Alto Shaam FGA-60FS Installation Manual

#8456 • 3/00

PRINTED IN U.S .A .

GAS FRYER

FGA-60FS

PHONE: 262.251.3800 FAX: 262.251.7067 - 800.329.8744 U.S. A./CANADA WEBSITE:

800.558.8744 U.S .A./CANADA 262.251.1907 INTERNATIONAL www.alto-shaam.com

W164 N9221 Water Street ●P.O. Box 450 ●Menomonee Falls, Wisconsin 53052-0450 U.S.A.

®

COOK/HOLD SERVE SYSTEMS by

OPERATION & CARE MANUAL

®

DELIVERY

The Alto-Shaam Gas Fryer has been

thoroughly tested and inspected to insure

only the highest quality unit is provided. When you receive

your fryer, check for any possible shipping damage and

report it at once to the delivering carrier.

See Transportation

Damage and Claims

section located in this manual.

The fryer, complete with unattached items and accessories,

may be delivered in one or more packages. Check to ensure

that all items have been received as standard with each unit.

Save all the information and instructions packed inside the

cabinet. Complete and return the warranty card to the

factory as soon as possible to assure prompt service in the

event of a warranty parts and labor claim.

This manual must be read and understood by all people

using or installing this fryer. Contact your local Alto-Shaam

distributor if you have any questions concerning installation,

operation and maintenance of this fryer.

NOTE:

All claims for warranty must include the full model

number and serial number of the cabinet.

SPECIFICATION INFORMATION

Capacity: 60 lb (27kg), Liquid Shortening ONLY

Fresh Chicken, 30 lb (13kg) (full size basket)

Frozen Chicken, 25 lb (11kg) (full size basket)

Controls: Solid State

Electrical: 120VAC, 1 Ph

ONLY

5.0 Amps

Gas Specification: 62,000

BTU/hr.

*Gas: Natural (3.5 water pressure)

*Field convertible to LP/Propane (10" water pressure)

by qualified technician/electrician

UNPACKING

1. Carefully remove the fryer from the carton.

NOTE: Do not discard the carton and other packaging

material until you have inspected the fryer for hidden

damage and tested it for proper operation.

2. Remove all protective plastic film, packaging materials

and accessories from the fryer and the filter reservoir

before connecting electrical power to the fryer. Store the

accessories in a convenient place for future use.

