Supply Board for:

AL300ULX(R)

AL400ULX(R)

A

L600ULX(R)

--- + --- +

Power Control

Keep power limited wiring separate

from non-power limited.

Use minimum .25" spacing.

Screw

Sub-Assembly

Stand-off

Stud

Enclosure

NC C NO COM

OUTPUT1

NC C NO COM

OUTPUT2

NO C NC

FACP

--- + --- +

Power Control

+ INP --- T + RET ---

INTERFACE

LED1

SW1 SW2 SW3

SW4

LED2 LED3 LED4

TRIGGER

INPUT

TRG

NC C NO COM

OUTPUT3

NC C NO COM

OUTPUT4

J2 J1

J3

IN GND

2

IN GND

1

IN GND

3

IN GND

4

10A

The following Altronix sub-assembly modules may be field installed in the AL300ULX(R), AL600ULX(R),

AL400ULX(R) power supply/chargers: ACM4 or ACM4CB

1. Disconnect power before proceeding with sub-assembly installation.

2. Fasten stand-offs (supplied) to the corresponding studs in the enclosure.

3. Align mounting holes of sub-assembly with stand-offs (Fig. 8, pg. 8).

Refer below for the location and position for placement of sub-assembly.

4. Fasten sub-assembly to enclosure using the four (4) screws (supplied) (Fig. 9, pg. 8).

5.

Connect red and black power leads of CM type jacketed wire (supplied), as shown below:

Terminals

P

ower Leads Power Supply Sub-Assembly

(provided) Output Input

Red Lead DC + Control +

Black Lead DC -- Control --

Fig. 9

Enclosure Dimensions:

13.5”H x 13”W x 3.25”D

Fig. 8

Mounting Position for

UL Listed Sub-Assembly Installation.

ACM4

ACM4CB

Altronix is not responsible for any typographical errors.

Altronix Corp.

140 58th Street, Brooklyn, New York 11220 USA, 718-567-8181, fax: 718-567-9056

web site: www.altronix.com, e-mail: info@altronix.com, Lifetime Warranty, Made in U.S.A.

IIACM4/ series J09H

- 8 - ACM4 series

MEMBER

Loading...

Loading...