Alto Shaam FAE-30F Installation Manual

PRINTED IN U.S .A .

ELECTRIC FRYER

MODEL: FAE-30F

PHONE: 262.251.3800 FAX: 262.251.7067 - 800.329.8744 U.S. A./CANADA WEBSITE:

800.558.8744 U.S .A./CANADA 262.251.1907 INTERNATIONAL www.alto-shaam.com

W164 N9221 Water Street ●P.O. Box 450 ●Menomonee Falls, Wisconsin 53052-0450 U.S.A.

®

COOK/HOLD SERVE SYSTEMS by

OPERATION & CARE MANUAL

®

#8450 • 3/00

The Alto-Shaam electric fryer has been

thoroughly tested and inspected to insure

only the highest quality unit is provided.

When you receive your fryer, check for any

possible shipping damage and report it at

once to the delivering carrier.

See Transportation Damage and Claims

section located in this manual.

The fryer, complete with unattached items and accessories, may

be delivered in one or more packages. Check to ensure that all

items have been received as standard with each unit.

Save all the information and instructions packed inside the

cabinet. Complete and return the warranty card to the factory as

soon as possible to assure prompt service in the event of a

warranty parts and labor claim.

This manual must be read and understood by all people using or

installing this fryer. Contact your local Alto-Shaam distributor if

you have any questions concerning installation, operation and

maintenance of this fryer.

NOTE: All claims for warranty must include the full model

number and serial number of the cabinet.