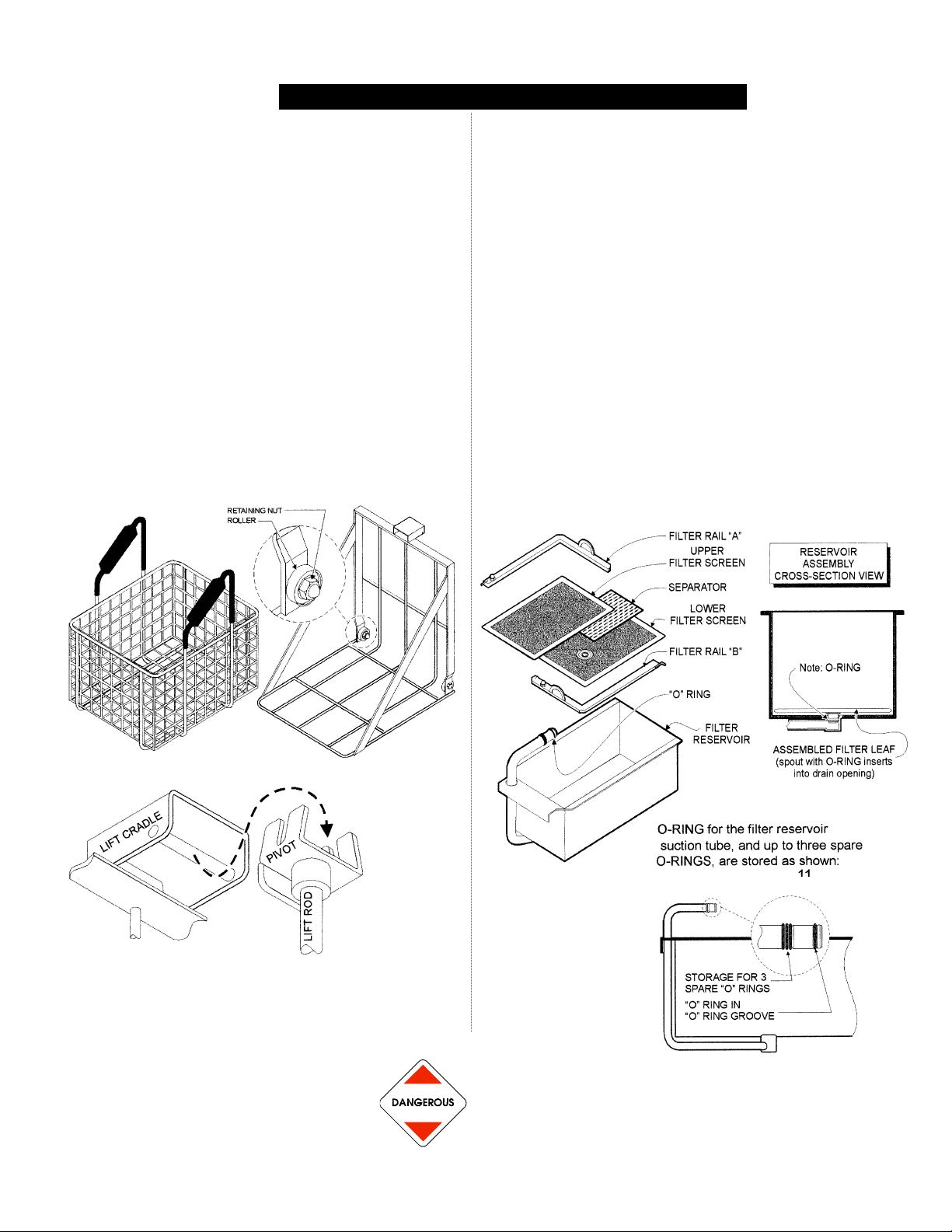

Components: Accessories:

Filter reservoir, 1 ea. Filter powder, 1 bx.

Filter leaf with O-ring, 1 ea. High temp brushes, 2 ea.

Filter reservoir suction tube O-ring Stainless steel shovel, 1 ea.

(on filter reservoir suction tube), 4ea. Cleanout dowel, 1 ea.

Fry basket , full size, 1 ea. T-shaped Scraper w/

Lift cradle, 1 ea. instructions, 1 ea.

Fry pot lid, 1 ea. Literature package, 1 ea.

3. Read all instructions in this manual carefully before

starting installation of this fryer. DO NOT DISCARD

THIS MANUAL. This manual is considered to be part

of the fryer and is to be given to the owner or manager

of the business, or to the person responsible for training

operators of the fryer. Additional manuals are available

from your Alto-Shaam distributor.

4. Improper installation, adjustment, alteration, service, or

maintenance can cause property damage, injury or

death. Read all installation, operating and maintenance

instructions thoroughly before installing or servicing this

equipment.

5. The purchaser of this fryer is required by regulation to

post in a prominent location all instruction for personnel

to follow in the event they smell gas. This information is

to be obtained from your local gas supplier.

