Page 1

#8451• 3/00

PRINTED IN U.S .A .

ELECTRIC FRYERS

FAE-55F • FAE-55FS

PHONE: 262.251.3800 FAX: 262.251.7067 - 800.329.8744 U.S. A./CANADA WEBSITE:

800.558.8744 U.S .A./CANADA 262.251.1907 INTERNATIONAL www.alto-shaam.com

W164 N9221 Water Street ●P.O. Box 450 ●Menomonee Falls, Wisconsin 53052-0450 U.S.A.

®

COOK/HOLD SERVE SYSTEMS by

OPERATION & CARE MANUAL

®

FAE-55FS

Solid State

Control

FAE-55F

Manual

Control

Page 2

The Alto-Shaam electric fryer has been

thoroughly tested and inspected to insure

only the highest quality unit is provided.

When you receive your fryer, check for any

possible shipping damage and report it at

once to the delivering carrier.

See Transportation

Damage and Claims

section located in this manual.

The fryer, complete with unattached items and accessories, may

be delivered in one or more packages. Check to ensure that all

items have been received as standard with each unit.

Save all the information and instructions packed inside the

cabinet. Complete and return the warranty card to the factory as

soon as possible to assure prompt service in the event of a

warranty parts and labor claim.

This manual must be read and understood by all people using or

installing this fryer. Contact your local Alto-Shaam distributor if

you have any questions concerning installation, operation and

maintenance of this fryer.

NOTE:

All claims for warranty must include the full model

number and serial number of the cabinet.

1. Carefully remove the fryer from the carton.

NOTE: Do not discard the carton and other packaging

material until you have inspected the fryer for hidden

damage and tested it for proper operation.

2. Read all instructions in this manual carefully before starting

installation of this fryer.

DO NOT DISCARD THIS MANUAL. This manual is

considered to be part of the fryer and is to be given to the

owner or manager of the business, or to the person

responsible for training operators of the fryer. Additional

manuals are available from your Alto-Shaam distributor.

3. Remove all protective plastic film, packaging materials and

accessories from the fryer and the filter reservoir before

connecting electrical power to the fryer. Store the accessories

in a convenient place for future use.

Components:

Accessories:

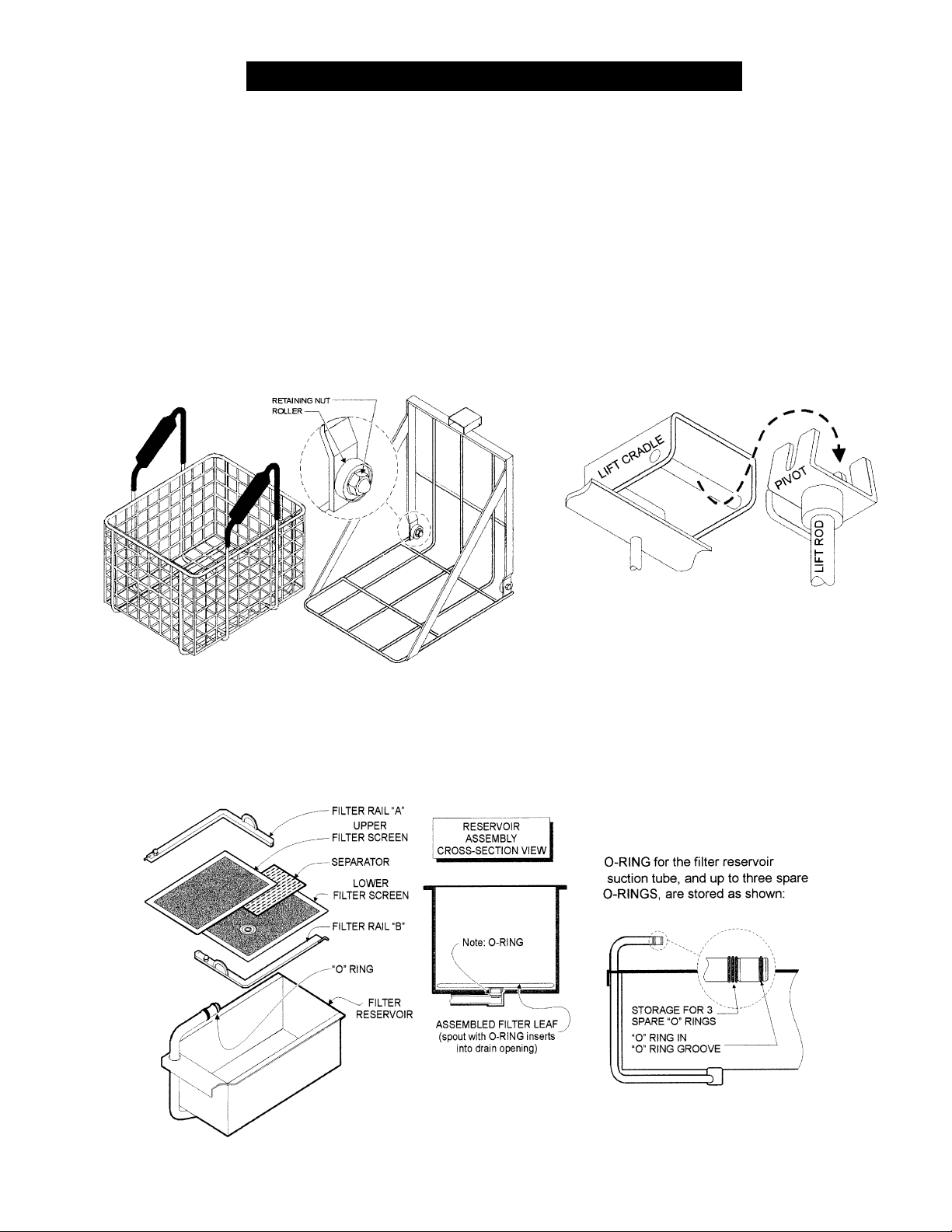

Filter reservoir, 1 ea. Filter powder, 1 box

Filter leaf, 1 ea. High temp.brushes, 2 ea.

Oil filter suction Stainless steel shovel, 1 ea.

tube O-ring, 4 ea. Cleanout dowel, 1 ea.

Fry basket, 1 ea. Street elbow, 1-1/4

NPT, 1 ea.

Lift cradle, 1 ea. Drain pipe,

1-1/4NPT X12", 1 ea.

Fry pot lid, 1 ea. Literature package, 1 ea.

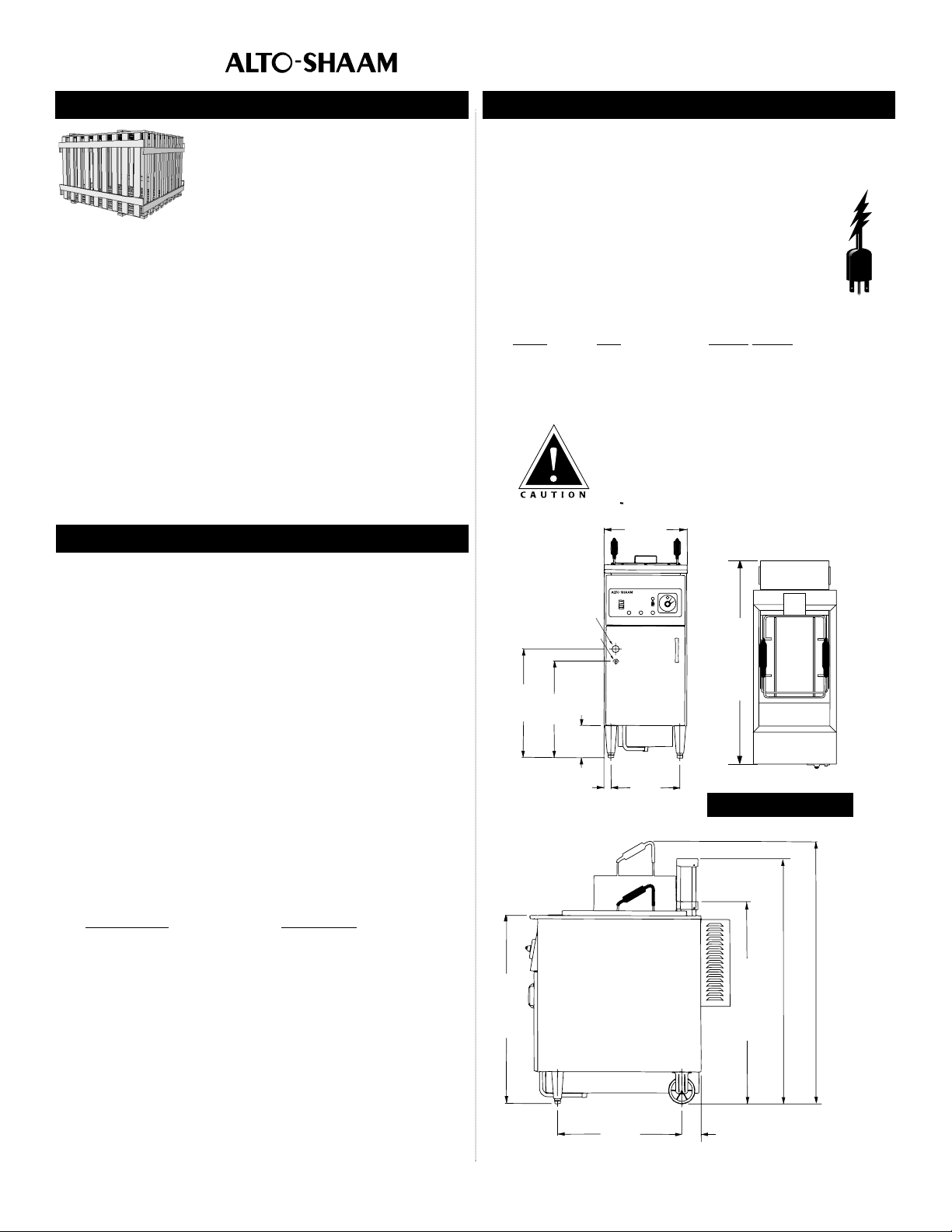

MODEL FAE-55F or FAE-55FS

1. Shortening Capacity: . . .55 lb (25kg)

2. Chicken (fresh) . . . . . . . . .30 lb (13kg)

3. Chicken (frozen) . . . . . . . .25 lb (11kg)

4. Phase Options: . . . . . . . . .

3 phase only

5. Line Frequency: . . . . . . . .50/60 Hz

6. Controls: . . . . . . . . . . . . . . .Manual or

Solid State

Electrical Specifications

Amps per Line

VAC kW Three Phase

208V 17.0 47.8 per line

240V 17.0 41.0 per line

380-415 17.4 L1-26.0, L2&L3-24.0

Operation and Care Manual #8451 • 1

— ELECTRIC FRYERS

DELIVERY

ENSURE POWER SOURCE MATCHES

VOLTAGE STAMPED ON UNIT

IDENTIFICATION TAG

SPECIFICATION INFORMATION

UNPACKING

37-3/8"—(948mm)