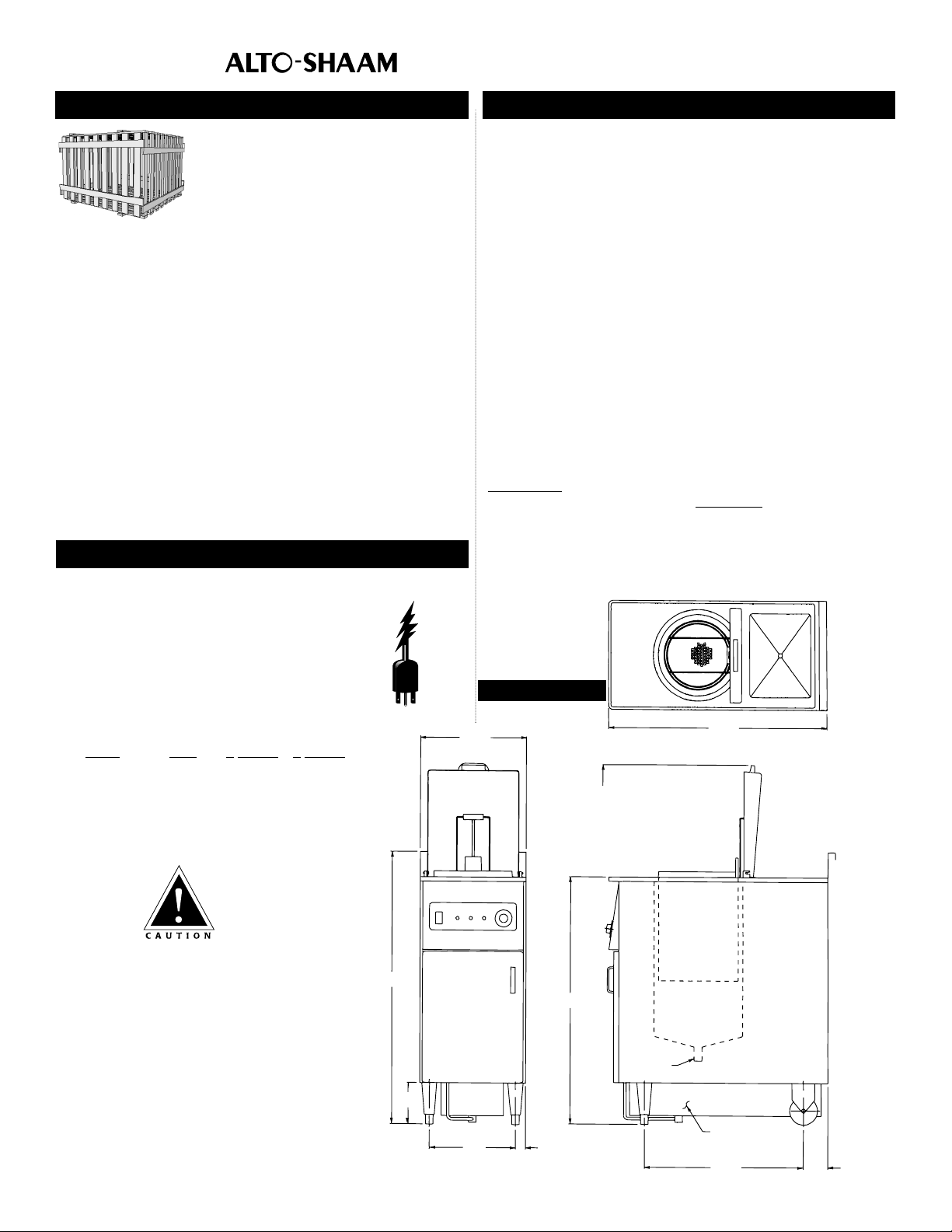

MODEL FAE-30F

1. Shortening Capacity: . . .30 lb (14kg)

2. Chicken (fresh) . . . . . . . . .14 lb (6kg)

3. Chicken (frozen) . . . . . . . .12 lb (5kg)

4. Phase Options: . . . . . . . . .1 & 3 phase*

5. Line Frequency: . . . . . . . .50/60 Hz

Electrical Specifications

AMPS AMPS

VAC KW 1 Phase 3 Phase

208 9.0 43.3 25.0 per line

240 9.0 37.5 21.7 per line

380-415 9.3

L1-14.3; L2&L3-13.0

*Units are shipped from factory as 3Ph; but are

field convertible to 1Ph.

Operation and Care Manual #8450 • 1.

— ELECTRIC FRYERS

DELIVERY

UNPACKING

SPECIFICATION INFORMATION

ENSURE POWER SOURCE

MATCHES VOLTAGE

STAMPED ON FRYER

IDENTIFICATION TAG

1. Carefully remove the fryer from the carton.

NOTE: Do not discard the carton and other packaging

material until you have inspected the fryer for hidden

damage and tested it for proper operation.

2. Read all instructions in this manual carefully before starting

installation of this fryer.

DO NOT DISCARD THIS MANUAL. This manual is

considered to be part of the fryer and is to be given to the

owner or manager of the business, or to the person

responsible for training operators of the fryer. Additional

manuals are available from your Alto-Shaam distributor.

3. Remove all protective plastic film, packaging materials and

accessories from the fryer and the filter reservoir before

connecting electrical power to the fryer. Store the accessories

in a convenient place for future use.