Operation and Care Manual #8456 • 1

GAS FRYER

FGA-60FS

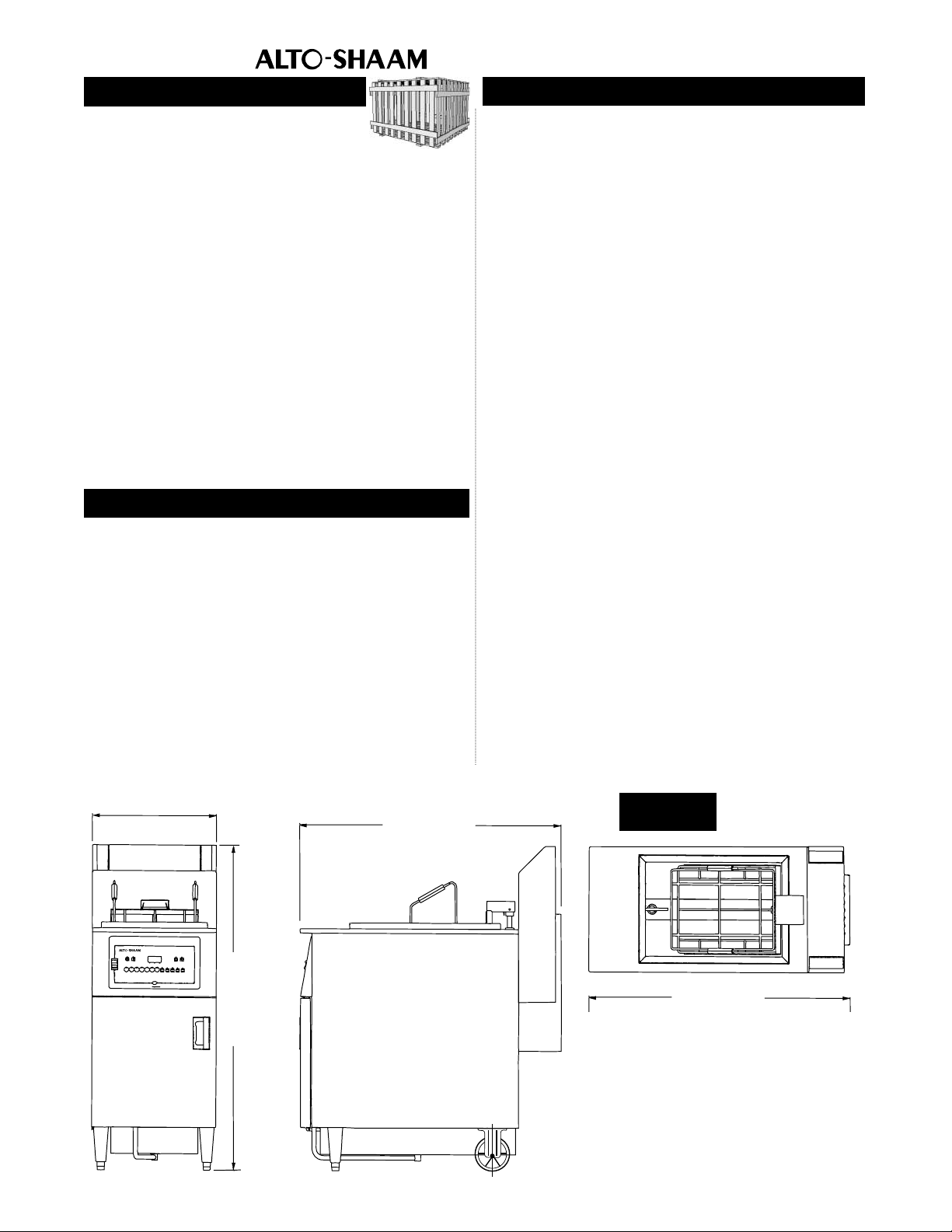

DIMENSIONS

38-1/4" (971mm)

47-7/16" (1205mm)

38-1/4" (971mm)

18-3/16"

(462mm)