15-11/16"

(398mm)

20-1/4"

(514mm)

KNOCK OUT:

1-3/8"

(35mm)

KNOCK OUT:

7/8"

(22mm)

6"

(152mm)

1-3/8"

(35mm)

13"

(330mm)

18"

(456mm)

®

DIMENSIONS

®

36"—(914mm)

48-15/16" (1241mm)

45-11/16" (1160mm)

37-11/16" (957mm)

FRYER BASKET IN UP POSITION

LIFT MECHANISM IN UP POSITION

23-3/8"

(594mm)

3-11/16"

(93mm)

Page 3

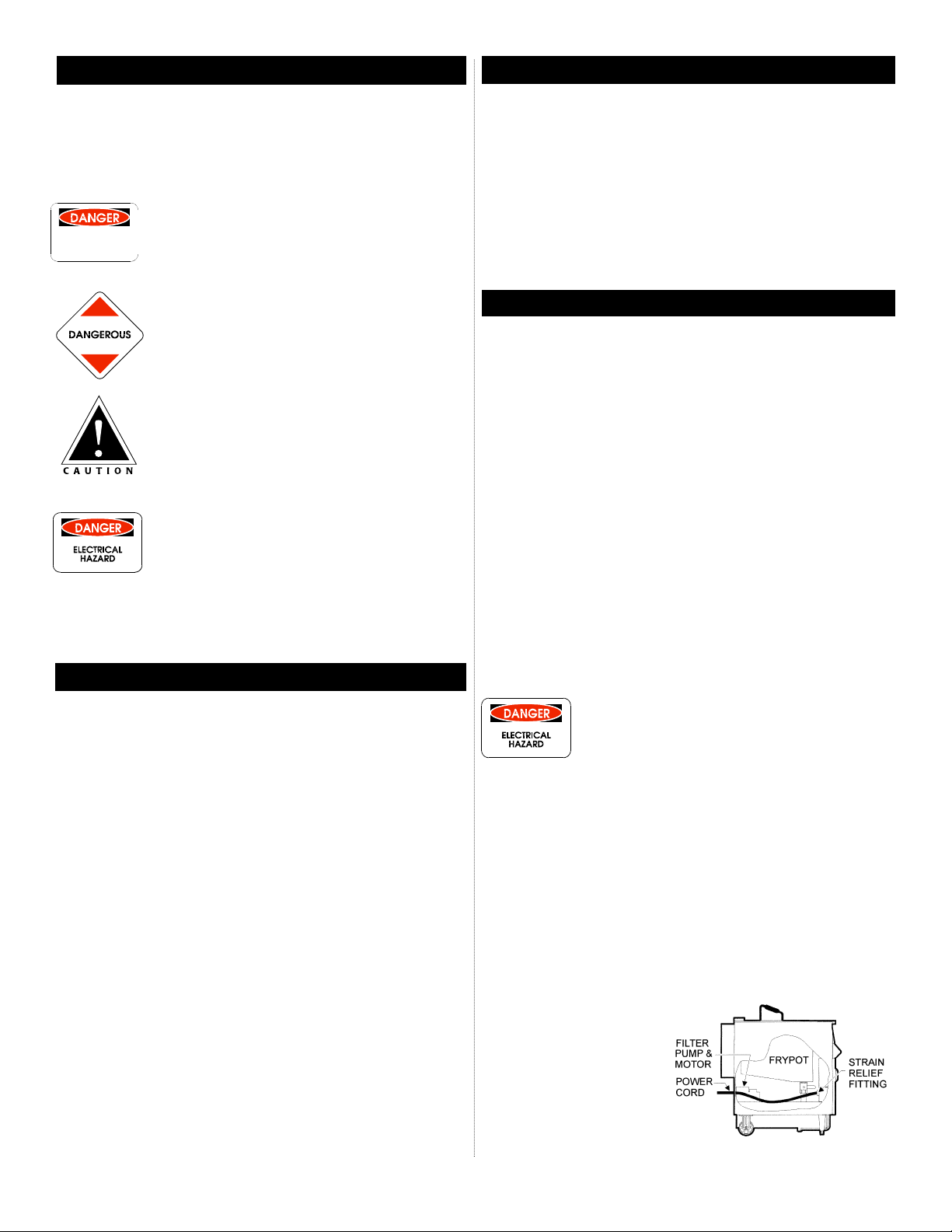

Knowledge of proper procedures is essential to the safe operation

of electrically energized equipment. In accordance with generally

accepted product safety labeling guidelines for potential hazards,

the following signal words and symbols are used throughout this

manual.

Used to indicate the presence of a hazard which

will cause severe personal injury, death, or

substantial property damage in the event the

statement is ignored.

Warning used to indicate the presence of a hazard

which can cause personal injury and possibly

death, or major property damage, in the event the

statement is ignored.

Caution is used to indicate the presence of a hazard

which will or can cause minor personal injury or

property damage in the event the statement is

ignored.

Used to indicate the presence of an electrical

hazard which will or can cause personal injury or

property damage in the event the statement is

ignored.

NOTE Used to notify personnel of installation, operation

or maintenance information which is important,

but not hazard related.

1. This fryer is intended to deep fry food products for human

consumption. No other use is authorized or recommended.

2. This fryer is intended for use in commercial establishments,

where all operators are familiar with the appliance use,

limitations, and associated hazards. Operating instructions

and warnings must be read and understood by all operators

and users.

3. This fryer is equipped with an oil filtration system which is

designed to filter hot liquid shortening ONLY. Water,

cleaning agents, or other liquids will damage the filter pump.

4. This piece of equipment is made in the USA and has

American size hardware.

5. Any trouble shooting guides, component views, or parts lists

included in this manual are for general reference only, and

are intended for use by qualified technical personnel.

6. This manual should be considered a permanent part of this

appliance. This manual and all supplied instructions,

diagrams, schematics, parts breakdowns, notices and labels

must remain with the appliance if it is sold or moved to

another location.

1. Set up the fryer on a firm, level, non-combustible surface

ONLY. Verify local codes for requirements. Concrete, tile,

terrazzo, or metal surfaces are recommended. Metal over

combustible material may not meet code for non-combustible

surfaces.

2.

Leveling: Verify that the fryer sits firmly on both casters and

on both legs. With a spirit level, check that the fryer is level

front-to-back and side-to-side. With the adjustable legs,

adjust as required to level the fryer.

1. Installation and start up should be referred to the local AltoShaam distributor. Installer must complete the warranty

registration/fryer checkout form, and record fryer

installation particulars on the back of this manual.

2. Verify that this fryer installation is in compliance with the

specifications listed in this manual and with local code

requirements. This is the responsibility of the installer.

3. Certain codes require fryers to be restrained with a cable or

other restraint device. It is the responsibility of the installer

to check with the authority having jurisdiction in order to

ascertain the applicability of this requirement to this specific

fryer installation.

4. Refer to the nameplate on the front the the fryer. Verify the

electrical service power. Voltage and phase must match the

nameplate specifications, and available electrical service

amperage must meet or exceed the specifications listed.

ELECTRICAL SHOCK HAZARD

Electrical connections must be made by a licensed

electrician. Electrical shock will cause death or

serious injury.

NOTE: Wire gauge, insulation type and temperature rating, as

well as type, size and construction of conduit, must meet

or exceed applicable specifications of local codes and of

the National Electrical Code.

5. The fryer is shipped from the factory wired for 3Ph electrical

service.

This fryer is not approved for conversion to single

phase. Converting to single phase will void the warranty

and invalidate the UL certification.

IMPORTANT: Field wiring must be routed and secured away

from the fry pot, tubing, and

filter pump and motor. Field

wiring must allow access to

the rear of the fryer for

cleaning and for access to the

oil filter pump motor reset

button and to the lift motor

lubrication point.

See illustration.