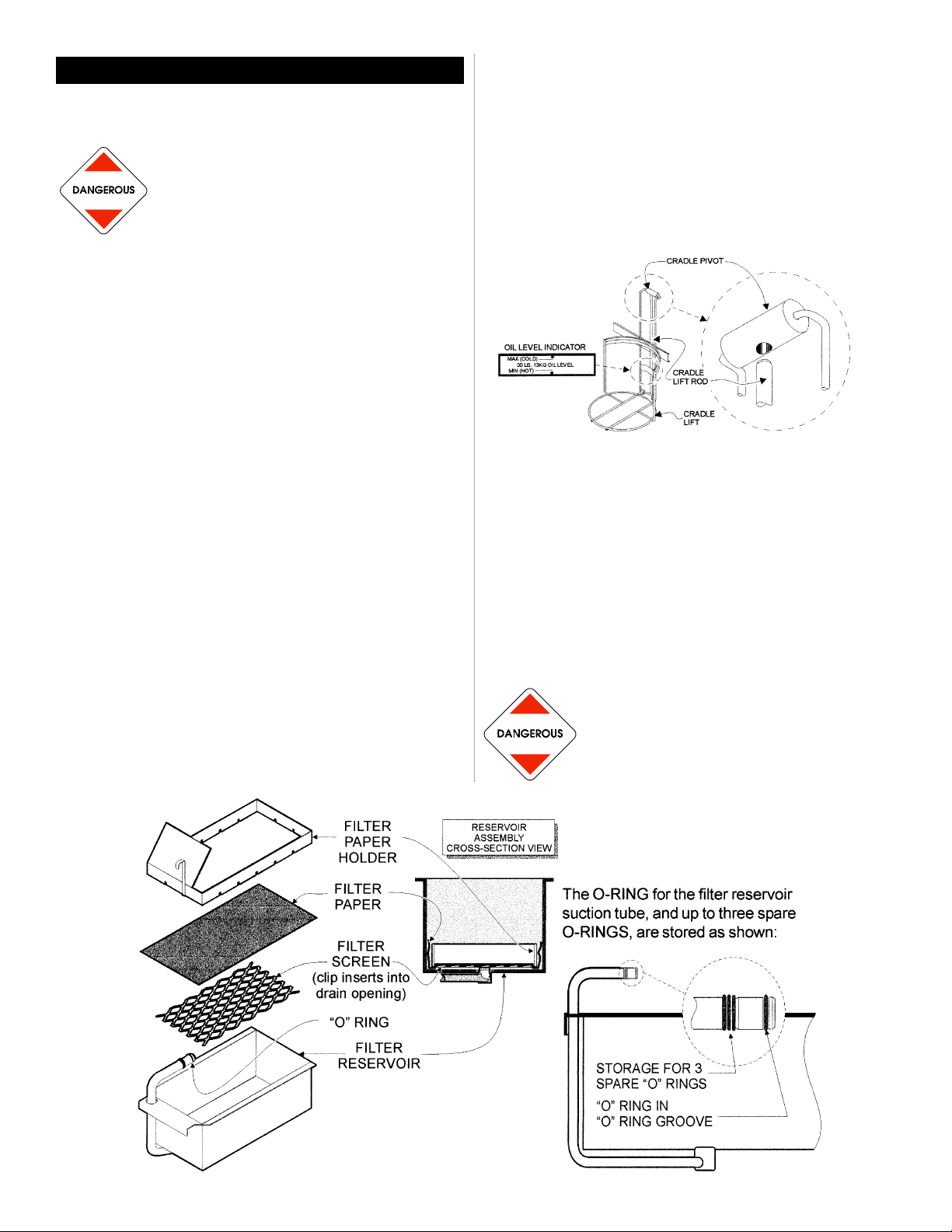

Components:

Condensate drip tray, 1 ea.

Filter reservoir, 1 ea.

Filter screen, 1 ea.

Filter paper holder, 1 ea.

Oil filter suction tube O-ring, 4 ea.

Basket, 1 ea.

Basket handle, 1 ea.

Accessories:

Filter paper, 1 pk.

Filter powder, 1 pk.

High temperature brush, 1 ea.

Cleanout dowel, 1 ea.

Literature Package, 1 ea.

6"

(152mm)

13"

(330mm)

1-3/8"

(35mm)

40"

(1016mm)

15-11/16"

(398mm)

52-7/8"

(1343mm)

(COVER IN UP POSITION)

33 -1/4"

(845mm)

36"

(914mm)

FRY POT

DRAIN

OPTIONAL BUILT-IN

FRYER FILTER

3-11/16"

(93mm)

23-3/8"

(594mm)