®

®

Operation and Care Manual #8456 • 2

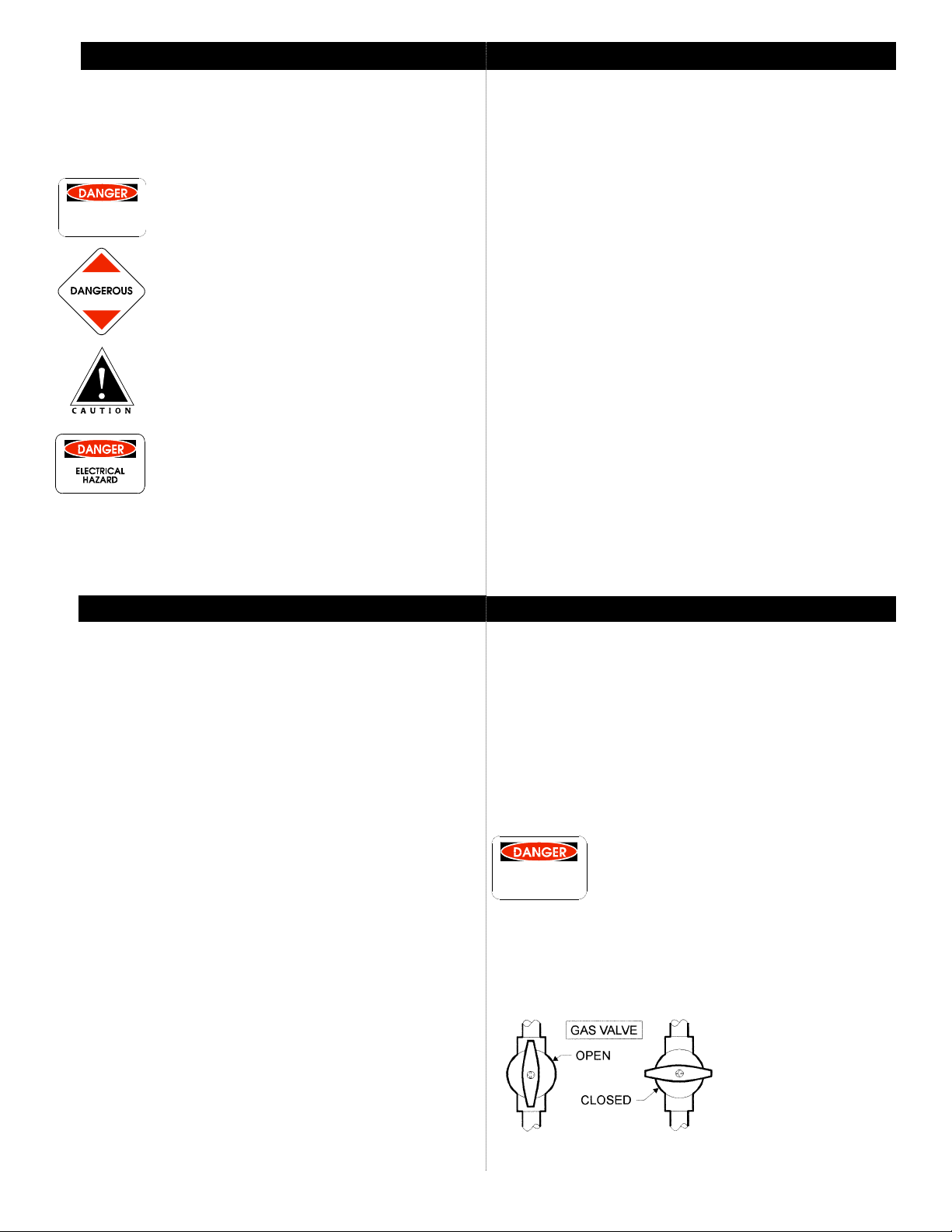

Knowledge of proper procedures is essential to the safe

operation of electrically energized equipment. In accordance

with generally accepted product safety labeling guidelines for

potential hazards, the following signal words and symbols are

used throughout this manual.

Used to indicate the presence of a hazard which

will cause severe personal injury, death, or

substantial property damage in the event the

statement is ignored.

Warning used to indicate the presence of a hazard

which can cause personal injury and possibly

death, or major property damage in the event the

statement is ignored.

Caution is used to indicate the presence of a hazard

which will or can cause minor personal injury or

property damage in the event the statement is ignored.

Used to indicate the presence of an electrical hazard

which will or can cause personal injury or property

damage in the event the statement is ignored.

NOTE Used to notify personnel of installation, operation

or maintenance information which is important, but

not hazard related.

1. This fryer is intended to deep fry food products for

human consumption. No other use is authorized or

recommended.

2. This fryer is intended for use in commercial establishments where all operators are familiar with the appliance

use, limitations and associated hazards. Operating

instructions and warnings must be read and understood

by all operators and users.

3. This fryer is equipped with an oil filtration system which is

designed to filter hot liquid shortening ONLY. Water,

cleaning agents, or other liquids will damage the filter pump.

4. This piece of equipment is made in the USA and has

American size hardware.

5. Any trouble shooting guides, component views, or parts

lists included in this manual are for general reference only,

and are intended for use by qualified technical personnel.

6. This manual should be considered a permanent part of this

appliance. This manual and all supplied instructions,

diagrams, schematics, parts breakdowns, notices and labels

must remain with the appliance if it is sold or moved to

another location.

7. Certain codes require fryers to be restrained with a cable or

other restraint device. It is the responsibility of the installer

to check with the authority having jurisdiction, in order to

ascertain the applicability of this requirement to this

specific fryer installation.