Operation and Care Manual #8451 • 2

SAFETY PROCEDURES

PRECAUTIONS & GENERAL INFORMATION

EQUIPMENT SET-UP PROCEDURES

INSTALLATION & ELECTRICAL INFO

Page 4

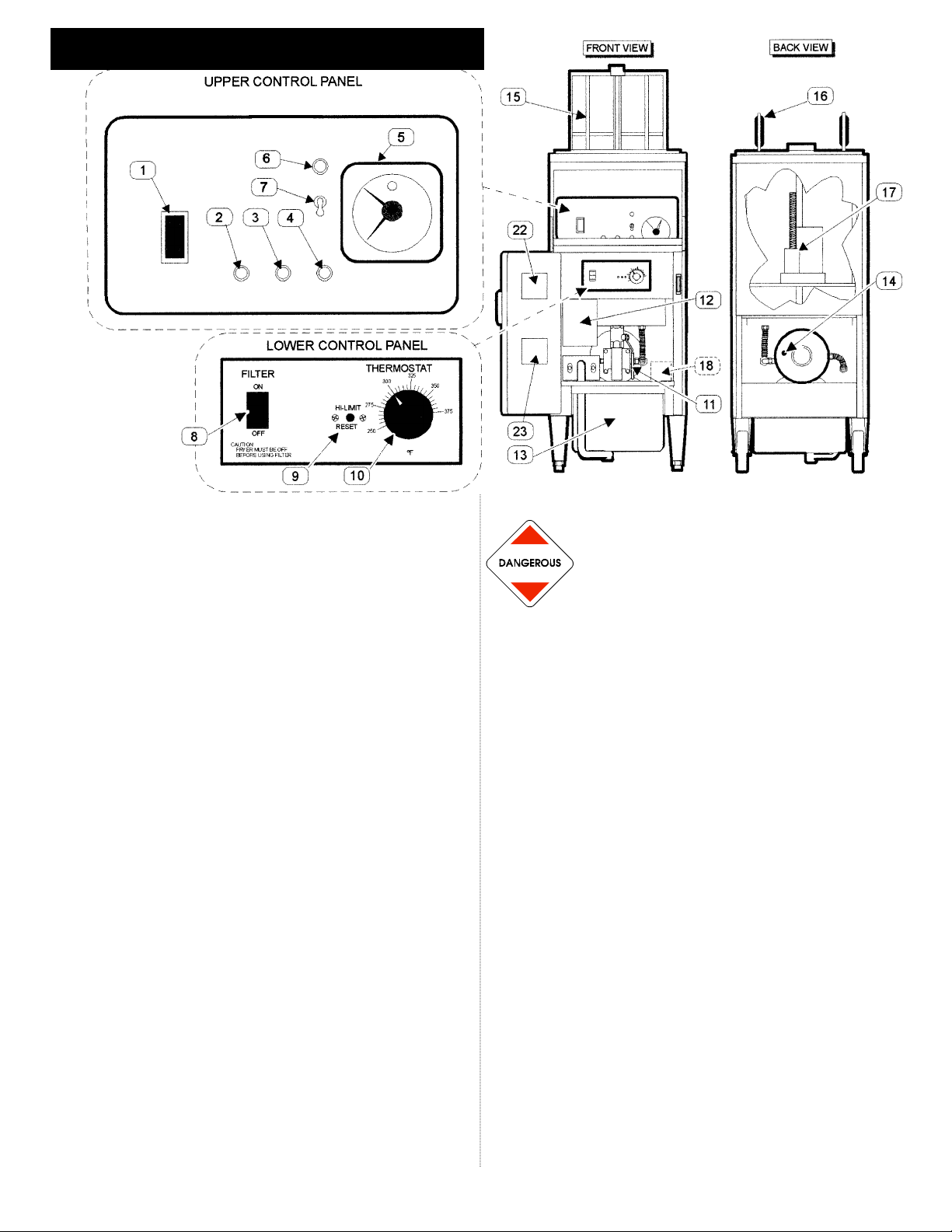

Operation and Care Manual #8451 • 3

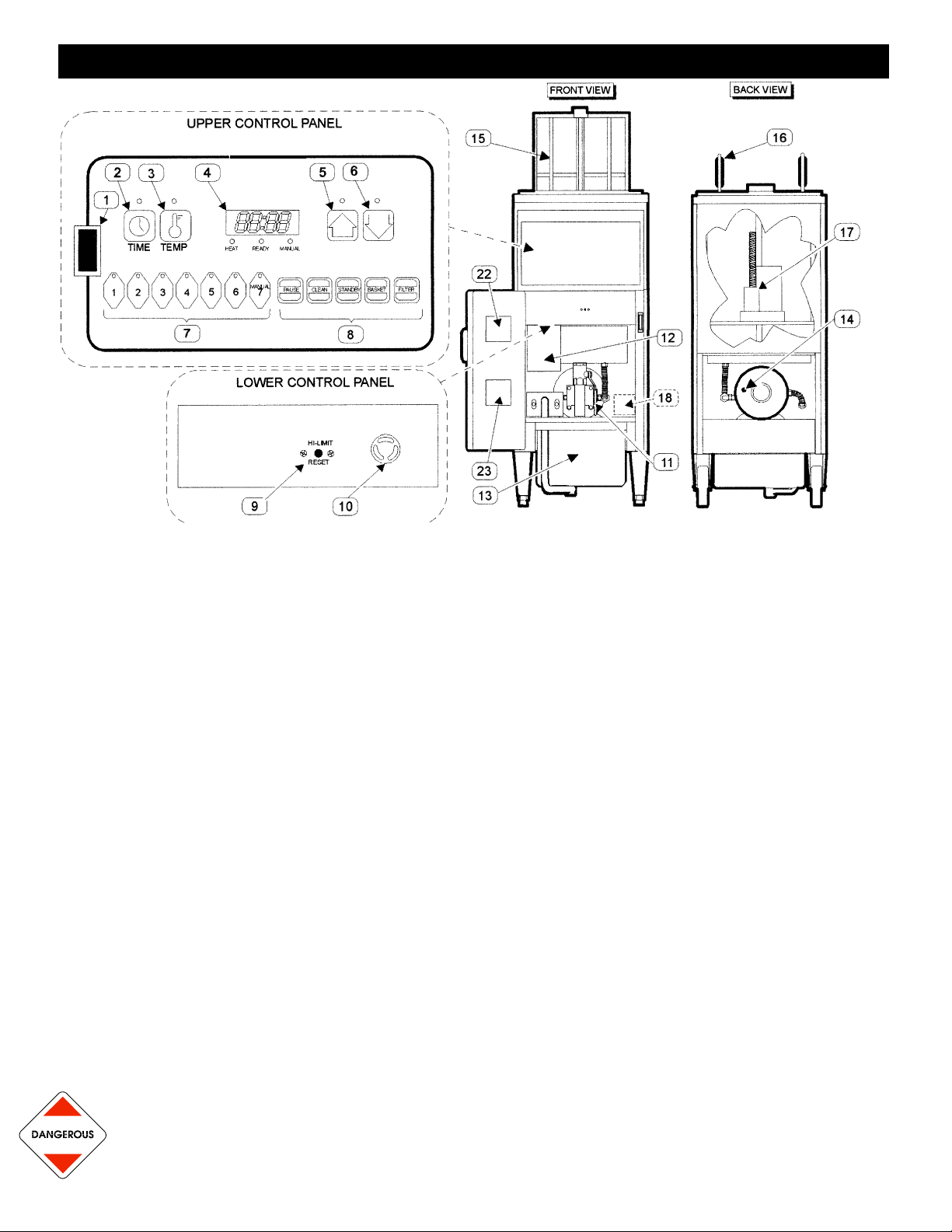

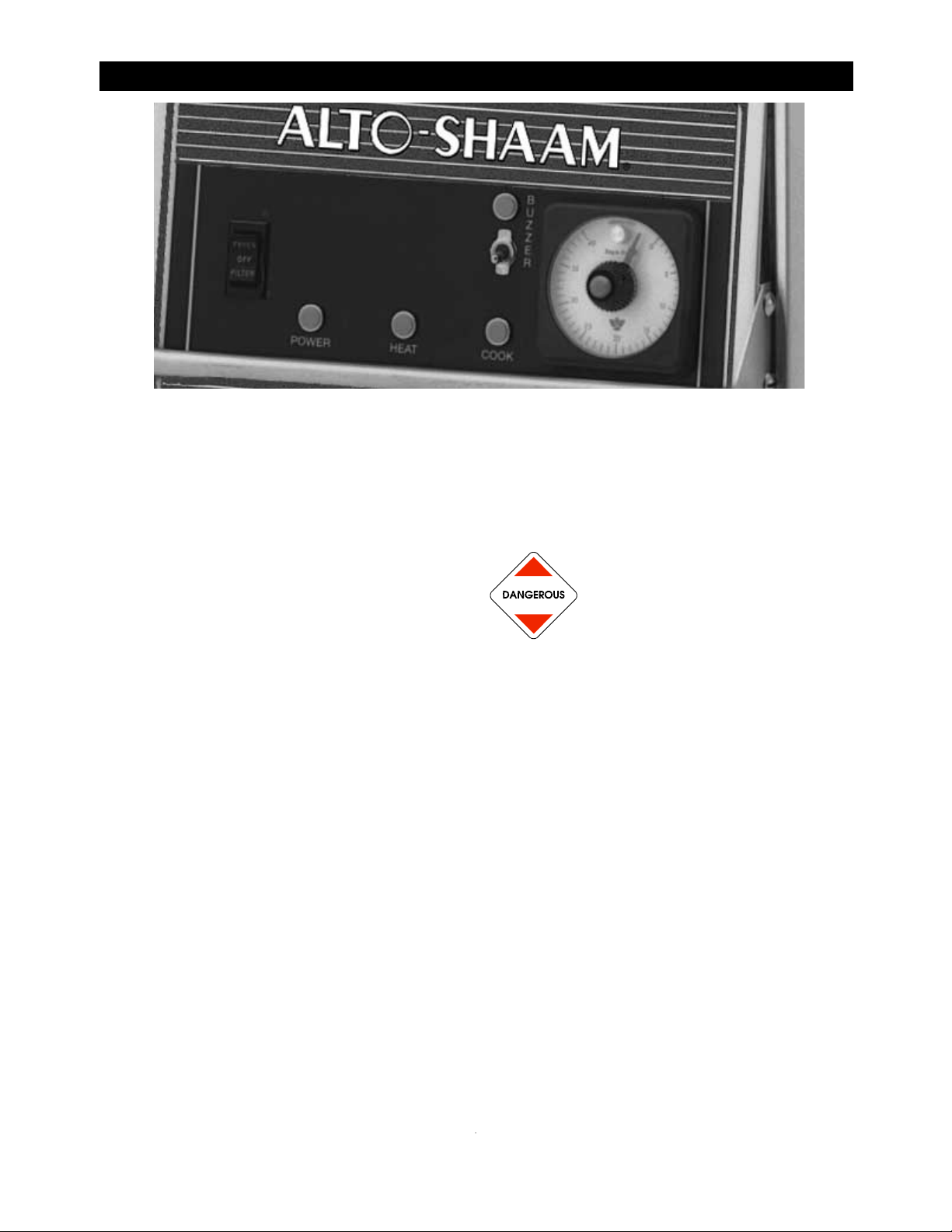

1. POWER SWITCH (FRYER-OFF-FILTER)

FRYER position turns ON the fryer and power light and turns

OFF the filter pump. Heating elements are energized and

regulate to the temperature set on the control thermostat

(#10). OFF position turns OFF the fryer and de-energizes the

lower panel filter pump switch (#8). FILTER position

energizes the lower filter pump switch (#8) and turns OFF the

fryer.

2. POWER LIGHT (AMBER)

When lit, indicates fryer is energized.

3. HEAT LIGHT (AMBER)

When lit, indicates heating element is energized. Light turns

OFF when oil has reached temp preset on control thermostat.

4. COOK LIGHT (AMBER)

When lit, indicates the timer (#5) is ON and the basket (#15) is

lowered.

5. TIMER

Controls the lift cradle and the buzzer. Timer is started by

pressing the red button in the center of the knob. When the

red button is pressed, the lift cradle lowers. The red pointer

on the dial shows time remaining. When timer reaches "0",

buzzer sounds and lift cradle raises.