DIMENSIONS

®

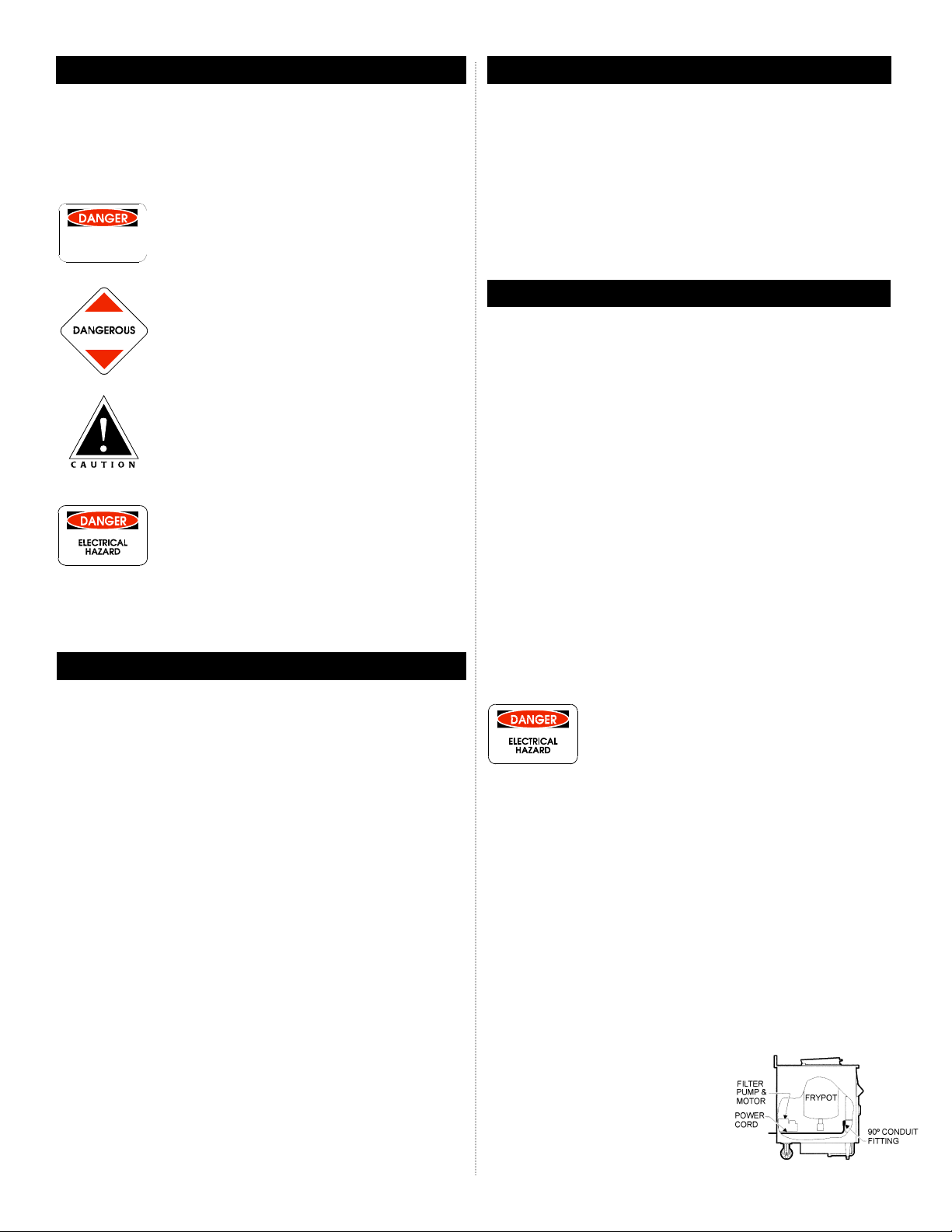

Knowledge of proper procedures is essential to the safe operation

of electrically energized equipment. In accordance with generally

accepted product safety labeling guidelines for potential hazards,

the following signal words and symbols are used throughout this

manual.

Used to indicate the presence of a hazard which

will cause severe personal injury, death, or

substantial property damage in the event the

statement is ignored.

Warning used to indicate the presence of a hazard

which can cause personal injury and possibly

death, or major property damage, in the event the

statement is ignored.

Caution is used to indicate the presence of a hazard

which will or can cause minor personal injury or

property damage in the event the statement is

ignored.

Used to indicate the presence of an electrical

hazard which will or can cause personal injury or

property damage in the event the statement is

ignored.

NOTE

1.

This fryer is intended to deep fry food products for human

consumption. No other use is authorized or recommended.

2. This fryer is intended for use in commercial establishments,

where all operators are familiar with the appliance use,

limitations, and associated hazards. Operating instructions

and warnings must be read and understood by all operators

and users.

3. This fryer is equipped with an oil filtration system which is

designed to filter hot liquid shortening ONLY. Water,

cleaning agents, or other liquids will damage the filter pump.

4. This piece of equipment is made in the USA and has

American sizes on hardware.

5. Any trouble shooting guides, component views, or parts lists

included in this manual are for general reference only, and

are intended for use by qualified technical personnel.

6. This manual should be considered a permanent part of this

appliance. This manual and all supplied instructions,

diagrams, schematics, parts breakdowns, notices and labels

must remain with the appliance if it is sold or moved to

another location.

1. Only set up the fryer on a firm, level, non-combustible

surface. Verify local codes for requirements. Concrete, tile,

terrazzo or metal surfaces are recommended. Metal over

combustible material may not meet code for non-combustible

surfaces.

2.

Leveling: Verify that the fryer sits firmly on both casters and

on both legs. With a spirit level, check that the fryer is level

front-to-back and side-to-side. With the adjustable legs,

adjust as required to level the fryer.

1. Installation and start up should be referred to the local AltoShaam distributor. Installer must complete the warranty

registration/fryer checkout form, and record fryer

installation particulars on the back of this manual.