1. A single FGA-60FS gas-fired fryer requires a minimum of

700 cu.ft. per hour (12CFM) make-up air. The ventilation

for the kitchen must have sufficient capacity to prevent a

negative-pressure condition. DO NOT obstruct or restrict

ventilation and make-up air required to support combustion.

2. Set up the fryer on a firm, level surface ONLY. Clearances

from all combustible and non-combustible construction is

1" minimum. The area around the fryer must be kept clear

of combustibles.

3. LEVELING: Verify that the fryer sits firmly on both casters

and on both legs. With a spirit level, check that the fryer is

level front-to-back and side-to-side. With the adjustable

legs, adjust as required to level the fryer.

4. DO NOT obstruct the flow of the two exhaust flues at the

top rear of the fryer. It is especially critical that gas supply

piping and electrical support cord and/or receptacle be

routed away from the path of the hot combustion fumes.

5. Install the fryer under a ventilation hood conforming to all

applicable local codes.

Combustion fumes must be vented in

accordance with local codes.

6. Cooking and cleaning functions require unobstructed

access. The fry pot, control panel and front access panel

must be maintained free from obstructions. The rear access

panel must be accessible for maintenance.

1. Installation and start up should be referred to the local

Alto-Shaam distributor. Installer must complete the

warranty registration/fryer checkout form, and record

fryer installation particulars at the back of this manual.

2. The installation of this fryer must conform to local codes.

In the absence of local codes, the installation of this fryer

must conform with the National Fuel Gas Code (ANSI

Z223.1). In Canada, the National Gas Installation Code

(CAN/CGAB 149.2) is applicable.

FIRE & EXPLOSION HAZARD

Gas connections and gas adjustments must be

made by a licensed plumber, certified in gas

installation. A gas explosion will cause death

or serious injury.

3. In any instance where gas supply pressure is in excess of

15" water pressure (1/2 psi or 3.45 kP), the fryer must be

isolated from the supply piping by closing its two

individual manual shut-off valves.

IMPORTANT:

Failure to isolate the fryer

from excessive pressure

will damage the gas

valves and allow raw gas

to leak into the room.