6. BUZZER LIGHT (AMBER)

When lit, indicates buzzer switch (#7) is turned ON and

buzzer circuit is active.

7. BUZZER SWITCH

Activates the buzzer circuit. When turned ON and timer has

reached "0", buzzer will sound until buzzer switch is turned

OFF or timer is activated.

8. FILTER PUMP SWITCH (ON-OFF)

Causes the oil to be filtered and pumped back into the fry pot.

The power switch (#1) must be in the FILTER position for the

filter pump switch to operate.

9. HI-LIMIT THERMOSTAT

Provides over temperature protection by de-energizing the

heating elements if the oil temperature exceeds the factory-set

limit. Reset must be performed manually. Allow the oil to

cool below 300°F (149°C), then firmly press the red button on

the lower control panel.

FIRE HAZARD

The hi-limit thermostat is a fire protection device.

If tripping persists, clean debris from the space

between the hi-limit bulb and the element to

enhance oil flow and facilitate reset. Otherwise,

contact your authorized service agency for repair.

DO NOT attempt to bypass or hold in the button of

the hi-limit thermostat, or a fire may occur.

10. TEMPERATURE CONTROL THERMOSTAT

Controls the oil temperature from 250°F (121°C) turned fully

counter-clockwise to 375°F (191°C) when turned fully clockwise.

11. DRAIN VALVE HANDLE

Opens and closes the drain valve. To open, rotate the handle

until it points down. To close, rotate the handle to the

horizontal position.

12. POWER OUTLET BOX

Contains the electrical service connection terminal block.

13. OIL FILTER RESERVOIR

Holds the filter screen.

14.

FILTER PUMP MOTOR RESET BUTTON (located at the rear

of the motor)

The filter pump motor is equipped with an overheating protection device. Reset must be performed manually. Allow the

motor to cool for approx. 15 minutes, then press the red button.

15. LIFT CRADLE

Raises and lowers fry basket.

16. FRY BASKET

Sits on the lift cradle and holds product to be cooked. Raised

and lowered by the lift cradle.

17. LIFT MOTOR

Raises/lowers lift cradle. Accessible for lubrication thru the

access plate in back panel.

18. DRIP PAN

Gathers fluids that accumulate on the top of the fryer section

of ventilator hood model VAE-55F.

22. ELECTRICAL DIAGRAM

Installation and troubleshooting (for qualified technicians).

23. IDENTIFICATION TAG

Identifies manufacturer, model, serial number, electrical.

MANUAL CONTROL • FAE-55F

FEATURES & OPERATING CONTROLS

Page 5

1. POWER SWITCH (FRYER-OFF-FILTER)

FRYER position turns ON the fryer and power light and

turns OFF the filter pump. Heating elements are energized

and regulate to the temperature set on the selected MENU

key (#7). OFF position turns OFF the fryer and de-energizes

the lower panel filter pump switch (#8). FILTER position

energizes the lower filter pump switch (#8) and turns OFF

the fryer.

2. TIME KEY

Used to check and set menu times.

3. TEMP KEY

Used to check and set menu temperatures.

4. READOUT

LED display of various data and functions.

5. UP ARROW KEY

Used to raise fry basket and raise program settings.

6. DOWN ARROW KEY

Used to lower fry basket and lower program settings.

7. MENU KEYS

Used to begin a menu time/temperature cycle. Keys 1-6 are

programmable for time and temp. Key 7 is available for

individually set time/temp cook cycles.

8. FUNCTION KEYS

Used to perform the functions of Pause, Clean, Standby,

Basket (raise/lower), and Filter (warning/acknowledge).

9. HI-LIMIT THERMOSTAT

Provides over temperature protection by de-energizing the

heating elements if the oil temperature exceeds the factoryset limit. Reset must be performed manually. Allow the oil

to cool below 300°F (149°C), then firmly press the red button

on the lower control panel.

FIRE HAZARD • The Hi-Limit Thermostat is a fire

protection device. If tripping persists, clean debris from the

space between the hi-limit bulb and the element to enhance

oil flow and facilitate reset. Otherwise, contact your

authorized service agency for repair. DO NOT attempt to

bypass or hold in the button of the hi-limit thermostat, or a

fire could occur.

10. SONALERT

Audible alarm to signal end of a cook cycle and other

programmed functions.

11. DRAIN VALVE HANDLE

Opens and closes the drain valve. To open, rotate the handle

until it points down. To close, rotate the handle to the

horizontal position.

12. POWER OUTLET BOX

Contains the electrical service connection terminal block.

13. OIL FILTER RESERVOIR

Holds the filter screen.

14.

FILTER PUMP MOTOR RESET BUTTON (located at the

rear

of the motor)

The filter pump motor is equipped with an overheating

protection device. Reset must be performed manually.

Allow the motor to cool for approx. 15 minutes, then press

the red button.

15. LIFT CRADLE

Raises and lowers fry basket.

16. FRY BASKET

Sits on the lift cradle and holds product to be cooked. Raised

and lowered by the lift cradle.

17. LIFT MOTOR

Raises/lowers lift cradle. Accessible for lubrication thru the

access plate in back panel.

18. DRIP PAN

Gathers fluids that accumulate on the top of the fryer section

of ventilator hood model VAE-55FS.

22. ELECTRICAL DIAGRAM

Installation and troubleshooting (for qualified technicians).

23. IDENTIFICATION TAG

Identifies the appliance manufacturer, model and serial

number, and electrical rating.

Operation and Care Manual #8451 • 4

SOLID STATE CONTROL • FAE-55FS • FEATURES & OPERATING CONTROLS

Page 6

1. CLEANING:

Prior to leaving the factory, the fryer is tested for proper

operation with peanut oil. After testing is complete, the oil is

removed but oil residue remains. Therefore, it is necessary to

clean the fry pot before filling it with fresh oil. See

Cleaning

the Fryer

section in this manual.

2. Examine the cradle rollers. Adjust or tighten as required.

Lubricate the rollers with vegetable oil. DO NOT operate the

fryer unless the cradle rollers are in place and rotating freely.

Serious damage to the fry pot will result if the rollers are

missing or do not rotate freely.

3. Install the lift cradle onto the cradle pivot. Set the fry basket

on the lift cradle.

4. Install the filter leaf into the filter reservoir. Suction tube

O-rings are shipped from the factory installed on the suction

tube. Examine to verify one O-ring is in the groove closest to

the end of the tube. Install the assembled filter reservoir into

the fryer.

Operation and Care Manual #8451 • 5

PREPARATION PRIOR TO OPERATION

Page 7

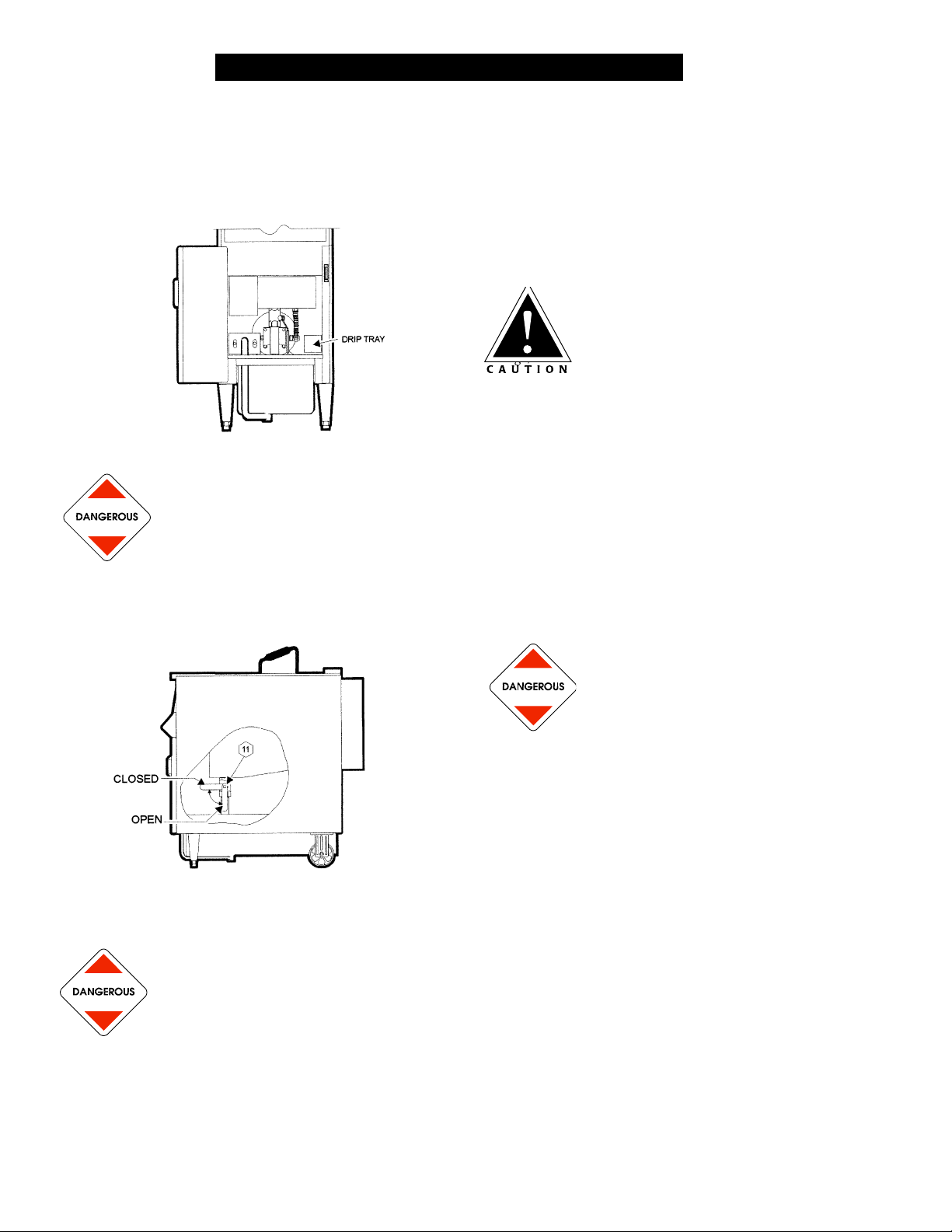

5. For Ventilator Hood models • VAE-55

Install the drip pan into the mounting bracket behind the

fryer door at the lower right front of the fryer.