2. Verify that this fryer installation is in compliance with the

specifications listed in this manual and with local code

requirements. This is the responsibility of the installer.

3. Certain codes require fryers to be restrained with a tether or

other restraint device. It is the responsibility of the installer

to check with the authority having jurisdiction in order to

ascertain the applicability of this requirement to this specific

fryer installation.

4. Refer to the nameplate on the front the the fryer. Verify the

electrical service power. Voltage and phase must match the

nameplate specifications, and available electrical service

amperage must meet or exceed the specifications listed.

Wiring must be no less than 12 ga. solid copper wire, rated

for at least 75°C.

ELECTRICAL SHOCK HAZARD

Electrical connections must be made by a licensed

electrician. Electrical shock will cause death or

serious injury.

NOTE: Wire gauge, insulation type, and temperature rating, as

well as type, size and construction of conduit, must meet

or exceed applicable specifications of local codes and of

the National Electrical Code.

5. Fryers are shipped from the factory wired for 3Ph electrical

service. Refer to the 3Ph wiring diagram included with this

fryer and verify that field wiring conforms to this diagram.

NOTE: Fryers are field convertible to 1Ph. If single-phase

operation is required, refer to the 3Ph to 1Ph instructions

included with the fryer, and verify that both internal

wiring and field wiring conform to the single-phase

wiring diagram.

IMPORTANT: Field wiring must be

routed and secured away from the

frypot, tubing and filter pump and

motor. Field wiring must allow access

to the rear of the fryer for cleaning and

for access to the oil filter pump motor

Reset Button.

See illustration.

Operation and Care Manual #8450 • 2.

SAFETY PROCEDURES

EQUIPMENT SET-UP PROCEDURES

PRECAUTIONS & GENERAL INFORMATION

INSTALLATION & ELECTRICAL INFO

Note is used to notify personnel of installation,

operation or maintenance information which is

important, but not hazard related.

Operation and Care Manual #8450 • 3.