SAFETY PROCEDURES

PLUMBING INSTALLATION

PRECAUTIONS & GENERAL INFO

EQUIPMENT SET-UP PROCEDURES

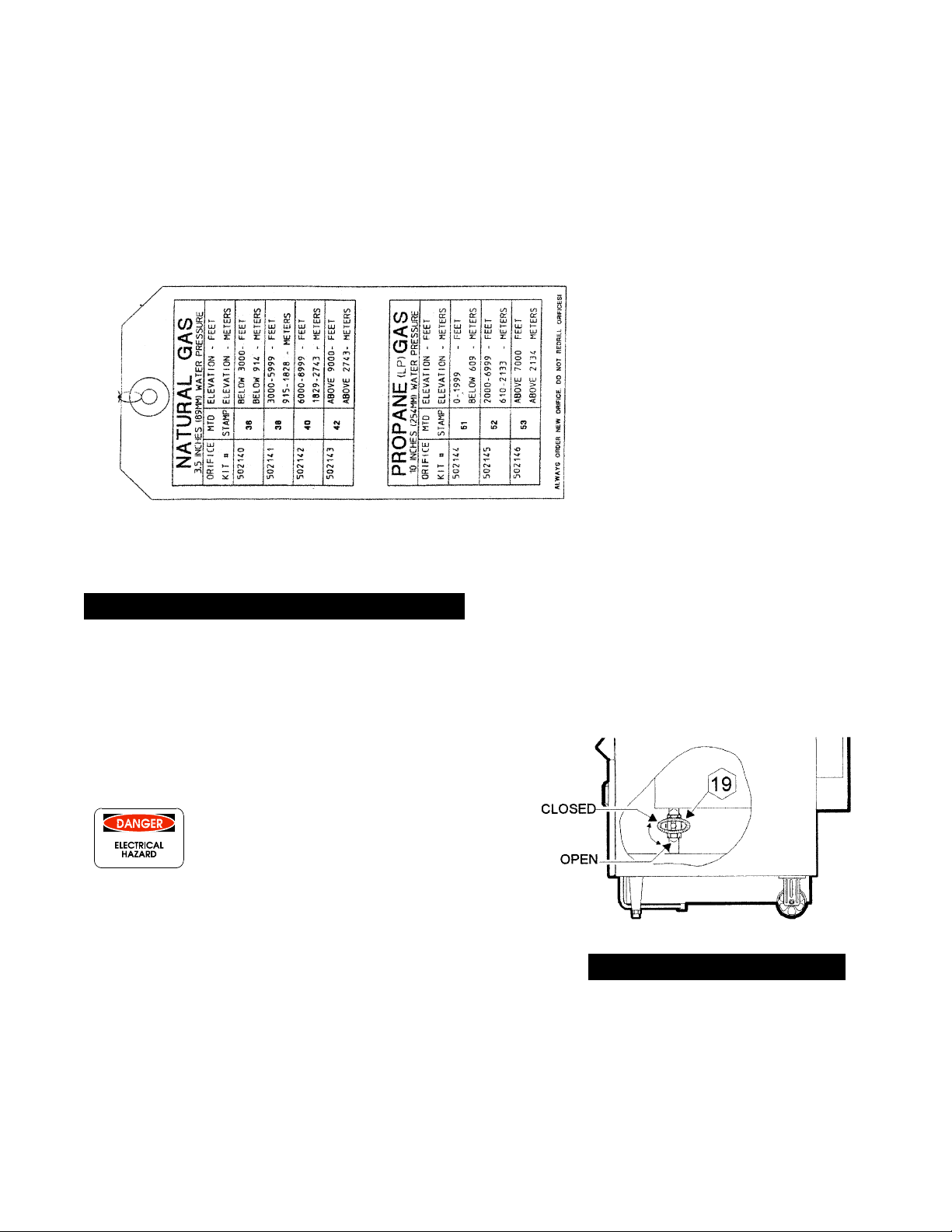

4. This fryer is orificed at the factory for natural gas at a

pressure of 3.5" of water column. The installed orifice is

suitable for use at -280 to 2999 feet (-85 to 914 meters)

elevation. It is the responsibility of the installer to install

the factory recommended orifice and pressure regulator

kit suitable for the fuel type and elevation at the final

installation site.

The red tag attached to the gas connection provides

pressure settings and part numbers for conversion kits

applicable to various fuels and altitude.

NOTE: Failure to install proper orifices can burn cooking oil

and cause potential burner and flue system failure.

Damage caused by improper orifice installation is

NOT covered by warranty.

1. Fryer electrical diagram and troubleshooting schematic

are located on the inside of the fryer door.

2. The fryer is equipped with a three-prong grounding

plug (NEMA 15-5P) for your protection against

shock hazard. The fryer must be plugged directly

into a properly grounded three-prong receptacle

(NEMA 15-5R).

Do not cut or remove the grounding prong

from the plug. Ungrounded electrical

equipment can cause personal injury and

property damage.

3. The installation of this fryer must conform to local codes.

In the absence of local codes, the installation of this fryer

must conform with the National Electrical Code (ANSI

Z223.1). In Canada, CSA C22.2 is applicable.

4. Because the fryer draws less than 8 amps, two fryers

may be plugged into the same 15 amp circuit if needed.

Operation and Care Manual #8456 • 3

ELECTRICAL INSTALLATION

Oval Drain Valve Handle

1. CLEANING:

Prior to leaving the factory, the fryer is tested for proper

operation with peanut oil. After testing is complete, the

oil is removed but oil residue remains. Therefore, it is

necessary to clean the fry pot before filling it with clean

oil. See

Cleaning the Fryer section in this manual.

2. Examine the cradle rollers. Adjust or tighten as

required. DO NOT operate the fryer unless the cradle

rollers are in place and rotating freely. Serious damage

to the fry pot will result if the rollers are not in position

and operating properly.

3. Install the lift cradle onto the cradle pivot. Set the fry

basket on the lift cradle.

4. Assemble the filter leaf and install into the filter

reservoir. Suction tube O-rings are shipped from the

factory installed on the suction tube. Examine to verify

one O-ring is in the groove closest to the end of the tube.

Install the assembled filter reservoir into the fryer.