If drip pan is not installed, oil will drip onto the floor which

could cause slipping or falling.

SLIPPING & FALLING HAZARD • SPILLED

OIL

Do not operate unless the drip pan is installed.

Oil will drip onto the floor and falls will result.

Death or serious injury may result from slipping

and falling in spilled oil.

6. Close the drain valve lever by turning the lever up to the

horizontal (closed) position.

SLIPPING & FALLING HAZARD • SPILLED

OIL

Close the drain valve before filling with oil. If the

drain valve is open, oil poured into the kettle will

drain into the filter reservoir or onto the floor. Oil

spills will occur, and death or serious injury could

result by slipping in oil.

7. Fill the fry pot to the COLD OIL LINE in the fry pot with

room temperature commercial quality shortening. This

requires 55 lbs. of liquid shortening.

Damage caused by attempts to pump anything other than

shortening in the liquid state is not covered by warranty.

IMPORTANT: This fryer is designed for liquid shortening ONLY.

Remember to fill the fryer to the COLD OIL LINE

with fresh shortening prior to turning the power

switch to the FRYER position.

Energizing the fryer without oil covering the elements will cause serious

damage, and this damage will not be covered by warranty.

8. Check operation of fryer and all controls. See Operating

Instructions

section in this manual.

9. DETERMINE MAXIMUM LOAD WEIGHT: For

operational safety, it is very important to determine the

maximum load weight for the specific operation. This can be

accomplished by starting out with small loads and gradually

increasing to the largest load size which allows a complete

cook cycle without oil foaming out of the fry pot.

POTENTIAL FOR OIL OVERFLOW

➔The weight of product which can be safely

cooked in this fryer will vary with oil level,

product moisture content, oil temperature, and

other various conditions. See

Determine

Maximum Load Weight above.

➔Failure to observe this warning will result in hot

oil release from the fryer. Hot oil causes severe

burns on contact.

Operation and Care Manual #8451 • 6

PREPARATION PRIOR TO OPERATION

Page 8

Operation and Care Manual #8451 • 7

OPERATING INSTRUCTIONS • FAE-55F • MANUAL CONTROL

PRE-HEATING THE FRYER

1.

Make sure fry pot is filled with liquid cooking oil to the

COLD OIL LINE inscribed on the inside of the fry pot.

2. Open the door to access the lower control panel, and set the

thermostat to the desired cooking temperature. Close door.

3. Set the power switch to FRYER. The power light and heat

light will turn ON. The heat light will cycle ON and OFF

with the heating elements. When the heat light first goes

OFF, the fryer is up to temperature and ready to cook the

product.

SET THE COOK TIMER AND LOAD PRODUCT

1.

Set the timer to the desired cooking time. Unless the timer

is reset, it will automatically return to the last time setting

when the red button is pressed.

2. Frozen Product: Set the basket on the lift cradle. Load

frozen product into the basket. Press the red button on the

timer to lower the basket into the fry pot.

3. Fresh Product: Set the basket on the lift cradle. Press the

red button on the timer to lower the basket into the fry pot.

Manually drop each piece of fresh product into the hot oil,

just above the oil level to minimize splattering.

Always use

protective clothing, such as insulated gloves, to protect against

hot oil burns.

BURN HAZARD • HOT OIL SPLATTER

Hot oil can cause serious burns on contact.

Wear protective clothing when cooking.

COOK CYCLE AND BUZZER

1.

When an audible alarm is desired at the end of the cook

cycle, turn the buzzer switch ON after the timer has been

started. The buzzer light will turn ON.

NOTE: If the buzzer switch is turned ON before the basket is

lowered, the buzzer will sound until the lift cradle is

down.

2. At the end of the cook cycle, the basket will raise, and the

buzzer will sound until the buzzer switch is turned OFF or

until the next cook cycle is started.

3. Use the plastic-coated handles of the basket to remove the

basket of cooked product from the lift cradle. Serve or

dispense cooked product as required.

Page 9

A. PROGRAMMING THE KEY FUNCTIONS

As each control panel key is pressed, a "beep" will sound. The

illuminated indicator for each key will light whenever the key is

pressed, and while the function associated with that key is active.

FRYER-OFF-FILTER

Allows the fryer to be placed in a normal cook mode (FRYER), an

oil-filtering mode (FILTER), or turned OFF.

TIME

Controls time functions.

TEMP

Controls temperature functions. Data can be read on the solid

state readout.

HEAT

Is lit whenever the burners are energized.

READY

Is lit when the oil is at the programmed temperature.

MANUAL

Is lit whenever MENU key 7 is selected.

ARROW

Up and down keys control the basket lift (after pressing the

BASKET key), and are used to scroll through program settings.

MENU keys 1 thru 7

Allow a choice of six (or seven) pre-programmed time/temp

settings. The solid state control is shipped from the factory with

all seven MENU keys programmed to ZERO time and 325°F

(165°C on units shipped to Europe).

➵MENU keys 1 and 2 incorporate a feature that will inform the

operator when to "drop" the wings and drumsticks during the

cooking cycle. The "drop" feature will allow cooking breasts

and thighs longer than the wings and drumsticks by audibly

beeping, and displaying "drop" on the readout. Your fryer

installer can program this feature into your control upon

request.

➵MENU key 7 is unprogrammed so that special or a one-of-a-

kind product may be programmed any time. Any time the

fryer is ON, press and hold the TIME key and MENU key 7 at

the same time. Press the UP or DOWN arrow key until the

desired time is displayed. If this MANUAL feature is not

desired, MENU key 7 may be programmed in the identical

fashion to MENU keys 1 thru 6.

➵Any selected MENU key can be cancelled by pressing and

holding for 3 seconds.

To program the control for cooking your product, first determine the

cooking time and temperature required to cook that product. Each

MENU key may be programmed for a different time and temperature,

depending upon the requirements of each menu item. It is the sole

responsibility of the end user to determine the time and temperature

requirements of each menu item, and to program each MENU key to the

determined time and temperature in order to insure completely and

safely cooked product.

B. TO PROGRAM MENU TIMES & TEMPERATURES

1.

Make sure fry pot is filled with shortening to the COLD OIL

LEVEL line inscribed on the inside of the fry pot. Do not

overfill or underfill the fryer.

2. Set the power switch to FRYER. After 10 seconds, the

readout will display "preheat" followed by the number of the

menu currently selected (the indicator of the selected menu

key will be lit). Press TEMP to verify the programmed

temperature setting of that menu. Press any MENU key to

change to that menu.

3. Enter the programming mode by pressing and holding TIME

and TEMP for 3 seconds, until the beep sounds and "prog" is

displayed on the readout.

Program MENU key 1 for the pre-determined cook time by

pressing and holding TIME and Menu key 1 at the same

time. Scroll to desired time by pressing UP or DOWN arrow

until the desired time is displayed on the readout.

Program MENU key 1 for the pre-determined cook

temperature by pressing and holding TEMP and MENU

key 1 at the same time. Scroll to the desired temp by

pressing UP or DOWN arrow until the desired temperature

is displayed on the readout. Range is 200°F to 375°F (93°C

to 191°C).

Operation and Care Manual #8451 • 8

FAE-55FS • SOLID STATE CONTROL • OPERATING INSTRUCTIONS

FRYER

OFF

FILTER

®

TIME

TEMP

2 3

1

4 5

HEAT READY

6 7

MANUAL

PAUSE

CLEAN

STANDBY BASKET

FILTER

Page 10

4. Program MENU keys 2 thru 6 in the same manner. MENU

key 7 can be programmed, or left as a "manual" menu key.

NOTE: Only MENU key 7 can be programmed while another

MENU is cooking.

5. Exit the programming mode by pressing and holding TIME

and TEMP keys for 1 second. The readout will display

"00:00" or "Preheat".

6. Be sure to record which MENU key corresponds to which

menu item or product to be cooked.

C. USING THE FUNCTION KEYS

PAUSE

Halts the time countdown while any menu is running and time

remaining is displayed on the readout. Allows user to raise the

basket to inspect the product in the middle of a cook cycle. Time

remaining is frozen until the PAUSE key is pressed again.

TO USE:

➵While a menu is running, press and hold the PAUSE key for 5

seconds until a beep sounds and the red indicator illuminates.

➵Raise the basket to inspect the product by pressing the BASKET

key and UP arrow key.

➵Resume cooking the product by pressing the BASKET key and

the DOWN arrow.

➵Resume the time countdown by pressing the PAUSE key.

TO CHANGE TIME REMAINING WHILE IN PAUSE:

➵This option uses the near-instant programming feature of the

MENU 7 "manual" key. Press and hold the TIME key plus

MENU 7 key at the same time.

➵Scroll in a new time remaining with the UP or DOWN arrow

keys. Release all keys. Press and hold the lit MENU key for 3

seconds. Display will read "00:00". Lower the basket by

pressing the BASKET key followed by the DOWN arrow key.

Press the "manual" MENU 7 key. The basket will rise when the

display reads "00:00".

➵If the original menu time or temperature must be adjusted, see

Programming Procedure section on preceding page.

CLEAN

Puts the fryer into the cleaning mode by setting the temperature

to approximately 200°F (94°C), which is just below the boiling

point of water.

TO USE: See Cleaning instructions in this manual.

STANDBY

Puts the fryer into a "standby" mode for off-peak periods when

the fryer is not needed, but when it is not desirable to perform a

complete oil cool down. This economy function allows the oil

temperature to cool to 275°F (135°C) when the fryer is not in use,

but it is not desirable to turn the fryer off.

TO USE:

➵While no menu is running and the display reads "00:00", press

and hold the STANDBY key until a "beep" sounds and the red

indicator illuminates.

➵To resume cooking after being in standby mode, press and hold

the STANDBY key until a "beep" sounds. The heating elements

will be energized. Fryer is ready for use when the READY light

illuminates.

BASKET

Allows the UP and DOWN arrow keys to raise or lower the basket.

TO USE:

➵Press and release the BASKET key. The red indicators over the

BASKET key and UP and DOWN arrow keys will light. Press

and release either arrow key. The indicator for the selected

arrow key will light.

➵All keys will be inactive for the 10 seconds of the raise/lower

cycle. This key is only active in the PREHEAT and PAUSE

MODES, or when "00:00" is displayed.