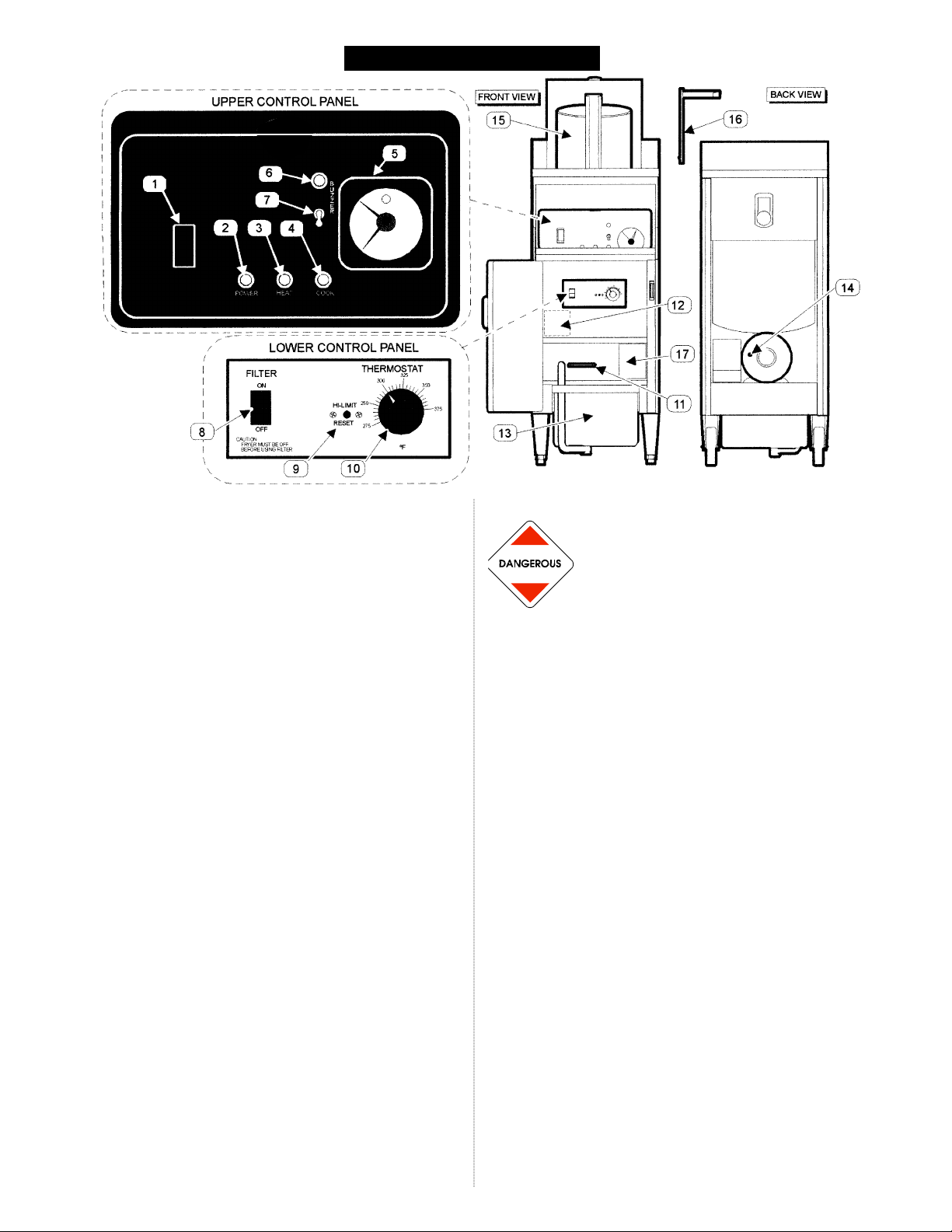

1. POWER SWITCH (FRYER-OFF-FILTER)

Fryer position turns ON the fryer, illuminates the power

light, and turns OFF the filter pump. The heating elements

are energized and regulate to the temperature set on the

control thermostat (#10). OFF position turns off the fryer and

de-energizes the lower panel pump switch (#8). FILTER

position energizes the lower filter pump switch (#8) and turns

OFF the fryer.

2. POWER LIGHT (AMBER)

When lit, indicates fryer is energized.

3. HEAT LIGHT (AMBER)

When lit, indicates heating element is energized. Light turns

OFF when oil has reached temperature preset on control

thermostat.

4. COOK LIGHT (AMBER)

When lit, indicates the timer (#5) is ON and the basket (#15) is

lowered.

5. TIMER

Controls the lift cradle and the buzzer. The timer is started

by pressing the red button in the center of the knob. When

the red button is pressed, the lift cradle lowers. The red

pointer on the dial shows time remaining. When timer

reaches "0", buzzer sounds and lift cradle raises.

6. BUZZER LIGHT (AMBER)

When lit, indicates buzzer switch (#7) is turned ON and

buzzer circuit is active.

7. BUZZER SWITCH

Activates the buzzer circuit. When turned ON and timer has

reached "0", buzzer will sound until buzzer switch is turned

OFF or timer is activated.

8. FILTER PUMP SWITCH (ON-OFF)

ON causes the oil to be filtered/pumped back into the frypot.

The power switch (#1) must be in the FILTER position for the

filter pump switch to operate.

FIRE HAZARD/HOT OIL

The hi-limit thermostat is a fire protection device. If

tripping persists, clean the space between the hi-limit

bulb and the element in order to enhance oil flow

and facilitate reset. Otherwise, contact your

authorized service agency for repair.

DO NOT

attempt to bypass or hold in the button of the hi-limit

thermostat. A fire may result.

9. HI-LIMIT THERMOSTAT

Provides protection by de-energizing the heating elements if

the oil temperature exeeds the factory-set limit. Reset must

be performed manually. Allow the oil to cool below 300°F

(93°C), then firmly press the red button on the lower control

panel until it resets (snaps).

10. TEMPERATURE CONTROL THERMOSTAT

Controls the oil temperature from 250°F (121°C) turned fully

counter-clockwise, to 375°F (191°C) fully clockwise.

11. DRAIN VALVE LEVER

Opens and closes the drain valve. To OPEN, turn the handle

counter-clockwise (vertical). To CLOSE, turn the handle

clockwise (horizontal).

12. POWER OUTLET BOX

Contains the electrical service connection terminal block.

13. OIL FILTER RESERVOIR

Holds the filter screen, filter paper and filter paper holder.

14. FILTER PUMP MOTOR RESET BUTTON

(located at the rear of the motor)

The filter pump motor is equipped with an overheating

protection device. Reset must be performed manually.