5. Close the oval drain valve handle by turning the handle to

the CLOSED position. See illustration on previous page.

NOTE: This fryer is designed for liquid shortening ONLY.

Do not use solid shortening or lard. Solid shortening

will solidify in the filter reservoir and filter pump.

This condition will render the filter system inoperable.

Repairs caused by the use of anything other than

liquid shortening are not covered by warranty.

6. Fill the fry pot to the COLD OIL LINE in the fry pot with

room temperature commercial quality liquid shortening.

This requires 60 lbs. of oil.

7. Check operation of fryer and all controls. See Operating

Instructions

section in this manual.

8. DETERMINE MAXIMUM LOAD WEIGHT: For

operational safety, it is very important to determine the

maximum load weight for the specific operation. This can

be accomplished by starting out with small loads and

gradually increasing to the largest load size which allows

a complete cook cycle without oil foaming out of the fry pot.

Operation and Care Manual #8456 • 4

PREPARATION PRIOR TO OPERATION

POTENTIAL FOR OIL OVERFLOW

The weight of product which can be safely cooked in this fryer

will vary with oil level, product moisture content, oil

temperature, and other various conditions. Failure to determine

maximum load weight can result in hot oil release which can

cause severe burns on contact.

Remember to fill the fryer to the COLD OIL LINE

with fresh liquid shortening prior to turning the

power switch to the FRYER position. Energizing

the fryer without oil can cause serious damage.

Damage due to operating the fryer without oil

is not covered by warranty.