FILTER

Acknowledges a filter alarm. The filter alarm is programmed to

sound after a preset number of cook cycles. This is factory set to

ZERO cycles. Your fryer installer can alter the number of cycles

upon request.

TO USE:

➵When the cycle count reaches the preset number, a "beep" will

sound. Press and release the FILTER key to cancel the alarm

and reset the filter load counter to "0". See

Filtering Oil section

in this manual.

D. PREHEAT THE FRYER

Press a MENU key. If the oil temperature has not reached the

programmed temperature, the readout will display "preheat"

followed by the menu key number, and the HEAT indicator will

light. When the oil has reached the programmed temperature,

the READY indicator will light, a "beep" will sound 5 times, and

the readout will display "00:00". The readout will normally

display the time remaining. To display the oil temperature of the

lit menu item press TEMP key.

E. TO COOK PRODUCT

1.

Press MENU key 1 thru 6 for the desired menu item. When

the oil reaches the programmed temperature for that MENU

key, the READY light will go ON, the HEAT light will to

OFF, and five "beeps" will sound.

2. FROZEN PRODUCT: Set the BASKET on the lift cradle in

the raised position. Load frozen product into the basket.

Lower the basket by pressing BASKET key, then DOWN

arrow. When the basket is fully down, start the time cycle by

pressing the appropriate MENU key. The basket will raise

automatically (and the 10 second buzzer will sound) at the

end of the timed cycle.

3. FRESH PRODUCT: Set the empty basket on the lift cradle

in the raised position. Lower the basket by pressing

BASKET, then DOWN arrow. Manually drop each piece of

fresh product into the hot oil just above the oil level to

minimize splattering.

Always use protective equipment, such as

insulated gloves, to protect against hot oil burns.

For chicken,

drop thighs and breasts first, followed by drumsticks, then

wings. Start a timed cycle by pressing the MENU key you

have programmed with the desired settings.

4. Use the plastic-coated handles of the basket to remove the

basket of cooked product from the lift cradle.

NOTE: MENU keys 1 and 2 can incorporate a feature that

"beeps" and displays "drop" on the readout to inform

when to "drop" the wings and drumsticks. The installer

can program this feature into your control upon request.

Operation and Care Manual #8451 • 9

SOLID STATE CONTROL OPERATING INSTRUCTIONS

CONTINUED......

Page 11

A. CRADLE LIFT ASSEMBLY LUBRICATION

Failure to keep the cradle lift screw properly

lubricated will result in premature wear of the

brass lift nut. Wear caused by lack of proper

lubrication is NOT covered by warranty.

Disconnect the fryer from electrical power

before lubricating the cradle lift drive

screw. The lift motor could start

unexpectedly, causing serious injury if

power is not disconnected.

1. Disconnect the fryer from electrical power.

2. Open the rear access panel. Coat the exposed threads of the

cradle lift screw with moly (molybdenum disulfide) grease.

3. Close the access panel and restore electrical power.

4. Recommended frequency is "as required" or at a minimum of

every six months. Lubricate the cradle lift screw

immediately if a grinding or rubbing noise is heard when the

basket is raising.

B. CRADLE ROLLER ASSEMBLIES

SLIPPING & FALLING HAZARD • SPILLED

OIL

Do not use cradle if the rollers do not spin freely.

Replace rollers immediately if they are frozen. Oil

spill may occur, and serious injury may result by

slipping in oil.

1. DAILY: Rinse the cradle with cold water and use a mild,

abrasive pad to clean off any debris.

2. Thoroughly flush the bearings

in the rollers with hot water

(under the faucet or with a

spray nozzle). Rinse and dry.

3. Check the rollers to be sure they

roll freely. Check the bearing

nuts. KEEP THEM TIGHT!

NOTE: If rollers are frozen or found to

not spin freely after being thoroughly cleaned, replace them

immediately. Smooth operation of the rollers is essential to the

life of the fry kettle. Worn rollers can wear grooves thru the

frypot. Damage by frozen rollers is not covered by warranty.

C. FILTER LEAF ASSEMBLY

Clean the filter leaf after each day's filtration, or as needed to

return oil promptly to the kettle. Make sure all oil is pumped into

the fry pot before proceeding.

1. Open the fryer door and slide the filter reservoir forward to

remove it. Remove the filter leaf from the reservoir.

2. Daily cleaning of filter leaf assembly: Scrape off any debris and

clean with a hot water rinse. Drain, and air dry overnite.

3. Weekly cleaning (or as needed) of filter leaf assembly:

Disassemble the filter leaf by separating the two side rails at

the joint with the straight pin. Scrape any debris off, clean

with a hot water rinse, and air dry overnite.

4. Assemble the screen with the separator installed between the

two screens. Verify that the O-ring is in place on the suction

tube on the bottom screen. See diagram in

Preparation Prior to

Operation

section in this manual.

5. Slide the screens into side rail B (L-shaped pin). Note that

the handle will point away from the suction tube on the

bottom screen. Hook side rail A over the pin on side rail B

and work the screens into side rail A until the straight pin on

side rail A is held by the bump on side rail B.

6. Inspect the filter leaf in the filter reservoir with the suction

tube firmly into the filter reservoir drain hole.

7. Install the O-ring on the filter suction tube for damage.

Using one of the spare O rings in the suction tube groove,

replace the O ring if it is cut, cracked or scuffed.

8. Install the filter reservoir into the fryer. Make sure the O-ring

closest to the end of the suction tube is firmly seated in the

suction line receptacle.

BURN HAZARD • HOT OIL SPLATTER

➔Do not remove filter reservoir when it contains

hot oil. Always remember to wear insulated

gloves – or allow the oil and the reservoir time

to cool.

➔Hot oil quickly heats the reservoir. Serious

burns could result.

Operation and Care Manual #8451 • 10

MAINTENANCE

Page 12

IMPORTANT: Filtering the cooking oil helps to ensure the

quality of the food product. Careful observation

of the finished food product will help you

determine your optimal filtering frequency.

Example: Filter the oil after each six loads of fresh

breaded product.

BURN HAZARD • HOT OIL SPLATTER

➔Protective clothing and gloves must be worn

during the filtering process. Hot oil may

splatter resulting in serious injury.

➔The fryer filtration system is designed to filter

hot liquid shortening ONLY. Water, cleaning

agents, or other liquids will damage the filter

pump.

➔DO NOT attempt to filter cold oil (less than

300°F or 149°C).

➔DO NOT store oil in the filter reservoir

overnight, or other extended periods.

➔DO NOT attempt to pump cold oil. The filter

pump will not pump cold oil through the filter

leaf. Pumping cold oil will result in premature

failure of the filter pump.

1. Press the power switch to the OFF position.

2. Remove and examine the filter reservoir. Make absolutely

certain that no water exists in the bottom of the pan.

Verify that

the filter leaf is properly installed, and that the suction tube

O-ring is in place and in good condition. Install the filter

reservoir assembly into the fryer, making sure the suction

tube is properly seated in the suction receptacle.

BURN HAZARD

The filter reservoir may be hot. Wear insulated

gloves or allow the filter reservoir to cool before

touching it.

IMPORTANT: Do not leave the fryer unattended during the

filtering process. Continuously monitor the oil

level in the reservoir to avoid overflowing the

reservoir and spilling oil on the floor.

3. Filter powder absorbs acids and other contaminants in the

cooking oil, allowing the cooking oil to be used for a longer

period of time before it must be replaced. Carefully and

slowly add the contents of one package of filter powder to

the oil in the fry pot. Stir in the powder with the "l" shaped

brush.

4. Slowly rotate the drain valve lever to the OPEN position.

The oil will drain from the kettle. If the kettle does not drain,

unplug the drain by using the wood cleanout dowel

provided with the fryer. Unplug the drain by pushing the

dowel down through the drain hole in the bottom front

center of the kettle.

BURN HAZARD

➔Protective clothing and insulated gloves

must be worn when cleaning the kettle with

the hi-temp brush and when unclogging

the drain with the wood cleanout dowel.

The kettle will be hot, hot oil may splatter,

and serious injuries may result.

➔Never attempt to remove the filter reservoir

when it is full of hot oil. Serious burns

could result from any hot oil spill.

5. Press the power switch to the FILTER position. The filter

pump will circulate the oil through the filter leaf, returning it

to the kettle.

6. Using the high temperature brush supplied with the fryer,

brush and scrape down the fry pot sides and bottom to

loosen crumbs and flush them from the fryer.

7. Be aware that filter powder and crumbs will accumulate on

the filter leaf. If the oil is slow to return to the fry pot

because of a plugged filter leaf, use the stainless steel shovel

supplied with the fryer to scoop the debris from the filter leaf

top surface. See

Cleaning Instructions in this manual.

8. When filtering is complete (5 to 7 minutes of pump running

with the drain valve open), rotate the oval drain valve handle

to the CLOSED position.

9. When bubbles begin to appear in the oil being pumped into

the fry pot, wait approximately 15 seconds. Then press the

power switch to the OFF position.

10. Service the filter leaf after each day's filtration, or as needed

to return oil promptly to the kettle.

IMPORTANT: Verify that all oil has been returned to the kettle

at the end of the filtering cycle.

Operation and Care Manual #8451 • 11

FILTERING OIL

Page 13

IMPORTANT: The following instructions for discarding old

oil from this fryer are to be disregarded if you

possess a Mobile Oil Caddy. This manual oil

pump/removal system allows you to hand

pump the used oil directly from the fry pot into

the Mobile Oil Caddy. You may then pump the

oil into the oil disposal drum by reversing the

pump rotation.

REMEMBER - Always and without fail, allow the oil to cool,

prior to pumping the oil into the Mobile Oil

Caddy.

HOT OIL WILL BURN YOU.

BURN HAZARD • HOT OIL

Oil must cool to 120°F (49°C) or cooler before

draining oil from the fryer for disposal. Normal

operation temperature of the fryer is 375°F

(191°C). Death or serious injury will result from

contact with hot oil.

SLIPPING & FALLING HAZARD •

SPILLED OIL

➔Do not use the filter reservoir to discard oil.

➔Do not fill disposal container more than 1/2 full.

➔Do not leave fryer unattended when draining

oil. Oil spills may occur. Death or serious

injury can occur from slipping and falling in

spilled oil.

BURN HAZARD • FILTER RESERVOIR

When removing the filter reservoir after filtering

oil, wear insulated gloves, or allow it time to cool.