Allow the motor to cool for approximately 15 minutes, then

press the red button.

15. BASKET

Sits on the lift cradle and holds product to be cooked. Raised

and lowered by the lift cradle.

16. BASKET HANDLE

Used to handle the basket when it is hot. Remove from basket

before activating timer.

17. DRIP PAN

Collects any liquids which accumulate on top of fryer.

CONTROLS & FUNCTIONS

BURN HAZARD/HOT WATER SPLATTER

➔Turn thermostat to lowest temperature setting

(fully counter-clockwise).

➔Use only low-foaming commercial fryer cleaner.

➔Carefully follow cleanser instructions and

warnings.

➔Do not leave fryer unattended while boiling out

the kettle.

➔When water foaming occurs, be prepared to

turn the power switch "OFF". Boiling water will

splatter and could result in serious injury.

1. CLEANING: Prior to leaving the factory, the fryer is tested

for proper operation with peanut oil. After testing is

complete, the oil is removed but oil residue remains.

Therefore, it is necessary to clean the frypot before filling it

with fresh oil.

NOTE: Use a non-caustic, low-foaming commercial fryer cleanser only.

a. Turn the temperature control thermostat to the lowest

temperature position (fully counter-clockwise).

b. Turn the drain valve lever to the CLOSED (horizontal)

position and fill the frypot with 4 gallons of water.

c. Press the power switch to the FRYER position.

d. When the water comes to a full boil, press the power

switch to OFF. When the boiling ceases, slowly add, and

stir in the low foaming commercial fryer cleanser. Using

the high temperature brush supplied with the fryer, stir

until the cleanser is completely mixed with water.

e. Press the power switch to FRYER. When the water

begins to boil, press it to OFF. When the boiling

subsides, again press the power switch to FRYER.

Repeat this procedure (i.e., FRYER-

boil-OFF)

continuously for 5 minutes.

f. Press the power switch OFF. Allow the solution to cool

to 120°F or less.

g. Place a suitable metal container under the drain valve.

Turn the drain valve lever to the OPEN position

(vertical) to drain the cleaning solution. To prevent

splashing and spilling, we recommend draining no more

than 4" of solution into the container at a time. Dispose

of the solution as required by local ordinances.

h. Rinse the frypot with clean water. Dry with a clean non-

abrasive cloth.

2. Install the lift cradle onto the cradle lift rod. Note the oil

level indicator.

3. Install the suction tube O-ring, filter screen, filter paper and

filter paper holder into the filter reservoir. Install the

assembled filter reservoir into the fryer.

4. Install the drip pan into the mounting bracket behind the

fryer door at the lower right front of the fryer.

5. Close the drain valve lever.

NOTE: Failure to install the drip pan will allow grease, moisture,

and other liquids that accumulate on the fryer top panel

to drip onto the floor, creating a slipping hazard.

SLIPPING & FALLING HAZARD - SPILLED OIL

➔Do not operate unless the drip pan is installed.

Oil will drip onto the floor and falls may result.

➔Close the drain valve before filling with oil;

otherwise oil poured into the kettle will drain

into the filter reservoir or onto the floor which

may cause injury by slipping in the oil.

Operation and Care Manual #8450 • 4.

PREPARATION PRIOR TO OPERATION

Operation and Care Manual #8450 • 5.

6. Lower the lift cradle. Fill the frypot to the COLD (MAX) line

on the lift cradle with room temperature commercial quality

liquid shortening. This requires 30 lbs. of oil

This fryer is designed for liquid shortening only. Do not use

solid shortening or lard. Solid shortening will solidify in the

Filter Reservoir and Filter Pump, rendering the filter

system inoperable. Repairs caused by the use of anything

other than liquid shortening are not covered by warranty.

7. Check operation of fryer and all controls.

8. DETERMINE MAXIMUM LOAD WEIGHT: For operational

safety, it is very important to determine the maximum load

weight for the specific operation. This can be accomplished

by starting out with small loads and gradually increasing the

largest load size that will allow a cook cycle to be completed

without oil foaming out of the frypot.

➾

Failure to observe this warning will result in hot oil

release from the fryer – which can cause severe burns on

contact.

POTENTIAL FOR OIL SPLATTER

The weight of product which can be safely cooked in this fryer

will vary with oil level, product moisture content, oil

temperature, and other various conditions.

Loading...

Loading...