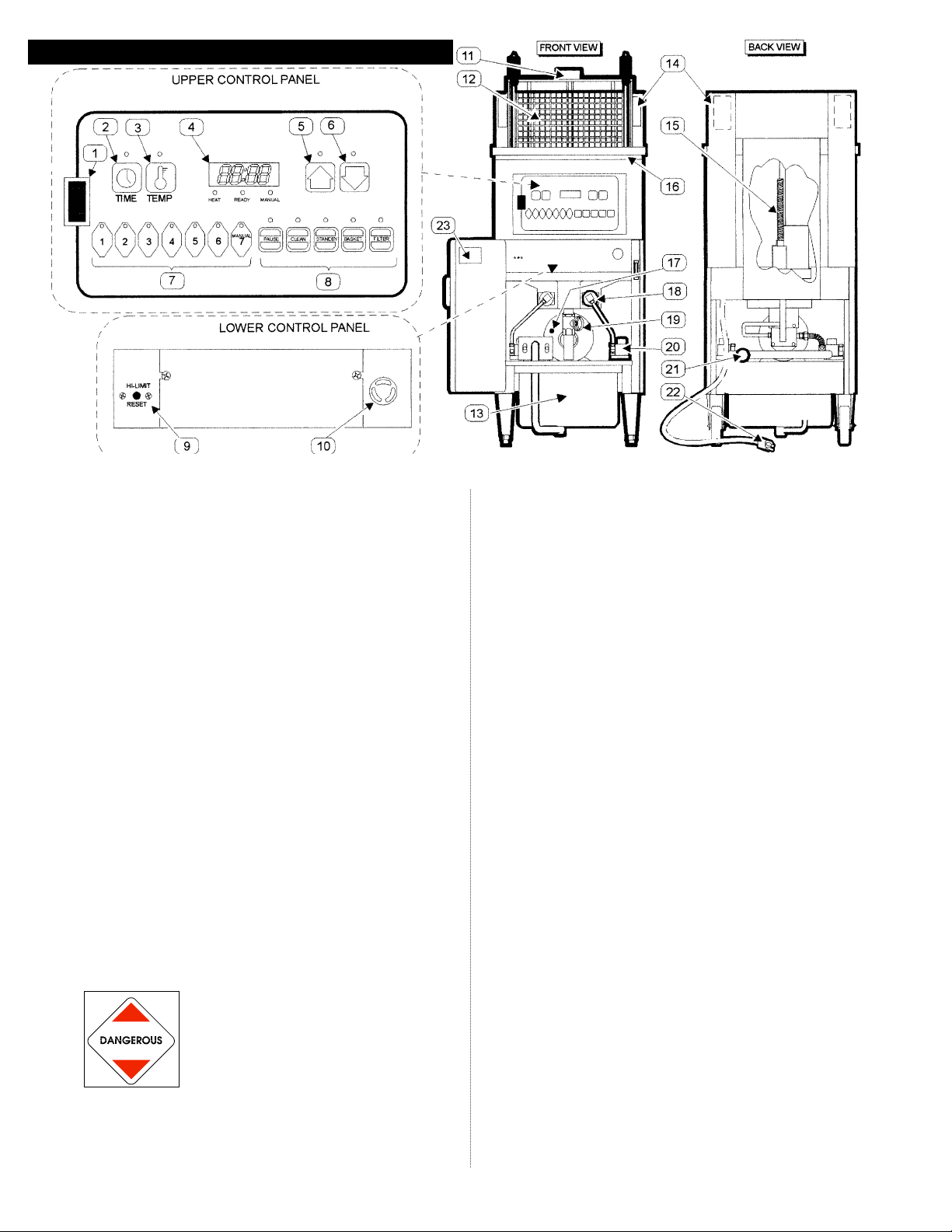

1. FRYER POWER SWITCH (FRYER-OFF-FILTER)

FRYER position turns ON the fryer and energizes the

upper control panel, and turns OFF the filter pump.

Burner circuits are energized and regulate to the

programmed temperature. OFF position turns off the

fryer. FILTER position energizes the filter pump.

2. TIME KEY

Used to check and set menu times.

3. TEMP KEY

Used to check and set menu temperatures.

4. READOUT

LED display of various data and functions.

5. UP ARROW KEY

Used to raise fry basket and raise program settings.

6. DOWN ARROW KEY

Used to lower fry basket and lower program settings.

7. MENU KEYS

Used to begin a menu time/temp cycle. Keys 1 thru 6

are programmable for time and temperature. Key 7 is

available for individually set time/temp cook cycles.

8. FUNCTION KEYS

Used to perform the functions of Pause, Clean, Standby,

Basket (raise/lower) and Filter (warning/acknowledge).

9. HI-LIMIT THERMOSTAT

Provides over-temperature protection by de-energizing

the gas valves if the oil temperature exceeds the factoryset limit. Reset must be performed manually. Allow the

oil to cool below 350°F (177°C), then firmly press the red

button on the lower control panel until it "clicks".

FIRE HAZARD • HOT OIL

The hi-limit thermostat is a fire protection

device. If tripping persists, contact your

authorized service agency for repairs. DO

NOT attempt to bypass or hold in the

button of the hi-limit thermostat, or a fire

may result.

10. SONALERT

Audible alarm to signal end of a cook cycle and other

programmed functions.

11. LIFT CRADLE

Raises and lowers fry basket.

12. FRY BASKET

Sits on the lift cradle and holds product to be cooked.

Raised and lowered by the lift cradle.

13. OIL FILTER RESERVOIR

Holds the filter element. Holds oil during filtering cycle.

14. EXHAUST FLUE

Twin flues. Hot flue gases exit here.

15. LIFT MOTOR

Raises/lowers lift cradle. Accessible for lubrication thru

the access plate in back panel.

16. VENTILATION SLOT

Provides air inlet for cooling fan inside control panel.

Never allow water to get into this slot.

17. FILTER PUMP MOTOR RESET BUTTON

The filter pump motor is equipped with an over-heating

protection device. Reset must be performed manually.

Allow the motor to cool for approx. 15 minutes, then

firmly press the red button on the back of the motor

until it "clicks".

18. BURNER ASSEMBLY

Two assemblies; comprised of orifice, shutter, burner,

and ignitor.

19. DRAIN VALVE OVAL HANDLE

Opens and closes the drain valve. To open, turn the

handle counter-clockwise (to vertical). To close, turn the

handle clockwise (to horizontal).

20. GAS SHUT OFF VALVES

Two valves, one located behind each gas control valve.

Allow isolation of either burner circuit.

21. GAS CONNECTION

Gas supply connects here.

22. POWER CORD

115V, 15 Amp, NEMA 5-15P

23. DATA PLATE

Identifies the appliance manufacturer, model and serial

number, and electrical ratings and gas ratings.

Operation and Care Manual #8456 • 5

FEATURES • OPERATING CONTROLS

Loading...

Loading...