The hot oil will quickly heat the reservoir.

Serious burns could result from touching the hot

filter reservoir with bare hands.

DISCARDING USED OIL WITHOUT USING THE MOBILE

OIL CADDY

1.

Press the power switch to OFF and allow the oil to cool to

120°F (49°C) or less, before attempting to drain the oil from

the fryer.

2. Using suitable gloves, remove the 1-1/4 NPT x 5-7/8" drain

pipe from the drain valve. Store this item in a convenient

place.

3. Screw the 1-1/4 NPT x street elbow that was supplied with

the fryer into the drain valve. Loosen it just enough to point

forward.

4. Screw the 1-1/4 NPT x 12" drain pipe into the elbow. Hand

tight is sufficient.

5. Place a suitable metal oil disposal container under the

drain pipe.

6. Slowly turn the drain valve lever down toward the OPEN

(vertical) position. Fill the container no more than 1/2 full.

Close the drain valve and allow the oil to finish draining

from the drain pipe before removing the container. Dump

the used oil into your waste oil container. Continue this

process until the kettle is empty.

7. Close the drain valve by rotating the drain valve lever up to

the CLOSED (horizontal) position.

8. Using suitable gloves, unscrew the 1-1/4 NPT x 12" drain

pipe from the elbow. Unscrew the elbow from the drain

valve. Store these items in a convenient place.

9. Reinstall the 1-1/4 NPT x 5-7/8" drain pipe into the drain

valve.

10. Clean up any spilled oil.

IMPORTANT: Remember to fill the fryer to the COLD OIL LINE

with fresh liquid shortening prior to turning the

power switch to the FRYER position. Energizing

the fryer without oil covering the elements will

cause serious damage. Damage due to operating

the fryer without oil covering the elements is

NOT covered by warranty.

Operation and Care Manual #8451 • 12

DISCARDING USED OIL

Page 14

KETTLE CLEANING INSTRUCTIONS

(After discarding old oil)

HOT BOIL OUT METHOD

(Use low foaming commercial fryer cleaner only.)

SLIPPING AND FALLING HAZARD • SPILLED OIL

Do not store oil in the filter reservoir while

cleaning the kettle. If cleaning solution is

accidentally drained into the filter reservoir oil will

spill on the floor. Death or serious injury may

result from slipping and falling in spilled oi

l.

1. Press the power switch to the OFF position.

2. Discard old oil. Refer to Discarding Used Oil instructions

in this manual.

3. Fill the fry pot to the COLD OIL FILL LINE with cold water.

BURN HAZARD • HOT WATER SPLATTER

➔Turn thermostat to lowest temperature setting

(fully counter-clockwise ).

➔Only use low foaming commercial fryer cleaner.

Follow container instructions and warnings.

➔ Do not leave fryer unattended while boiling out

kettle.

➔ If water foaming occurs, be prepared to press

power switch to OFF. Boiling water may

splatter resulting in serious injuries.

4. For FAE-55F Model, press the power switch to the FRYER

position. Allow the water to come to a full boil, then press

the power switch to OFF. When the boiling ceases, slowly

add and stir in the low foaming commercial fryer cleanser.

Stir until the cleanser is completely mixed with the water

using the high temperature brush supplied with the fryer.

Press the power switch to FRYER. When the water begins to

boil, press to OFF. When the boiling subsides, again press

the power switch to FRYER. Repeat this procedure (i.e.,

FRYER-boil-OFF) continuously for at least 15 minutes.

For

FAE-55FS Model, press the power switch to the FRYER

position. Wait 10 seconds, then press and hold CLEAN

button for six seconds until a "beep" sounds and "BOIL" is

displayed. Slowly add the low foaming commercial fryer

cleanser to the water. Stir until the cleanser is completely

mixed with the water using the high temperature brush

supplied with the fryer.

5. For FAE-55F, allow the cleaning solution to set for 30 minutes

with the power switch in the OFF position.

For

FAE-55FS, time displayed is elapsed time. When the

display reads "1:30", press the power switch to the OFF

position. Allow the solution to cool to a safe temperature.

6. To exit Clean mode, turn power switch OFF. With the power

switch in the OFF position, drain the cleaning solution.

NOTE: For safe handling if using a metal container, allow

the solution to cool to 120°F or below. Always safely

dispose of used cleaning solution as required by

local ordinances.

7. Rinse the kettle thoroughly with clean, warm water. Drain

into the same container as used to dispose of the cleaning

solution.

IMPORTANT: NEVER turn the filter pump ON with

anything other than commercial quality

liquid shortening in the filter reservoir.

Water will cause severe oil splatter, damage

the pump, and contaminate the cooking oil.

Clean the reservoir only when empty. The filter reservoir and

filter leaf should be cleaned after each day's filtration, or as

needed to return oil promptly to the kettle.

1. Remove the empty filter reservoir from the fryer. Clean the

filter reservoir and the filter leaf components using a hot

water rinse. Let dry overnite, or dry with a non-abrasive

cloth.

BURN HAZARD • FILTER RESERVOIR

When removing the filter reservoir after filtering

oil, wear insulated gloves, or allow it time to cool.

The hot oil will quickly heat the reservoir.

Serious burns could result from touching the hot

filter reservoir with bare hands.

2. Rinse the reservoir thoroughly with clean, warm water to

remove all residue. Be sure to flush out the filter reservoir

suction tube. Tip the filter reservoir upside down and allow

all water to drain from the reservoir and suction tube.

3. Dry all parts thoroughly with a non-abrasive cloth.

4. Assemble and reinstall the filter leaf and filter reservoir.

Refer to

Preparation Prior to Operation section in this manual.

As required, wash the exterior of the fryer with warm water, mild

soap or detergent, and a clean, non-abrasive cloth. Dry with a

clean, non-abrasive cloth.

Any components of the fryer that come in contact with the liquid

shortening should NOT be cleansed with soap or detergent. If

this does happen, rectify the situation by rinsing these parts with

a mild vinegar/water solution (2 teas. vinegar per 1 gal. water).

Then, rinse again thoroughly with clear water, and dry with a

clean, non-abrasive cloth.

Operation and Care Manual #8451 • 13

CLEANING THE FRYER

CLEANING THE RESERVOIR

DAILY CLEANING OF FRYER

WARNING • SOAP USE

Page 15

PROBLEM REMEDY

DISPLAY not lit.

➔Check the service power breaker. Reset if tripped. If breaker continues to trip, contact a licensed

electrician to repair field wiring (if that is the cause), or contact an authorized service agency.

➔Fryer is at programmed temperature. Display reads "00:00". Check programmed temperature by

pressing TEMP key. If programmed temperature is too low, adjust temperature or select another

menu key. (See

Operating Instructions for Solid State Control, in this manual).

➔Fryer is in CLEAN mode. If CLEAN indicator is lit and display reads "boil", press power switch

to the OFF position, wait 10 seconds, then press power switch back to the FRYER position.

➔Fryer is in STANDBY mode. If the STANDBY indicator is lit, press STANDBY key for 3 seconds

until a beep sounds. Press and release a MENU key to resume cooking.

➔If the above instructions do not solve problem, contact an authorized service agency for repair.

➔Check the hi-limit thermostat. Reset by firmly pressing the hi-limit reset button on the lower

control panel until it "clicks".

FIRE HAZARD/HOT OIL

The hi-limit thermostat is a fire protection device. If tripping persists, clean the space

between the hi-limit bulb and the element to enhance oil flow and facilitate reset.

Otherwise, contact your authorized service agency for repairs. Do not attempt to

bypass or hold in the button of the hi-limit thermostat, or a fire may result.

➔Probable cause is a damaged internal component. Contact an authorized service agency.

➔Cradle lift must be lowered manually, but will raise automatically at the end of a cook cycle.

During the period between cook cycle, in the PAUSE mode or during PREHEAT, the cradle lift is

lowered by pressing BASKET key, then DOWN arrow, and raised by pressing BASKET key, then

UP arrow.

➔The lift motor has a 10 second delay (after an up or down command is entered) until it will accept

another command. The lift motor is de-energized during a cook cycle.

➔At the end of a cook cycle, when the time remaining on the readout reaches 00:00, the cradle lift

should raise.

➔If the cradle lift does not behave as described above, probable cause is a damaged control, an

internal adjustment or one or more damaged internal components. Contact a factory authorized

service agency for repair.

➔Verify that the power switch (upper control panel) is in the

FILTER position.

➔Press the red reset button on the filter pump motor,

accessible on the back of the fryer. If the pump motor

continues to trip out, or if no other cause is apparent for the

pump's failure to run, contact a factory authorized service

agency.

BURN HAZARD • HOT OIL SPLATTER

Protective clothing and gloves must be worn

whenever servicing the filter during the filtering

cycle. Hot oil may splatter which could result in

serious injury.

continued.......

Operation and Care Manual #8451 • 14

TROUBLESHOOTING • FAE-55FS • SOLID STATE CONTROL

FRYER WILL NOT HEAT

WHEN POWER SWITCH IS

IN

FRYER POSITION

DISPLAY LIT,

READY indicator lit,

HEAT indicator not lit.

DISPLAY not lit,

HEAT indicator lit.

DISPLAY LIT,

HEAT indicator lit,

hi-limit thermostat not

"tripped"

CRADLE LIFT WILL NOT

LOWER - or CRADLE LIFT WILL NOT

RAISE

FILTER PUMP WILL NOT

RUN

NOTE: Any servicing or adjustment which requires the removal of any cover or other protective panel

must be performed by a factory authorized service agency.

Page 16

Operation and Care Manual #8451 • 15

PROBLEM REMEDY

FRYER WILL NOT HEAT

Power light NOT ON.

➔Check the service power breaker. Reset if tripped. If breaker continues to trip, contact a licensed

electrician to repair field wiring (if that is the cause) or contact an authorized service agency.

➔Check the hi-limit thermostat. Reset by pressing the hi-limit reset button on the lower control

panel until it "clicks".

FIRE HAZARD/HOT OIL

The hi-limit thermostat is a fire protection device. If tripping persists, clean debris from

the space between the hi-limit bulb and the element to enhance oil flow and facilitate

reset. Otherwise, contact your authorized service agency for repairs. Do not attempt to

bypass or hold in the button of the hi-limit thermostat, or a fire may result.

➔Check setting of temperature control thermostat. If turning the thermostat fully clockwise

(i.e., to a higher temp) does not turn the heat light ON, and also cause the oil to heat, or if the

control thermostat calibration is significantly incorrect, contact an authorized service agency.

➔Probable cause is a damaged internal component. Contact an authorized service agency.

➔Verify that the timer is set to time other than 0. When the red button in the center of the timer is

pressed, the cradle lift should lower.

➔When the timer reaches 0, the cradle lift should raise.

➔If the cradle lift does not behave as described above, probable cause is an internal adjustment, or

one or more damaged internal components. Contact an authorized service agency.

➔Verify that the power switch (upper control panel) is in the FILTER

position. On FAE-55F,. also verify that the filter pump switch

(lower control panel) is in the ON position.

➔Press the red reset button on the filter pump motor, accessible on

the back of the fryer. If the pump motor continues to trip out, or if

no other cause is apparent for the pump's failure to run, contact a

factory authorized service agency.

The surface of the filter leaf may become clogged with crumbs or other debris.

If this happens:

➔Turn OFF the drain valve handle and press the power switch OFF.

➔Using appropriate gloves, carefully and very slowly slide the filter reservoir out approximately

6". Gently run the stainless steel shovel across the surface of the filter leaf and scrape the crumbs

toward the rear. Carefully and very slowly slide the filter reservoir back into place, making sure

the suction tube is properly seated in the receptacle.

BURN HAZARD/HOT OIL SPLATTER

Protective clothing and gloves must be worn whenever servicing the filter during the

filtering cycle. Hot oil may splatter which could result in serious injury.

Bubbles in the oil while filtering and/or a failure of the pump to achieve or maintain prime indicate that air is

entering the suction side of the pump.

➔Examine the suction tube O-ring. A damaged or improperly seated O-ring can cause the filter

pump to lose suction. This will result in a failure to filter the oil, and in a failure of the oil to be

returned to the fry pot. Replace suction tube O-ring if it is missing, cracked, distorted, or scuffed.

➔Verify that the suction tube is fully seated in the suction line receptacle.

NOTE: Any servicing or adjustment which requires the removal of any cover or other protective panel

must be performed by a factory authorized service agency.

TROUBLESHOOTING • FAE-55F • MANUAL CONTROL

Power light ON;

Heat light NOT ON.

Power Light ON;

Heat Light ON.

CRADLE LIFT WILL NOT

LOWER - or - CRADLE

LIFT WILL NOT RAISE

FILTER PUMP WILL NOT

RUN

OIL NOT RETURNING

TO FRY POT DURING

FILTER CYCLE

FILTER PUMP WILL NOT

PUMP - or -PUMPS AIR

DURING FILTERING.

Page 17

PROBLEM REMEDY

The surface of the filter leaf may become clogged with crumbs or other debris. If this happens:

➔Turn OFF the drain valve handle and press the power switch OFF.

➔Using appropriate gloves, carefully and very slowly slide the filter reservoir out approximately

6". Gently run the stainless steel shovel across the surface of the filter leaf and scrape the crumbs

toward the rear. Carefully and very slowly slide the filter reservoir back into place, making sure

the suction tube is properly seated in the receptacle.

Bubbles in the oil while filtering, and/or a failure of the pump to achieve or maintain prime indicate that air

is entering the suction side of the pump.

➔Examine the suction tube O-ring. A damaged or improperly

seated O-ring will cause the filter pump to lose suction. This

will result in a failure to filter the oil, and in a failure of the oil

to be returned to the fry pot. Replace suction tube O-ring if it

is missing, cracked, distorted, or scuffed.

➔Verify that the suction tube is fully seated in the suction line

receptacle.

BURN HAZARD • HOT OIL SPLATTER

Protective clothing and gloves must be worn

whenever servicing the filter during the filtering

cycle. Hot oil may splatter which could result in

serious injury.

Operation and Care Manual #8451 • 16

FILTER PUMP WON'T PUMP

- or - PUMPS AIR DURING

FILTERING

SERVICE PARTS LIST

Use only factory authorized service parts and replacement filters.

Contact the Alto-Shaam factory for advice.

Fryer Accessories

Basket

Lift Cradle

Brush, heating element cleaning

Flavor Saver oil filter powder (45pk)

Mobile Oil Disposal Caddy

Paddle, stirring chicken

Brush, fry pot cleaning

Drip pan

Filter leaf assembly

Stainless steel shovel

Kettle cover

Maintenance Items

Lube, molybdenum disulfide

O-ring, suction tube

Dowel, cleaning

O-ring, filter leaf

TROUBLESHOOTING • FAE-55FS • SOLID STATE CONTROL

NOTE: Any servicing or adjustment which requires the removal of any cover or other protective panel

must be performed by a factory authorized service agency.

OIL NOT RETURNING TO

FRY POT DURING FILTER

CYCLE

Page 18

Operation and Care Manual #8451 • 17

Page 19

Operation and Care Manual #8451 • 18

Page 20

Operation and Care Manual #8451 • 19

Page 21

Operation and Care Manual #8451 • 20

Page 22

Operation and Care Manual #8451 • 21

Page 23

Transportation

Damage and Claims

All Alto-Shaam equipment is

sold F.O.B. shipping point,

and when accepted by the

carrier, such shipments

become the property of

the consignee.

Should damage occur in shipment, it is a matter between the carrier

and the consignee. In such cases, the carrier is assumed to be

responsible for the safe delivery of the merchandise, unless

negligence can be established on the part of the shipper.

1. Make an immediate inspection while the equipment is still in

the truck or immediately after it is moved to the receiving area.

Do not wait until after the material is moved to a storage area.

2. Do not sign a delivery receipt or a freight bill until you have

made a proper count and inspection of all merchandise received.

3. Note all damage to packages directly on the carrier’s delivery

receipt.

4. Make certain the driver signs this receipt. If he refuses to sign,

make a notation of this refusal on the receipt.

5. If the driver refuses to allow inspection, write the following on

the delivery receipt:

Driver refuses to allow inspection of

containers for visible damage.

6. Telephone the carrier’s office immediately upon finding

damage, and request an inspection. Mail a written confirmation

of the time, date, and the person called.

7. Save any packages and packing material for further inspection

by the carrier.

8. Promptly file a written claim with the carrier and attach copies

of all supporting paperwork.

We will continue our policy of assisting our customers in collecting

claims which have been properly filed and actively pursued. We

cannot, however, file any damage claims for you, assume the

responsibility of any claims, or accept deductions in payment for

such claims.

Record the model and serial numbers of the unit for easy reference. Always refer

to both model and serial numbers in your correspondence regarding the unit.

Model: _______________________________________________________

Serial Number: _________________________________________________

Purchased From: ________________________________________________

Date Installed: _______________ Voltage: ___________________

Alto-Shaam, Inc. warrants to the original purchaser that any original part that

is found to be defective in material or workmanship will, at our option, subject

to provisions hereinafter stated, be replaced with a new or rebuilt part.

The labor warranty remains in effect one (1) year from installation or fifteen

(15) months from the shipping date, whichever occurs first. Alto-Shaam will

bear normal labor charges performed during standard business hours not

subject to overtime, holiday rates, or any additional fees.

The parts warranty remains in effect one (1) year from installation or fifteen

(15) months from the shipping date, whichever occurs first.

This warranty does not apply to:

1. Safety thermostat, circuit breaker and overload protector reset or fuse

replacement unless specifically warranted.

2. Any and all malfunction due to operation at voltages other than specified

on the equipment. Conversion to correct voltage and phase are the

responsibility of the purchaser.

3. Any and all problems due to electrical connections not in accordance with

electrical code requirements and the wiring diagrams supplied with the

equipment.

4. Calibration of heat controls on original components after the first sixty

(60) days.

5. Replacement of items subject to normal wear. Such items include but are

not limited to knobs, light bulbs, baskets, grids, mechanical timers,

thermocouples, fuses and indicating lights.

6. Normal maintenance functions including lubrication, adjustments of airflow, thermostats, door mechanisms, micro-switches, burners and pilot

burners.

7. Installation labor, inspection, and start-up are not considered warranty

items.

8. Charges incurred by delays or operational restrictions which hinder the

ability of a service technician to perform service are not covered by

warranty.

9. Equipment damage caused by accident, shipping, improper installation or

alteration.

10. Equipment used under conditions of abuse, misuse, carelessness or

abnormal conditions including equipment subjected to harsh or

inappropriate chemicals, poor water quality or equipment with missing or

altered serial numbers.

11. Any losses or damages resulting from malfunction, including loss of

product or consequential or incidental damages of any kind.

12. Equipment modified in any manner from original model, substitution of

parts other than factory authorized parts, removal of any parts or addition

of any parts.

Alto-Shaam factory authorized replacement parts are warranted for ninety (90)

days from date of purchase on non-warranty equipment. Replacement parts

warranty is limited to the defective part only. The use of parts other than

factory authorized Alto-Shaam replacement parts completely voids warranty

coverage.

This warranty is exclusive and is in lieu of all other warranties, expressed or

implied, including the implied warranties of merchantability and fitness for

purpose. In no event shall the Company be liable for loss of use, loss of

revenue, or loss of product or profit, or for indirect or consequential damages.

This warranty is in lieu of all other warranties expressed or implied and AltoShaam, Inc. neither assumes or authorizes any persons to assume for it any

other obligation or liability in connection with Alto-Shaam equipment.

COOK/HOLD/SERVE SYSTEMS BY

W164 N9221 Water Street ●P.O. Box 450 ●Menomonee Falls, Wisconsin 53052-0450 ●U.S.A.

PHONE: 262.251.3800 FAX: 262.251.7067

●

800.329.8744 U .S .A ./CANADA WEBSITE:

800.558.8744 U .S .A ./CANADA 262.251.1907 INTERNATIONAL WWW.alto-shaam.com

PRINTED IN U.S .A .

Fryer • Original Equipment Limited Warranty

®

Page 24

Operation and Care Manual #8451 • 23

Business Name_______________________ Location________________

Installation Date_____________________Technician_________________

Service Co.__________________________________________________

Address__________________________State_________Zip_____

Telephone No. ( )_________________________

Equipment Model No.____________________

Equipment Serial No._____________________

Voltage

✔ one ❑ 208V ❑ 240V ❑ 380-415V

Please have this information available if calling for service.

Loading...

Loading...